Method for controlling rotating electric machine, particularly alternator

A technology for alternating current generators and rotating electrical machines, which is applied to control the direction of generators, battery circuit devices, and current collectors through changes in the magnetic field. It can solve problems such as internal combustion engine stalling and excessive torque, and achieve the effect of improving regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

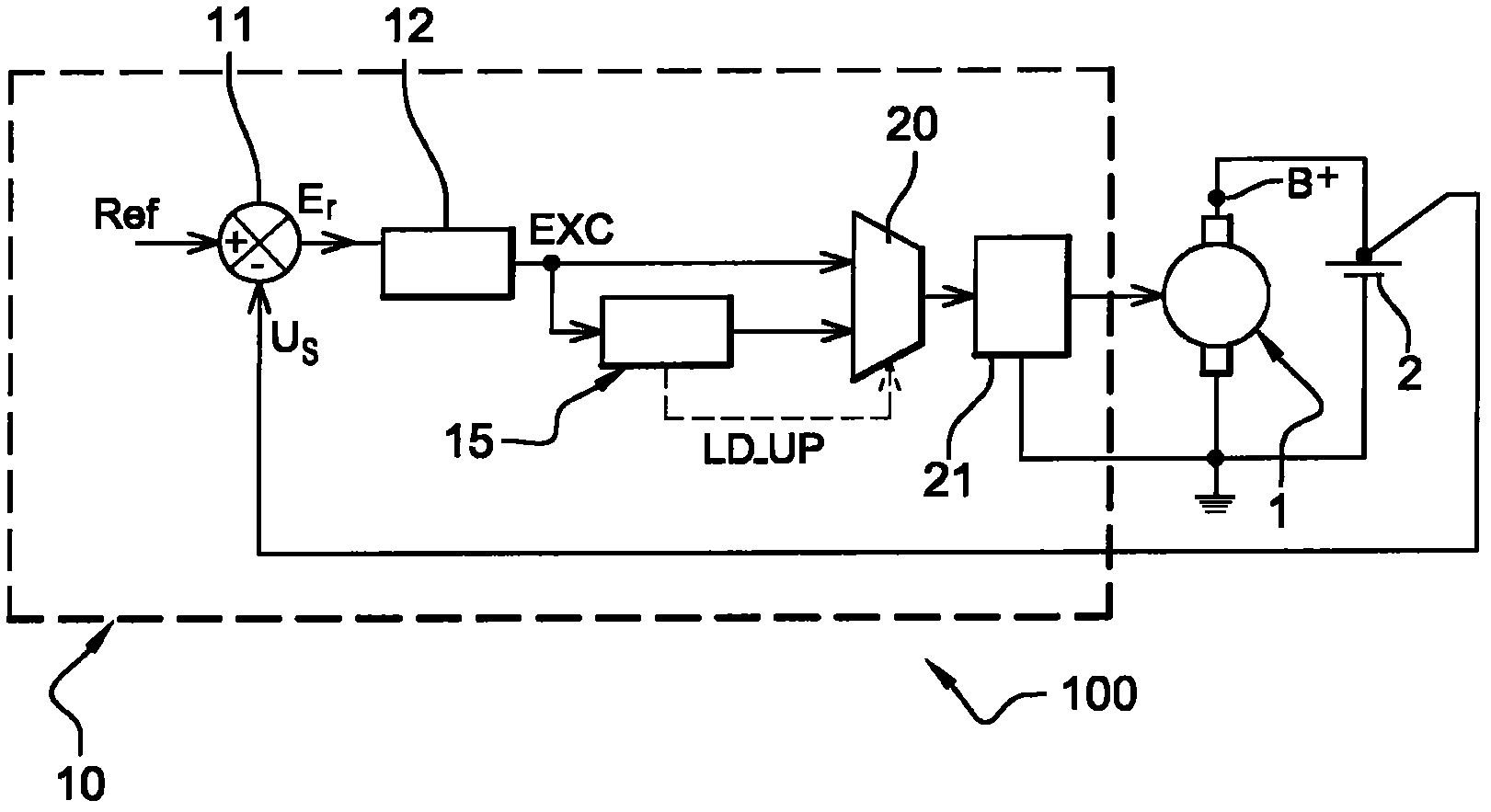

[0048] figure 1 An assembly 100 of a motor vehicle is shown comprising a polyphase rotating electric machine 1 formed in the example concerned by an alternator.

[0049] The alternator 1 can be rotated by the internal combustion engine of the motor vehicle in order to generate electrical energy.

[0050] In known manner, the alternator 1 firstly comprises a stator comprising windings which, in the example described, form three phases, and secondly a rotor comprising an excitation winding.

[0051] As a variant, the electric machine 1 can be an alternator-starter.

[0052] The alternator 1 is connected to an on-board battery 2 on the motor vehicle.

[0053] The assembly 100 additionally includes a device 10 for controlling the alternator 1 , which can supply an electric current whose intensity varies depending on a signal or excitation pulse EXC generated by the control device 10 .

