Patents

Literature

74results about How to "High discharge pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

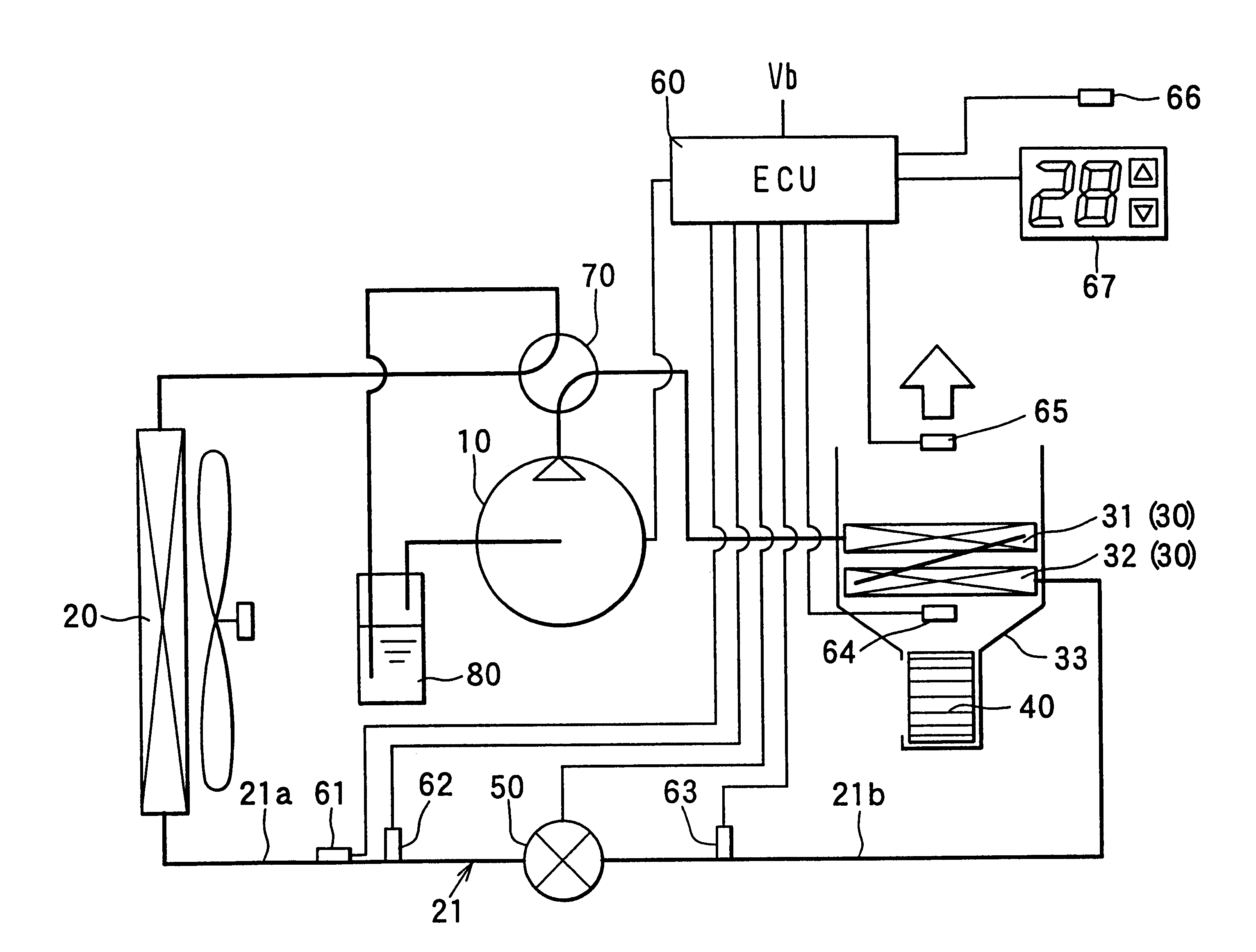

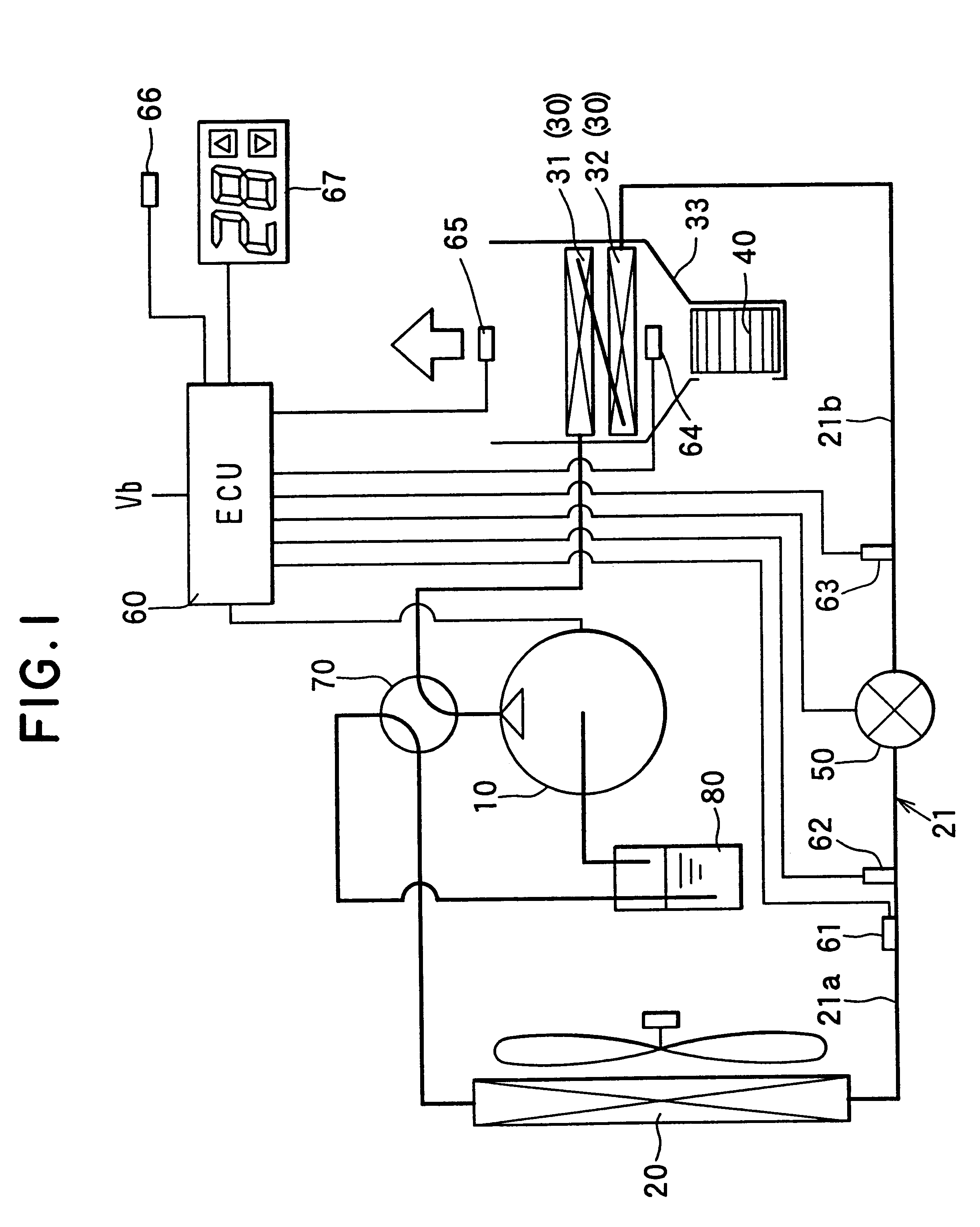

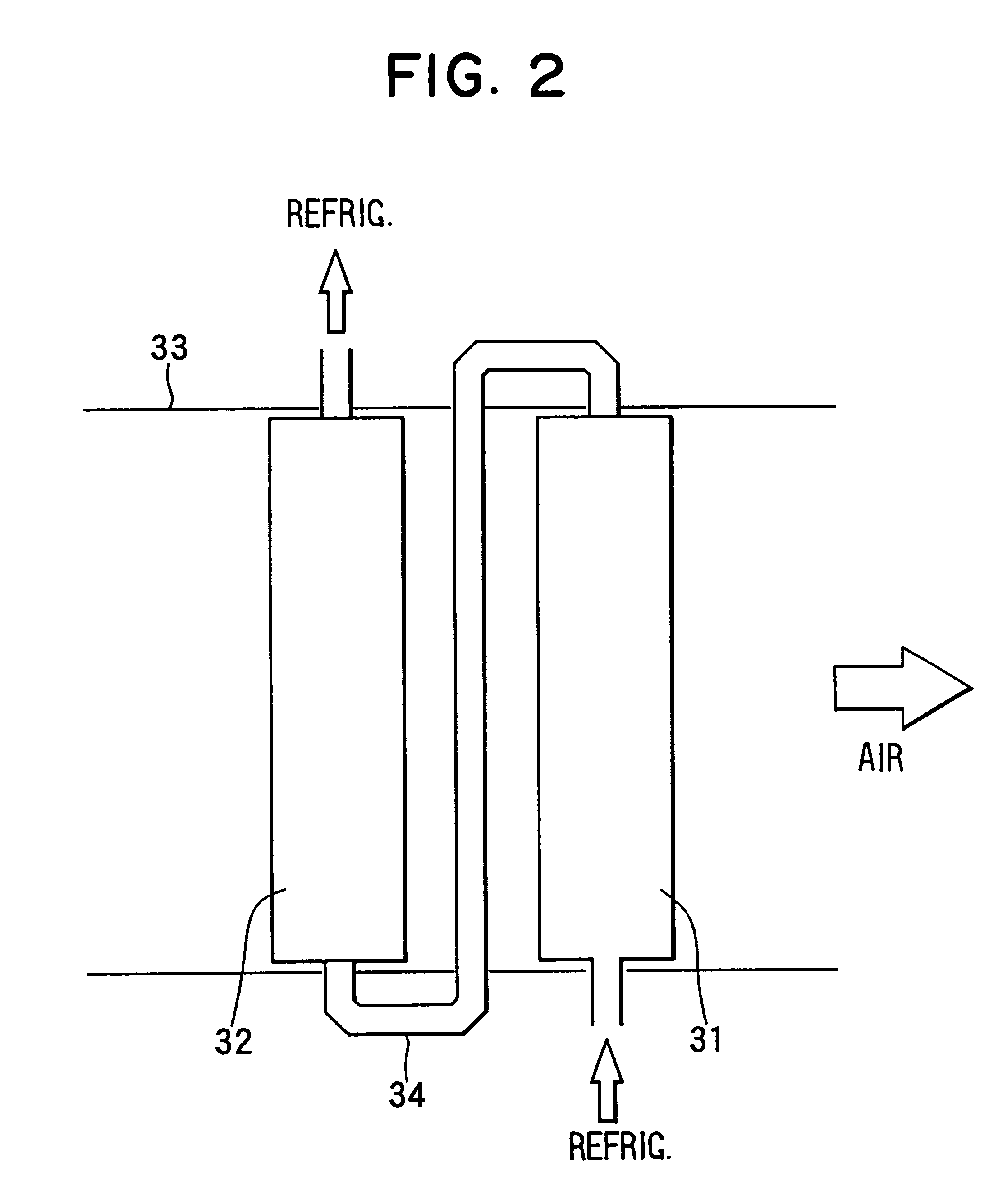

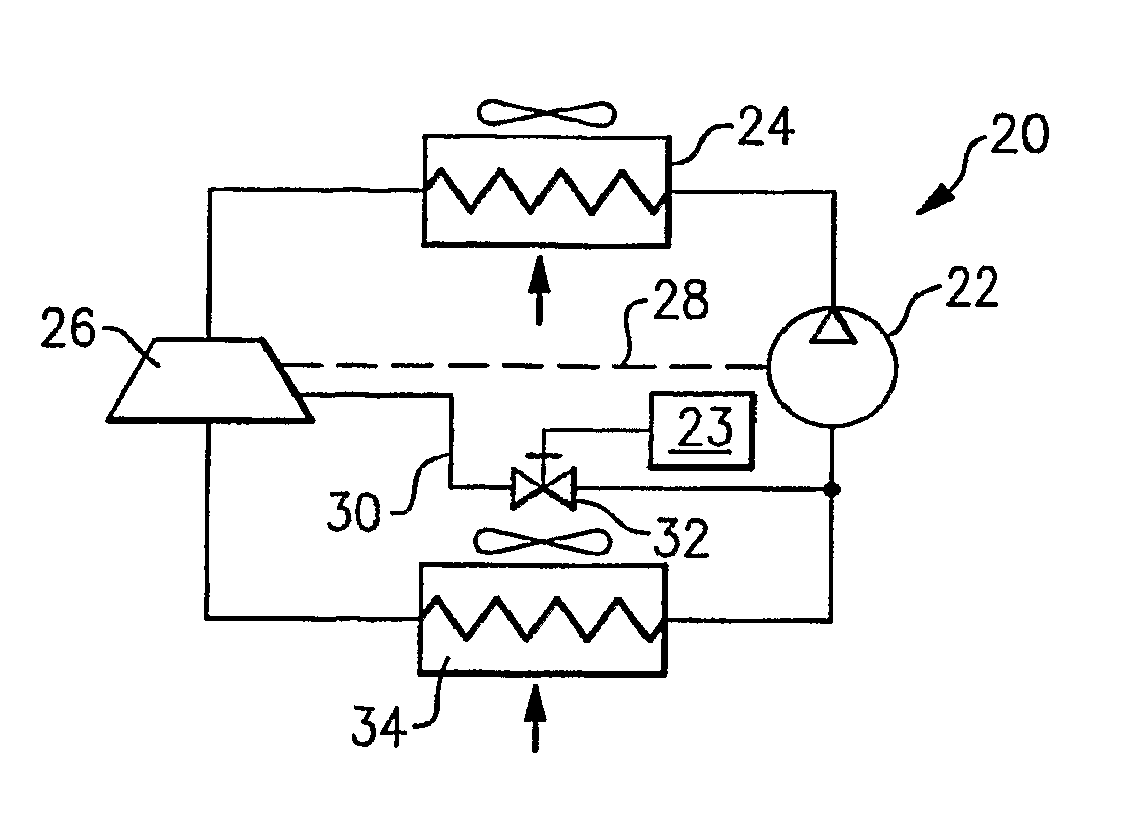

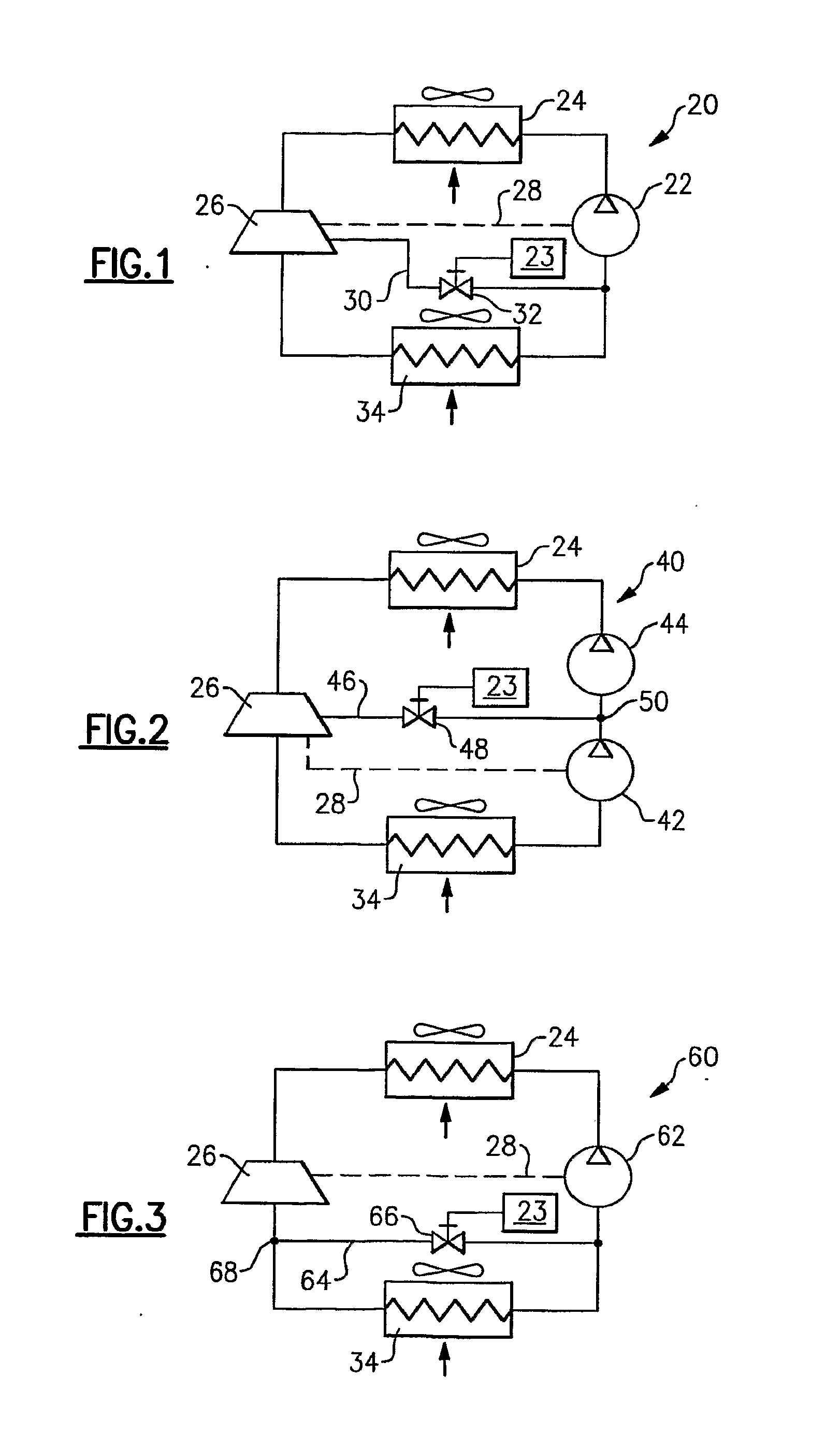

Heat pump cycle system

InactiveUS6230506B1Improve the heating effectImprove the overall coefficientMechanical apparatusAir-treating devicesLower limitEngineering

A heat pump cycle system which can switches cooling operation and heating operation for a compartment includes a first inside heat exchanger and a second inside heat exchanger disposed in an air conditioning case. The first inside heat exchanger is disposed in the air conditioning case at a downstream air side of the second inside heat exchanger, while being arranged in line in a flow direction of refrigerant. The first inside heat exchanger is upstream from the second inside heat exchanger in the flow direction of refrigerant during the heating operation. In the heat pump cycle system, an expansion valve is controlled so that coefficient of performance in each operation becomes approximately maximum. Thus, during the heating operation of the heat pump cycle system, a lower limit temperature of air blown from the inside heat exchangers can be increased so that temperature of air blown into the compartment is increased, while the coefficient of performance is improved.

Owner:DENSO CORP

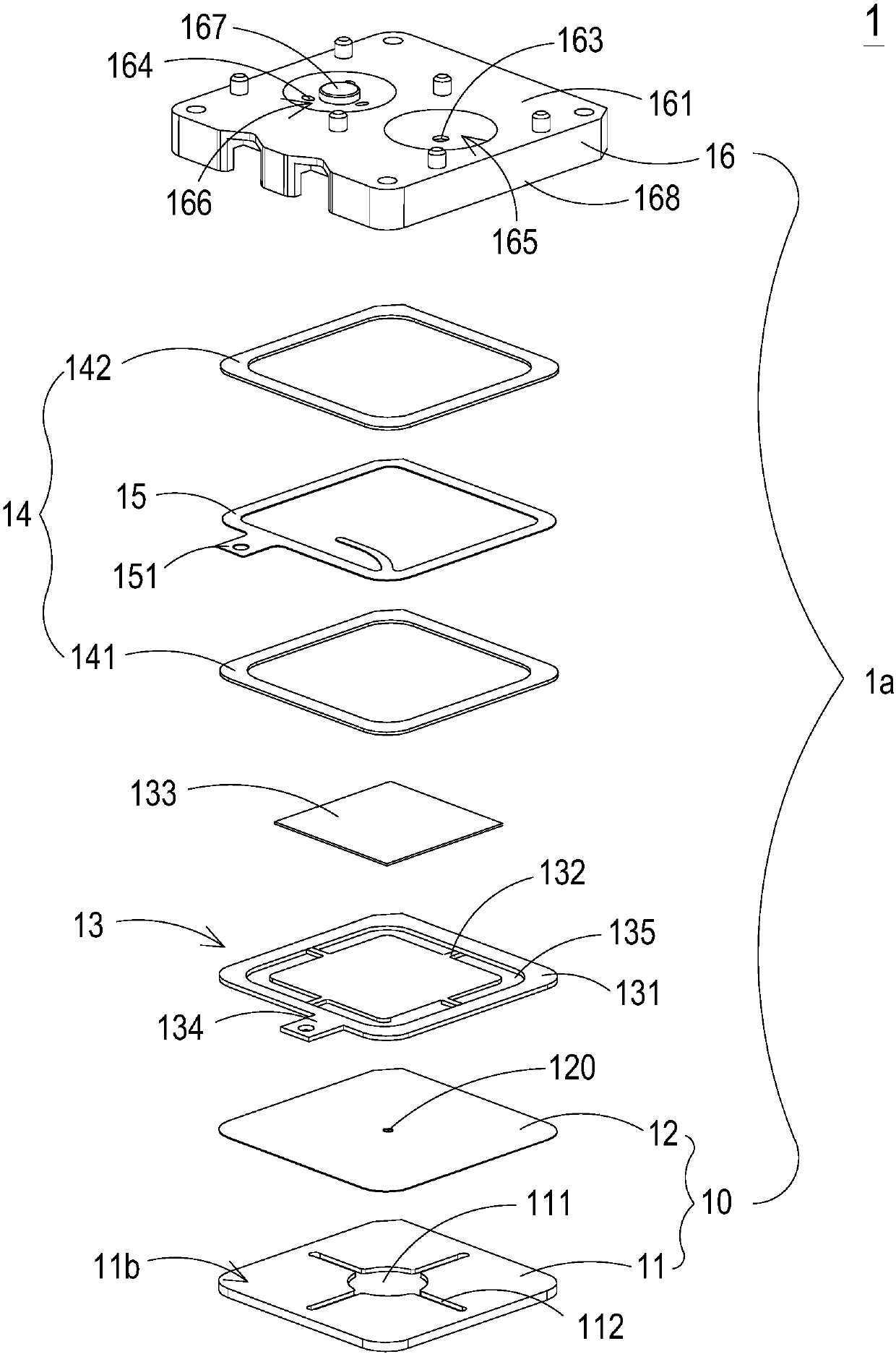

Fluid control device

ActiveUS20130058819A1Reduce rateLow profileFlexible member pumpsPositive-displacement liquid enginesFluid controlEngineering

A fluid control device includes a vibrating plate including a first main surface and a second main surface, a driver that is provided on the first main surface of the vibrating plate and vibrates the vibrating plate, and a plate that is provided on the second main surface of the vibrating plate and has a hole provided thereon. At least one of either the vibrating plate or the plate is positioned between the hole and a region of the vibrating plate facing the hole, and includes a projection projecting in a direction intermediate between the hole and the region of the vibrating plate facing the hole.

Owner:MURATA MFG CO LTD +1

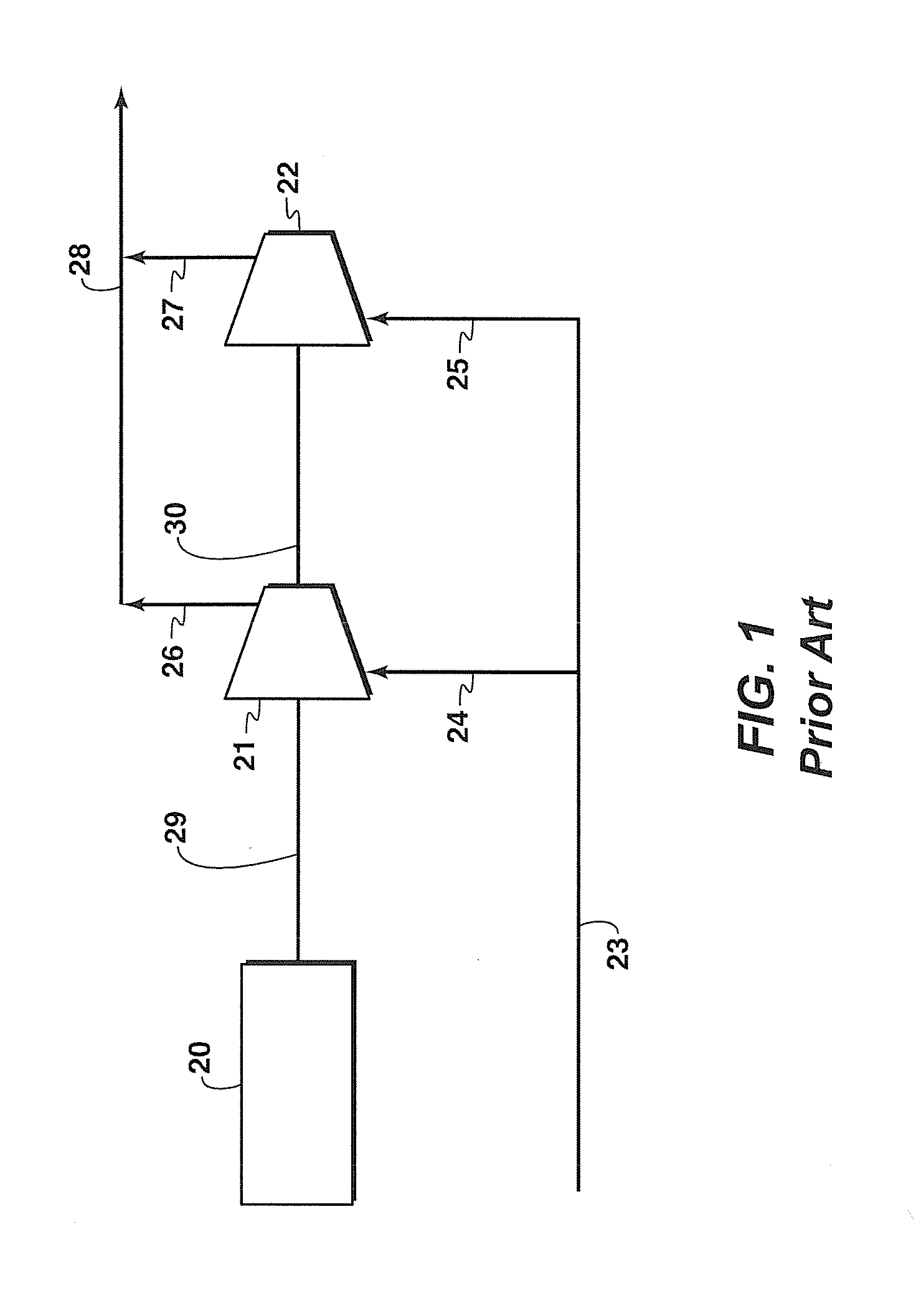

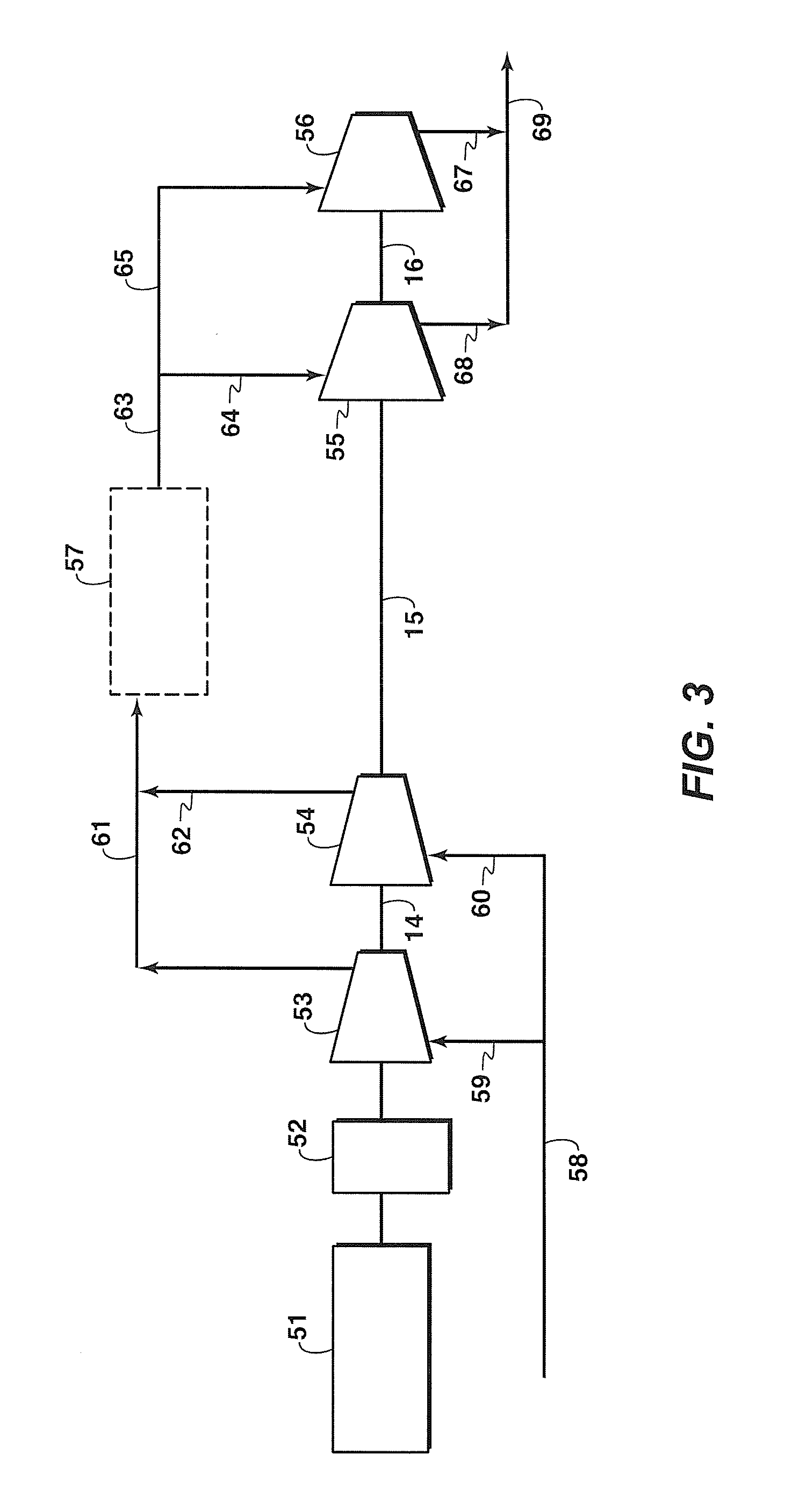

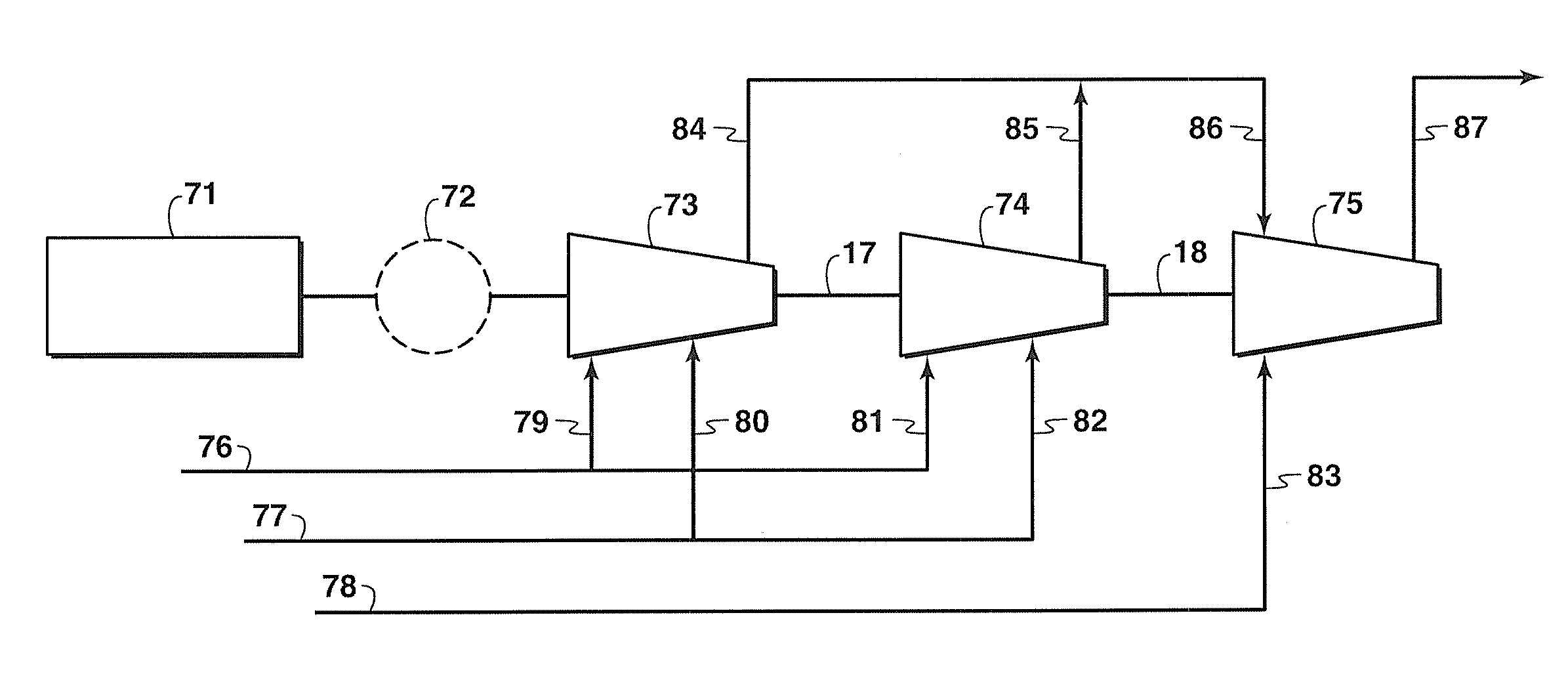

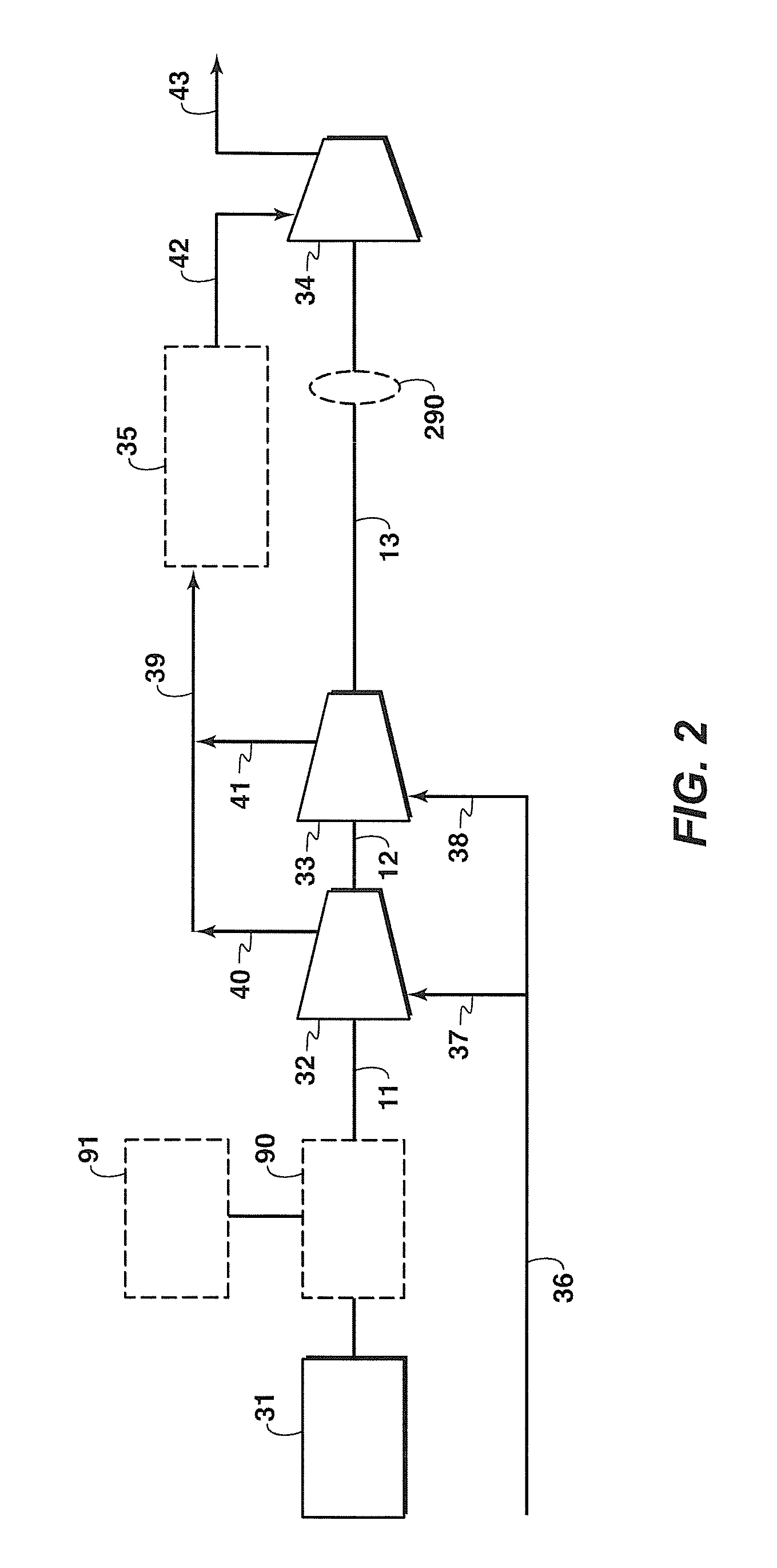

Parallel Dynamic Compressor Arrangement and Methods Related Thereto

ActiveUS20130058800A1Improve efficiencyLess spaceSolidificationLiquefactionParallel dynamicsEngineering

This disclosure is directed to a novel arrangement for equipment used to compress fluids. A single prime mover is connected to a plurality of compressors. A supply conduit with parallel branch conduits directs fluid to be compressed to at least two compressors and parallel output conduits from each compressor are connected to a common output conduit, which directs compressed fluids to at least one additional compressor.

