Downloading type plunger valve

A plunger valve and plunger technology, applied in the field of bottom-mounted plunger valves, can solve the problems of uneven pressing force between the valve ball sealing ring and the ball, errors, and the difficulty of ensuring accuracy of PE materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

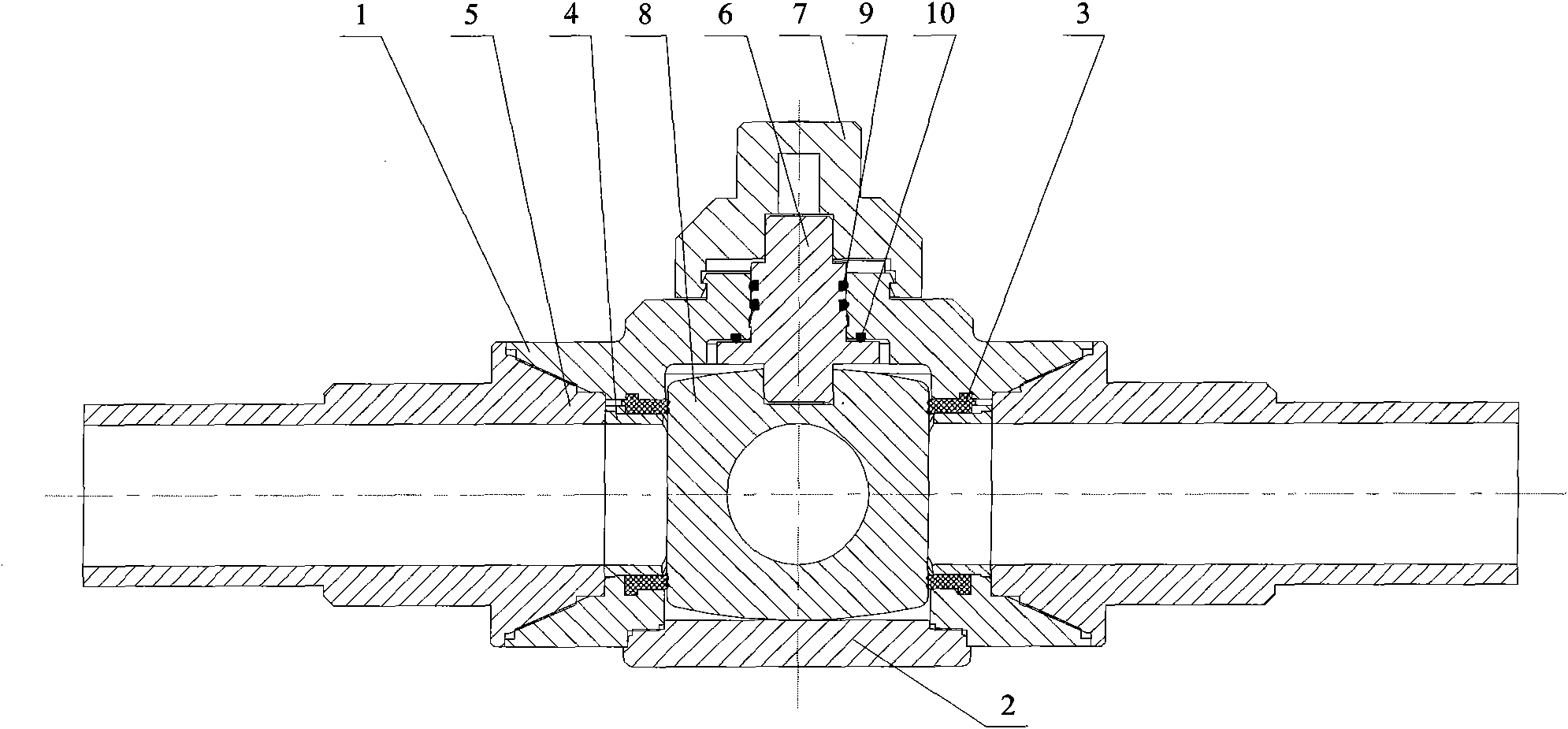

[0032] Refer to attached figure 1 The overall structure of the bottom entry plunger valve. Including valve body 1, valve bottom cover 2, plunger seal ring 3, plunger seal ring support ring 4, left and right connecting pipes 5, valve stem 6, valve stem cap 7, plunger 8, valve stem seal ring 9, valve stem end face sealing ring 10.

