Patents

Literature

52results about How to "Increase discharge flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

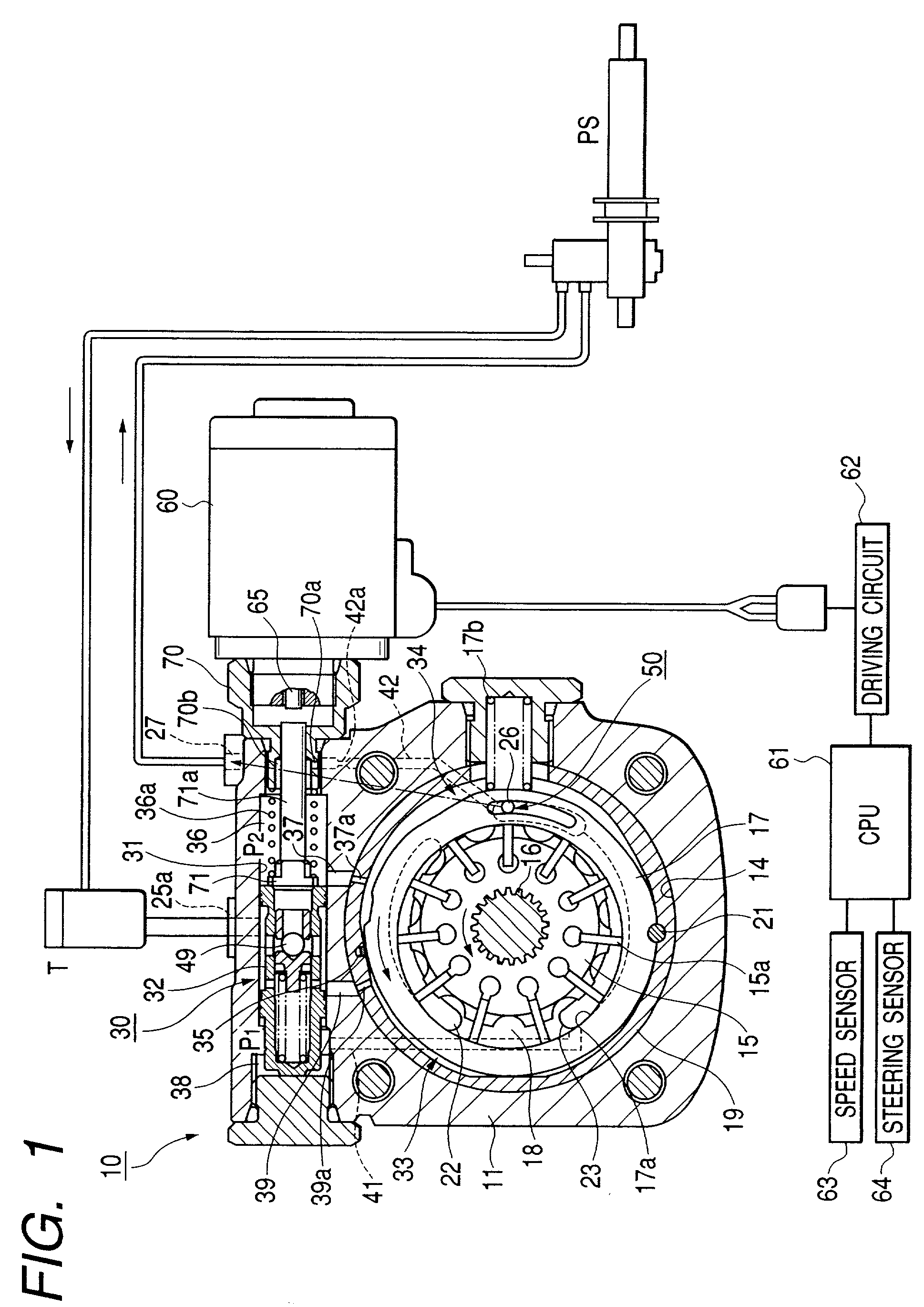

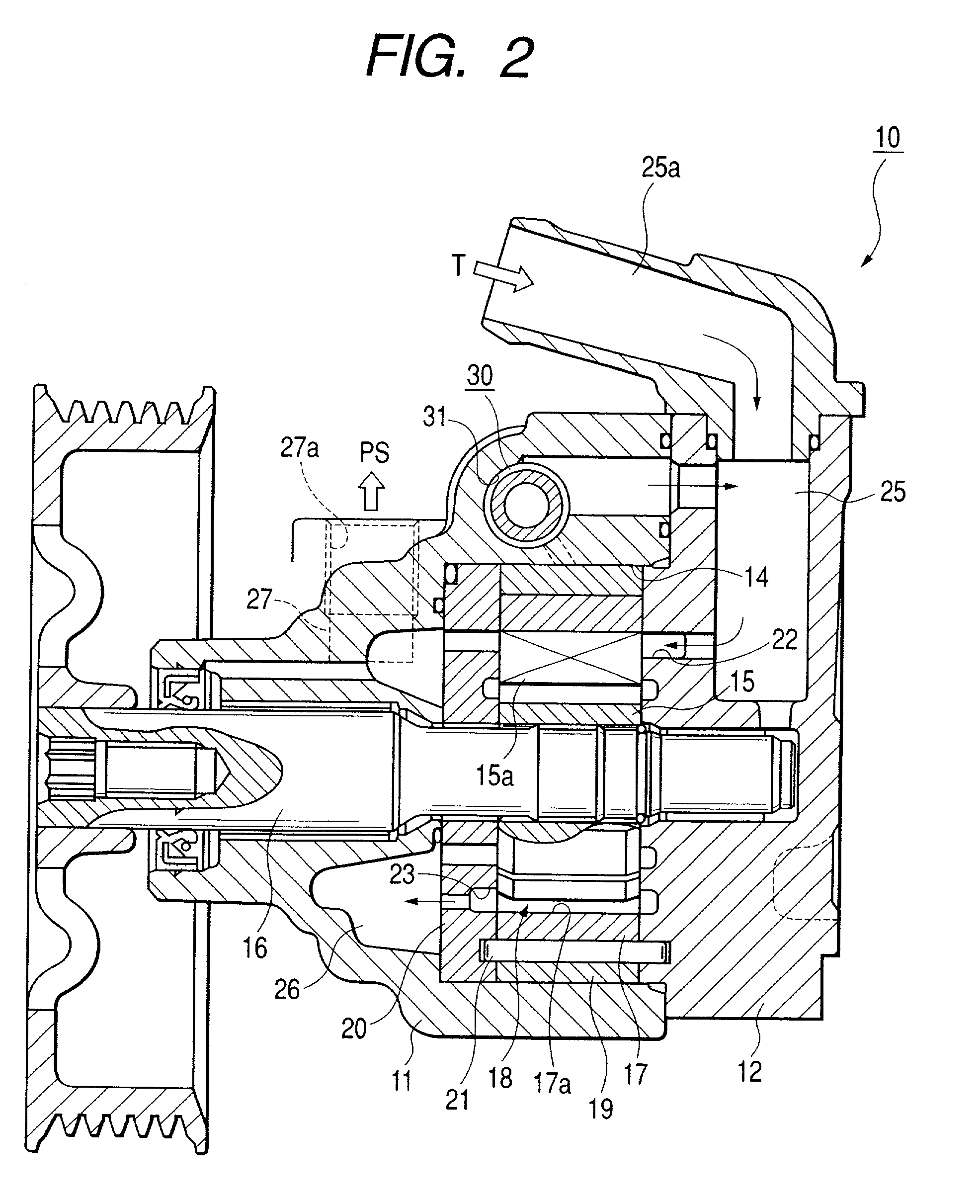

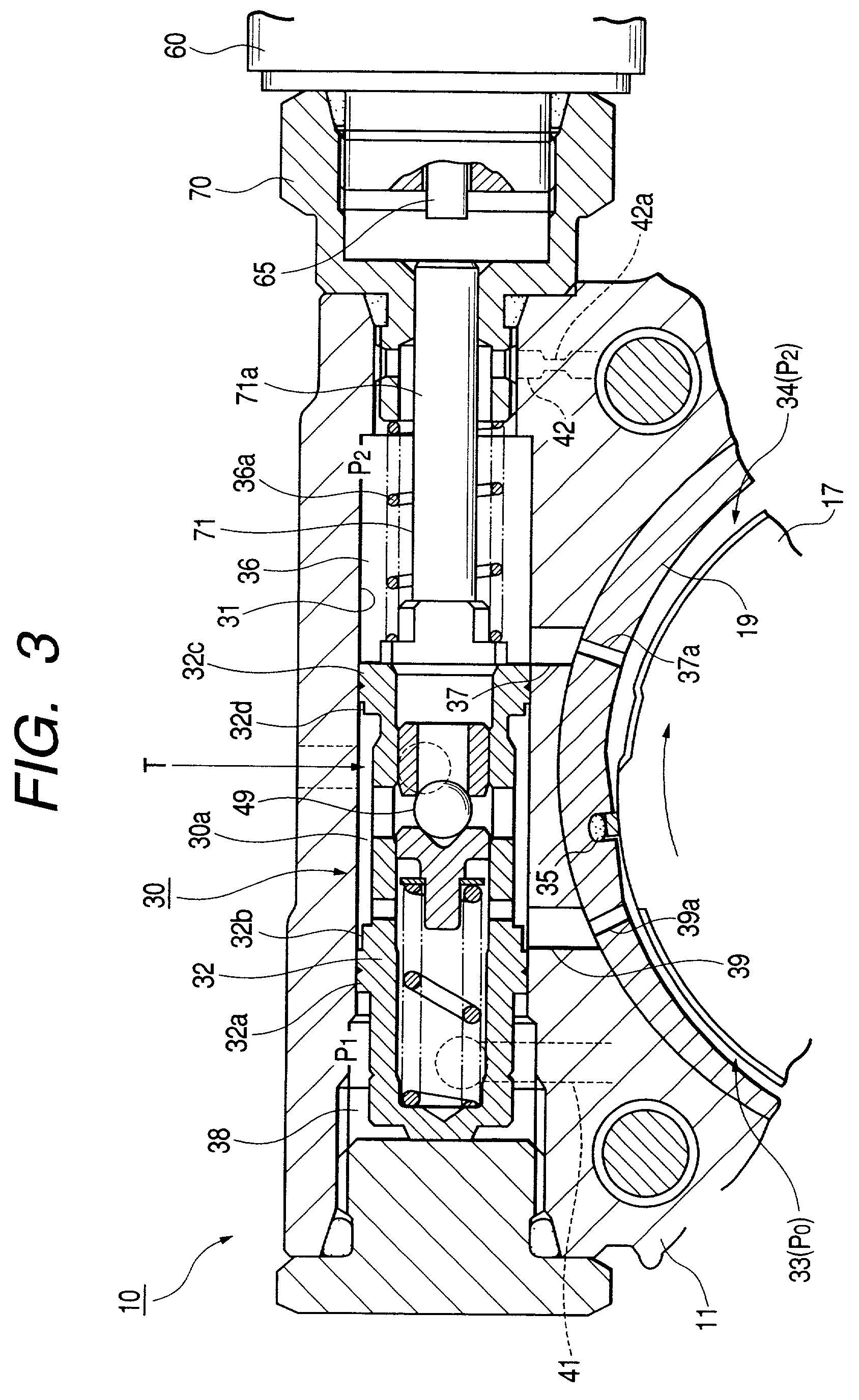

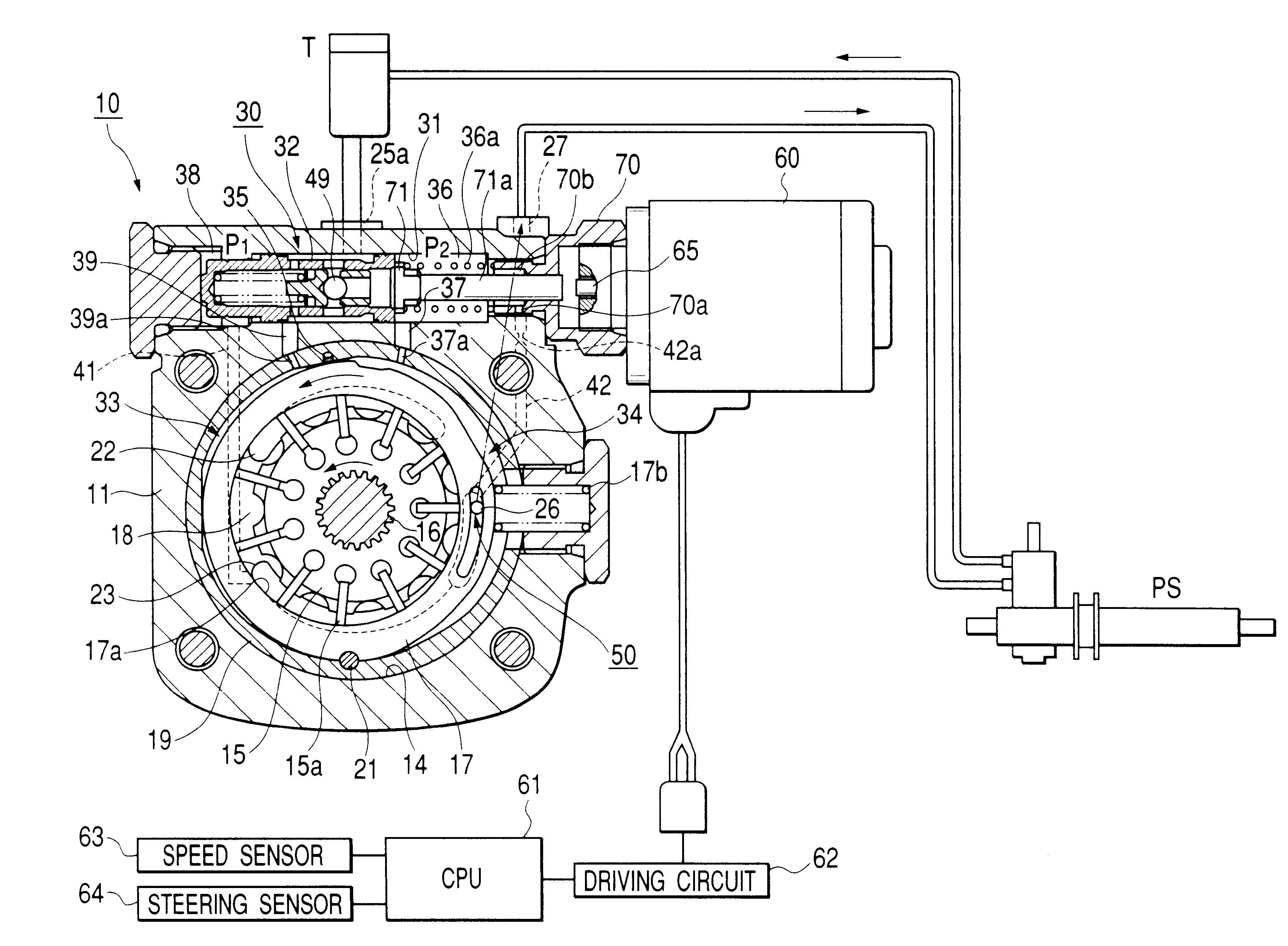

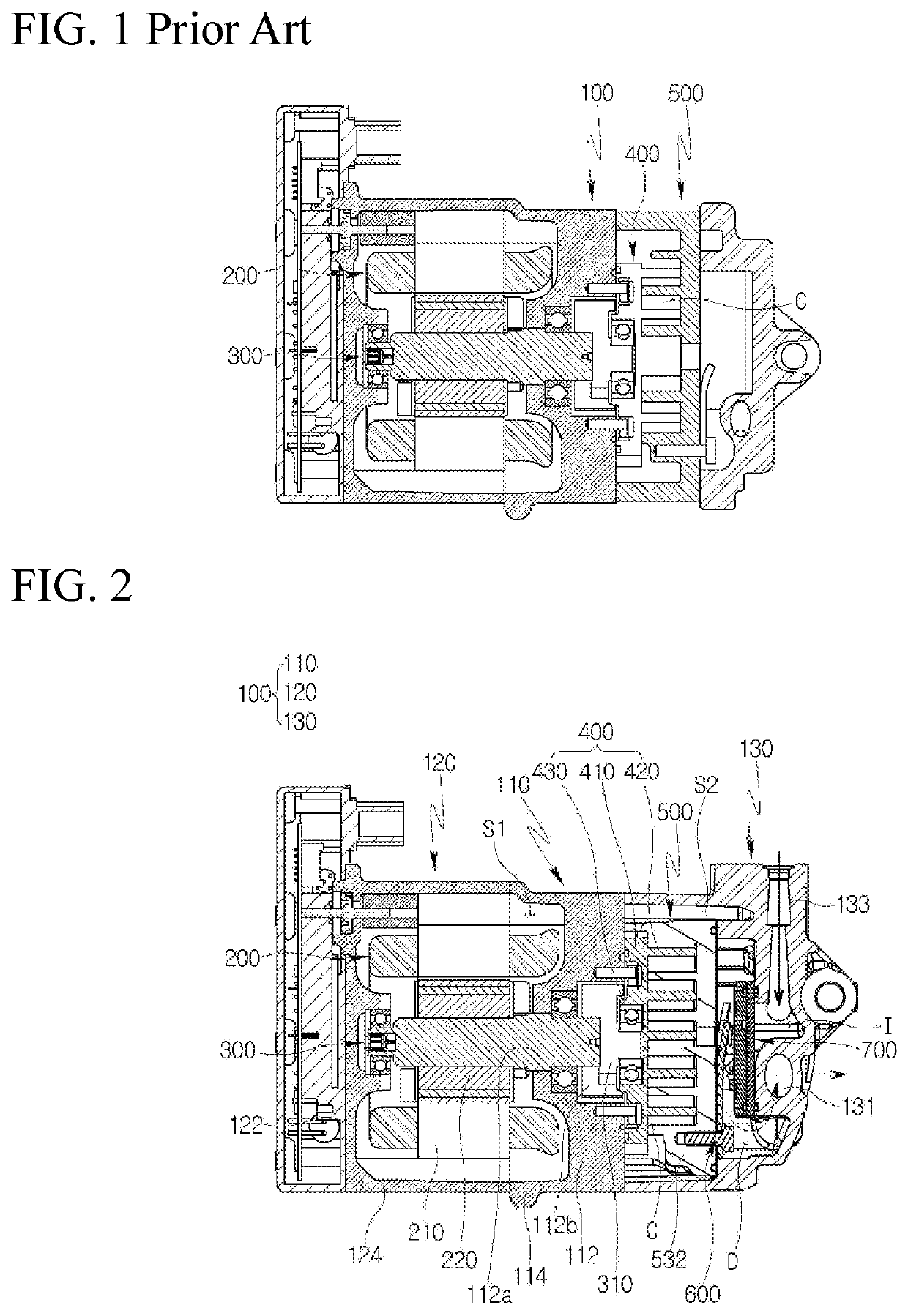

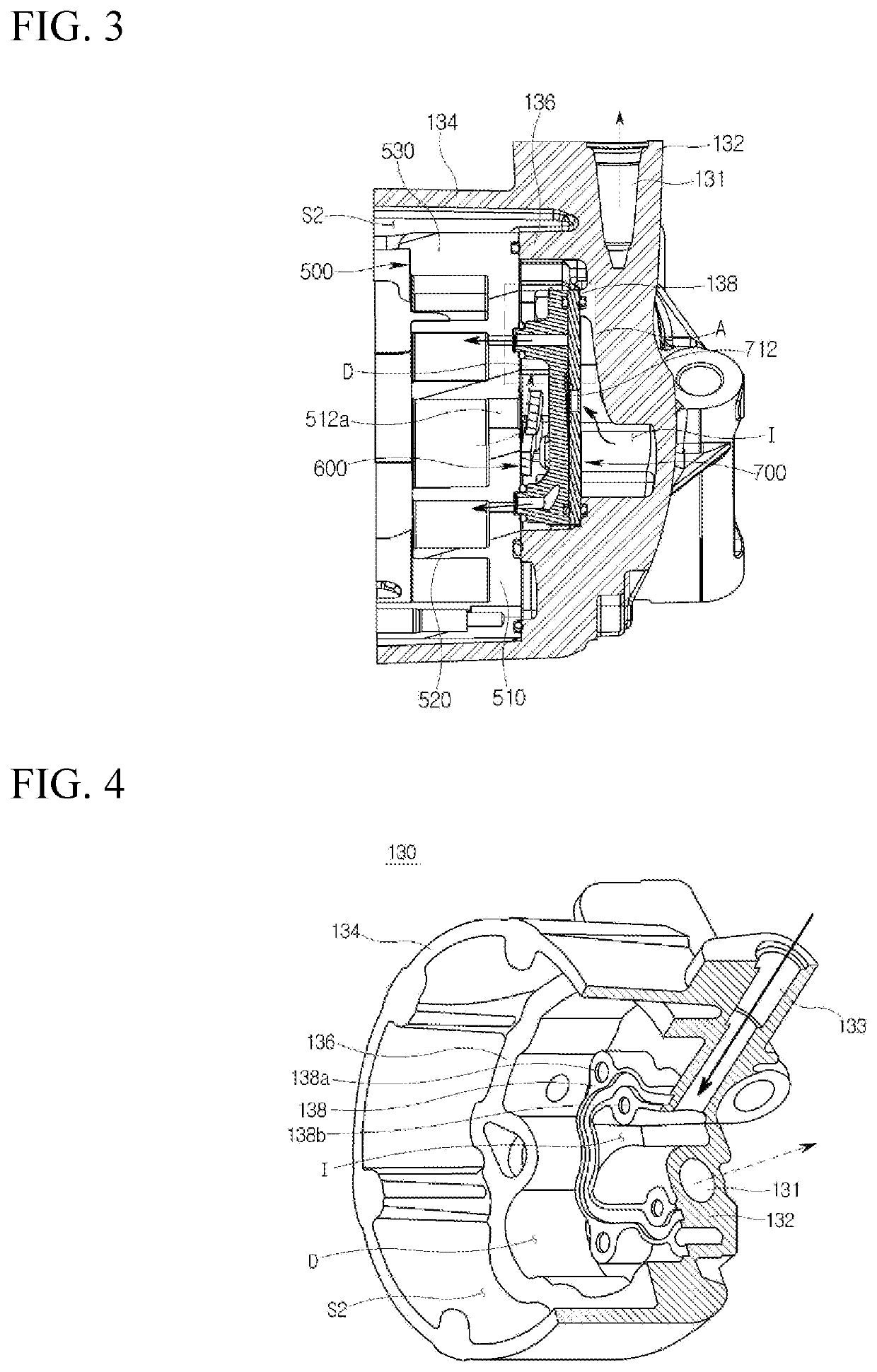

Variable displacement pump

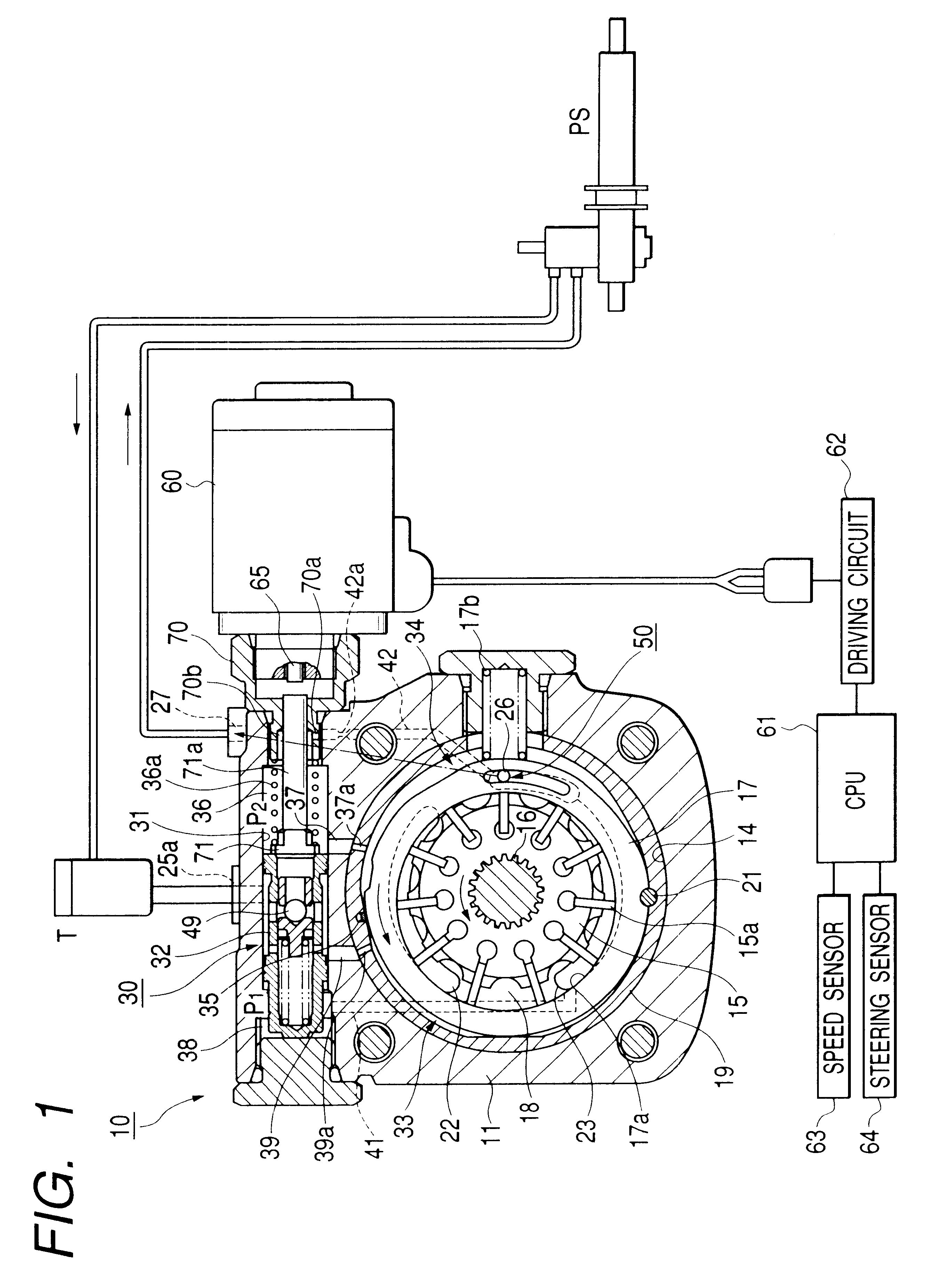

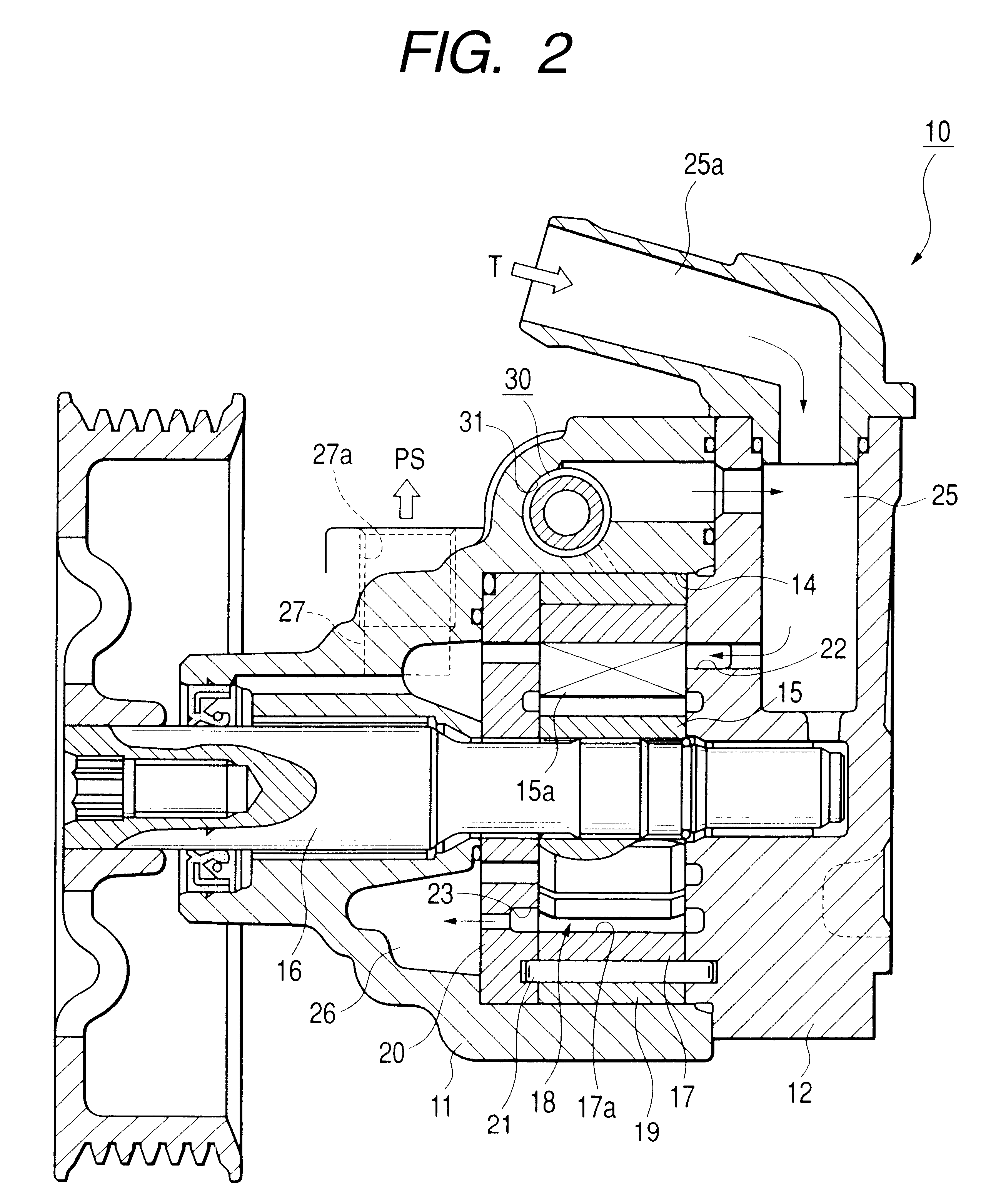

InactiveUS20010036412A1Feel comfortableEnergy saving effectSteering linkagesRotary piston pumpsPump chamberControl valves

A pump chamber 18 is formed between a cam ring 17 and a rotor 15 in a pump body 11. The cam ring is formed so as to move to direction that pump capacity of the pump chamber increases and decreases. A first and second fluid pressure chambers 33 and 34 are formed at both sides of moving direction of the cam ring 17. The pump has a spool operates to axis direction by difference in fluid pressure of upper and lower stream sides of a metering throttle 50 formed on a way of a discharge side passage 27 of the pump chamber and provides at least a control valve 30 controlling fluid pressure in the first fluid pressure chamber. An electronic driving unit applying thrust to axis direction to the spool of the control valve, for example, a solenoid 60 is provided.

Owner:HITACHI AUTOMOTIVE SYST STEERING

Variable displacement pump including a control valve

InactiveUS6524076B2Feel comfortableSaving effectSteering linkagesRotary piston pumpsPump chamberAxial thrust

A pump including a pump chamber 18, formed in a pump body 11, between a cam ring 17 and a rotor 15. The cam ring is formed so as to move in a direction whereby the pump capacity of the pump chamber increases and decreases. First and second fluid pressure chambers 33 and 34 are formed at opposite sides of the cam ring 17. The pump has a spool that is axially moved by a difference in fluid pressure between upper and lower stream sides of a metering throttle 50 connected to a discharge side passage 27 of the pump chamber. The spool is part of a control valve 30 that controls fluid pressure in at least the first fluid pressure chamber. An electronic driving unit, for example, a solenoid 60, applies axial thrust to the spool of the control valve.