Owner:EXXONMOBIL UPSTREAM RES CO

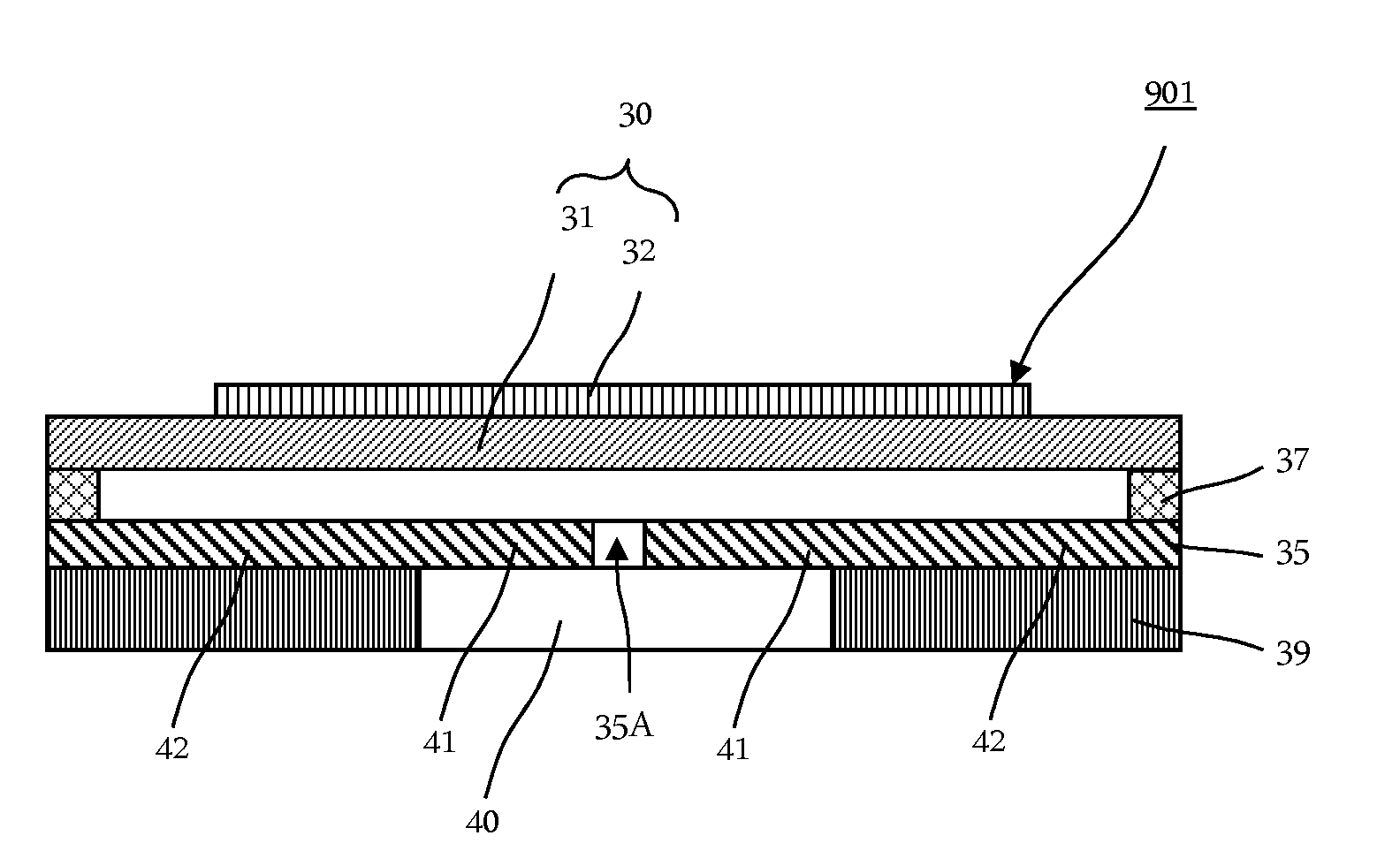

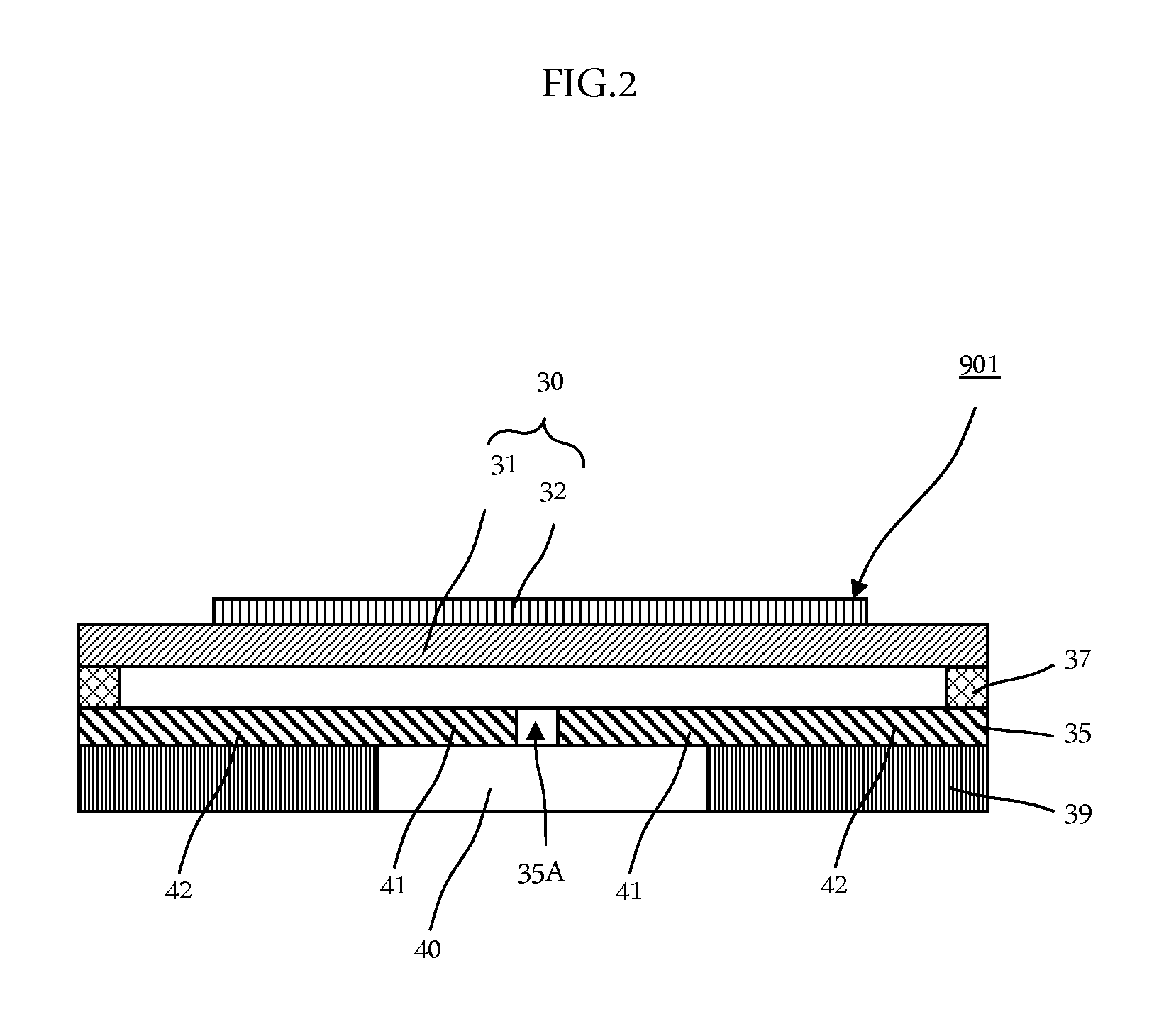

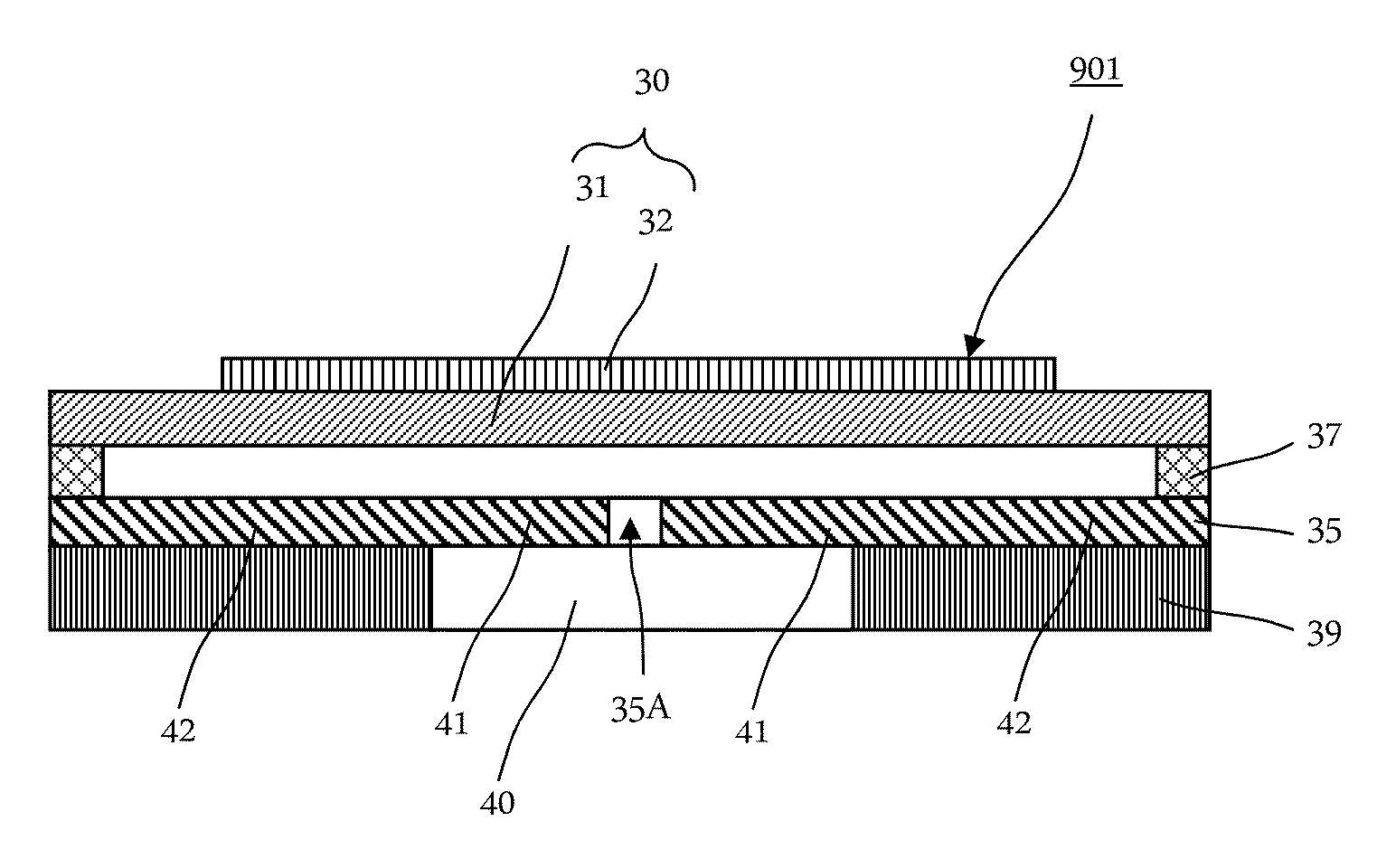

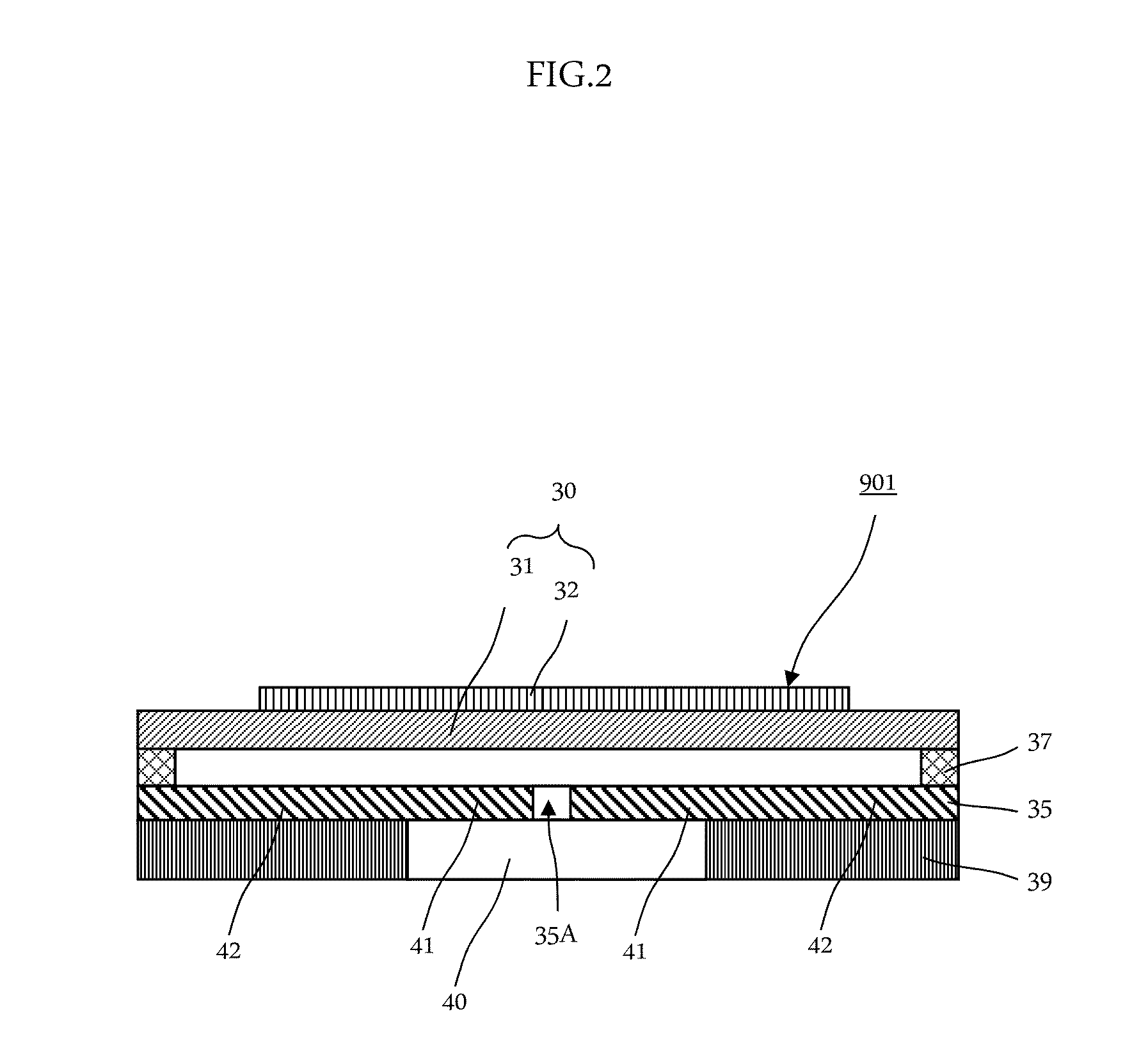

Fluid control device

ActiveUS20130058810A1High discharge pressureLarge discharge flow rateFlexible member pumpsPositive-displacement liquid enginesFluid controlEngineering

A fluid control device includes a vibrating plate unit, a driver, a flexible plate, and a base plate. The vibrating plate unit includes a vibrating plate including first and second main surfaces, and a frame plate surrounding the surrounding of the vibrating plate. The driver is bonded to the first or the second main surface of the vibrating plate and vibrates the vibrating plate. The flexible plate includes a hole provided therein, and is bonded to the frame plate so as to face the vibrating plate. The base plate is bonded to the main surface of the flexible plate on a side opposite to the vibrating plate. A size relationship between the coefficients of linear expansion of the material of the base plate and the frame plate is equal to a size relationship between the coefficients of linear expansion of the material of the vibrating plate and the driver.

Owner:MURATA MFG CO LTD

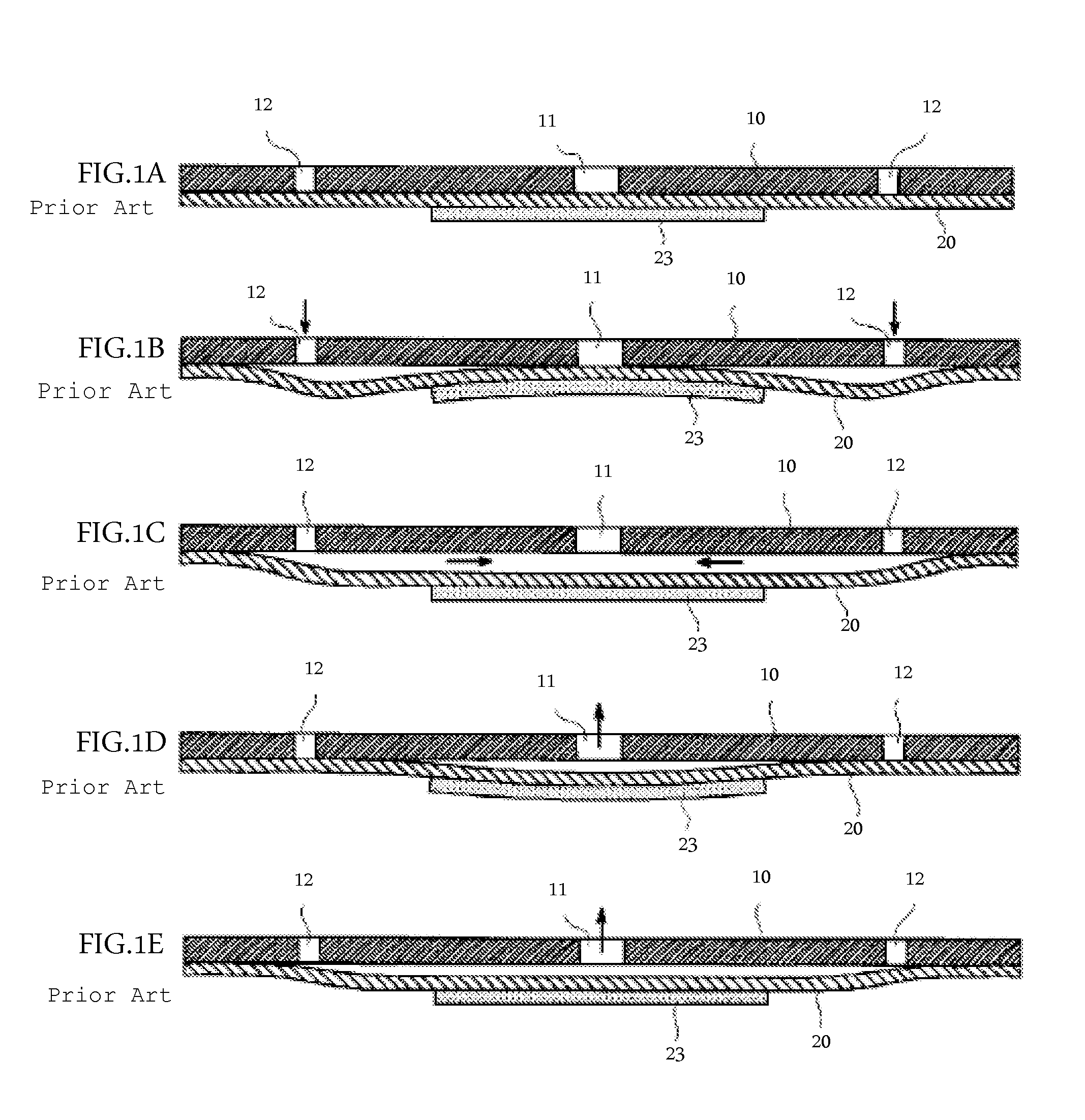

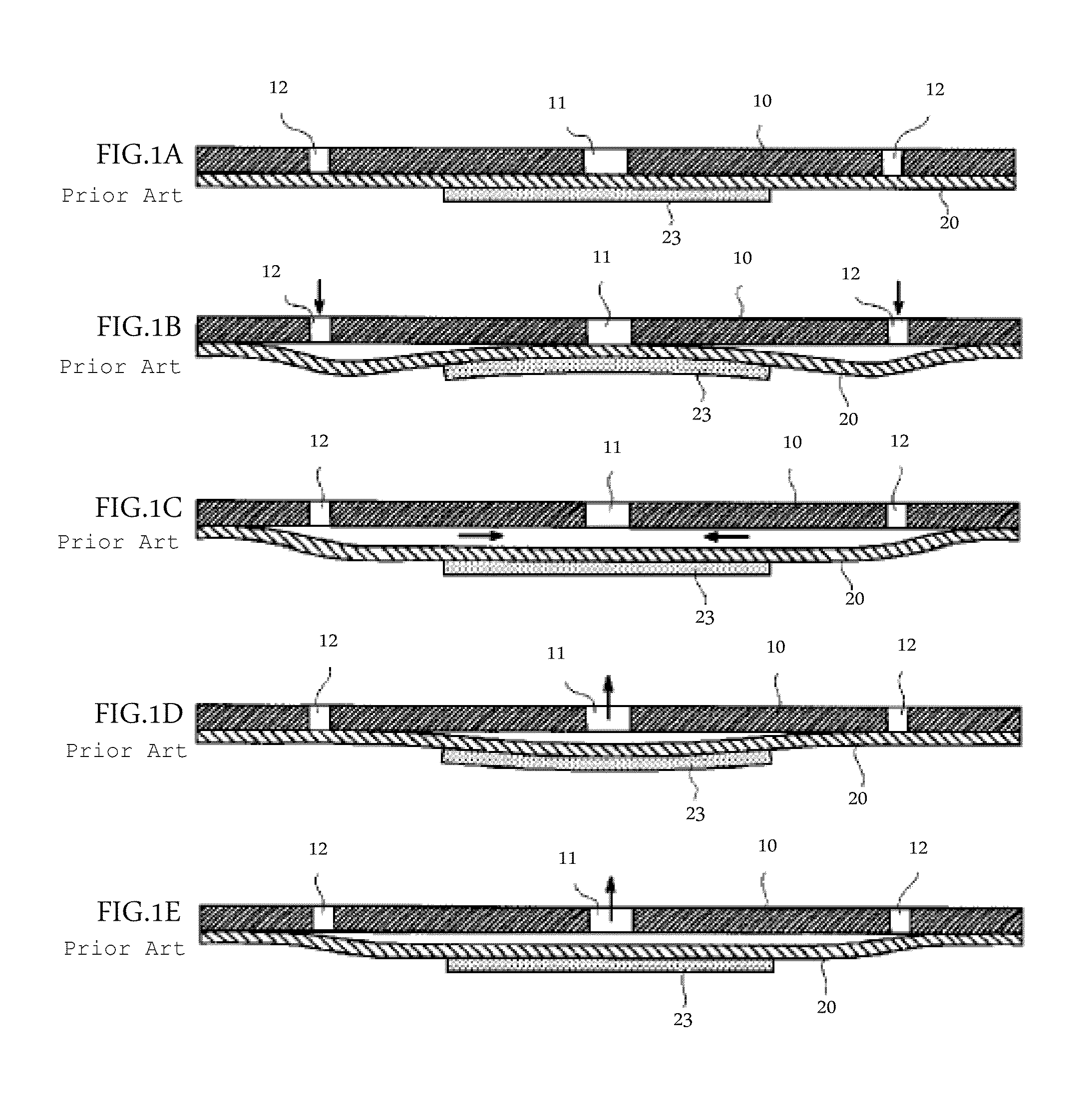

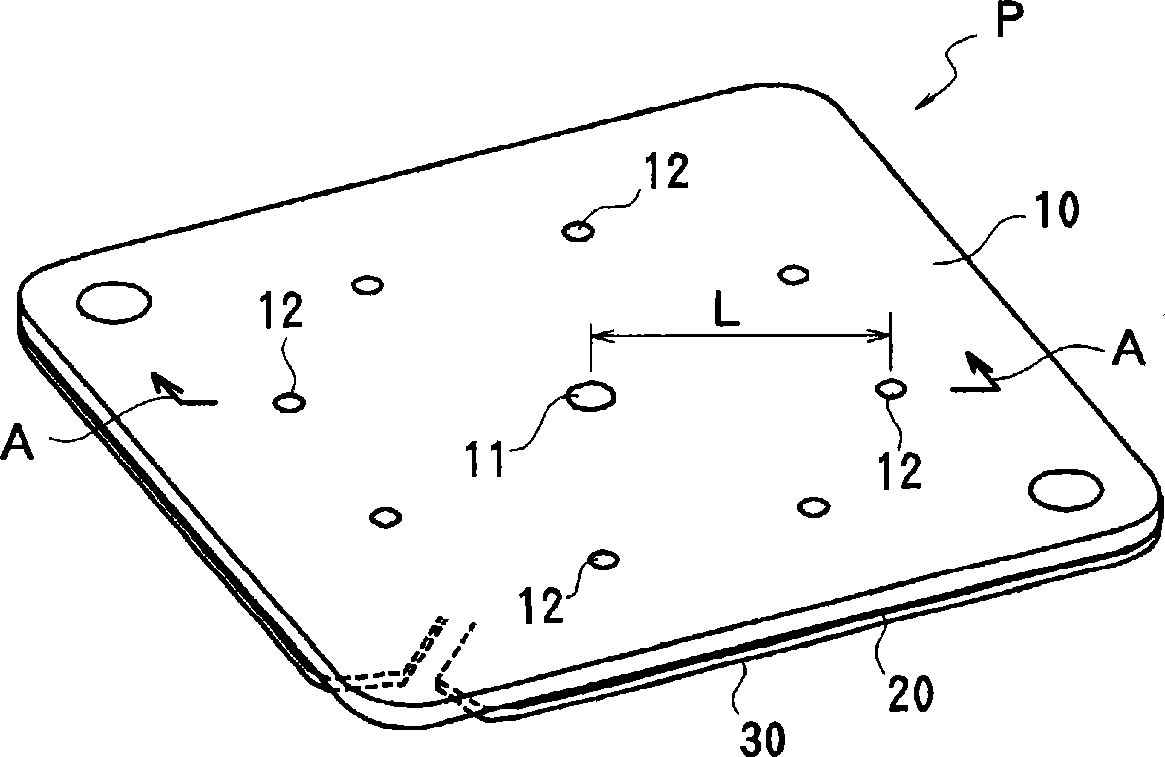

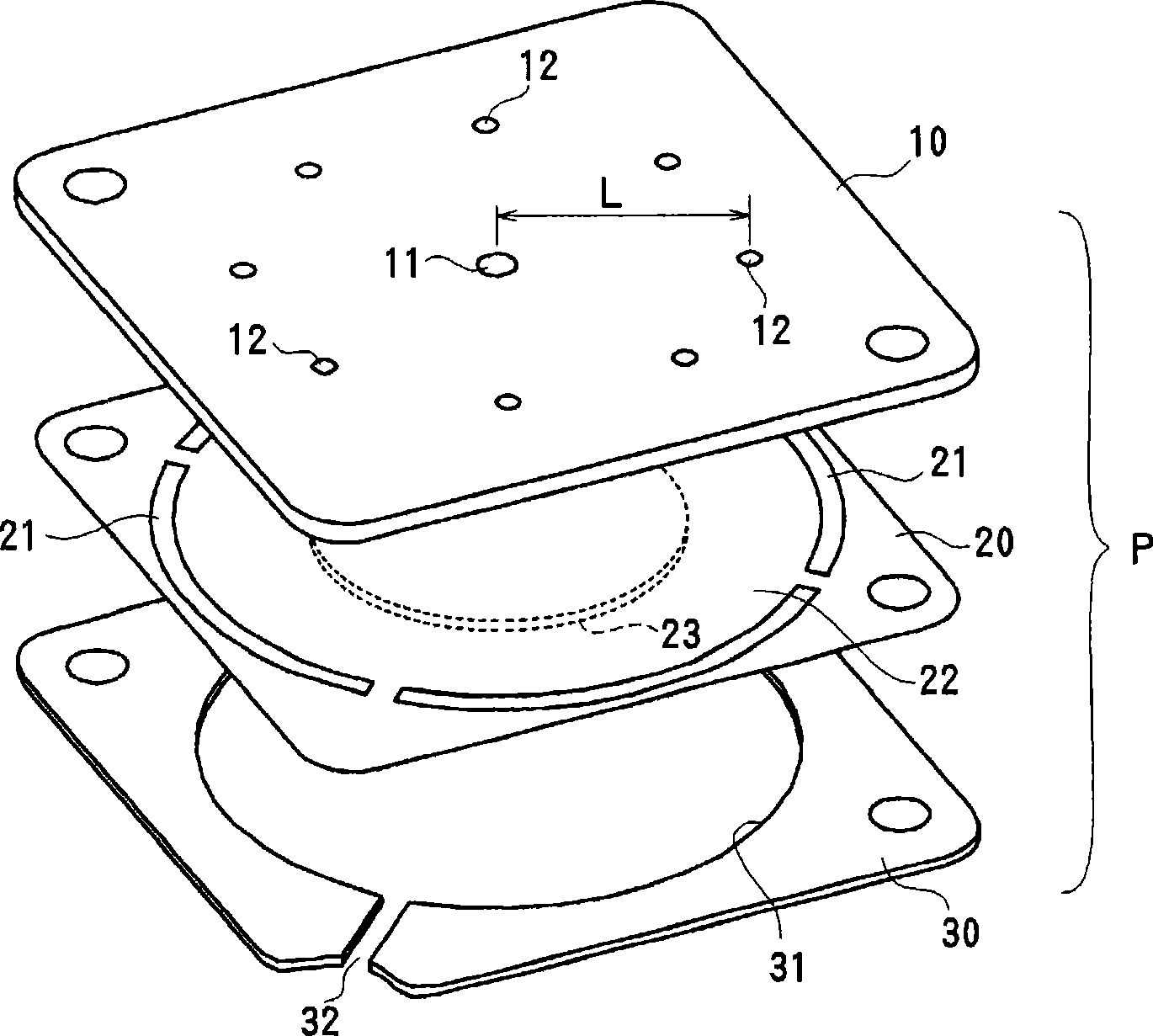

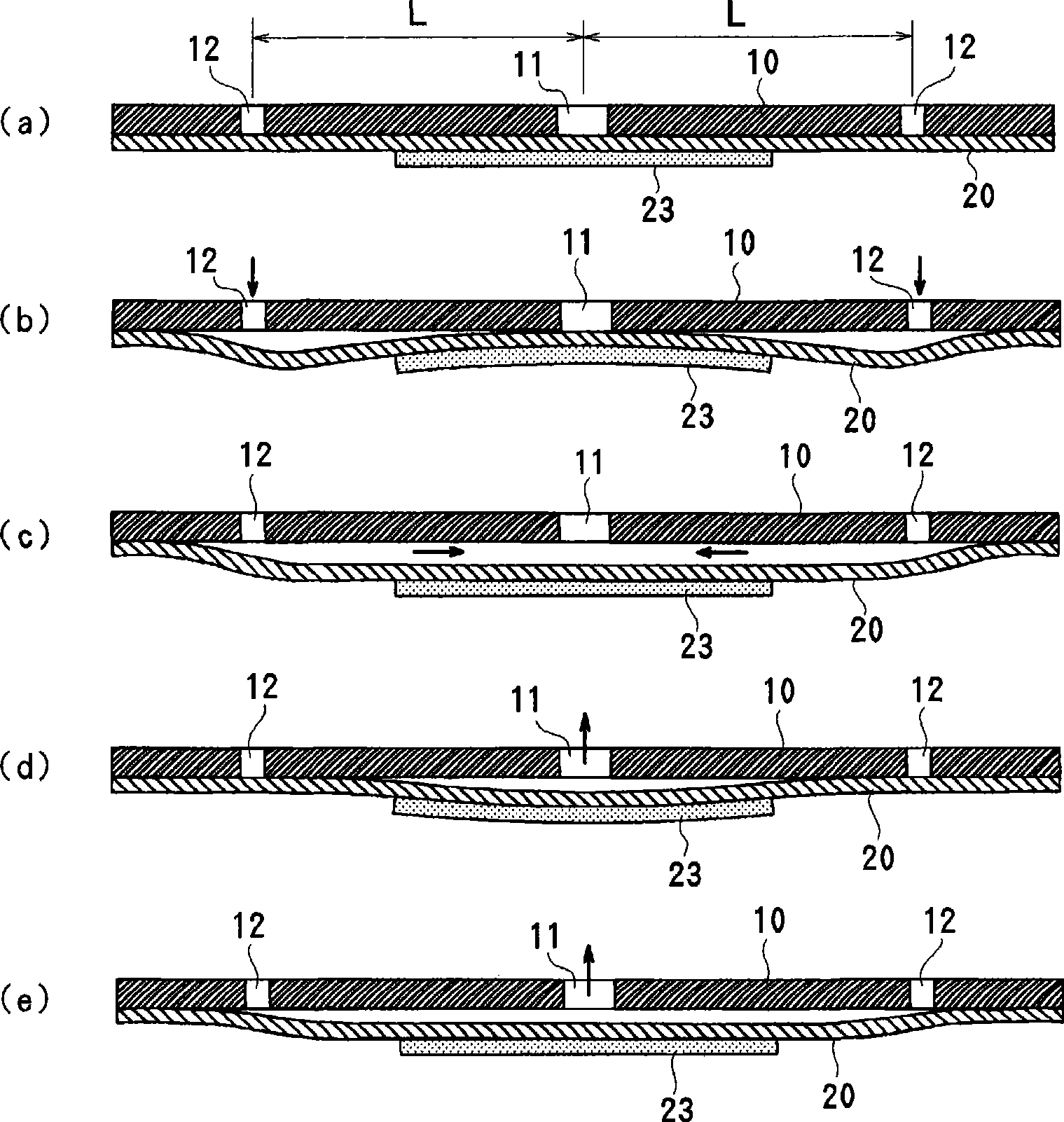

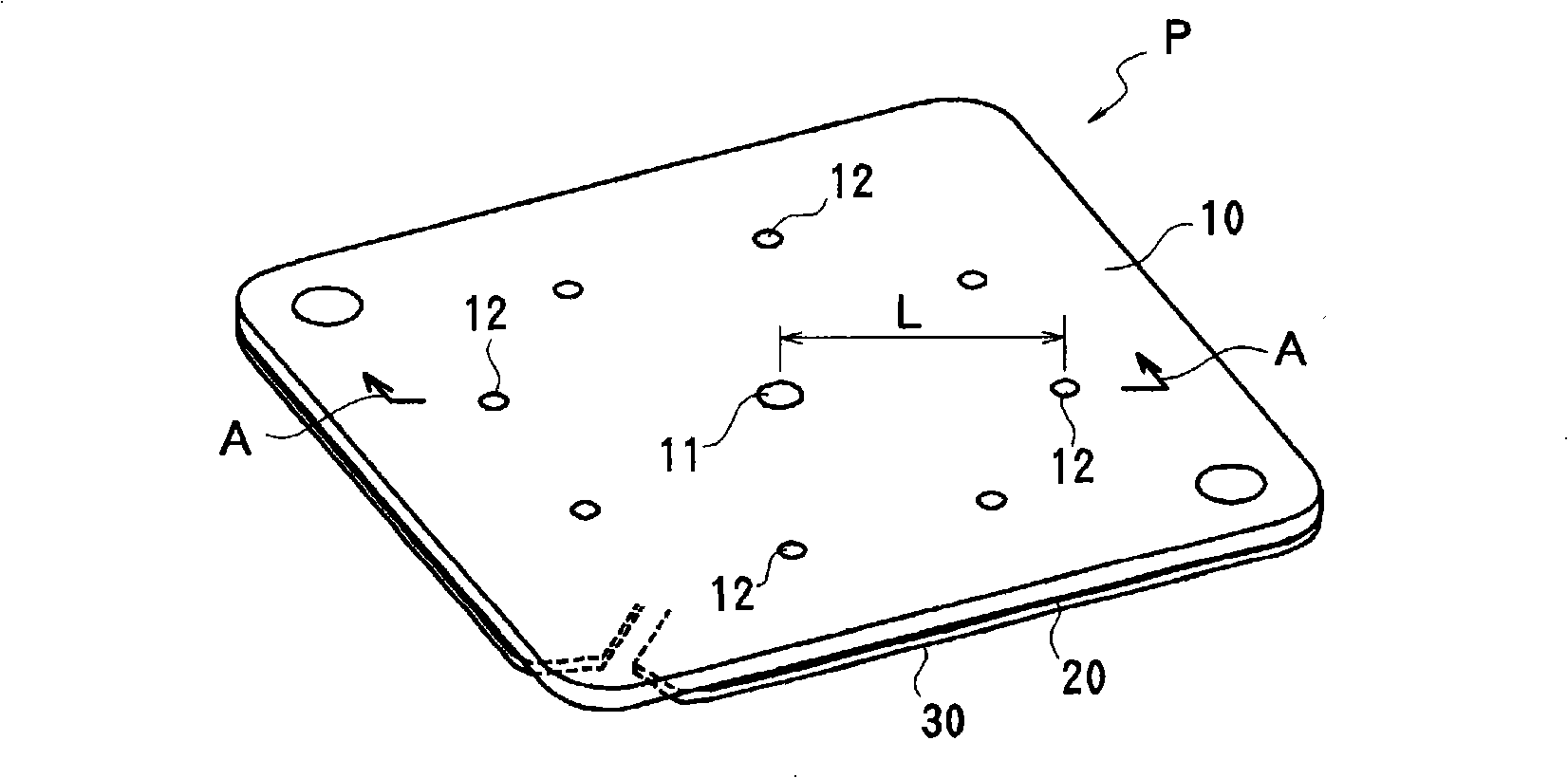

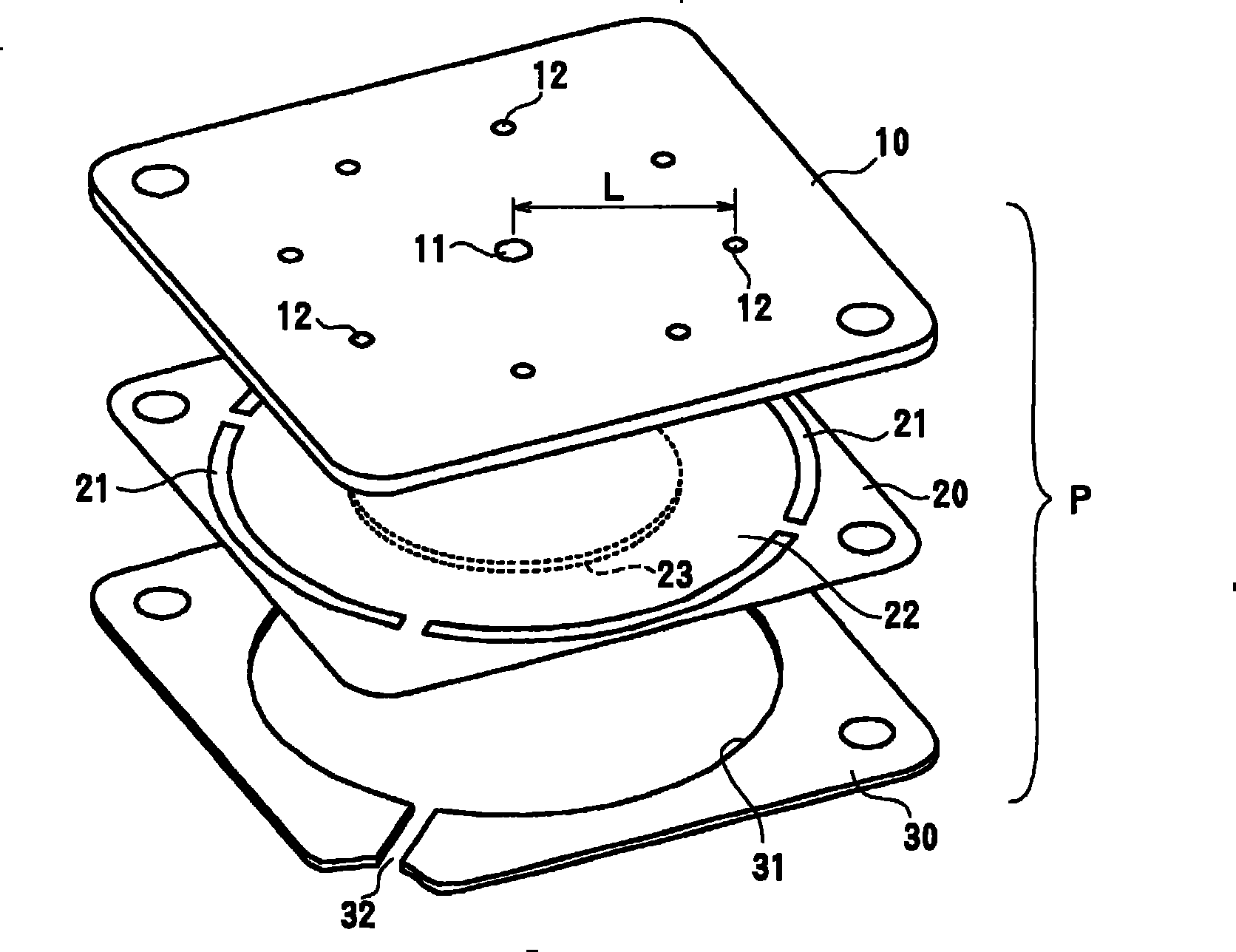

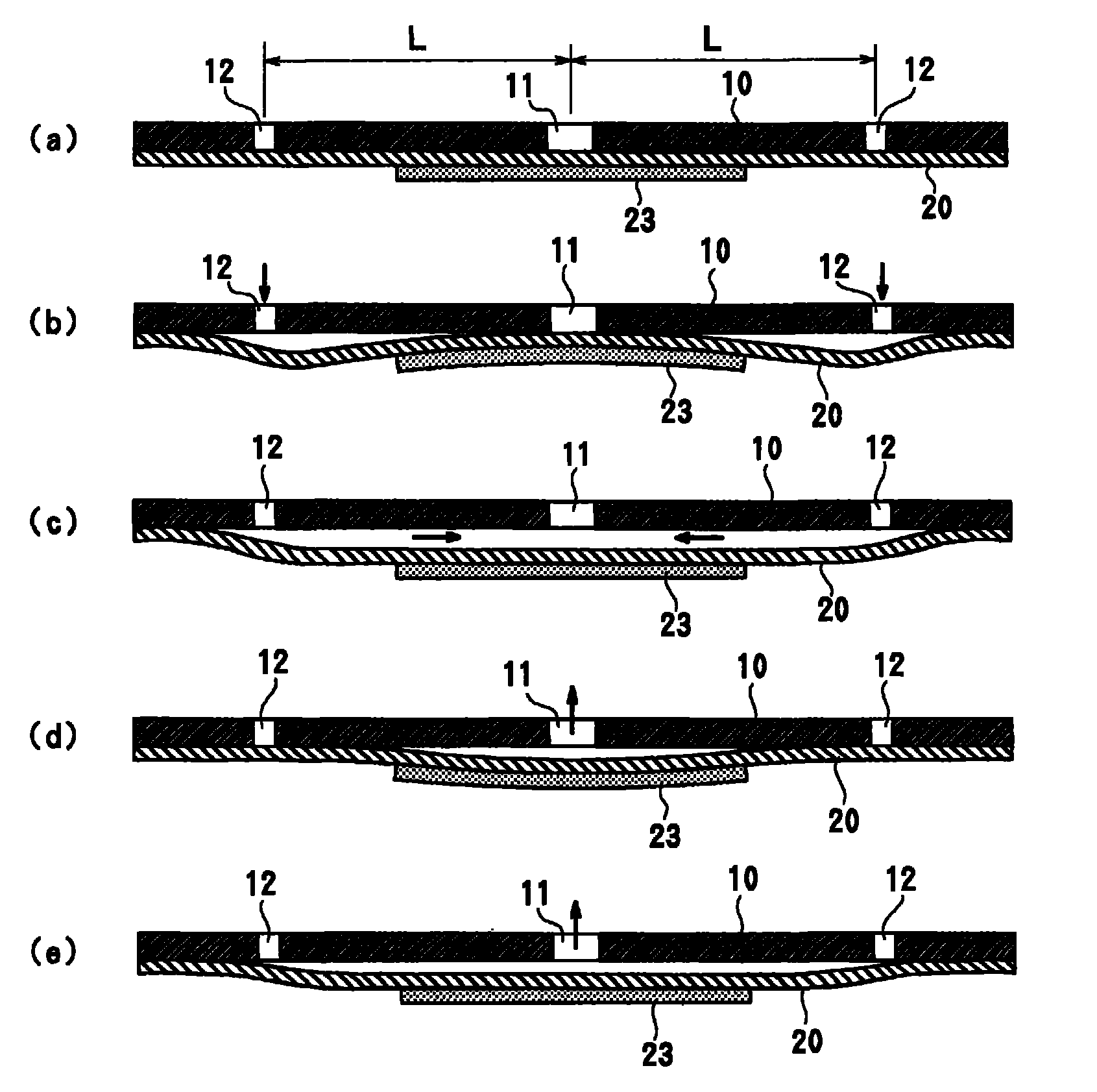

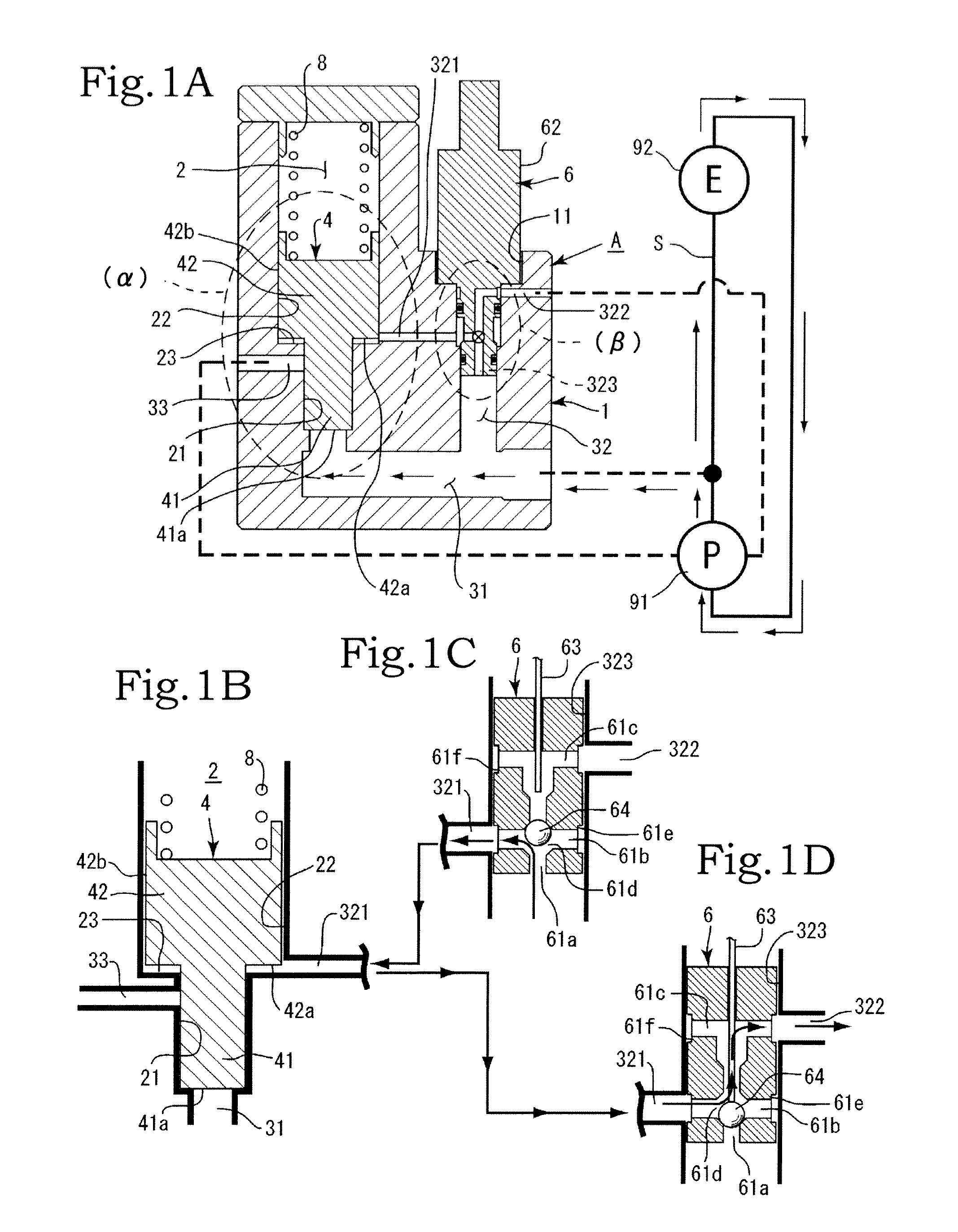

Piezoelectric pump

ActiveCN101490419AInflow fastEasy inflowEngine fuctionsWorking fluid for enginesElectricityResonance

