Electromagnetic metering pump driving circuit and driving control method

A technology for driving circuits and metering pumps, applied in pumps, electrical components, machines/engines, etc., can solve the problems of low power energy utilization efficiency, long transition time, unstable flow, etc., to expand the pump flow and increase the maximum impulse. Second, the effect of stable flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

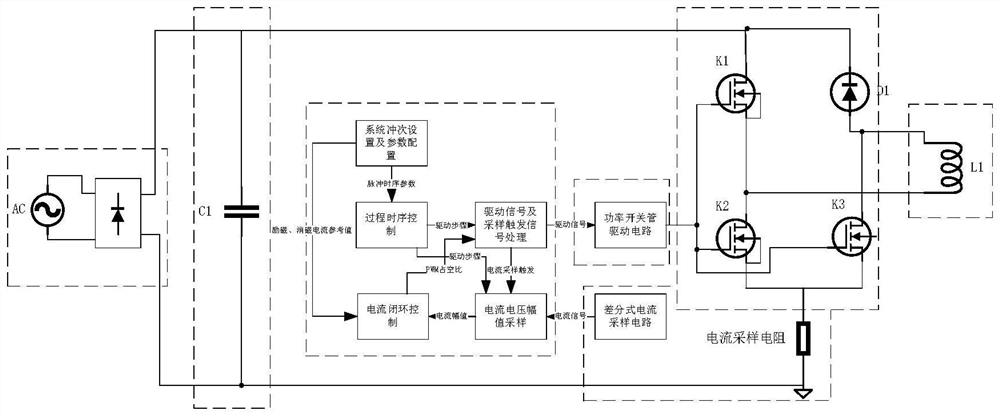

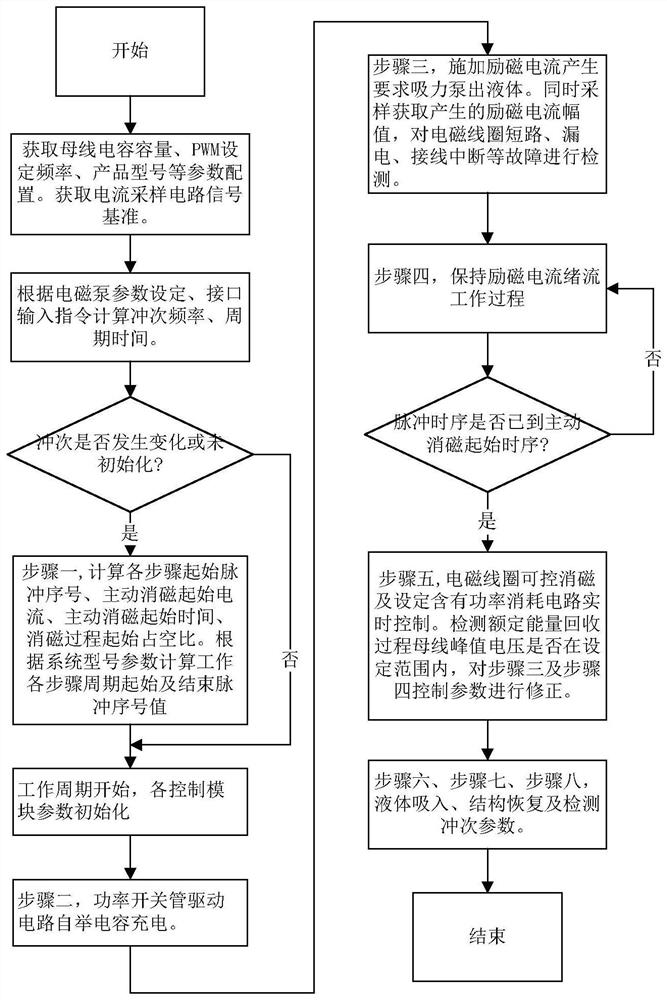

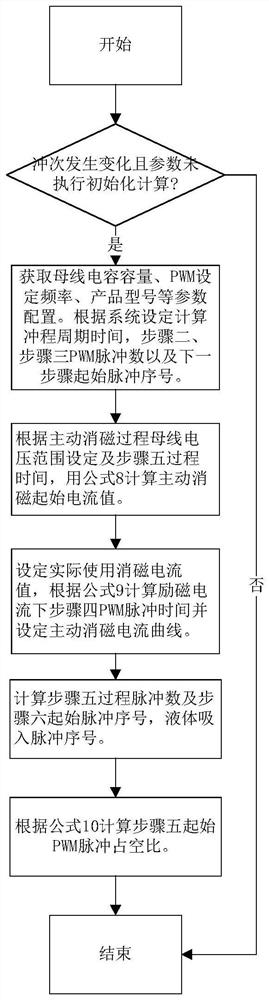

[0060] like figure 1 As shown, an electromagnetic metering pump drive circuit includes an AC power supply, a full-bridge circuit, a switch tube drive circuit, a current sampling circuit, a signal processing module and an electromagnetic coil; wherein the AC circuit passes through the full-bridge circuit and the input end of the switch tube drive circuit. The output end of the switch tube drive circuit is connected with the electromagnetic coil, and the switch tube drive circuit is also connected with the current sampling circuit; the current sampling circuit is also connected with the control end of the switch tube drive circuit through the signal processing module. In this example, the current sampling circuit is used to collect the output current of the switching tube driving circuit, and the signal processing module is used to amplify and filter the current signal collected by the current sampling circuit, and input it to the switching tube driving circuit to realize closed-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com