Owner:HITACHI AUTOMOTIVE SYST STEERING

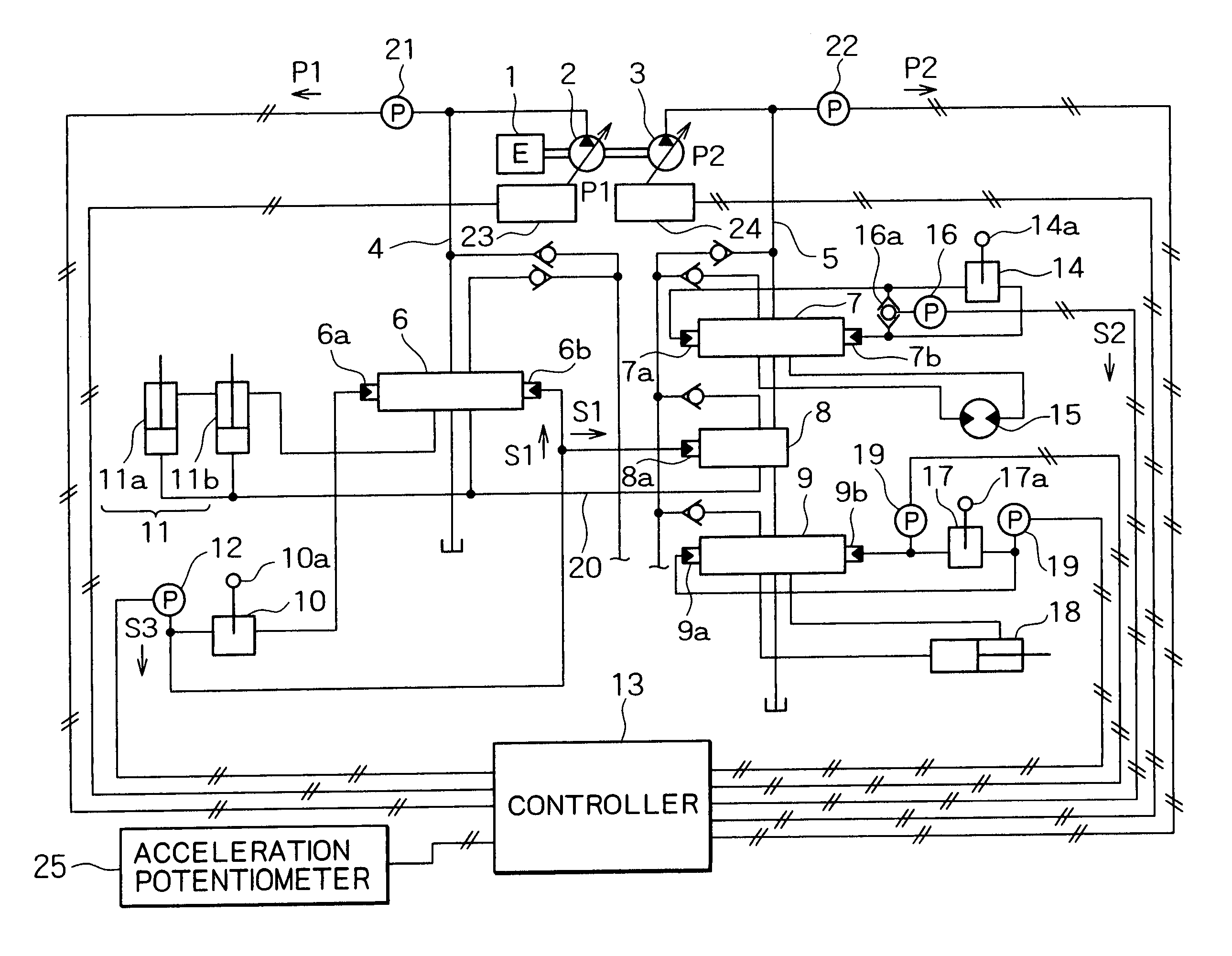

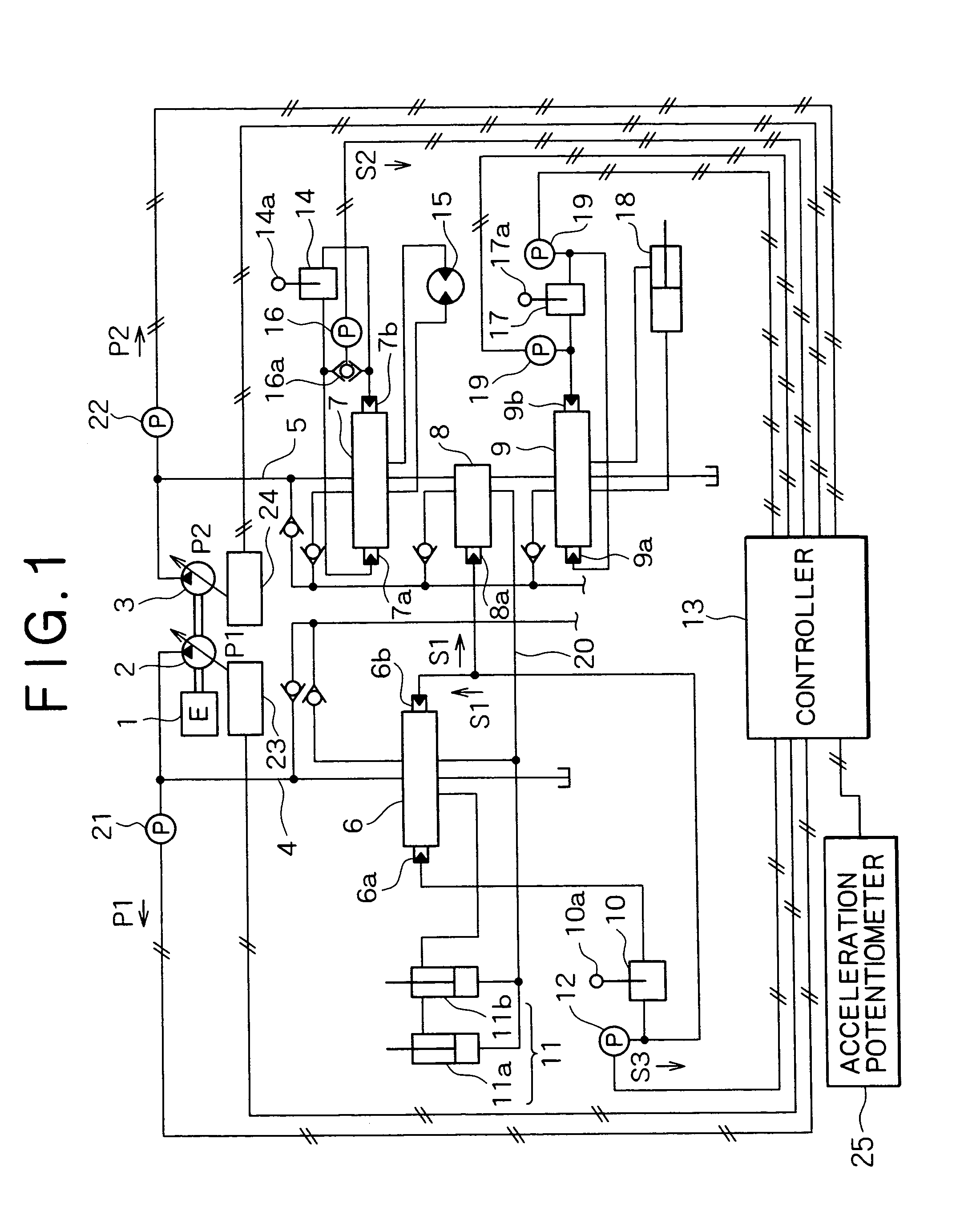

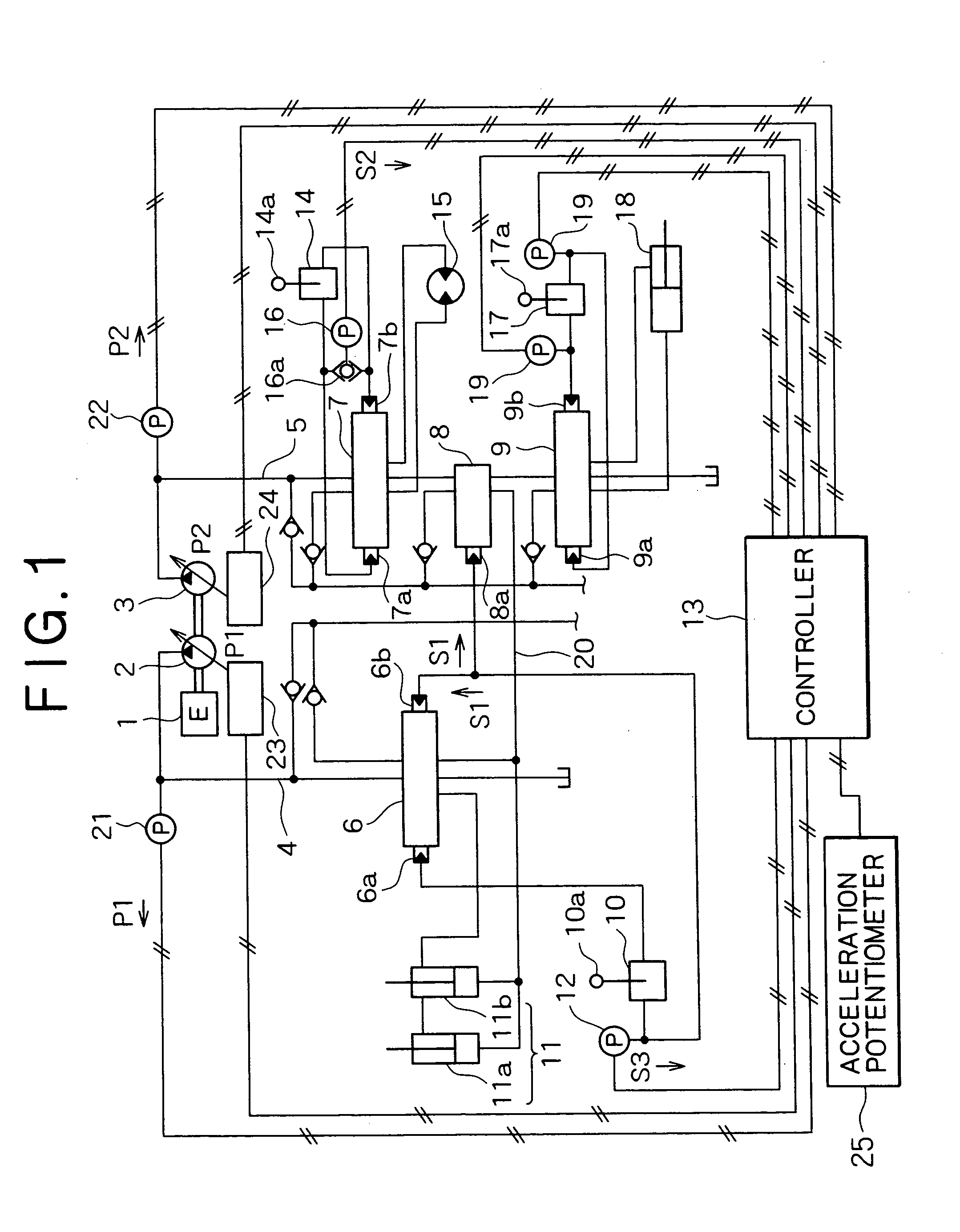

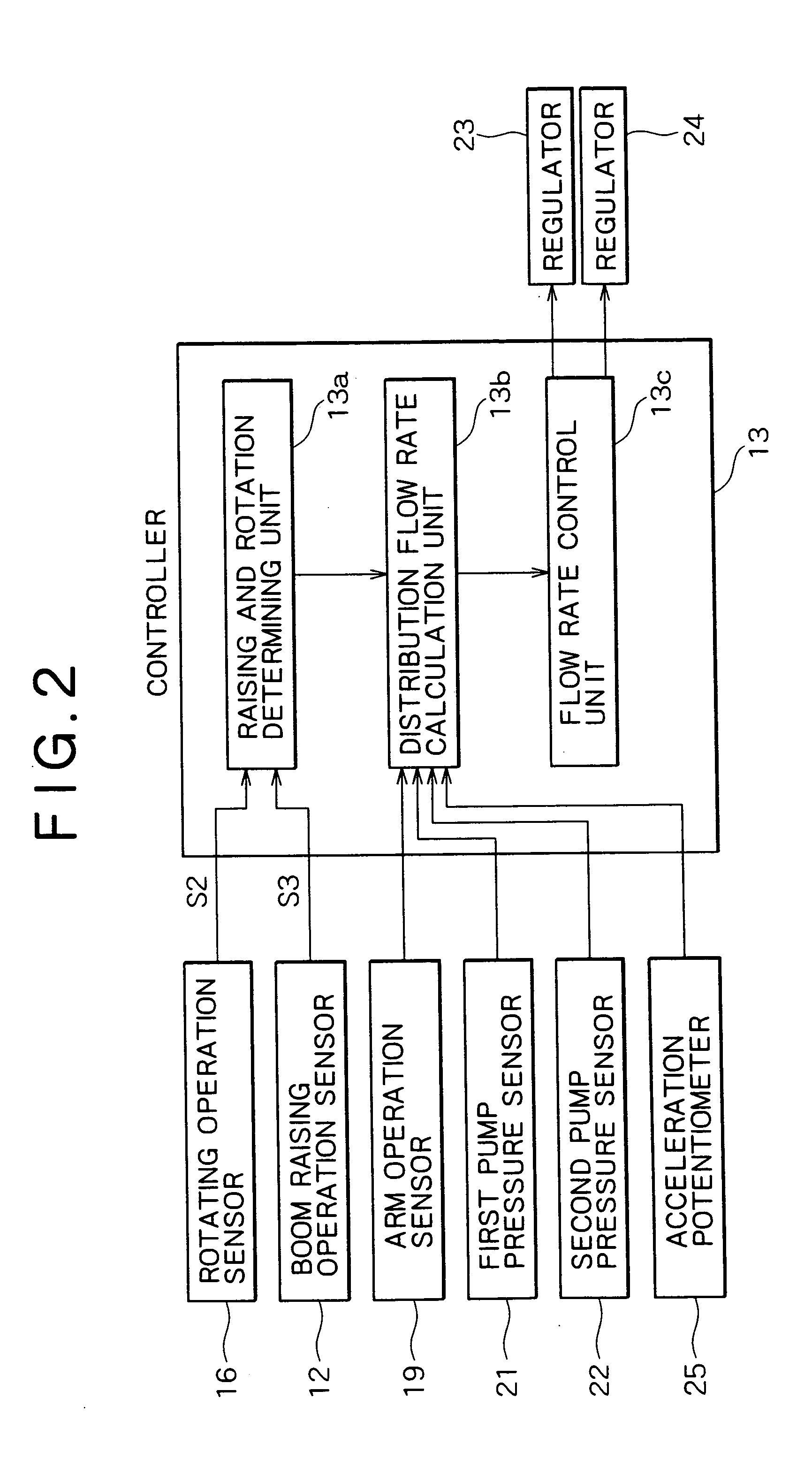

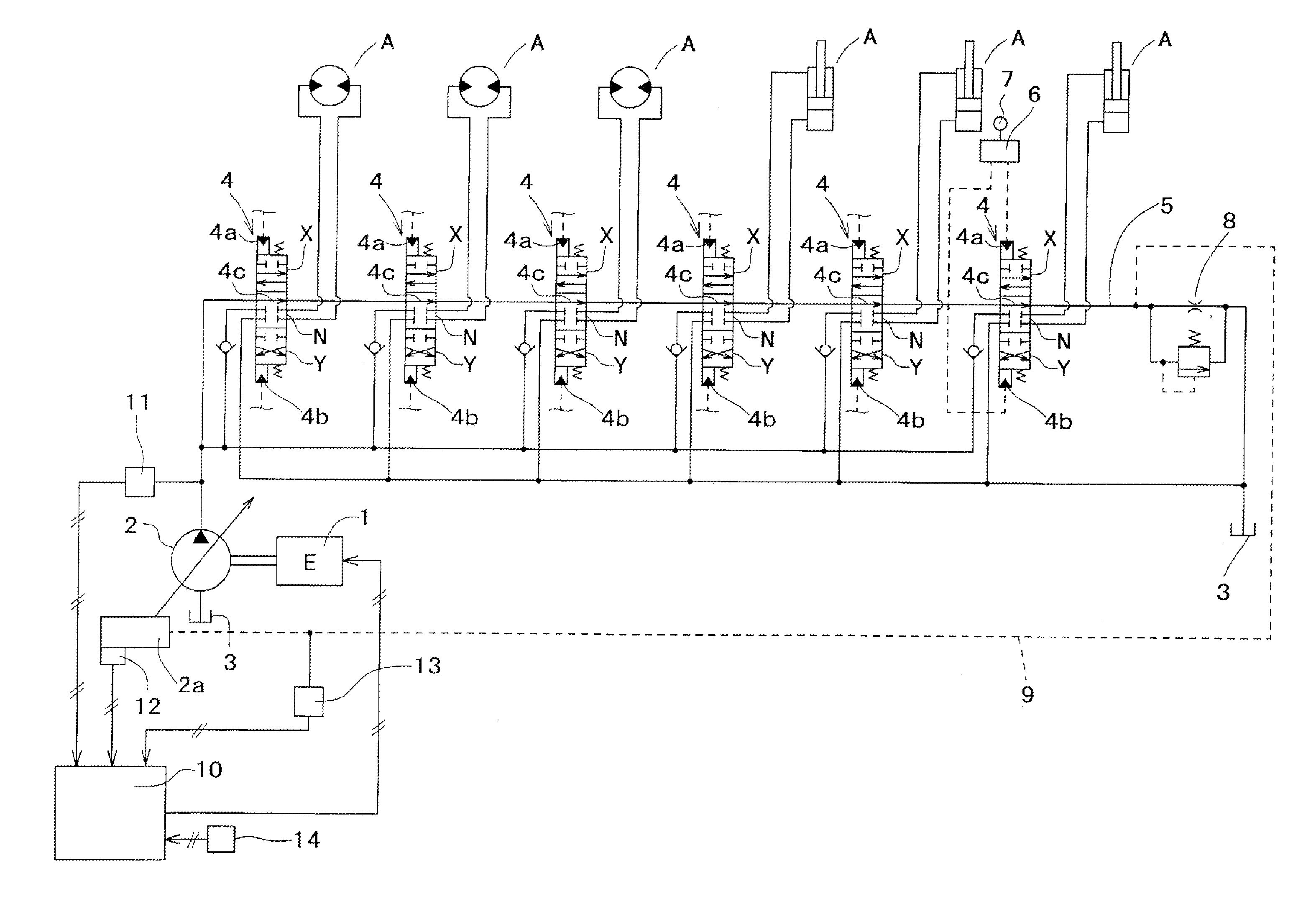

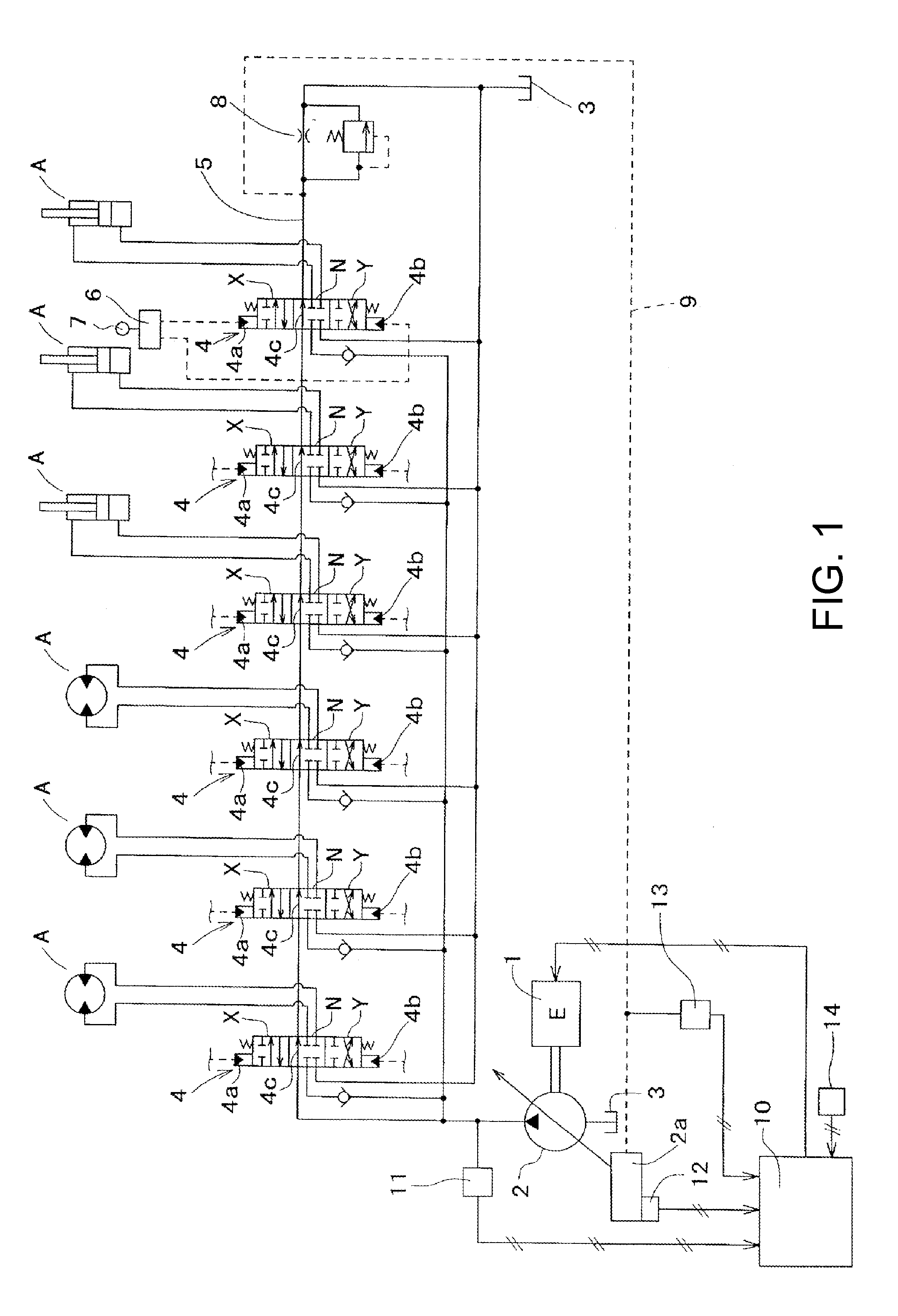

Hydraulic controller for construction machine

ActiveUS7059125B2Improve distributionHigh speedFluid couplingsServomotorsHydraulic pumpDischarge pressure

Owner:KOBELCO CONSTR MASCH CO LTD

Rotation drive controlling system for construction machine

ActiveUS20110020146A1Same operabilityReduce dischargeServomotorsSoil-shifting machines/dredgersDischarge pressureRelief valve

The system includes: a variable displacement hydraulic pump supplying pressure oil to a hydraulic actuator; a pressure detector detecting a pump discharge pressure from the hydraulic pump; a control valve controlling a supply of the pressure oil to the hydraulic actuator; a controller controlling a pump displacement of the hydraulic pump; a hydraulic motor rotating an upper structure of the construction machine; a swing relief valve defining a relief pressure of the hydraulic motor; and a control lever switching a control valve for the hydraulic motor. The controller includes: an adjuster that, when a pump discharge pressure detected by the pressure detector exceeds a first set value, conducts an adjustment to reduce the pump displacement; and a canceller that cancels the adjustment when the pump discharge pressure falls below a second set value. The second set value is equal to or larger than the first set value.

Owner:KOMATSU LTD

Pump

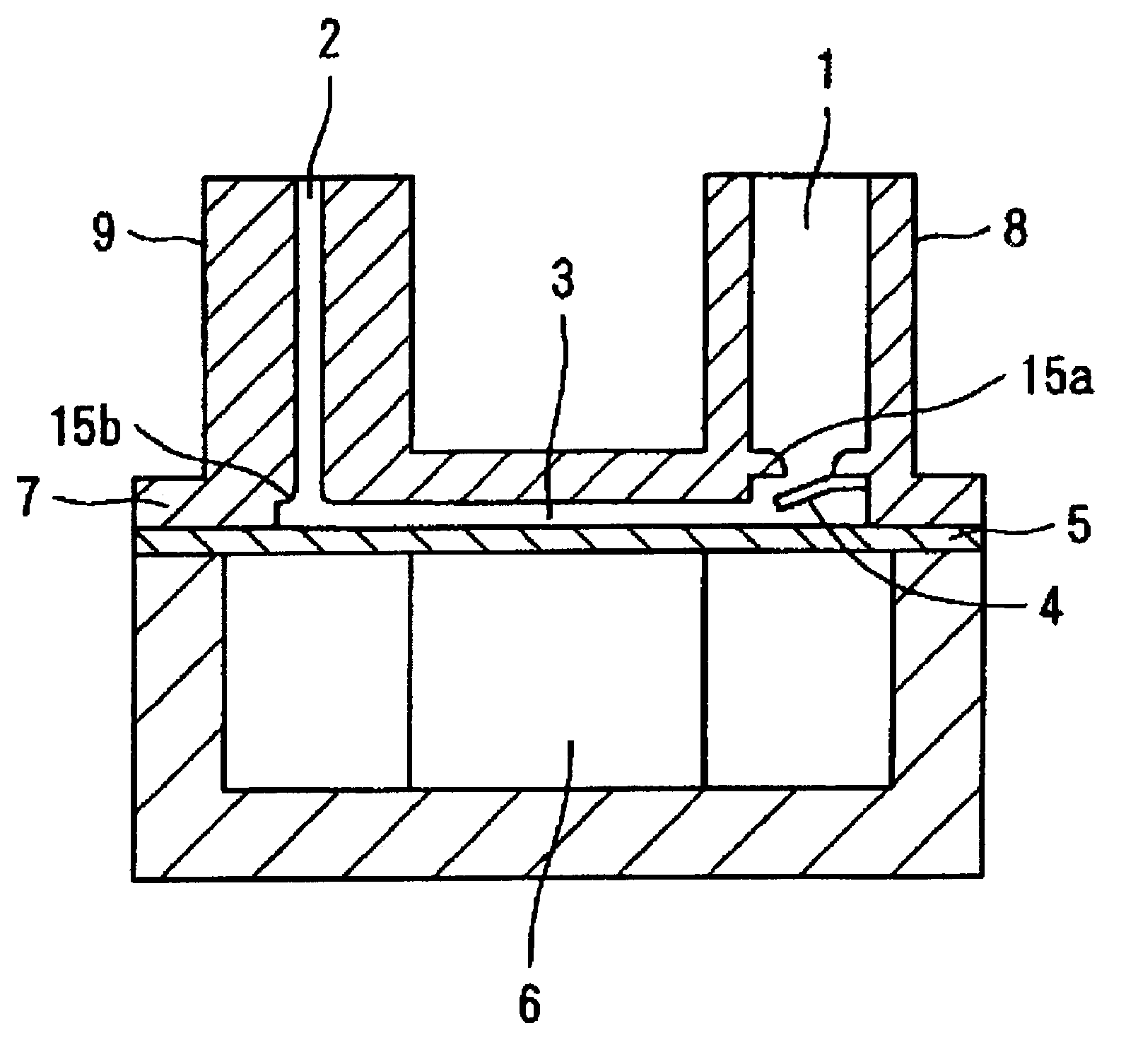

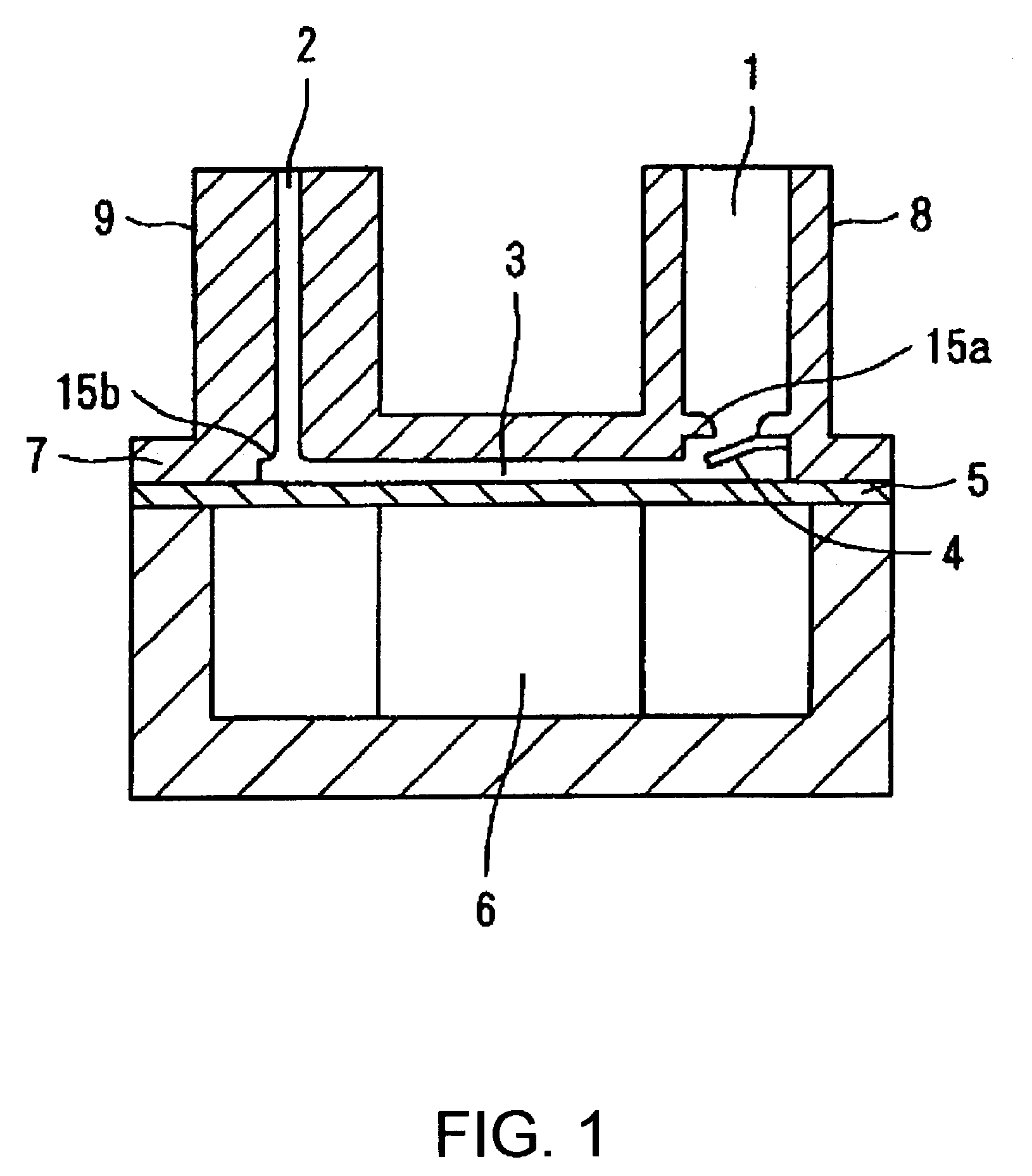

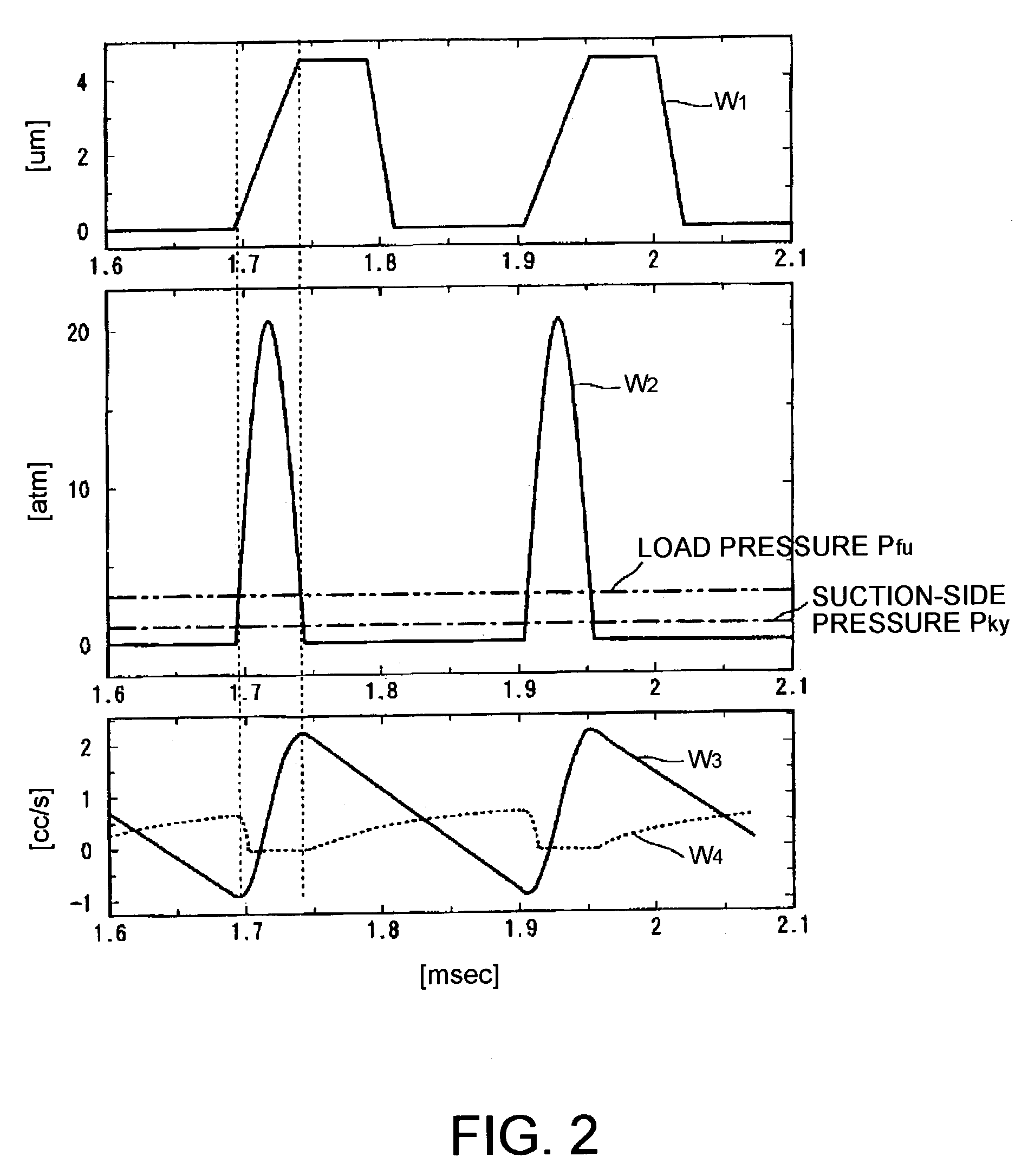

ActiveUS7059836B2Little resistanceA large amountPositive displacement pump componentsPump controlElectricityPump chamber

The invention provides a pump which has reduced pressure loss by using fewer mechanical on-off valves, which has increased reliability, which can be used under a high load pressure, which can be driven at a high frequency, and which has good drive efficiency by increasing discharge fluid volume per pumping period. A circular diaphragm, disposed at the bottom portion of a case, has its outer peripheral edge secured to and supported by the case. A piezoelectric device to move the diaphragm is disposed at the bottom surface of the diaphragm. A space between the diaphragm and the top wall of the case is a pump chamber. An inlet flow path, having a check valve serving as a fluid resistor disposed thereat, and an outlet flow path, which opens to the pump chamber during operation of the pump, open towards the pump chamber. In the pump, driving of the piezoelectric device is controlled so that an average displacement velocity in a pump chamber volume reducing step of the diaphragm becomes a velocity at which the diaphragm reaches the reached-displacement-position in a time equal to or less than ½ and equal to or greater than 1 / 10 of a natural vibration period T of fluid inside the pump chamber and the outlet flow path.