The invention provides a piezoelectric pump having a simple structure and high discharge pressure. A first opening (11) is formed at the center of a pump body (10), and a second opening (12) is formed at a position away from the center. The outer periphery of a metal diaphragm (20) is fixed to the pump body (10), and a piezoelectric element (23) is bonded to the center on the rear side of the diaphragm (20). The piezoelectric element (23) has a size covering the first opening (11) but not reaching the second opening (12). When a voltage near the resonance frequency is applied to the piezoelectric element (23), that portion of the diaphragm (20) that faces the first opening (11) and that portion of the diaphragm (20) that faces the second opening (12) are bent and deformed in the directions opposite to each other. This causes fluid to be drawn from either one of the first opening (11) and the second opening (12) and discharged from the other. The piezoelectric pump can have high discharge pressure, which enables the pump to reliably discharge fluid even in conditions where the pressure on the discharge side is high.

Owner:MURATA MFG CO LTD

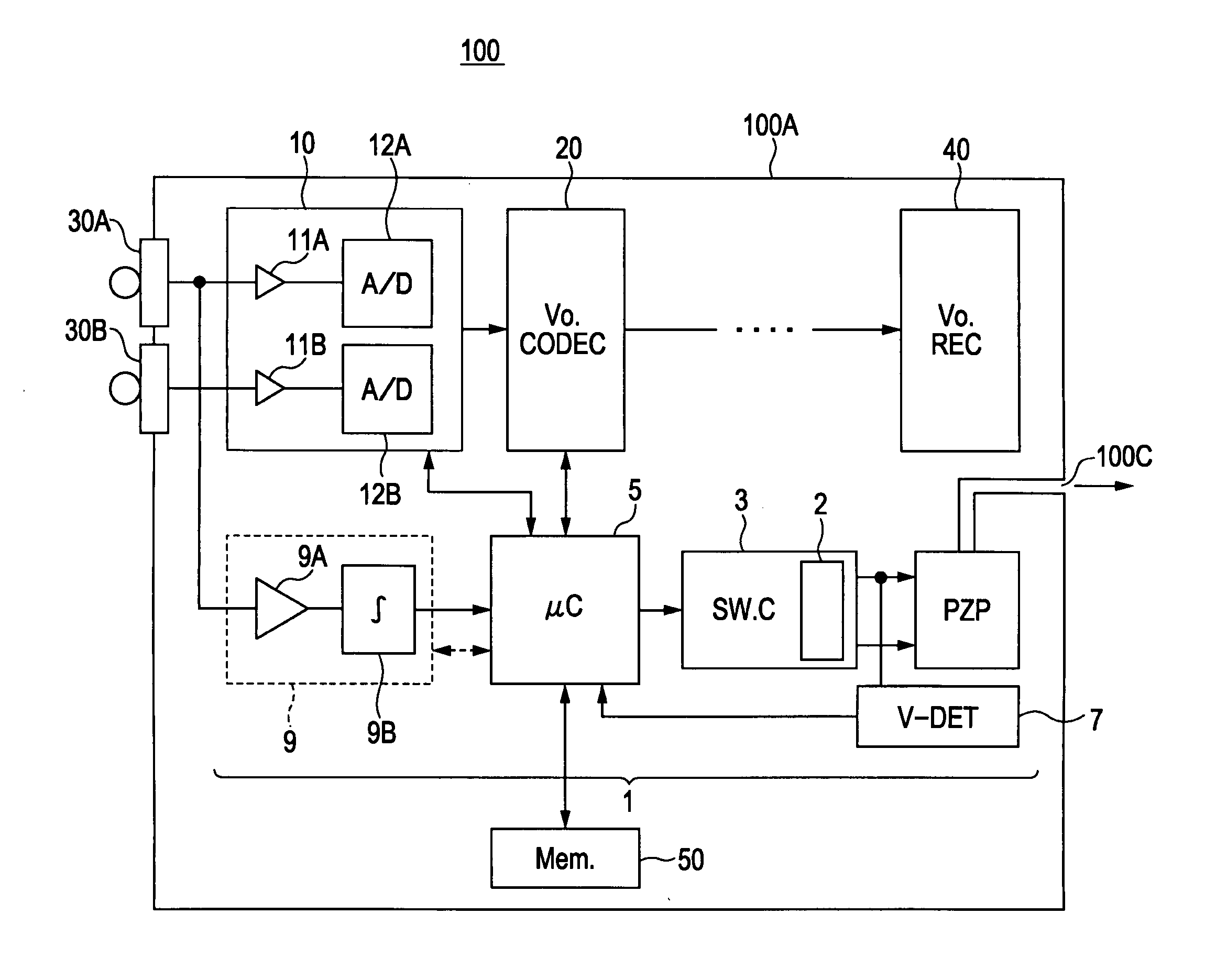

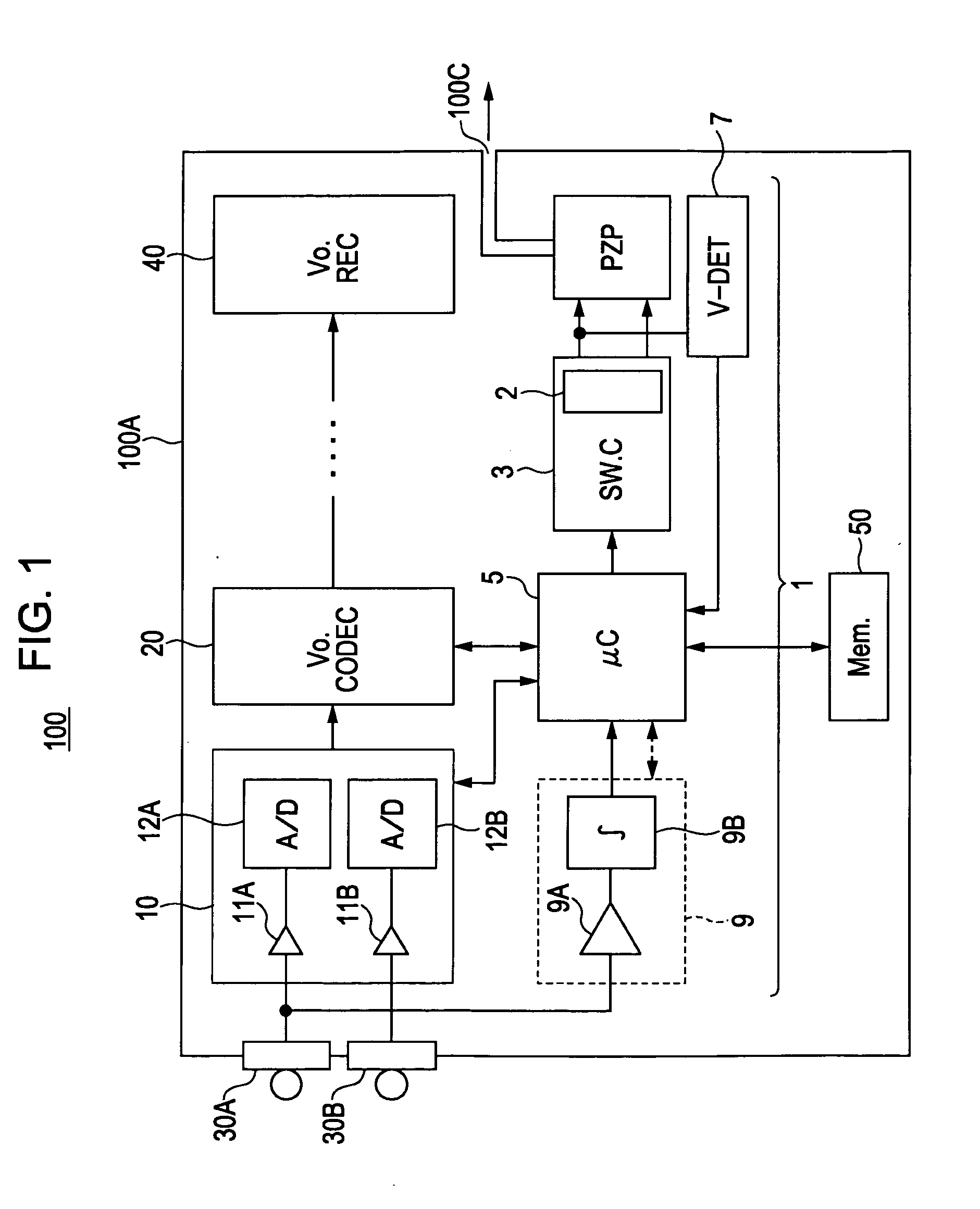

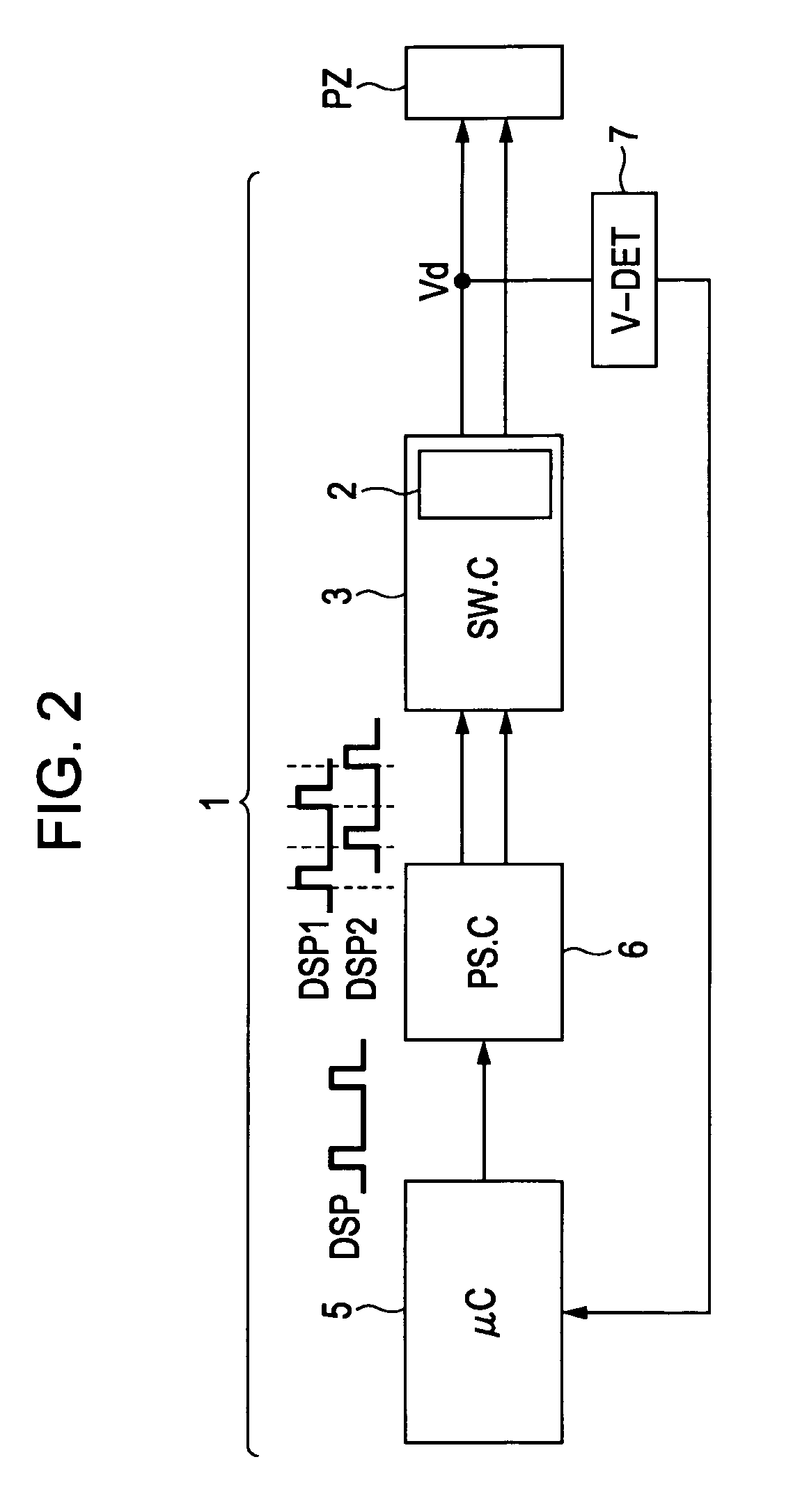

Electronic device having piezoelectric pump

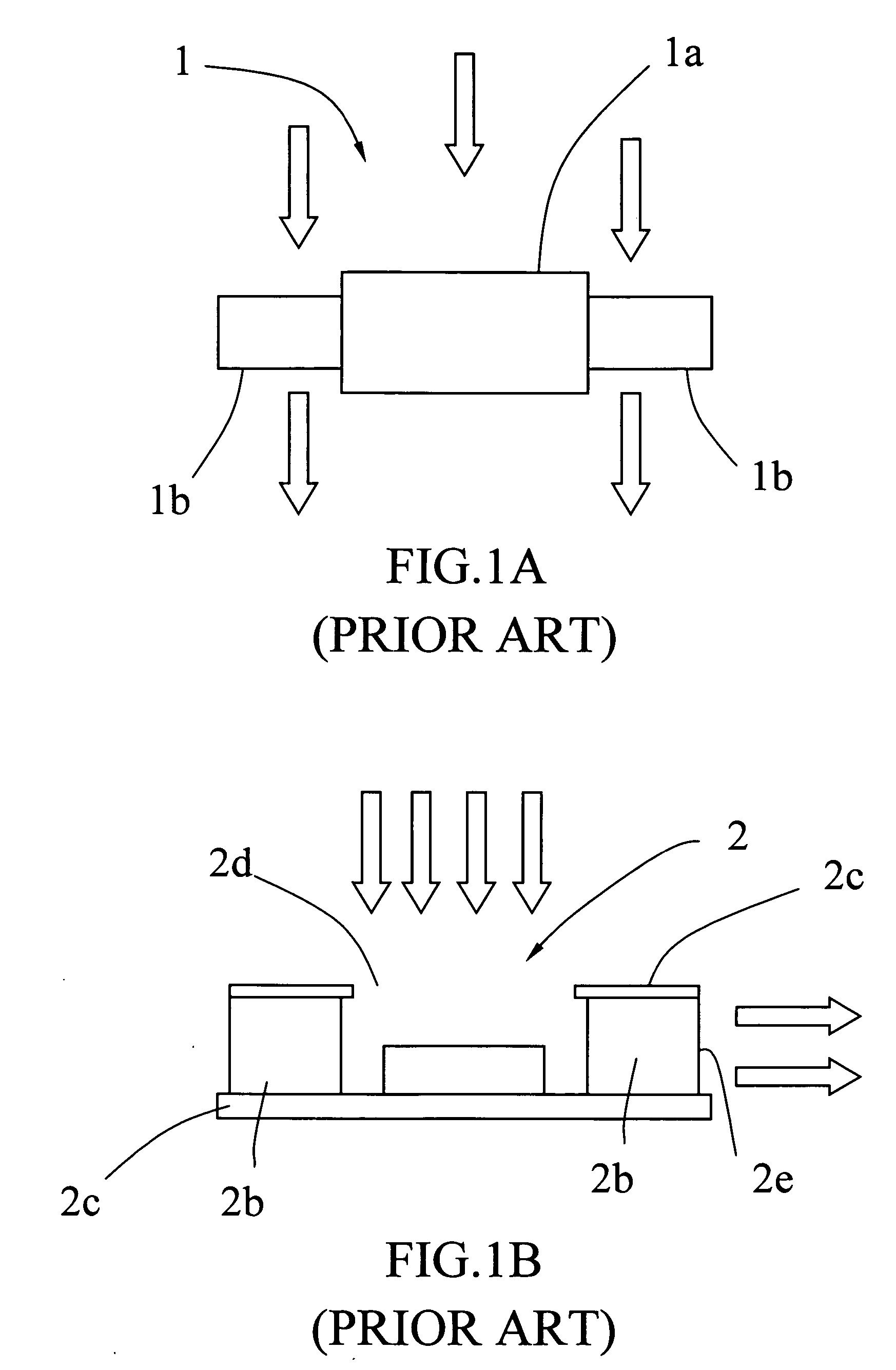

InactiveUS20090206699A1Prevent and reduce deteriorationReduce power consumptionPiezoelectric/electrostriction/magnetostriction machinesFlexible member pumpsPiezoelectric pumpAudio frequency

An electronic device having a piezoelectric pump. The electronic device includes: an audio input section; an audio recording section recording input sound from the audio input section; a piezoelectric pump cooling air by a piezoelectric element; a drive circuit driving the piezoelectric element; and a control circuit monitoring and controlling operation of the audio input section, the audio recording section, and the drive circuit, wherein when an operation mode being monitored is an audio recording mode, in which the input sound is used for recording by the audio recording section, the control circuit controls the drive circuit to decrease the amount of air flow exhausted outside from the piezoelectric pump, and when the operation mode being monitored is another mode without audio recording, the control circuit maintains the amount of the air flow.

Owner:SONY CORP

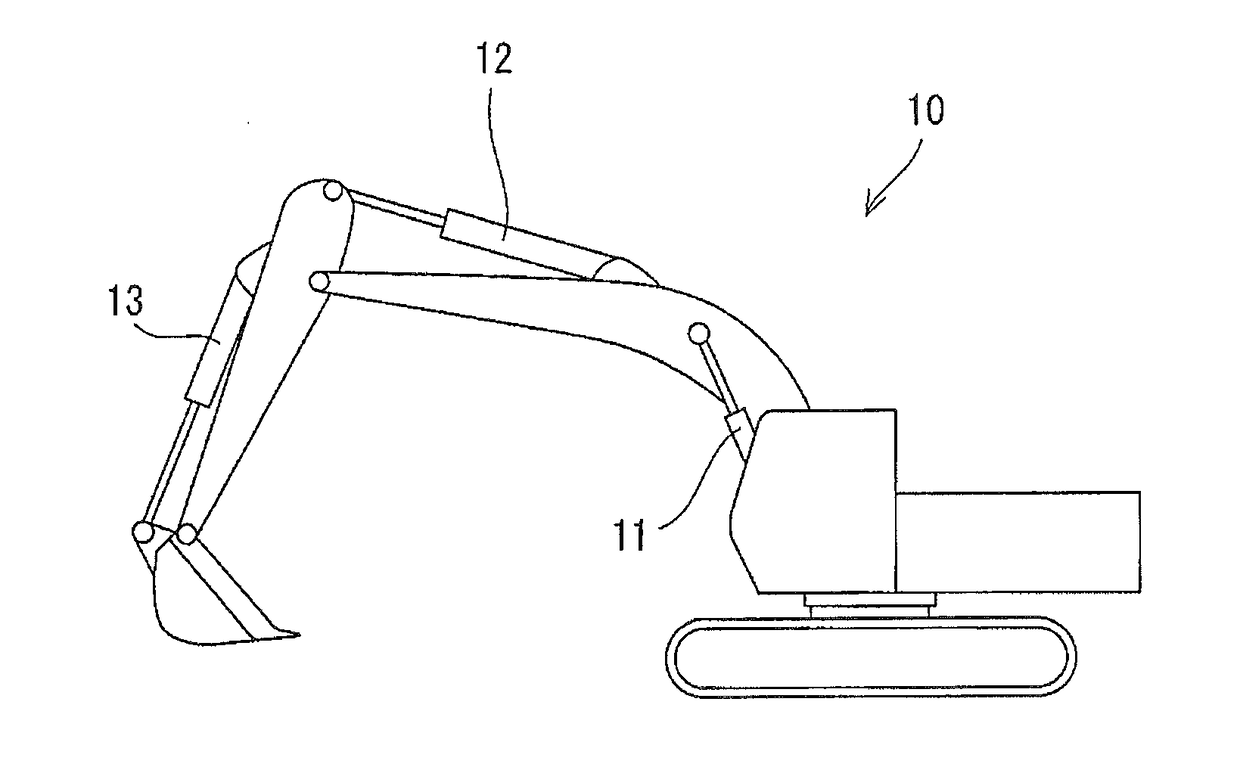

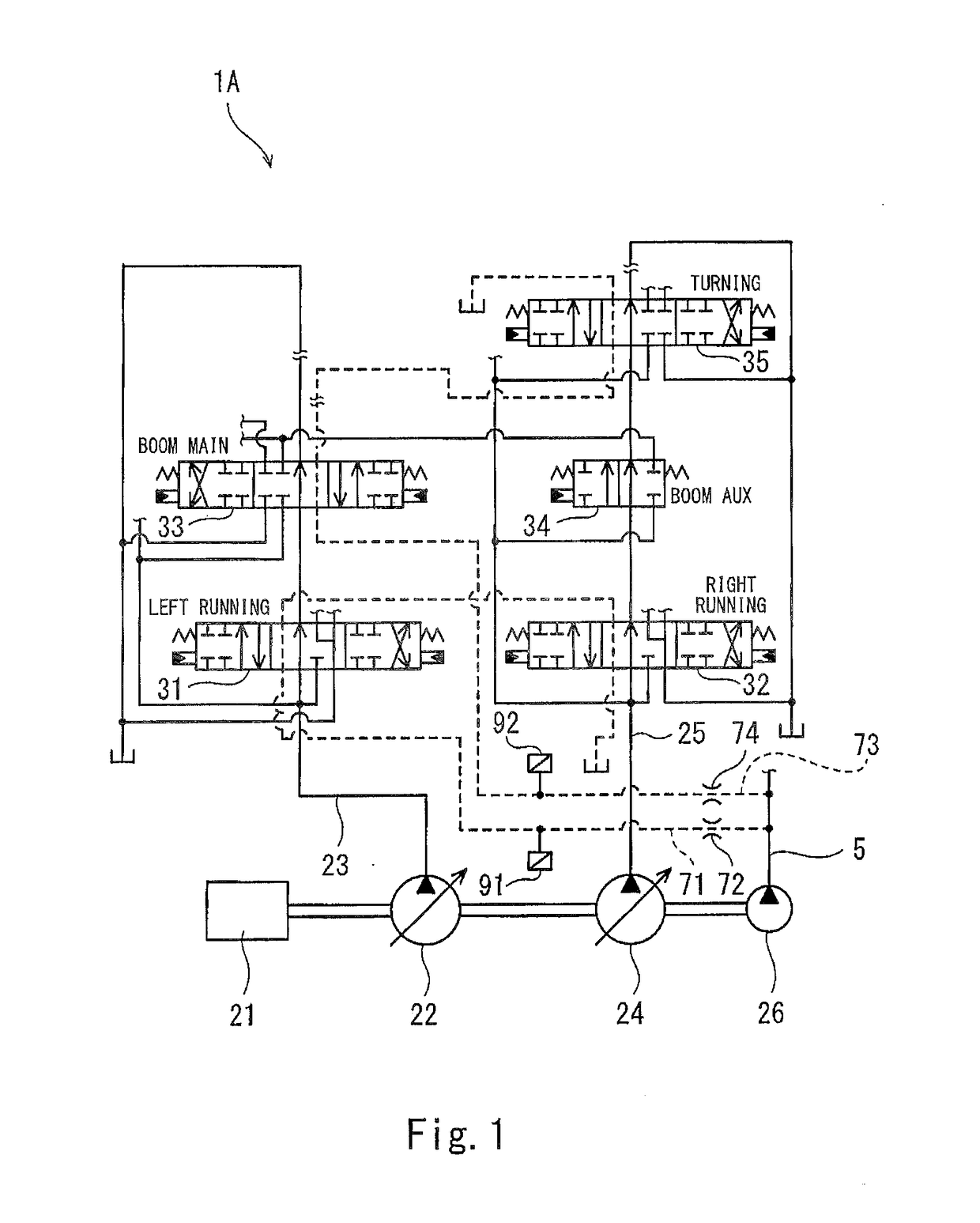

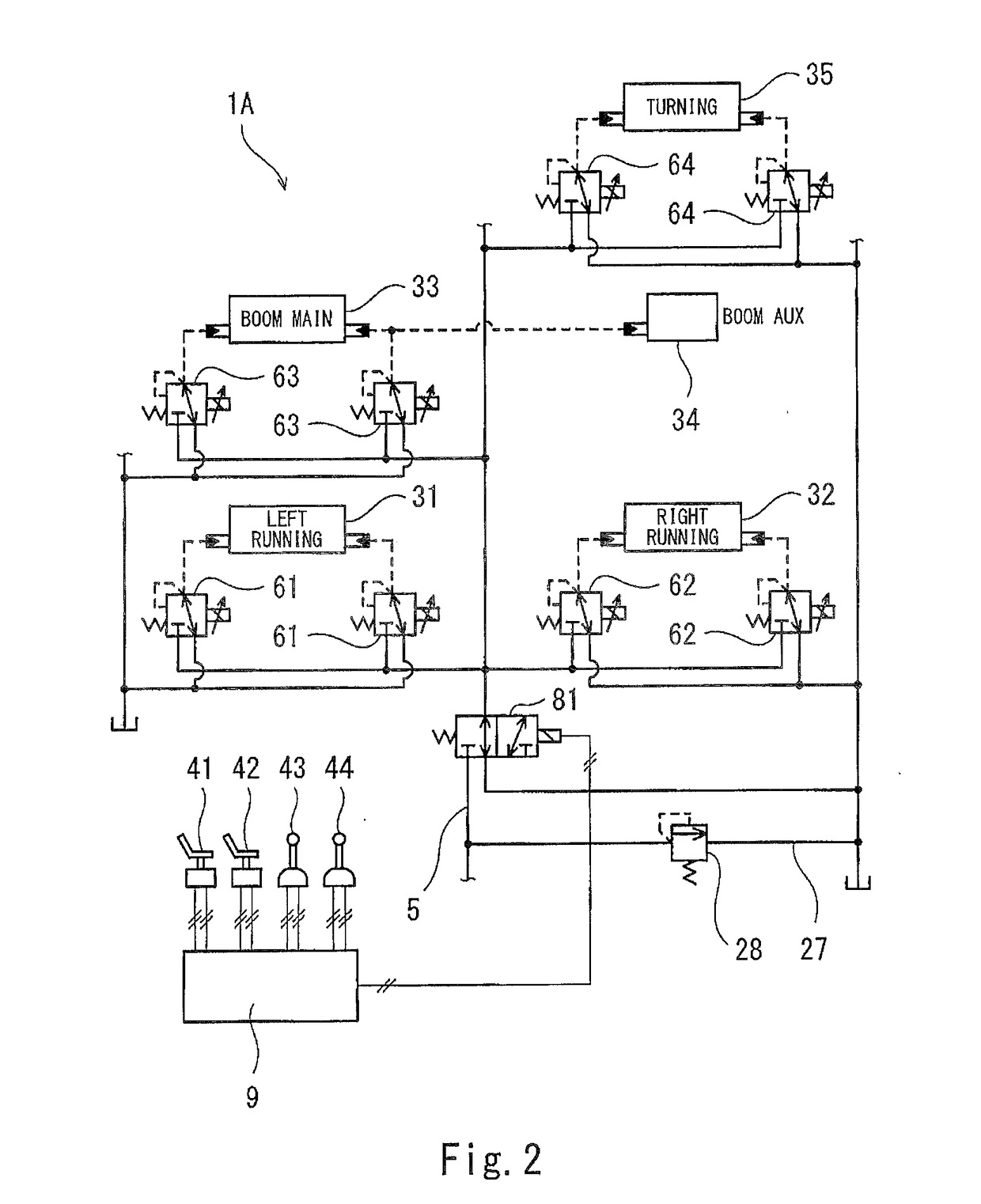

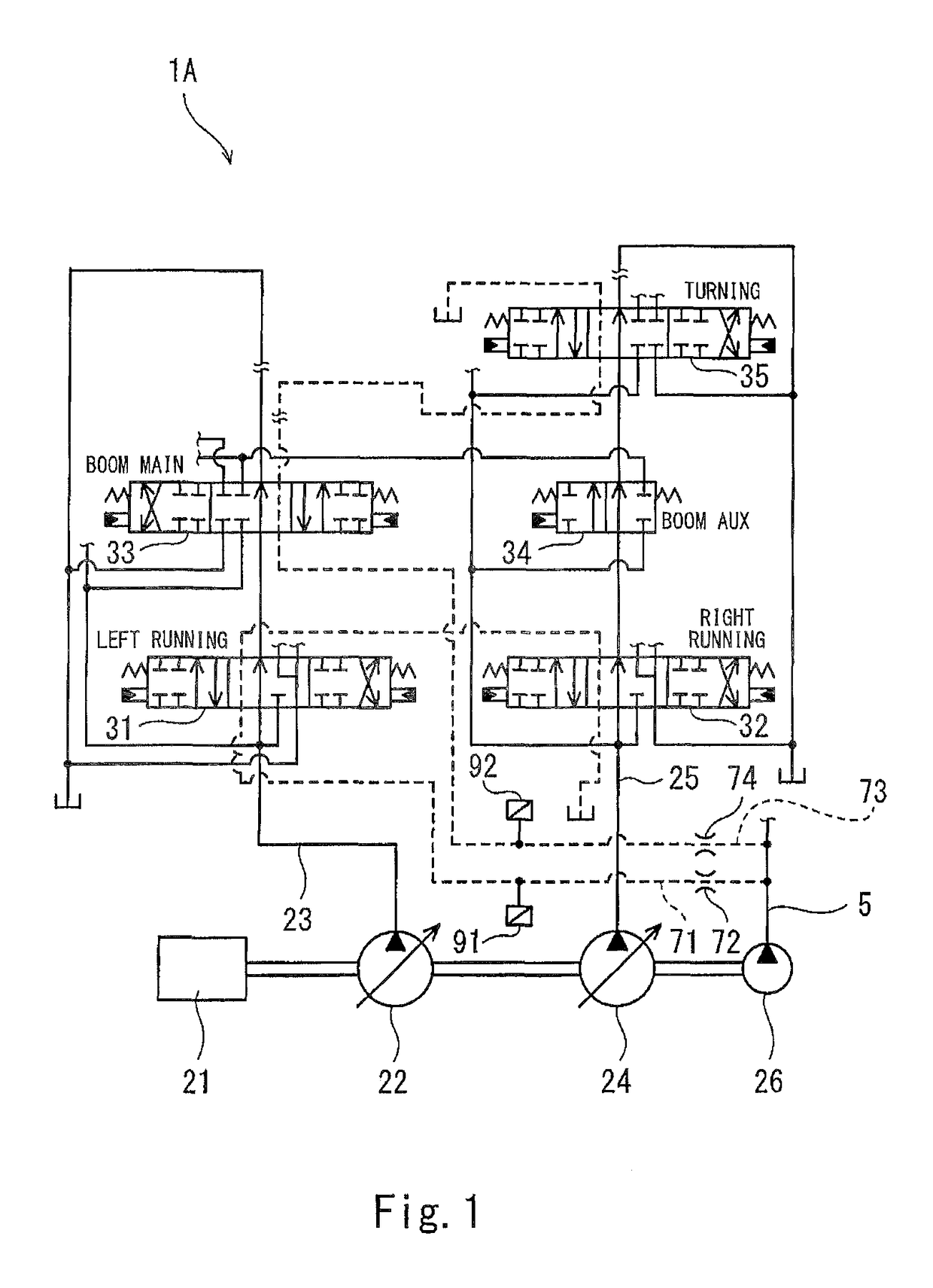

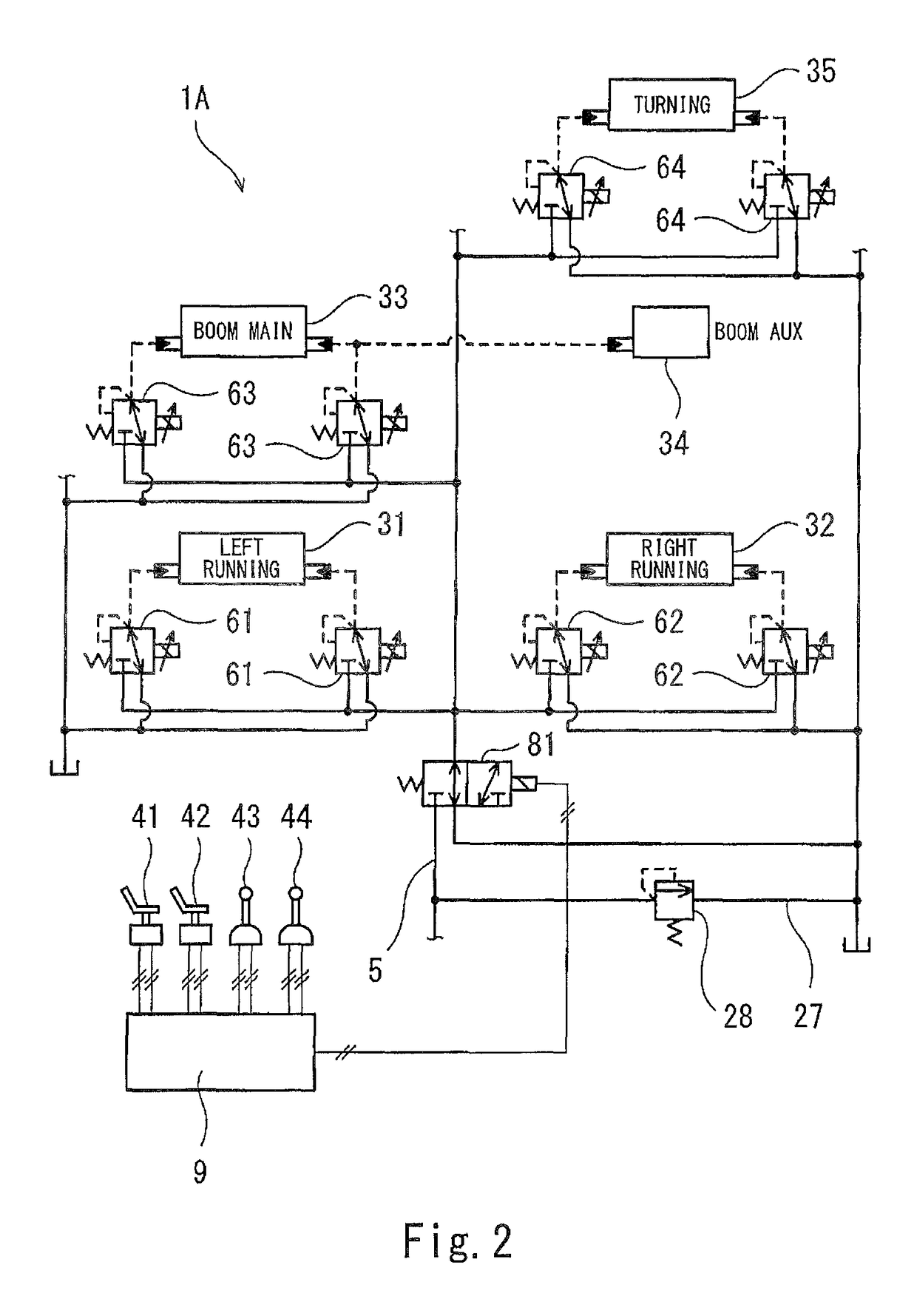

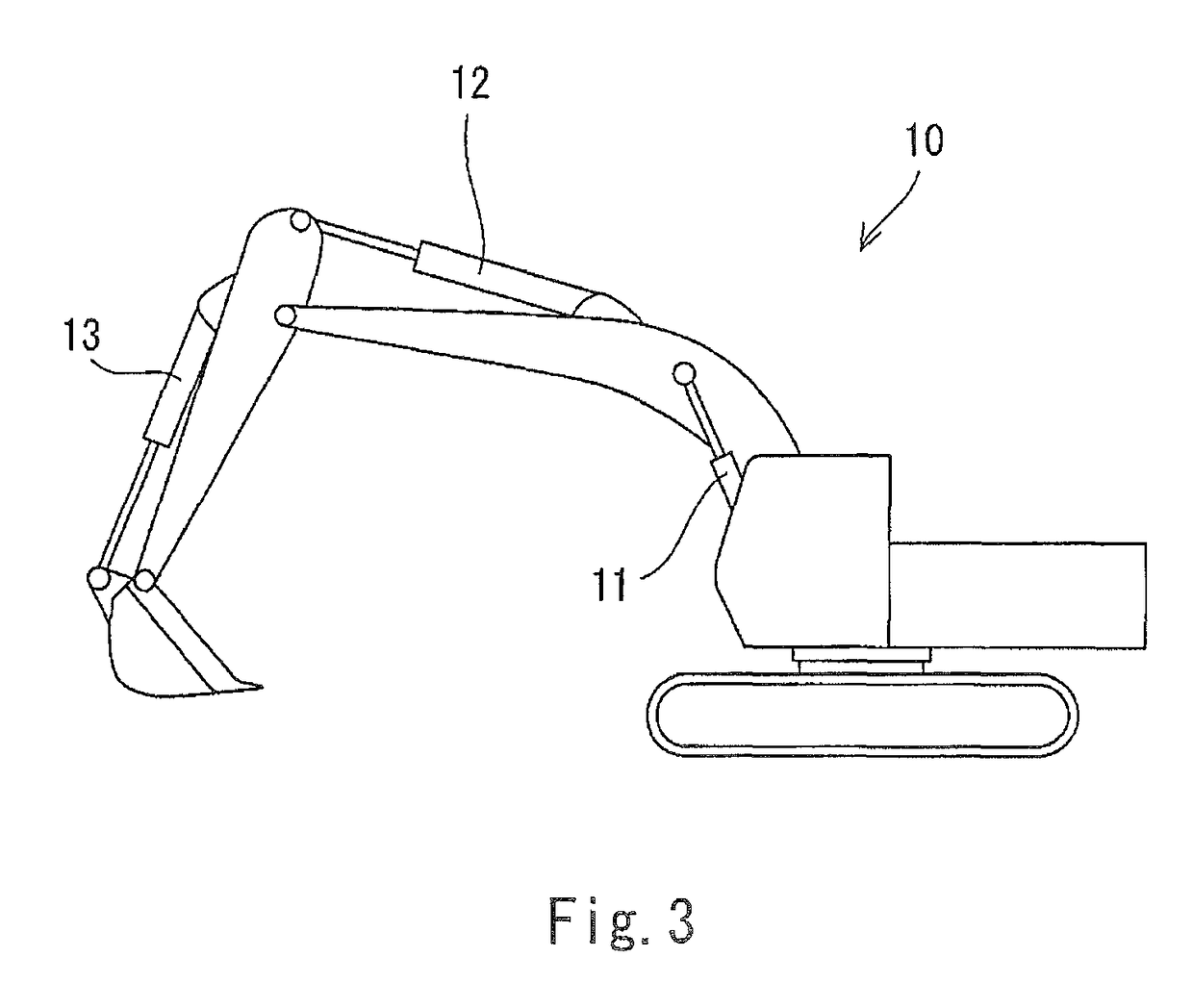

Hydraulic drive system

ActiveUS20170166253A1Configuration economyLow costFluid-pressure actuator safetyFluid-pressure actuator testingTarget controlProportional valve

A hydraulic drive system includes: control valves; solenoid proportional valves outputting pilot pressures to the control valves; a controller controlling each of the solenoid proportional valves; a primary pressure line leading hydraulic oil from an auxiliary pump to the solenoid proportional valves; a solenoid switching valve provided on the primary pressure line; a movement detection line blocked when any of movement detection target control valves has moved; and a movement detection pressure sensor provided on the movement detection line. The controller controls the solenoid switching valve while all of operation devices are outputting electrical signals indicating that their operating levers are in neutral, such that: the solenoid switching valve opens the primary pressure line if a measurement value of the pressure sensor is less than a threshold; and the solenoid switching valve blocks the primary pressure line if the measurement value of the pressure sensor is greater than the threshold.