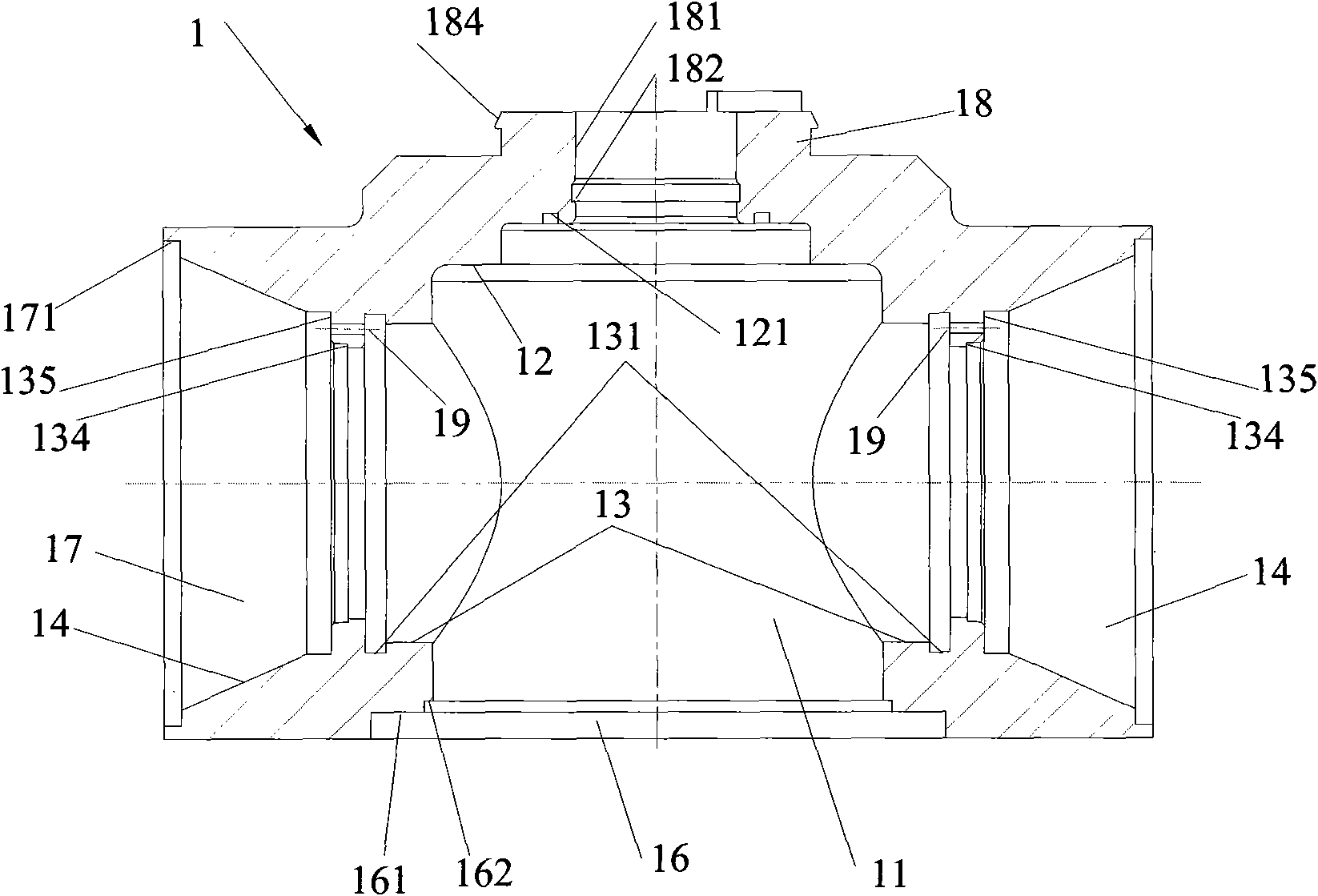

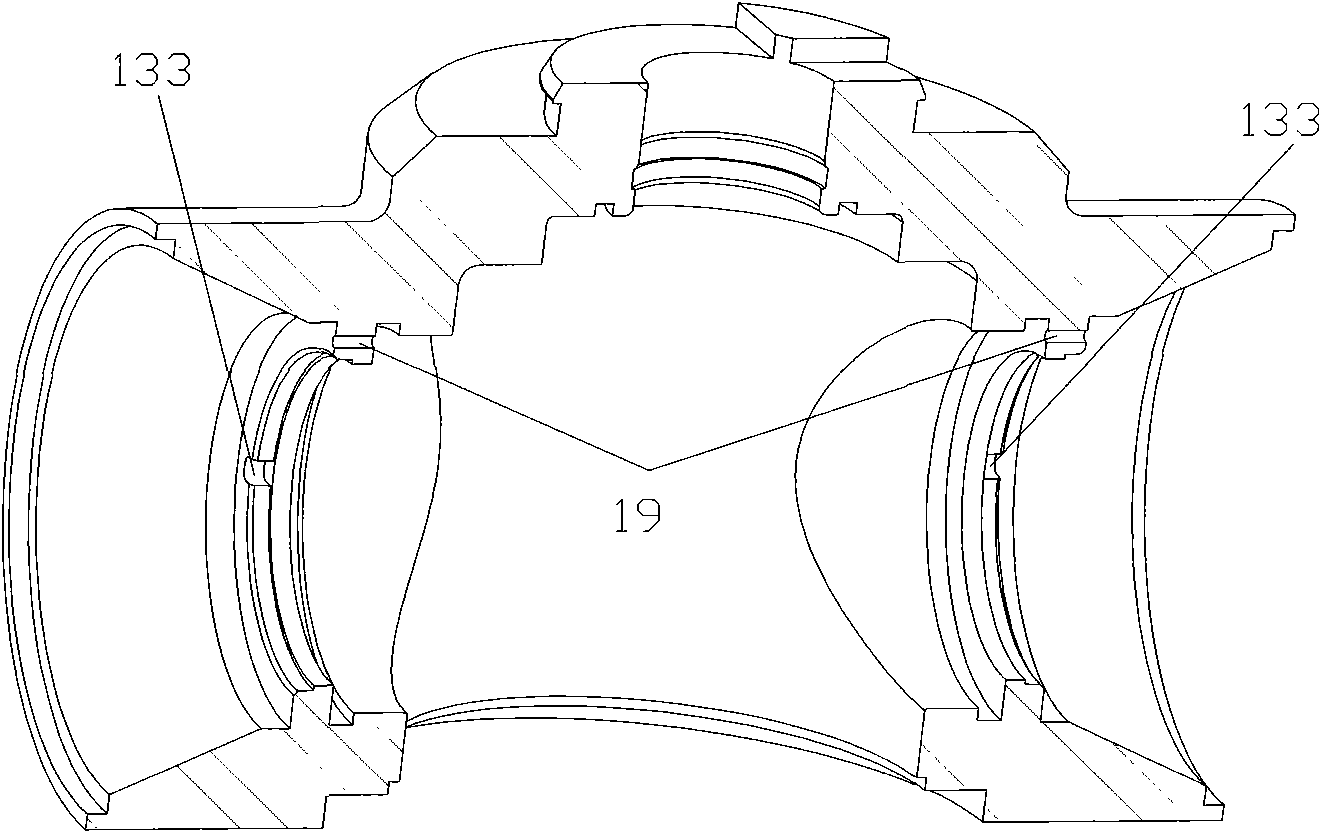

[0033] Refer to attached figure 2 , 3Shown is the structural diagram of the valve body 1 of the bottom-mounted plunger valve; the plunger chamber 11 of the valve body is an inner cylindrical cavity structure, and the lower part of the cylinder is in the form of an opening, which is processed with an end face or The conical surface 161, in the direction perpendicular to the axis of the plunger chamber 11 and located on both sides of the plunger chamber 11, has a coaxial cylindrical hole 13 for installing the plunger sealing ring 3 and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com