Owner:SEIKO EPSON CORP

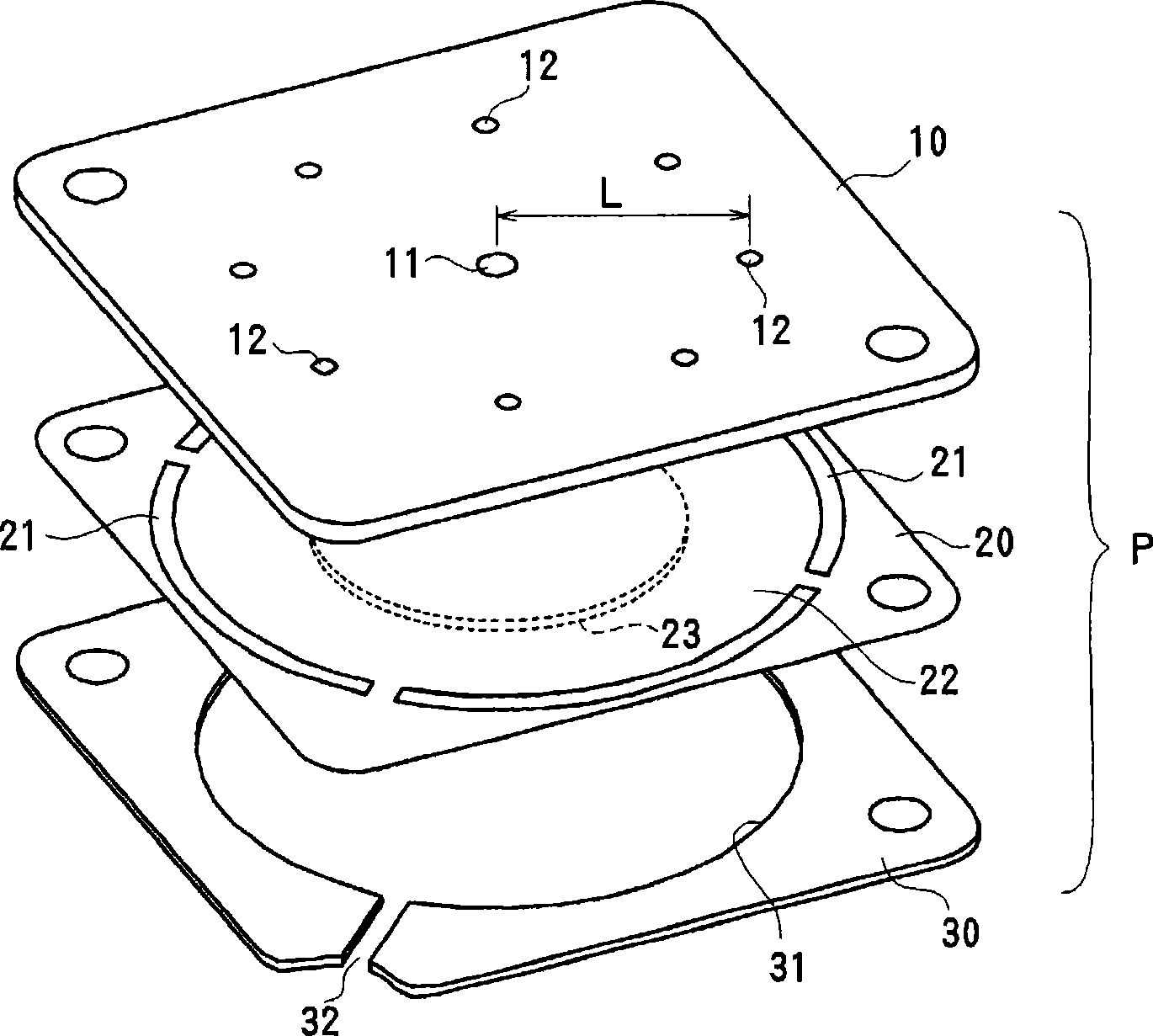

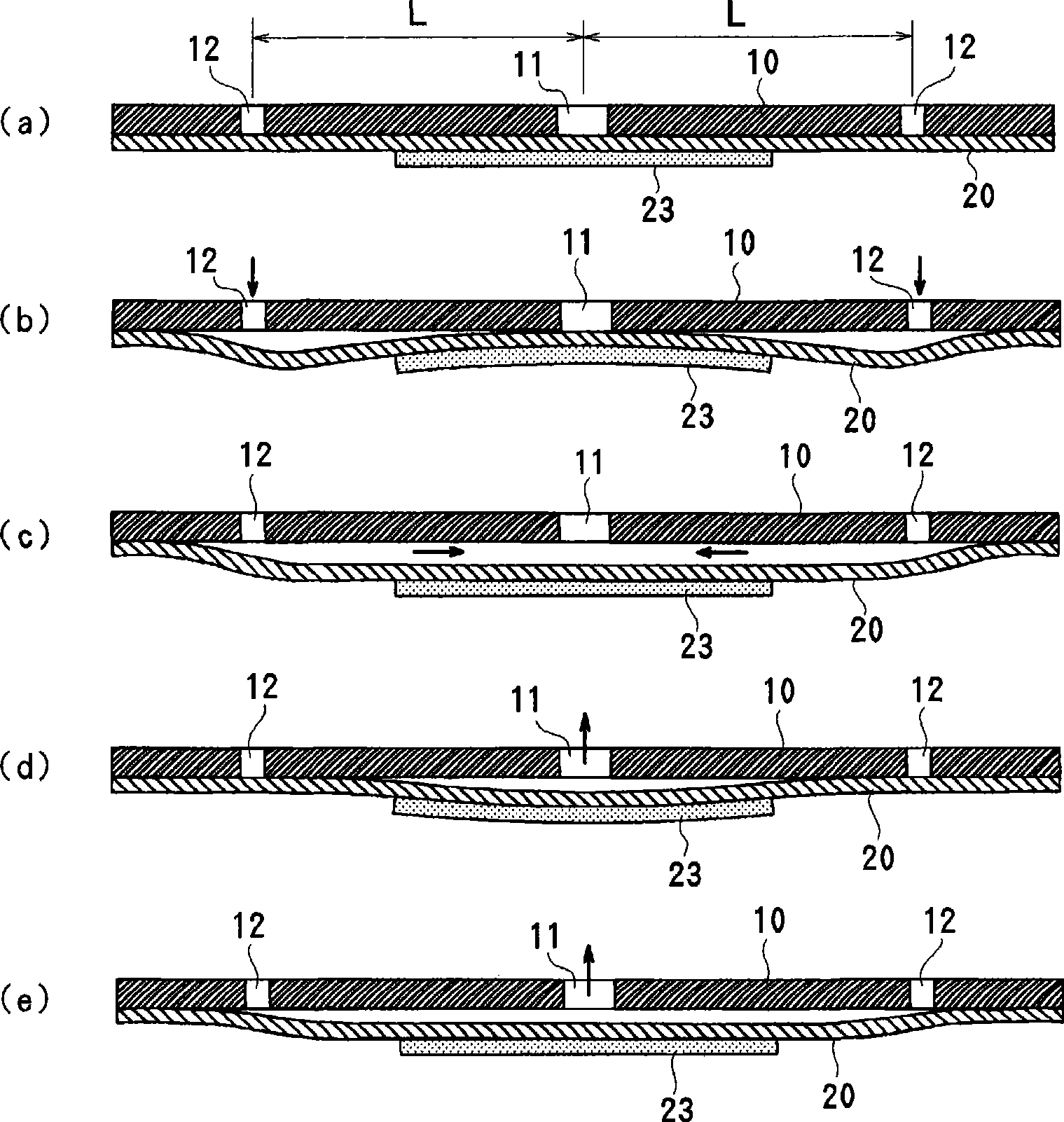

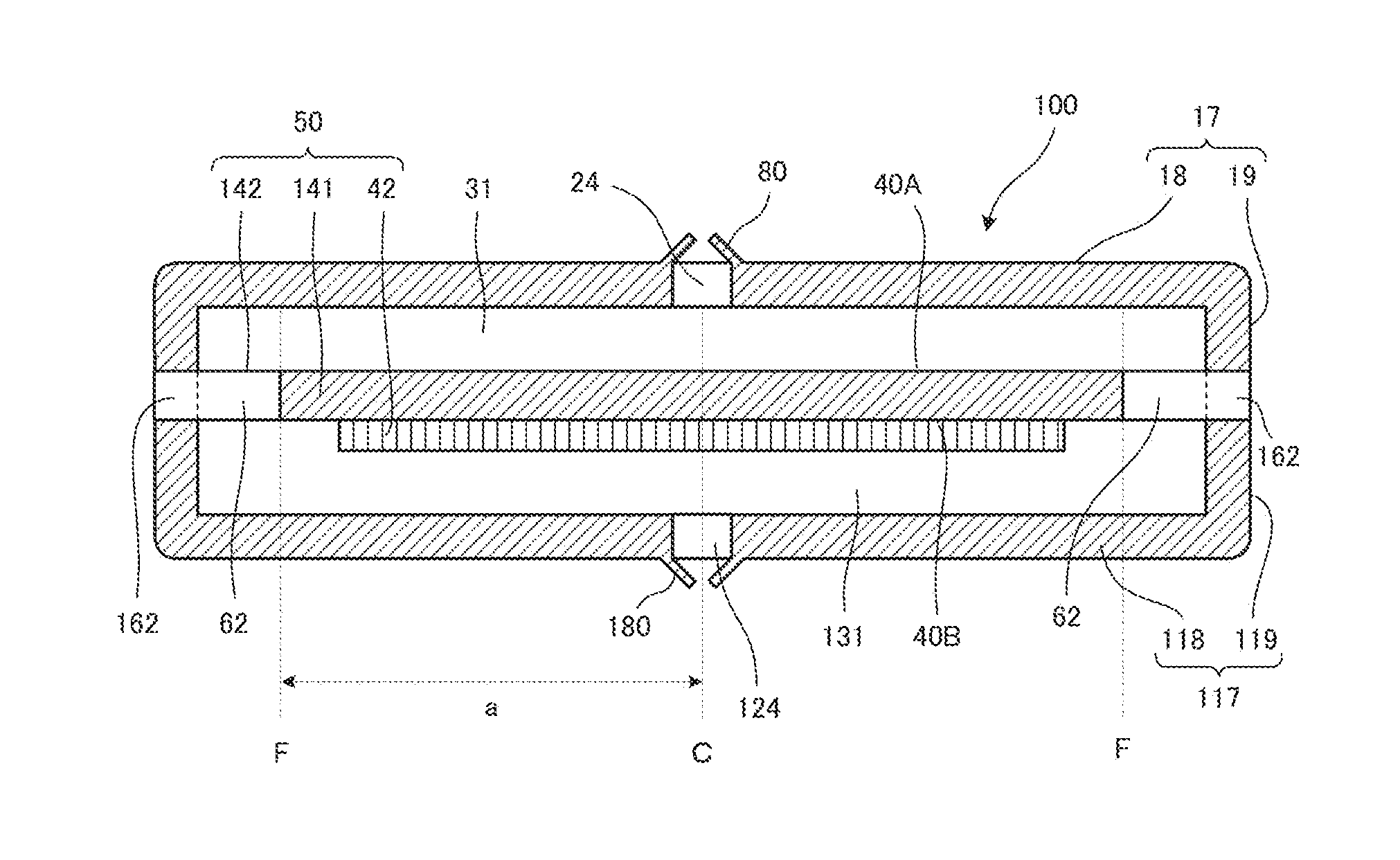

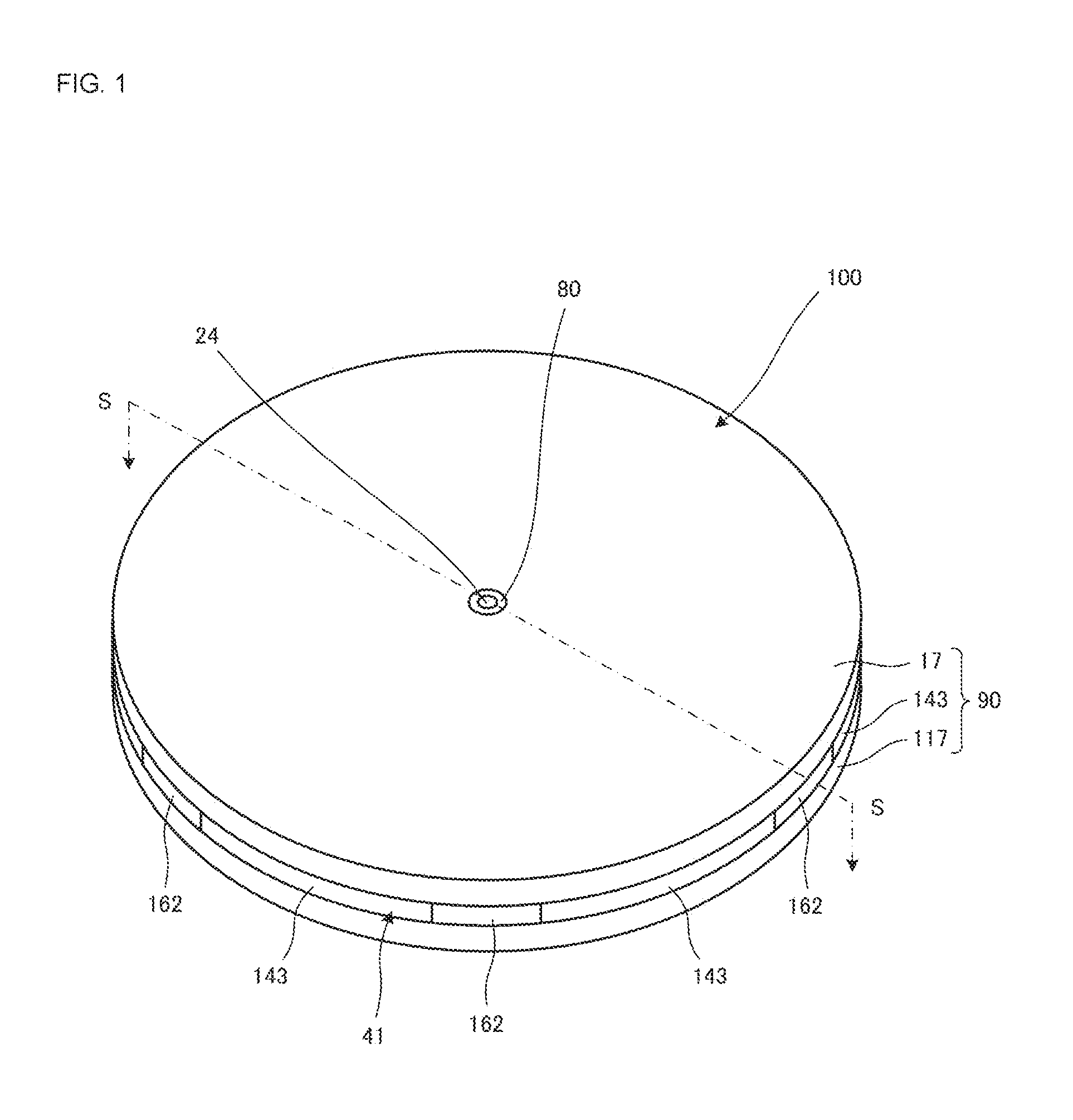

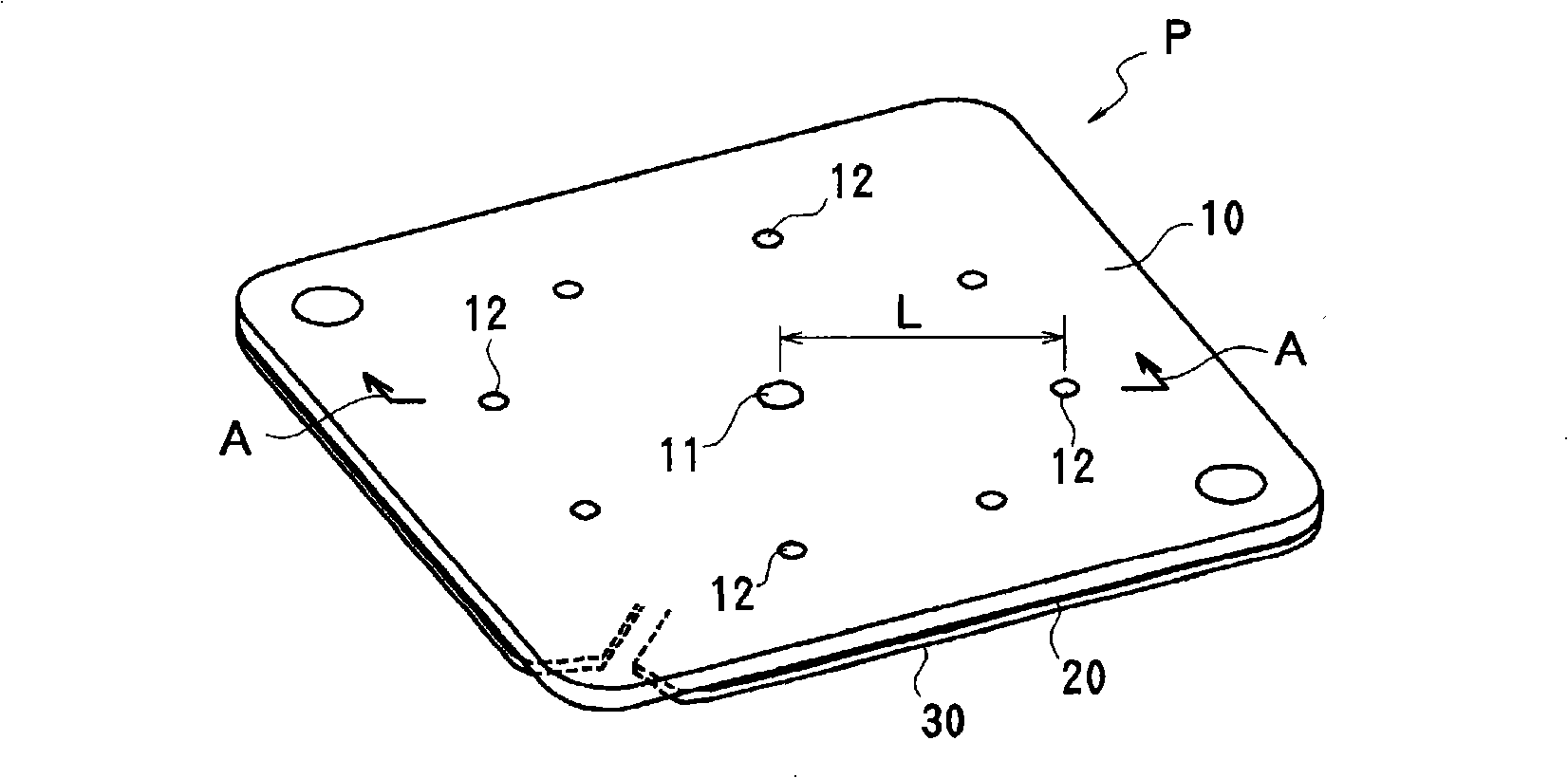

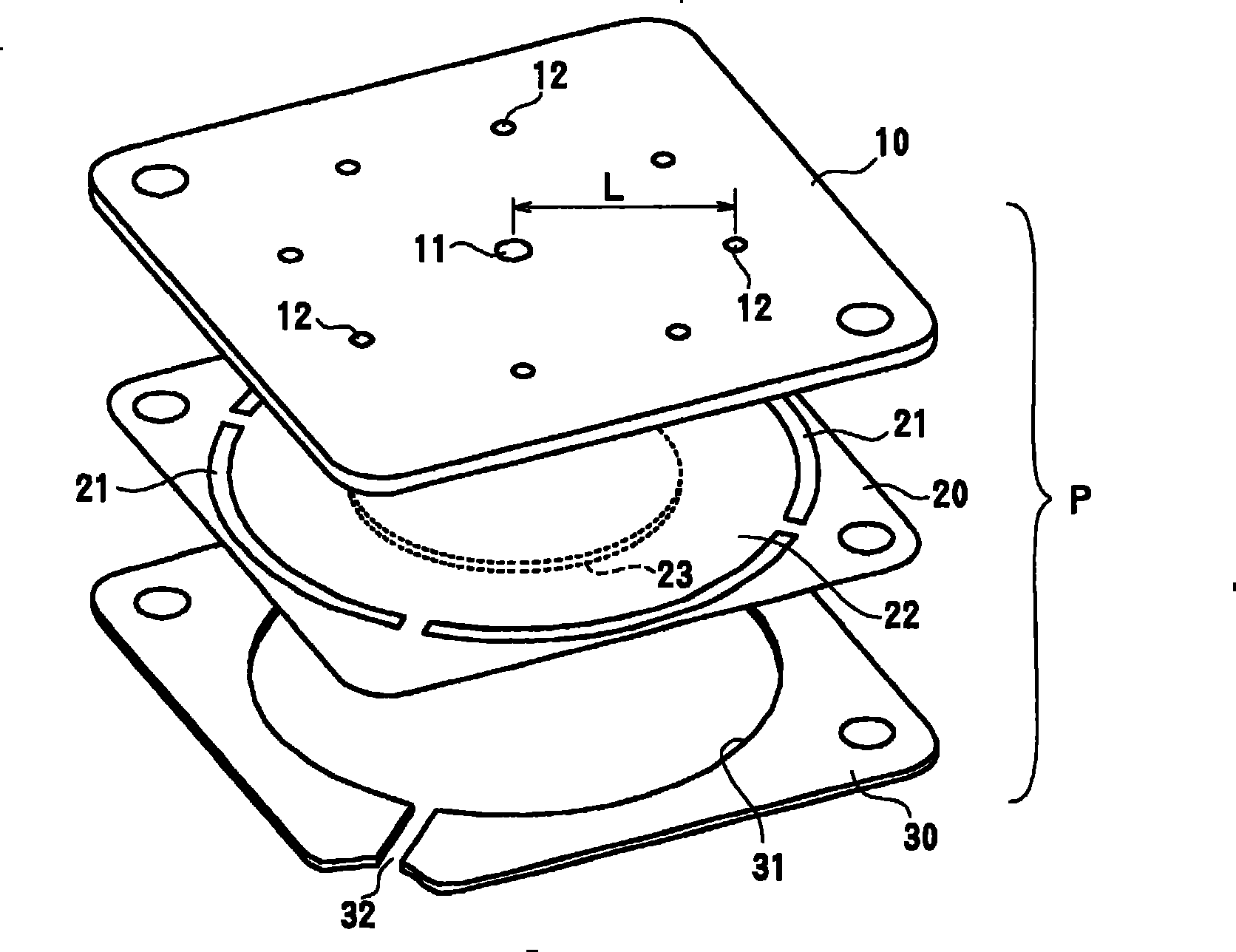

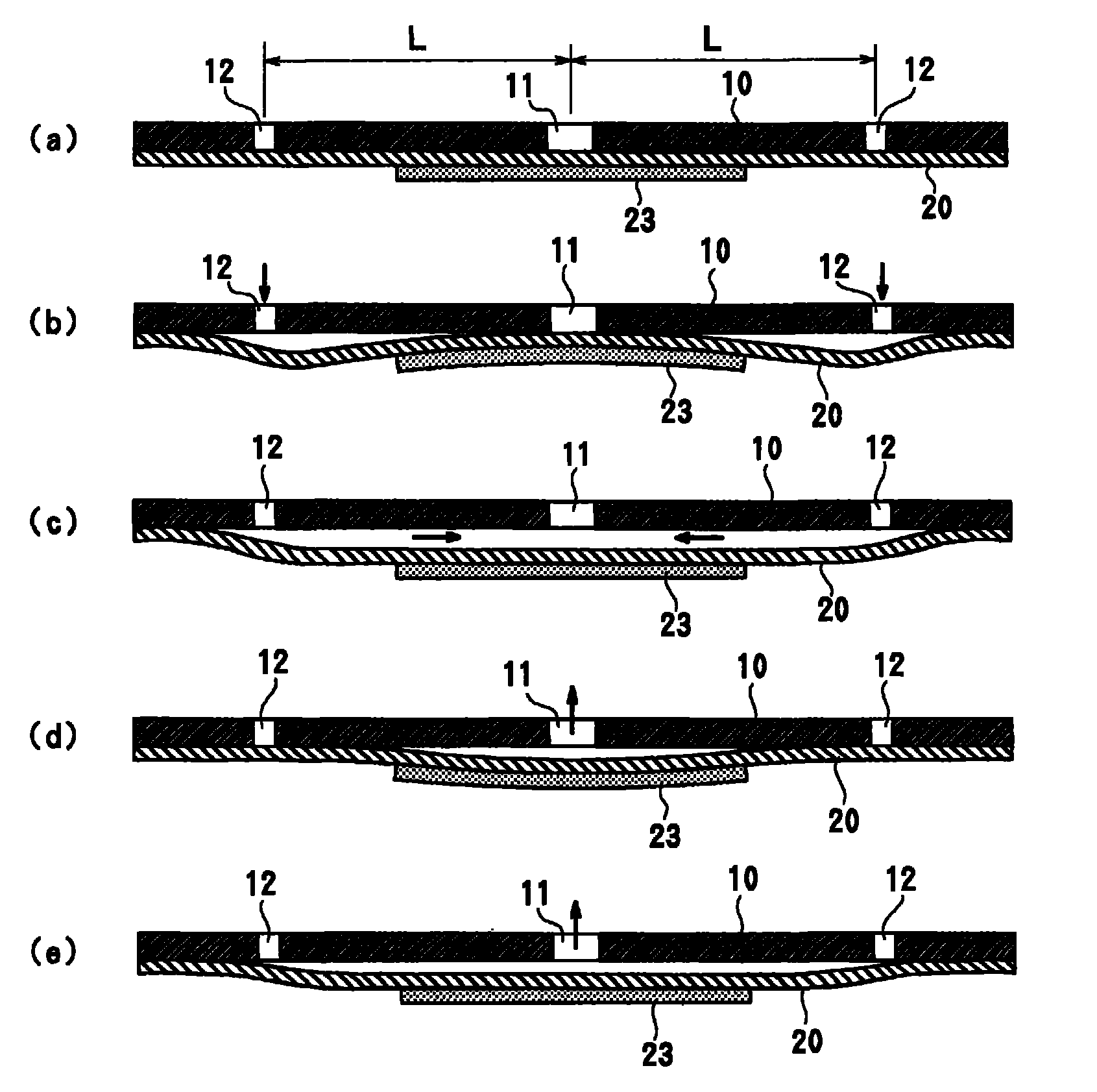

Piezoelectric pump

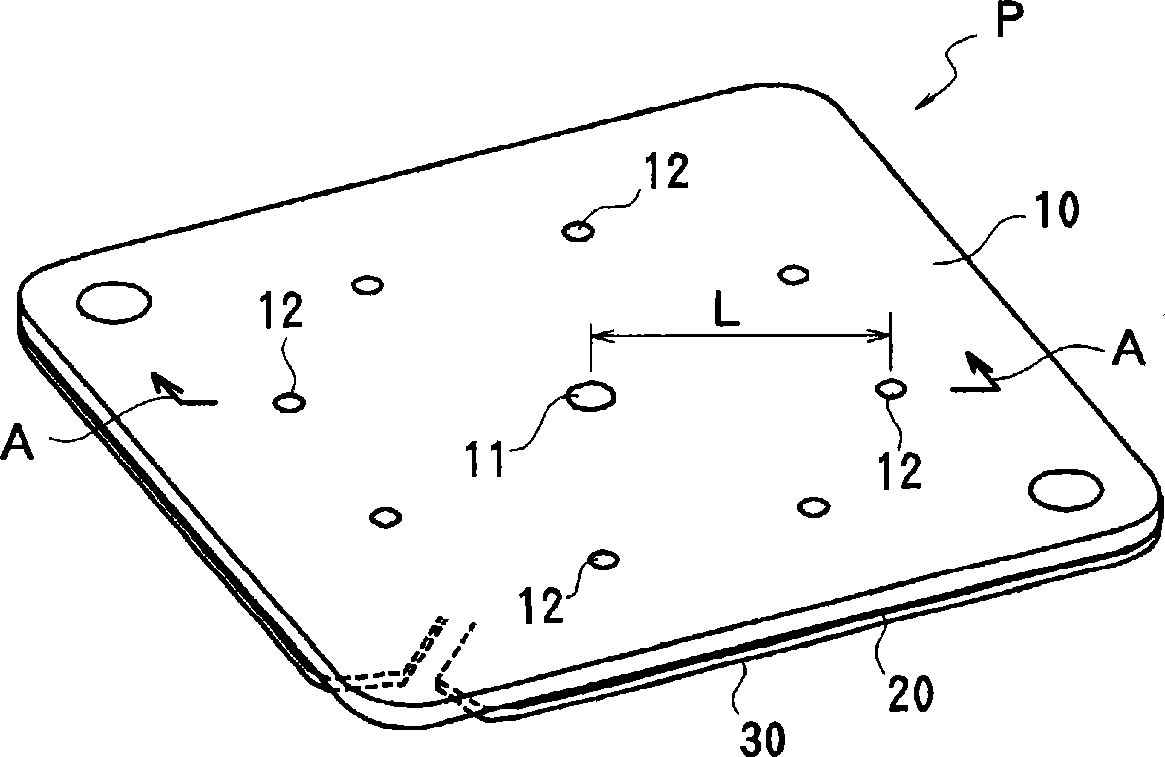

ActiveCN101490419AInflow fastEasy inflowEngine fuctionsWorking fluid for enginesElectricityResonance

The invention provides a piezoelectric pump having a simple structure and high discharge pressure. A first opening (11) is formed at the center of a pump body (10), and a second opening (12) is formed at a position away from the center. The outer periphery of a metal diaphragm (20) is fixed to the pump body (10), and a piezoelectric element (23) is bonded to the center on the rear side of the diaphragm (20). The piezoelectric element (23) has a size covering the first opening (11) but not reaching the second opening (12). When a voltage near the resonance frequency is applied to the piezoelectric element (23), that portion of the diaphragm (20) that faces the first opening (11) and that portion of the diaphragm (20) that faces the second opening (12) are bent and deformed in the directions opposite to each other. This causes fluid to be drawn from either one of the first opening (11) and the second opening (12) and discharged from the other. The piezoelectric pump can have high discharge pressure, which enables the pump to reliably discharge fluid even in conditions where the pressure on the discharge side is high.

Owner:MURATA MFG CO LTD

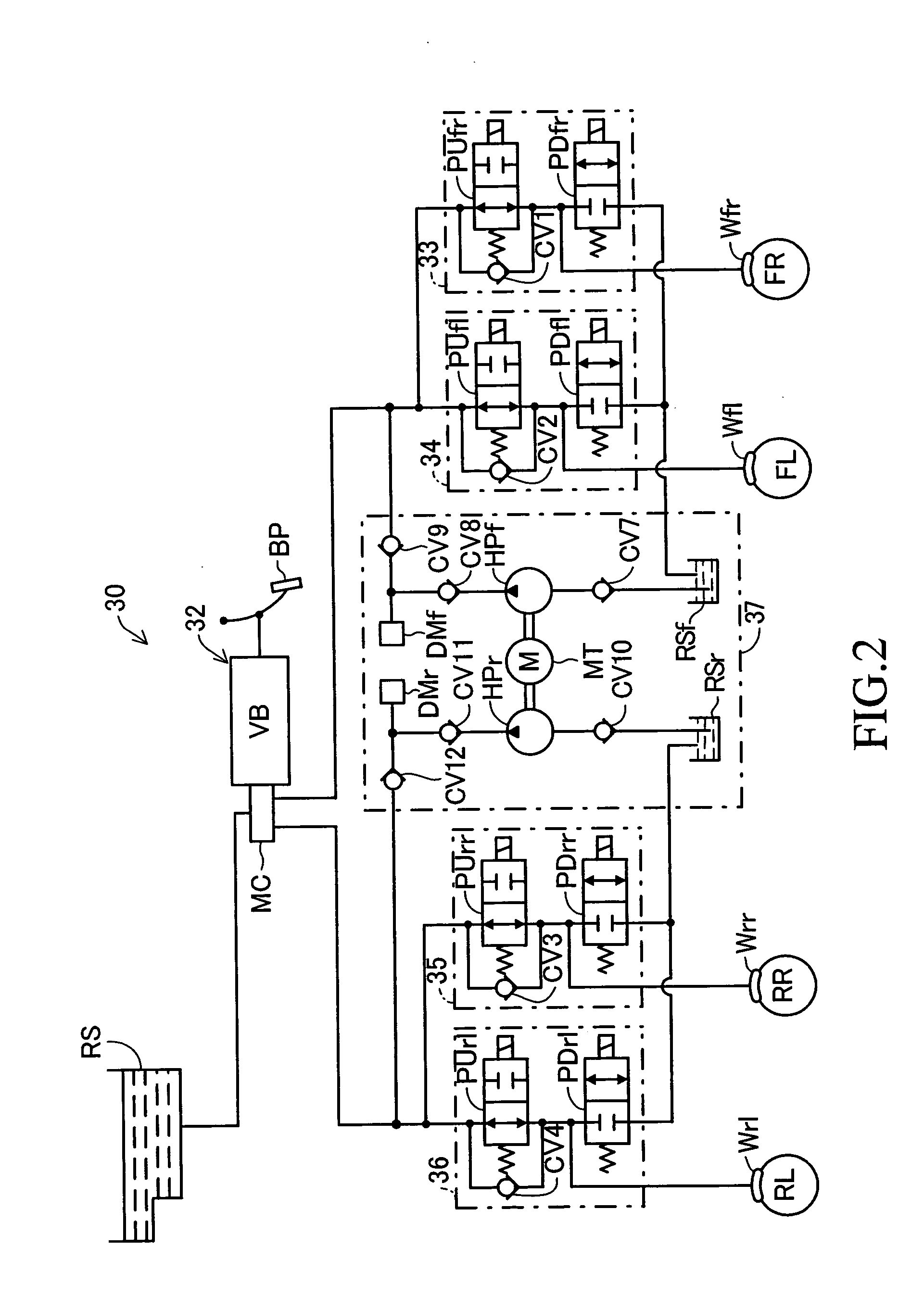

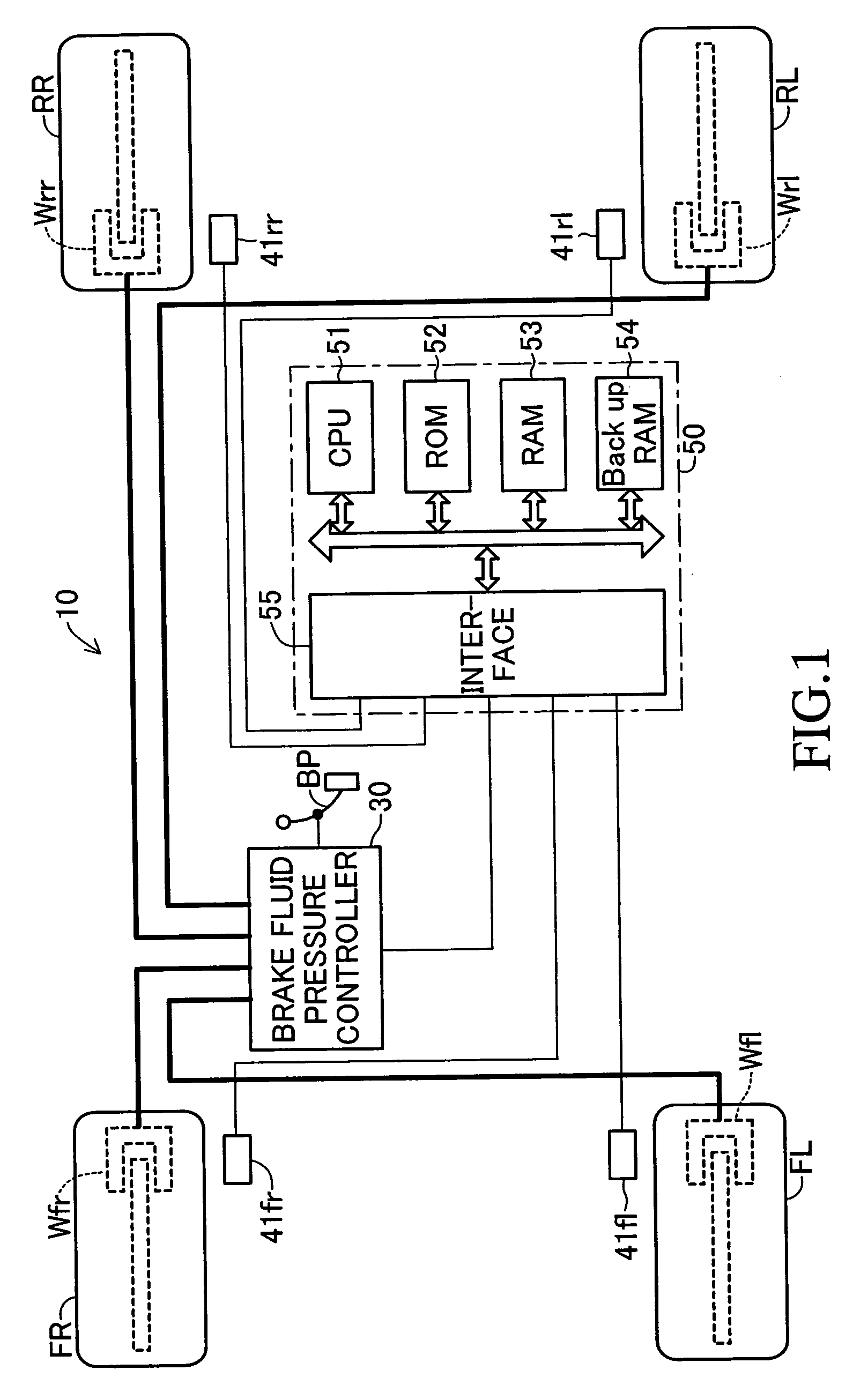

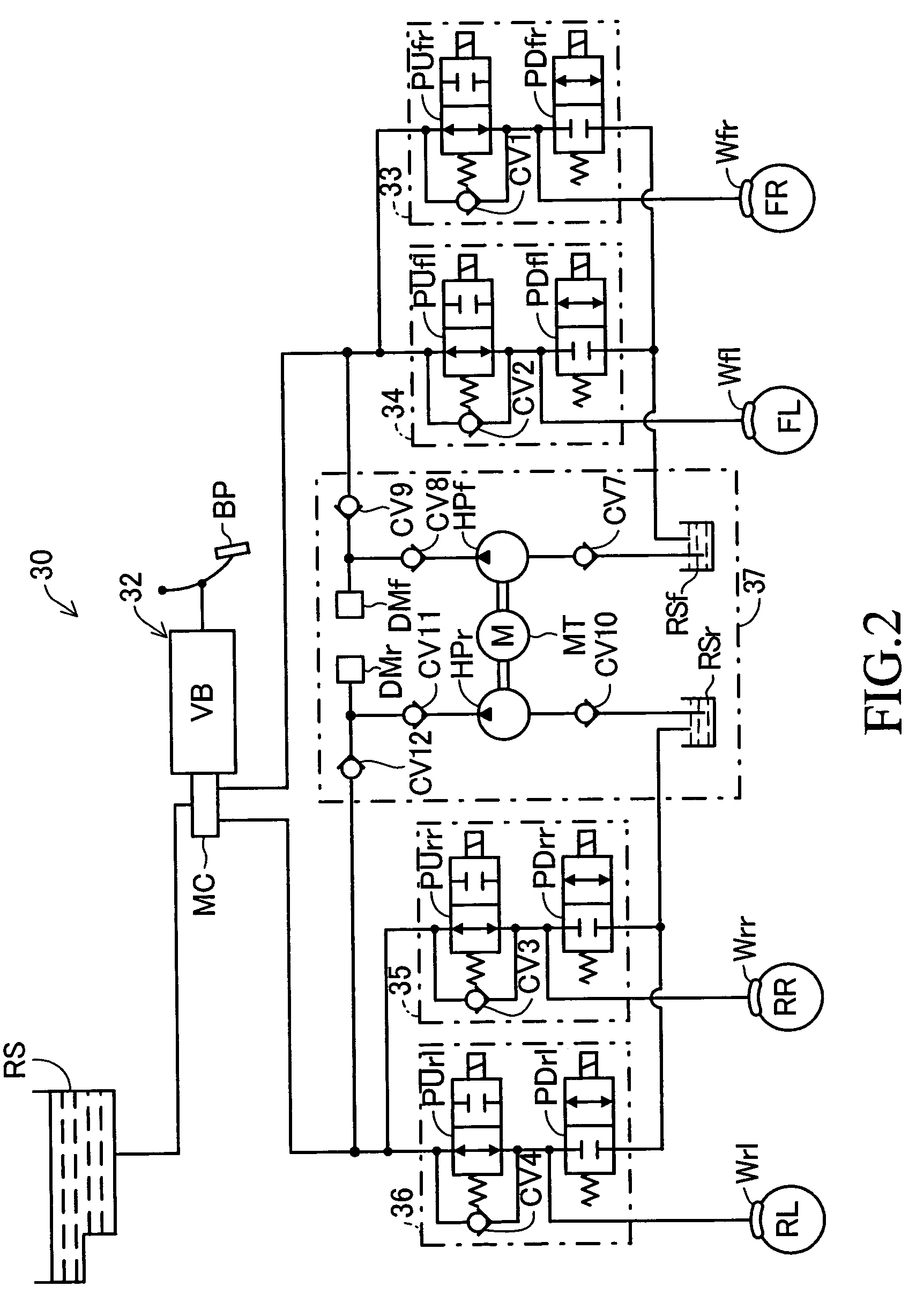

Pump drive motor control apparatus

ActiveUS20050069418A1Avoid failureSimple and reliable processBraking action transmissionField or armature current controlElectricityHydraulic pump

A pump drive motor control apparatus controls a motor used for driving a hydraulic pump. Every time the supply of electricity to the motor is resumed (every time the motor control signal changes from a low level to a high level), the apparatus measures a time which the voltage generated by the motor requires to decrease by a predetermined amount, the time indicating the decreasing speed of the generated voltage. The apparatus normally sets the high-level maintenance time, in which the motor control signal is maintained high, to a base time. When a state in which the measured time is not longer than a reference time is detected a predetermined number of times (3 times) or more, the apparatus determines that the load of the pump is heavy. In such a case, the apparatus increases the average rotational speed of the motor by increasing the high-level maintenance time.