Owner:KAWASAKI HEAVY IND LTD

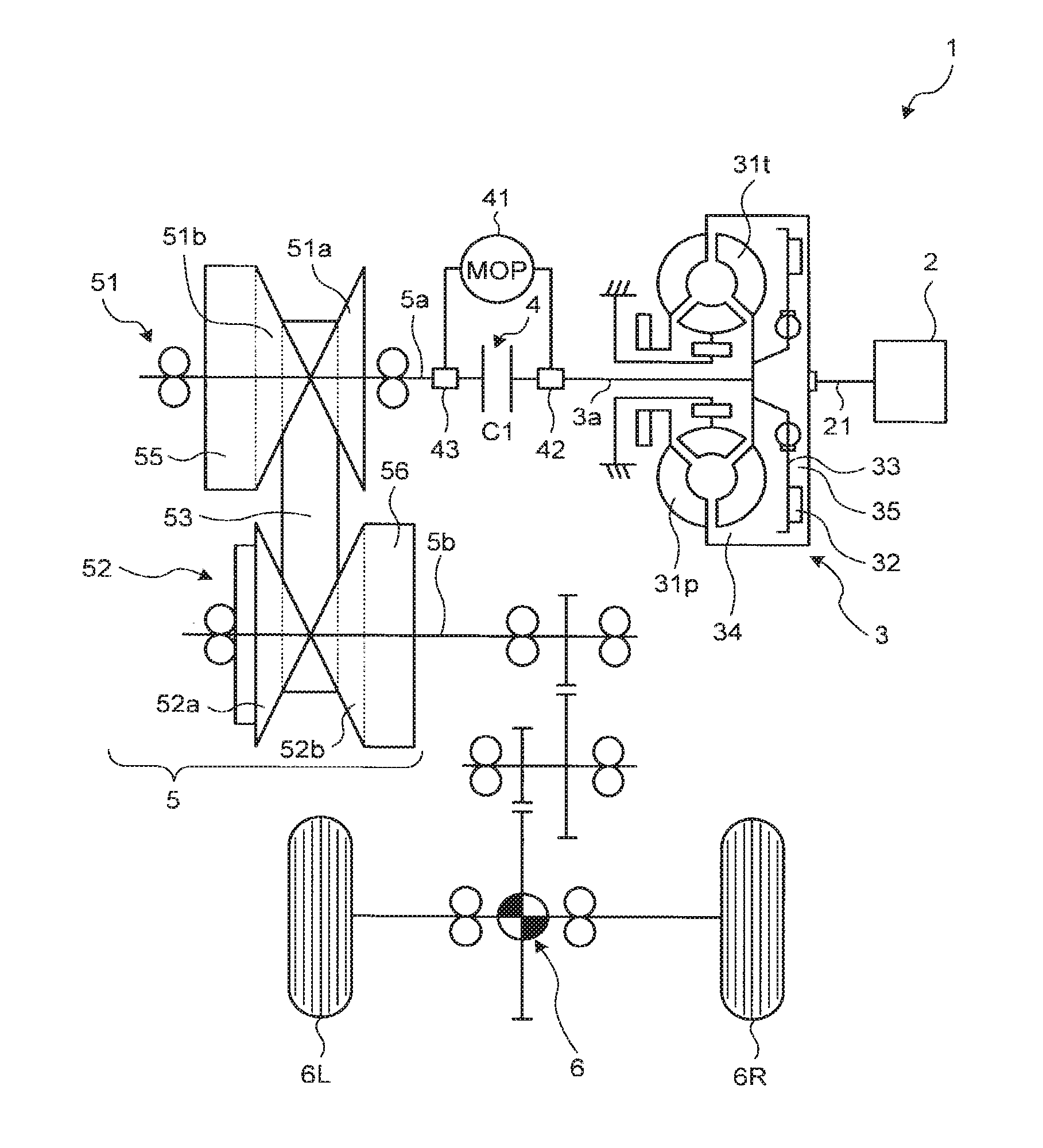

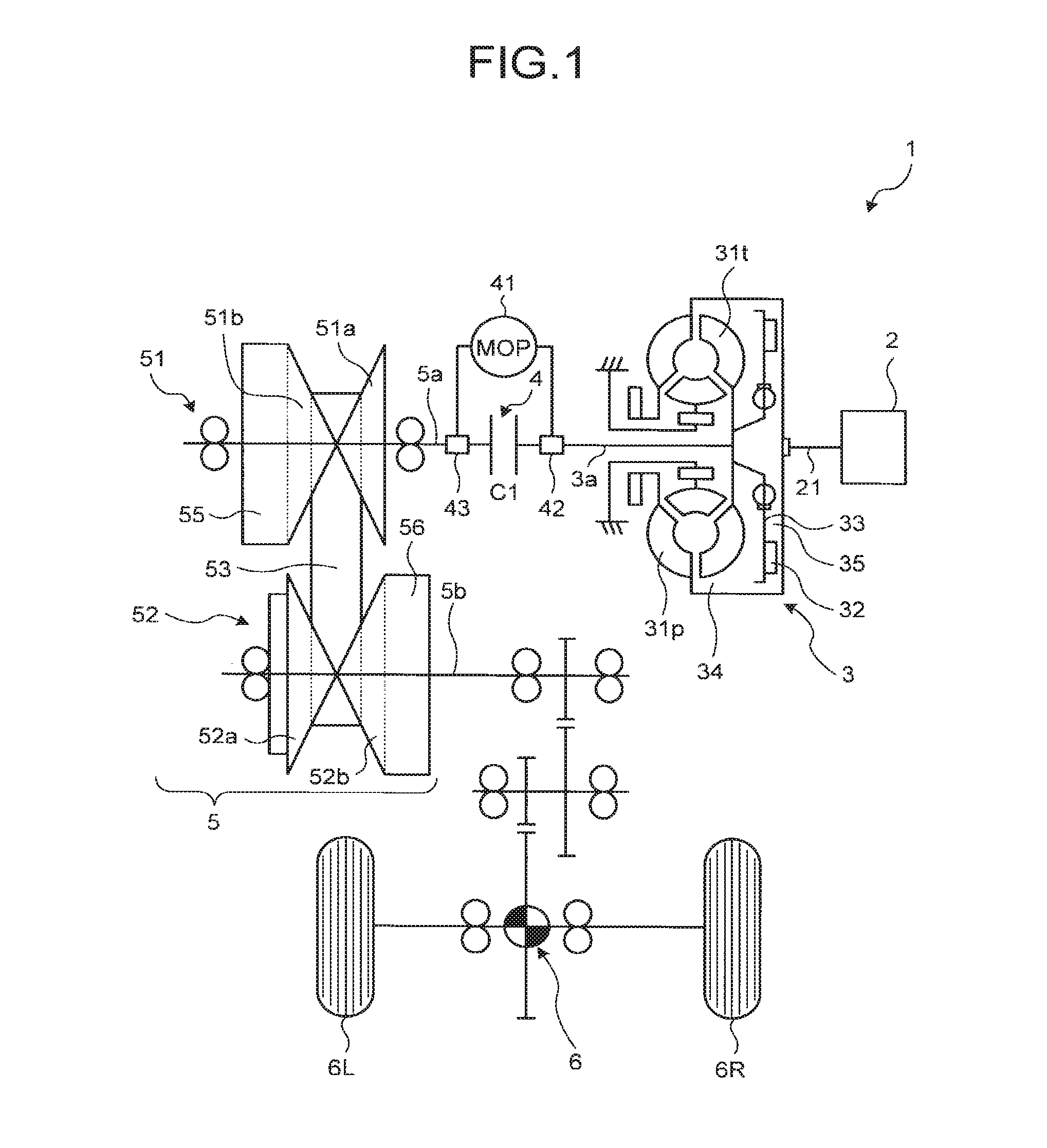

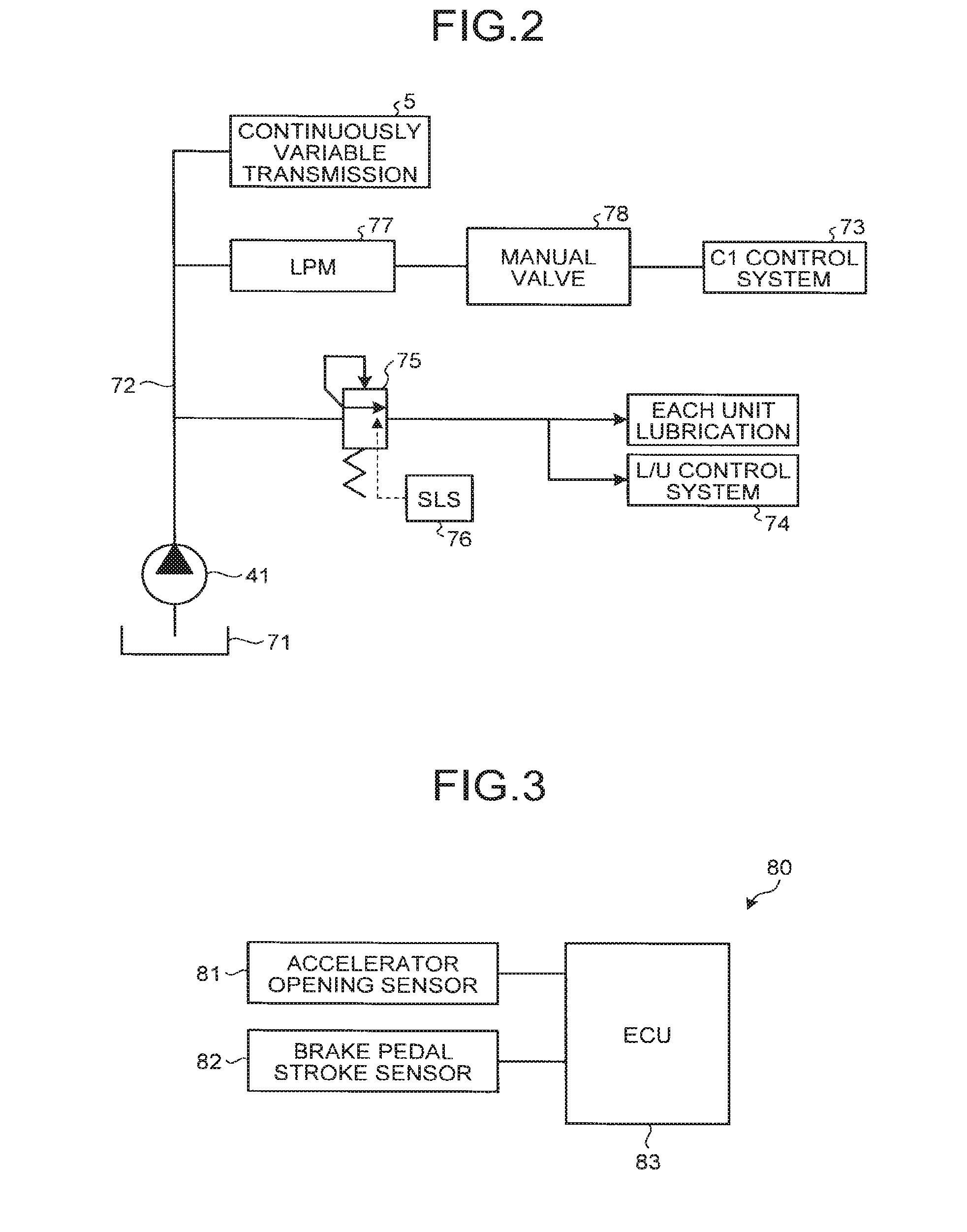

Vehicle driving device

ActiveUS20160230821A1Inhibit deterioration in fuel costIncrease discharge pressureClutchesInternal combustion piston enginesDrive wheelMOPS

In a coasting control process, an ECU increases line pressure PL of a hydraulic path to predetermined pressure P1 such that discharge pressure of an MOP becomes higher than that before a C1 clutch is disengaged at timing when an executing condition of coasting control is satisfied (time t=t1). According to such coasting control process, driving torque of the MOP increases, so that deceleration (deceleration G) caused by driving of the MOP by a drive wheel becomes larger than that in conventional coasting control in which the discharge pressure of the MOP is not increased. As a result, it is possible to inhibit a driver from feeling discomfort due to free-running feeling generated during the coasting control.

Owner:TOYOTA JIDOSHA KK

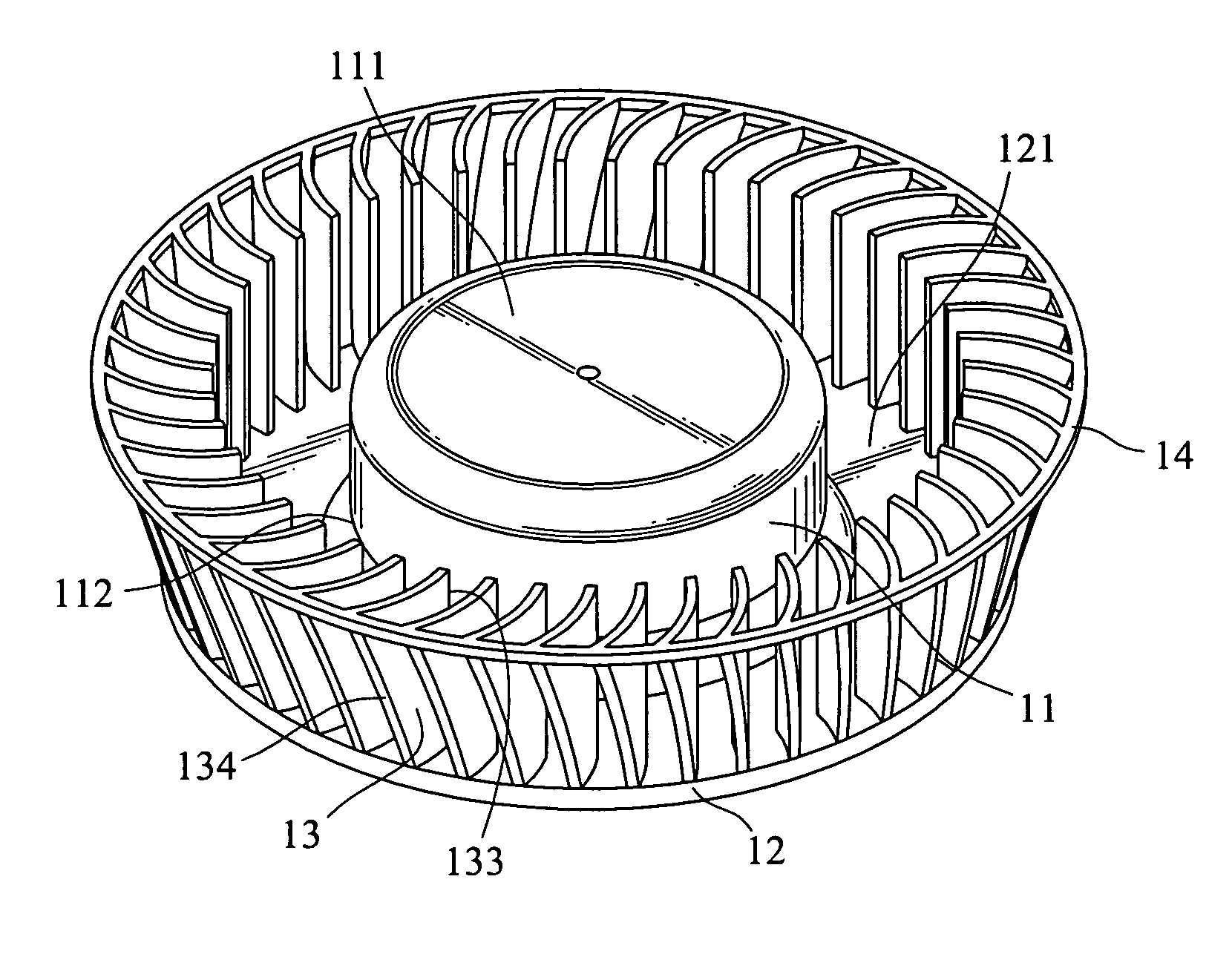

Airflow generating structure and the apparatus thereof

An airflow generating structure and the apparatus thereof includes a hub, a holding section extended outwards from one end of the hub, and a plurality of spoilers located on the periphery of the holding section in the axial direction that are spaced from one another. Each of the spoilers has two curved surfaces and an outer edge inclined outwards so that the area that all the tips of the spoilers enclose is larger than that of the holding section. Air is sucked in through one end of the hub remote from the holding section and flows towards the other end, and is discharged through the periphery of the holding section.

