Pump unit

A pump unit, fixed volume technology, applied in pump control, mechanical equipment, machine/engine, etc., can solve the problems of large-scale pump unit cost, high speed, high noise and vibration of pump unit, and achieves omission of wiring and simple operation. , the effect of preventing fluctuations in pressure and flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the present invention will be described in detail with reference to the illustrated embodiments.

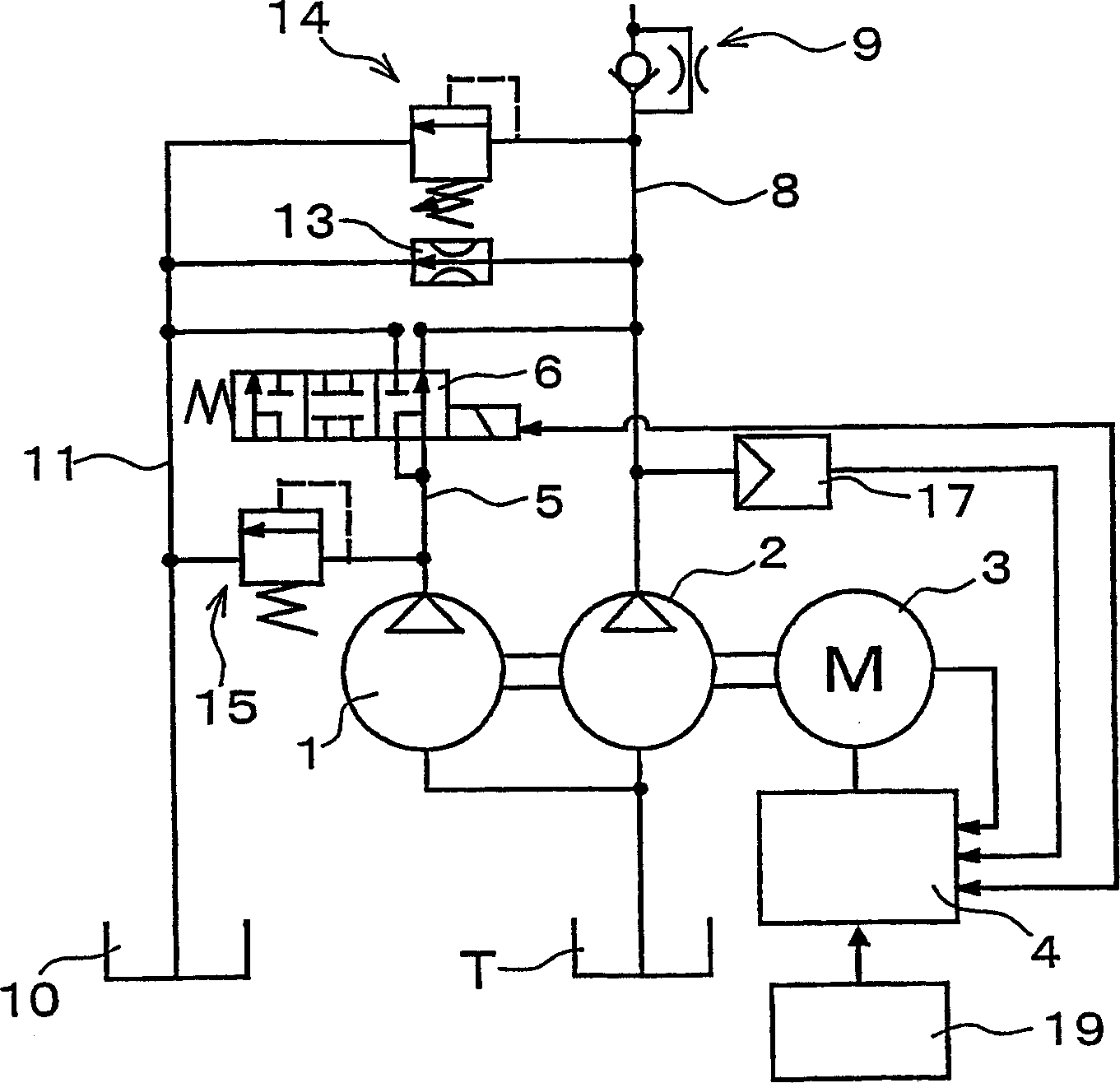