Owner:ADVICS CO LTD

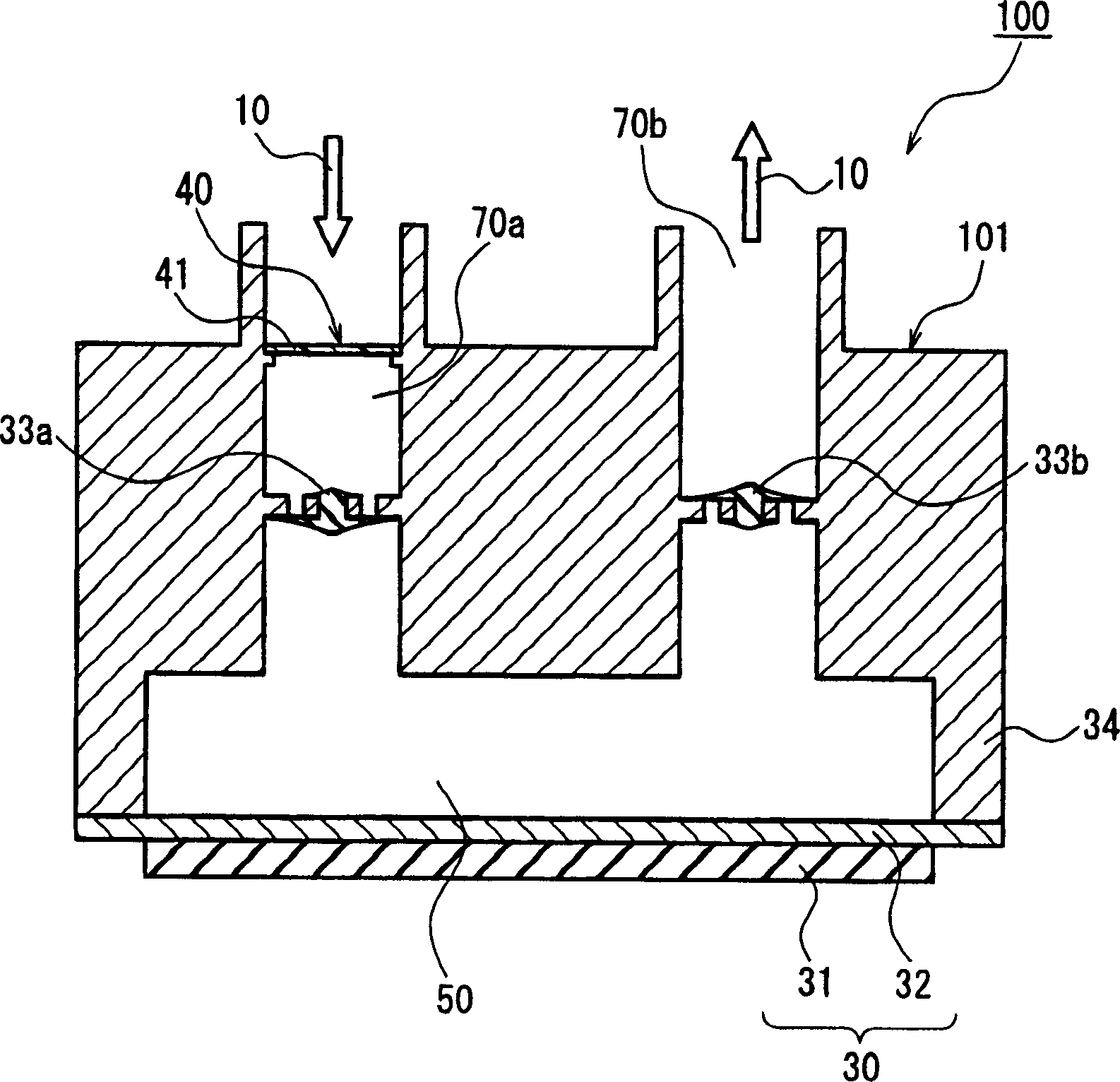

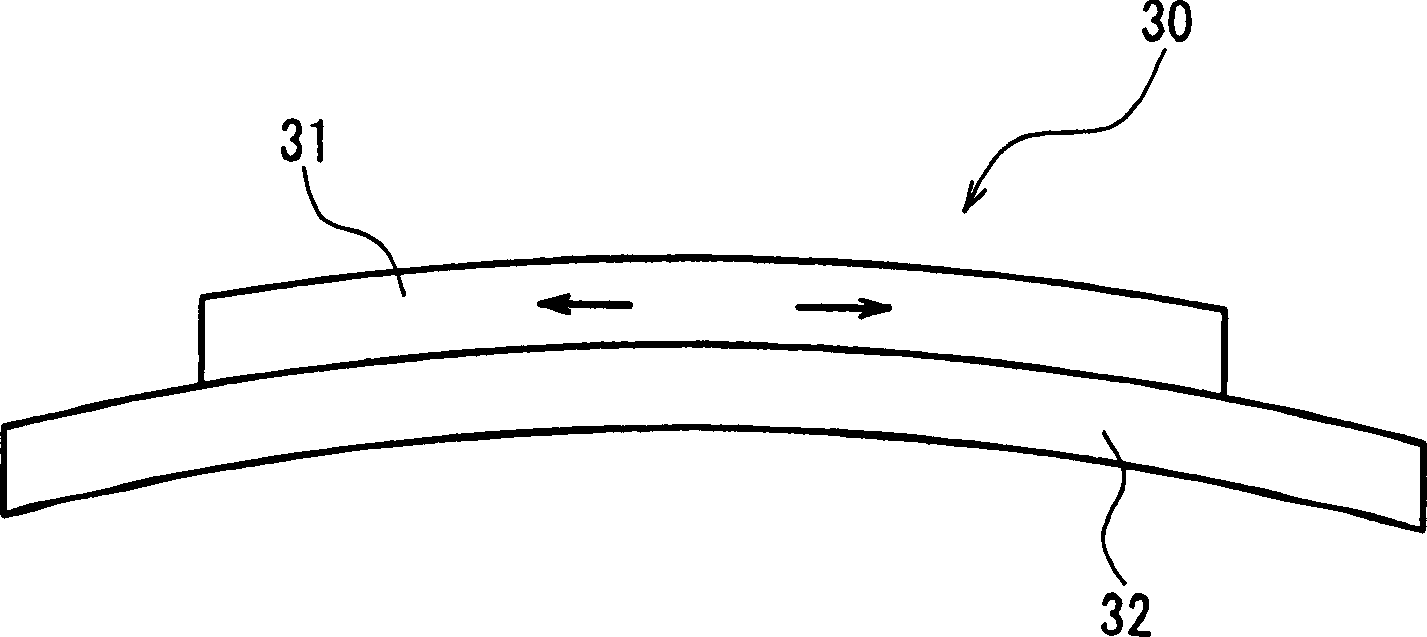

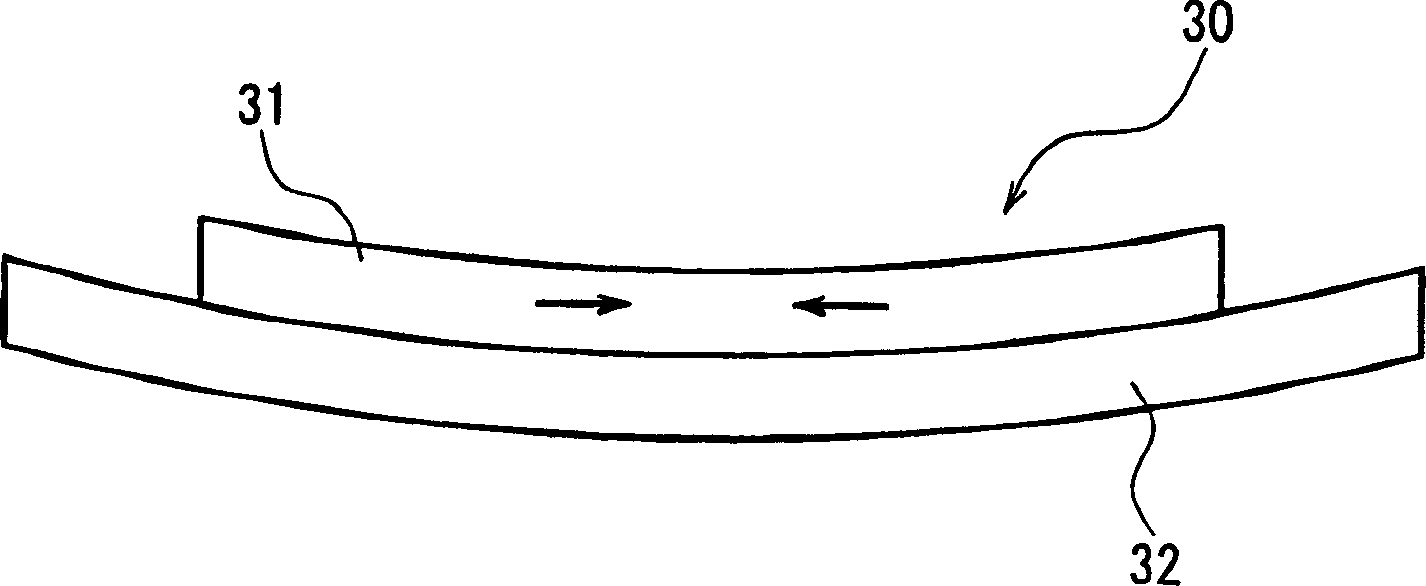

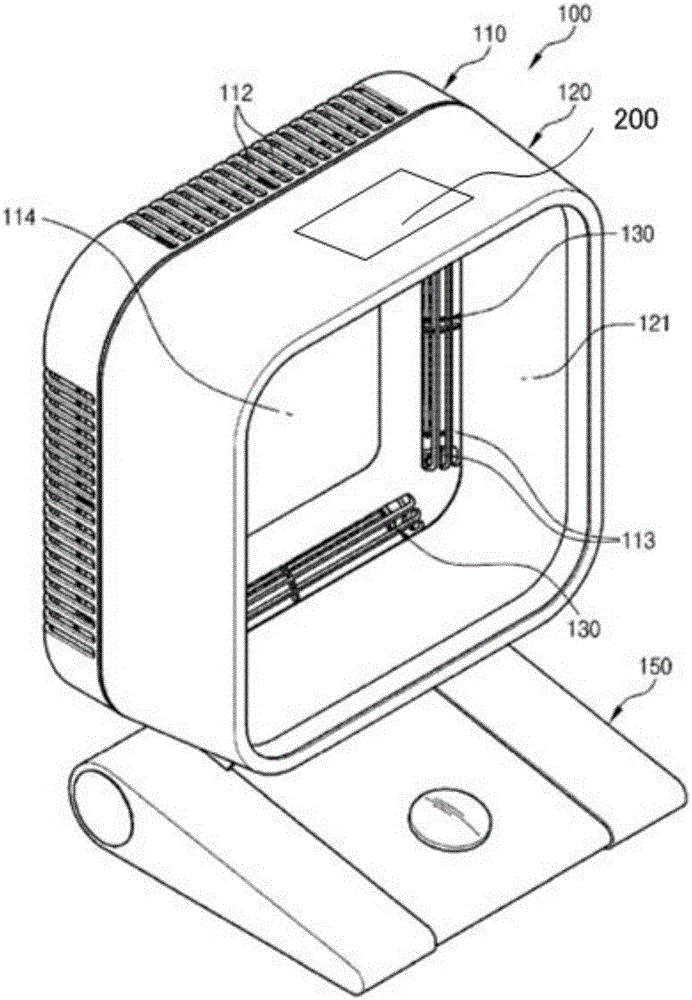

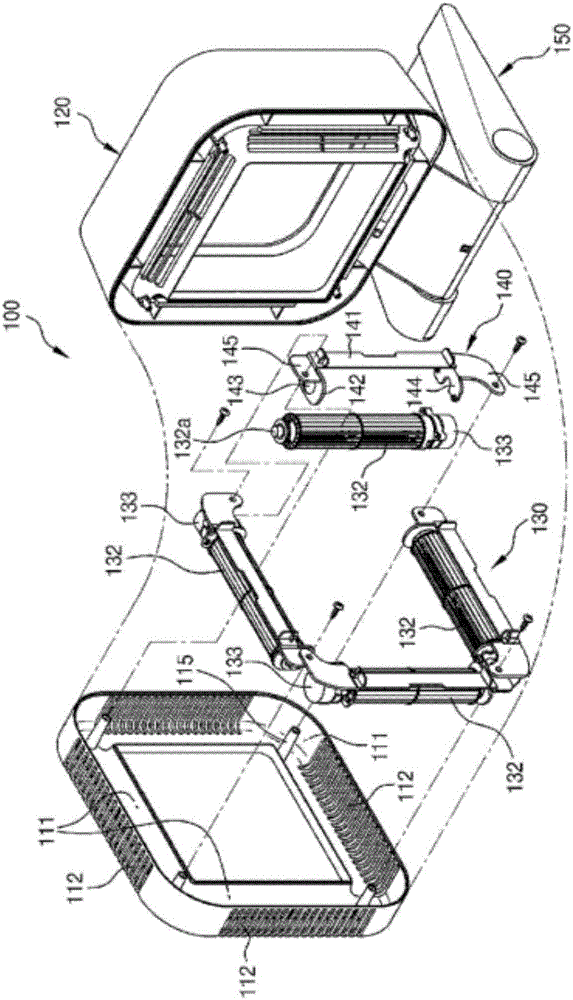

Small pump, cooling system and portable instrument

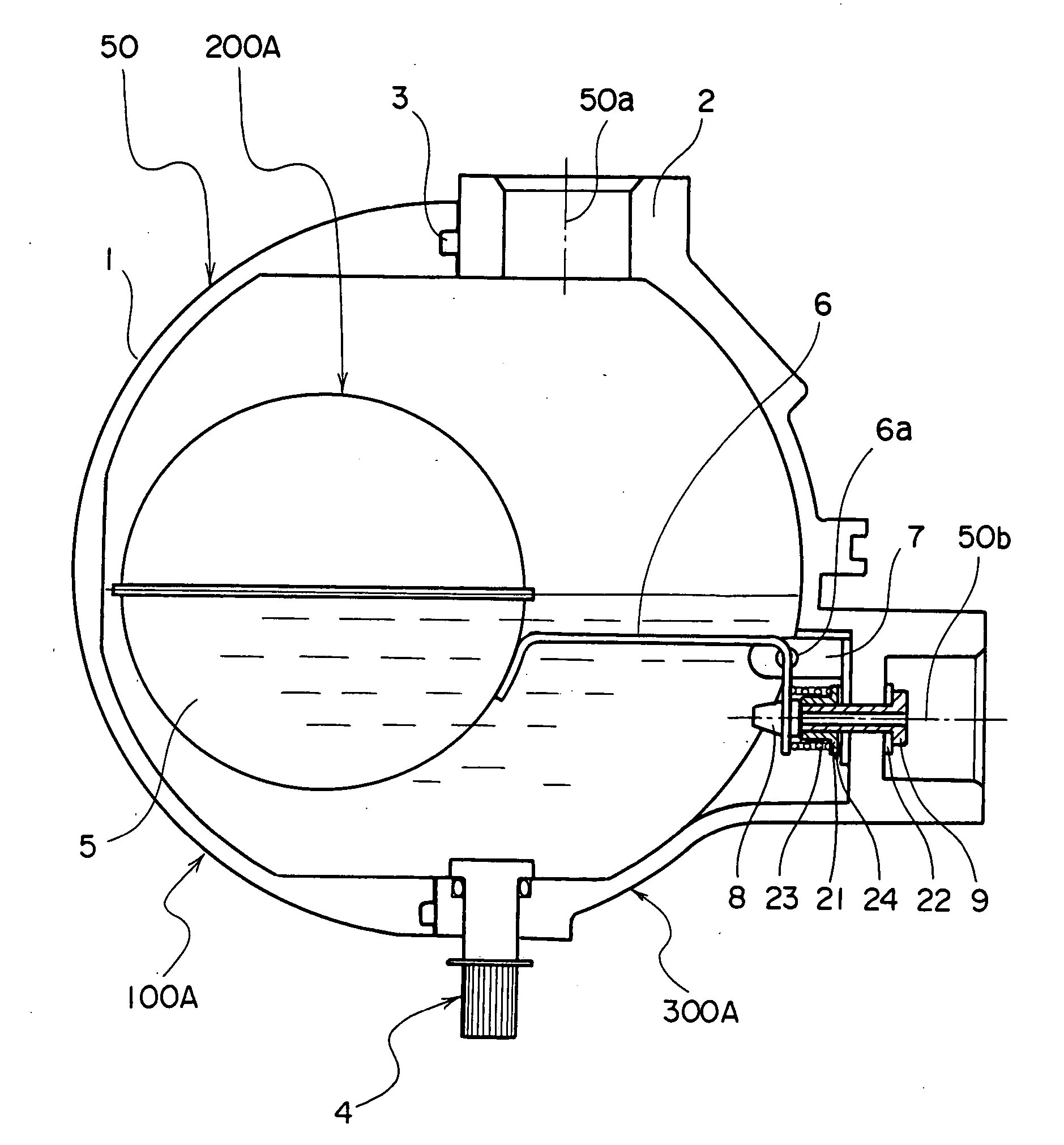

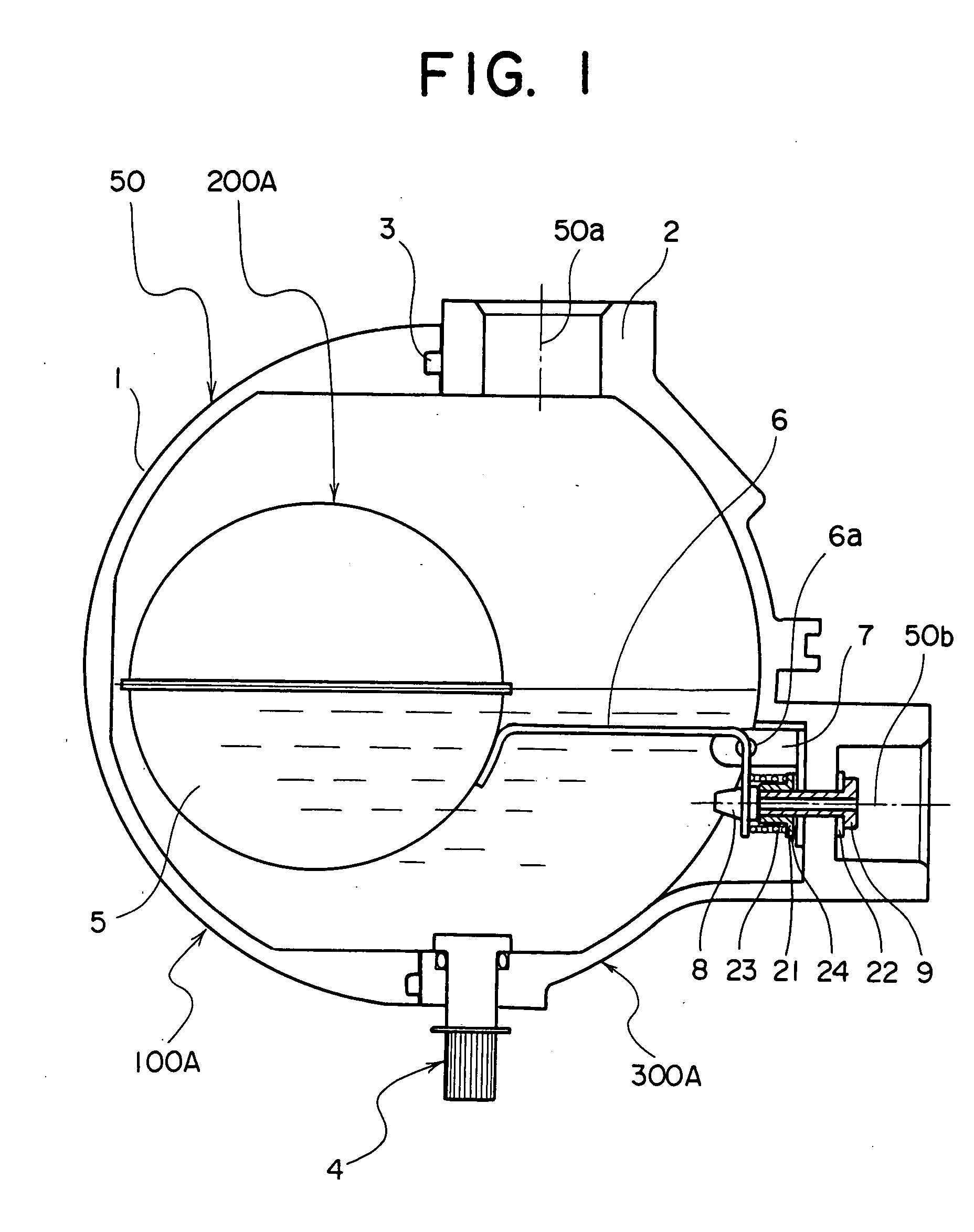

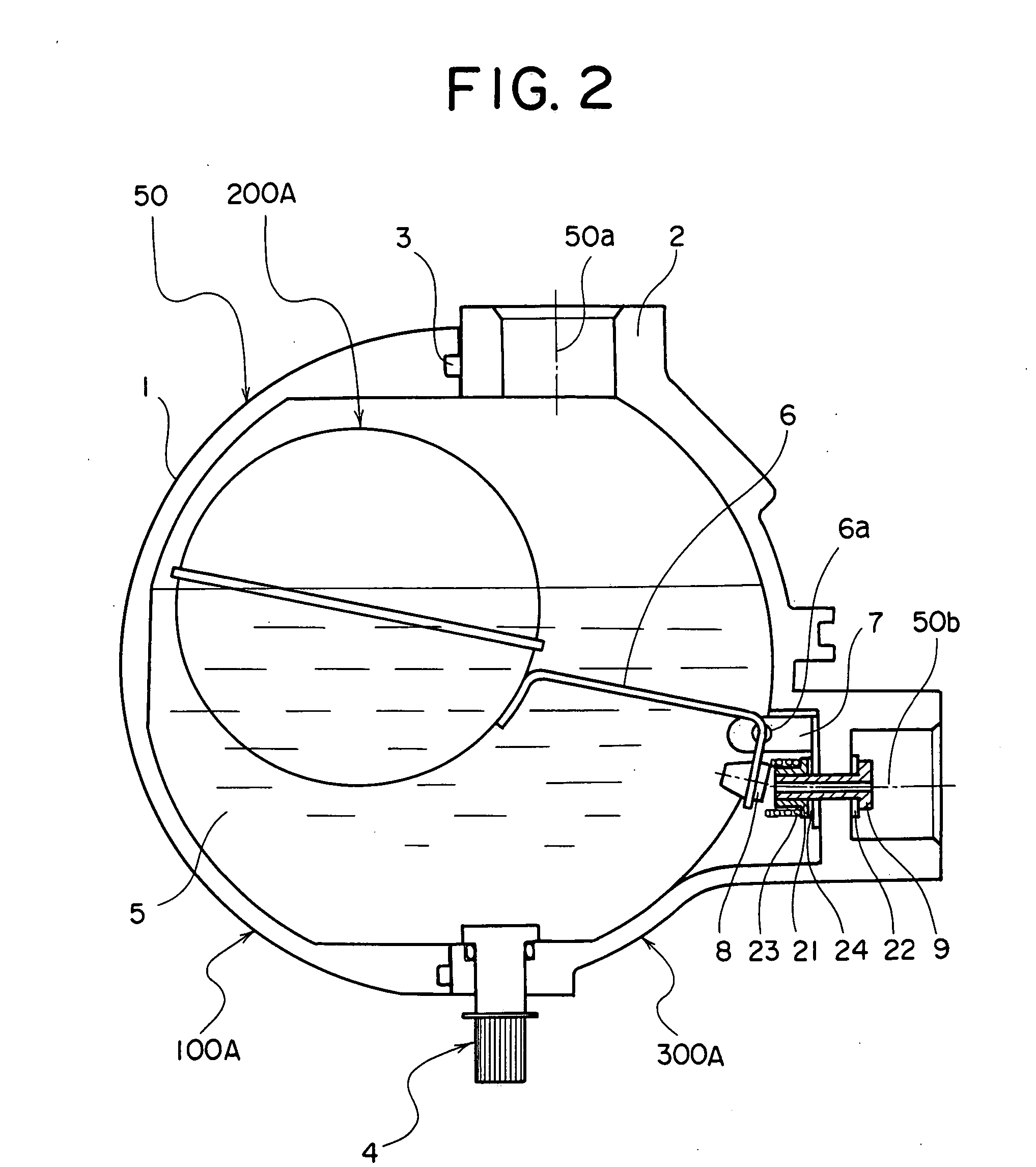

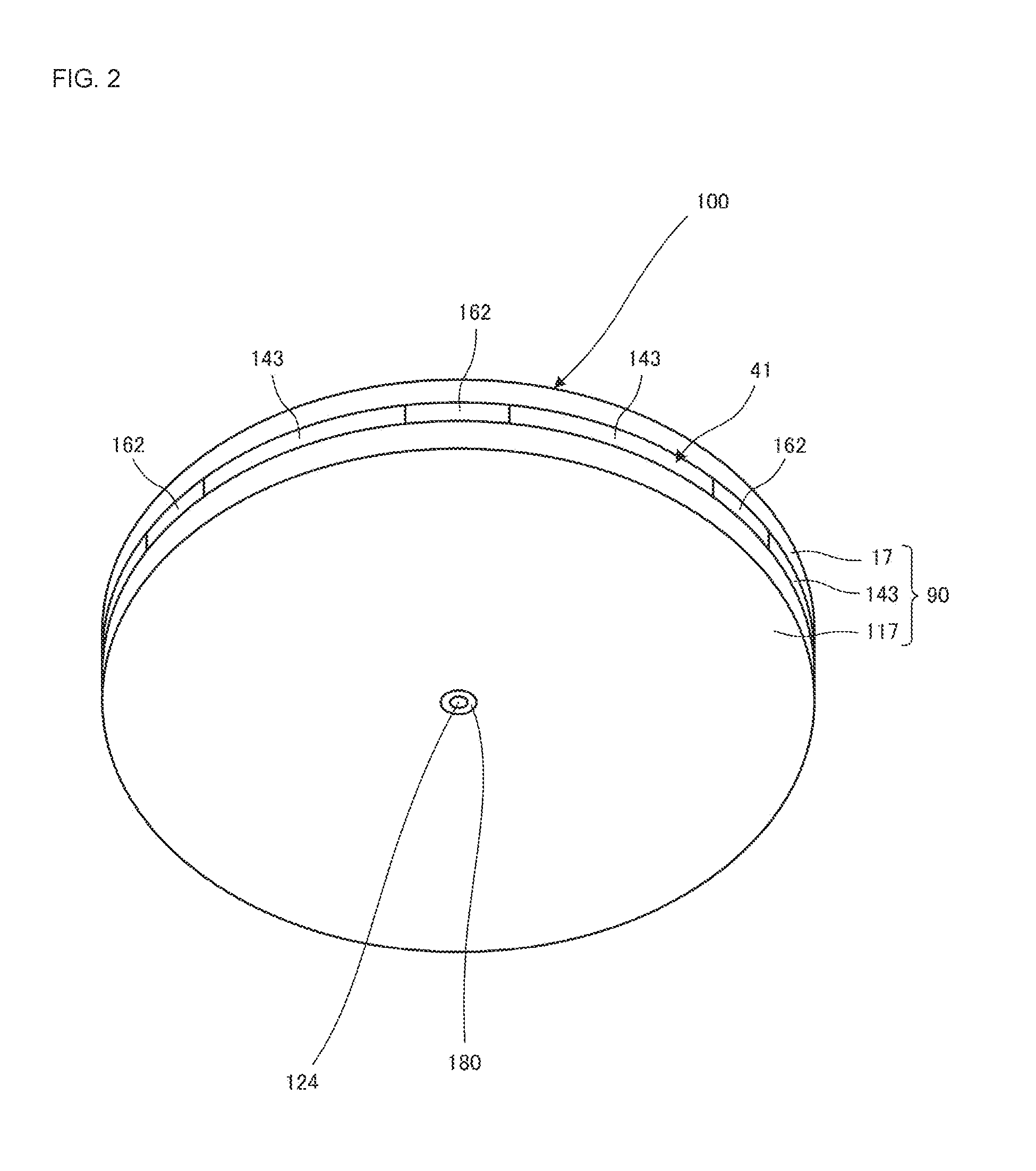

InactiveCN1397734AIncrease discharge flowStable discharge flowPositive displacement pump componentsFlexible member pumpsEngineeringInstrumentation

A miniature pump 100 includes a miniature pump portion 101 including a suction passage 70a through which a liquid flows in, and a discharge passage 70b through which the liquid flows out, and a bubble trap portion 40 for blocking an entry of air bubbles into the miniature pump portion 101. Since the bubble trap portion 40 prevents the entry of air bubbles into the miniature pump portion 101, a deterioration of pump characteristics owing to the entry of air bubbles can be suppressed, making it possible to obtain a miniature pump that achieves both a large discharge flow rate and stable discharge flow rate characteristics.

Owner:PANASONIC CORP

Buoyancy type drain trap

InactiveUS20060272705A1Reduce weightIncrease discharge flowOperating means/releasing devices for valvesSteam trapsWater dischargeEngineering

Provided are a drain water discharging method and a buoyancy type drain trap in which a float is accommodated in a case and drain water allowed to flow into the case can be discharged by buoyancy acting on the float. In a case where an inner diameter of the valve is increased in order to increase a discharge flow rate at a valve connected to an outlet port formed in the case, the movement of a valve seat for opening the valve is facilitated through addition of some force to increase the buoyancy or through a reduction in a weight of the float itself.

Owner:FUKUHARA KK

Hydraulic controller for construction machine

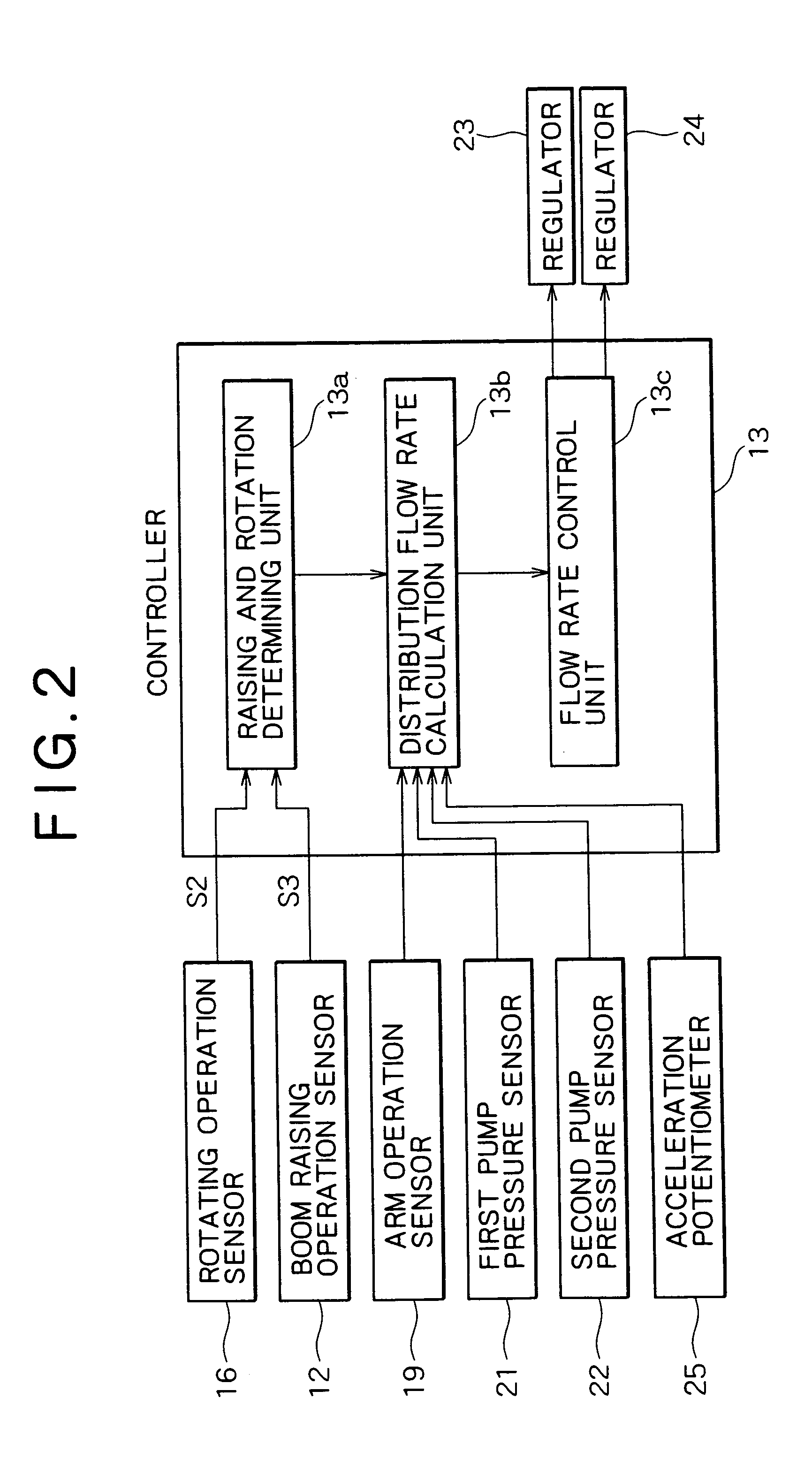

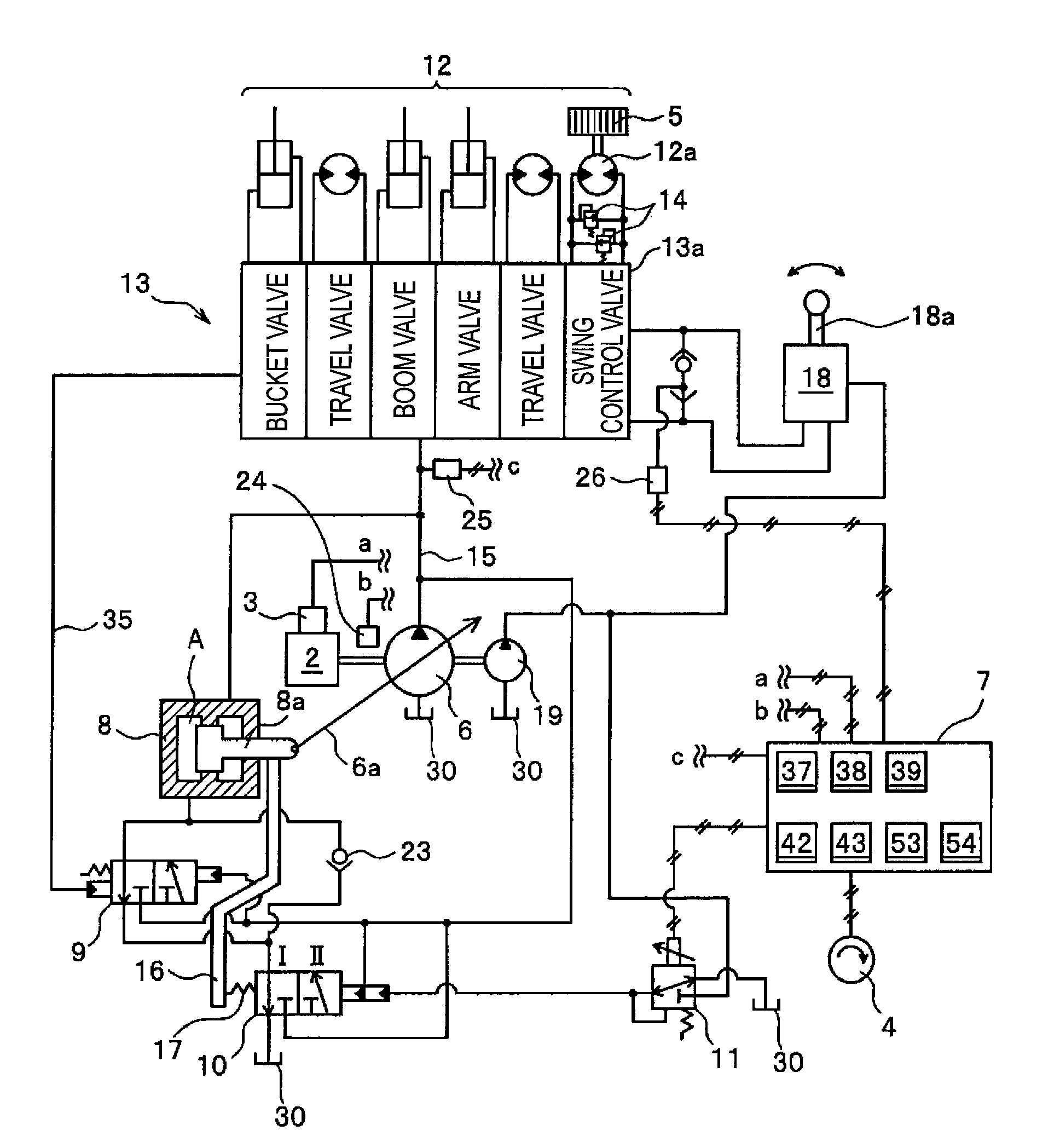

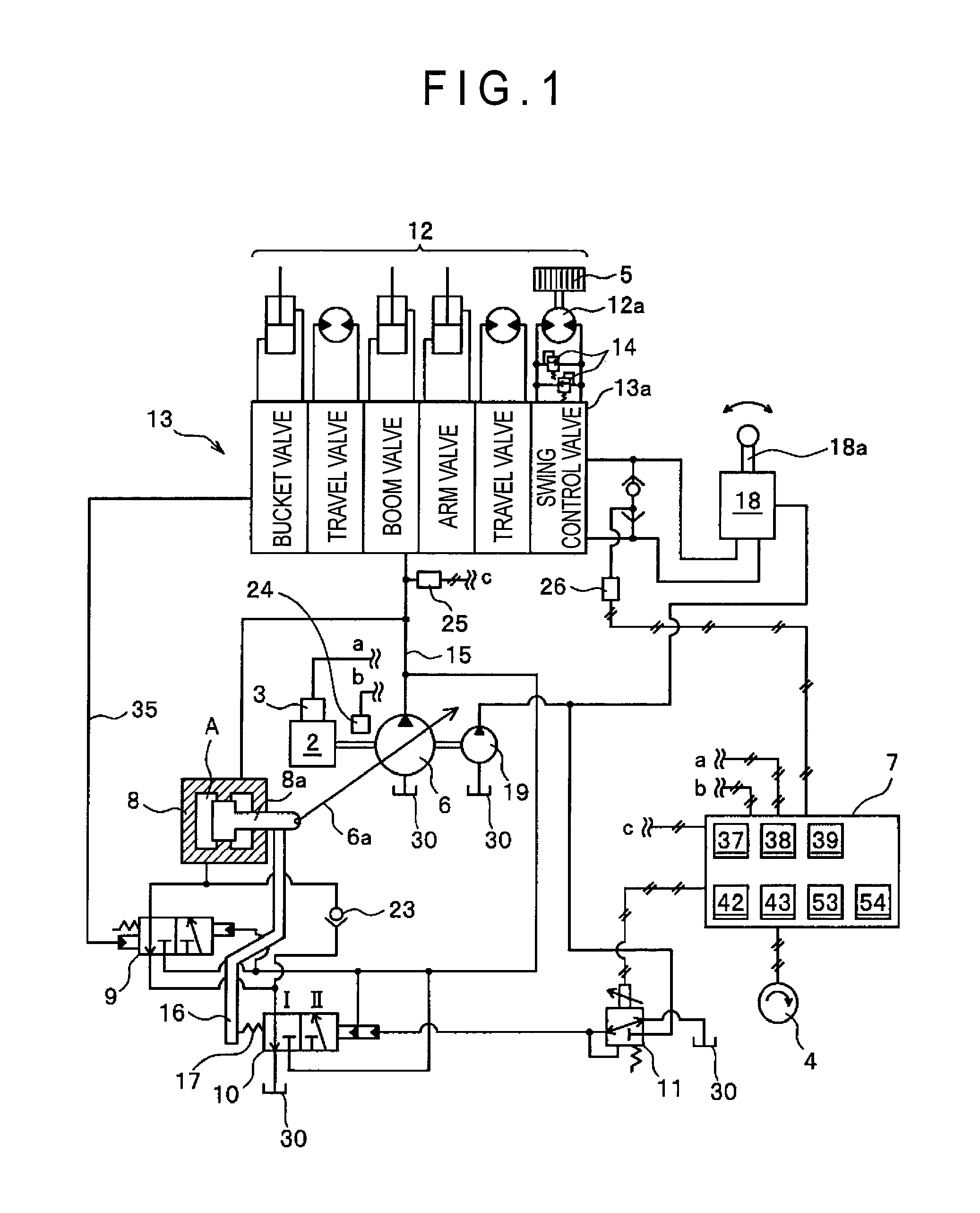

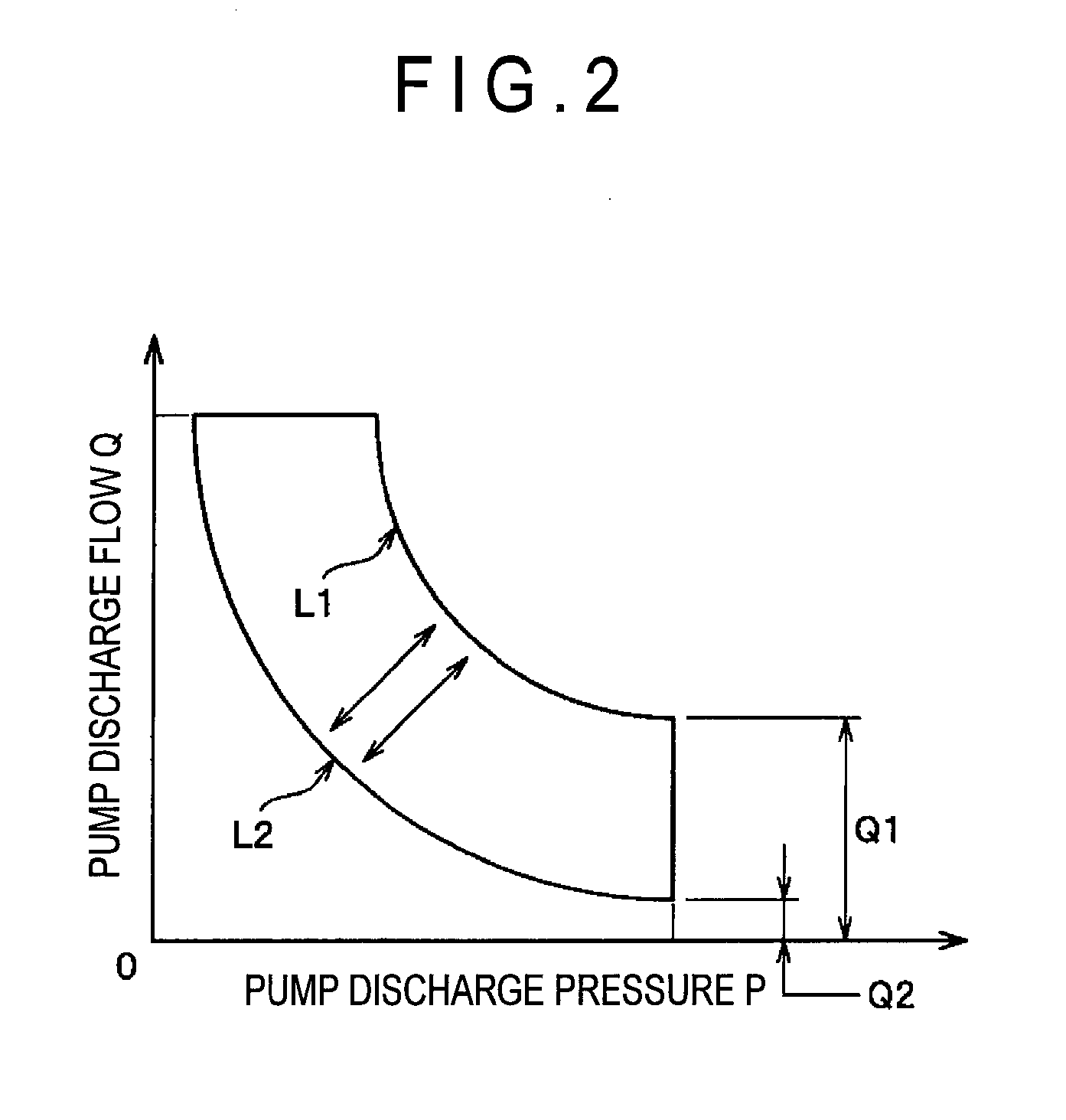

ActiveUS20050060993A1Improve distributionHigh speedRotary clutchesServomotorsElectric machineHydraulic pump

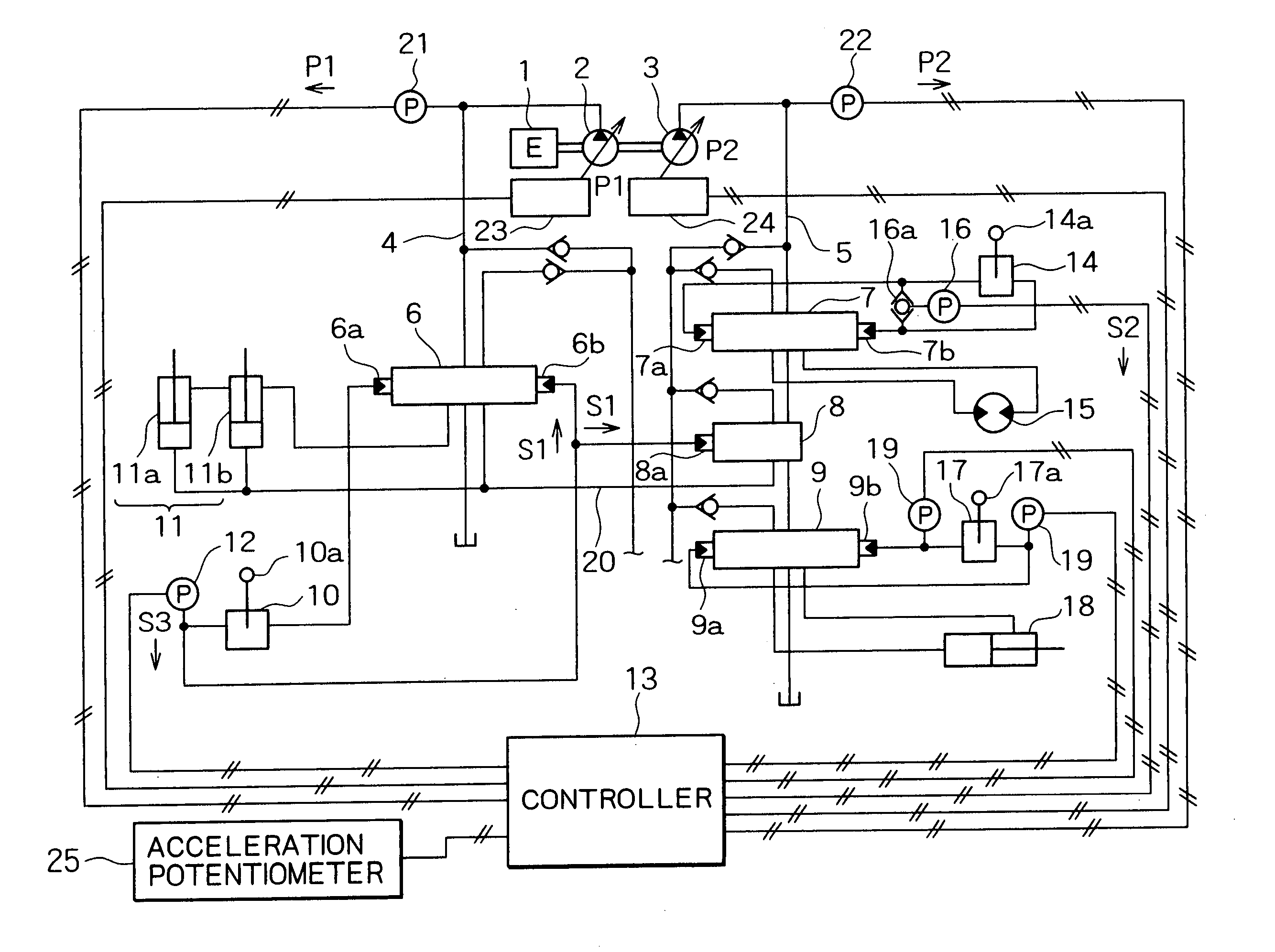

In a hydraulic controller for construction machine according to the present invention, wherein there are provided regulators for each of a first and a second capacity variable hydraulic pump, each of the regulators being controlled, detecting the discharge pressure of each pump, in such a manner that one of the pumps absorbs a part of torque while the other thereof absorbs the remaining torque, and wherein a boom raising operation causes pressure oil from the pumps to be joined together and then supplied to a boom cylinder, while also a rotating operation causes pressure oil from the second pump to be supplied to a rotating motor, is provided a flow rate distribution controller adapted to control the regulators in such a manner that a difference in flow rate is provided between the pumps so that the first pump shows a higher flow rate at the start of a combined operation of raising and rotating, and that, on a steady rotating state which results in an increase in the discharge pressure difference between the pumps, the difference in flow rate is reduced. This enables pump horsepower to be distributed optimally between the boom cylinder and rotating motor during the raising and rotating operation.