Owner:RISUN EXPANSE

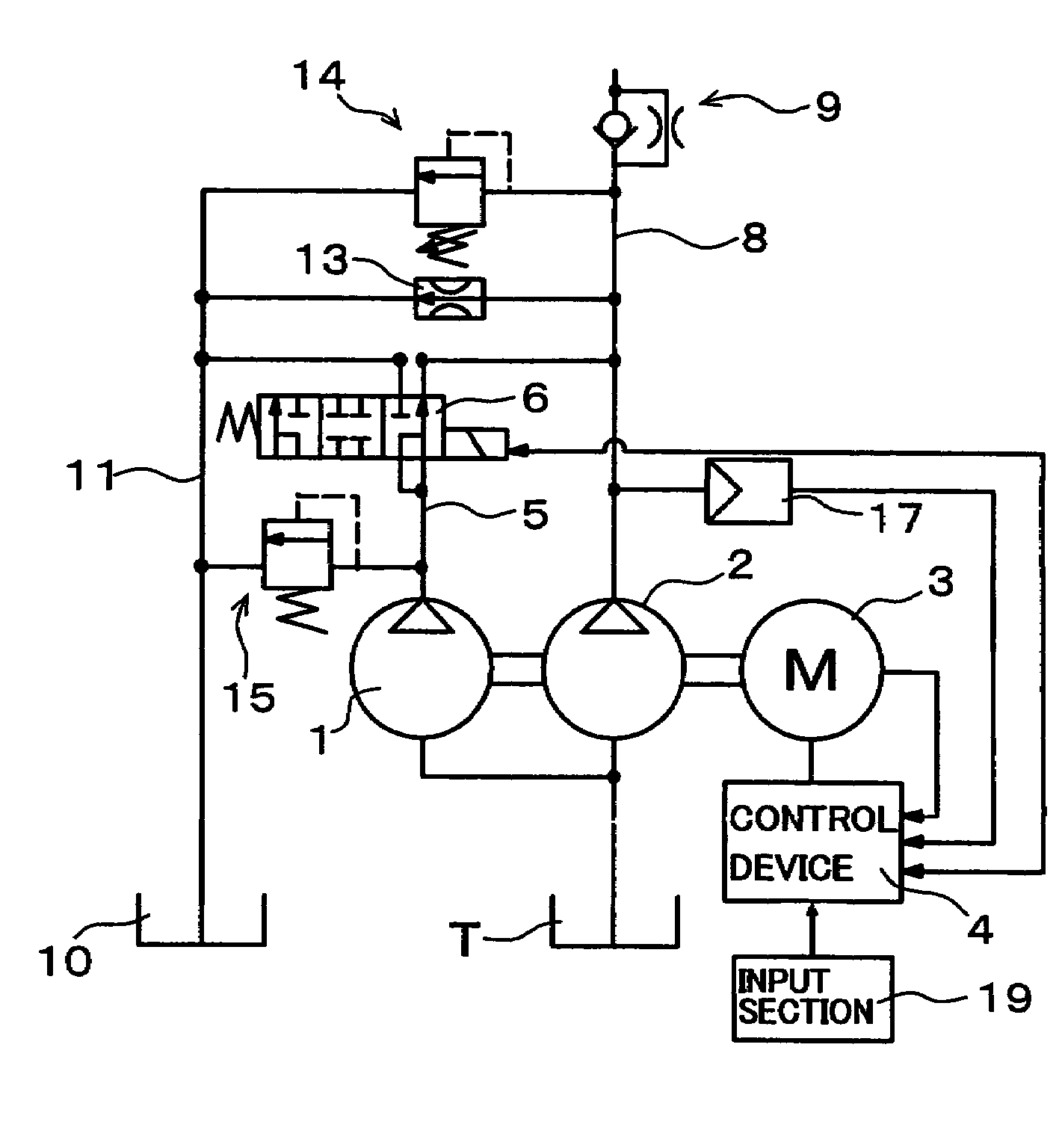

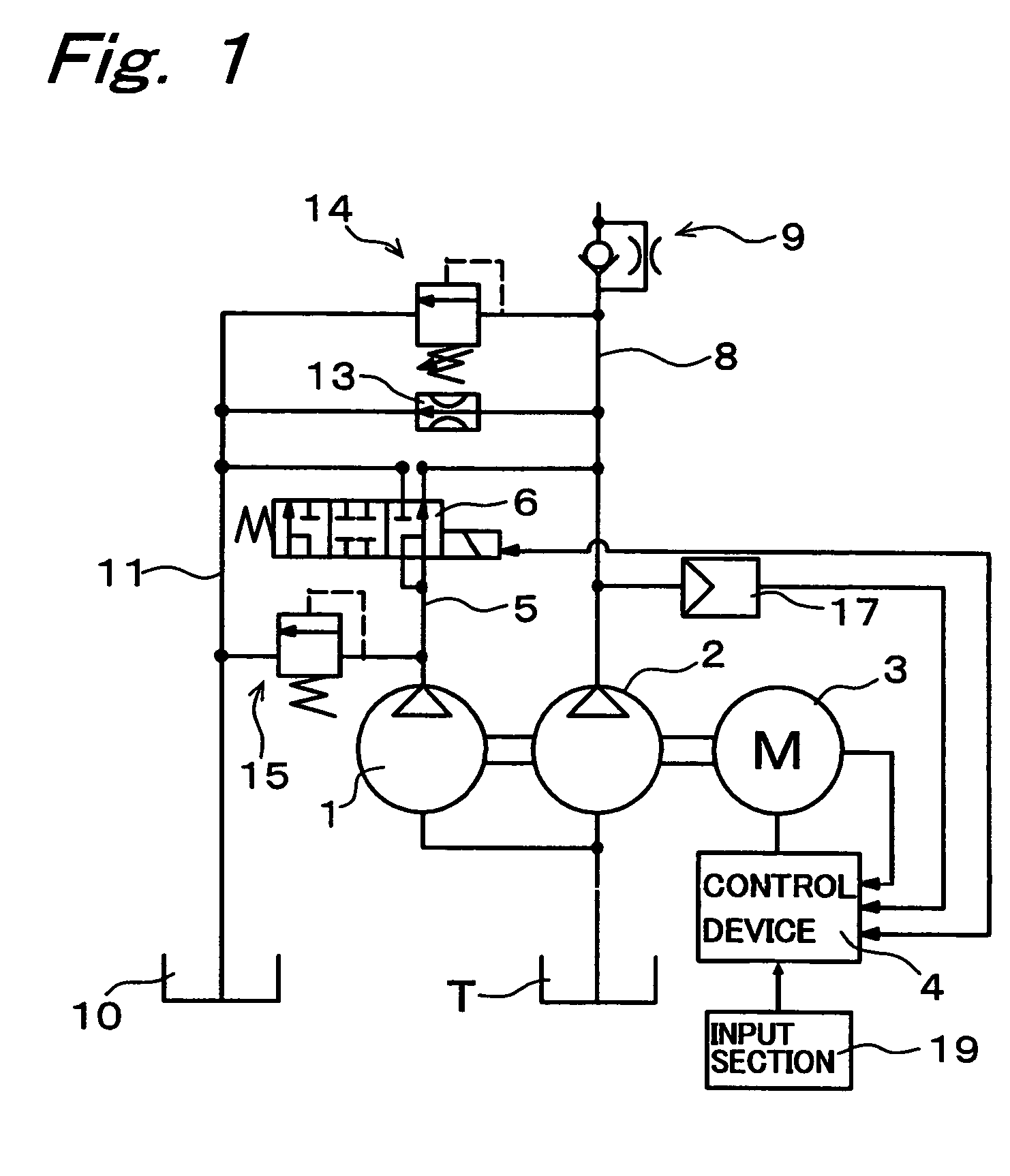

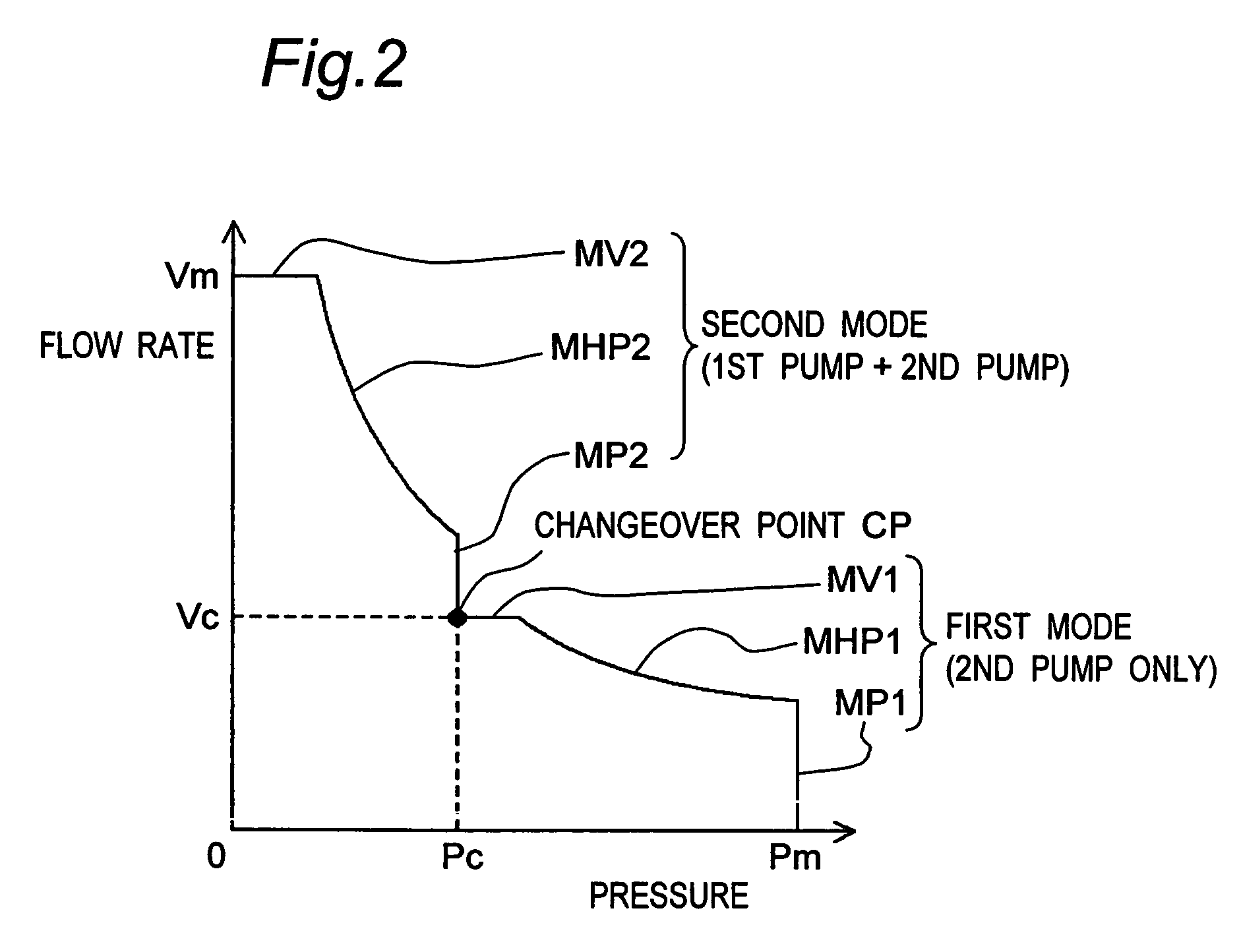

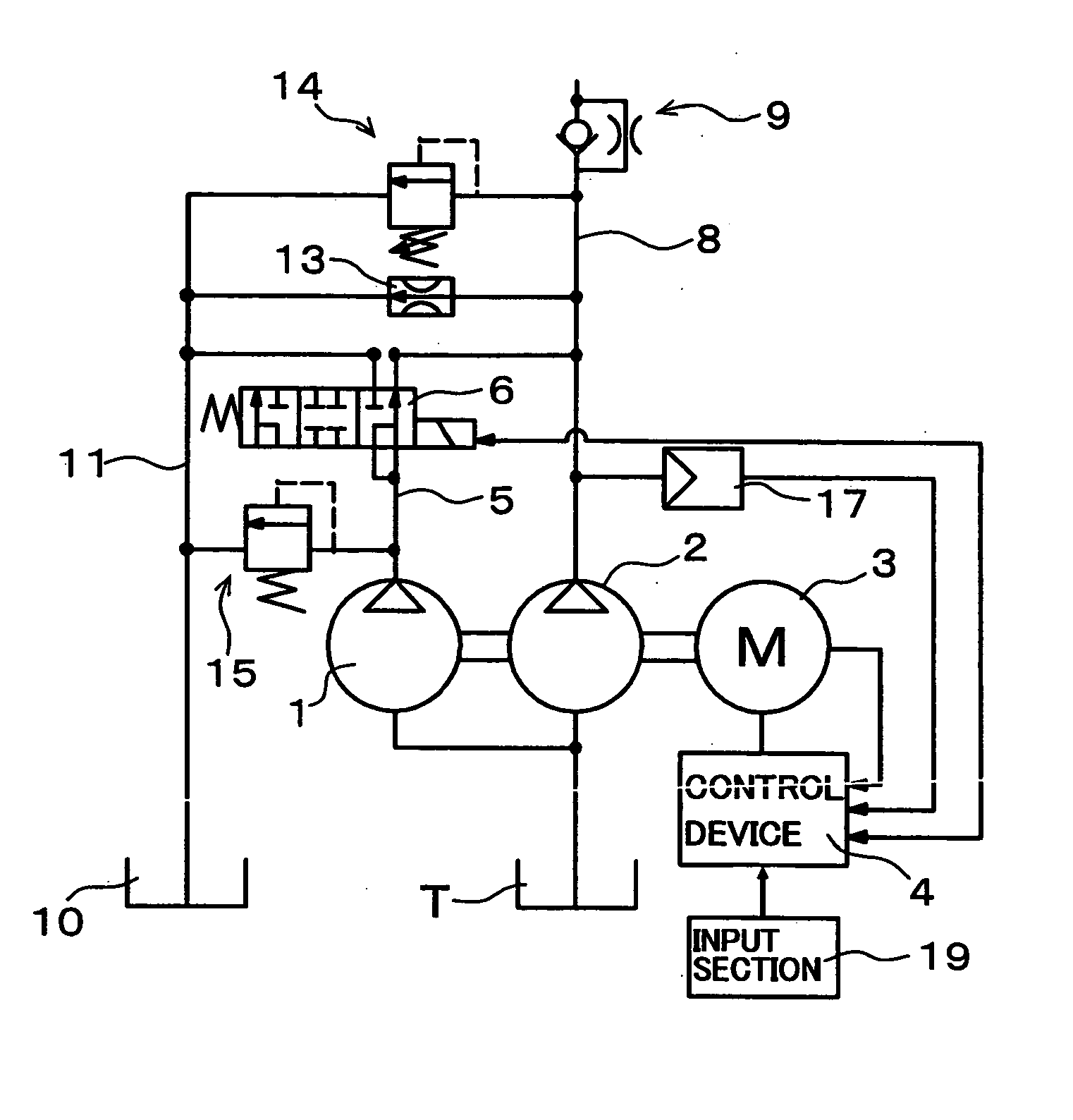

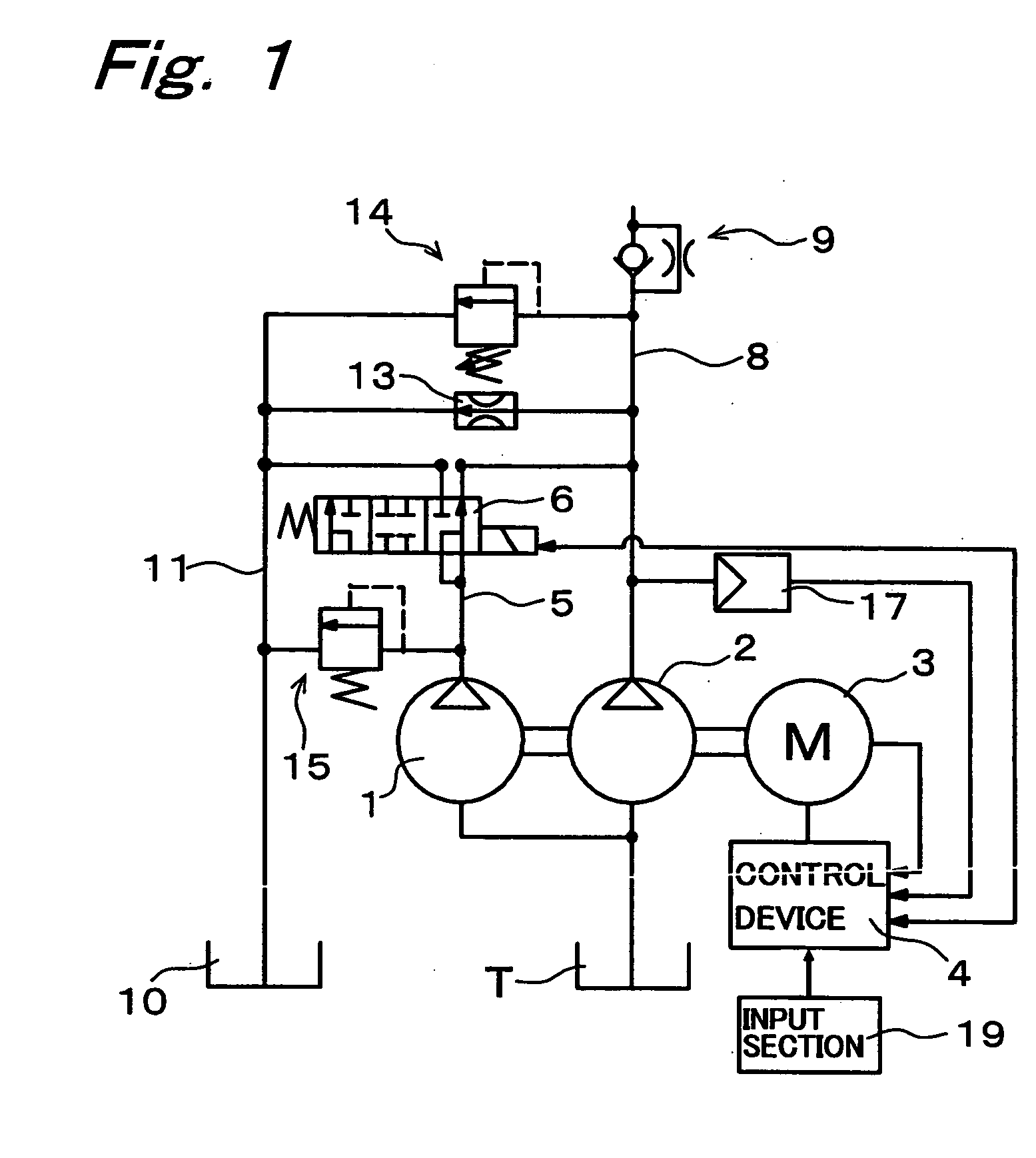

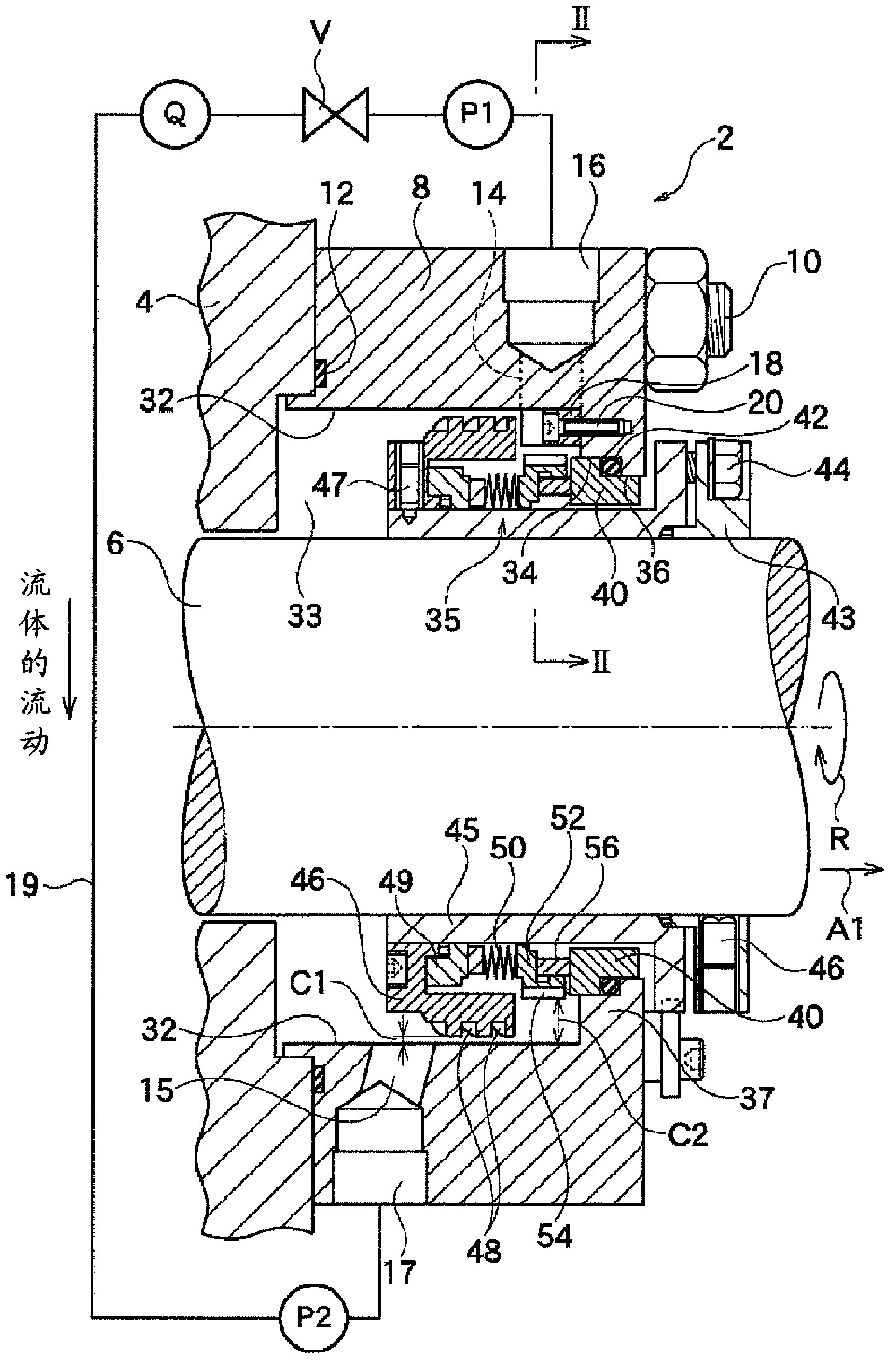

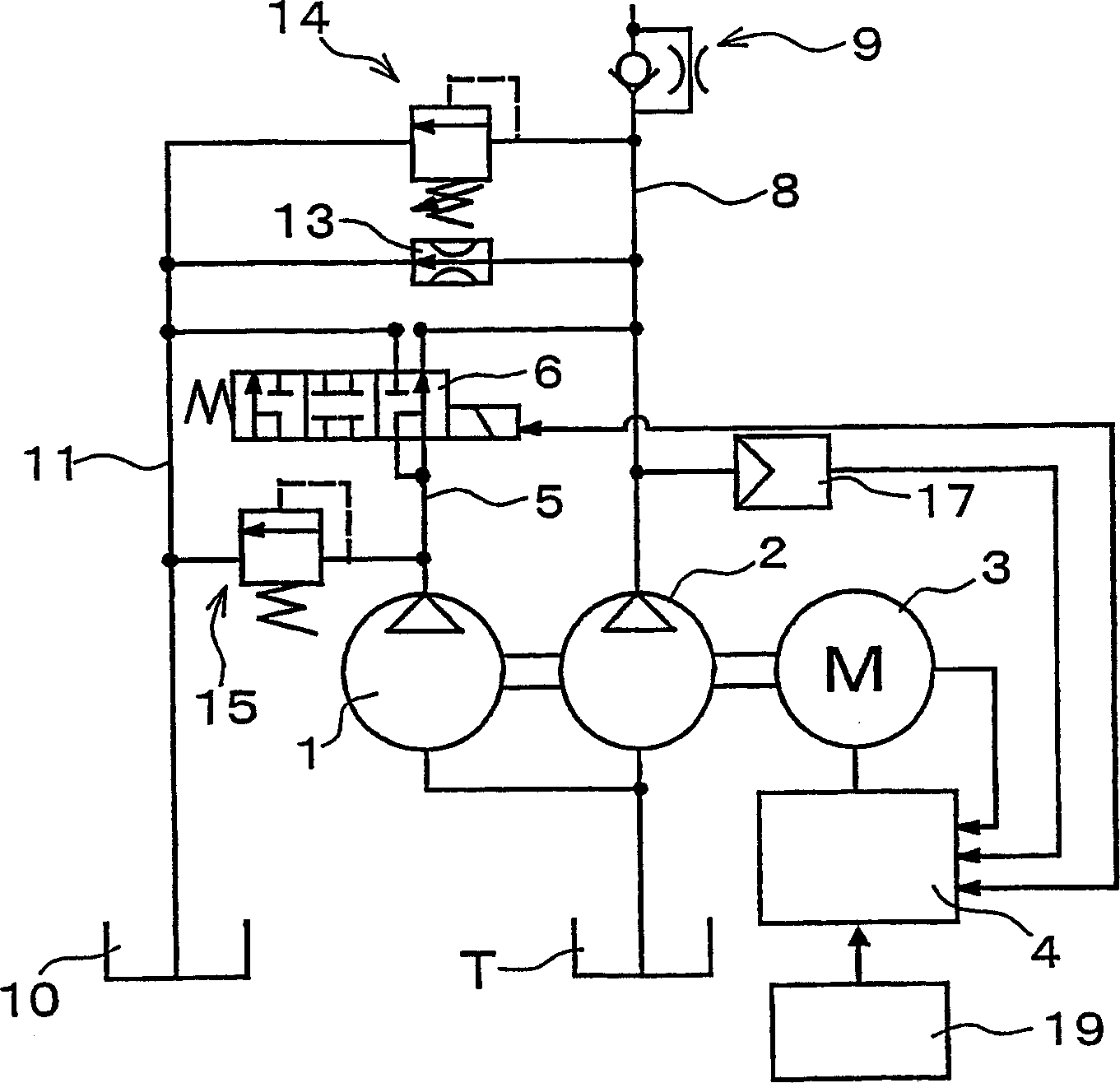

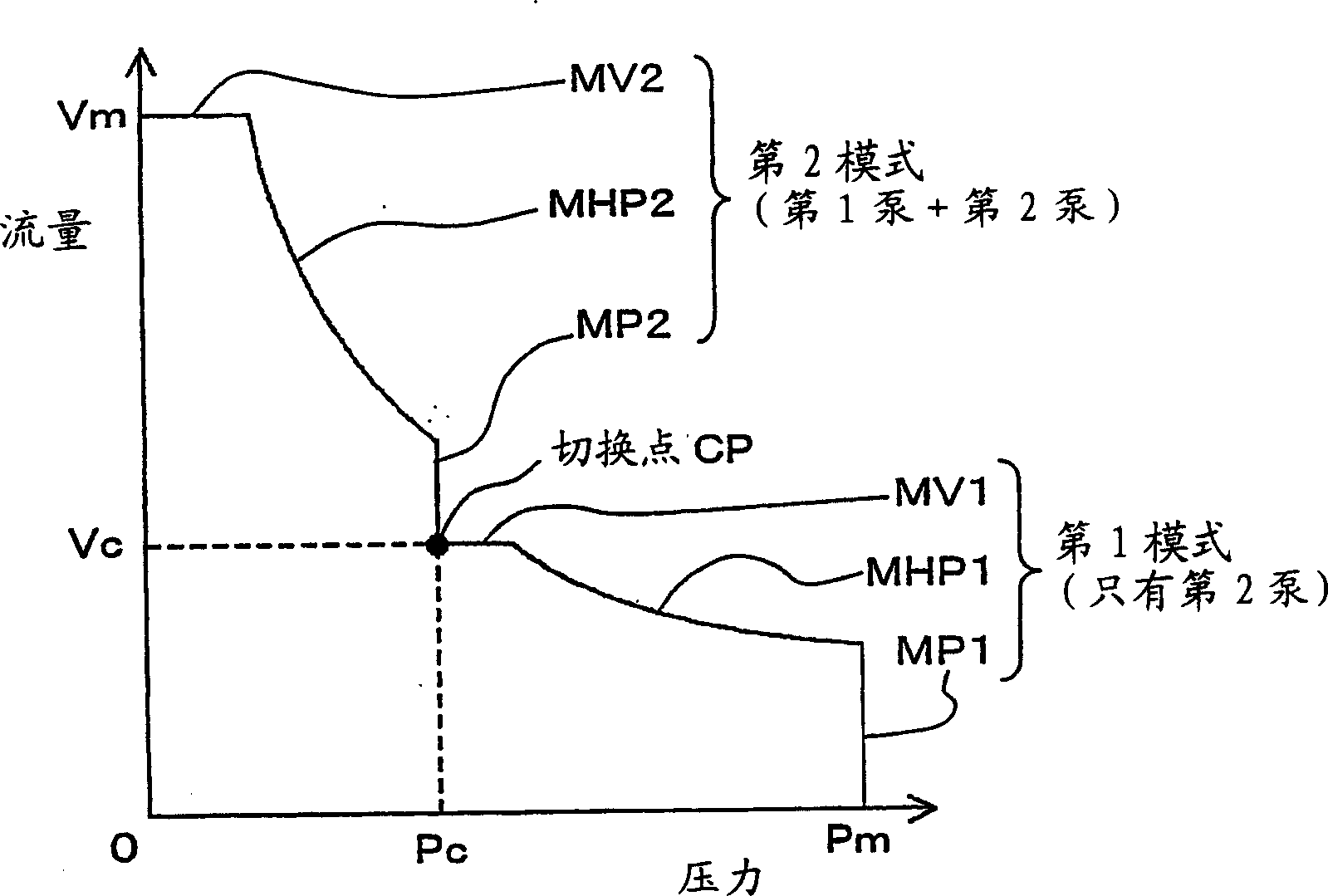

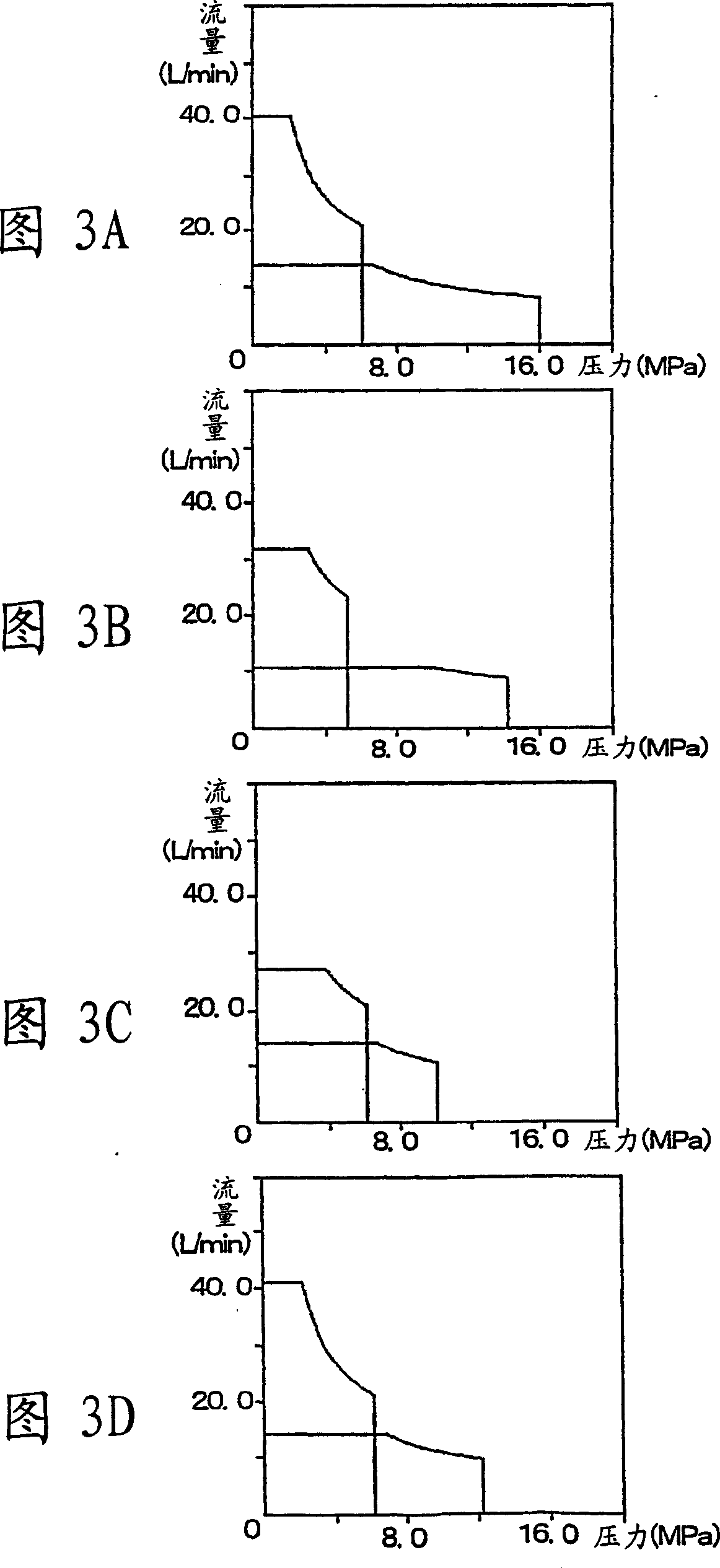

Pump unit with multiple operation modes

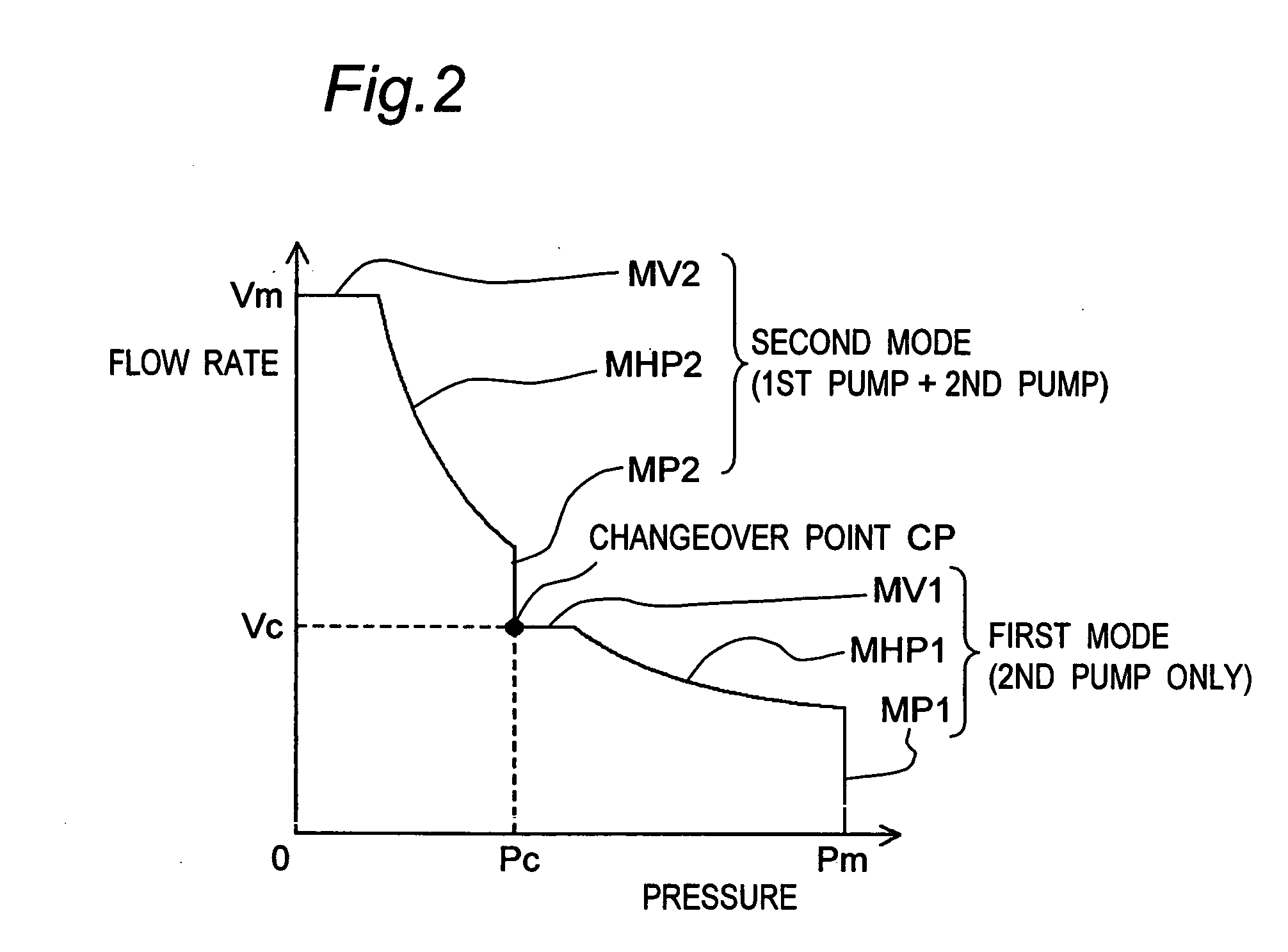

ActiveUS7399165B2High discharge pressureReduce noisePump controlPositive-displacement liquid enginesRotation velocityOperation mode

A first pump of small capacity and a second pump of large capacity are connected directly with each other and are driven by a variable-speed motor. The rotational speed of the variable-speed motor is controlled by a control device. In a first mode, a first discharge line of the first pump and a second discharge line of the second pump are disconnected with each other, making the first pump unloaded. With the first pump in the unloaded state, a constant-horsepower operation is performed, where the discharge fluid is brought into a high pressure by relatively small torque. In a second mode, the first discharge line and the second discharge line are connected with each other by a switching valve. With the first and second discharge lines in the connected state, a constant-horsepower operation is performed, where a high flow rate of discharge fluid is discharged at relatively low rotational speed.

Owner:DAIKIN IND LTD

Pump unit

ActiveUS20050180855A1High discharge pressureReduce noisePump controlPump installationsHigh pressureVALVE PORT

A first pump of small capacity and a second pump of large capacity are connected directly with each other and are driven by a variable-speed motor. The rotational speed of the variable-speed motor is controlled by a control device. In a first mode, a first discharge line of the first pump and a second discharge line of the second pump are disconnected with each other, making the first pump unloaded. With the first pump in the unloaded, state, a constant-horsepower operation is performed, where the discharge fluid is brought into a high pressure by relatively small torque. In a second mode, the first discharge line and the second discharge line are connected with each other by a switching valve. With the first and second discharge lines in the connected, state, a constant-horsepower operation is performed, where a high flow rate of discharge fluid is discharged at relatively low rotational speed.

Owner:DAIKIN IND LTD

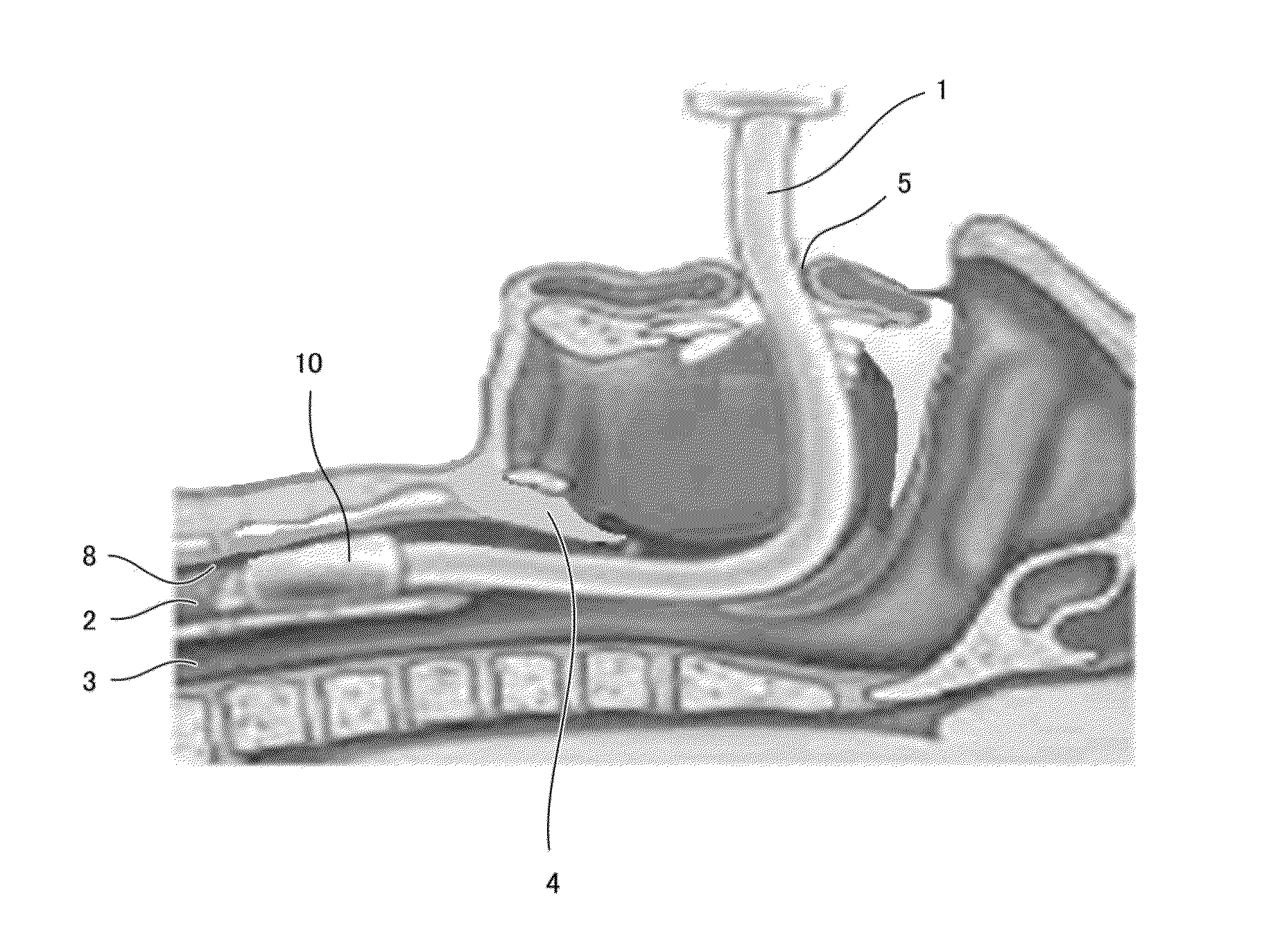

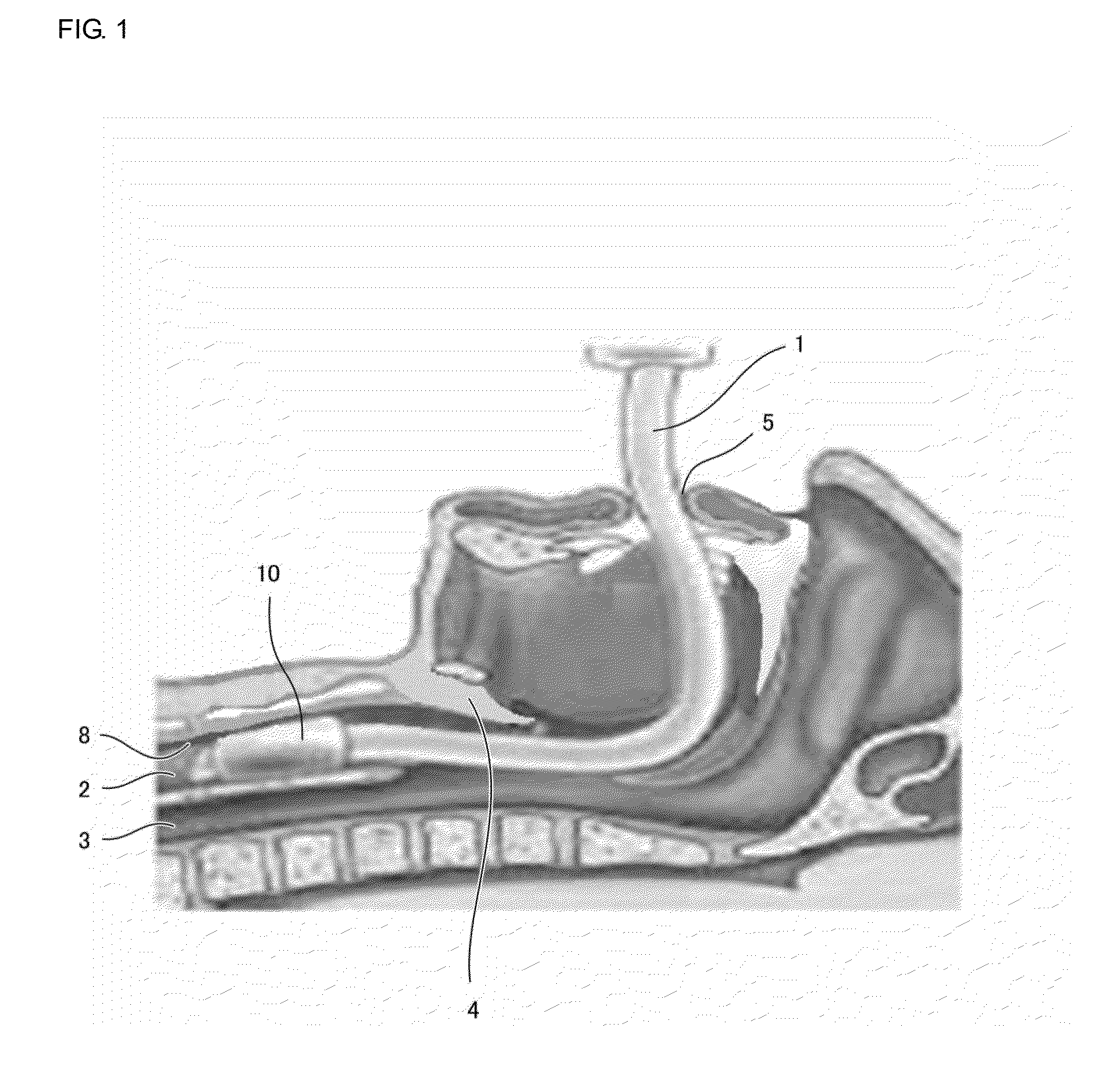

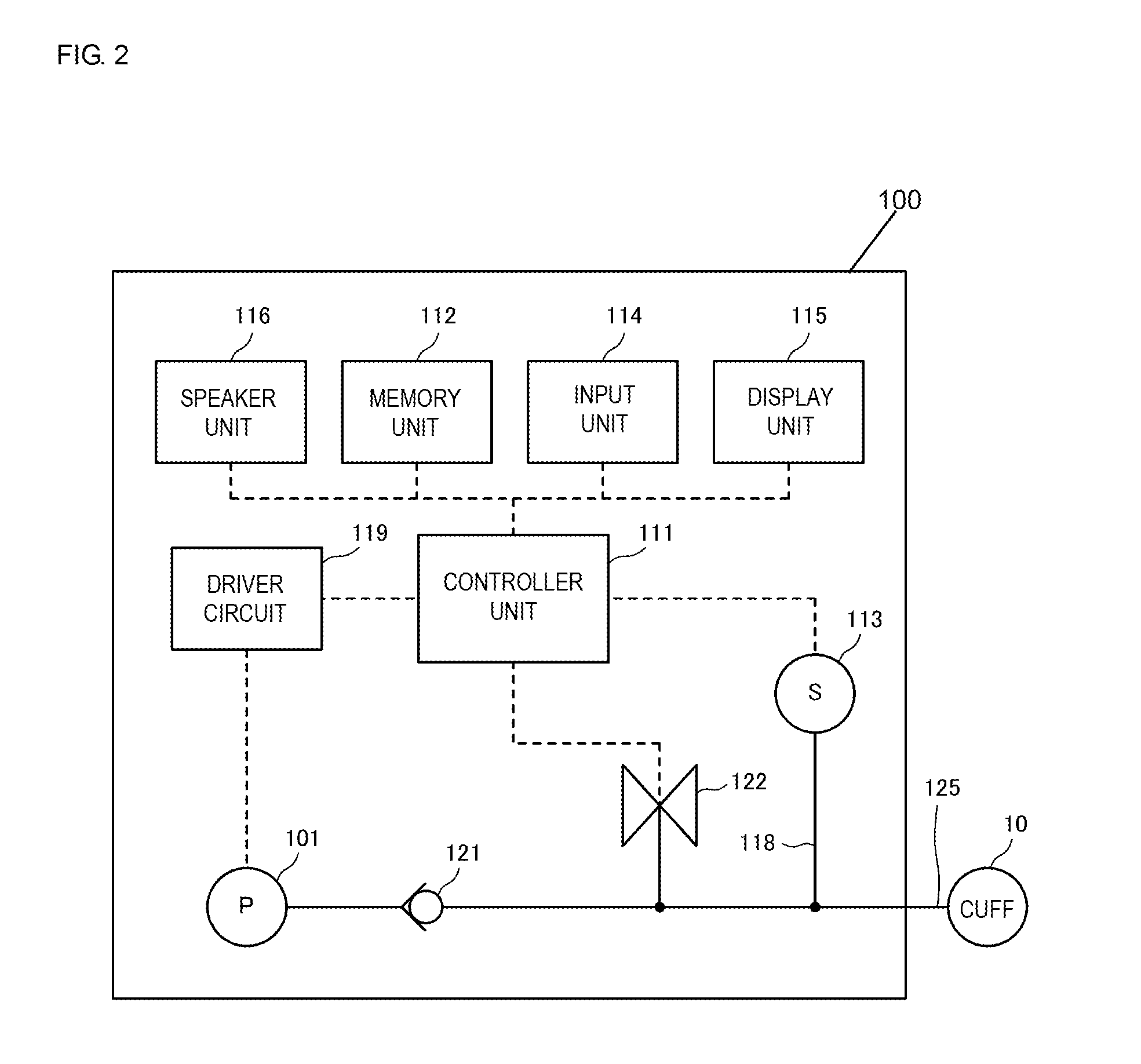

Cuff pressure controller device

ActiveUS20160038699A1High discharge pressureLarge discharge flow volumeTracheal tubesFlexible member pumpsUrologyPiezoelectric pump

A cuff pressure controller device (100) is connected to a foregoing cuff (10) via an air supply tube (125). The cuff pressure controller device (100) includes a controller unit (111), a cuff pressure detector unit (113), a driver circuit (119), a piezoelectric pump (101), a check valve (121), and a release valve (122). The cuff pressure detector unit (113) detects the cuff pressure of the cuff (10). The driver circuit (119) drives the piezoelectric pump (101) at a drive frequency of 20 kHz or higher. The controller unit (111) controls the cuff pressure detector unit (113), the driver circuit (119), and the release valve (122) in such a way that the cuff pressure stays within a predetermined range based on detection results of the cuff pressure detector unit (113) and the like.

Owner:MURATA MFG CO LTD

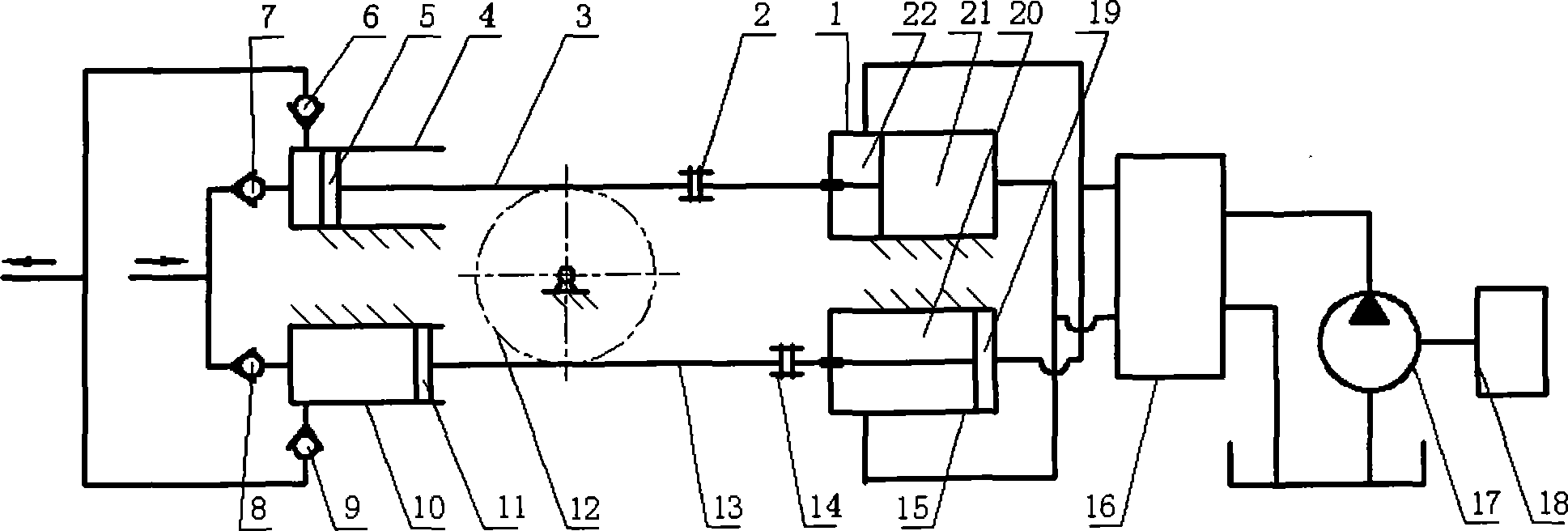

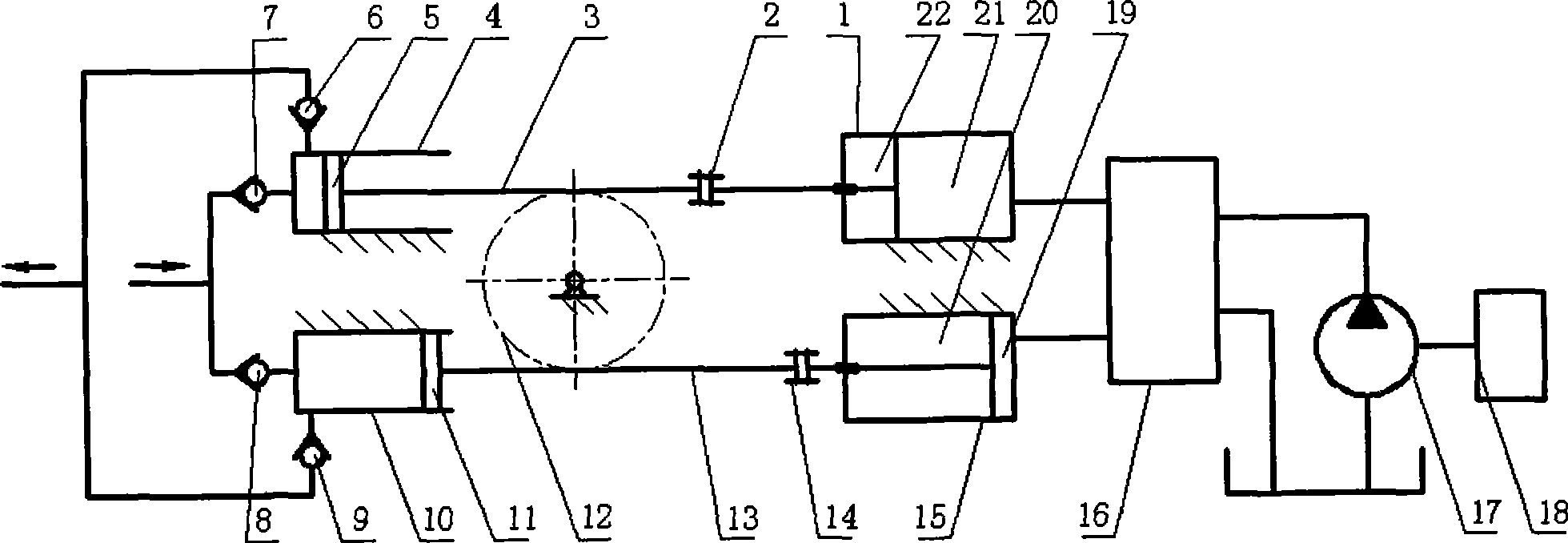

Rack-and-pinion coupled hydraulic multi-cylinder reciprocating pump

InactiveCN101476553AReduce degradationReduce shearPiston pumpsPositive-displacement liquid enginesPhase differenceGear wheel

The invention relates to a gear wheel and rack coupled hydraulic multi-cylinder reciprocating pump, which consists of a hydraulic oil cylinder, a coupling, a cylinder sleeve of a working hydraulic cylinder, a piston, a piston rod, a gear wheel, a suction valve, a discharge valve, a hydraulic directional control valve, a hydraulic oil pump, an electric motor, and the like which are assembled and connected. The piston rod is provided with a rack; the hydraulic oil cylinder and the piston rod are arranged parallelly; the gear wheel is engaged with racks on the two piston rods simultaneously; and the two piston rods are arranged according to the movement phase difference of 180 degrees. Two hydraulic oil cylinders and two working hydraulic cylinders form a basic unit, and for the two hydraulic oil cylinders in the basic unit, oil can be provided to both non-rod chambers and rod chambers, and can be only provided to the non-rod chambers of the oil cylinders. The invention can be combined into a multi-cylinder reciprocating pump with two cylinders, four cylinders, six cylinders, and more even cylinders. The hydraulic multi-cylinder reciprocating pump has the advantages of high systematic efficiency, long stroke, low stroke frequency, large displacement, high pump pressure, long service life of wearing parts, small fluctuation of the displacement and the pump pressure, good suction performance, and simple and convenient maintenance.

Owner:SOUTHWEST PETROLEUM UNIV

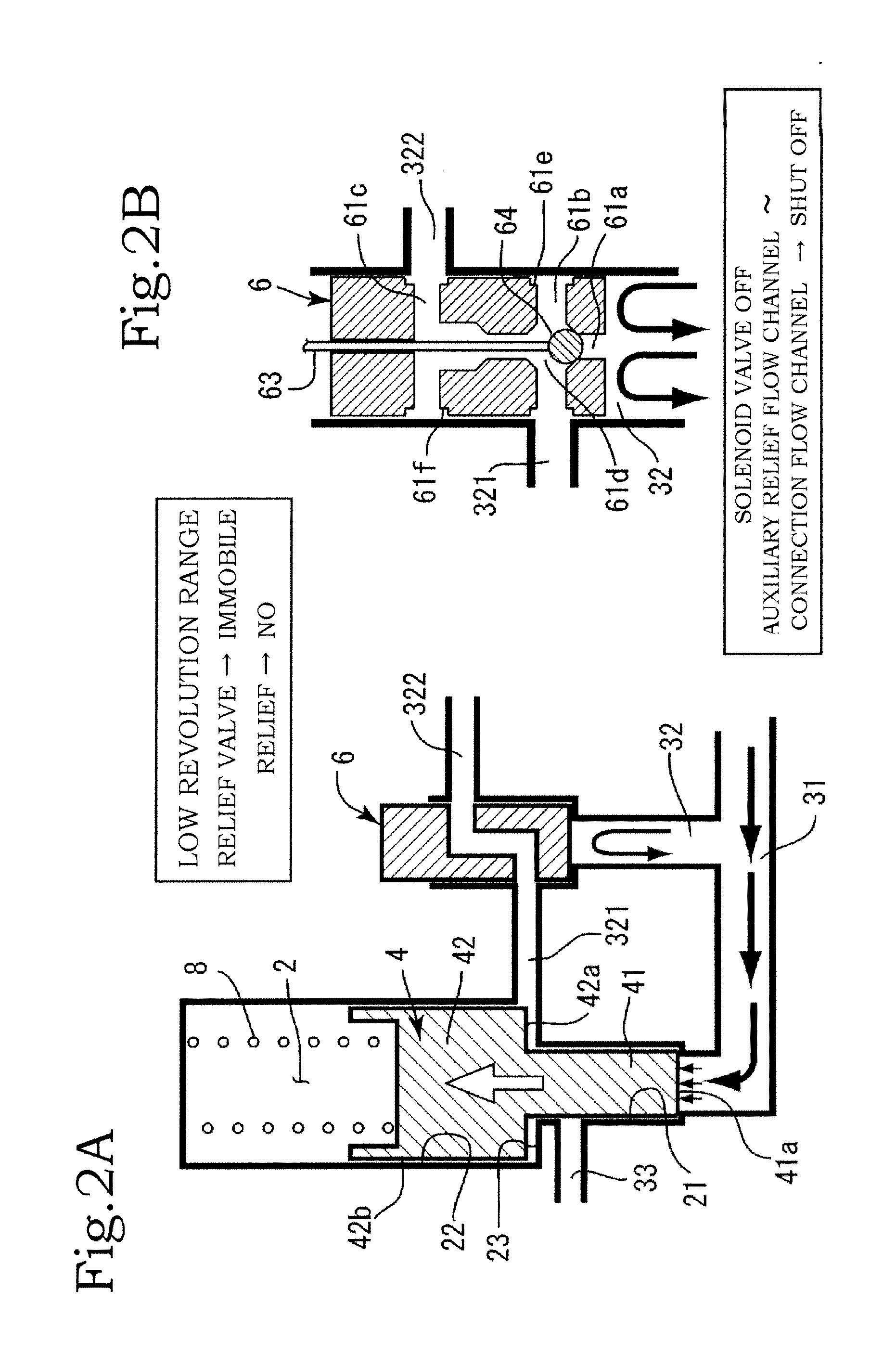

Relief valve device

ActiveUS20120241022A1Reduce flowReduce pressureOperating means/releasing devices for valvesLubrication pressure controlSolenoid valveEngineering

The invention allows securing greater discharge pressure and flow rate at high revolutions of an engine in order to secure lubrication and cooling, while reducing discharge pressure and flow rate at low and medium revolutions of the engine in order to improve efficiency. The invention includes a housing; a relief valve; a valve passage; a main discharge flow channel; a main relief flow channel; an auxiliary relief flow channel; a solenoid valve mounted on the auxiliary relief flow channel; and a spring. The solenoid valve is controlled so as to switch between communication and shut-off between the auxiliary relief flow channel and the large-diameter passage section in accordance with an increase or decrease in engine revolutions, and oil in the large-diameter passage section is discharged when the shut-off is implemented.

