Hydraulic Machinery

a technology of hydraulic pump and hydraulic pump, which is applied in the direction of rotary clutches, electrical control, fluid couplings, etc., can solve the problems of insufficient speed and inability to solve, and achieve the effects of improving the discharge flow rate of hydraulic pumps, improving operability, and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

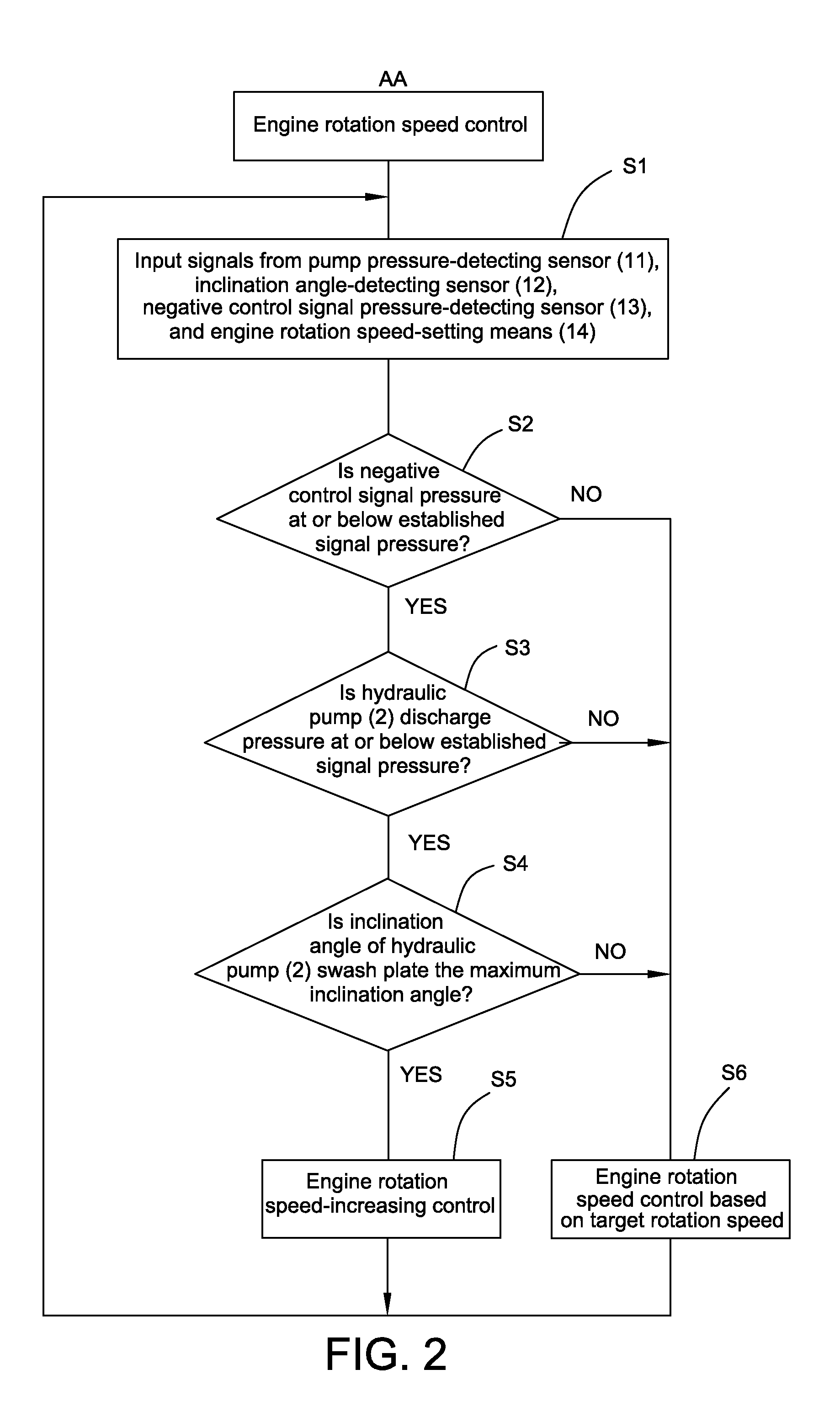

[0010]An embodiment of the present invention is described below by referring to the drawings.

