Micro-dosing pump and method for producing micro-dosing pump

A quantitative supply, miniature technology, applied to the components, pumps, pump elements of the pumping device for elastic fluids, etc., can solve the problem of the limit of miniaturization, and achieve the effect of high discharge pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

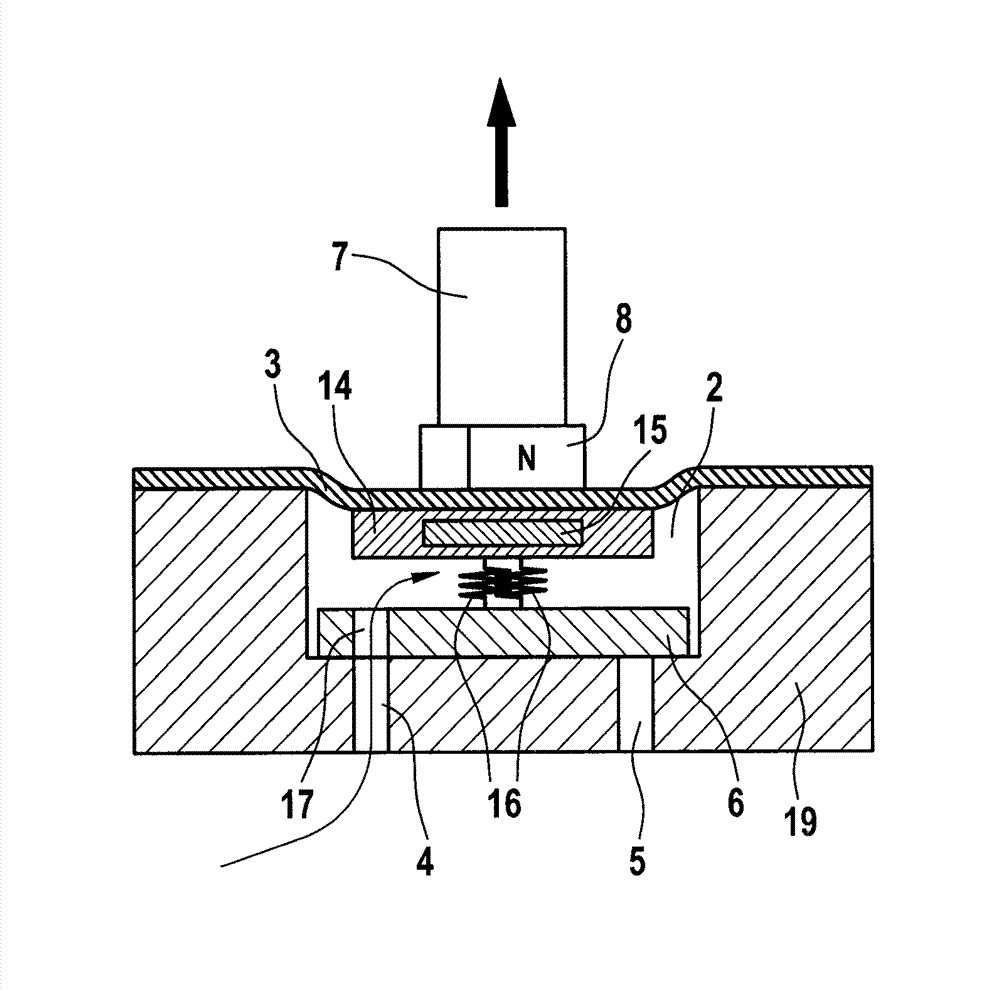

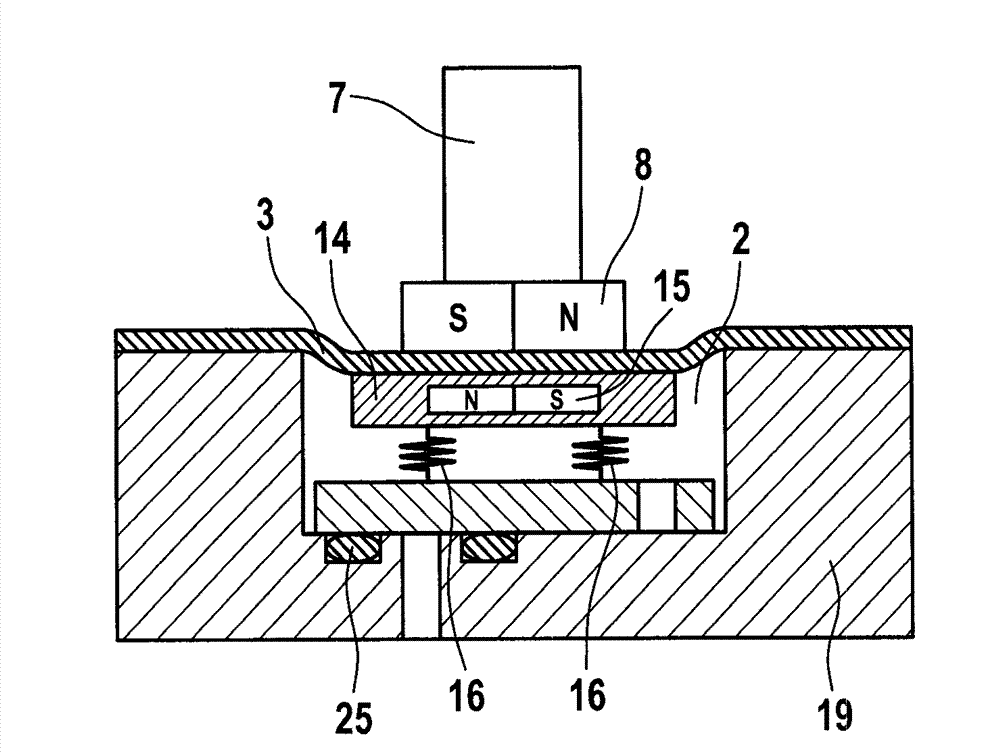

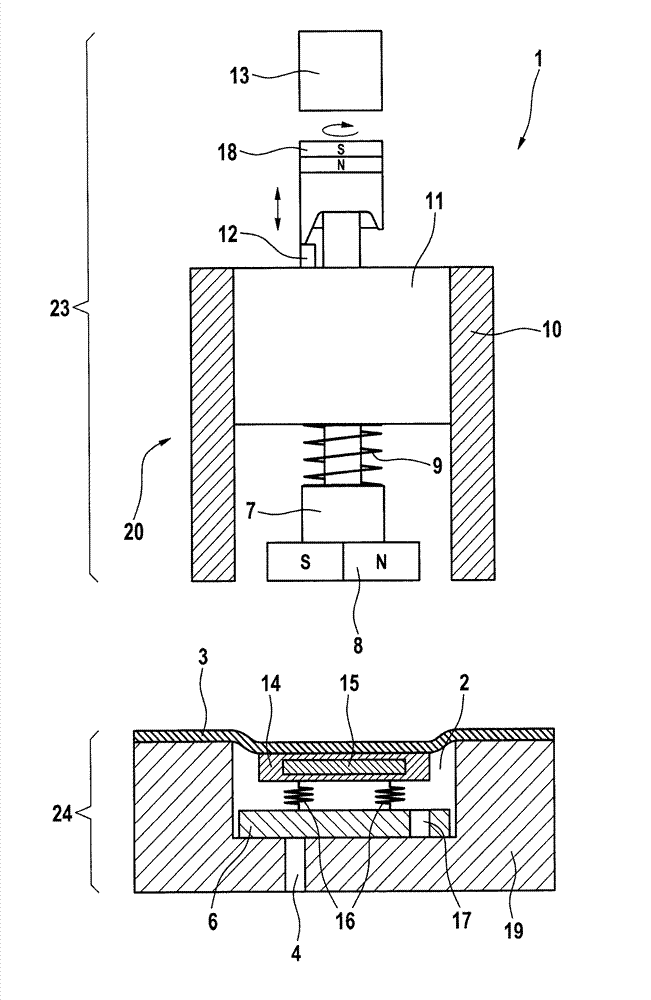

[0037]FIG. 1 shows a schematic cross-sectional view of a micro-dosing pump 1 . The micro dosing pump basically has a durable unit 23 and a disposable unit 24 . The disposable unit 24 has a pump chamber base 19 with the pump chamber 2 arranged therein. The pump chamber base 19 can be formed, for example, by injection molding from polycarbonate, polypropylene, PVC, polystyrene, polytetrafluoroethylene (Teflon) and / or PFPE. However, other materials are also suitable for the manufacture of the pump chamber substrate 19, such as metal and / or semiconductor materials. The flexible membrane 3 is fluid-tightly connected to the pump chamber base 19 on one side with few bases. The pump chamber base 19 has at least one fluid line 4 which enables fluid to flow into and out of the pump chamber 2 of the pump chamber base 19 . Furthermore, a rotatable valve disk 6 is arranged in the pump chamber 2 . The rotatable valve disk 6 has a fluid passage opening 17 and is arranged above the fluid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com