Owner:YAMADA SEISAKUSHO KK

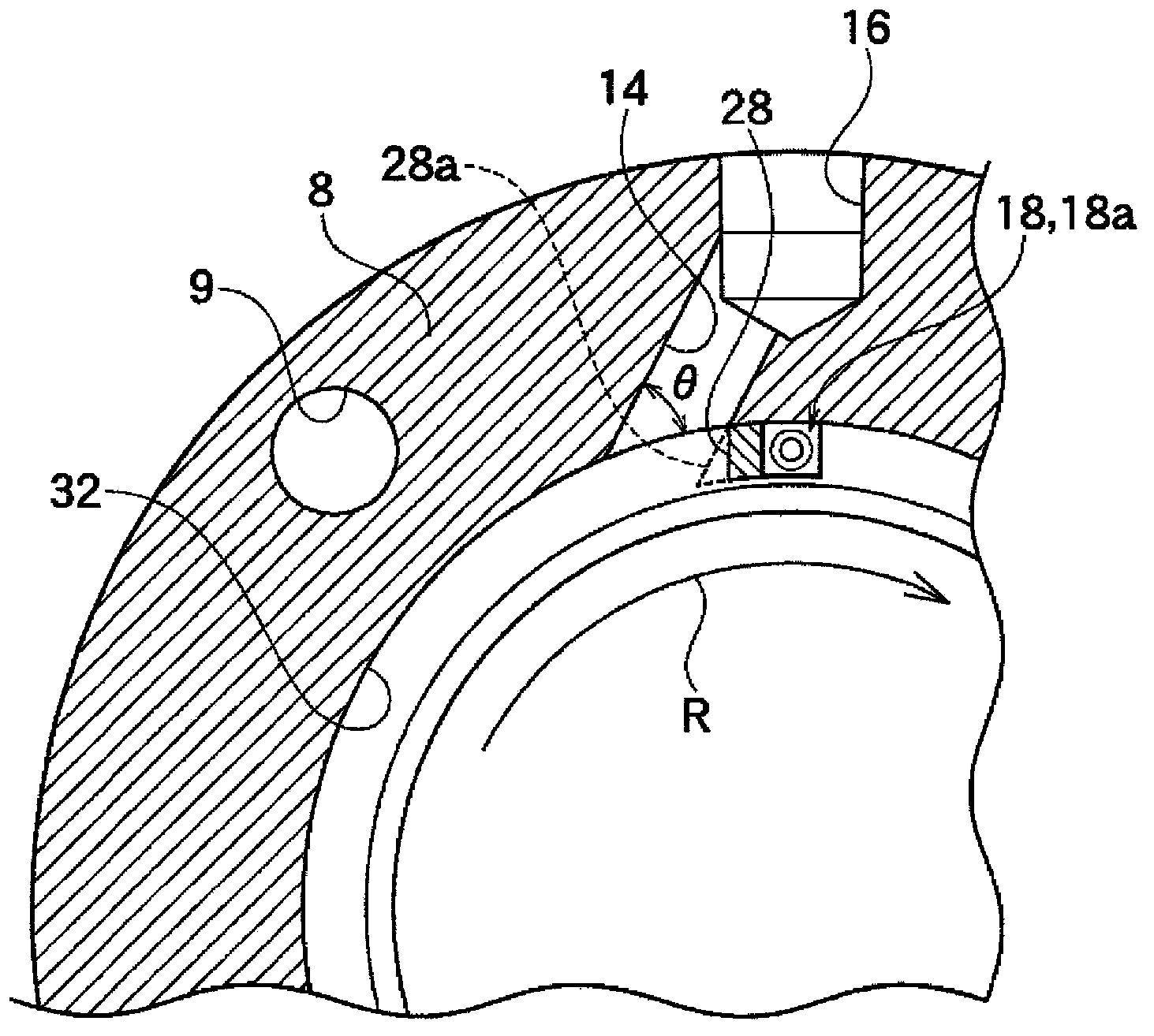

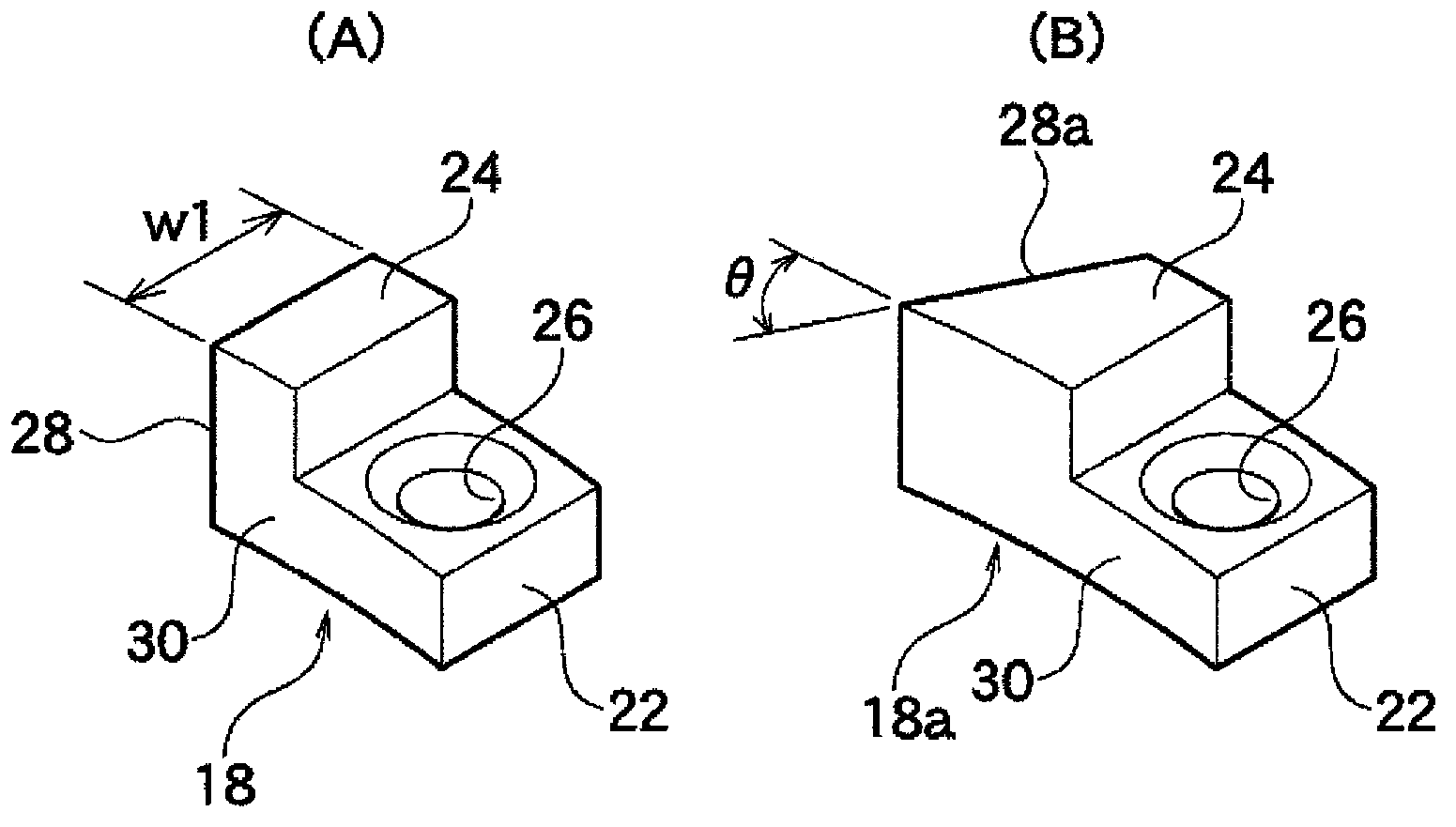

Shaft seal apparatus

A pumping ring (46), producing an axial flow of a sealed fluid so that a sealed fluid positioned in a sealed space (33) flows along the central axial direction of a rotating shaft (6), is secured to a rotating shaft (6) in an axial position different than a rotating ring (56). A discharge hole (14) is formed in the inner circumferential surface of a seal cover (8) positioned on the downstream side of the axial flow of the sealed fluid resulting from the rotation of the pumping ring (46). An inflow hole (15) is formed in a position on the upstream side of the axial flow of the sealed fluid resulting from the rotation of the pumping ring (46). The configuration is such that sealed fluid discharged from the discharge hole (14) returns to the interior of the sealed space (33) from the inflow hole (15). A rectifying member (18) is provided so as to protrude toward the inside in a radial direction in the inner circumferential surface of the seal cover (8) where the discharge hole (14) is formed. The rectifying member retains the flow of the sealed fluid along the rotational direction of a retainer (52) and orients the sealed fluid toward the discharge hole (14).

Owner:EAGLE INDS

Hydraulic drive system

ActiveUS10227090B2Low costConfiguration economyFluid-pressure actuator safetyFluid-pressure actuator testingTarget controlEngineering

A hydraulic drive system includes: control valves; solenoid proportional valves outputting pilot pressures to the control valves; a controller controlling each of the solenoid proportional valves; a primary pressure line leading hydraulic oil from an auxiliary pump to the solenoid proportional valves; a solenoid switching valve provided on the primary pressure line; a movement detection line blocked when any of movement detection target control valves has moved; and a movement detection pressure sensor provided on the movement detection line. The controller controls the solenoid switching valve while all of operation devices are outputting electrical signals indicating that their operating levers are in neutral, such that: the solenoid switching valve opens the primary pressure line if a measurement value of the pressure sensor is less than a threshold; and the solenoid switching valve blocks the primary pressure line if the measurement value of the pressure sensor is greater than the threshold.

Owner:KAWASAKI HEAVY IND LTD

Piezoelectric pump

Owner:MURATA MFG CO LTD

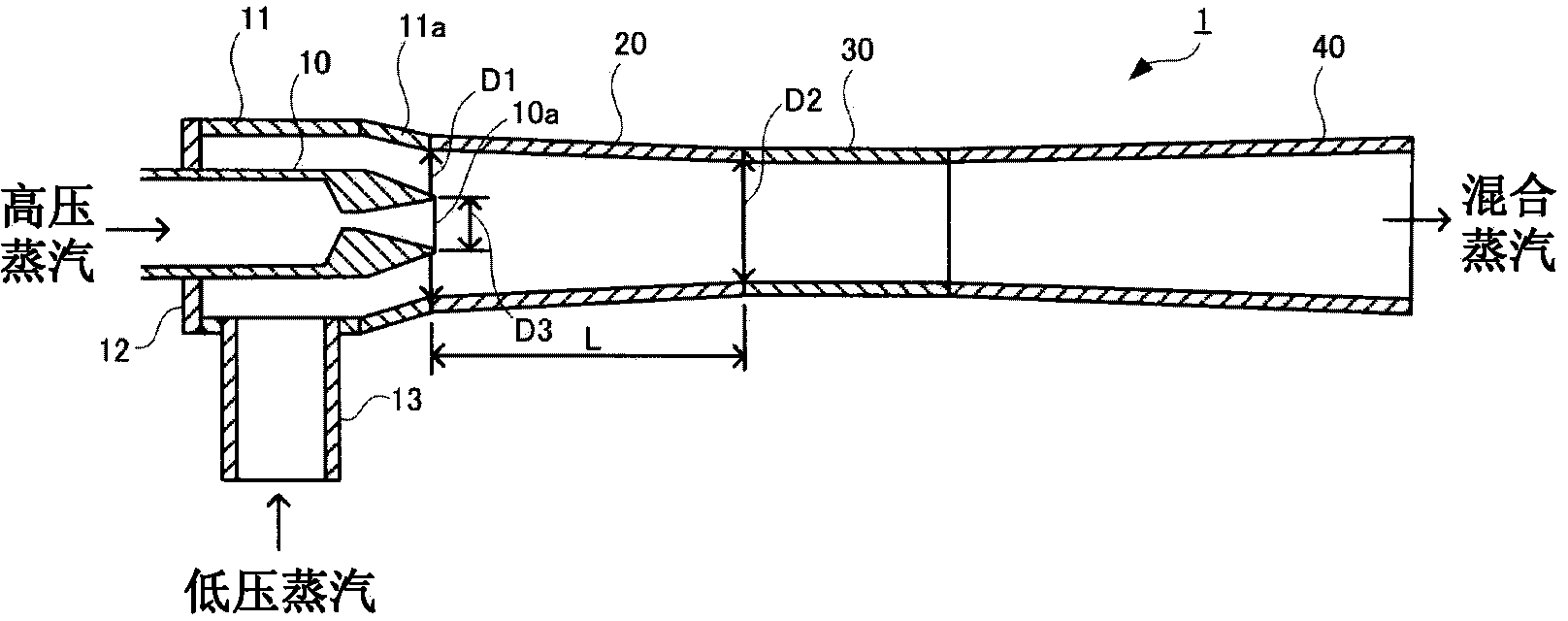

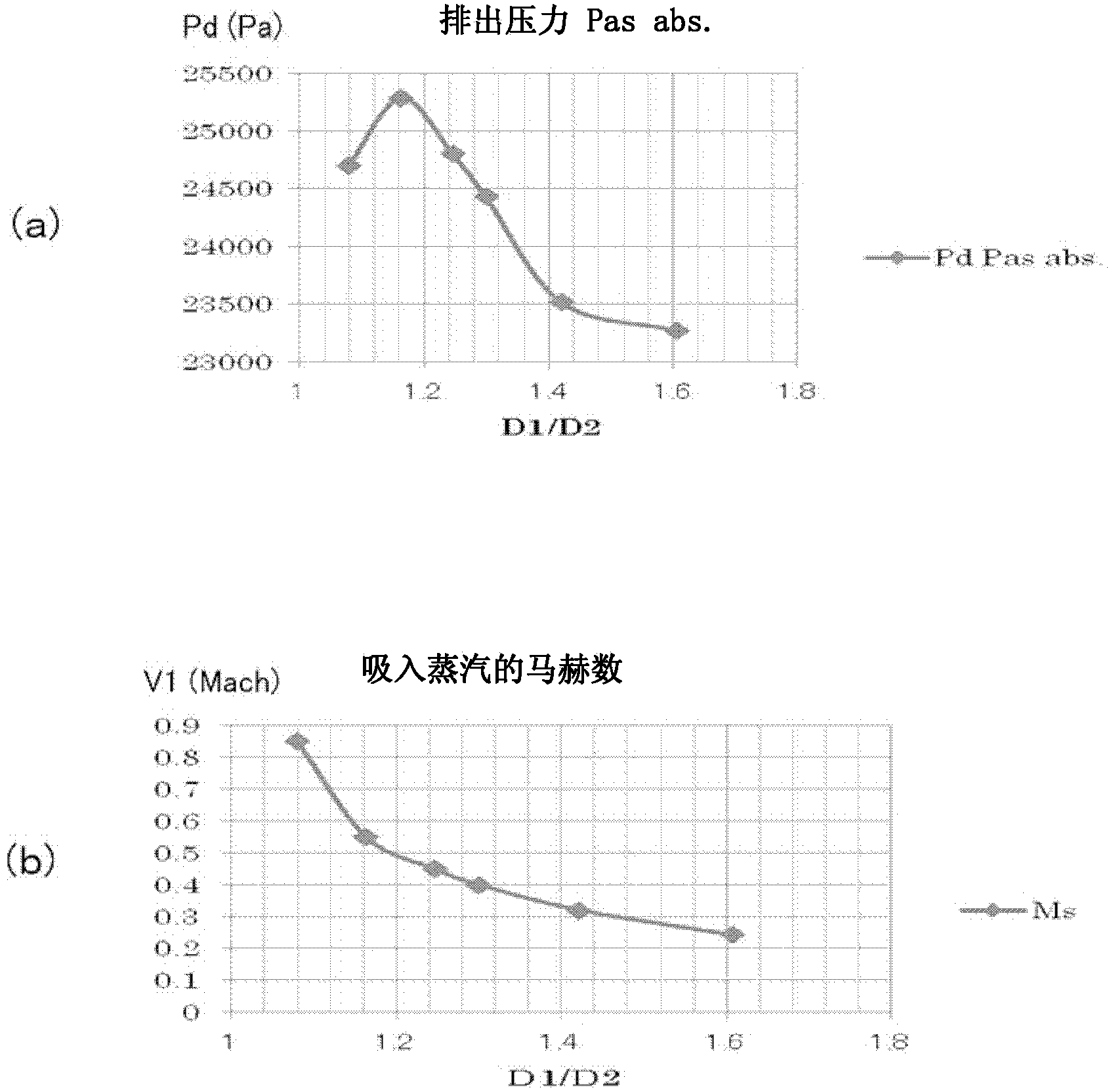

Thermocompressor

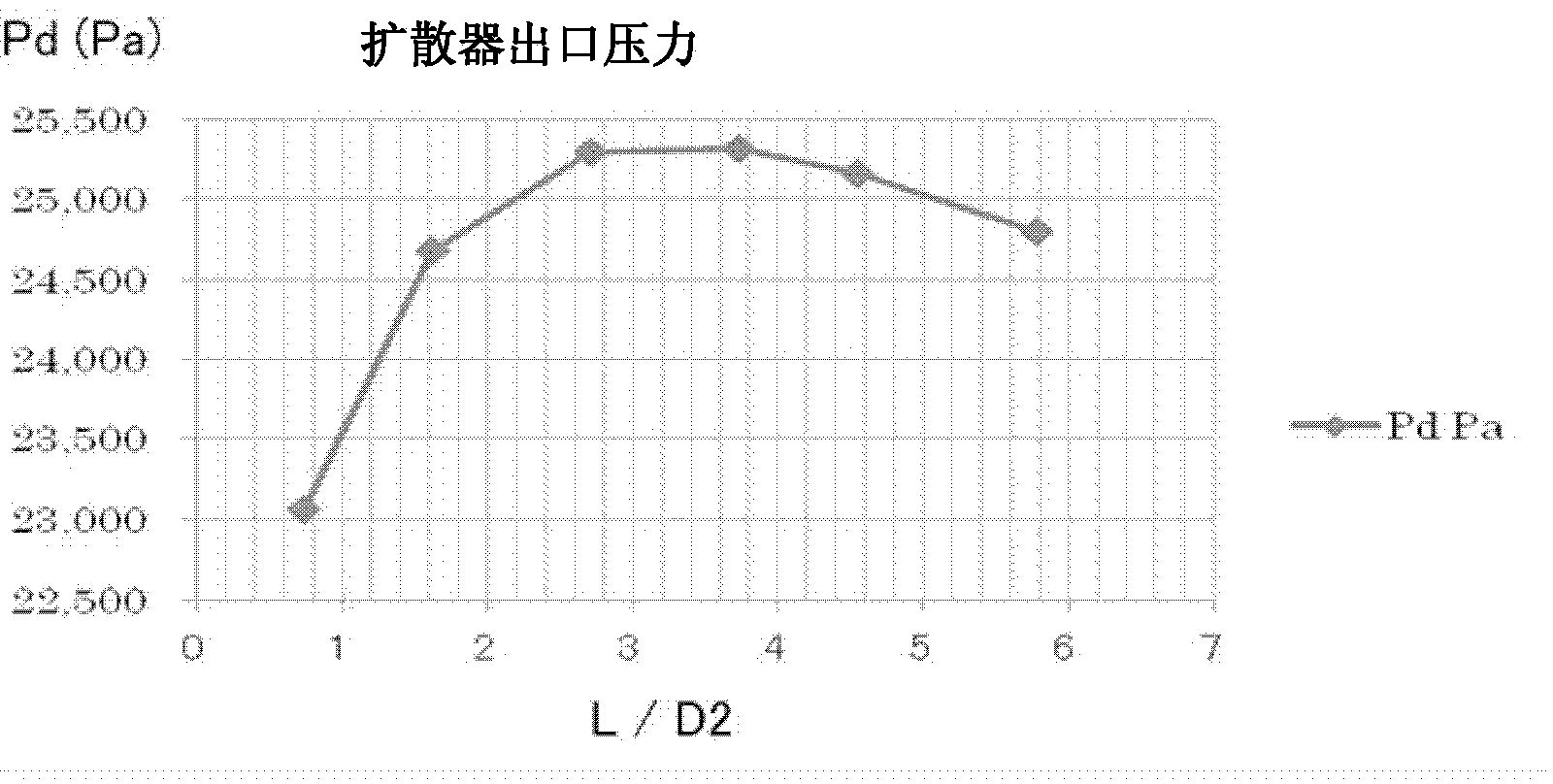

The present invention provides a thermocompressor capable of improving exhaust pressure of mixed steam of drive steam and intake steam. The thermocompressor comprises: a steam nozzle (10) ejecting high pressure steam from an ejection opening (10a) formed at the front end; a mixing chamber (20) formed to be cylinder-shaped with two ends open and configured with the ejection opening (10a) at one end; and a diffuser (40) connected with the other end side of the mixing chamber (20). The high pressure steam is ejected from the ejection opening (10a), low pressure steam is attracted in the mixing chamber (20) from the periphery of the ejection opening (10a), pressure of the mixed steam is raised in the diffuser (40), and then the mixed steam is exhausted to the outside. The inner diameter of the mixing chamber (20) is reduced from one end to the other end, and the ratio (D1 / D2) of the inner diameter (D1) of one end and the inner diameter (D2) is in a range of 1.1-1.3.

Owner:SASAKURA ENG CO LTD

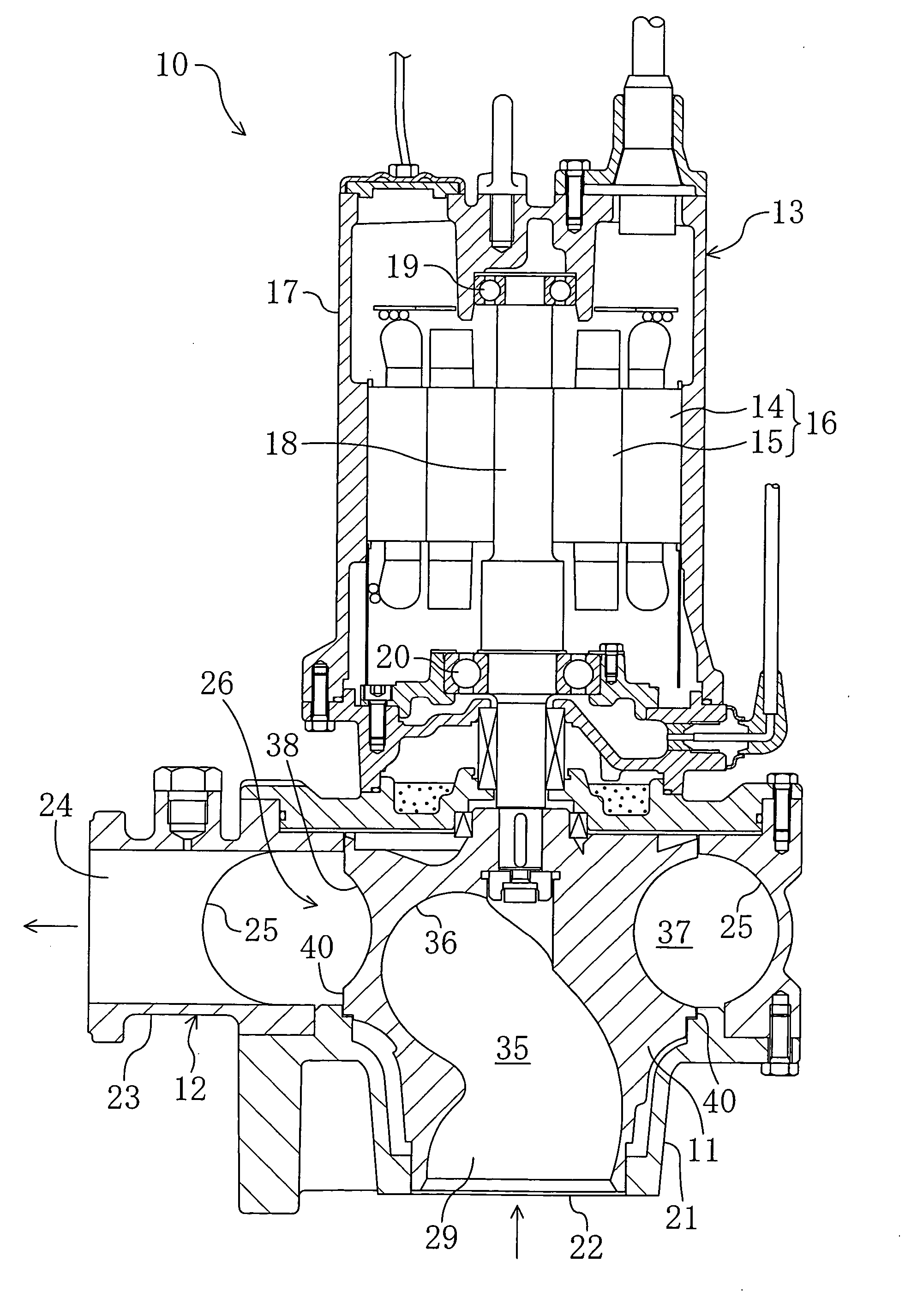

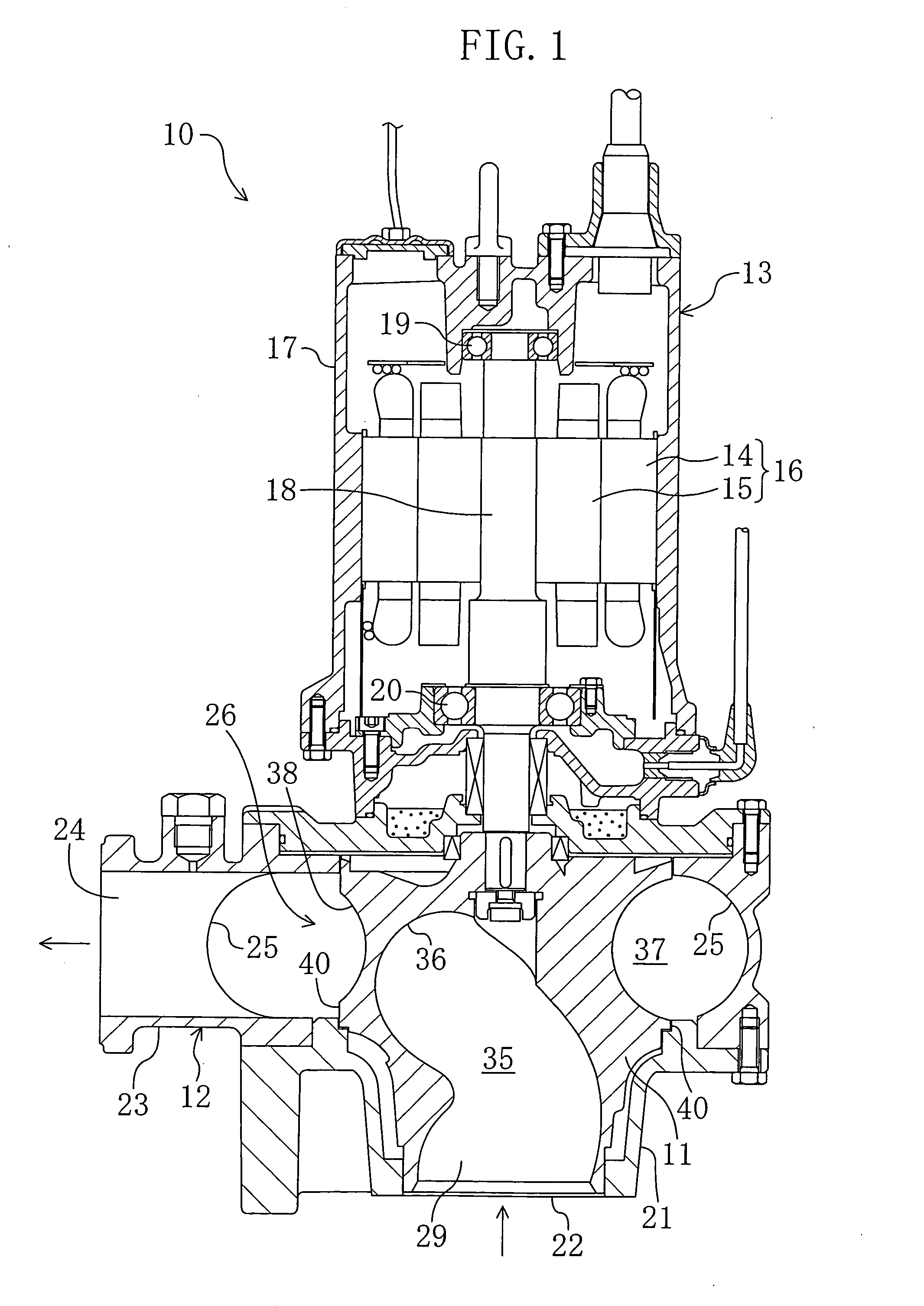

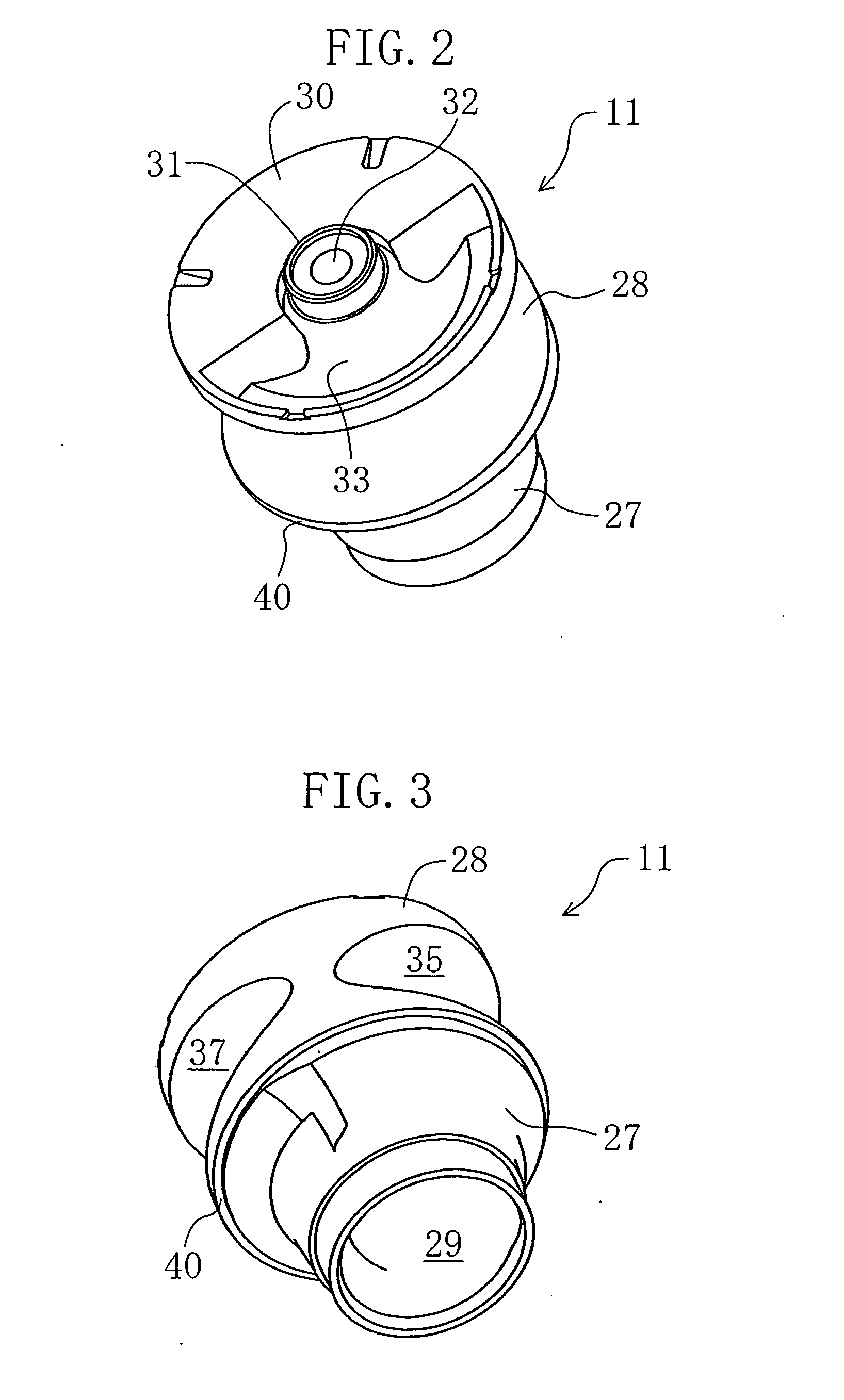

Impeller and sewage treatment pump including the same

ActiveUS20050013688A1High efficiencySpeed up the flowSpecific fluid pumpsPropellersImpellerPrimary channel

In an impeller 11, an inlet portion and an outlet portion are provided at one end side and the other end side in the axial direction, respectively. An inlet 29 is formed in the lower part of the inlet portion, and an outlet is formed in the side face of the outlet portion. The inlet portion and the outlet portion are partitioned by a flange portion 40. The impeller 11 includes a primary vane 36 and a secondary vane 38. The primary vane 36 defines a spiral primary channel 35 that connects the inlet 29 and the outlet. The secondary vane 38 is formed in a shape that a part of the outer periphery of the outlet portion is gouged inward so as to define a secondary channel 37 connected to the primary channel 35 and extending circumferentially around the outer periphery.

Owner:SHIN MEIWA IND CO LTD

Injection of refrigerant in system with expander

InactiveUS20100058783A1Effective expansionLower the discharge temperatureDomestic cooling apparatusCompression machines with non-reversible cycleEngineeringRefrigerant

A refrigerant system incorporates an expander. At least a portion of refrigerant bypasses an evaporator and is injected into the compression process to cool main refrigerant vapor flow and compressor elements. In disclosed embodiments, the injected refrigerant may be partially expanded in the expander and routed either into the compressor suction or to an intermediate point in the compression process. A valve may control the amount of the injected refrigerant to achieve desired operational characteristics for the refrigerant system.

Owner:CARRIER CORP

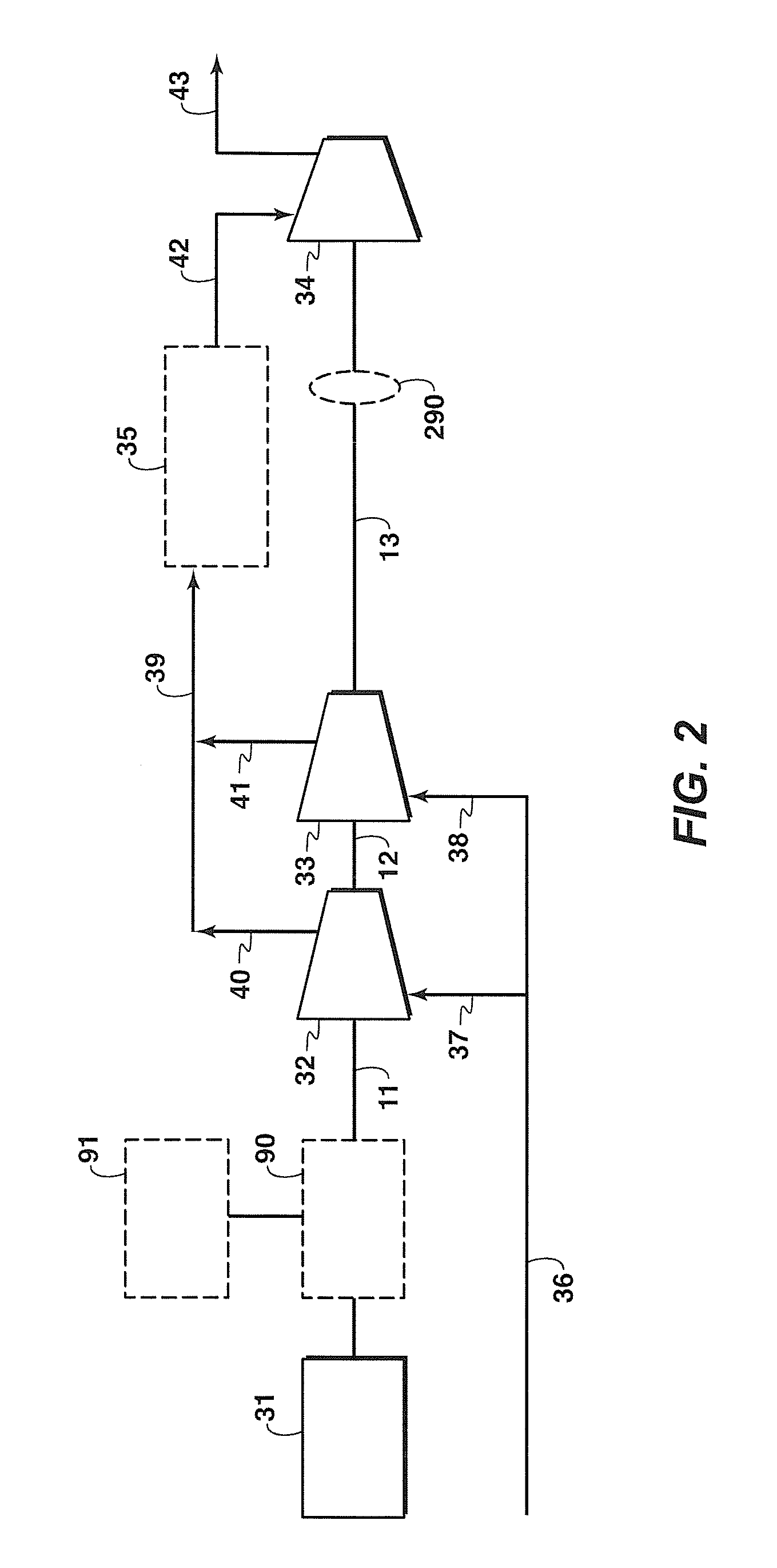

Parallel dynamic compressor arrangement and methods related thereto

ActiveUS9284964B2Improve efficiencyHigh outputSolidificationLiquefactionParallel dynamicsEngineering

This disclosure is directed to a novel arrangement for equipment used to compress fluids. A single prime mover is connected to a plurality of compressors. A supply conduit with parallel branch conduits directs fluid to be compressed to at least two compressors and parallel output conduits from each compressor are connected to a common output conduit, which directs compressed fluids to at least one additional compressor.

Owner:EXXONMOBIL UPSTREAM RES CO

Relief valve device

ActiveUS9038659B2Reduce flowReduce pressureOperating means/releasing devices for valvesServomotor componentsSolenoid valveEngineering

The invention allows securing greater discharge pressure and flow rate at high revolutions of an engine in order to secure lubrication and cooling, while reducing discharge pressure and flow rate at low and medium revolutions of the engine in order to improve efficiency. The invention includes a housing; a relief valve; a valve passage; a main discharge flow channel; a main relief flow channel; an auxiliary relief flow channel; a solenoid valve mounted on the auxiliary relief flow channel; and a spring. The solenoid valve is controlled so as to switch between communication and shut-off between the auxiliary relief flow channel and the large-diameter passage section in accordance with an increase or decrease in engine revolutions, and oil in the large-diameter passage section is discharged when the shut-off is implemented.