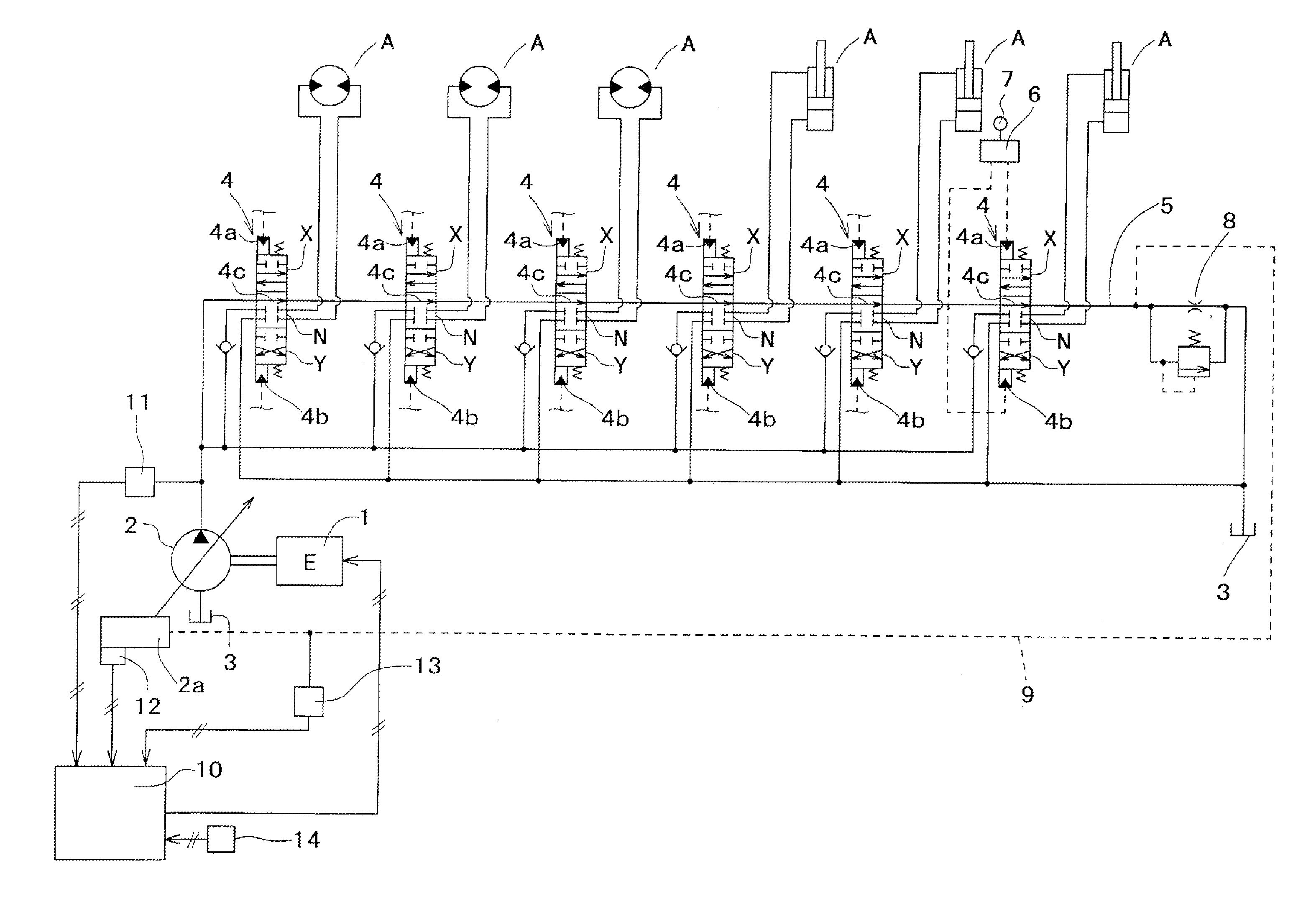

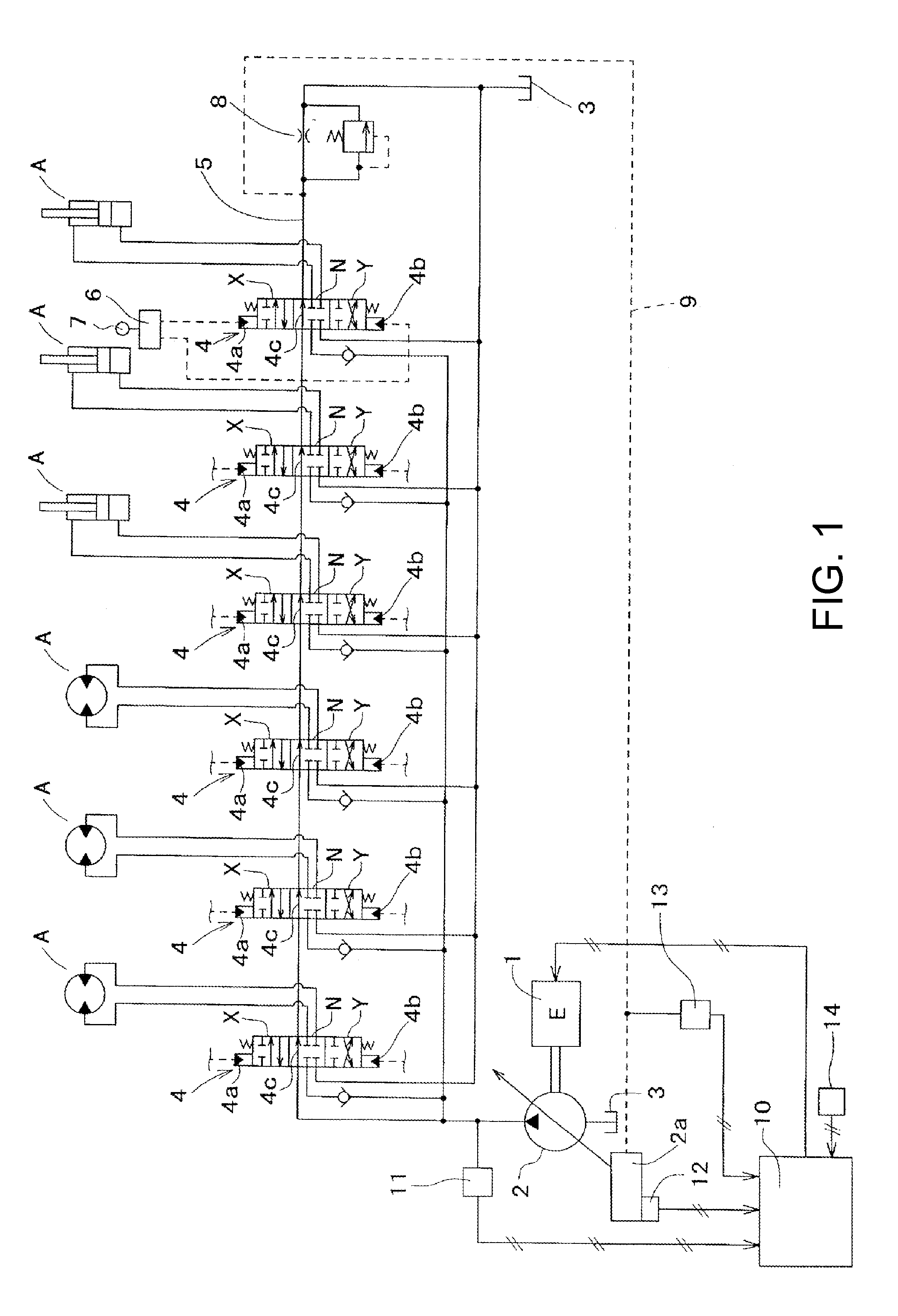

[0011]A hydraulic pressure control circuit provided to a hydraulic shovel, as an example of a hydraulic work machine, is illustrated in FIG. 1, in which 1 denotes an engine, 2 denotes a variable capacity hydraulic pump driven by the engine 1, 2a denotes capacity varying means of the hydraulic pump 2, 3 denotes an oil tank, and A denotes hydraulic actuators that operate using the hydraulic pump 2 as a hydraulic pressure supply source. In this embodiment, the hydraulic shovel includes, as the hydraulic actuators A, left and right drive motors, a swing motor, a boom cylinder, an arm cylinder, and a bucket cylinder. In this embodiment, an axial piston pump, in which a capacity changes in accordance with a inclination angle of a swash plate, is used as the hydraulic pump 2.

[0012]Furthermore, 4 denotes control valves that perform oil supply / discharge control for the respective hydraulic actuators ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com