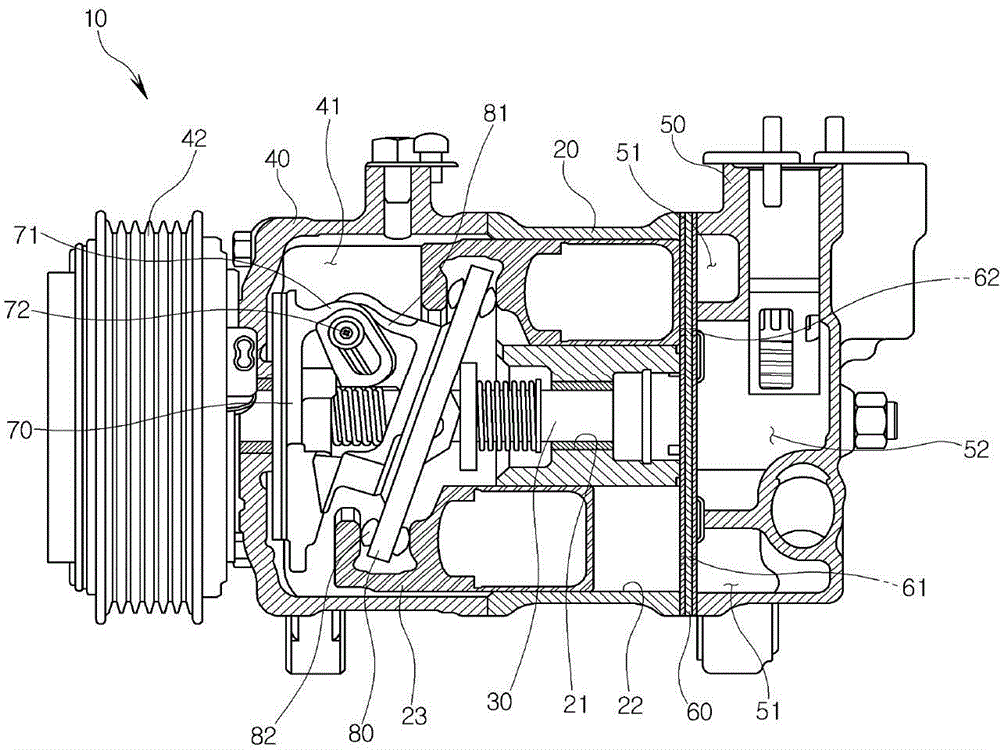

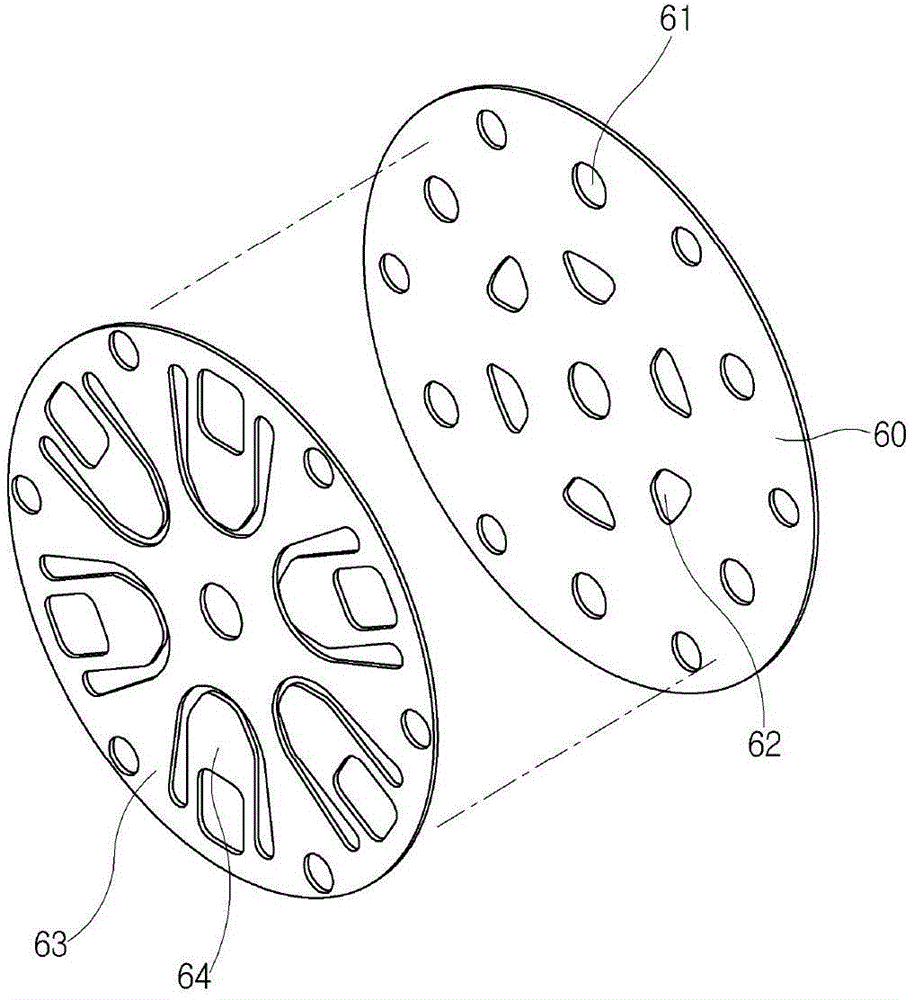

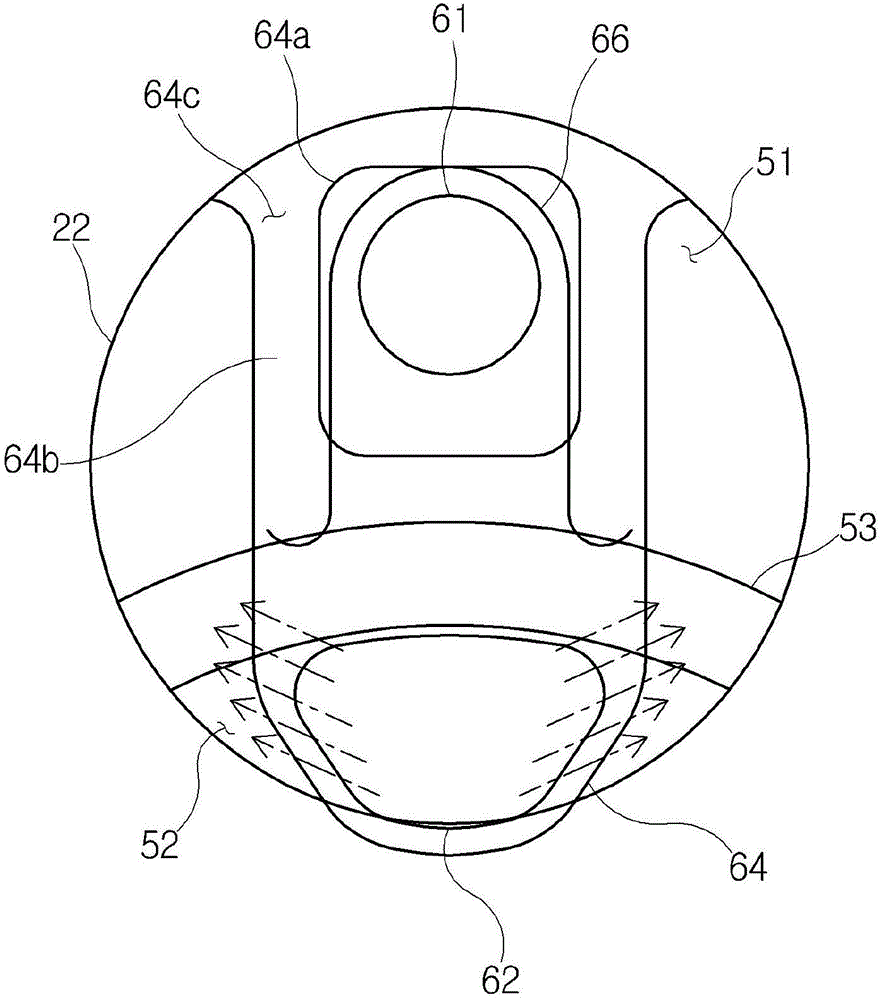

Valve assembly for variable swash plate compressor

一种斜盘式、压缩机的技术,应用在变容式泵部件、液体变容式机械、泵元件等方向,能够解决无法正常实现制冷剂压缩和排出过程、无法正常实现制冷剂吸入、基端部64c断裂等问题,达到性能提高、排出量增加、防止驱动速度的增加的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The present invention can be modified variously and has various embodiments, and specific embodiments are shown in the drawings and described in detail. However, this should not be understood as limiting the present invention to specific embodiments, but should be understood as including all modifications, equivalent technical solutions, and replacement technical solutions included in the spirit and technical scope of the present invention. The thickness of lines or the size of structural elements shown in the drawings may be exaggerated for clarity and convenience of description.

[0085] In addition, the terms described later may be defined in consideration of functions in the present invention and may vary depending on the user's or operator's intention or precedents. Therefore, the definitions of these terms should be defined based on the contents of this specification as a whole.

[0086] Hereinafter, preferred embodiments of the present invention will be describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com