Owner:YAMADA MANUFACTURING CO LTD

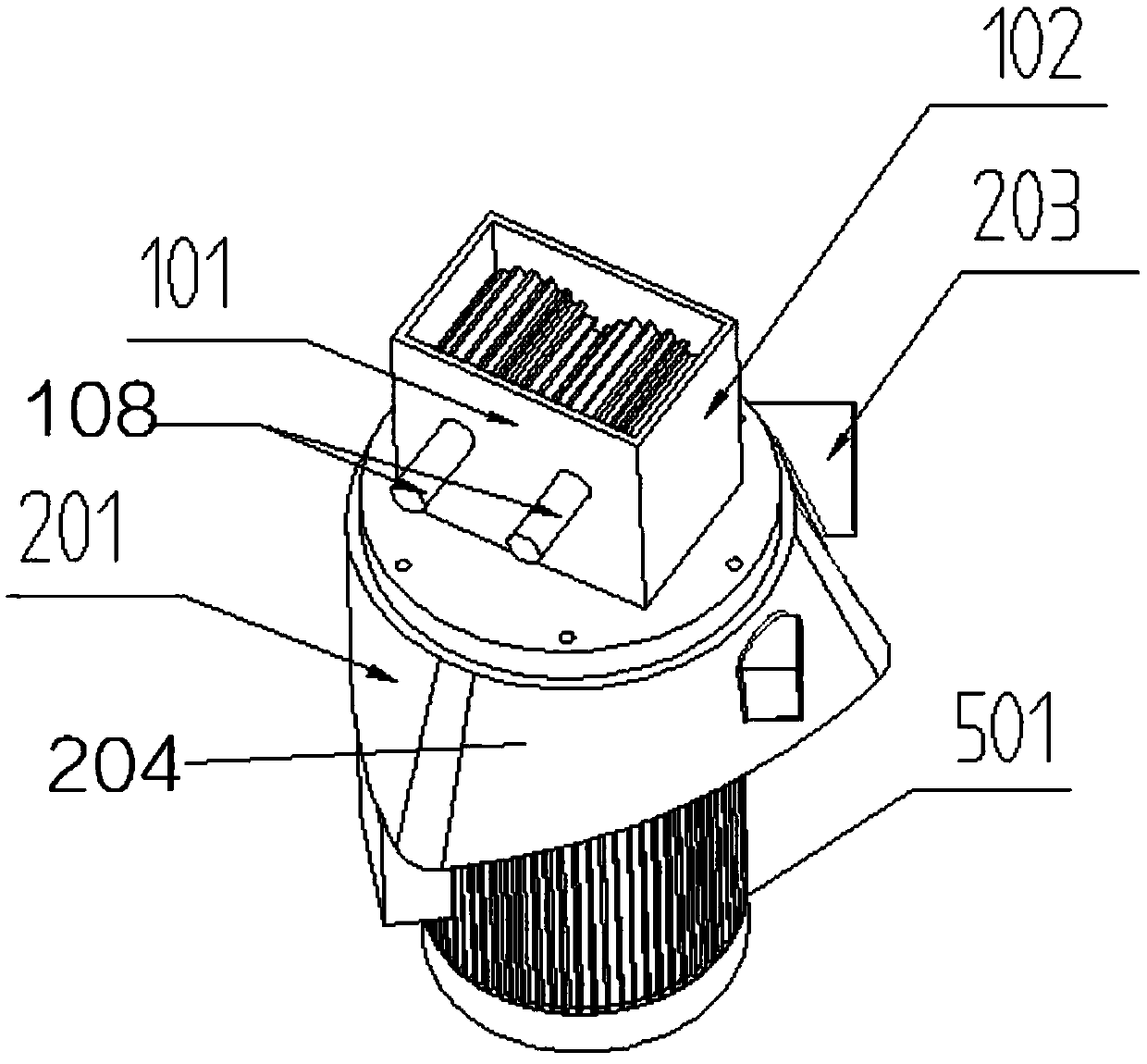

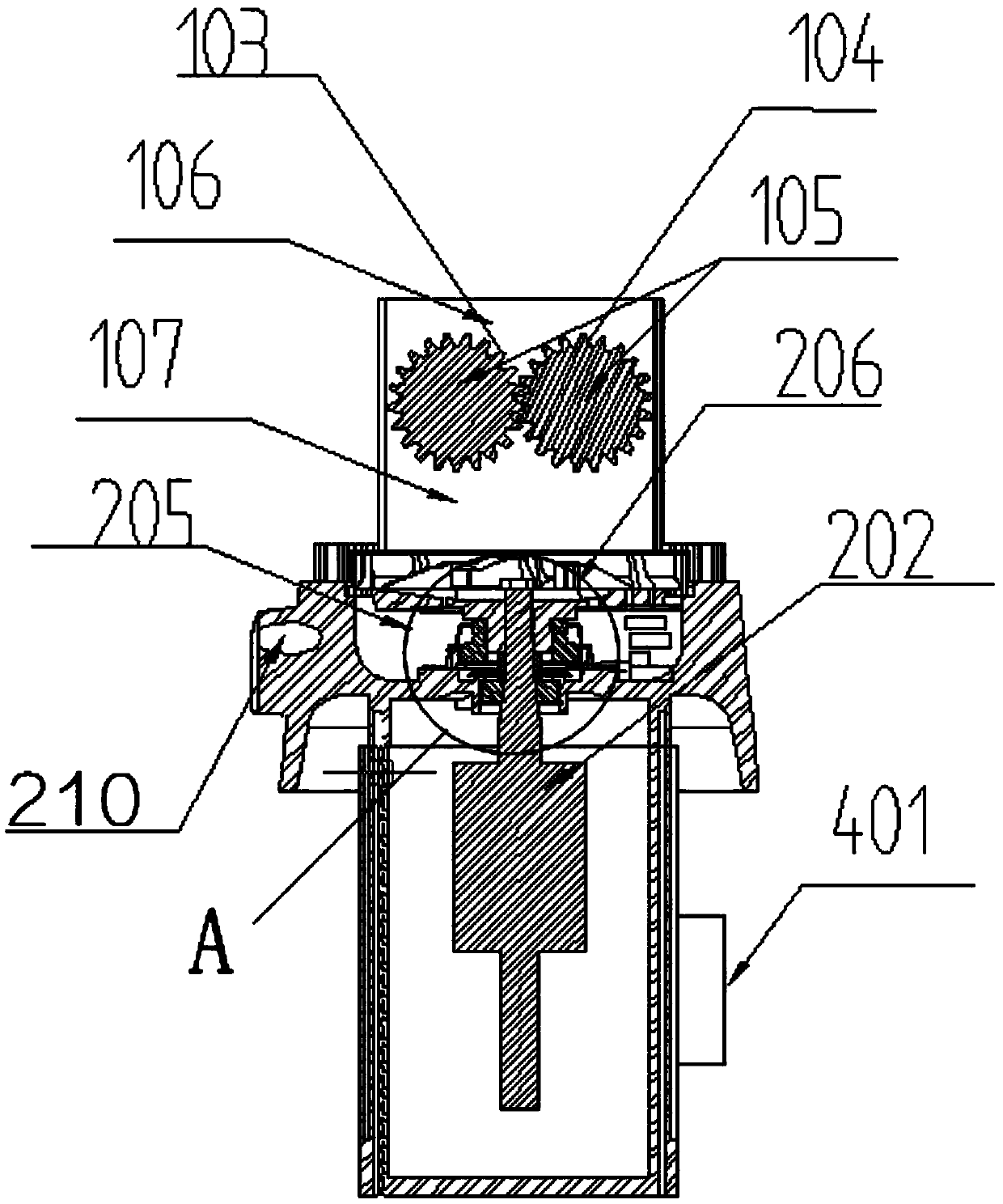

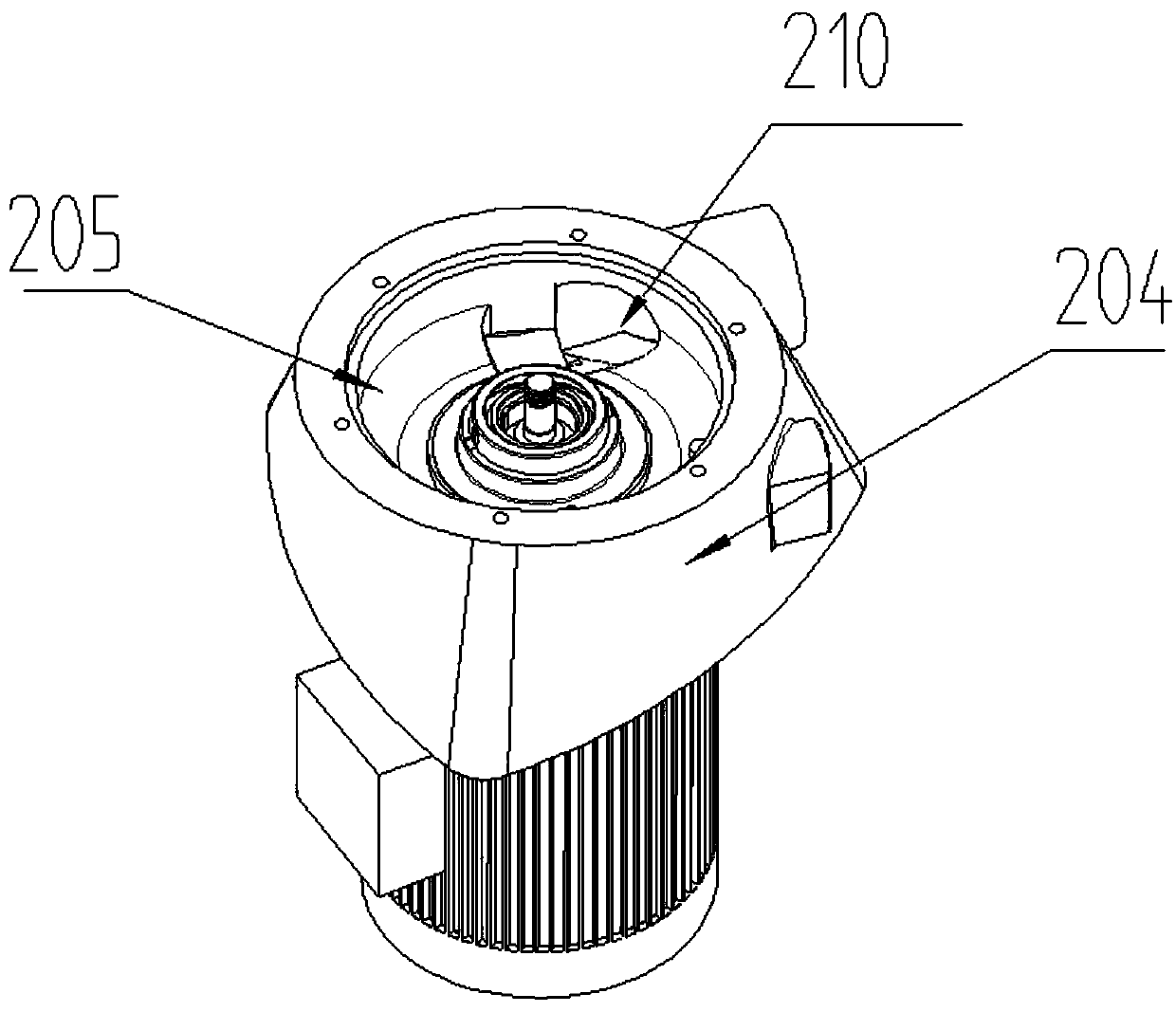

Crushing conduction enhanced kitchen waste disposal plant

InactiveCN109622134AImprove crushing abilityEnhanced handling and crushing capabilitiesDomestic plumbingGrain treatmentsHigh frequencyWaste disposal

The invention discloses a crushing conduction enhanced kitchen waste disposal plant. The crushing conduction enhanced kitchen waste disposal plant comprises a first-stage crushing body and a second-stage crushing body, wherein the first-stage crushing body comprises a first-stage shell and a first-stage crushing component, waste is crushed and extruded by a gear by virtue of the rotation of the first-stage crushing body, bones are extruded and crushed to enter a first-stage crushing lower cavity, a second-stage crushing component is arranged on the second-stage crushing body, a crushing hammerand a crushing wall are arranged on the upper surface of the second-stage crushing component, a pressure reinforcing piece and a cutting knife are arranged on the lower surface of the second-stage crushing component, a second-stage crushing power shaft rotates so as to drive the second-stage crushing component to rotate, kitchen waste is stricken at high frequency between the crushing hammer andthe crushing wall so as to be crushed, and then the kitchen waste is cut and crushed by virtue of the rotation of a cutting ring and the cutting knife and then is discharged. The device has the characteristics of rapidity, reliability, low cost and practicability, and the problems of no thoroughness in crushing the kitchen waste, poor universality, difficulty in discharging the waste, easiness inblockage and the like in the prior art can be solved.

Owner:泰州首创环保科技有限公司

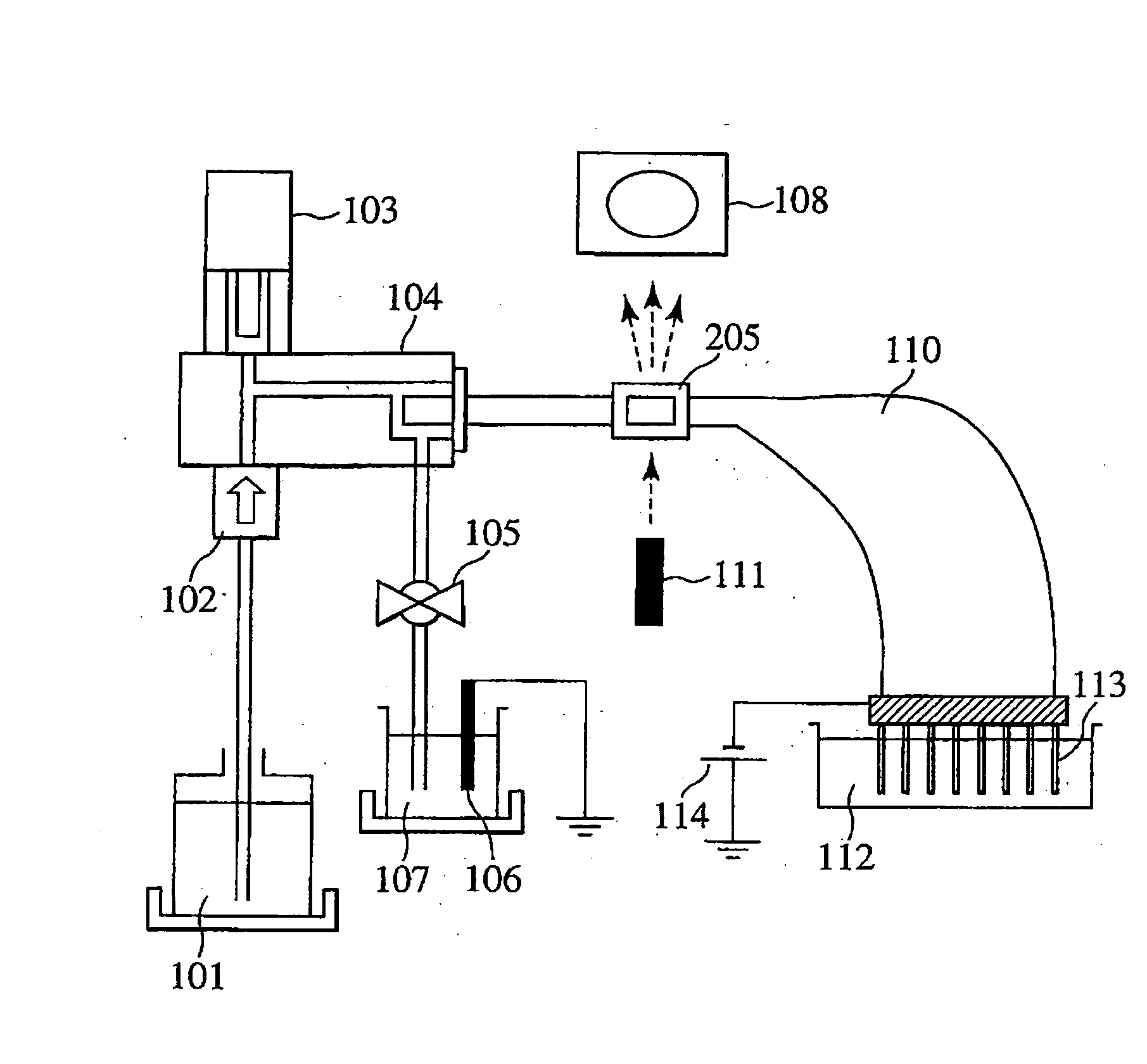

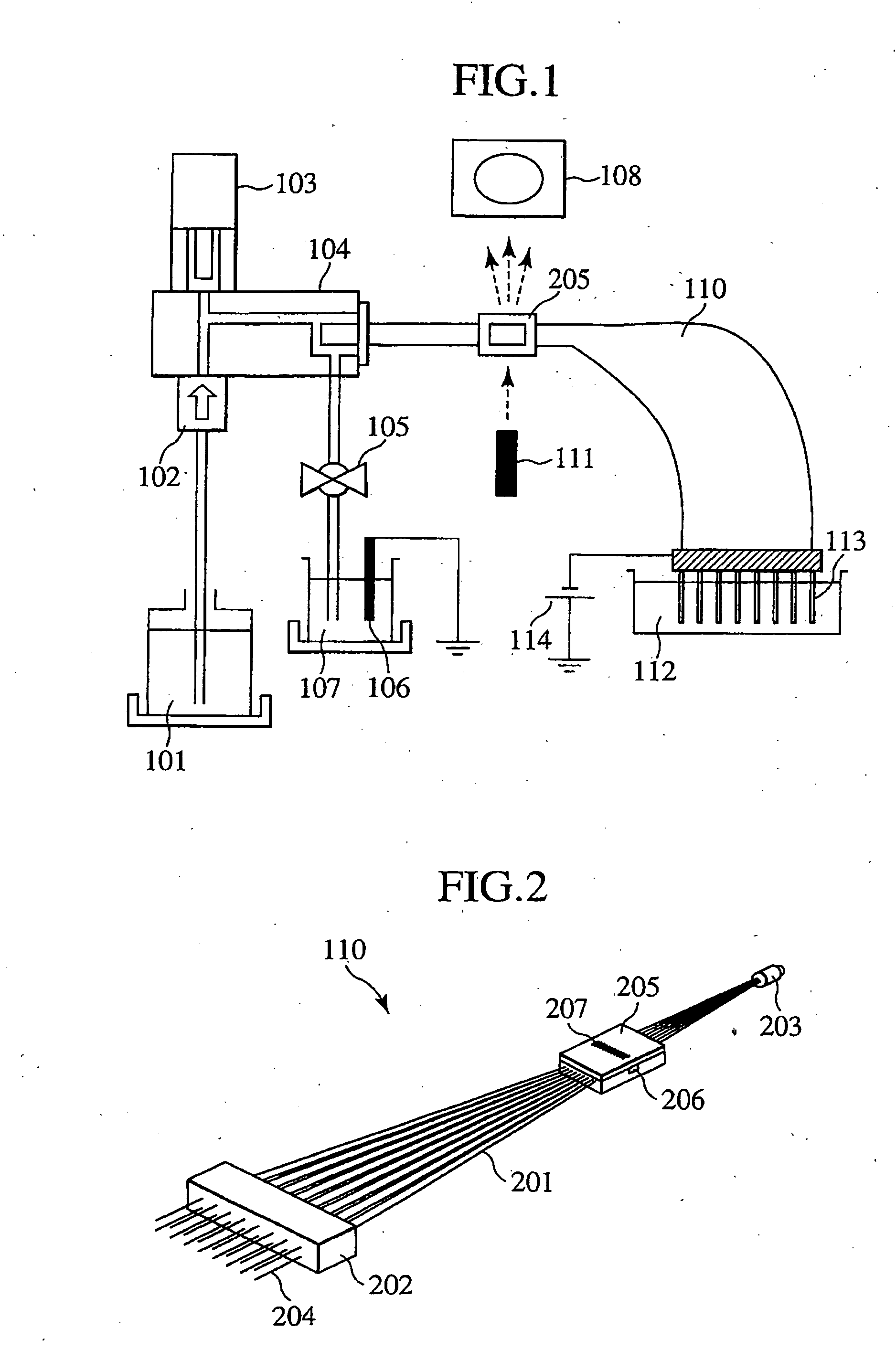

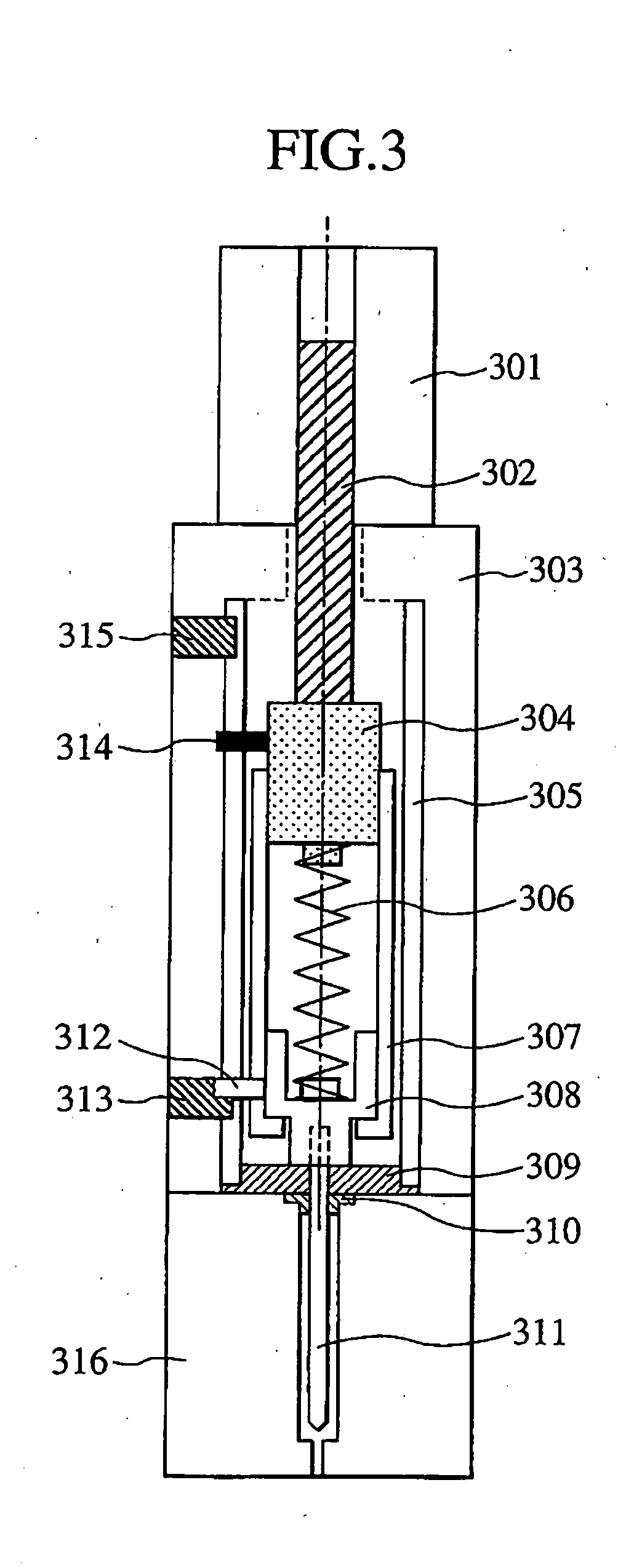

Electrophoresis apparatus and pump mechanism used in the same

To obtain a stable pressure to inject polymer into a capillary array in order to shorten the injection time and raise the processing capacity of the apparatus.Disclosed herein is an electrophoresis apparatus comprising one or more capillaries to be filled with an electrophoretic medium and a pump mechanism which can be connected to the capillaries for filling the capillaries with an electrophoretic medium. The pump mechanism comprises a plunger; a slider which is bonded to the plunger and moves together with the plunger; a spring which gives force to the slider; a cover which limits the range of displacement of the slider; and a linear motion system which is bonded to the cover and moves linearly, wherein the cover and the slider move as one body when the electrophoretic medium is taken to the plunger, and the plunger is pushed by the action of the spring when the electrophoretic medium is injected from the plunger into the capillaries.

Owner:HITACHI HIGH-TECH CORP

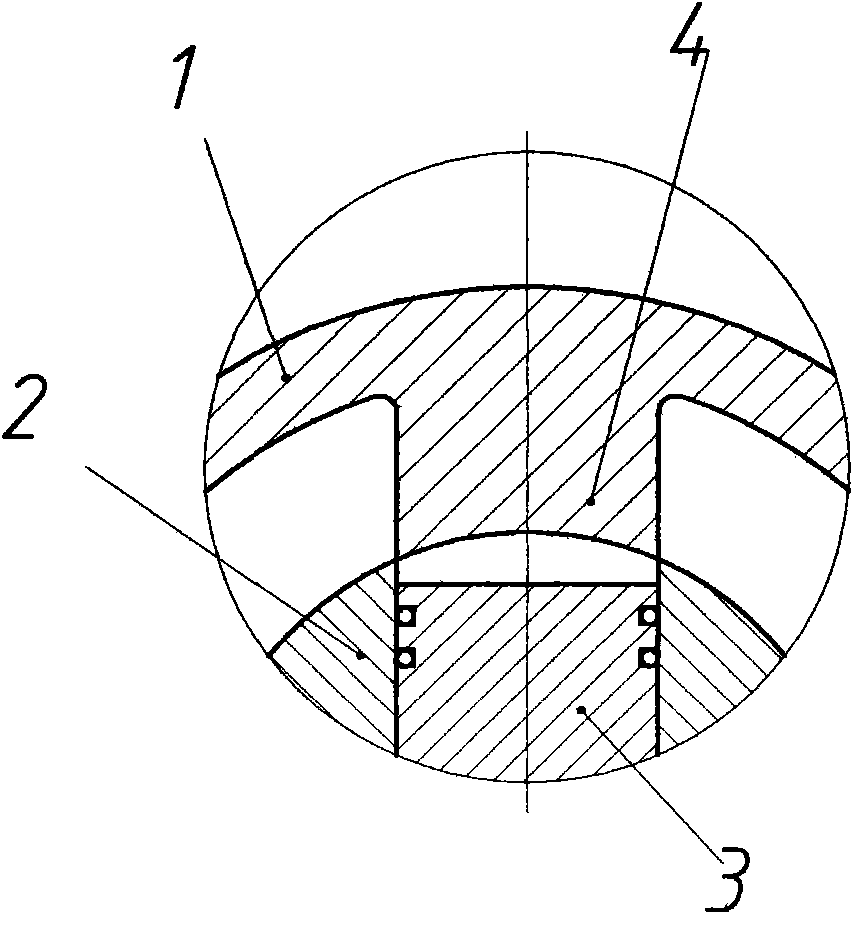

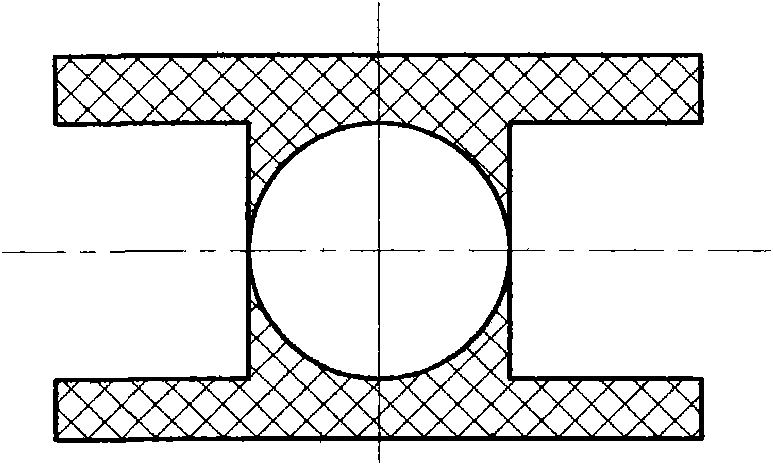

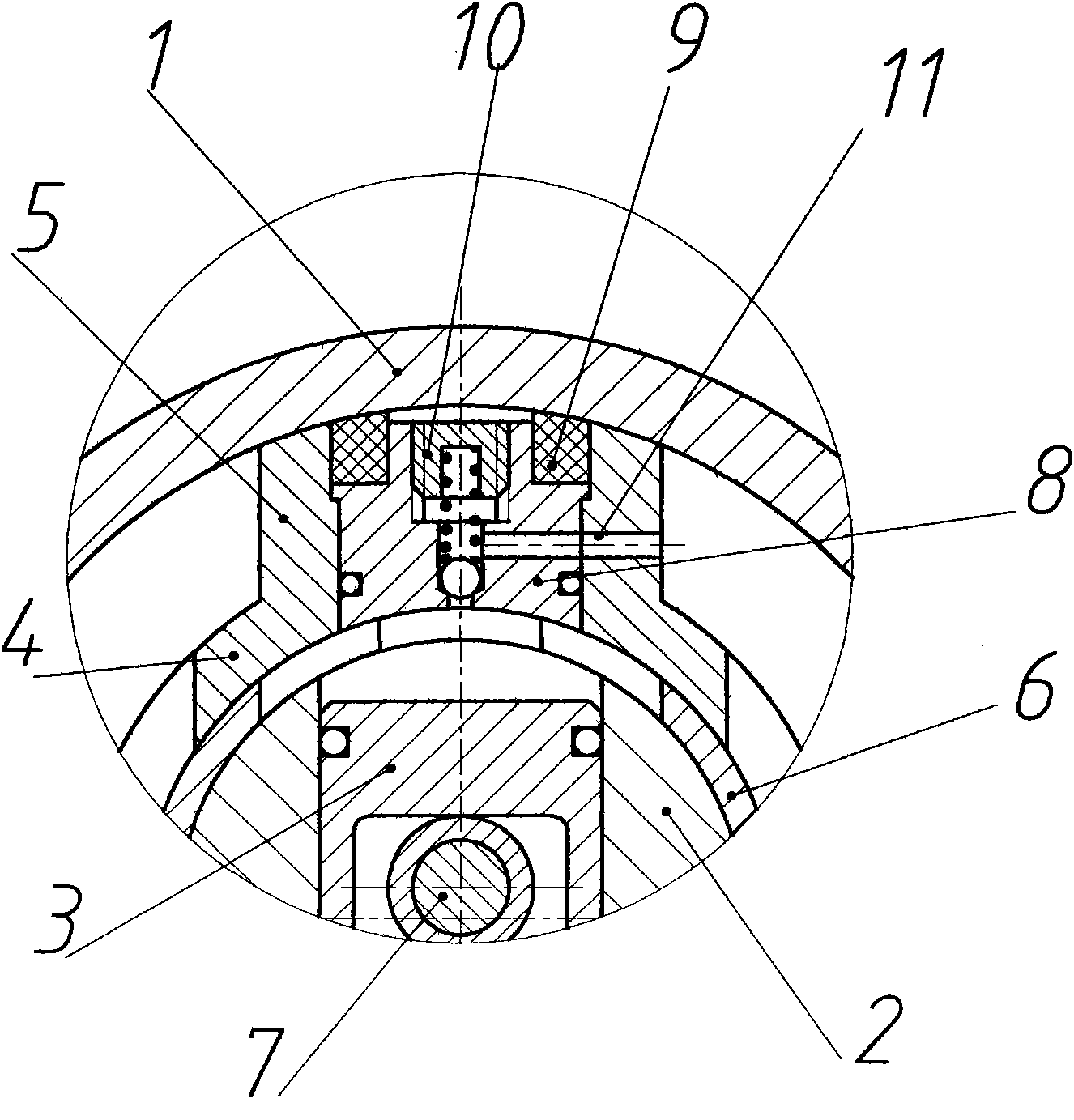

Small-flow high-lift radial piston pump

InactiveCN101871450AGood self-primingUnobstructed runnerRotary piston pumpsRotary piston liquid enginesViscous liquidRadial piston pump

The invention relates to a small-flow high-lift radial piston pump, which is mainly formed by a pump body, a pump cover, a piston, a rotor, an eccentric shaft and a motor. A rotor bushing is fixedly installed on the external circle of the rotor. A radial hole with smaller diameter which is coaxial with the radial through hole of the rotor is arranged on the rotor bushing. Narrow grooves which are communicated with the radial through hole are arranged on the two sides of the radial hole. A volute tongue bushing is installed in the pump body. A sealing compensation block is installed in the volute tongue of the volute tongue bushing. A discharge check valve is arranged in the sealing compensation block. The width of the volute tongue is larger than the width of a radial passage on the rotor bushing. By adopting the structure, the area and the length of the sealing surface of the clearance of the volute tongue are increased, the radial sealing clearance between the sealing compensation block and the rotor bushing is kept to be zero, the discharge pressure can be obviously improved and the goals of small flow and high lift are reached. Moreover, in combination with the advantages of an original rotor pump that the efficiency is high, the energy is saved, the self-absorption performance is superior, the runner is smooth and the pump can be used for delivering viscous liquid with fibrous or particle impurities and the like, and the application prospect of the small-flow high-lift radial piston pump is wide.

