Patents

Literature

145results about How to "Improve crushing ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

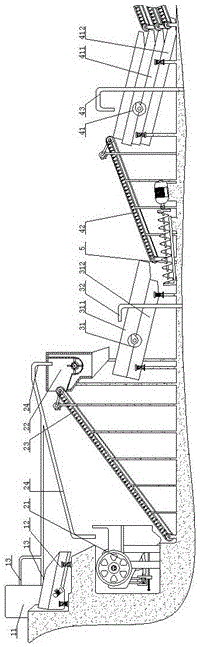

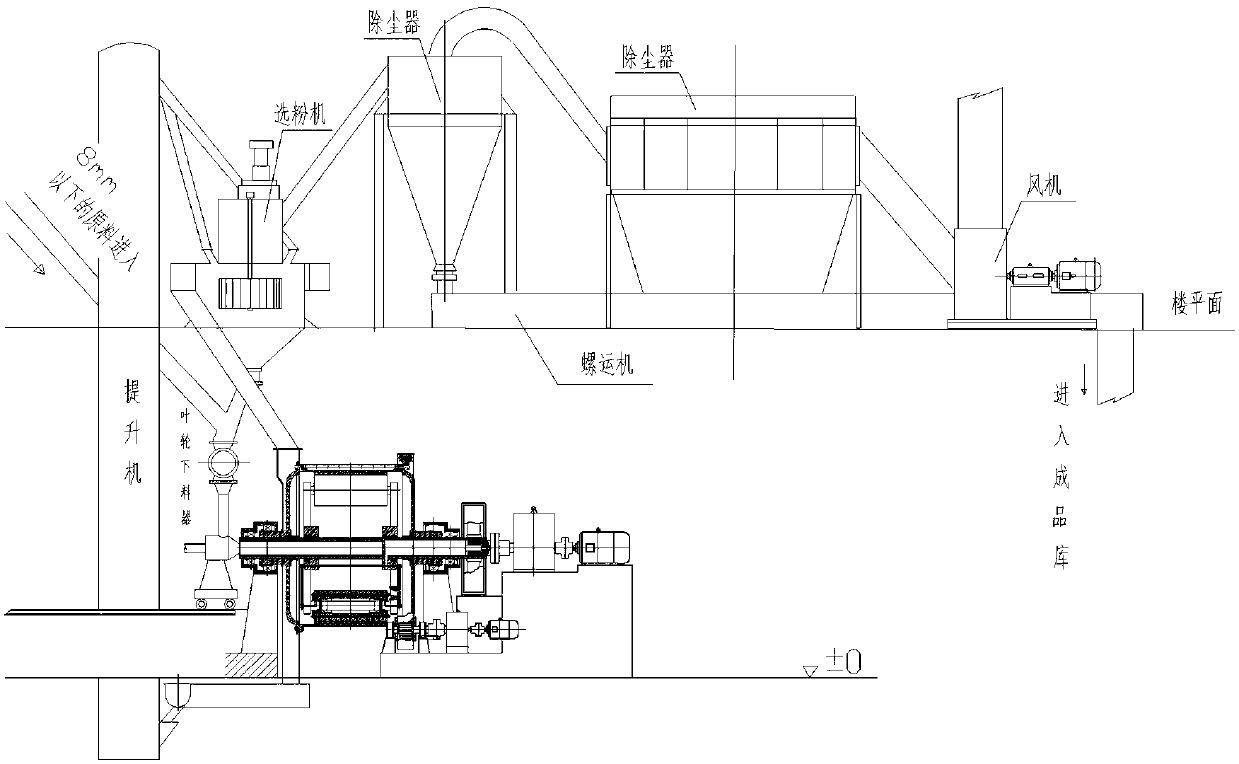

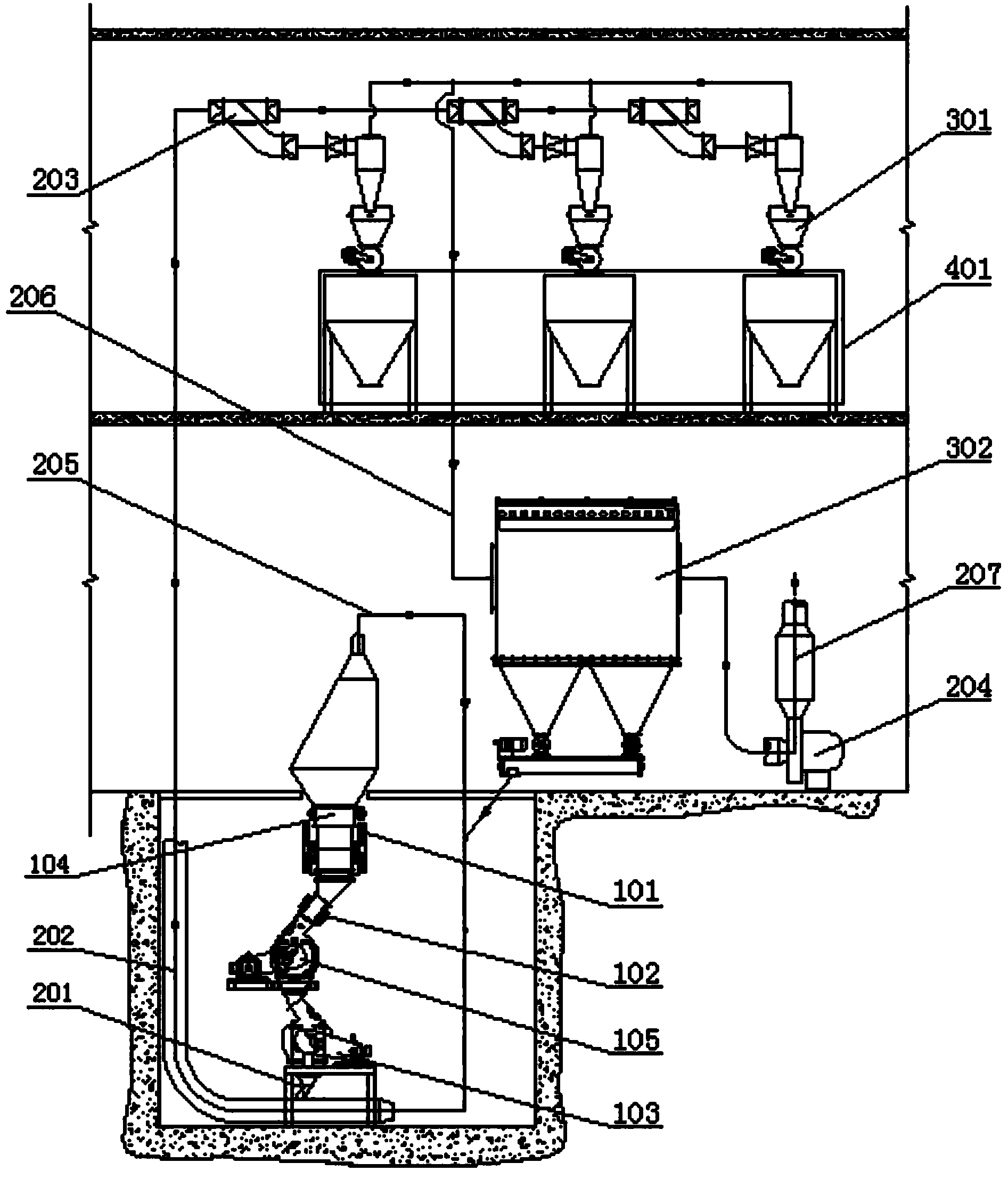

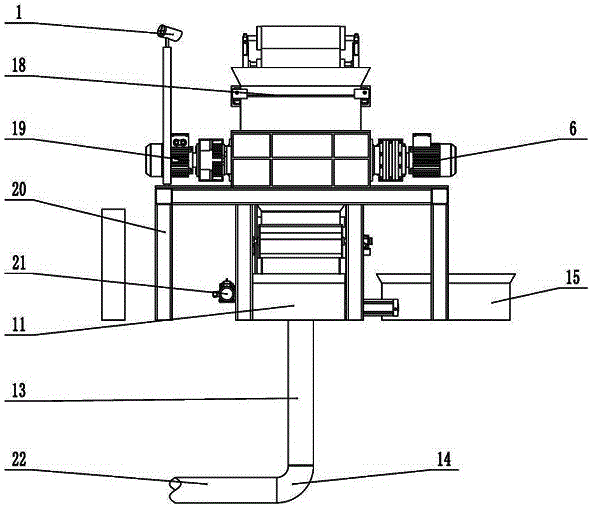

Mudstone environmental protection regeneration system

The invention discloses a mudstone environmental protection regeneration system. The mudstone environmental protection regeneration system comprises a feeding mechanism; the feeding mechanism comprises a stock bin, a vibrating feeding machine, a crushing mechanism which comprises a jaw type rough crushing machine and a hammer type fine crushing machine, a sand and gravel separating mechanism, a gravel fine separating mechanism and a mud and sand water passing mechanism; the sand and gravel separating mechanism comprises a rough separating vibrating screen; the rough separating vibrating screen comprises a gravel layer and a mud and sand layer; the gravel fine separating mechanism comprises a fine separating vibrating screen; the fine separating vibrating screen comprises a multi-layer finished product layer and a fine sand layer; the mud and sand water passing mechanism comprises a spiral conveyer; other devices except the spiral conveyer is provided with a spraying water pipe respectively. The mudstone environmental protection regeneration system can crush and clean gravel residues containing soil to enable the gravel residues to be recycled and has huge economic benefits and a remarkable environmental friendly effect.

