Stirring blade structure of sludge drier

A sludge drying and stirring paddle technology, which is applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of endangering the normal operation of the system, increasing the driving load of the hollow hot shaft, and reducing the space of the sludge slurry channel, etc. It is not easy to damage the machine, it is not easy to accidentally get stuck, and the heat exchange efficiency is increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further specifically described below through examples.

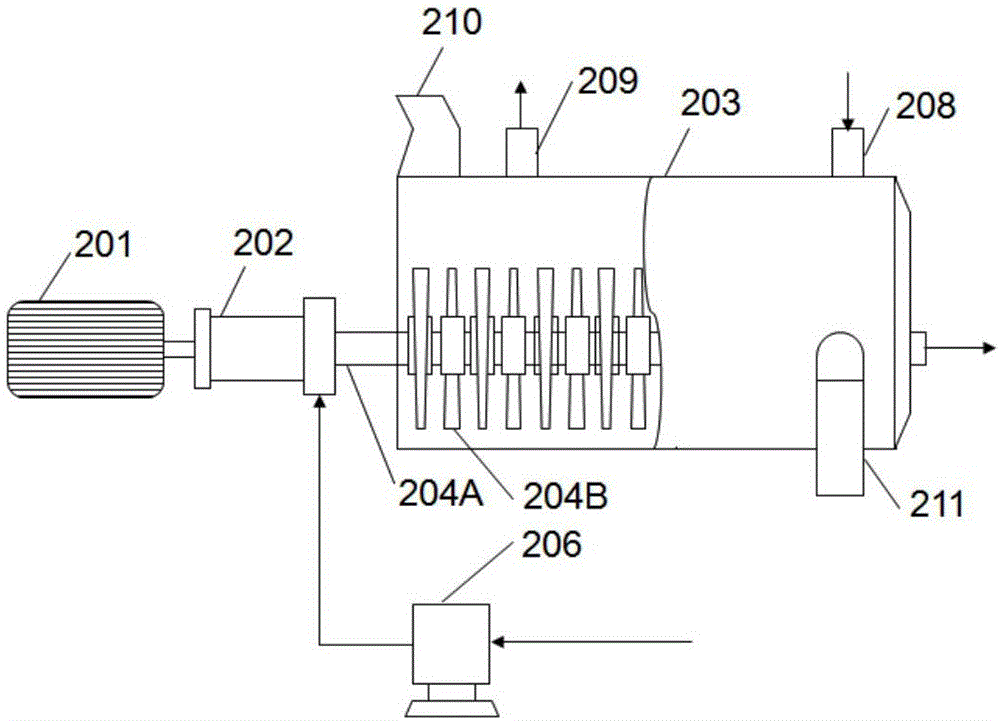

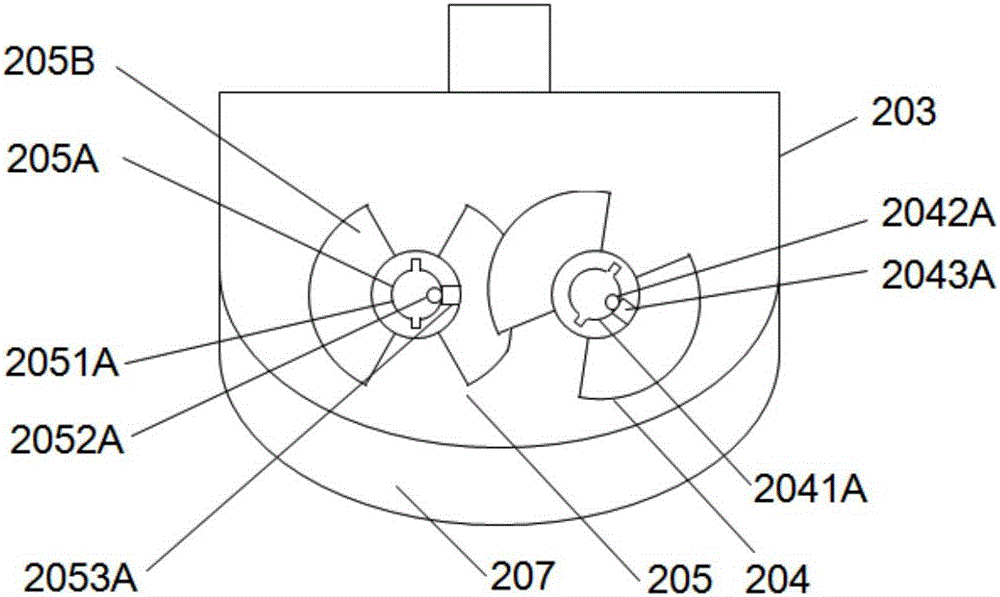

[0028] first preferred embodiment

[0029] The stirring paddle structure provided by the invention is applied to a hollow paddle sludge dryer. Figure 2A-2BA hollow paddle sludge dryer equipped with the stirring paddle structure is shown. The drying machine includes a drive motor 201, a biaxial transmission box 202, a heat exchange chamber 203, a first hollow paddle 204, a second hollow paddle 205, a heat medium delivery pump 206, a heat conduction jacket 207, an air inlet 208, and a steam outlet 209, material inlet 210 and material outlet 211. The drive motor 201 is used to provide driving force for the rotation of the first hollow paddle 204 and the second hollow paddle 205 around its hollow paddle shaft; the double shaft transmission box 202 is connected to the motor shaft of the drive motor 201 and has two torque output shafts, two The two torque outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com