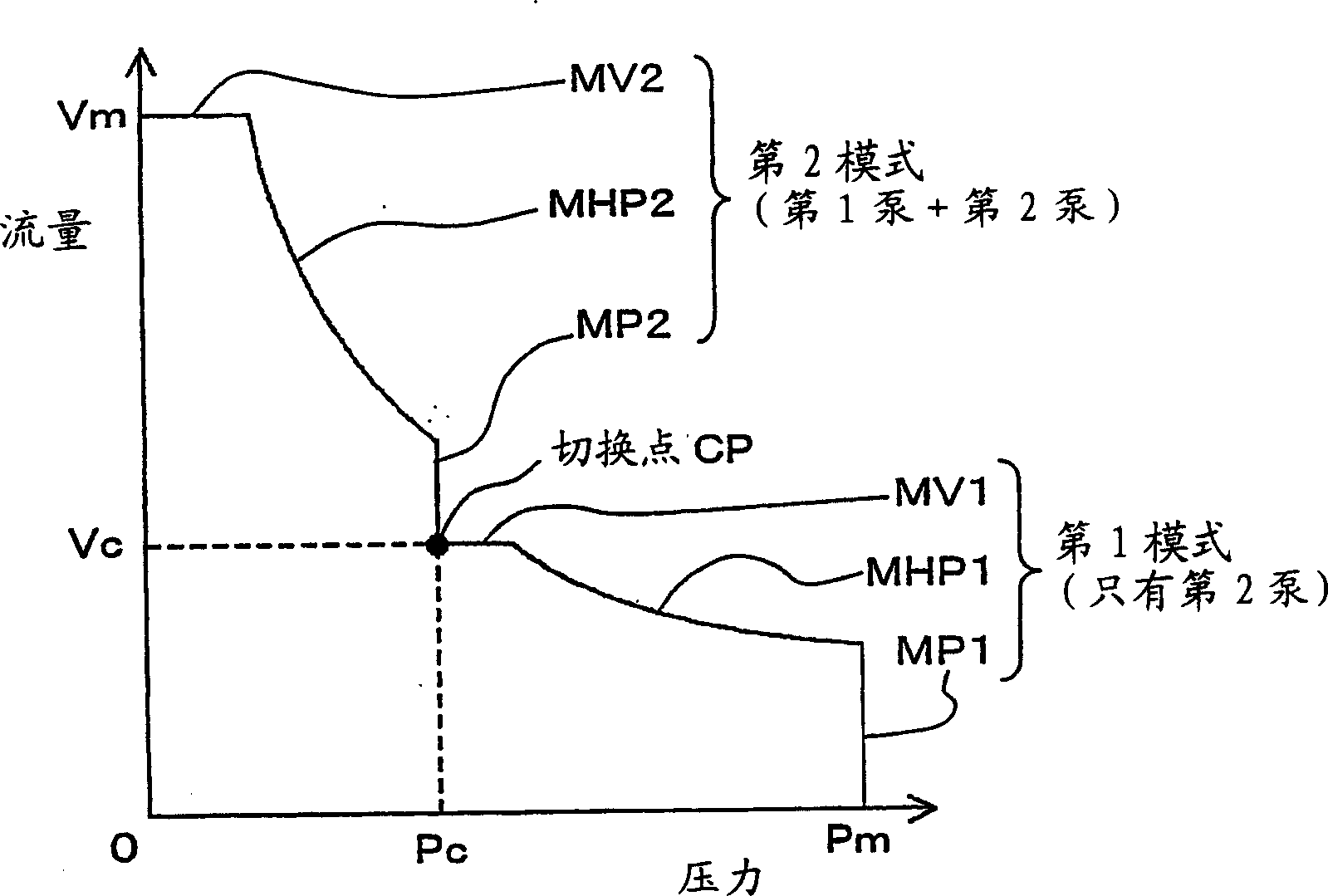

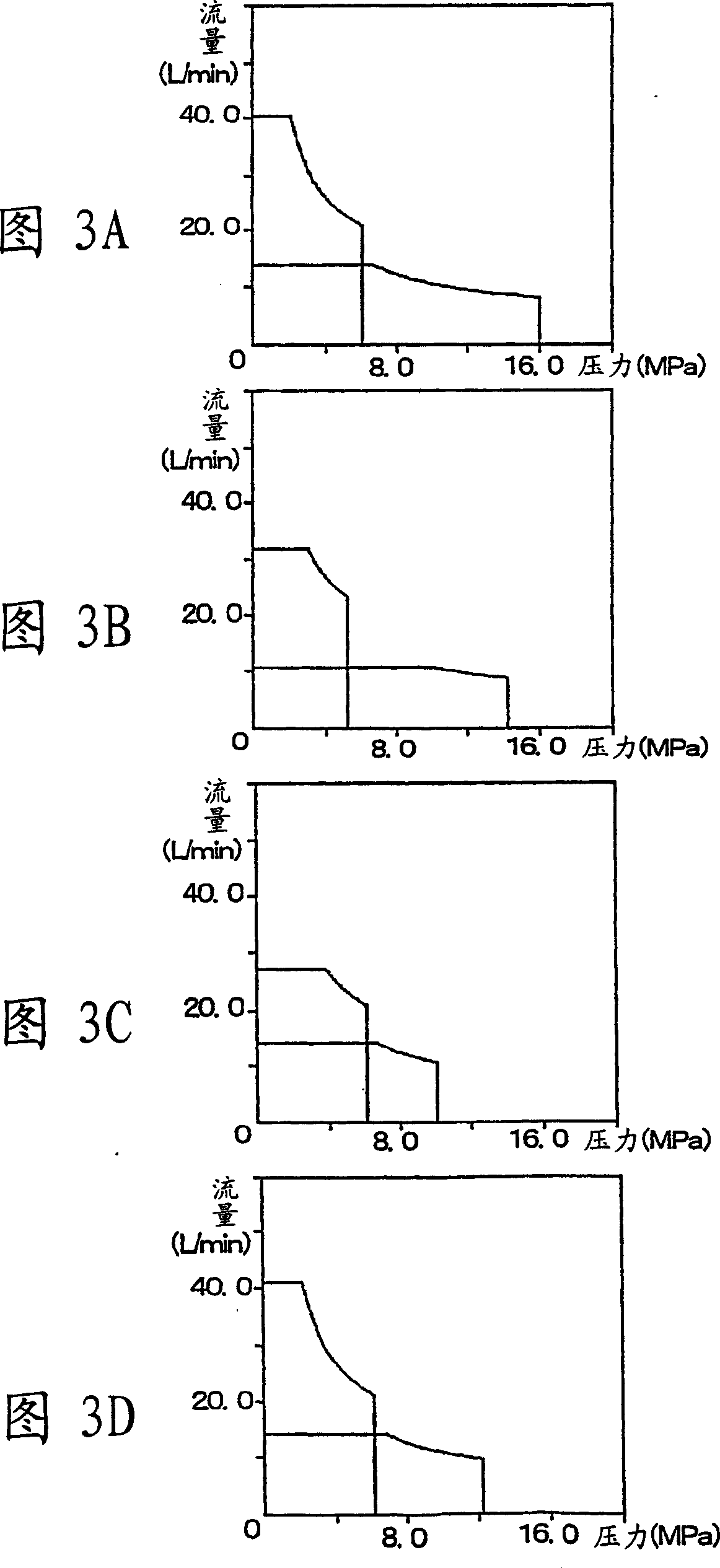

[0024] figure 1 It is a figure which shows the pump unit which concerns on embodiment of this invention. This pump unit is a pump unit that supplies the working fluid in the oil tank T to a hydraulic drive device such as a hydraulic cylinder (not shown). The pump unit has a first pump 1 as a large-capacity first fixed-displacement pump, and a second pump 2 as a small-capacity second fixed-displacement pump directly connected to the first pump 1 . The first pump 1 is composed of a 5.5cc / rev gear pump, and the second pump 2 is composed of a 3.5cc / rev gear pump. The first pump 1 and the second pump 2 are connected to a variable speed motor 3 , and the variable speed motor 3 is electrically connected to a control device 4 . The discharge passage 5 of the first pump is connected to a switching valve 6 , and can be switched to the discharge passage 8 of the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com