Owner:KOBELCO CONSTR MASCH CO LTD

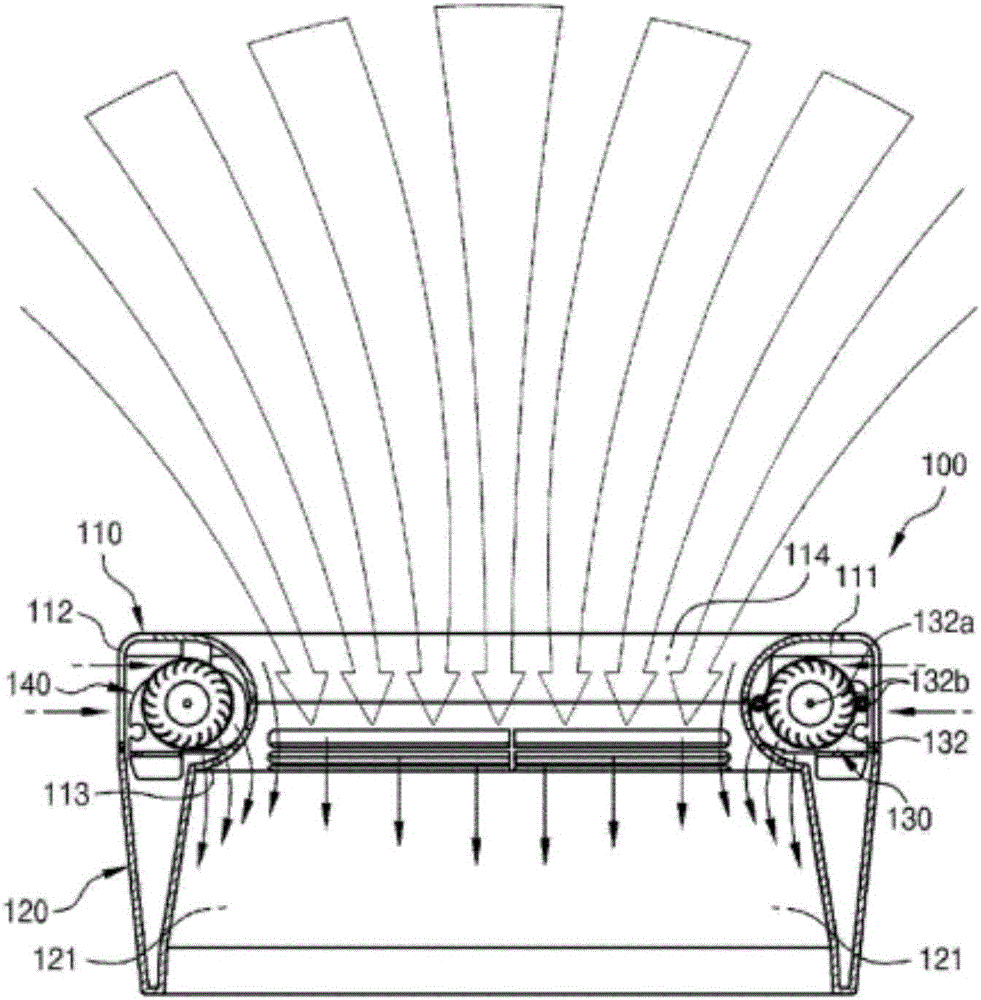

Blower

ActiveUS20170058884A1Increase power consumptionReduce power consumptionPositive displacement pump componentsFlexible member pumpsActuator

A piezoelectric blower includes a first valve, a first housing, a vibrating plate, a piezoelectric element, a second housing, and a second valve. The first housing forms, together with the vibrating plate, a first blower chamber. A first top plate portion includes a first vent hole that allows an inside of the first blower chamber to communicate with an outside of the first blower chamber. The second housing forms, together with an actuator, a second blower chamber. A second top plate portion includes a second vent hole that allows an inside of the second blower chamber to communicate with an outside of the second blower chamber. The vibrating plate includes an opening portion and a third vent hole, the opening portion allowing an outer periphery of the first blower chamber and an outer periphery of the second blower chamber to communicate with each other.

