Shaft seal apparatus

A technology of shaft sealing and fluid sealing, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of insufficient fluid circulation, insufficient fluid discharge, insufficient fluid discharge force, etc., to improve the discharge pressure, increase the The effect of large fluid discharge and easy cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

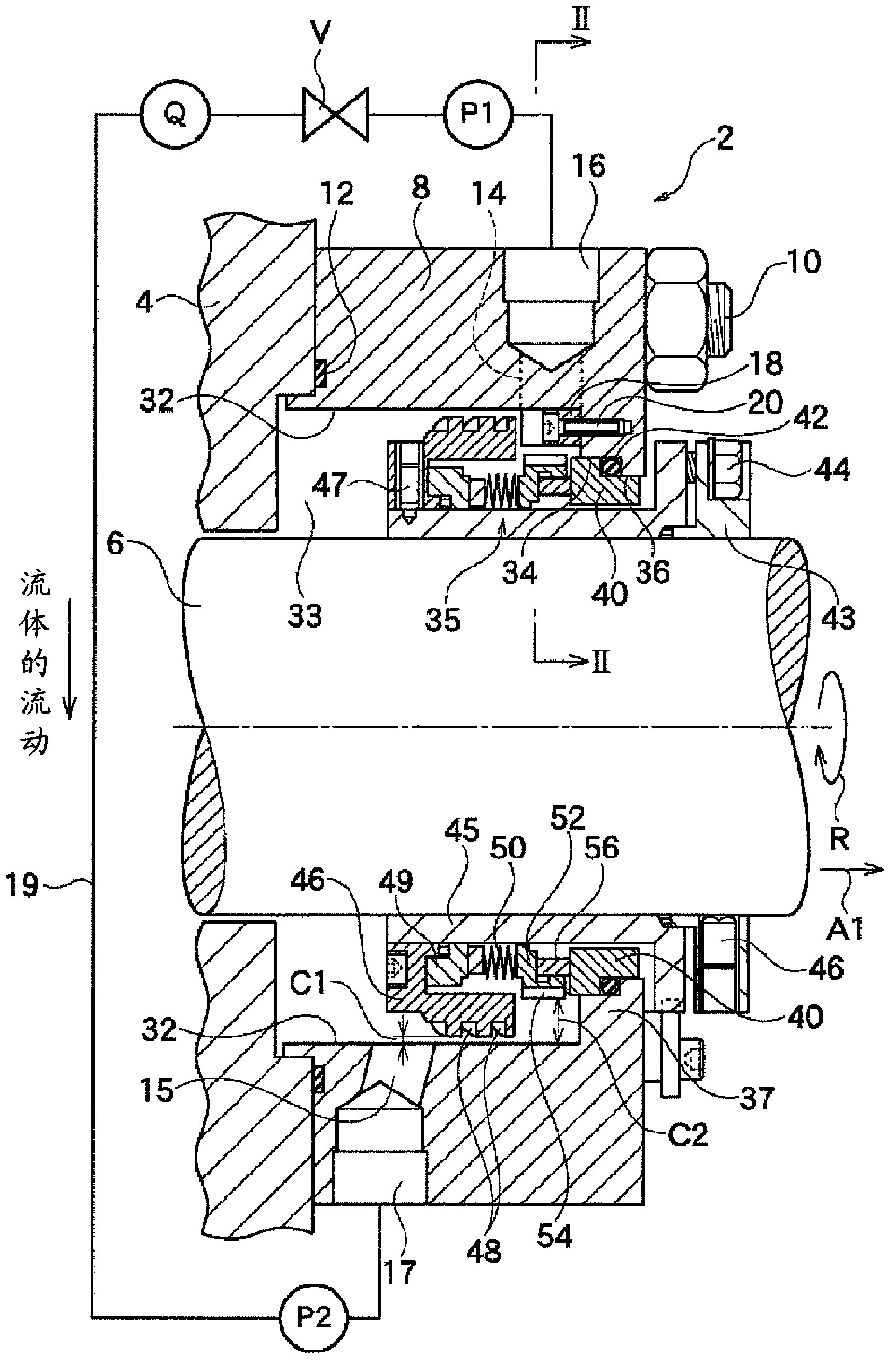

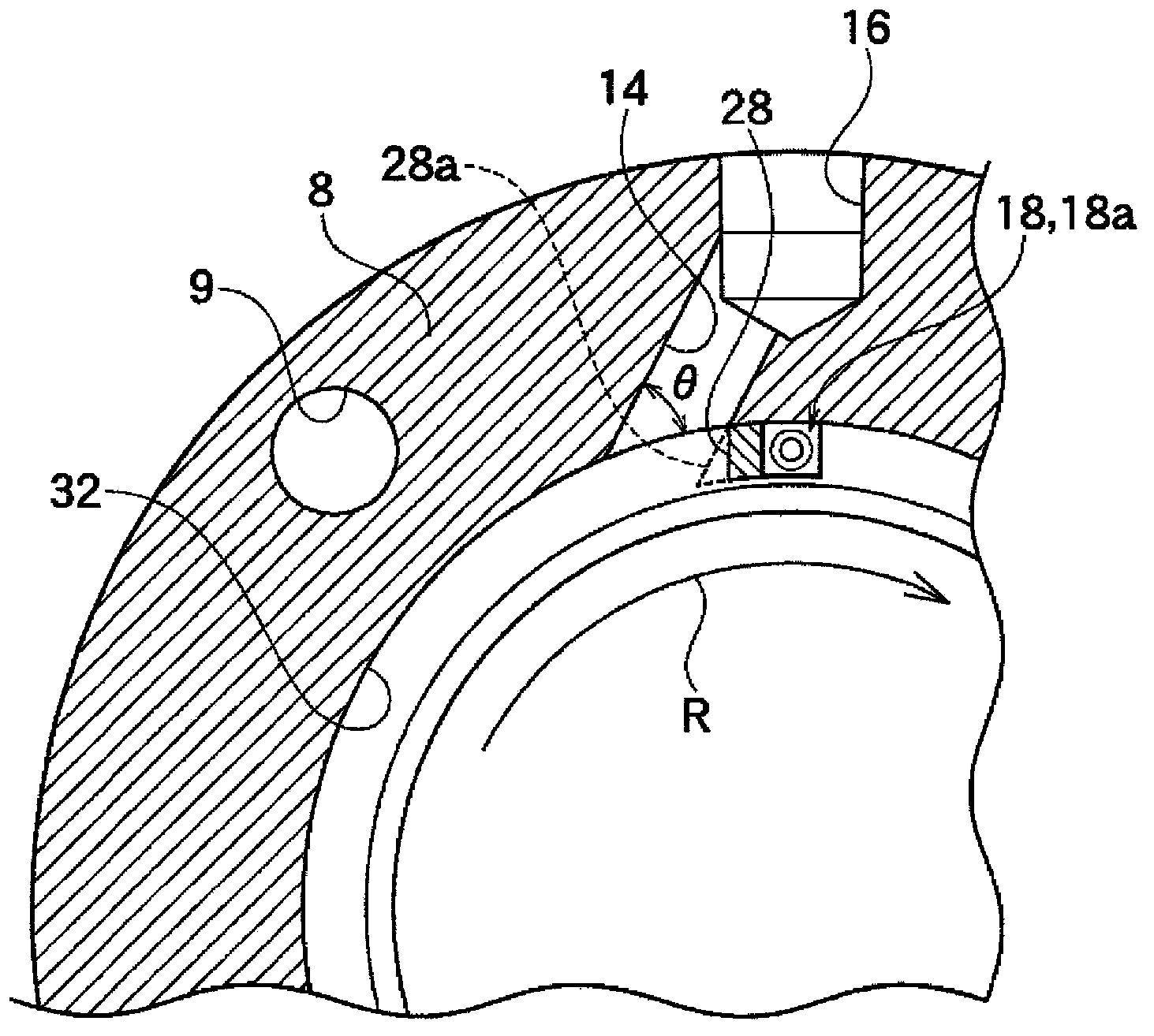

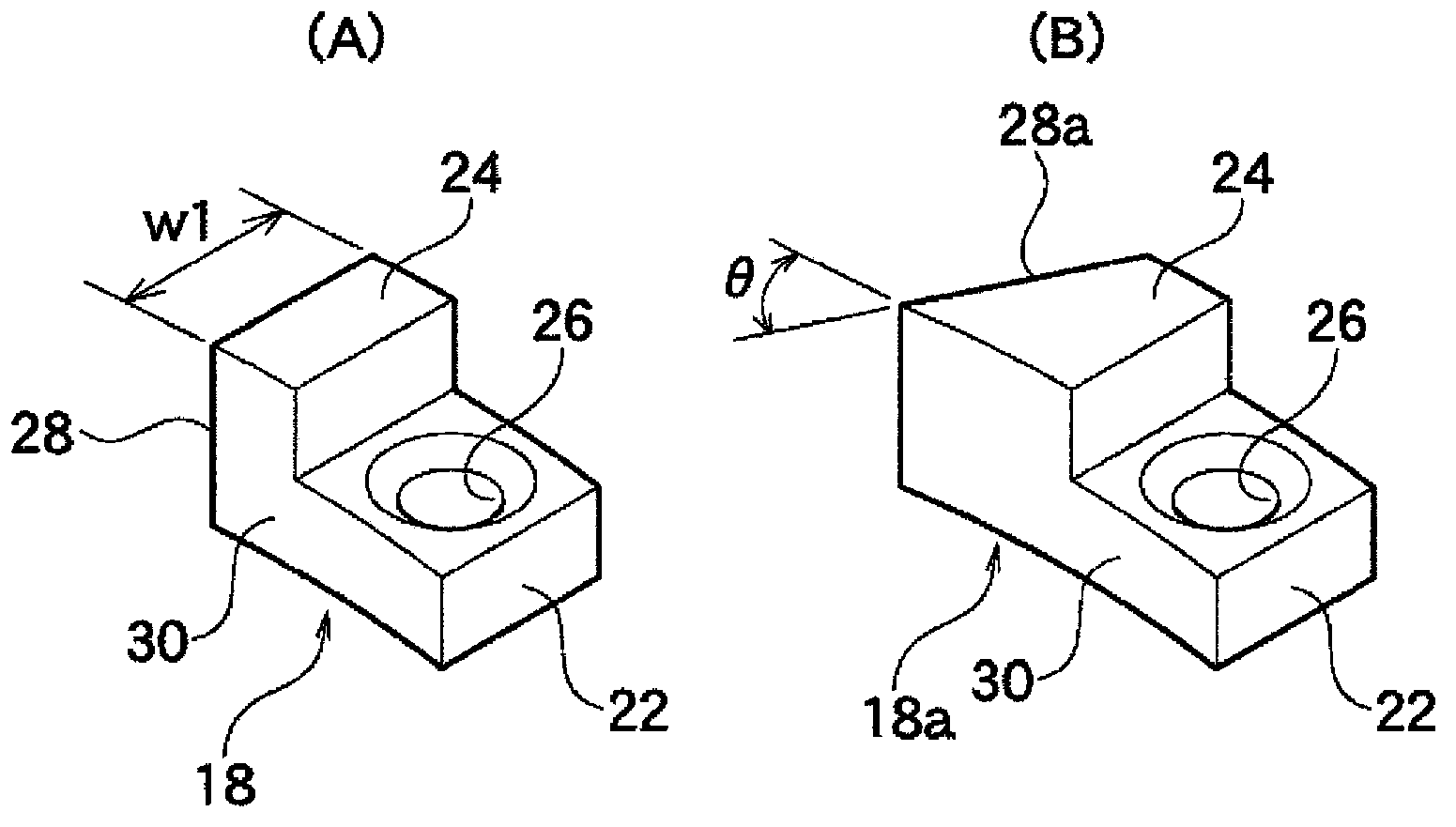

[0062] Such as figure 1 As shown, the shaft sealing device 2 according to one embodiment of the present invention is a device for realizing a fluid seal between a housing (stationary part) 4 and a rotating shaft (rotating body) 6 in a fluid machine such as a pump or a compressor.