Owner:魏根友

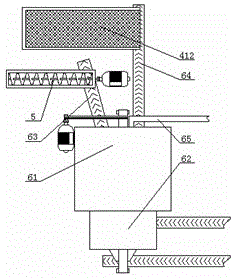

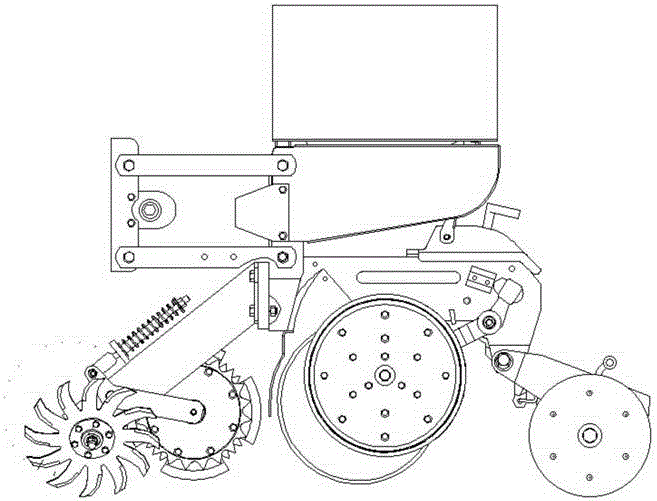

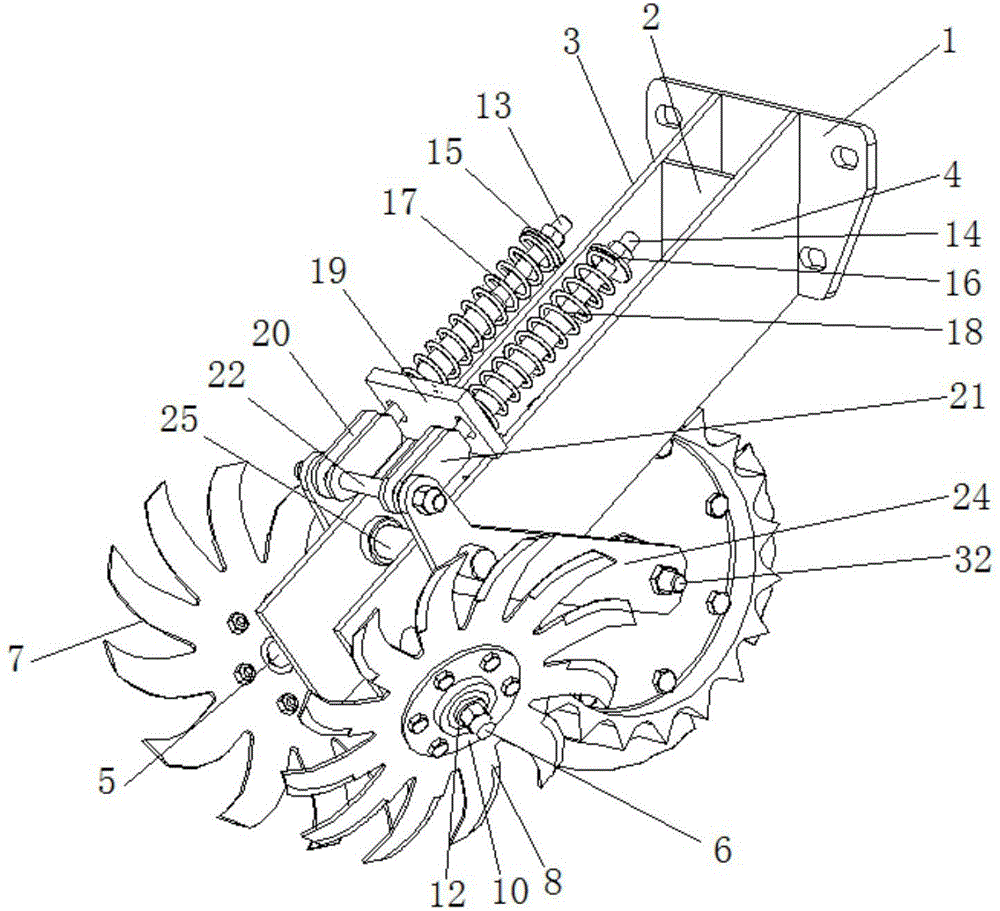

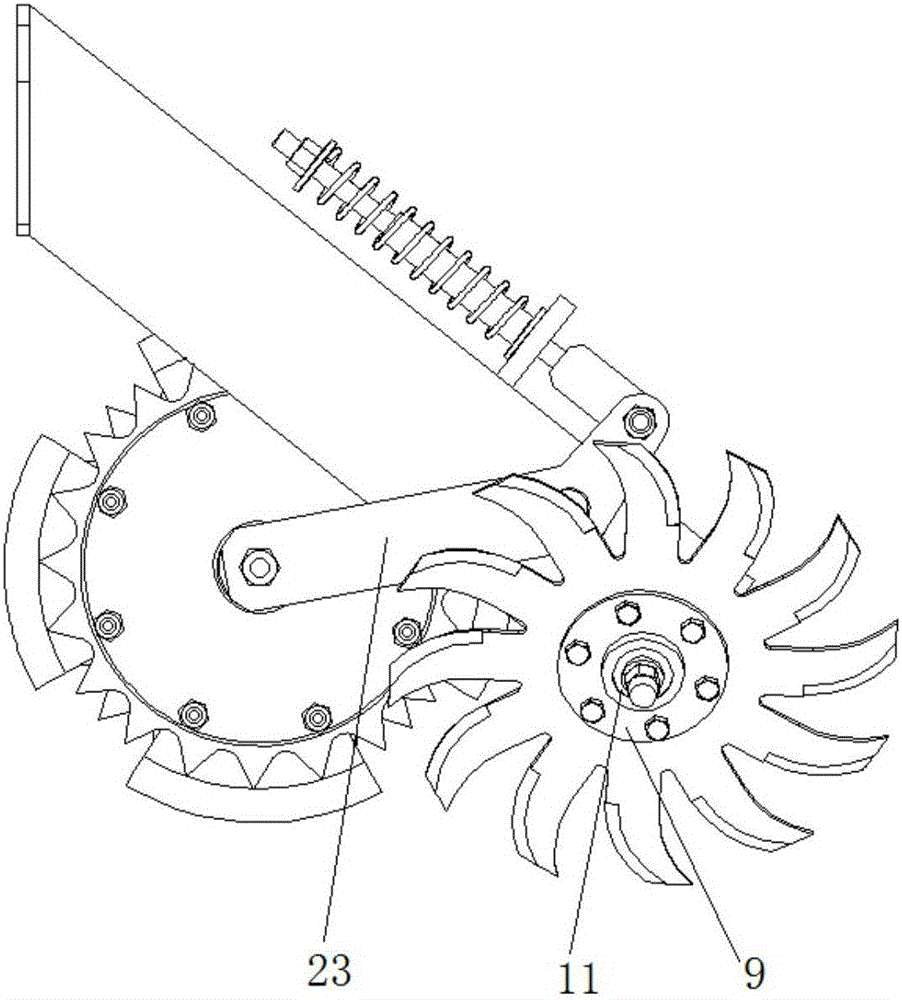

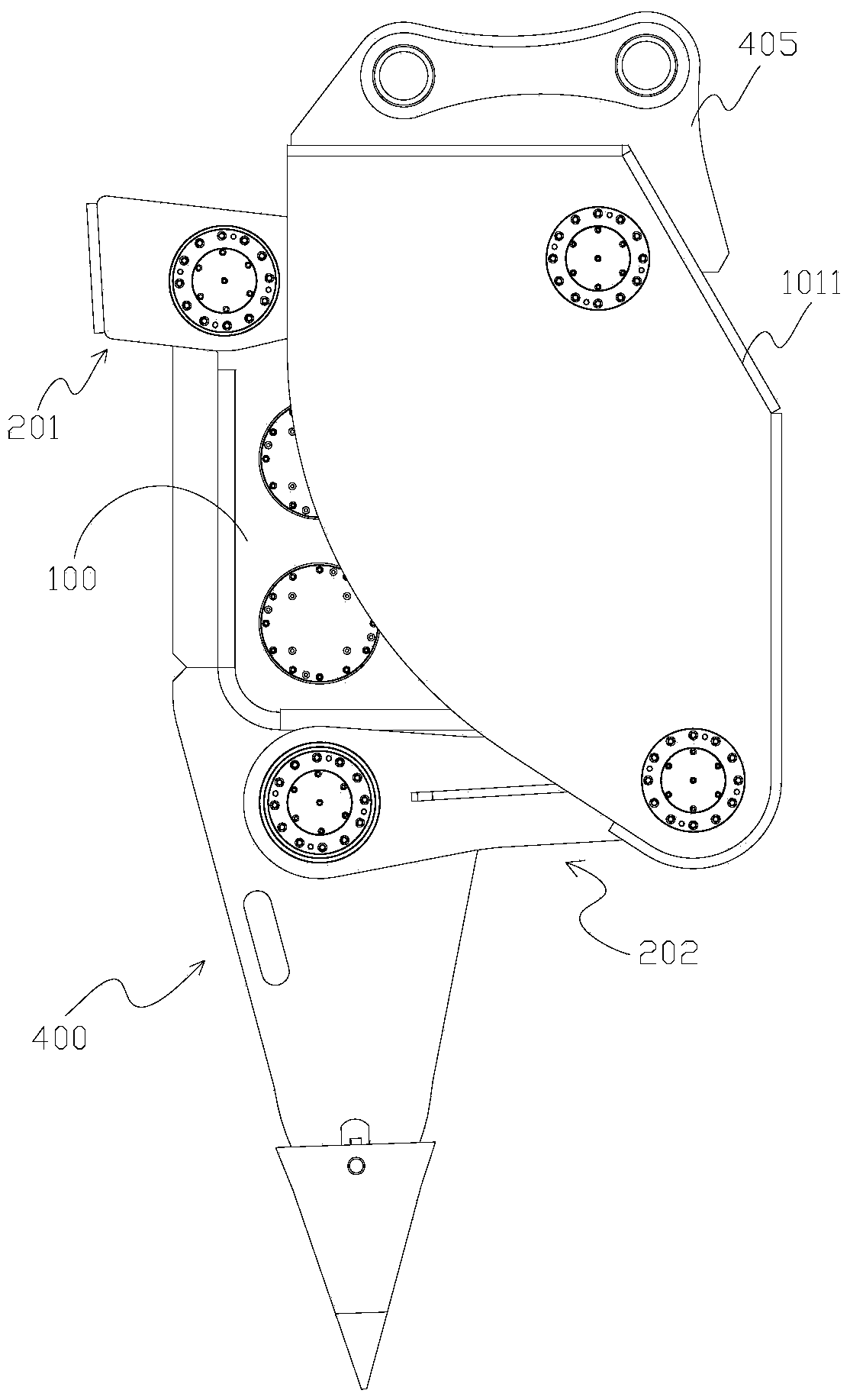

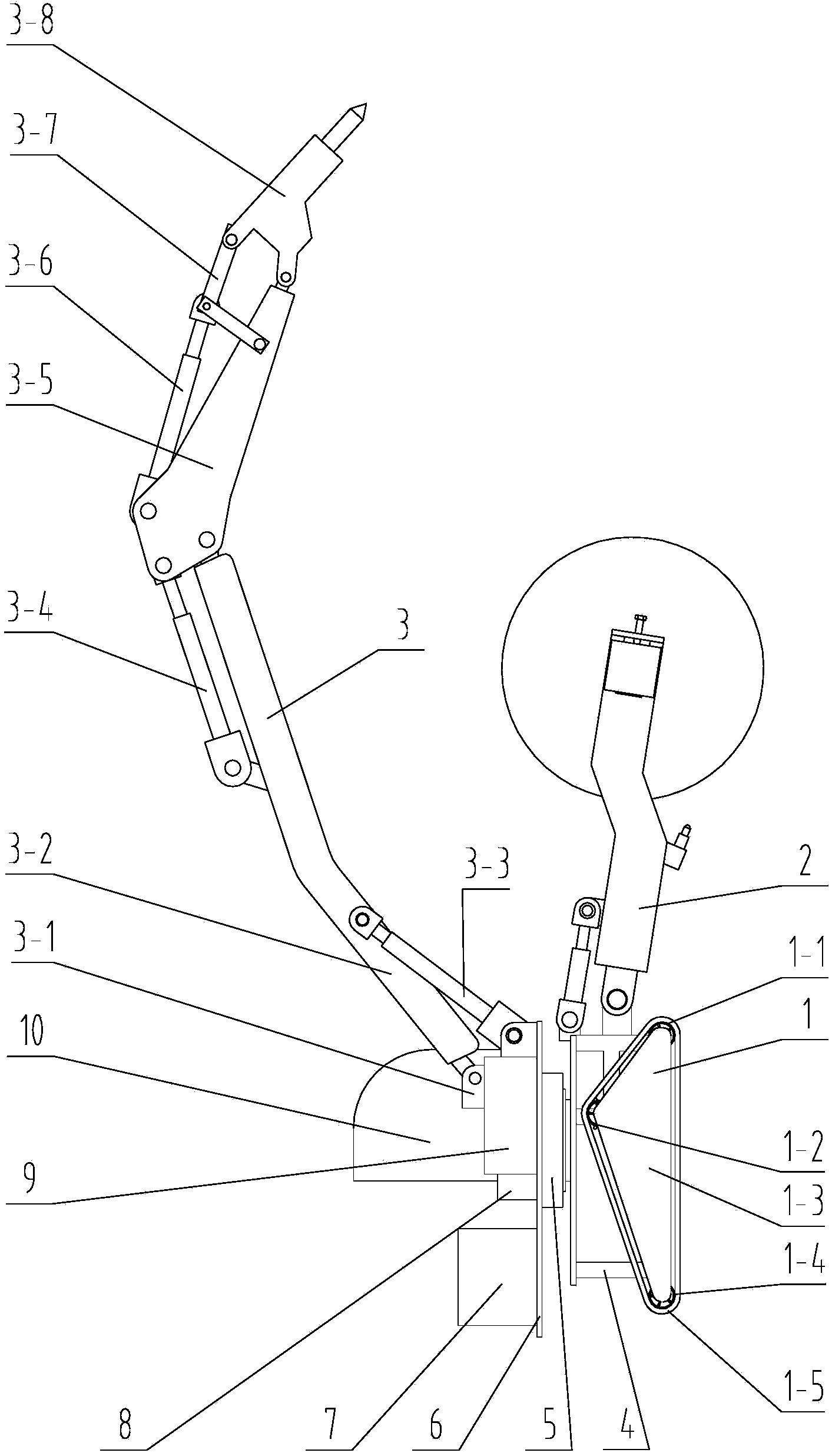

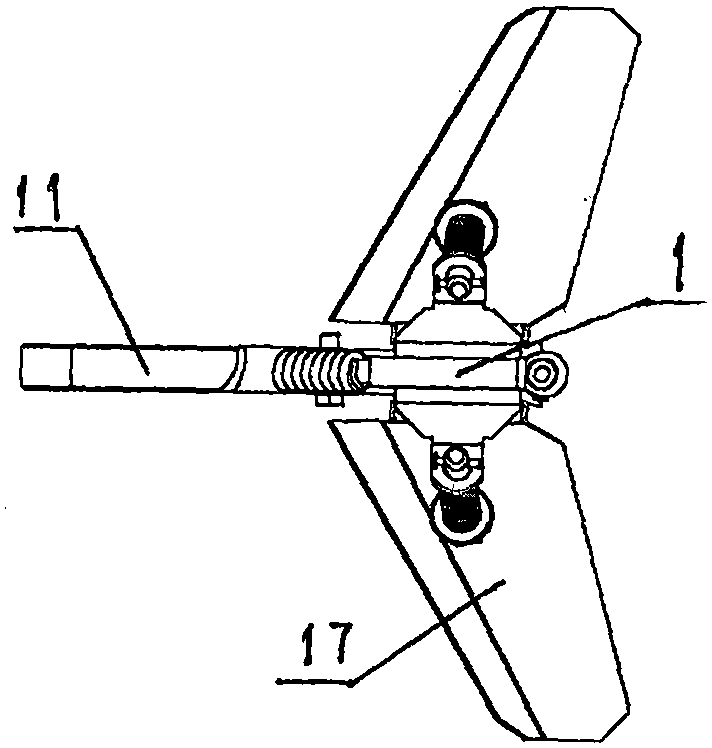

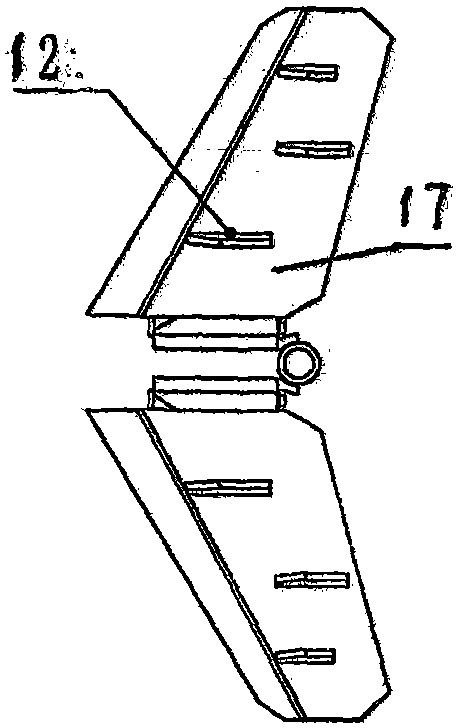

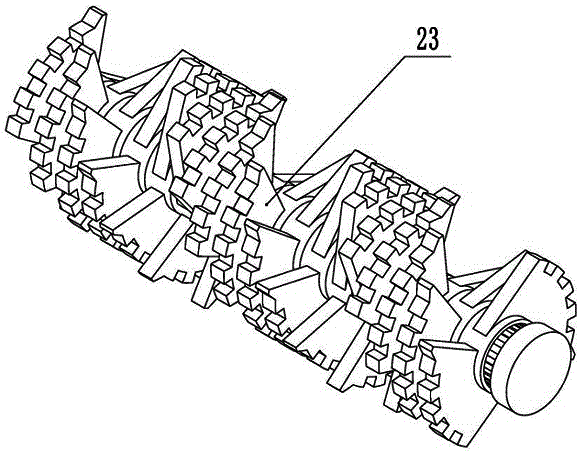