Owner:MURATA MFG CO LTD

Piezoelectric pump

Owner:MURATA MFG CO LTD

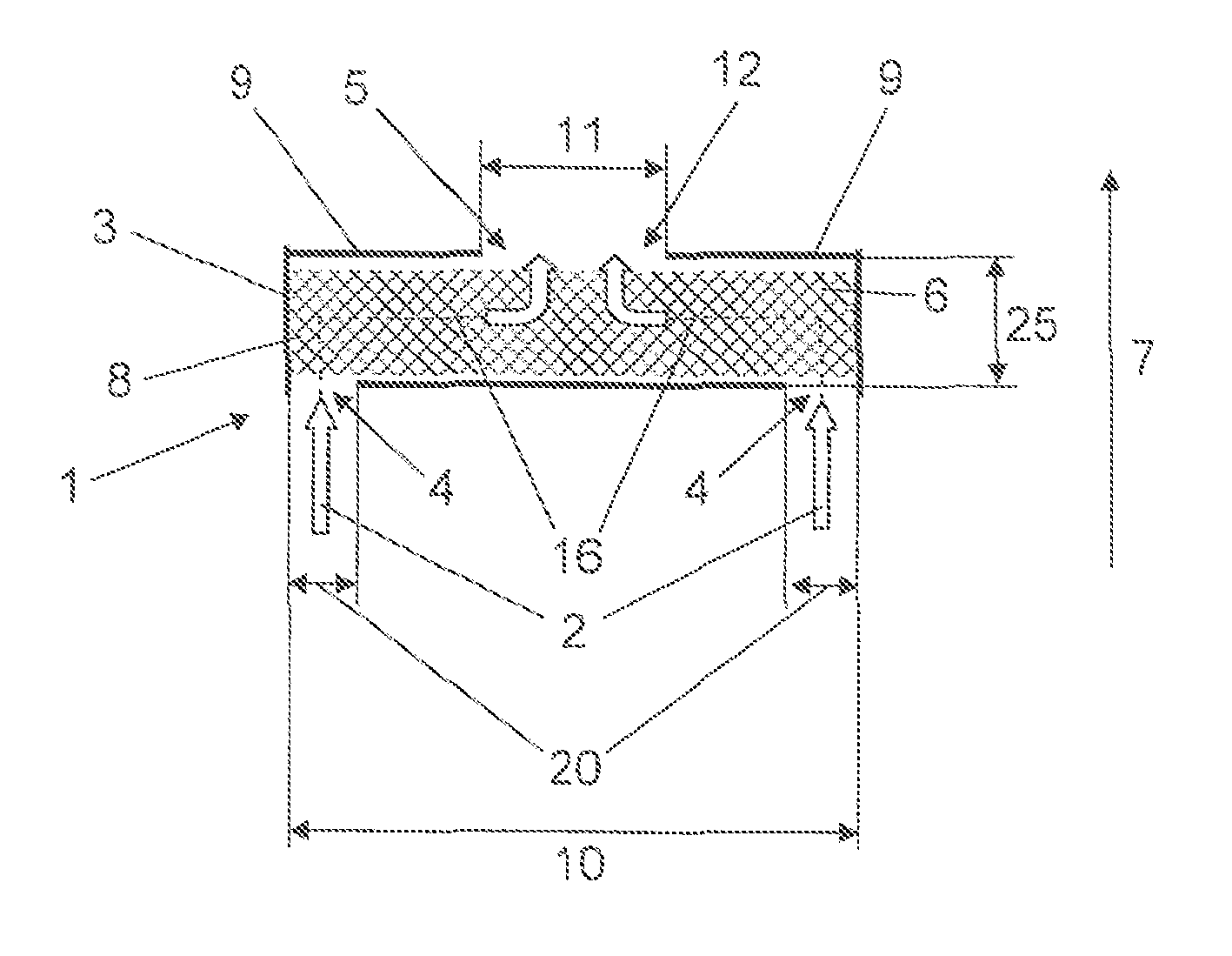

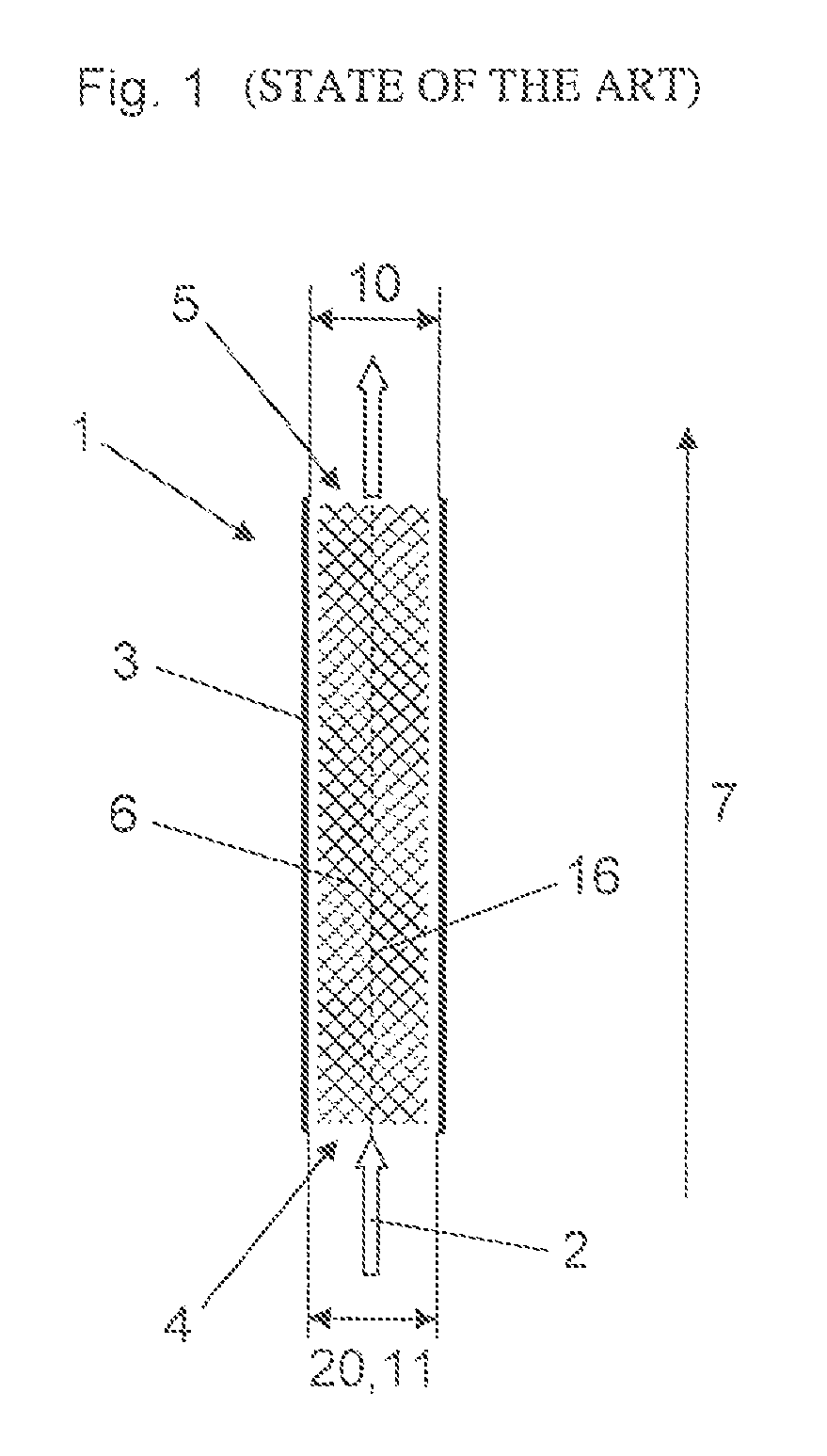

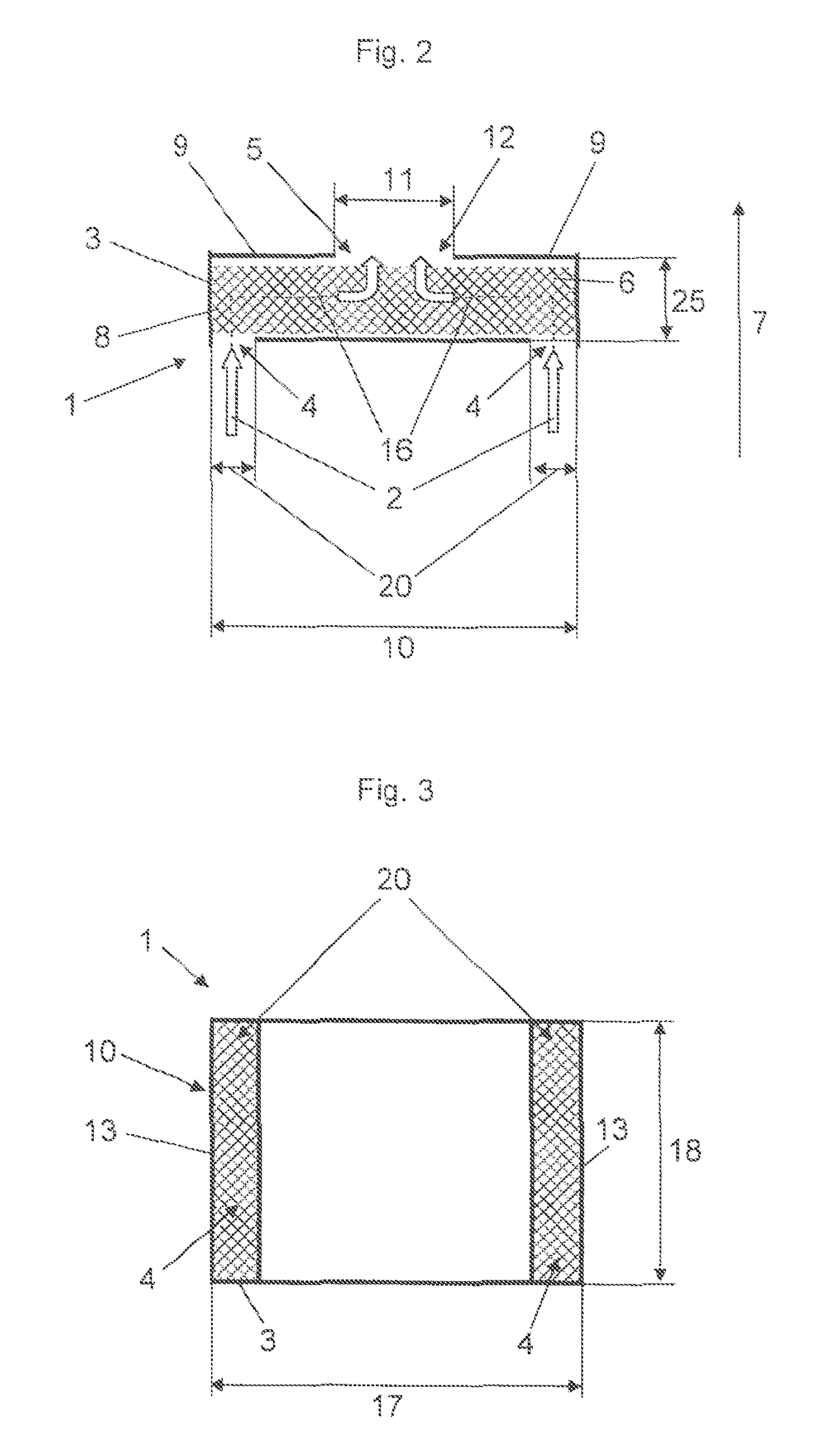

Fan arrangement

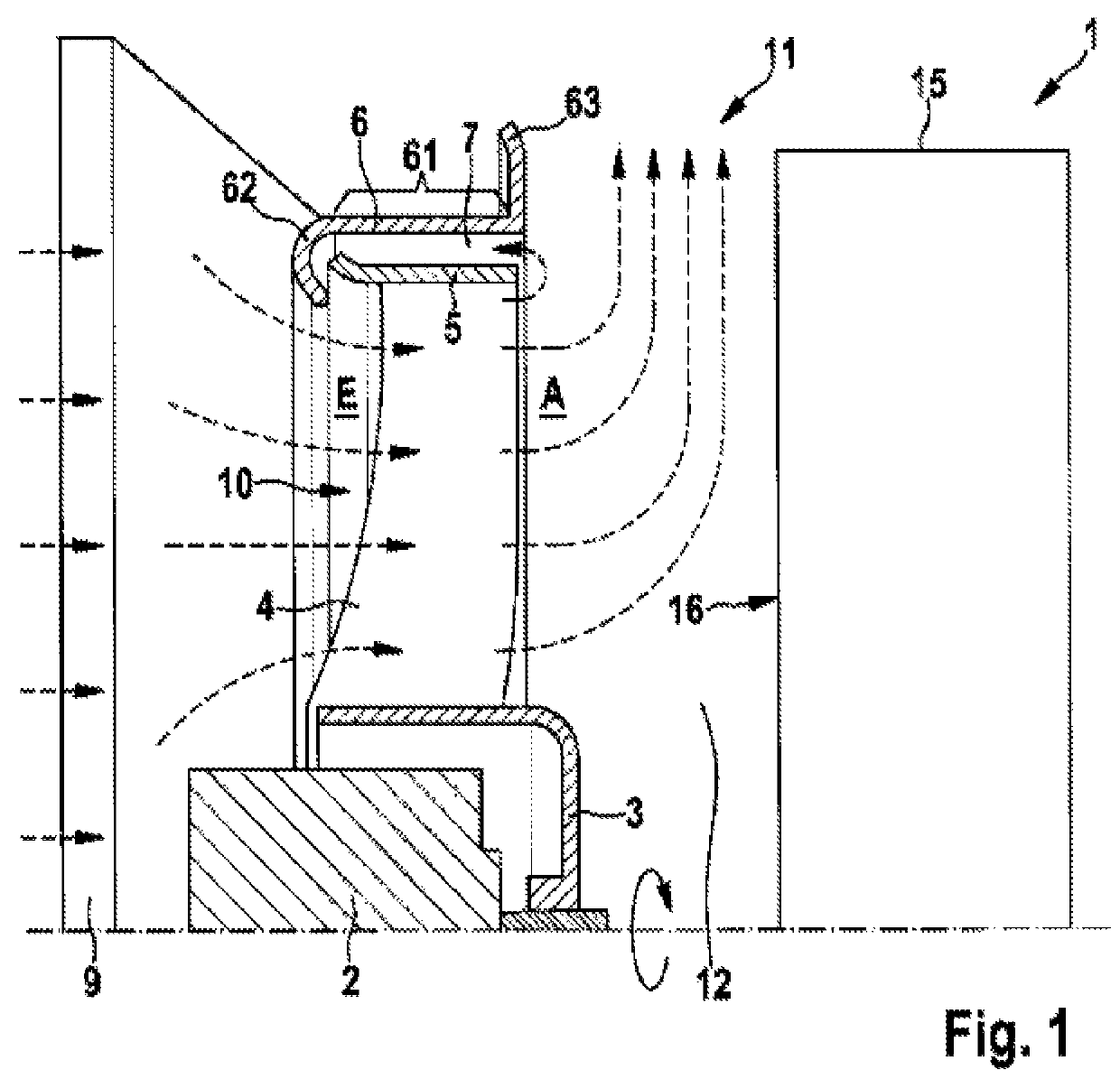

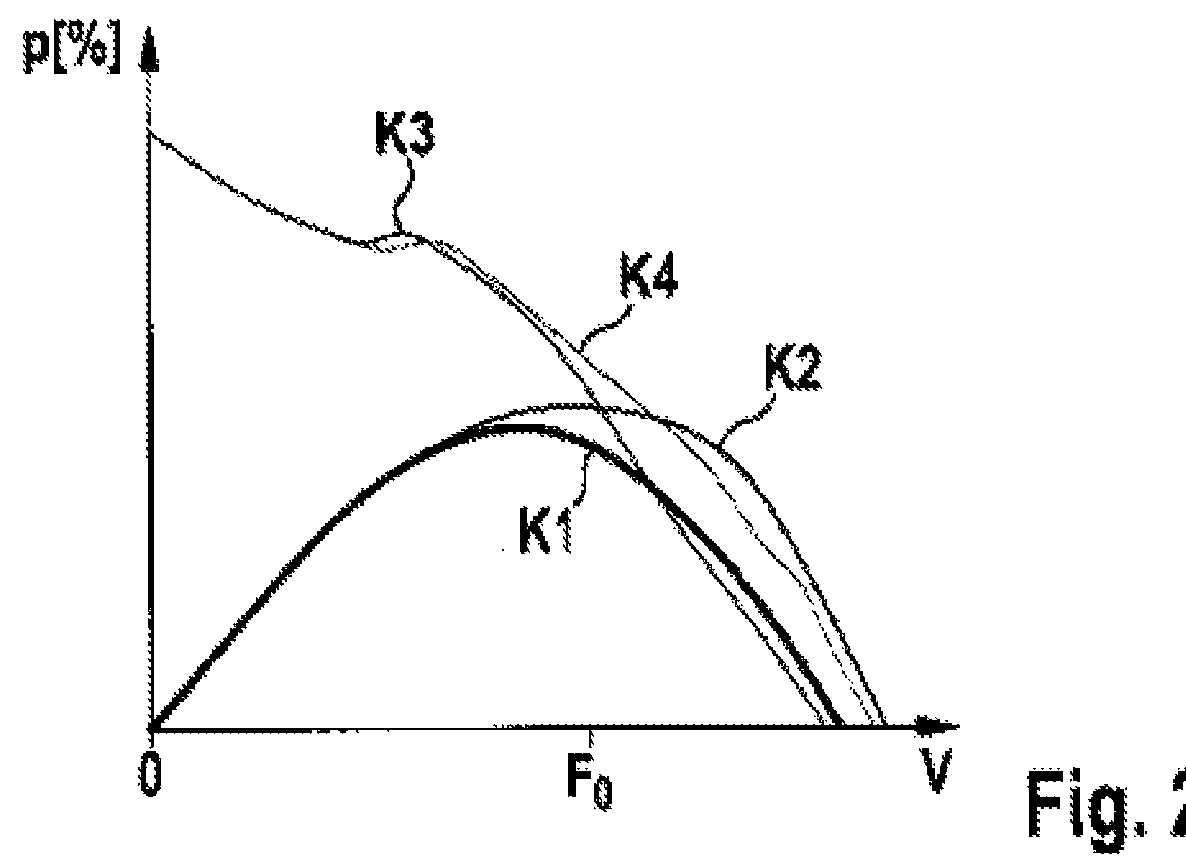

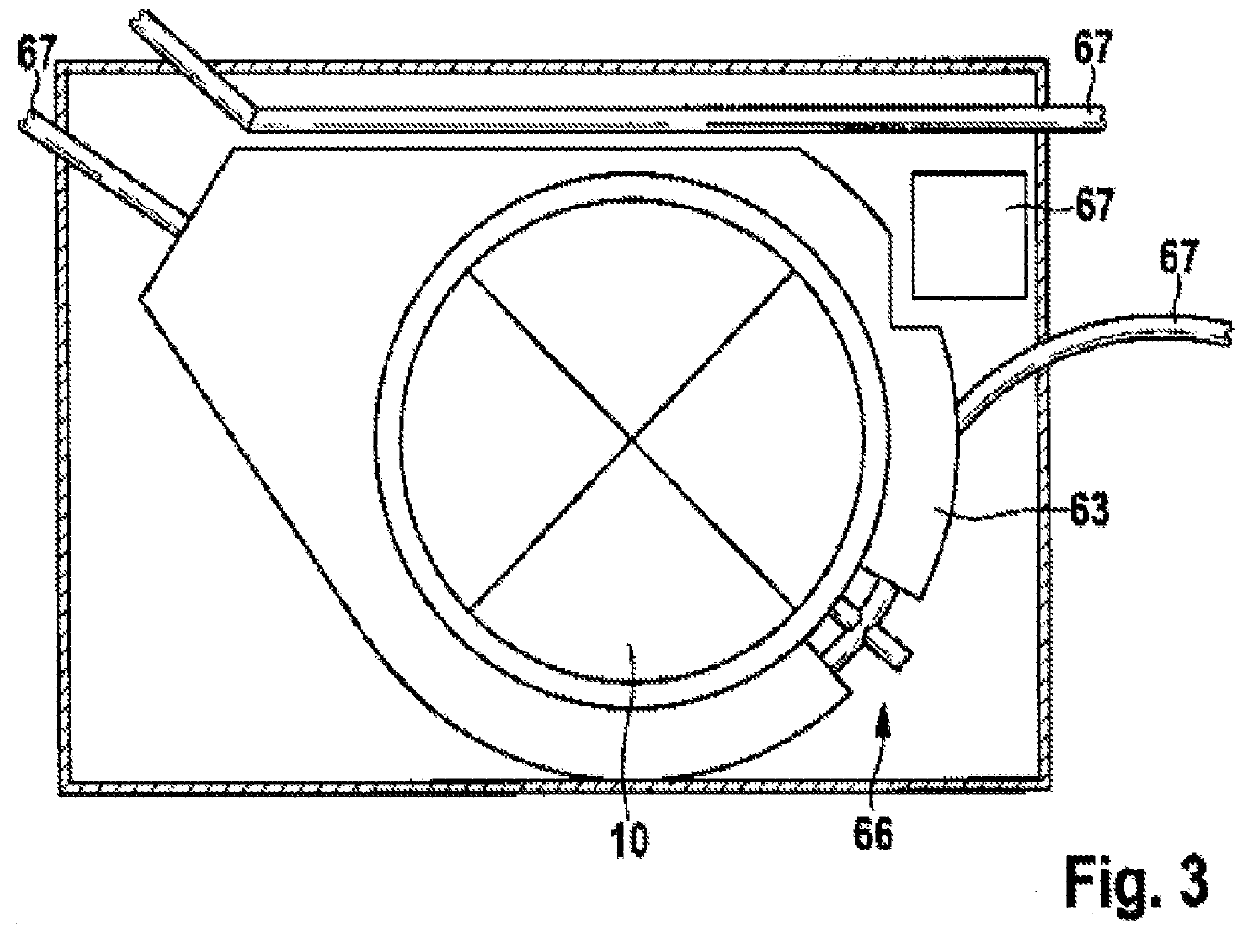

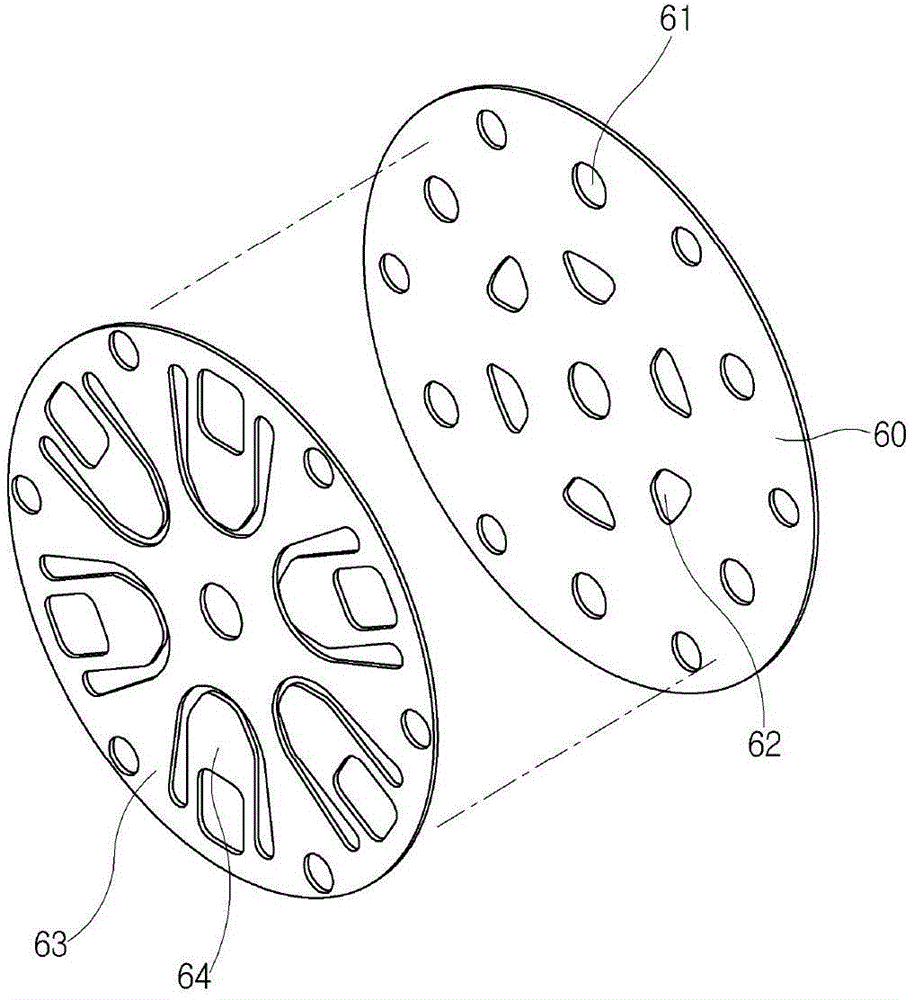

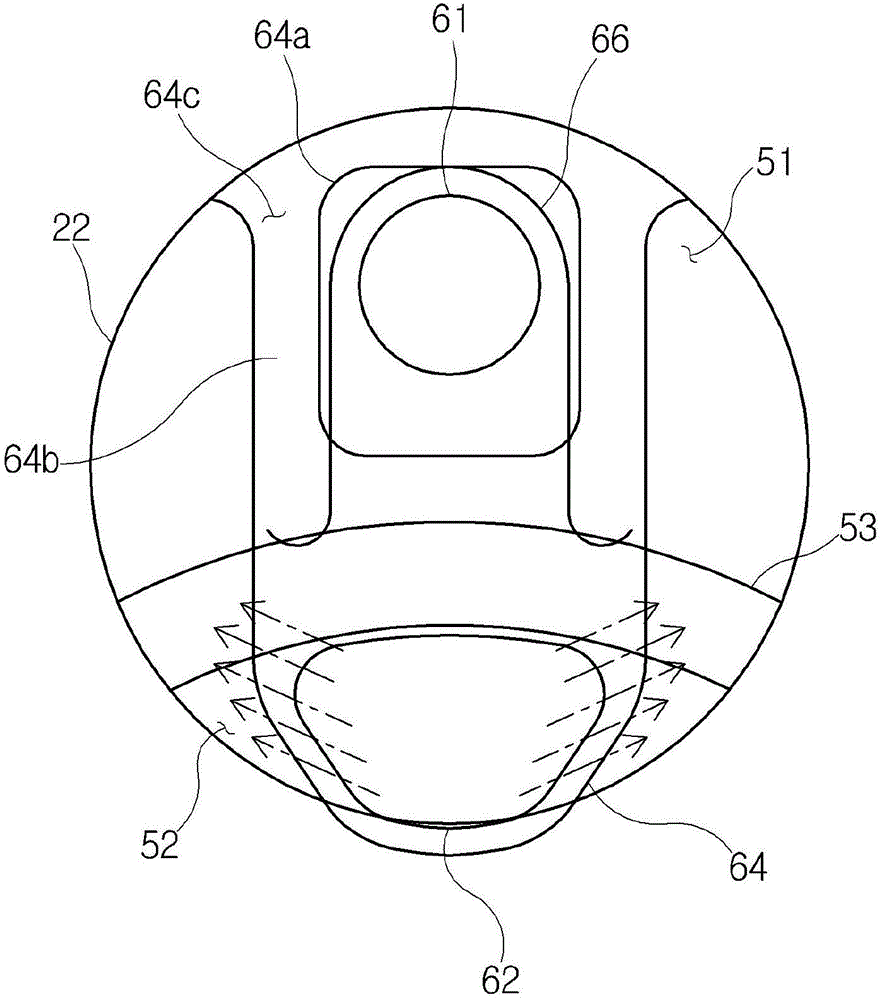

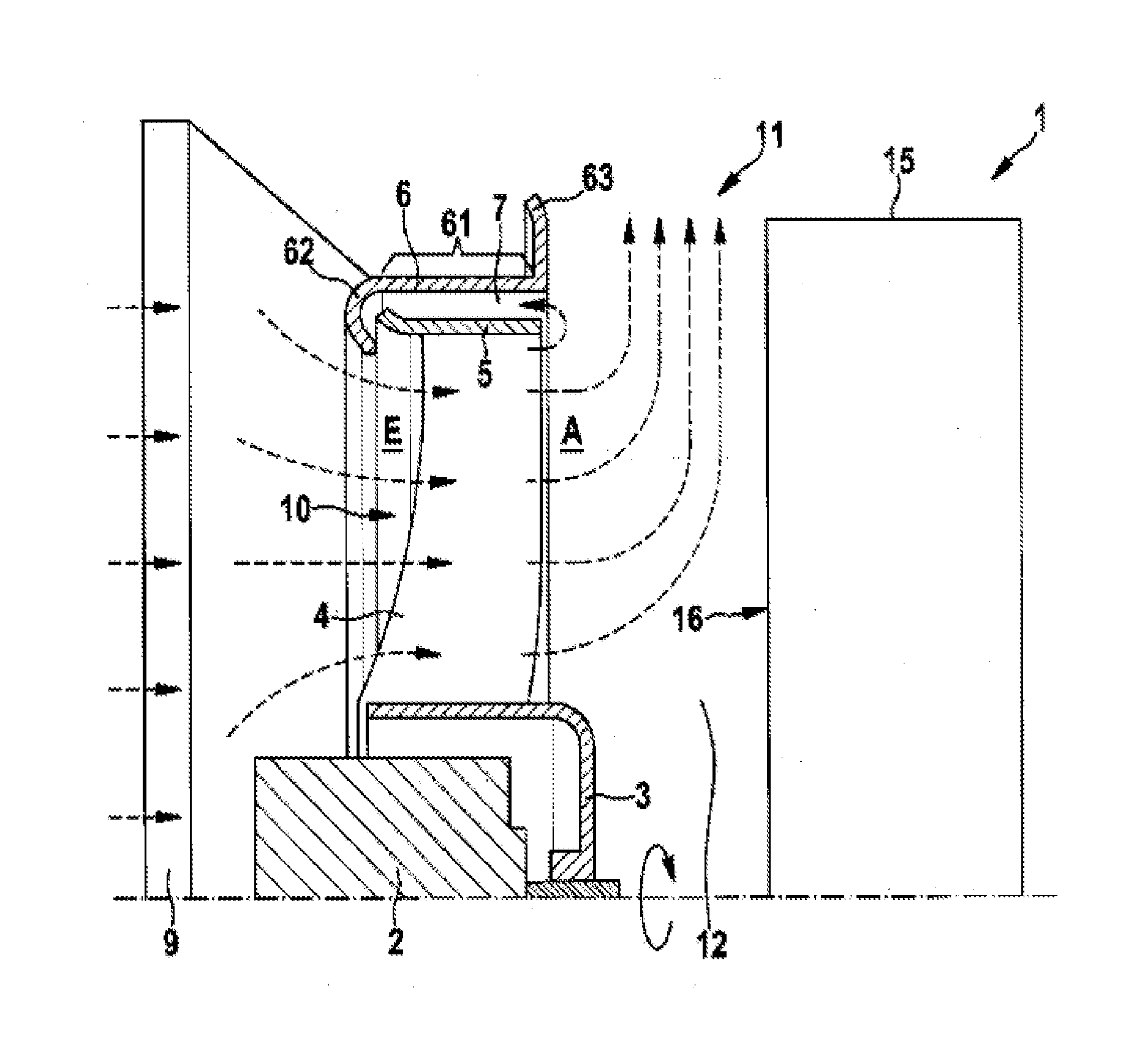

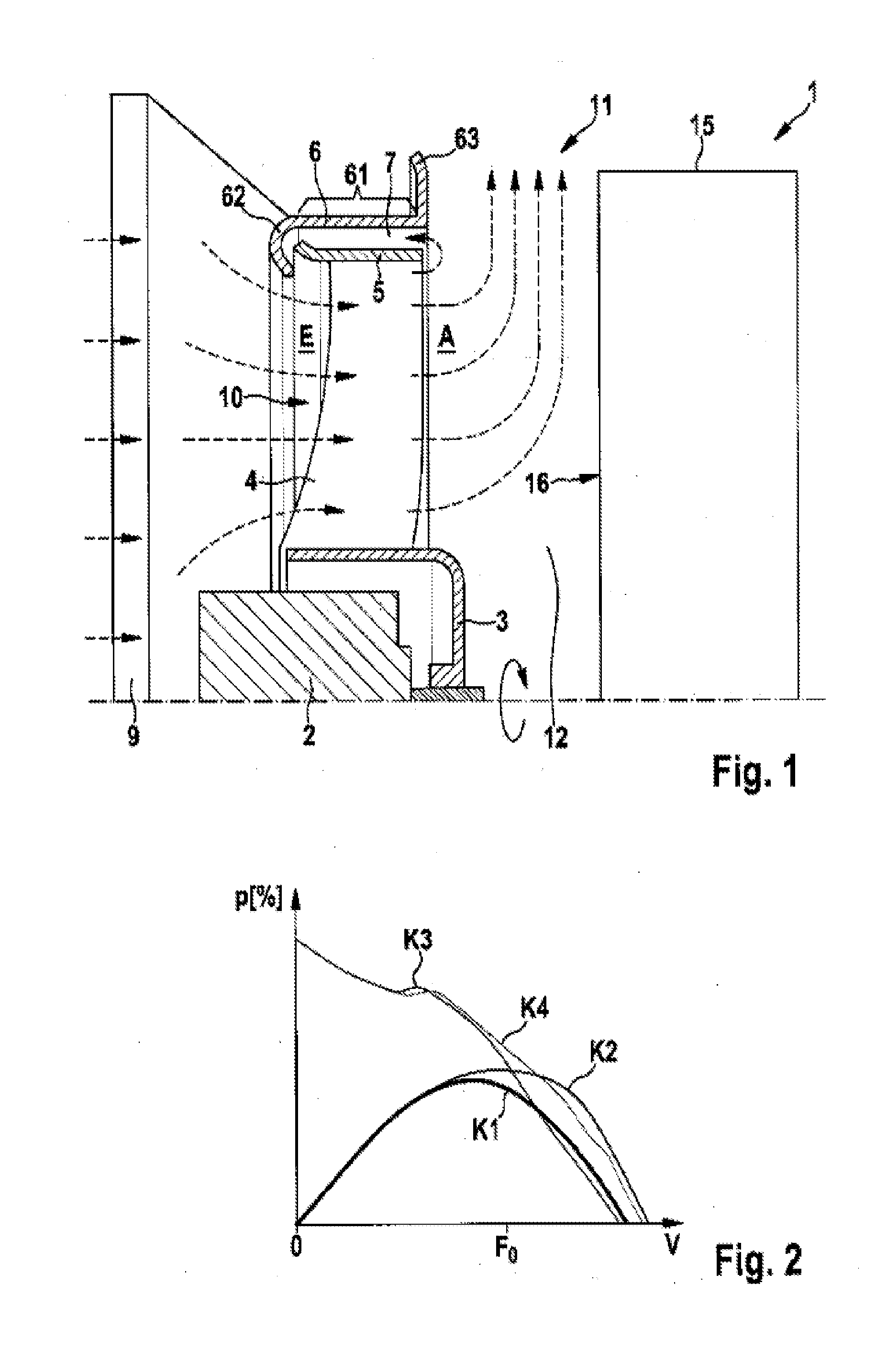

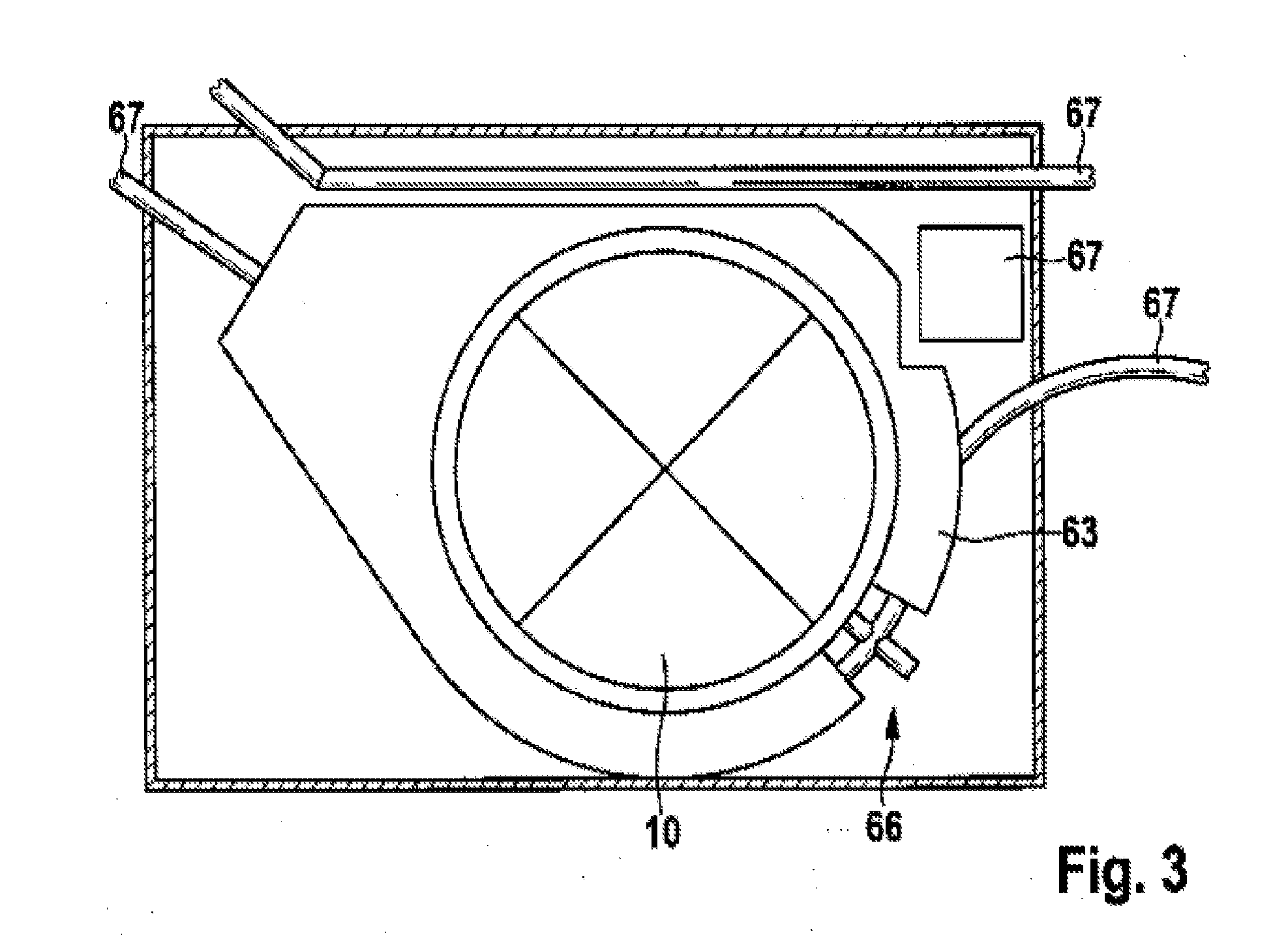

InactiveUS9334877B2Increase discharge flowImprove efficiencyPropellersRotary propellersImpellerEngineering

A fan arrangement (1), in particular for cooling an engine system, comprising: an impeller (10) having one or more blades (4) which in operation convey a medium in the direction of an axis of rotation of the impeller (10) from an inlet side (E) to an outlet side (A); a housing shroud (6) having a base part (61) which extends in the direction of the axis of rotation and surrounds the impeller (10) completely or partially, wherein, on an end of the base part (61) oriented towards the outlet side (A) of the impeller (10), there is provided a discharge flow element (63) which extends radially outwards from the end of the base part (61).

Owner:ROBERT BOSCH GMBH

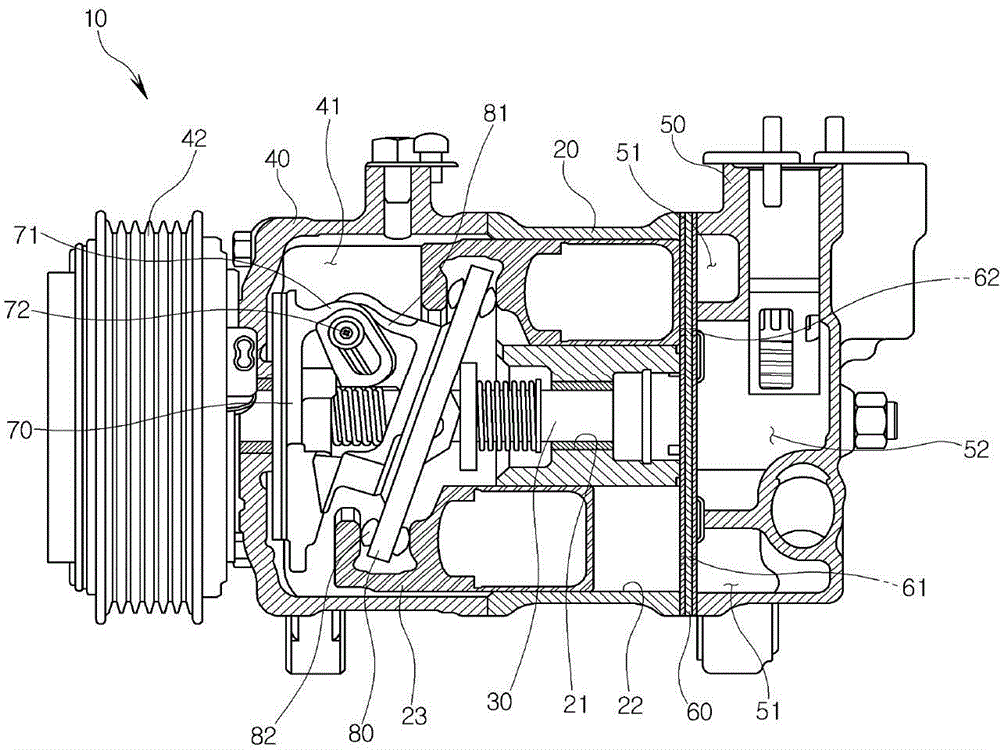

Valve assembly for variable swash plate compressor

ActiveCN104454464AIncrease suction flowAccurate opening and closingPositive displacement pump componentsMulti-stage pumpsEngineeringRefrigerant

Owner:HANON SYST

Fan arrangement

InactiveUS20130142652A1Increase discharge flowImprove efficiencyPropellersRotary propellersImpellerEngineering

A fan arrangement (1), in particular for cooling an engine system, comprising: an impeller (10) having one or more blades (4) which in operation convey a medium in the direction of an axis of rotation of the impeller (10) from an inlet side (E) to an outlet side (A); a housing shroud (6) having a base part (61) which extends in the direction of the axis of rotation and surrounds the impeller (10) completely or partially, wherein, on an end of the base part (61) oriented towards the outlet side (A) of the impeller (10), there is provided a discharge flow element (63) which extends radially outwards from the end of the base part (61).

Owner:ROBERT BOSCH GMBH

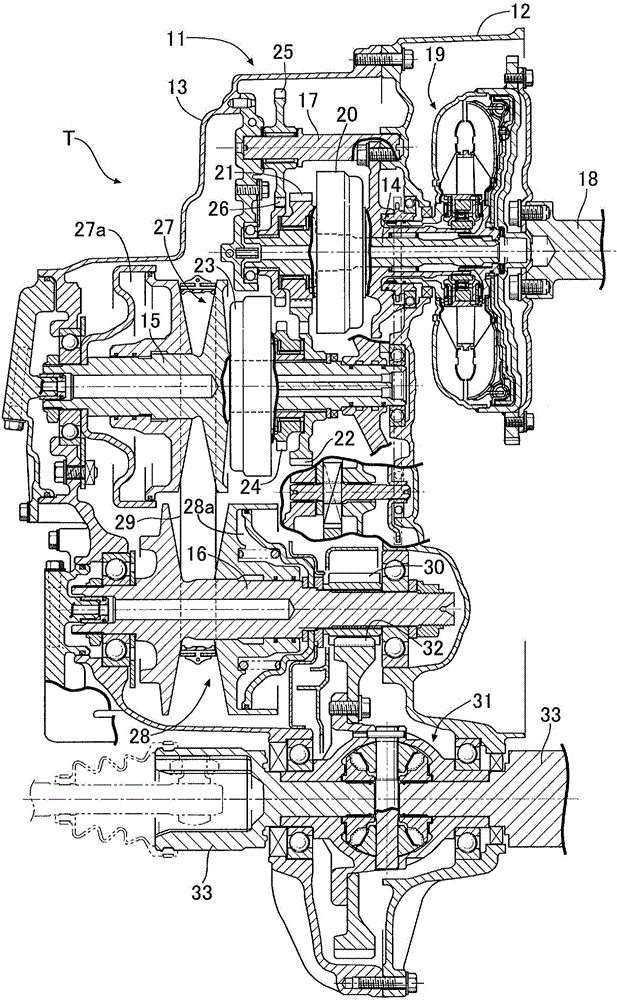

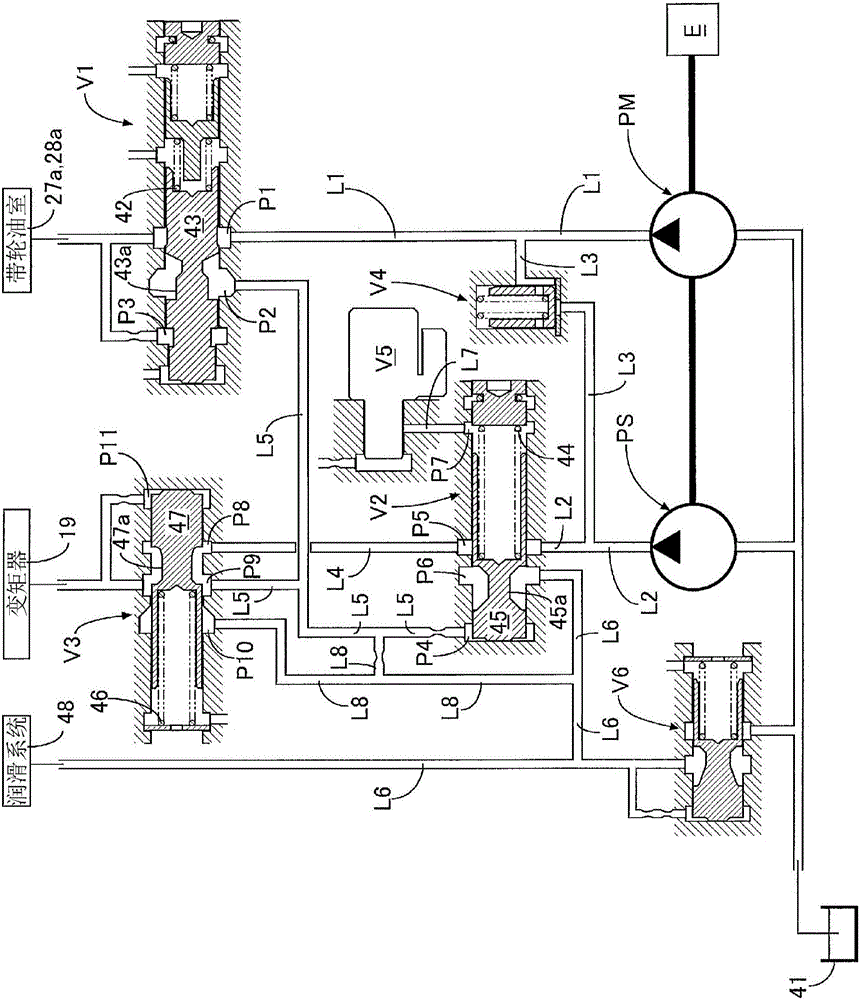

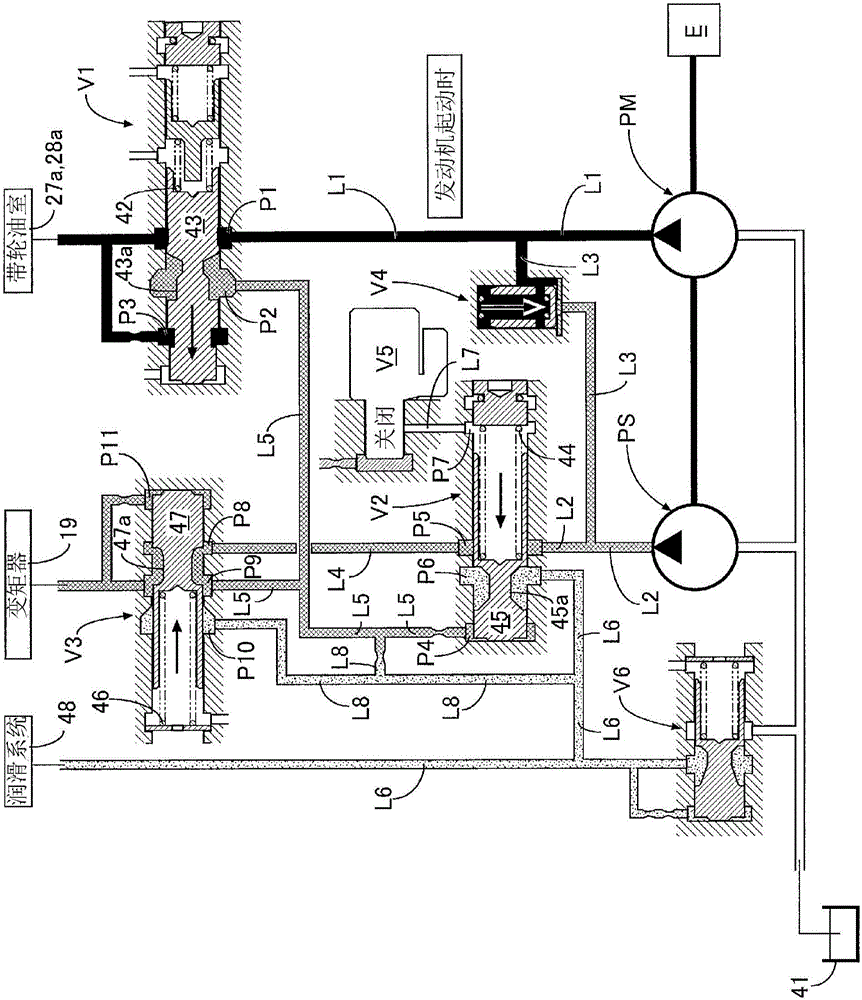

Hydraulic circuit for transmission

ActiveCN105874244AReduce driving loadVariable speedGearing controlGearing detailsInternal pressureHydraulic circuit

In a hydraulic circuit for a transmission, the circuit being provided with a main pump and a sub-pump, when the main pump (PM) and the sub-pump (PS) are driven by an engine (E) after being stopped for a long period of time, the oil pressure transmitted via a fifth oil path (L5) to a feedback port (P4) of a switching valve (V2) is insufficient because the internal pressure of a torque converter (19) is low, and because the connection between a first port (P5) and a second port (P6) of the switching valve (V2) is blocked, oil discharged by the sub-pump (PS) is not supplied to a lubricating system (48) via a sixth oil path (L6) and is supplied along the following route: second oil path (L2) - first port (P5) of switching valve (V2) - fourth oil path (L4) - first port (P8) and second port (P9) of second pressure regulating valve (V3) - torque converter (19). As a result, the interior of the torque converter (19) quickly fills with oil and drive force can be transmitted.

Owner:HONDA MOTOR CO LTD

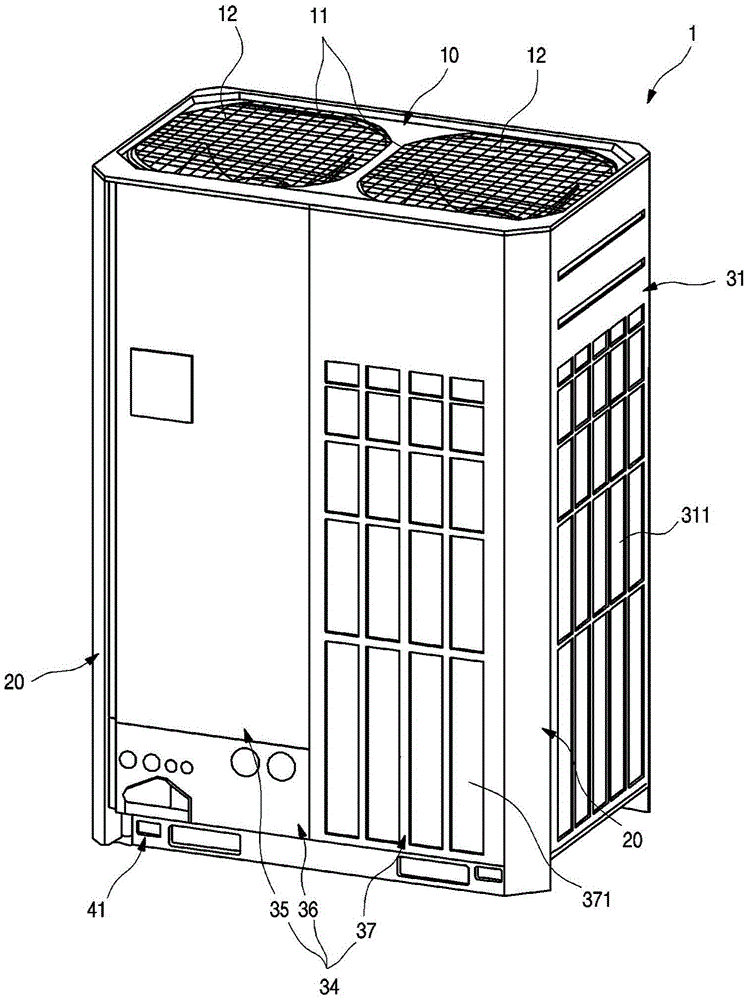

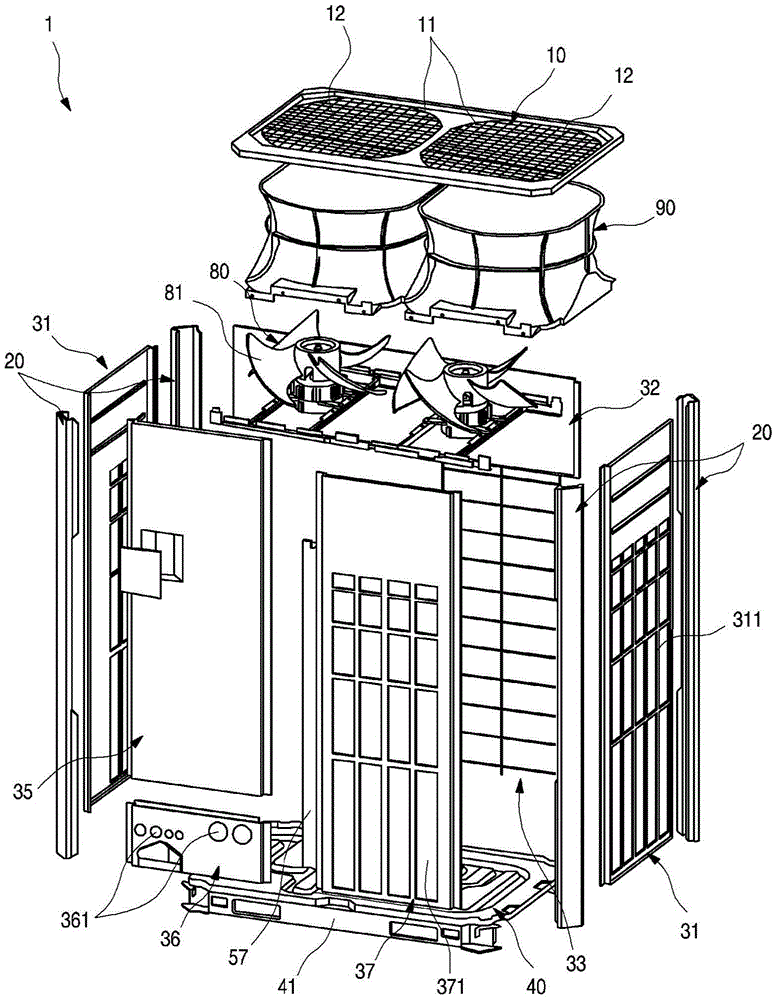

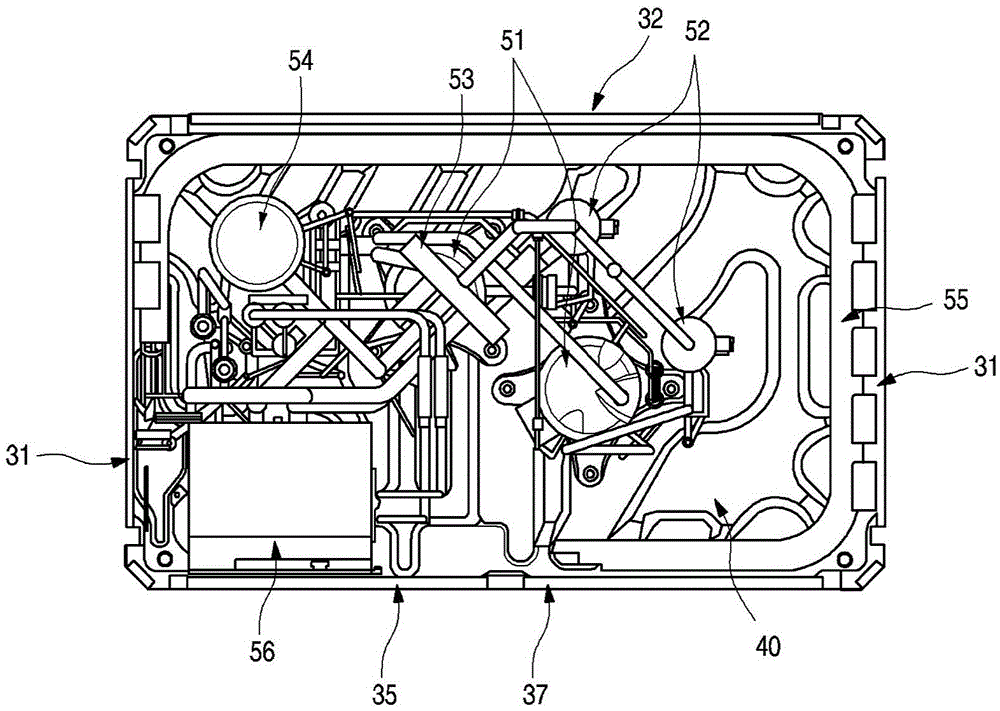

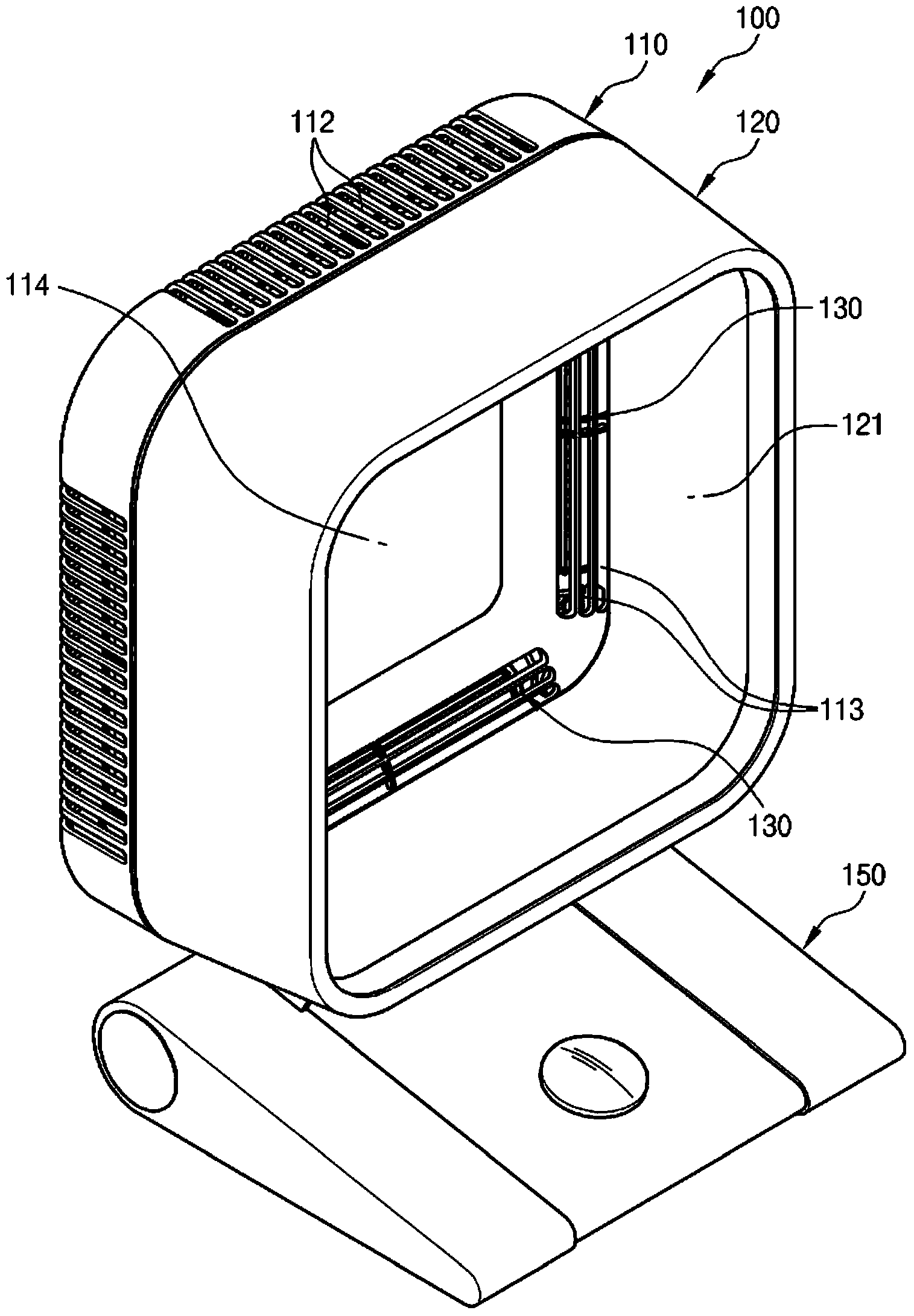

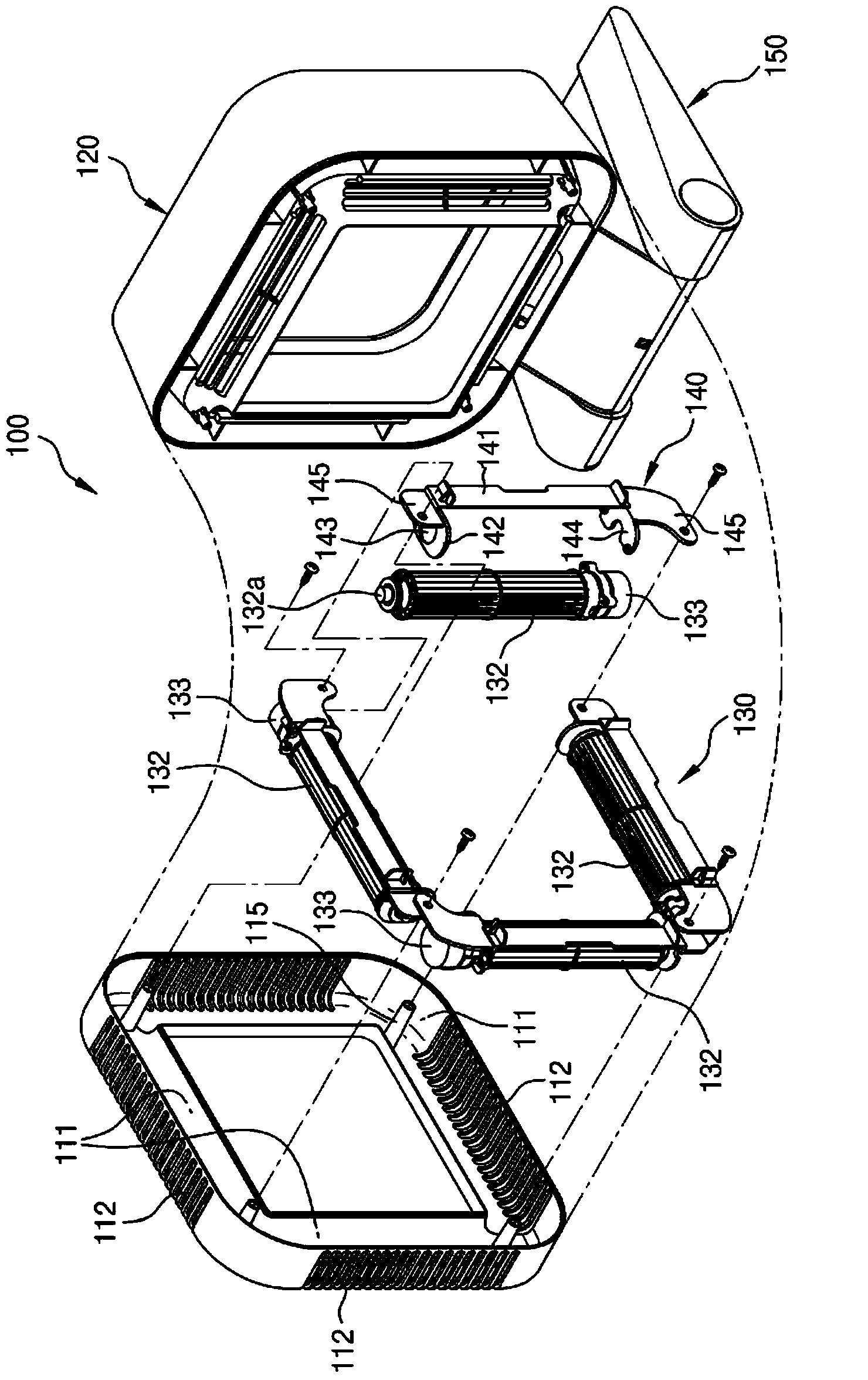

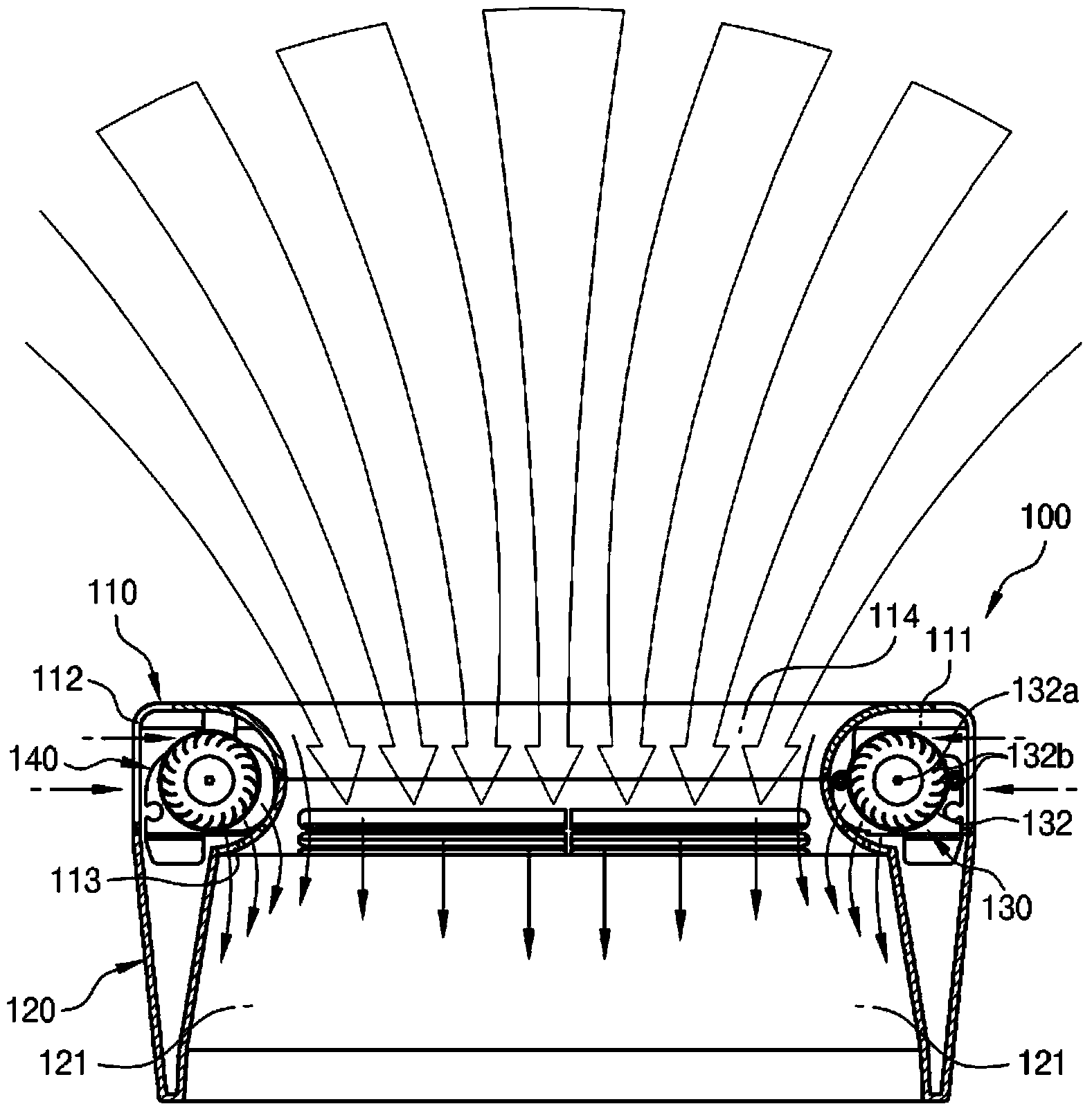

Outdoor device of air conditioner

ActiveCN105737274AEasy to moveIncrease discharge flowLighting and heating apparatusSpace heating and ventilation detailsEngineeringMechanical engineering

An outdoor device of an air conditioner is provided and may include a top cover that forms an upper surface of the outdoor device and provided with a discharge port through which air may be discharged, a fan provided under the top cover, and a shroud that accommodates the fan and that connects with the discharge port to guide air flow. A transverse width of the shroud that passes through central lines of the side surfaces of the shroud and the fan may be constant from height direction of the shroud. A cross sectional area of the outlet port may gradually increase toward the discharge port.