Owner:余文凌

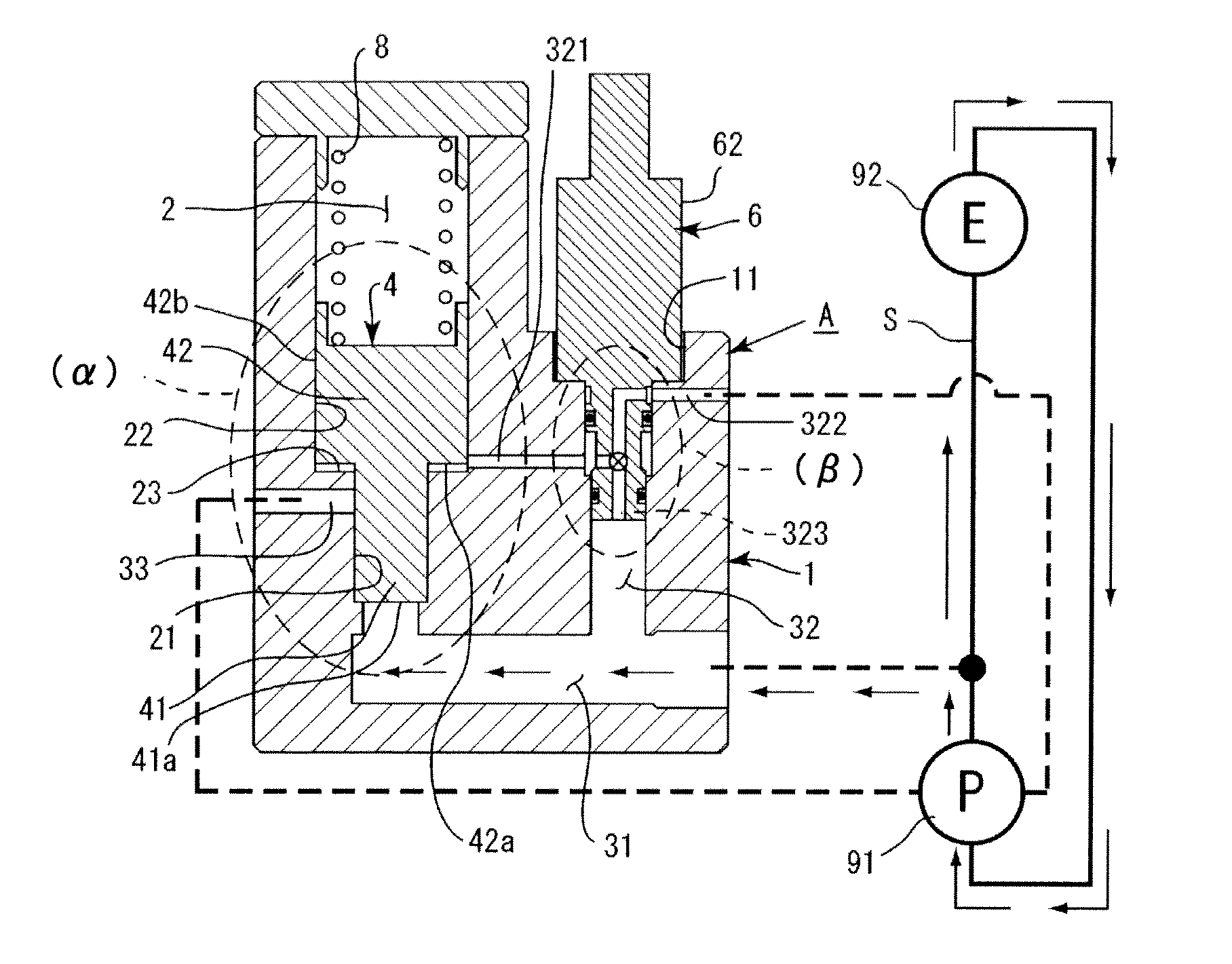

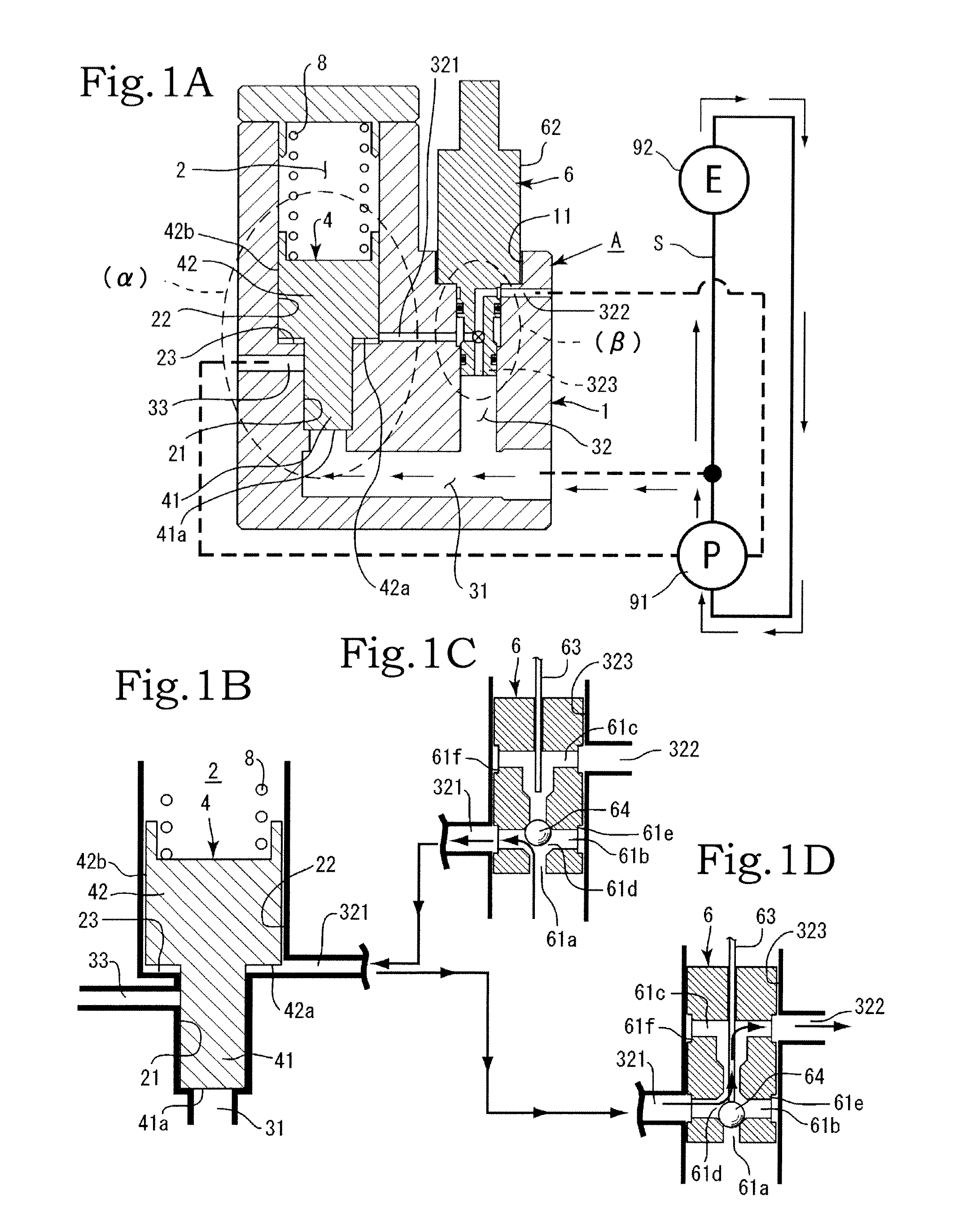

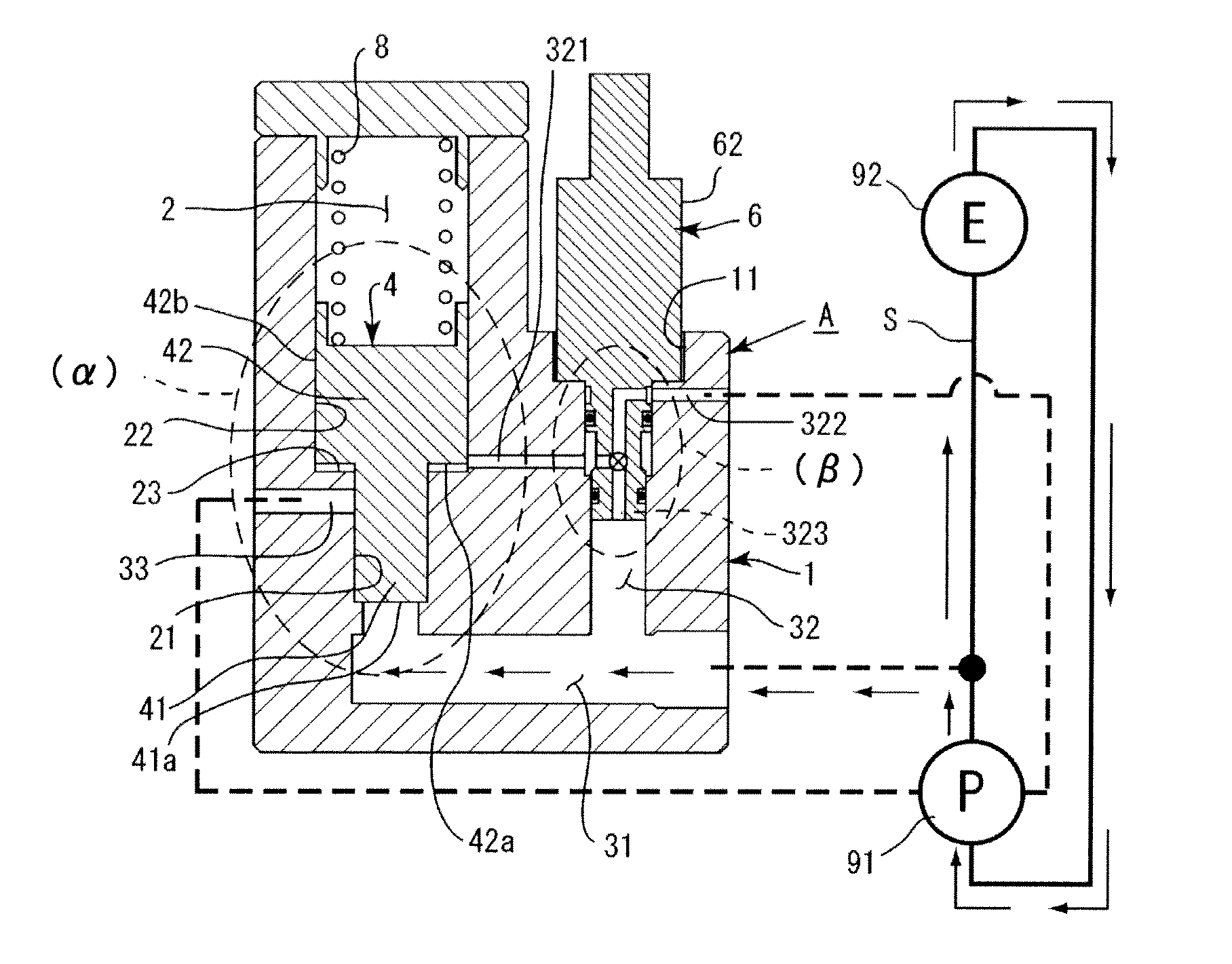

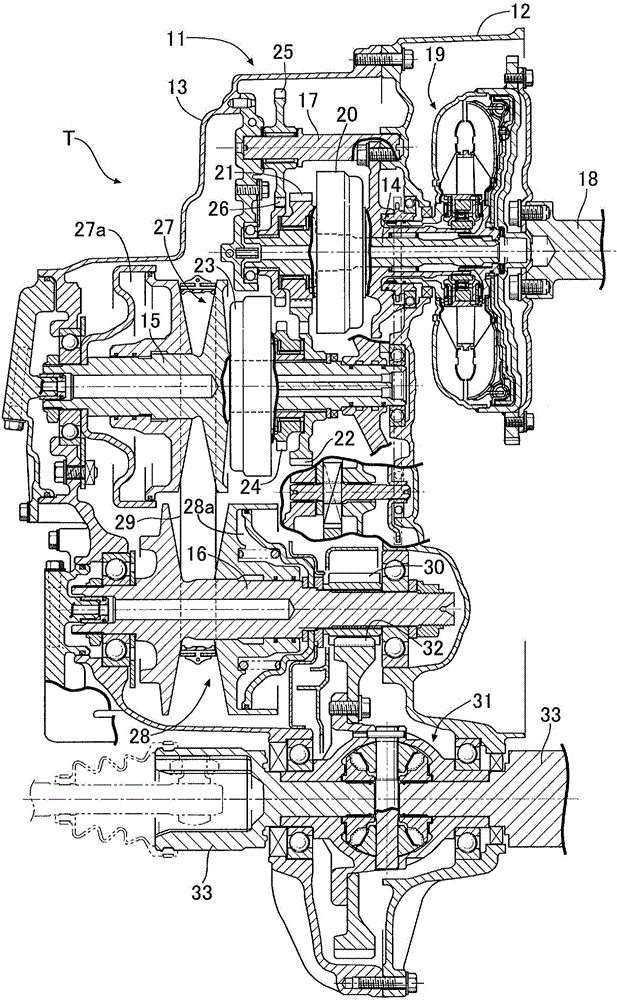

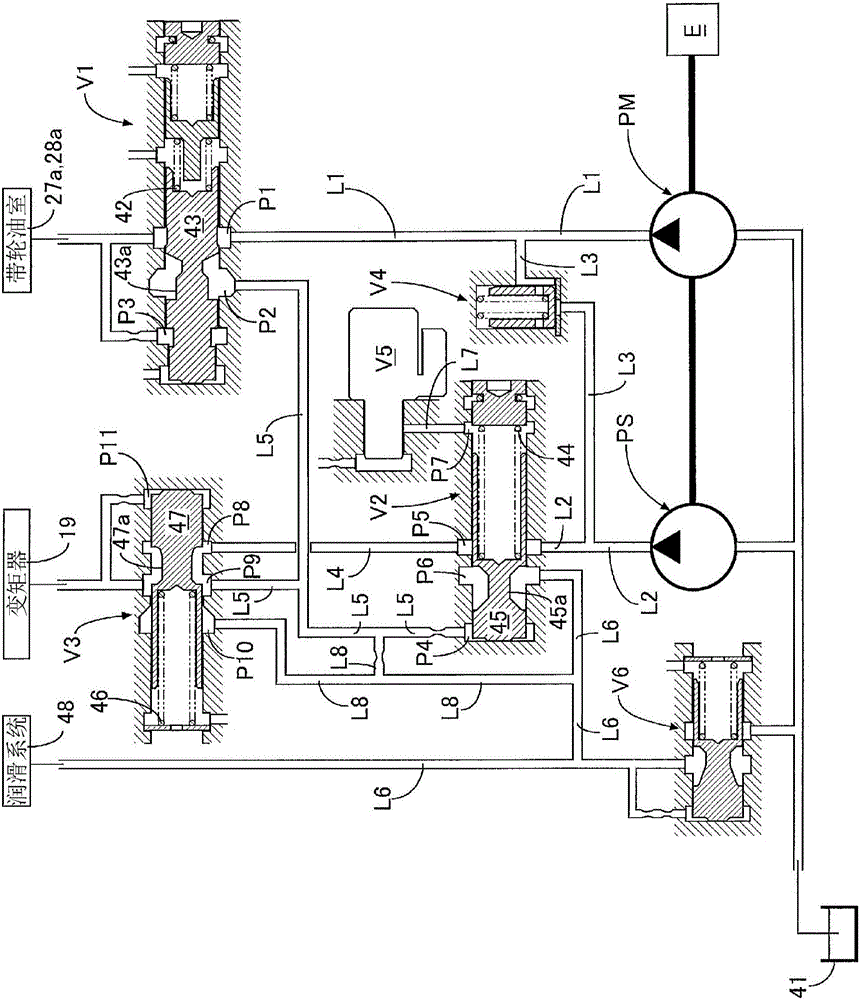

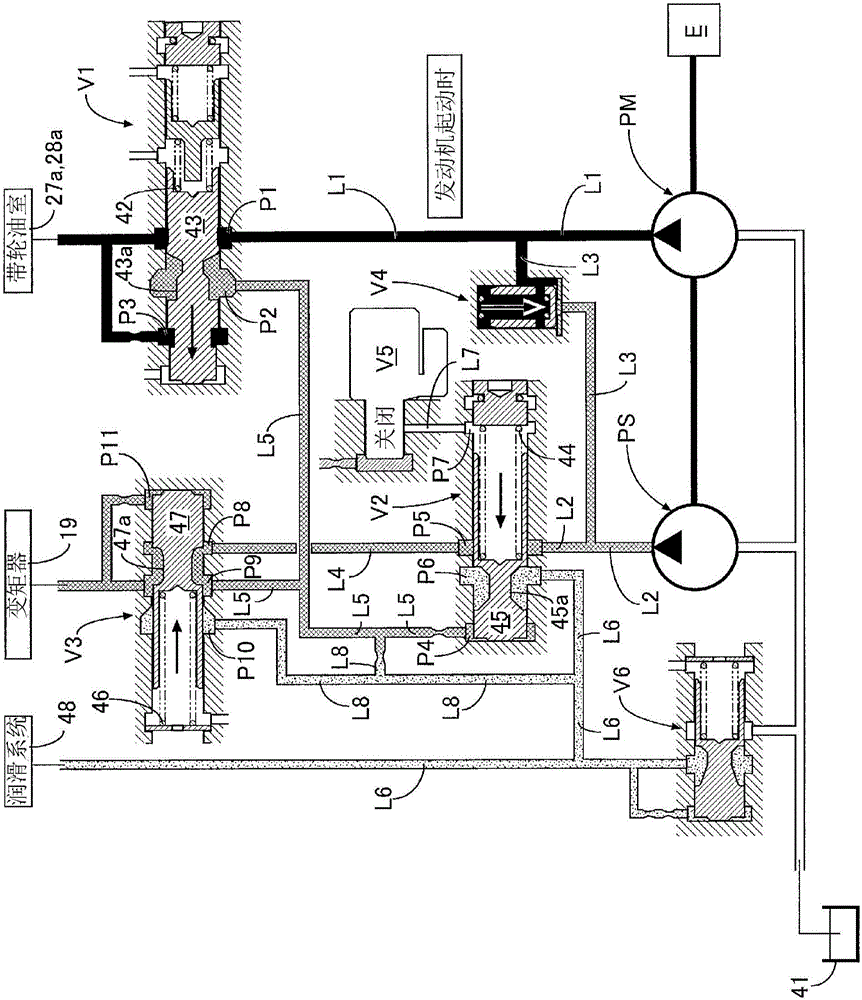

Hydraulic circuit for transmission

ActiveCN105874244AReduce driving loadVariable speedGearing controlGearing detailsInternal pressureHydraulic circuit

In a hydraulic circuit for a transmission, the circuit being provided with a main pump and a sub-pump, when the main pump (PM) and the sub-pump (PS) are driven by an engine (E) after being stopped for a long period of time, the oil pressure transmitted via a fifth oil path (L5) to a feedback port (P4) of a switching valve (V2) is insufficient because the internal pressure of a torque converter (19) is low, and because the connection between a first port (P5) and a second port (P6) of the switching valve (V2) is blocked, oil discharged by the sub-pump (PS) is not supplied to a lubricating system (48) via a sixth oil path (L6) and is supplied along the following route: second oil path (L2) - first port (P5) of switching valve (V2) - fourth oil path (L4) - first port (P8) and second port (P9) of second pressure regulating valve (V3) - torque converter (19). As a result, the interior of the torque converter (19) quickly fills with oil and drive force can be transmitted.

Owner:HONDA MOTOR CO LTD

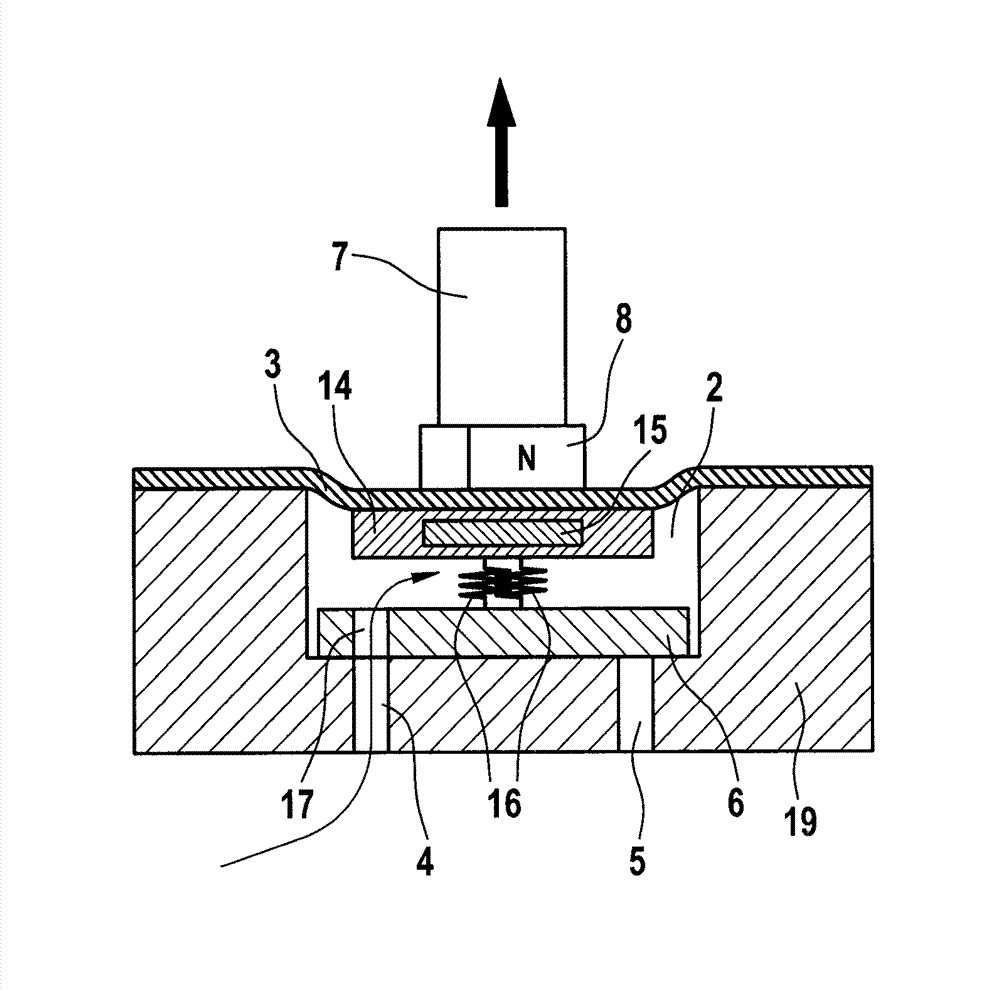

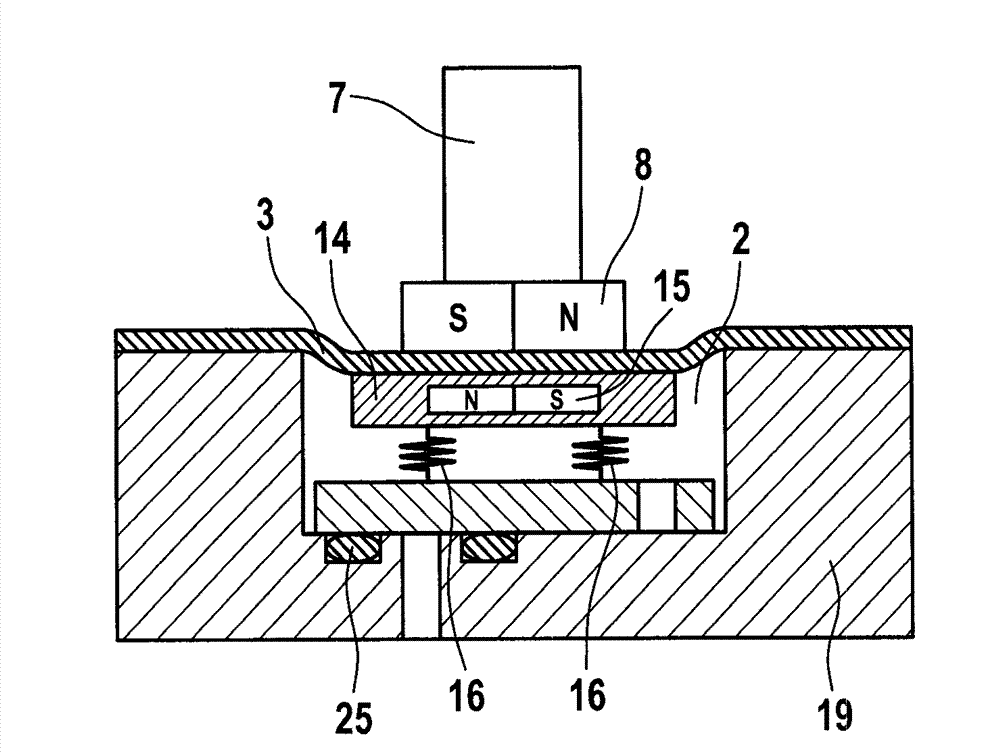

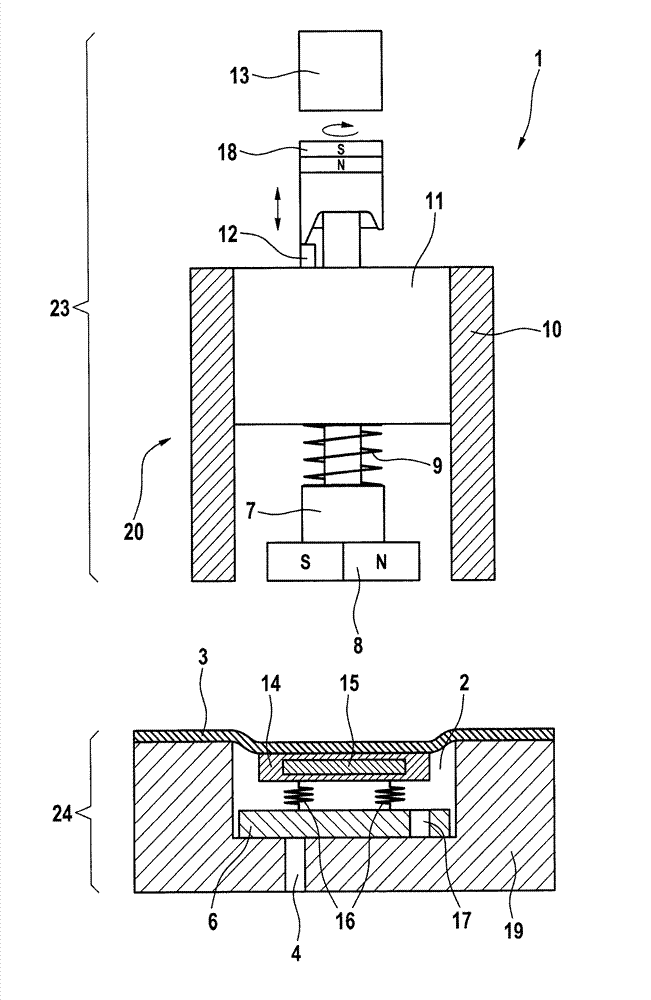

Micro-dosing pump and method for producing micro-dosing pump

InactiveCN103206363AHigh discharge pressureIncrease pressurePositive displacement pump componentsFlexible member pumpsEngineeringActuator

The invention relates to a micro-dosing pump and a method for producing the micro-dosing pump. The micro-dosing pump includes a pump chamber substrate, a flexible membrane, a fluid line, a valve disk, a magnetizable actuator disk, and a drive unit. The pump chamber substrate has a pump chamber. The flexible membrane is on a first side of the pump chamber substrate and covers the pump chamber in a fluid-tight manner. The fluid line is on a second side of the pump chamber substrate such that fluid can enter and leave the pump chamber. The valve disk, arranged inside the pump chamber, has a fluid through-opening and is configured to close the fluid line by rotating and to open it via the through-opening. The actuator disk is coupled to the valve disk such that rotating the actuator disk rotates the valve disk. The drive unit has a pump plunger configured to move the membrane for suction or ejection of fluid and to rotate the actuator disk.

Owner:ROBERT BOSCH GMBH

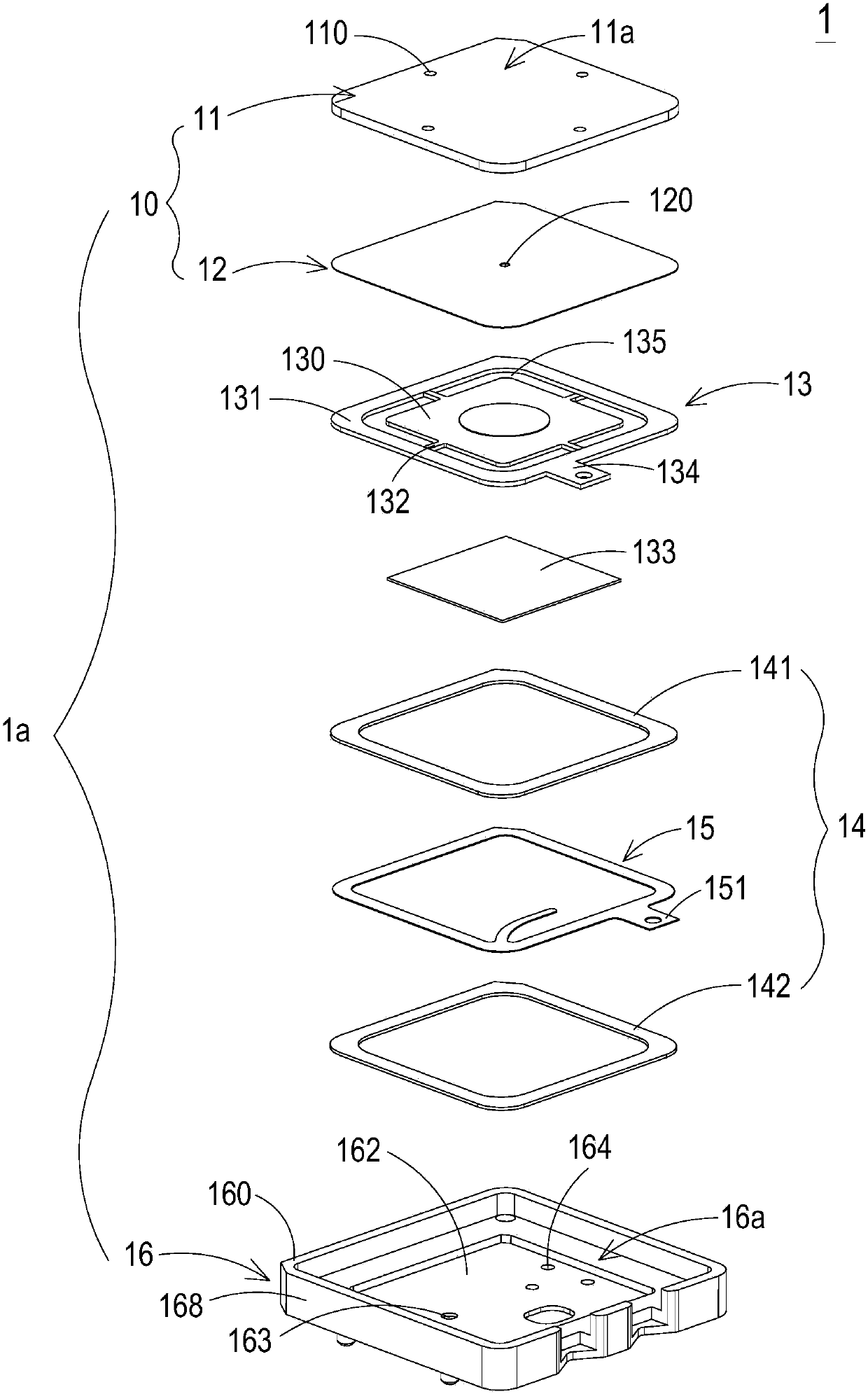

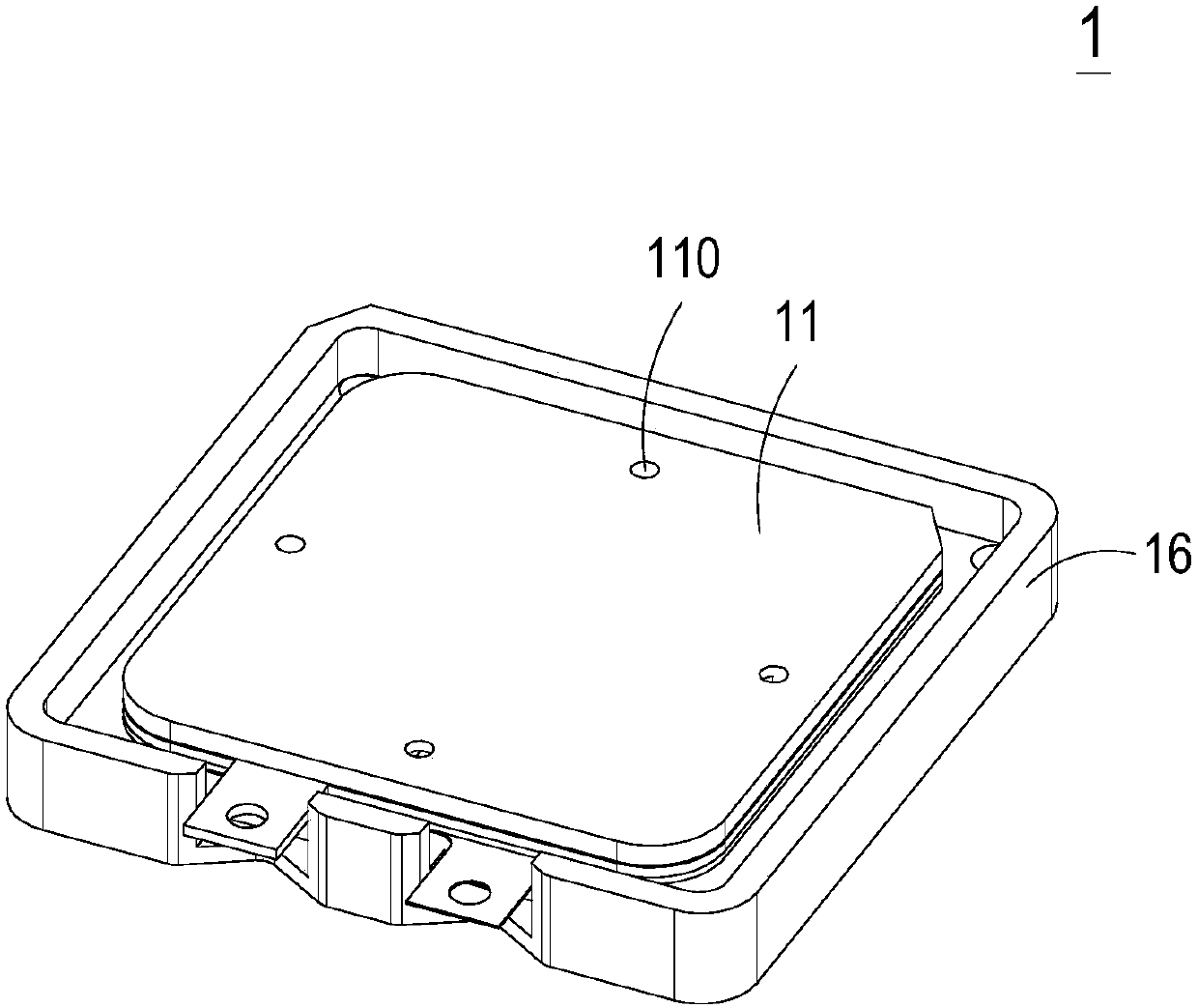

Micro fluid control device

ActiveCN107795465AVolume reduction and thinningReduce assembly errorsFlexible member pumpsPositive-displacement liquid enginesFluid controlPiezoelectric actuators

A micro fluid control device comprises a piezoelectric actuator and a shell. The piezoelectric actuator is provided with a suspension plate, an outer frame, a support and a piezoelectric ceramic plate. The suspension plate is in a square form and is provided with a first surface and a second surface, and the second surface is provided with a convex part. The outer frame is arranged outside the suspension plate in a surrounding mode and is also provided with a first surface and a second surface. The areas except the second surface of the outer frame and the convex part of the second surface ofthe suspension plate are all coplanar. The shell comprises a gas collection plate and a base. The gas collection plate is of a frame structure with a holding space. The base is formed by connecting agas inlet plate and a resonantor and is arranged in the holding space so as to close the piezoelectric actuator. A glue layer is arranged between the second surface of the outer frame of the piezoelectric actuator and the resonantor of the base, so that a needed depth of a compression cavity is maintained between the piezoelectric actuator and the resonantor.

Owner:MICROJET TECH

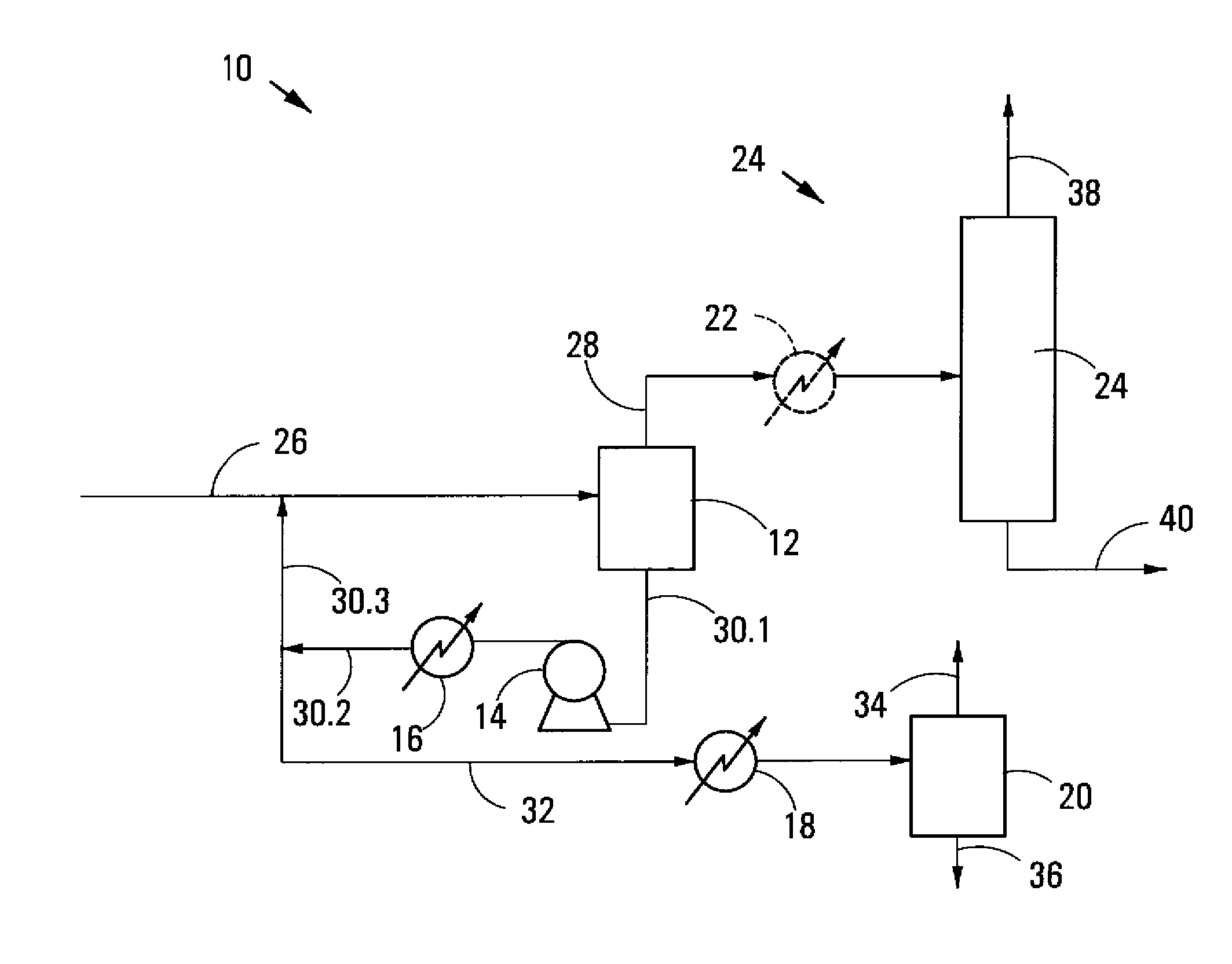

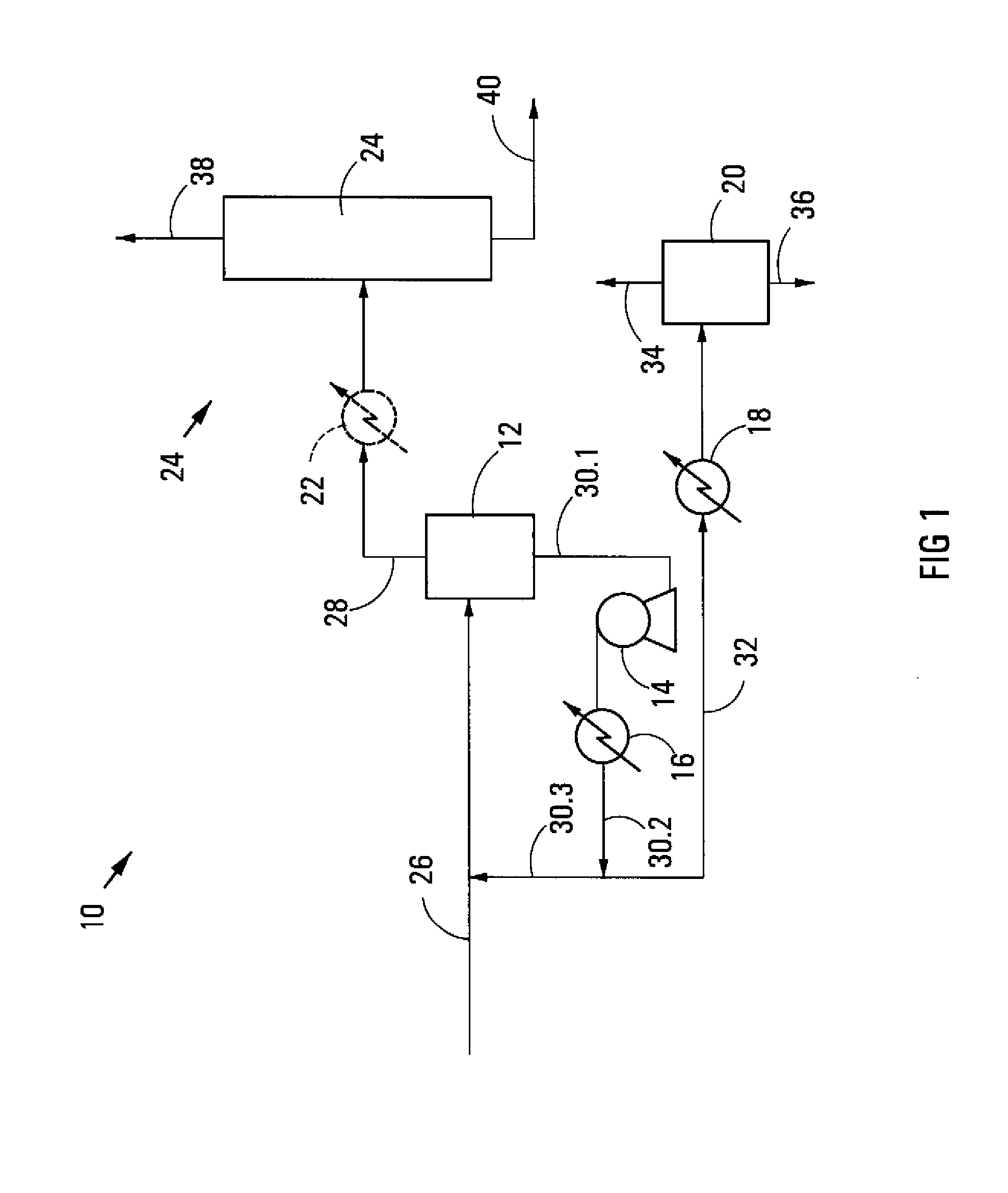

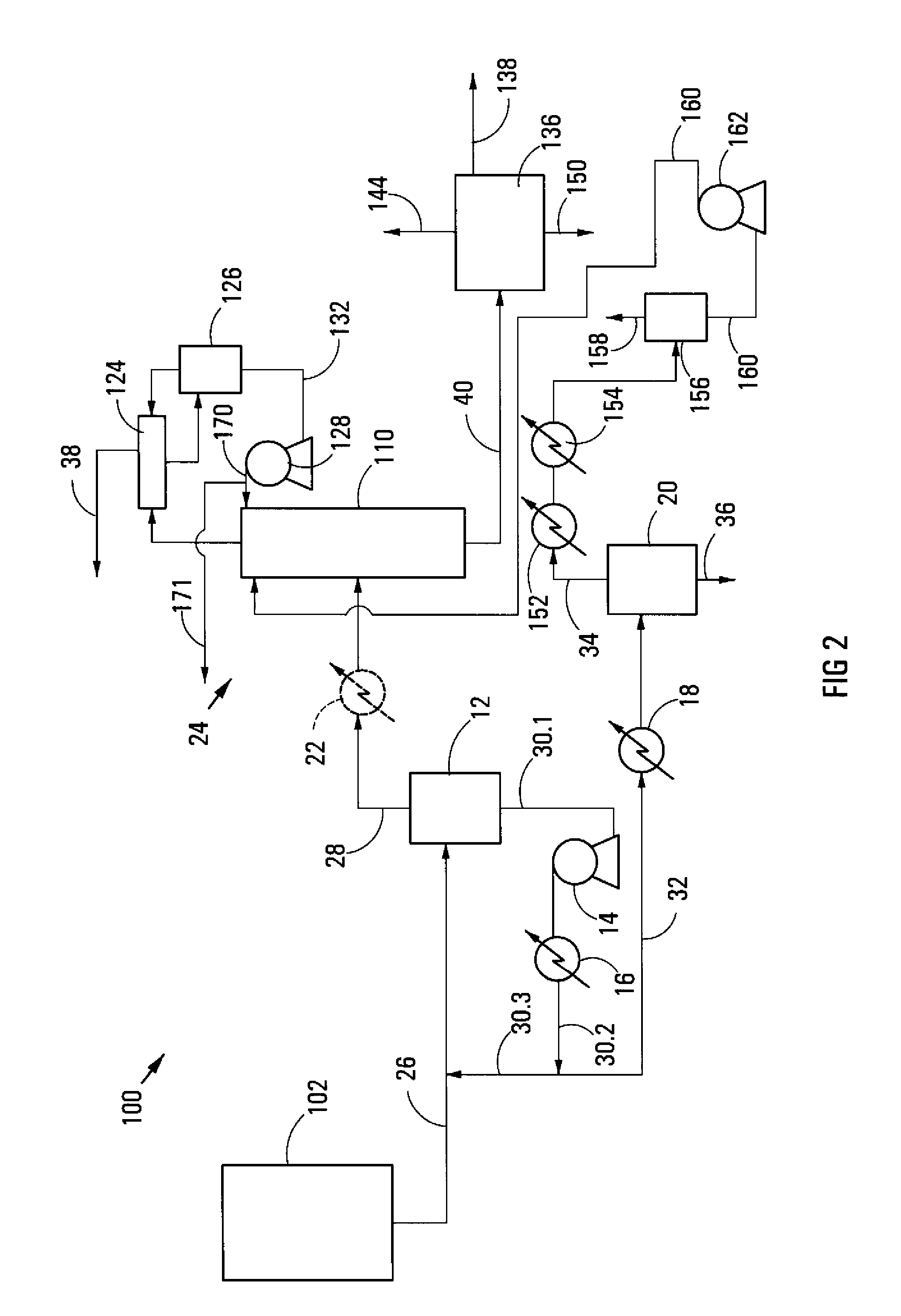

Separation of components from a multi-component hydrocarbon stream

ActiveUS20150133707A1Lower cost of capitalReduce operating costsCatalystsHydrocarbon preparation catalystsChemistryHigh pressure

A process (10) to separate a multi-component hydrocarbon stream (26) comprising ethylene, at least one polymer and other components includes flashing the multi-component hydrocarbon stream in a first flash stage (12) from an elevated pressure of more than 30 bar(a) and an elevated temperature in the range of 150° C. to 185° C. to a flash pressure in the range of 10 bar(a) to 30 bar(a), producing a first ethylene-containing vapour overheads product (28) at a pressure in the range of 10 bar(a) to 30 bar(a) and a first flash stage bottoms product (30.1) which includes some ethylene, the at least one polymer and some of the other components. The flash pressure and the elevated temperature of the multi-component hydrocarbon stream (26) are selected such that the first flash stage bottoms product (30.1) has a concentration of the at least one polymer of less than 5% by mass to render the viscosity of the first flash stage bottoms product (30.1) at the temperature of the first flash stage bottoms product (30.1) in the first flash stage (12) at less than 1000 cP at a shear of 1 per second. At least a portion of the first flash stage bottoms product (30.1) is heated to a temperature in excess of 150° C. to form a heated first flash stage bottoms product (30.2). A recycle portion (30.3) of the heated first flash stage bottoms product (30.2) is combined with the multi-component hydrocarbon stream (26), which is at a temperature less than 150° C. before combination with the recycle portion (30.3), thereby to heat the multi-component hydrocarbon stream (26) to the elevated temperature in the range of 150° C. to 185° C. At least a portion (32) of the first flash stage bottoms product and the first ethylene-containing vapour overheads product (28) are withdrawn from the first flash stage (12).

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Pump unit

InactiveCN1659380AReduce noiseReduce vibrationPump controlPositive-displacement liquid enginesGear pumpDischarge pressure

Provided is a pump unit capable of obtaining high discharging pressure by a motor having comparatively small torque, and decreasing noise / vibrations at the time of large flow operation. A first pump (1) made from a gear pump of a small capacity, and a second pump made from a gear pump of a large capacity are directly united by a variable speed motor (3) controlled in the number of revolutions by a control device (4). In a first mode. a discharge line (5) of the first pump is diverted from a discharging line (8) of the second pump, and the first pump is unloaded to carry out constant horsepower operation, thereby making a discharge fluid have high pressure by comparatively small torque. In a second mode, the discharging line (5) of the first pump is merged with the discharging line (8) of the second pump to carry out the constant horsepower operation, thereby discharging the large flow amount of the discharge fluid at a comparatively low number of revolutions. When the number of revolutions of the variable speed motor (3) is lower than a specified value, a switch valve (6) is switched from a merging state to a diverting state. When discharging pressure is lower than a specified value, the switch valve (6) is switched from the diverting state to the merging state.

Owner:DAIKIN IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com