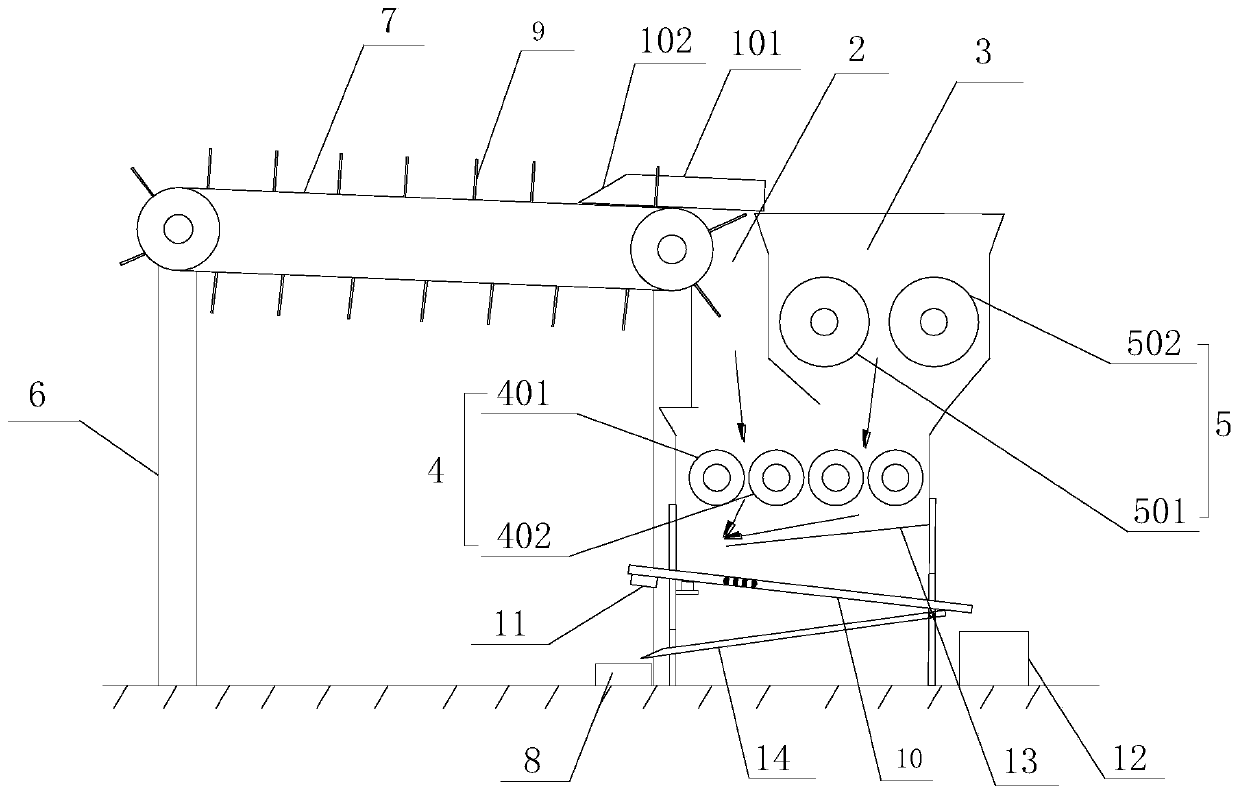

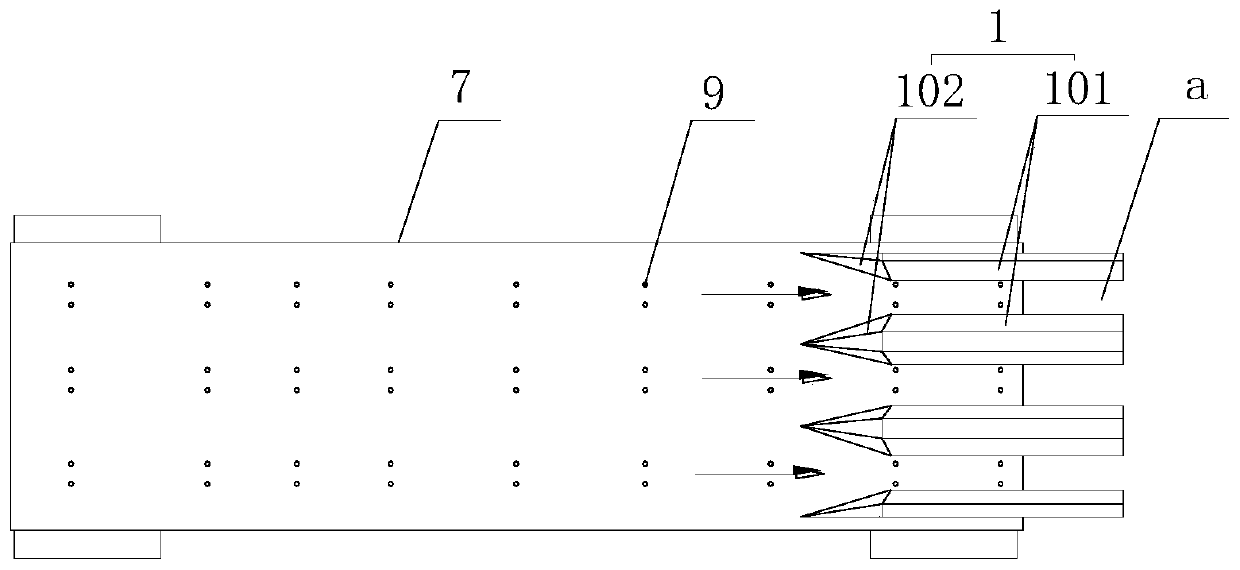

Soil strip breaking mechanism of no-tillage planter

The invention discloses a soil-strip breaking mechanism of a no-tillage planter, which comprises a connection frame, a star-shaped cutter disc assembly and a soil-breaking wheel assembly, wherein the star-shaped cutter disc assembly comprises two star-shaped cutter discs with identical structures; the two star-shaped discs with the identical structures are respectively set outer sides of two support plates in symmetrical way through a star-shaped cutter disc fixation shaft; the soil-breaking wheel assembly comprises a spring combination structure, a soil-breaking wheel combination structure and two cranked level supports; the two cranked level supports are rotatingly connected to outer sides of the two support plates of the connection frame through a connection shaft; the spring combination structure is fixed on top surfaces of the two support plates; a front end of the spring combination structure is rotatingly connected to upper arms of the two cranked level supports through the connection shaft; and the soil-breaking wheel combination is rotatingly connected to lower arms of the two cranked level supports through a rotary shaft and the soil-breaking combination is located below the connection frame. According to the invention, the soil strip breaking mechanism is mounted on a front end of a planting monomer of the no-tillage planter; before the no-tillage planter moves forward, strip breaking to the soil within the planting range is performed in advance.