Owner:LG ELECTRONICS INC

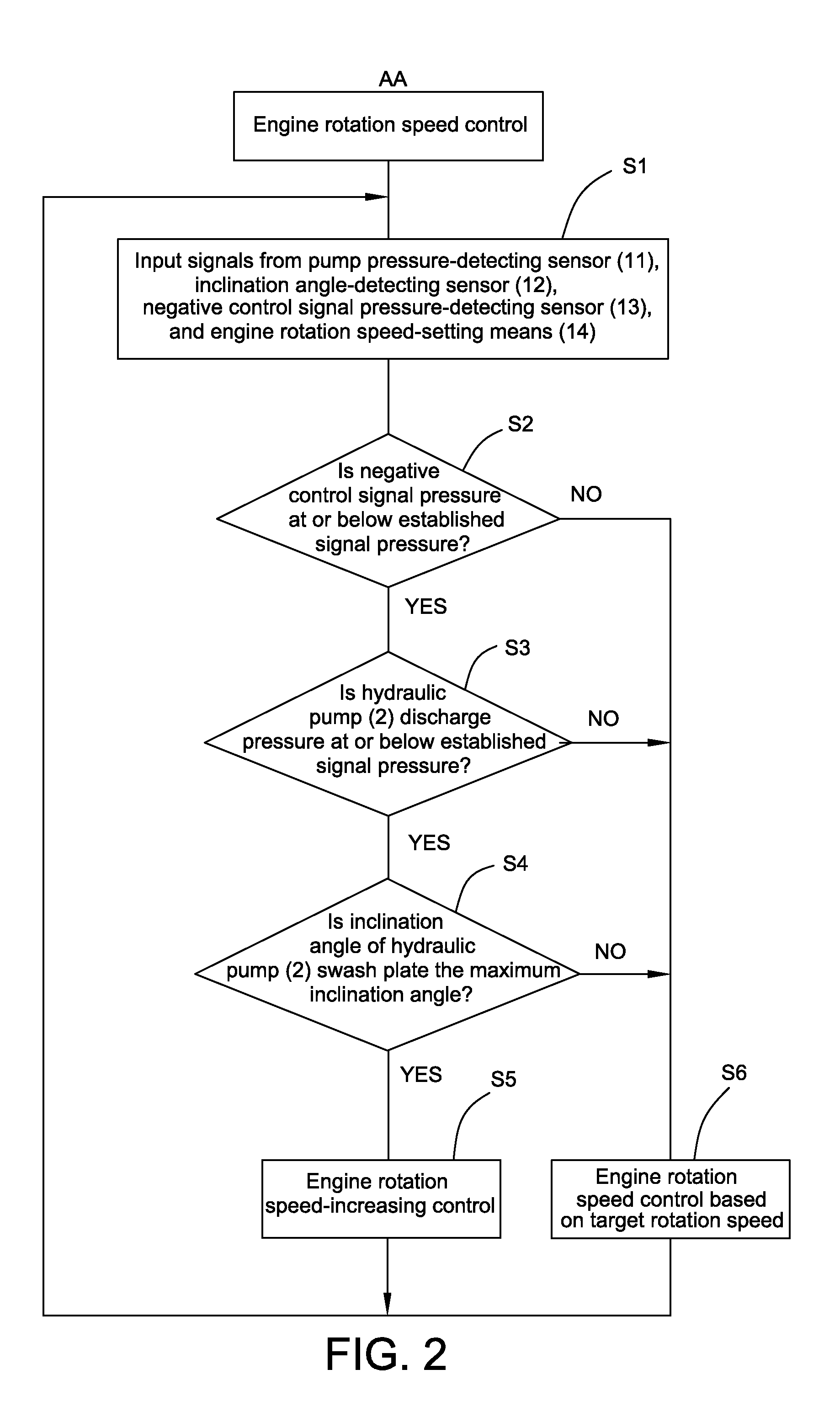

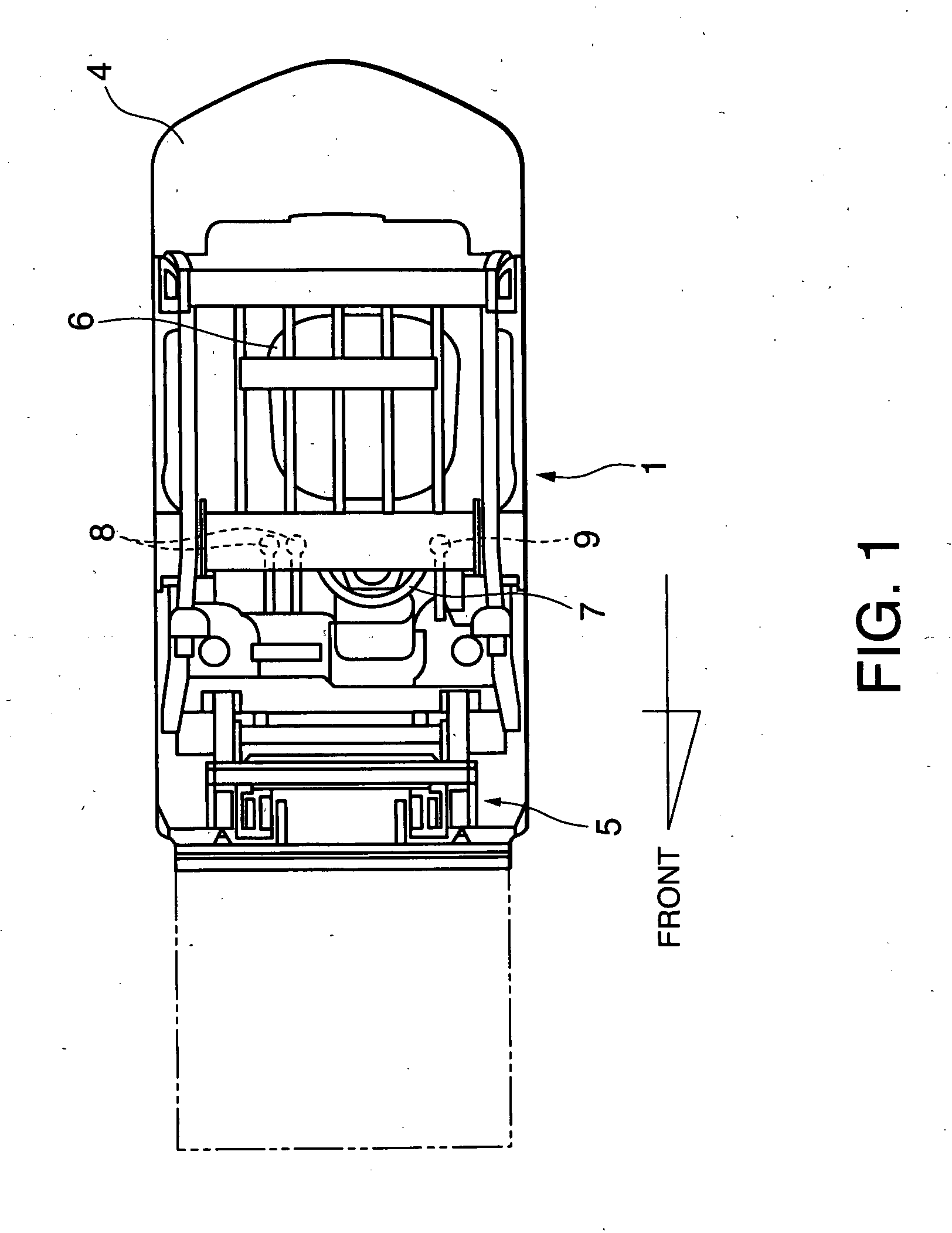

Hydraulic Machinery

InactiveUS20140331660A1Reduce fuel consumptionEasy to operateElectrical controlRotary clutchesControl signalHydraulic machinery

The invention addresses the problem of avoiding insufficient flow being supplied to the hydraulic actuator and speed becoming insufficient during light loads in hydraulic machinery such as hydraulic shovels when the engine rotation speed is set low during normal work. The solution is to increase the discharge flow of the hydraulic pump (2) by increasing the rotation speed of the engine (1) above the target rotation speed set by the engine rotation speed-setting means (14) when the hydraulic pump (2) discharge pressure is at the light load pump discharge pressure, the hydraulic pump (2) inclination angle is at the maximum inclination angle, and the negative control signal pressure is at the signal pressure when the hydraulic actuator-operating means (7) is at full operation.

Owner:CATEPILLAR SARL

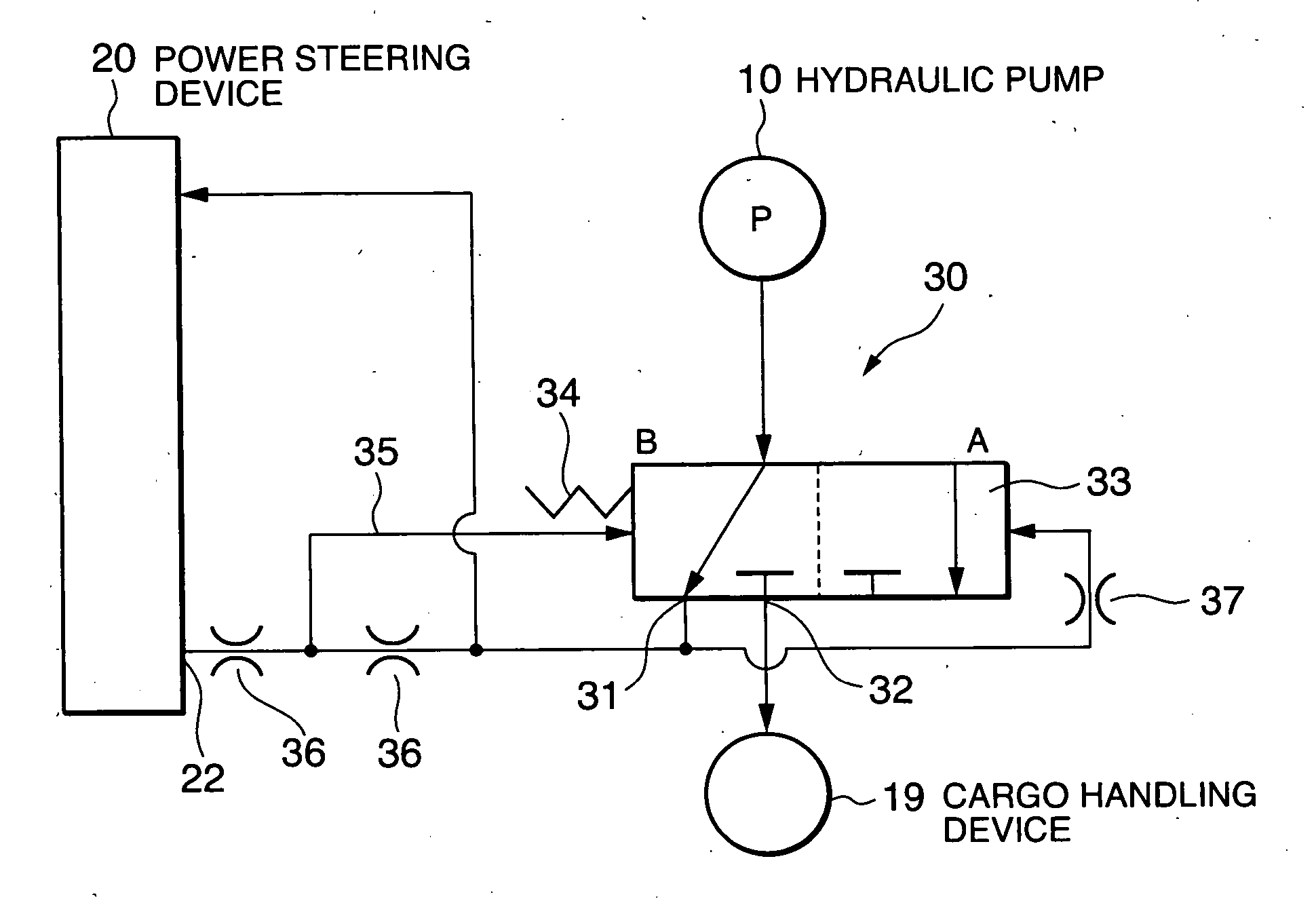

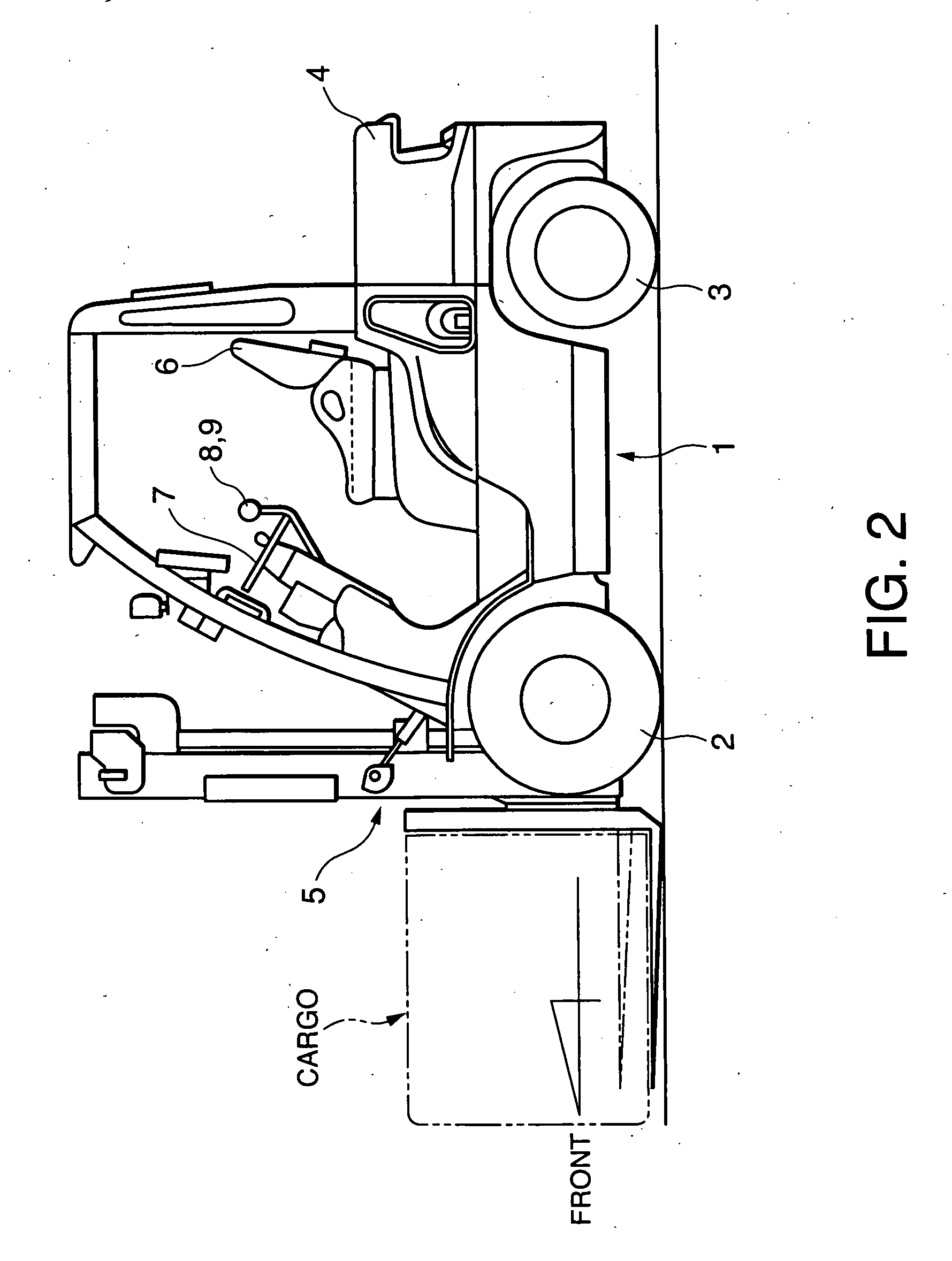

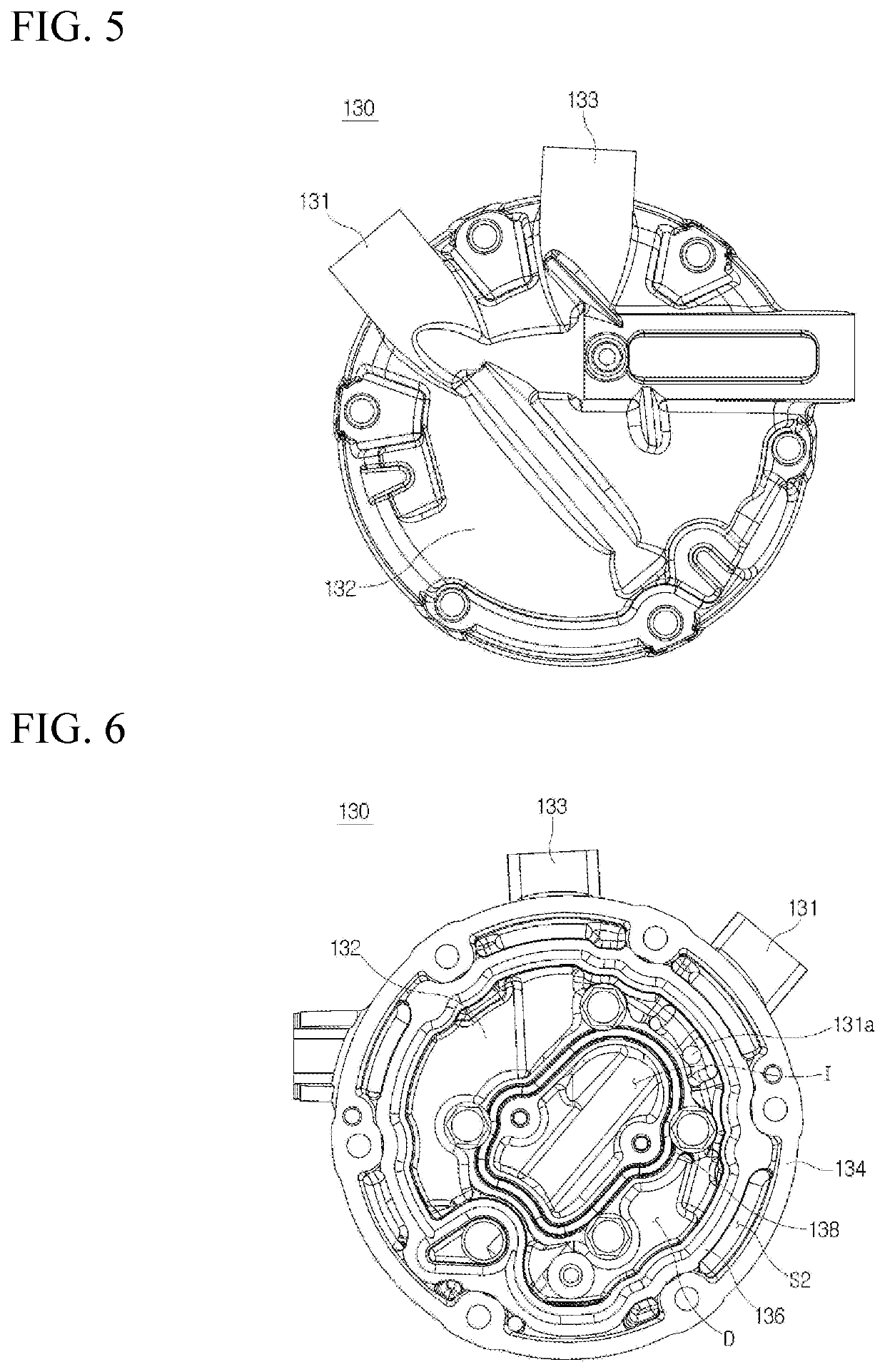

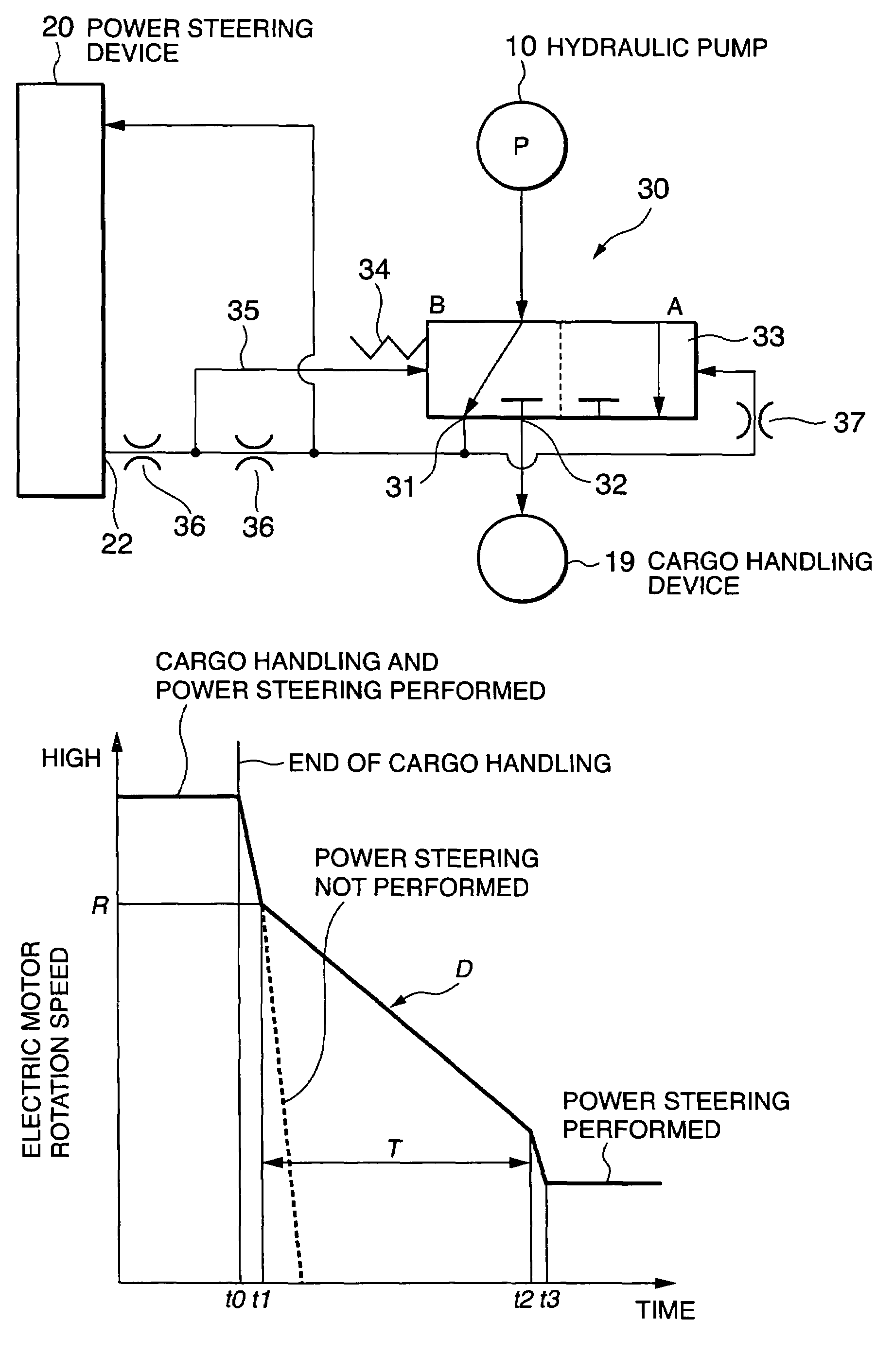

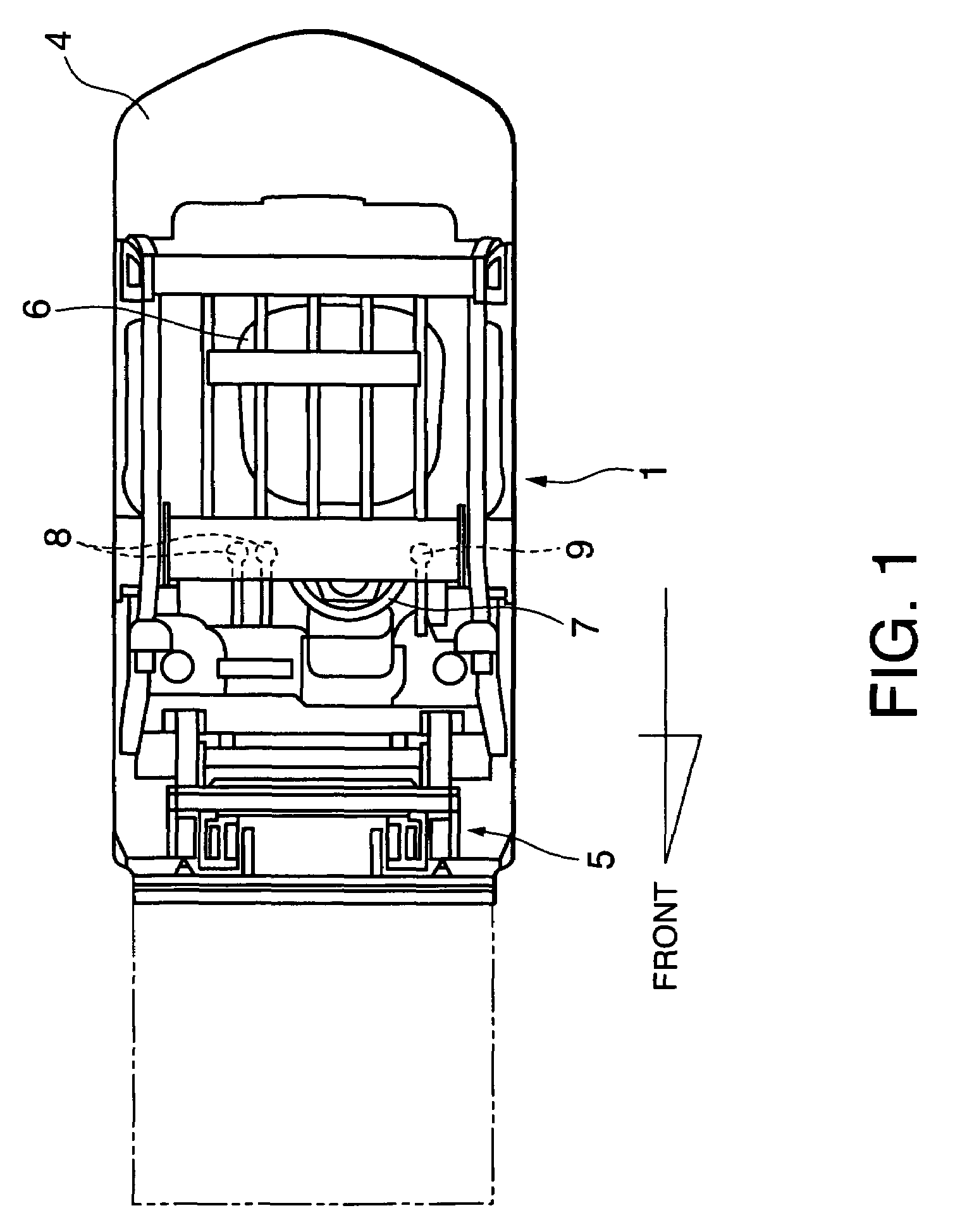

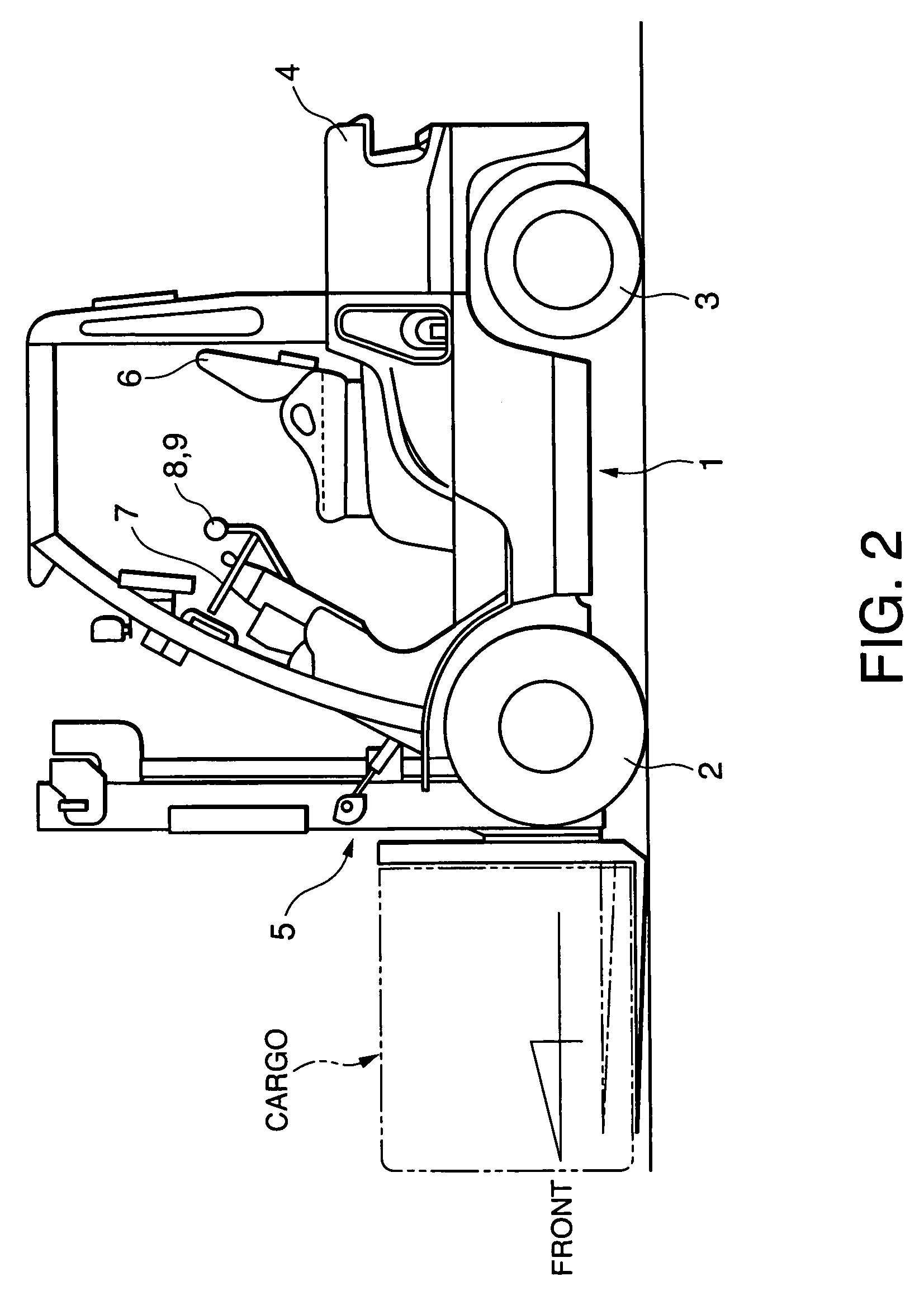

Hydraulic pressure supply control in industrial vehicle

ActiveUS20060260301A1Prevent kickbackReduce rateFluid couplingsLifting devicesPower steeringEngineering

A priority flow rate control valve (30) distributes pressurized working oil discharged from a hydraulic pump (10) driven by an electric motor (11) to a power steering device (20) first, and distributes the residual pressurized working oil to a cargo handling device (19). The rotation speed of the electric motor (11) and the distribution ratio of the pressurized working oil of the priority flow rate control valve (30) vary depending on the operation states of these devices (19, 20). By decreasing the rotation speed of the electric motor (11) at a rate smaller than a normal decrease rate when the cargo handling device (2) stops operation in a state where the power steering device (20) and the cargo handling device (19) are in operation, a kickback in a steering wheel (7) due to a response delay of the priority flow rate control valve (30) can be prevented.

Owner:NISSAN FORKLIFT CO LTD

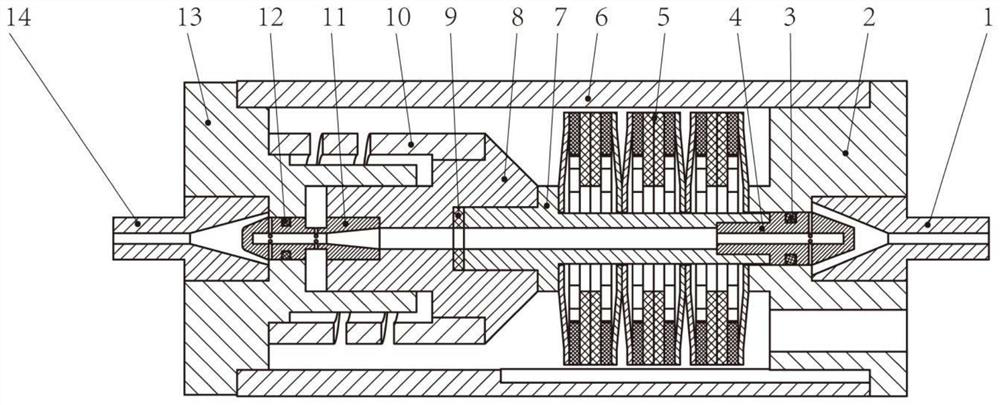

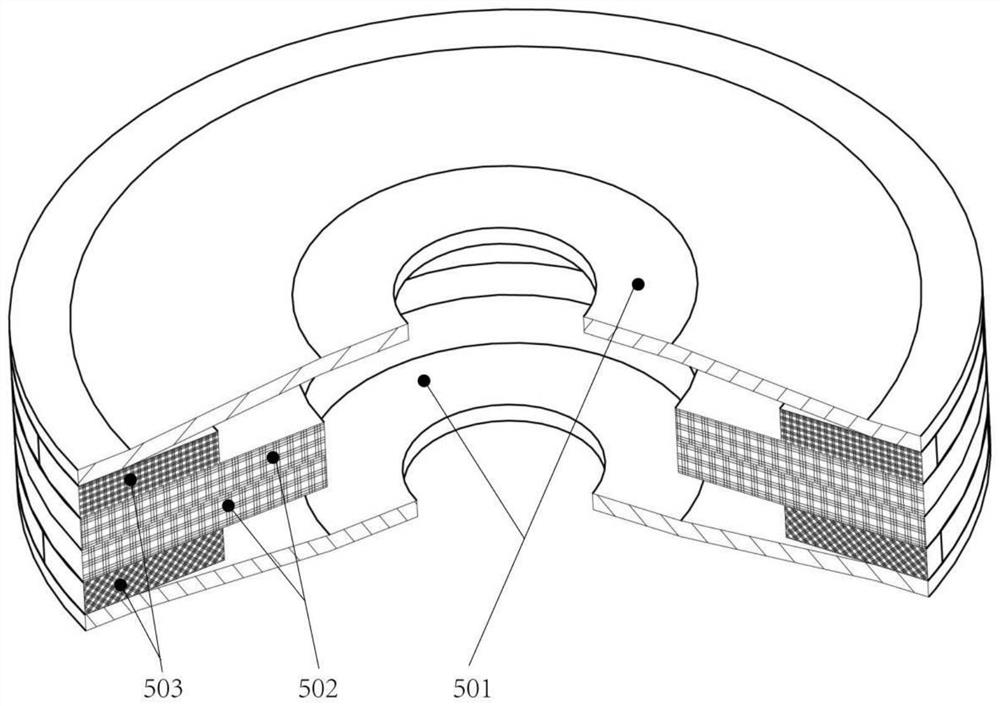

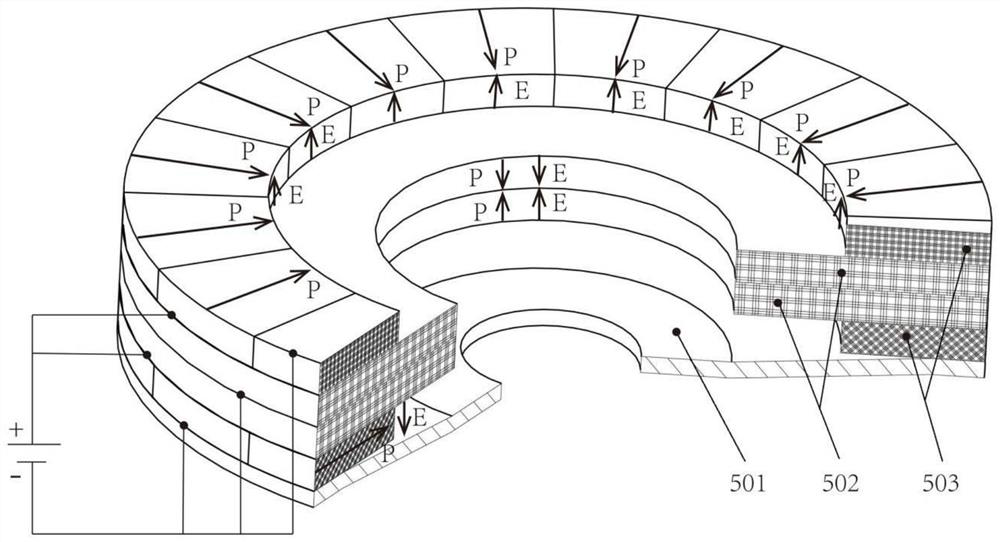

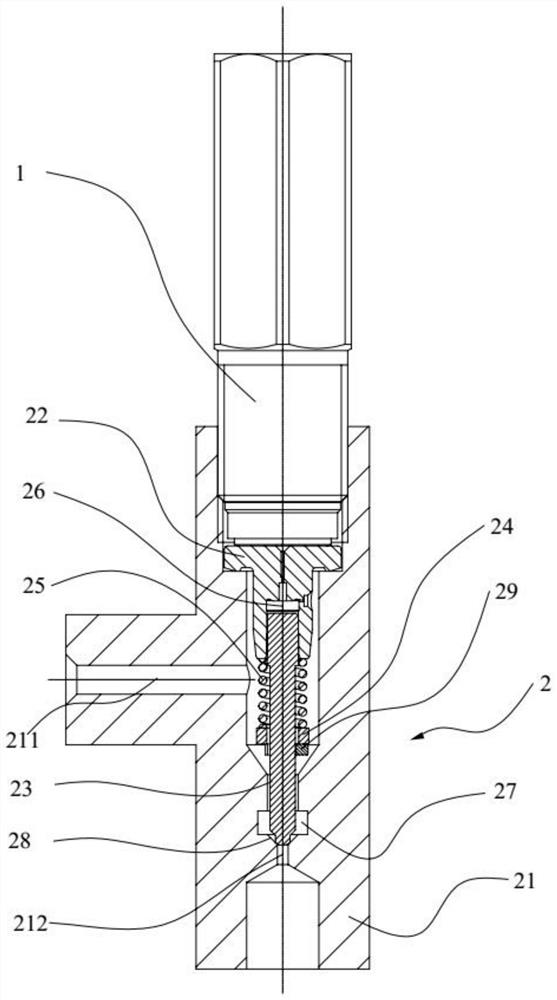

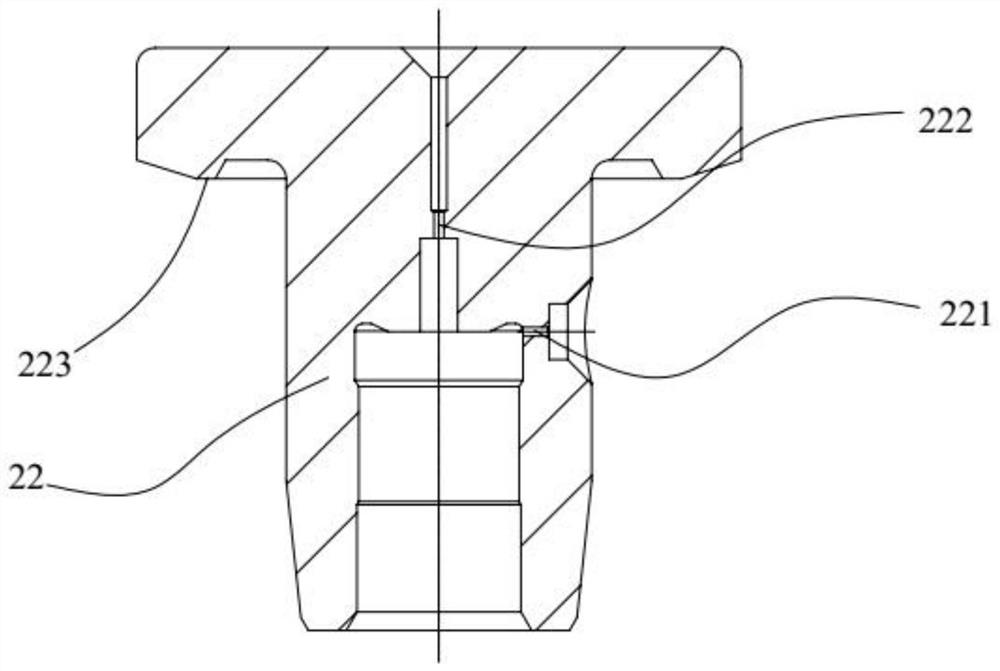

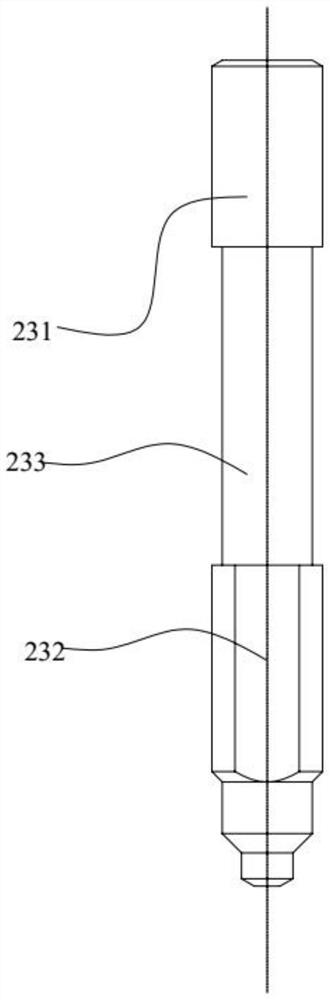

Resonant type piezoelectric stack pump with sliding valves

ActiveCN112081729ALarge displacementIncrease discharge flowPiezoelectric/electrostriction/magnetostriction machinesPositive displacement pump componentsSpool valveReciprocating motion

The invention discloses a resonant type piezoelectric stack pump with sliding valves. The pump comprises a water inlet, a first end cover, the inlet sliding valve, a cymbal-shaped piezoelectric stack,a shell, a middle connecting pipe, a piston, a cylinder with a spiral groove, the outlet sliding valve, a second end cover and a water outlet. The two ends of the shell are sealed through the first end cover and the second end cover. The water inlet is formed in the first end cover, and the water outlet is formed in the second end cover. The inlet sliding valve, the middle connecting pipe, the piston and the outlet sliding valve which are fixedly connected are sequentially arranged in a space defined by the shell and the two end covers. The cymbal-shaped piezoelectric stack is stacked on themiddle connecting pipe in a sleeving manner. One end, away from the water inlet, of the cymbal-shaped piezoelectric stack is attached to the side face of a flange on the middle connecting pipe together, and the other end is attached to the first end cover together. The cymbal-shaped piezoelectric stack drives the piston to do reciprocating motion under driving of alternating voltage. The piezoelectric stack pump has the advantages that working frequency is high, lag of opening and closing of valve ports is avoided, and flow can be controlled precisely.