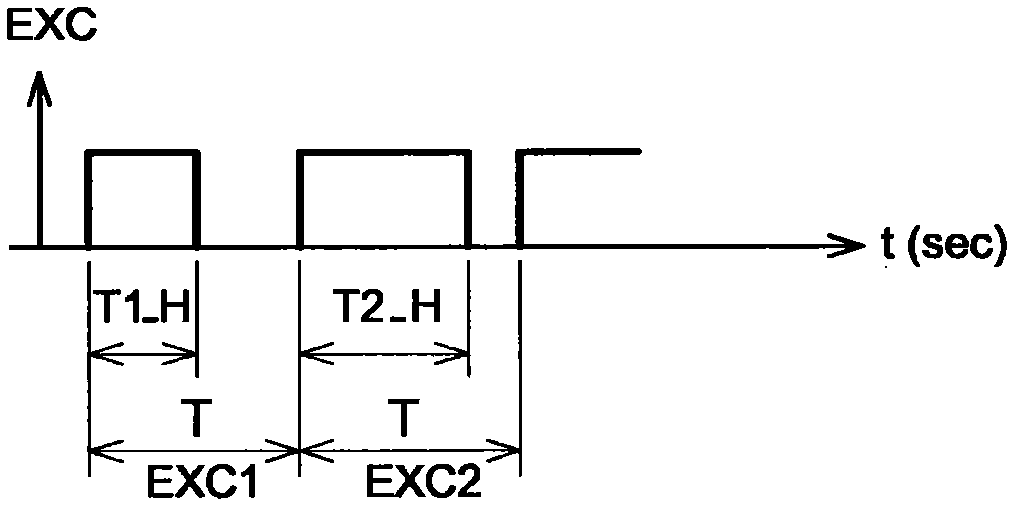

[0054] A duty cycle DC1; DC2 is associated with each excitation signal EXC.

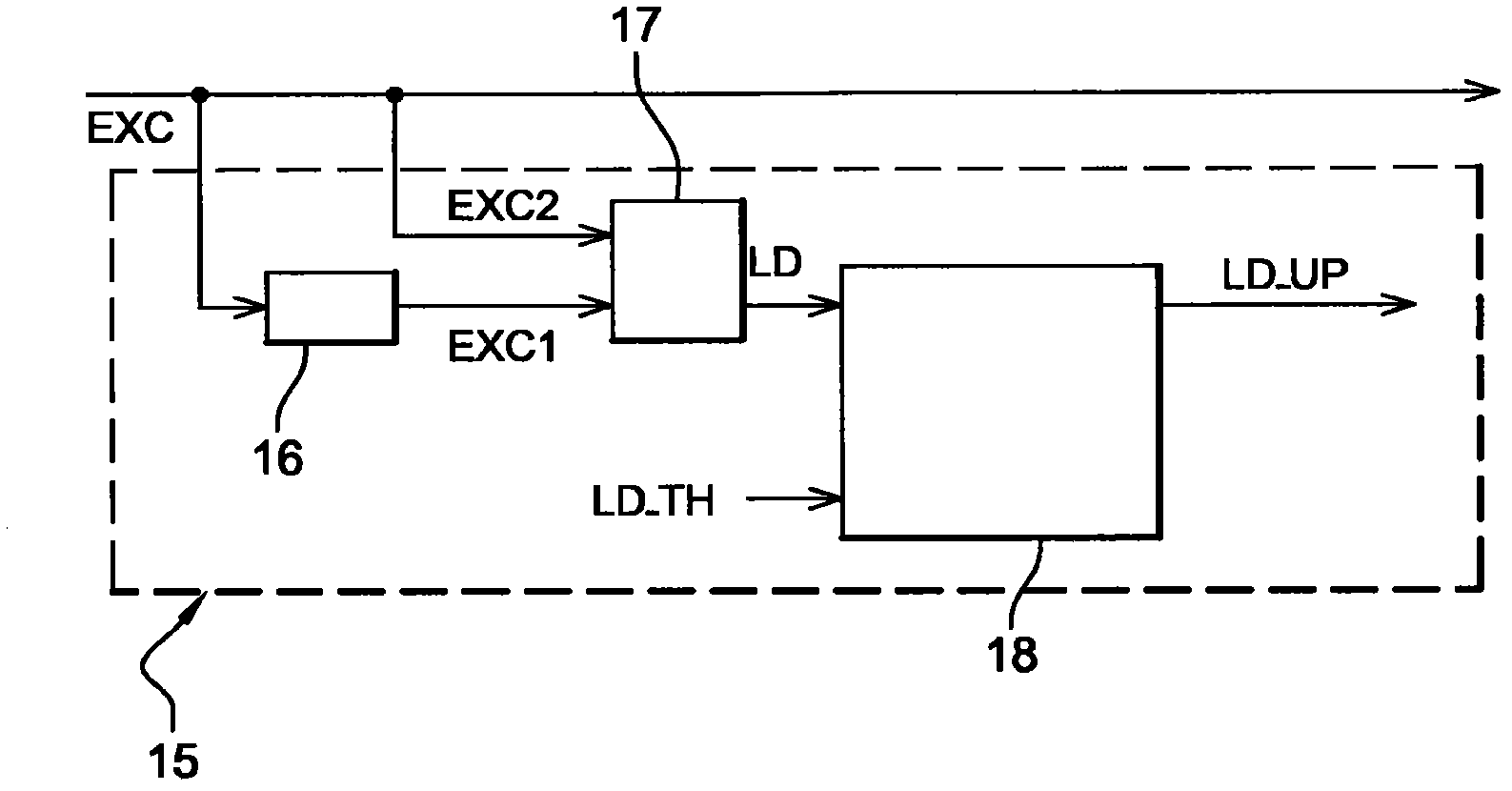

[0055] imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com