Hydraulic circuit for transmission

A technology of hydraulic circuit and transmission, applied in the direction of components with teeth, transmission control, belt/chain/gear, etc., can solve the problems of vehicle starting delay, oil loss, time-consuming, etc., and achieve the effect of reducing the driving load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

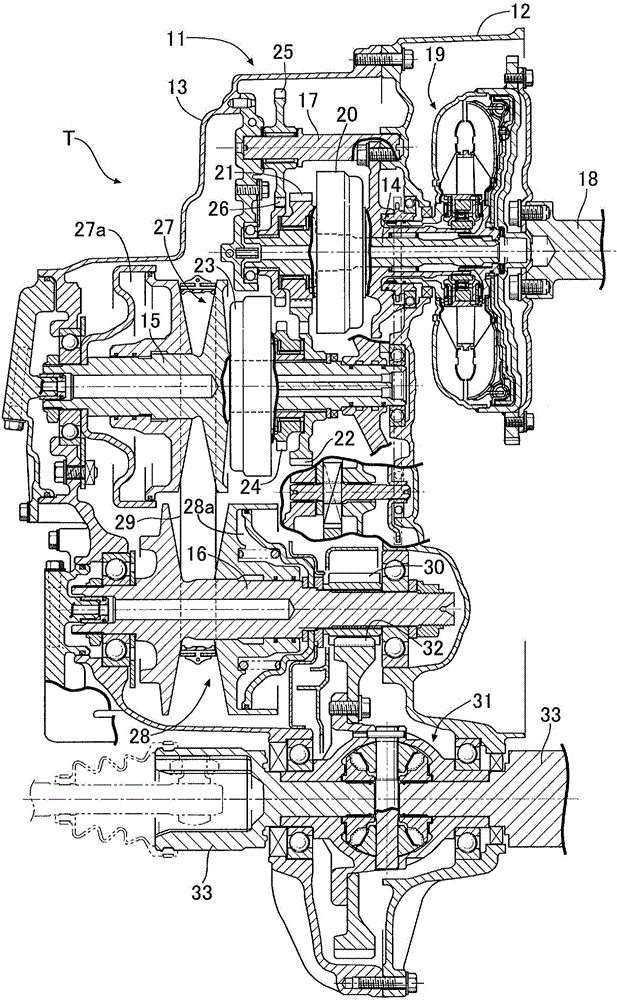

[0061] First, based on figure 1 The overall structure of the belt type continuously variable transmission T will be described. The transmission case 11 of the belt-type continuously variable transmission T includes a torque converter case 12 connected to an engine (not shown), a transmission case main body 13 connected to the torque converter case 12, an input shaft 14, and a drive pulley shaft 15. , the driven pulley shaft 16 and the idle shaft 17 are supported inside the transmission case 11 in parallel.

[0062] On the input shaft 14 connected to the crankshaft 18 of the engine via a torque converter 19, a forward drive gear 21 is supported in a relatively rotatable manner, and the forward drive gear 21 can be coupled to the input shaft 14 via a forward clutch 20. The forward drive gear 21 meshes with a forward driven driven gear 22 fixed to the drive pulley shaft 15 . The driven pulley shaft 15 is relatively rotatably supported with a reverse driven gear 24 that can be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com