[0063] The rotating shaft 6 extends inside the casing 4 , and an impeller (not shown) etc. is attached to the rotating shaft 6 , and the pressure of the processing fluid is controlled inside the casing 4 . The shaft sealing device 2 of this embodiment is configured so that the processing fluid inside the housing 4 does not leak to the outside from the gap between the housing 4 and the rotating shaft 6 at the end of the housing 4 along the rotating shaft 6 . figure 1 Only the shaft sealing device 2 installed on one end of the housing 4 along the rotating shaft 6 is shown in the figure, but there is also a shaft sealing device 2 installed on the other end of the housing 4 along the rotating shaft 6 C...

no. 2 approach

[0100] Figure 8 The other embodiments of the invention shown relate to shaft seals 2b different from figure 1 and Figure 7 The single type mechanical seal shown is a tandem type mechanical seal, and two first and second mechanical seals 35a and 35b are installed in the axial direction. In the following instructions, only the detailed description differs from Figure 1 to Figure 7 For the part of the embodiment shown, description of some common parts will be omitted.

[0101] Such as Figure 8 As shown, in this embodiment, the first sealing cover 8 a is detachably mounted and fixed on the outer end (in the direction of arrow A1 ) of the housing 4 via the second sealing cover 8 b through bolts 10 . The first seal member 12a such as a gasket is sandwiched between the first seal cover 8a and the second seal cover 8b, and the second seal member 12b is sandwiched between the second seal cover 8b and the case 4 to seal the gap between them.

[0102] The same mechanical seal de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com