Owner:SOUTH CHINA AGRI UNIV

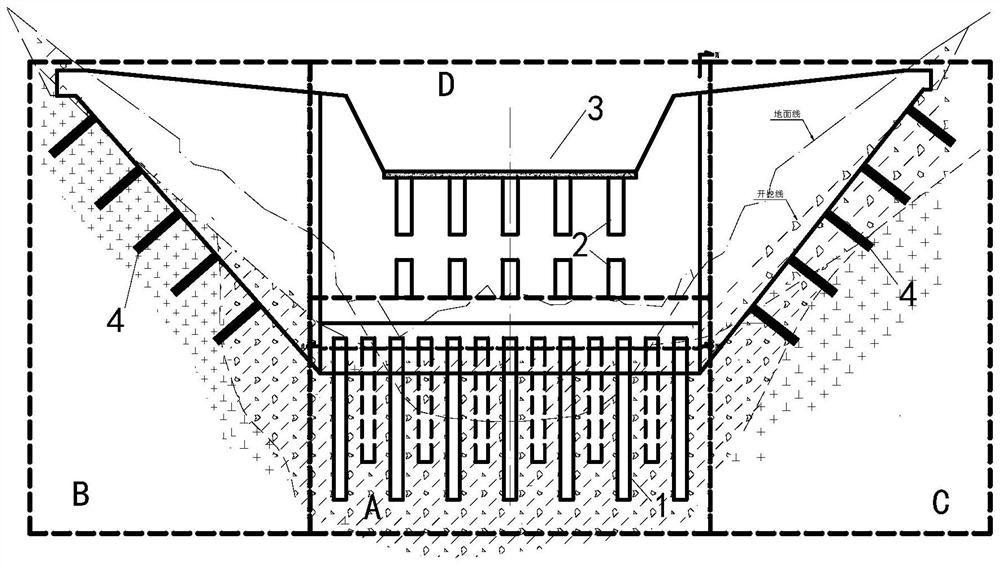

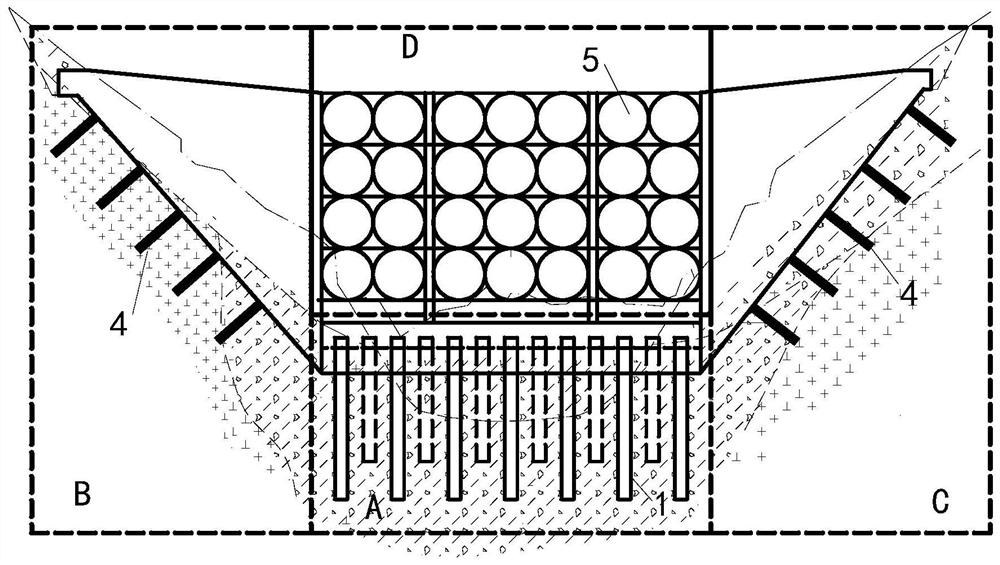

Ultra-large-scale flood mud-rock flow prevention and control method

ActiveCN111608139AReduce harm and threatsLow maintenanceDamsBulkheads/pilesStream flowGeotechnical engineering

The invention provides an ultra-large-scale flood mud-rock flow prevention and control method. Firstly, a scale corresponding to a certain standard flood mud-rock flow in a watershed is determined, and then the level of the flood mud-rock flow is judged; a protection design standard of a control engineering system in the watershed is determined for prevention and control of the super-large-scale flood mud-rock flow, and a design standard of the key control engineering is further determined; and finally, a sand blocking dam design method with different functional partitions is provided according to the design standard of the key control engineering. Under the condition of ensuring the safety of the whole watershed control engineering system, a critical control sand blocking dam part dam body is allowed to collapse to increase the over-flow cross section area and the lower leakage flow, the dam body base portion of a non-collapse area can effectively control channel downward cutting andregulate the flow speed through the section, and thus the threat and harm to railways, highways, bridges, tunnels and the like in the downstream area can be reduced to the maximum extent.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI +1

Scroll compressor

PendingUS20220268282A1Improving performance and efficiencyIncrease discharge flowRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsRotational axisElectric machinery

A scroll compressor including: a housing; a motor provided in the housing; a rotary shaft configured to be rotated by the motor; an orbiting scroll configured to orbit in conjunction with the rotary shaft; and a fixed scroll configured to define compression chambers together with the orbiting scroll, in which the housing includes: a center housing penetrated by the rotary shaft; a front housing configured to define a motor accommodation space that accommodates the motor; and a rear housing configured to define a discharge chamber for accommodating a refrigerant discharged from the compression chambers, and an introduction chamber for accommodating a middle-pressure refrigerant introduced from the outside of the housing, in which the fixed scroll has a plurality of injection ports that guides the refrigerant in the introduction chamber to the compression chambers.

Owner:HANON SYST

Hydraulic pressure supply control in industrial vehicle

ActiveUS7353649B2Reduce rateIncrease the allocation ratioFluid couplingsLifting devicesSteering wheelHydraulic pump

A priority flow rate control valve (30) distributes pressurized working oil discharged from a hydraulic pump (10) driven by an electric motor (11) to a power steering device (20) first, and distributes the residual pressurized working oil to a cargo handling device (19). The rotation speed of the electric motor (11) and the distribution ratio of the pressurized working oil of the priority flow rate control valve (30) vary depending on the operation states of these devices (19, 20). By decreasing the rotation speed of the electric motor (11) at a rate smaller than a normal decrease rate when the cargo handling device (2) stops operation in a state where the power steering device (20) and the cargo handling device (19) are in operation, a kickback in a steering wheel (7) due to a response delay of the priority flow rate control valve (30) can be prevented.

Owner:NISSAN FORKLIFT CO LTD

Fan

A fan of the present invention comprises: a case as a frame having an internal space, a first opening formed in the middle thereof, and inlet and outlet holes formed in the inner and outer surfaces of the periphery of the frame; a rotational part with blades mounted in the internal space, the blades being rotated by a power means to draw external air through the inlet holes into the internal space and to discharge it through the outlet holes; and a cover mounted on the front of the case and provided with a second opening communicating with the first opening so as to discharge the air from the inside of the second opening through the outlet holes towards the outside

Owner:河成又

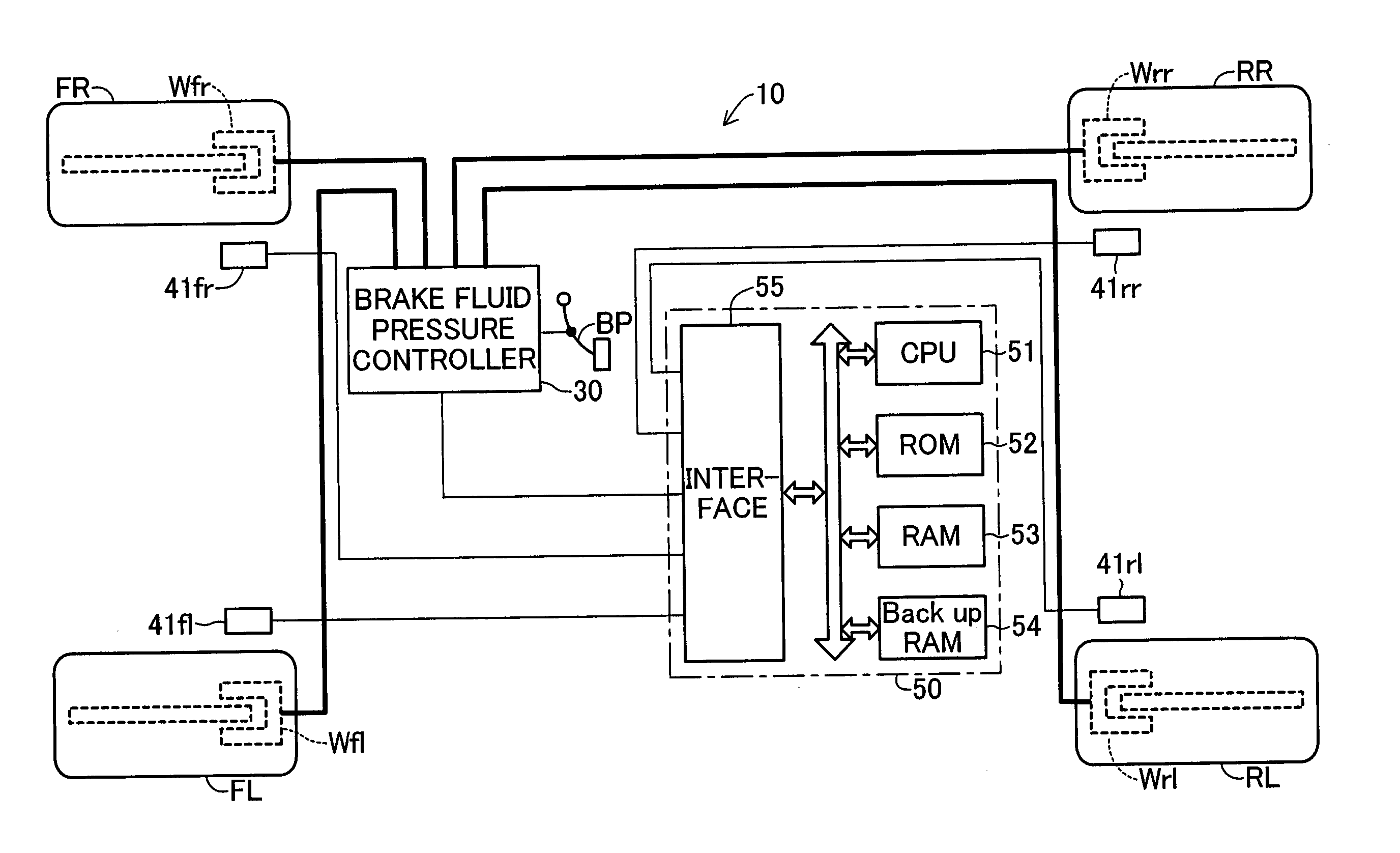

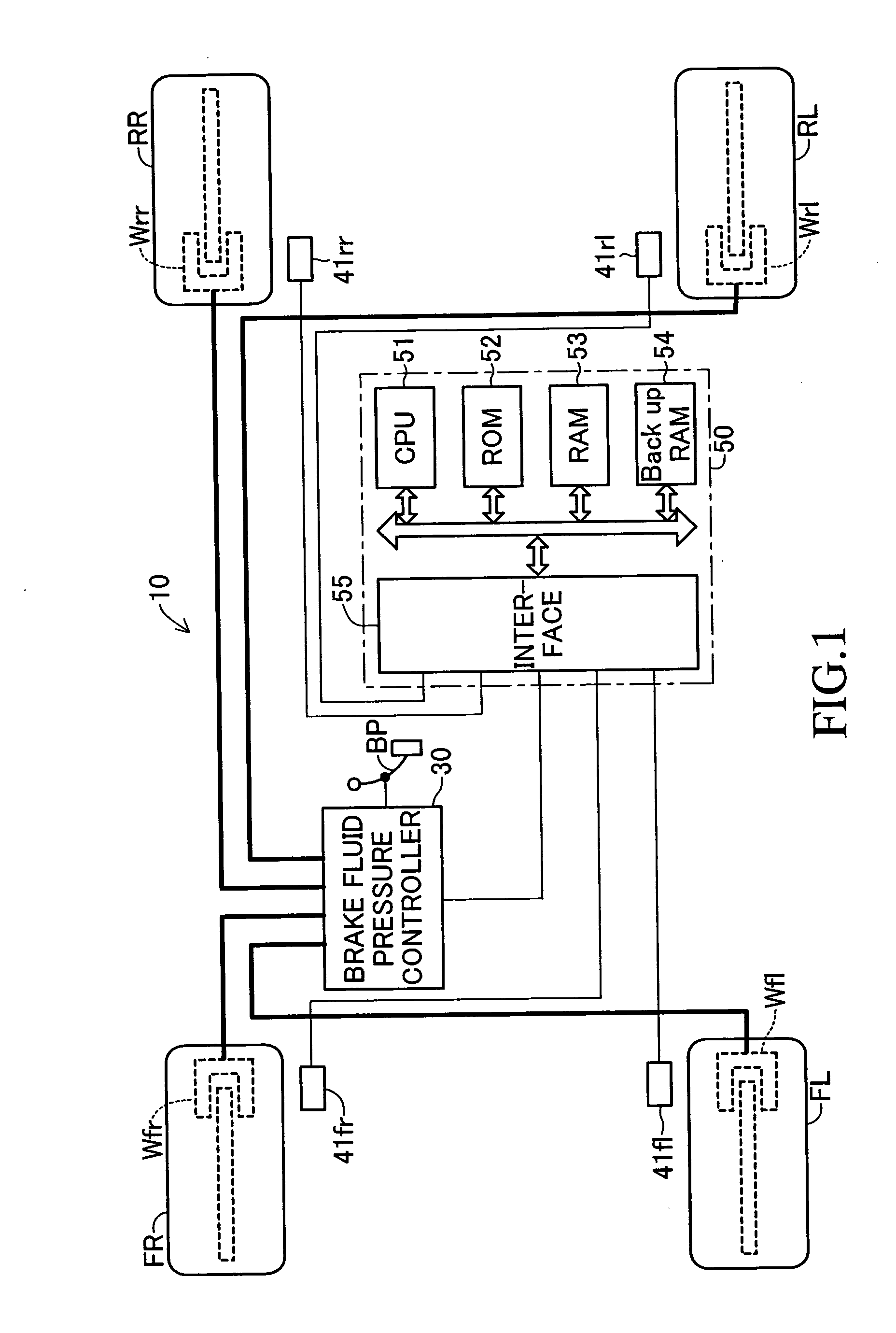

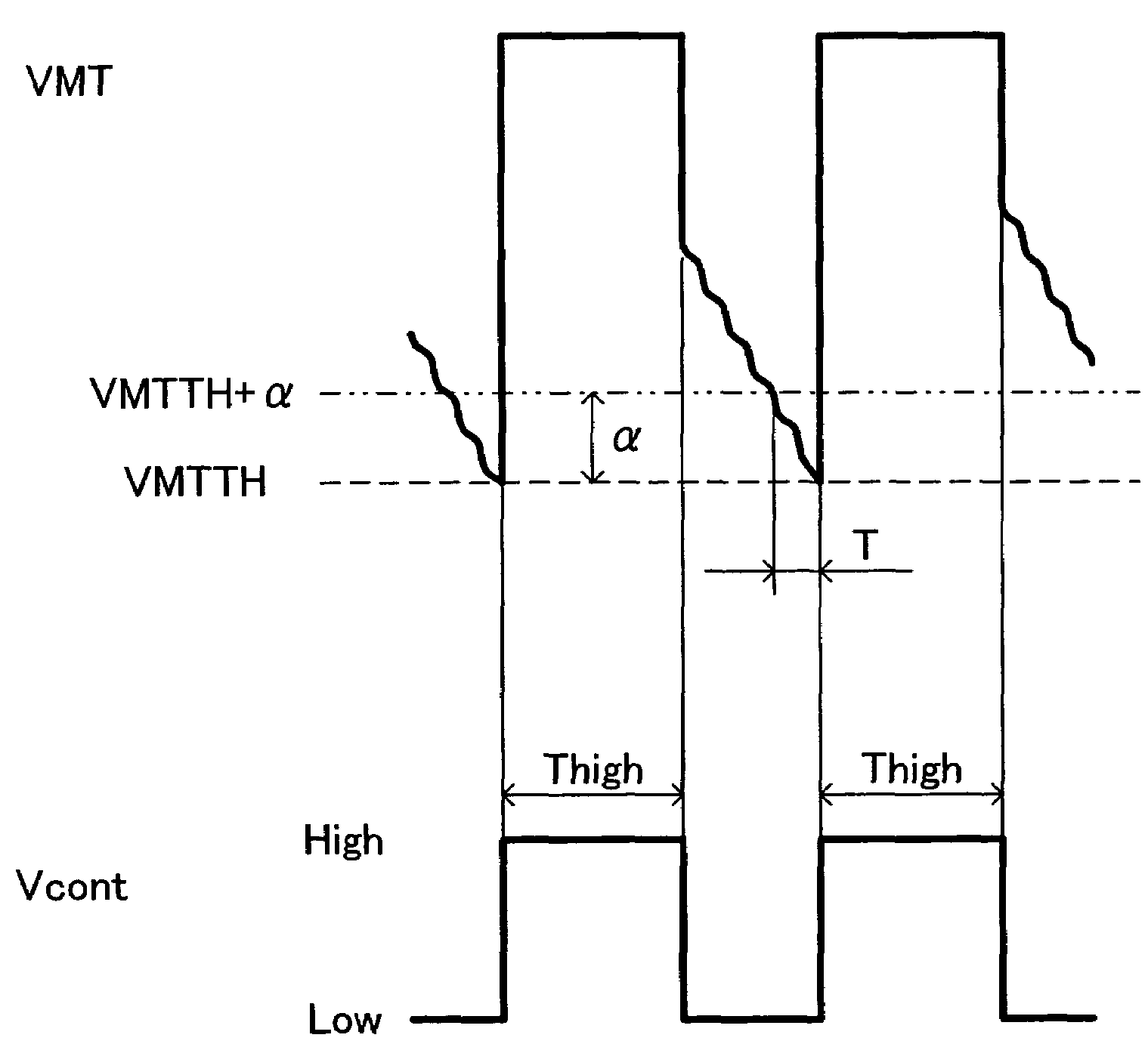

Pump drive motor control apparatus

ActiveUS7303241B2Simple and reliable processIncrease discharge flowBraking action transmissionField or armature current controlElectricityHydraulic pump

A pump drive motor control apparatus controls a motor used for driving a hydraulic pump. Every time the supply of electricity to the motor is resumed (every time the motor control signal changes from a low level to a high level), the apparatus measures a time which the voltage generated by the motor requires to decrease by a predetermined amount, the time indicating the decreasing speed of the generated voltage. The apparatus normally sets the high-level maintenance time, in which the motor control signal is maintained high, to a base time. When a state in which the measured time is not longer than a reference time is detected a predetermined number of times (3 times) or more, the apparatus determines that the load of the pump is heavy. In such a case, the apparatus increases the average rotational speed of the motor by increasing the high-level maintenance time.

Owner:ADVICS CO LTD

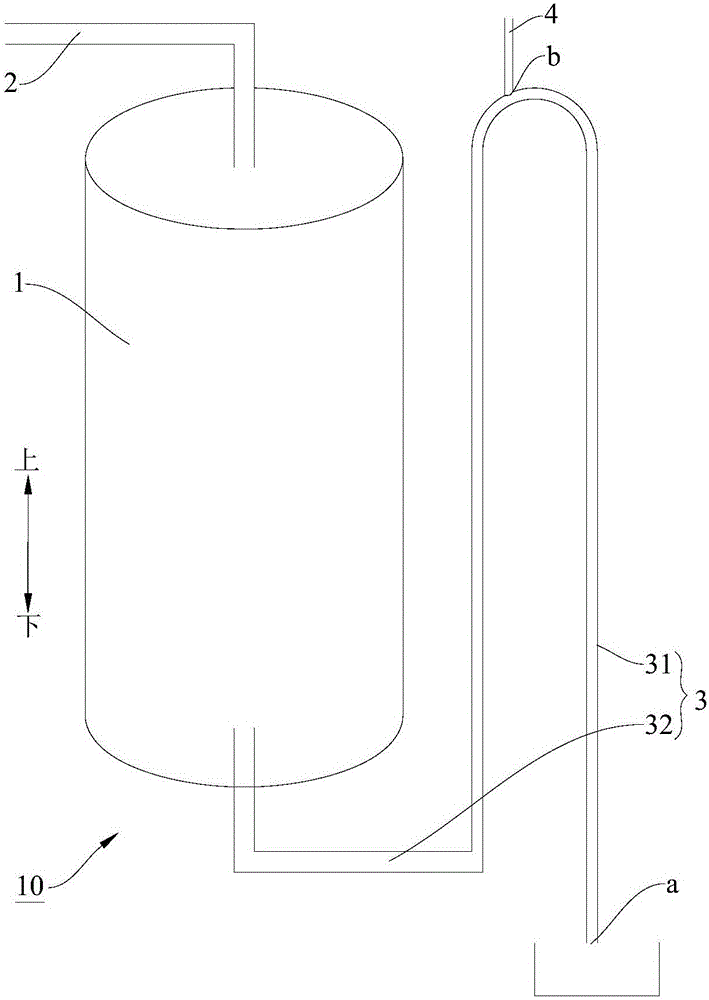

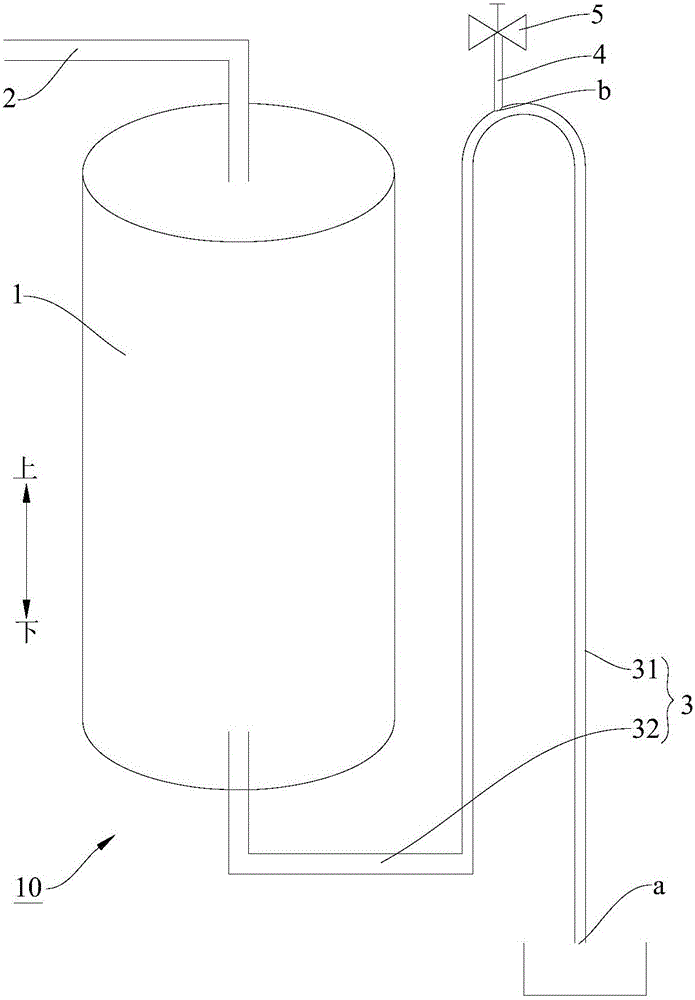

Ion exchanger

InactiveCN106076440AImprove regenerationImprove regeneration pass rate and regeneration qualityIon-exchange process apparatusGastric tube feedingIon exchange

The invention discloses an ion exchanger. The ion exchanger comprises a body, a regenerated liquid feeding tube and a regenerated liquid discharging tube, the regenerated liquid feeding tube is connected to the top end of the body, and the regenerated liquid discharging tube is connected to the bottom end of the body, wherein the regenerated liquid discharging tube comprises a discharging adapter and an inverted U-shaped tube, one end of the inverted U-shaped tube forms a discharging opening, the other end of the inverted U-shaped tube is connected with the body through the discharging adapter, and the inverted U-shaped tube is provided with an air vent. The inverted U-shaped tube of the regenerated liquid discharging tube is provided with the air vent to destroy the siphon phenomenon of the inverted U-shaped tube in order to make the whole ion exchanger be full of a regenerated liquid and the regenerated liquid flow and be regenerated, so the regeneration effect is improved, the regeneration qualification rate and the regeneration quality are improved, the running period of the ion exchanger is prolonged, the production cost is saved, and the working intensity of employees is reduced.

Owner:YUNNAN WENSHAN ALUMINUM

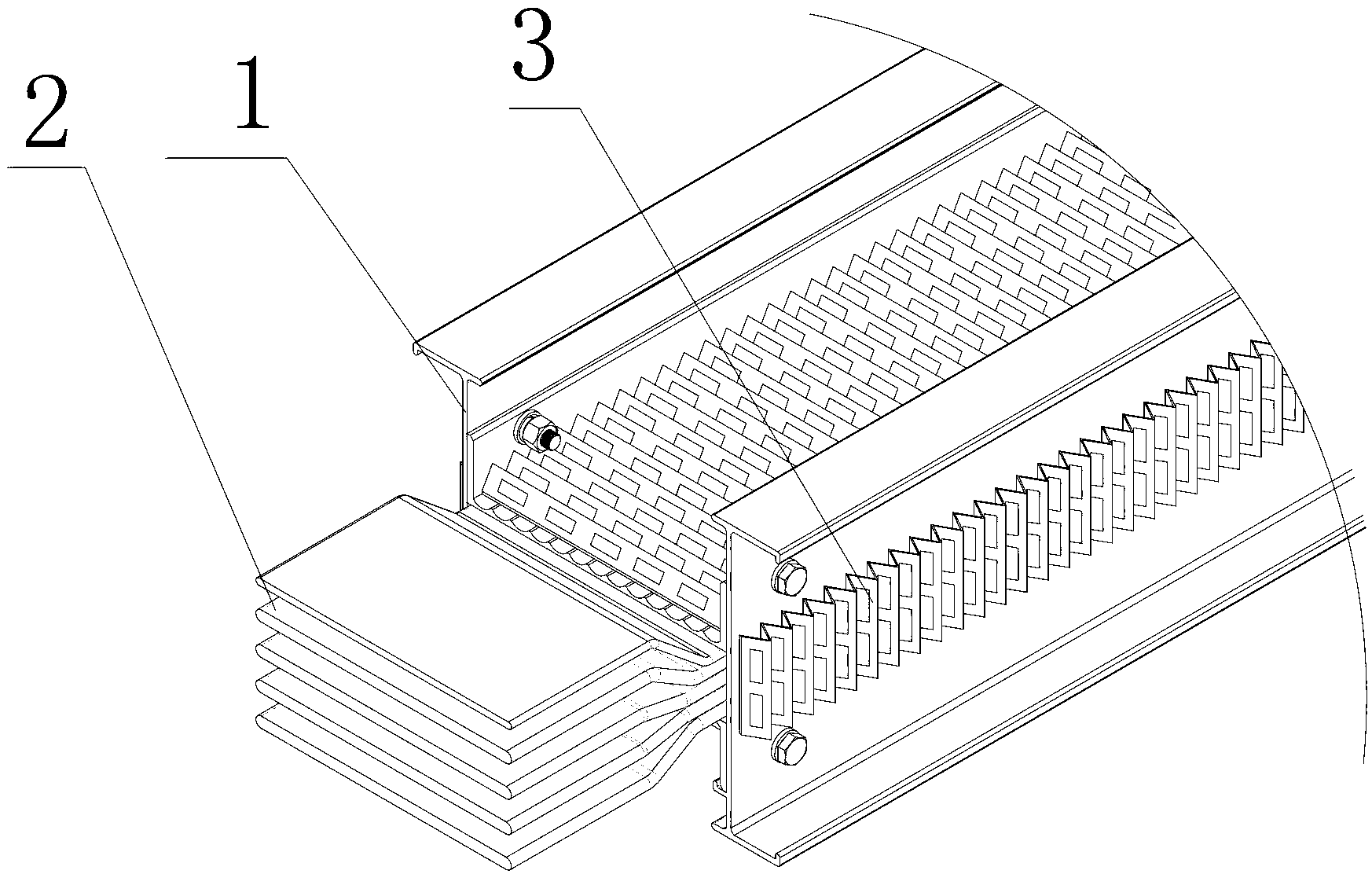

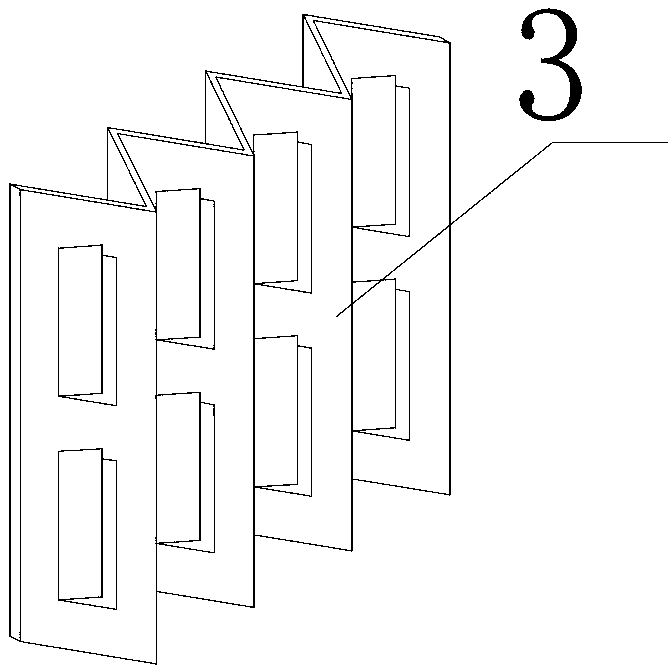

Novel energy-saving bus duct with high heat dissipation performance

InactiveCN102938549AImprove cooling effectEliminates heat spikesCooling bus-bar installationsTotally enclosed bus-bar installationsEmbedded systemHigh heat

The invention discloses a novel energy-saving bus duct with high heat dissipation performance, which includes a casing and a plurality of bus bars mounted in the casing and sleeved with insulating films; the bus bars are tightly arranged; and the bus bars and the inner wall of the casing are tightly fit. In the bus duct, the bus bars and the inner wall of the casing are tightly fit, and aluminium alloy heat dissipation elastic sheets are welded on the casing of the bus bar, so that the heat dissipation performance of the bus duct is further improved, and the problem that the temperature of the bus duct is increased sharply because the environment temperature is too high and the bus duct runs under overload operation in a short period; and the sections of the bus bars in the bus duct can be smaller than that of a common bus duct, so that the material is saved and the product performance is improved.

Owner:江苏金华厦电气有限公司

Electric fan with air monitoring function

InactiveCN105020154AHigh trafficHigh strengthPump componentsPump controlAir monitoringIndoor air quality

The invention discloses an electric fan with an air monitoring function. The electric fan is characterized in that the electric fan comprises an electric fan body, a control panel and an internal electric source circuit, wherein the control panel and the internal electric source circuit are arranged on the electric fan body; the electric fan body comprises a casing, rotating units and a cover; a PM2.5 detector, an oxygen concentration detector and a prompting device are arranged on the control panel, a control module is also arranged at the inner part of the control panel, the PM2.5 detector and the oxygen concentration detector are respectively connected with the internal electric source circuit and the control module, and the prompting device is connected with the control module. According to the electric fan disclosed by the invention, a monitoring and alarming system for PM2.5 and oxygen concentration is additionally arranged on a traditional electric fan, so that the problem that a person cannot know the indoor air quality of a room in which the person is located is solved, through the monitoring and alarming system, taking measures in time to improve the indoor air quality by people is facilitated, and the body health of the people is facilitated.

Owner:候钧伦

Oil mist separator

ActiveUS9540975B2Increase flow rateReduced flow cross sectionDispersed particle filtrationTransportation and packagingSuspended particlesPetroleum engineering

An oil mist separator includes at least one filter device for separating off liquid suspended particles from a carrier gas. The filter device includes a housing having at least one inlet opening for introducing the carrier gas and at least one outlet opening for discharging the filtered carrier gas. Arranged in the housing is at least one filter insert through which the carrier gas can flow along a flow direction. There is also provided at least one guide device by which the flow path can be deflected. The at least one filter device can be arranged releasably in the oil mist separator, and a seal is provided preferably between a first fixing surface of the oil mist separator and a second fixing surface, to be fixed thereto, of the filter device.

Owner:GE JENBACHER

Flow adjusting device and common rail system

InactiveCN113062823AIncrease oil drainageLarge leakageFuel injection apparatusMachines/enginesCommon railEngineering

The invention belongs to the technical field of hydraulic pressure, and discloses a flow adjusting device and a common rail system. The flow adjusting device comprises a pressure limiting valve and a flow amplifying mechanism, the flow amplifying mechanism comprises a valve body, and an oil inlet channel and an oil outlet channel which communicate with each other are arranged on the valve body. The pressure limiting valve penetrates through the valve body in a sealed mode and abuts against a valve sleeve, an oil inlet throttling hole and an oil outlet throttling hole are formed in the valve sleeve, the oil inlet throttling hole communicates with the oil inlet channel, the oil outlet throttling hole selectively communicates with the pressure limiting valve, and the flow of the oil inlet throttling hole is smaller than that of the oil outlet throttling hole. One end of a valve element penetrates through the valve sleeve, the other end of the valve element penetrates through the valve body, a first volume cavity is formed between the valve element and the valve sleeve, the first volume cavity communicates with the oil inlet throttling hole and the oil outlet throttling hole, a second volume cavity is formed between the valve element and the valve body, and the valve element can slide relative to the valve body so that the valve element can selectively block the oil outlet channel. The flow adjusting device can meet the requirements for large flow and high pressure at the same time.

Owner:FAW JIEFANG AUTOMOTIVE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com