Owner:JILIN UNIV

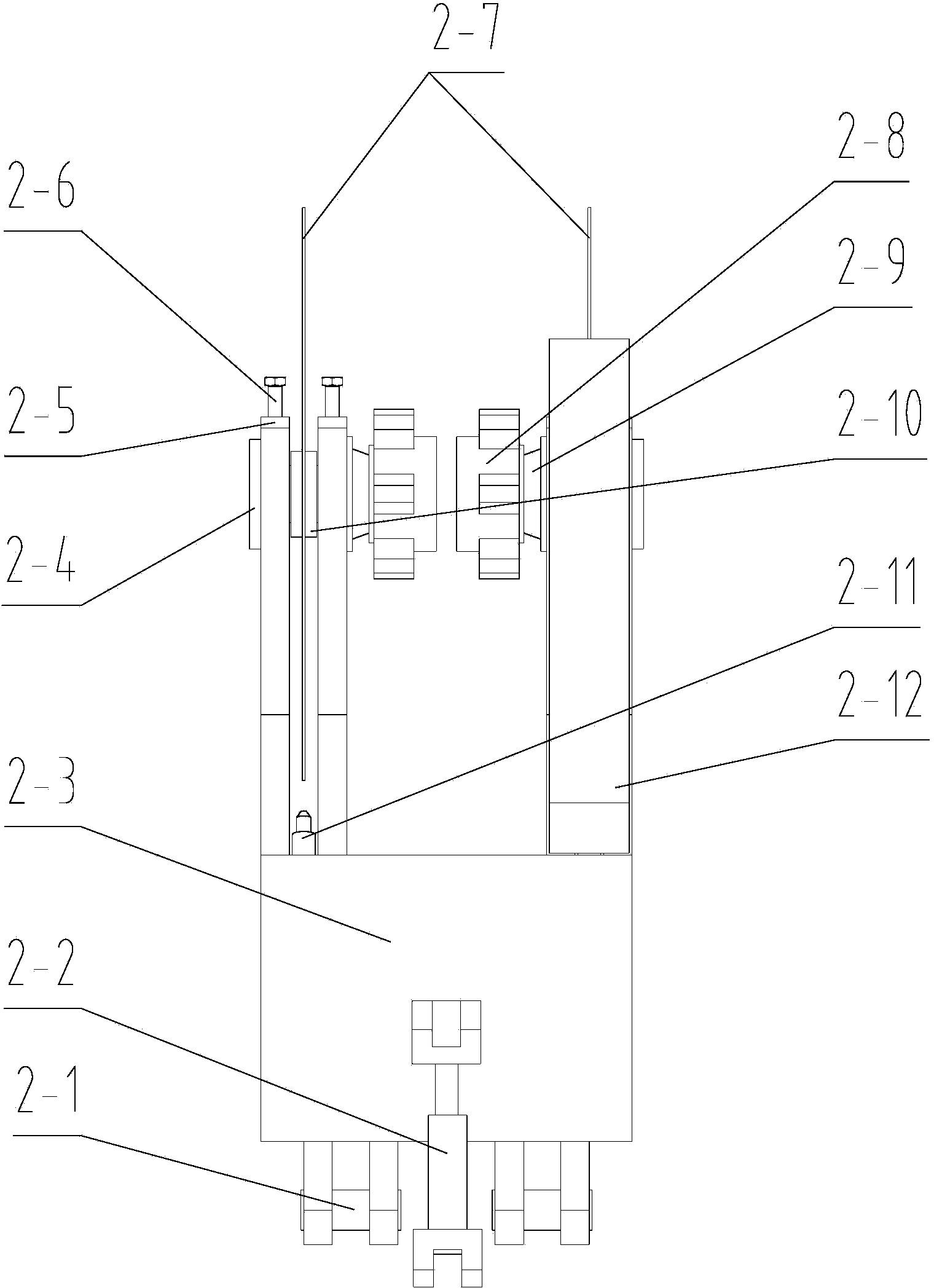

High-frequency breaking hammer

ActiveCN103706451AStrong crushingHigh crushing precisionSoil-shifting machines/dredgersGrain treatmentsDrive shaftEngineering

The invention discloses a high-frequency breaking hammer which comprises an installation shell, a vibration exciter, a four-bar mechanism and a vibration knife bar, wherein the vibration exciter comprises a shell, a first drive shaft arranged in the shell, a first driven shaft mutually meshed with the first drive shaft through a gear, a second drive shaft, a second driven shaft mutually meshed with the second drive shaft through a gear, and a bridging shaft arranged between the first drive shaft and the second drive shaft, wherein a first drive motor and a second drive motor are respectively arranged at one ends of the first drive shaft and the second drive shaft; central axes of the first drive shaft and the second drive shaft are positioned on the same vertical surface; and the first drive shaft, the first driven shaft, the second drive shaft and the second driven shaft are positioned on the same horizontal plane. According to the high-frequency breaking hammer, two groups of drive shafts are adopted and are matched with two drive motors; and compared with a breaking hammer driven by one motor, the high-frequency breaking hammer has the advantages of large breaking force, high breaking precision, small noise and strong breaking capability, thereby prolonging the working time of the breaking hammer and increasing the breaking efficiency.

Owner:苏州鸣尼克重工机械有限公司

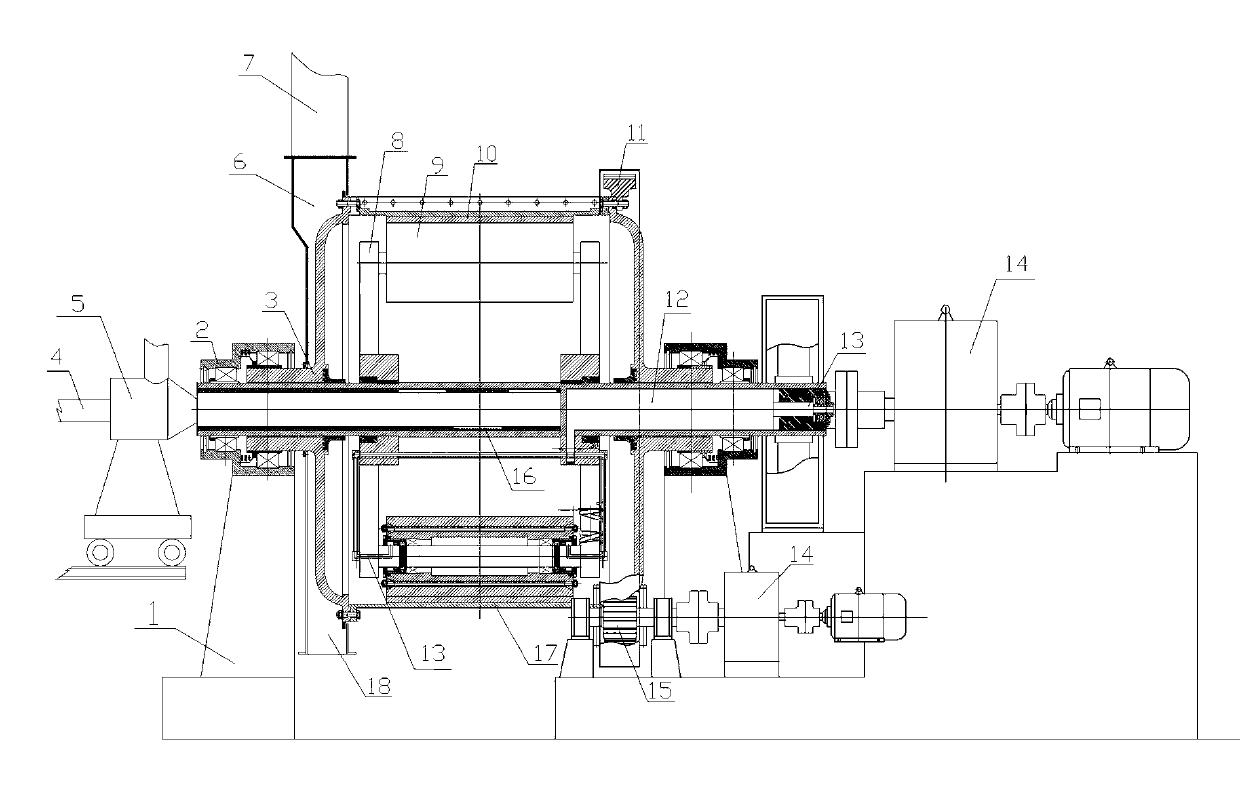

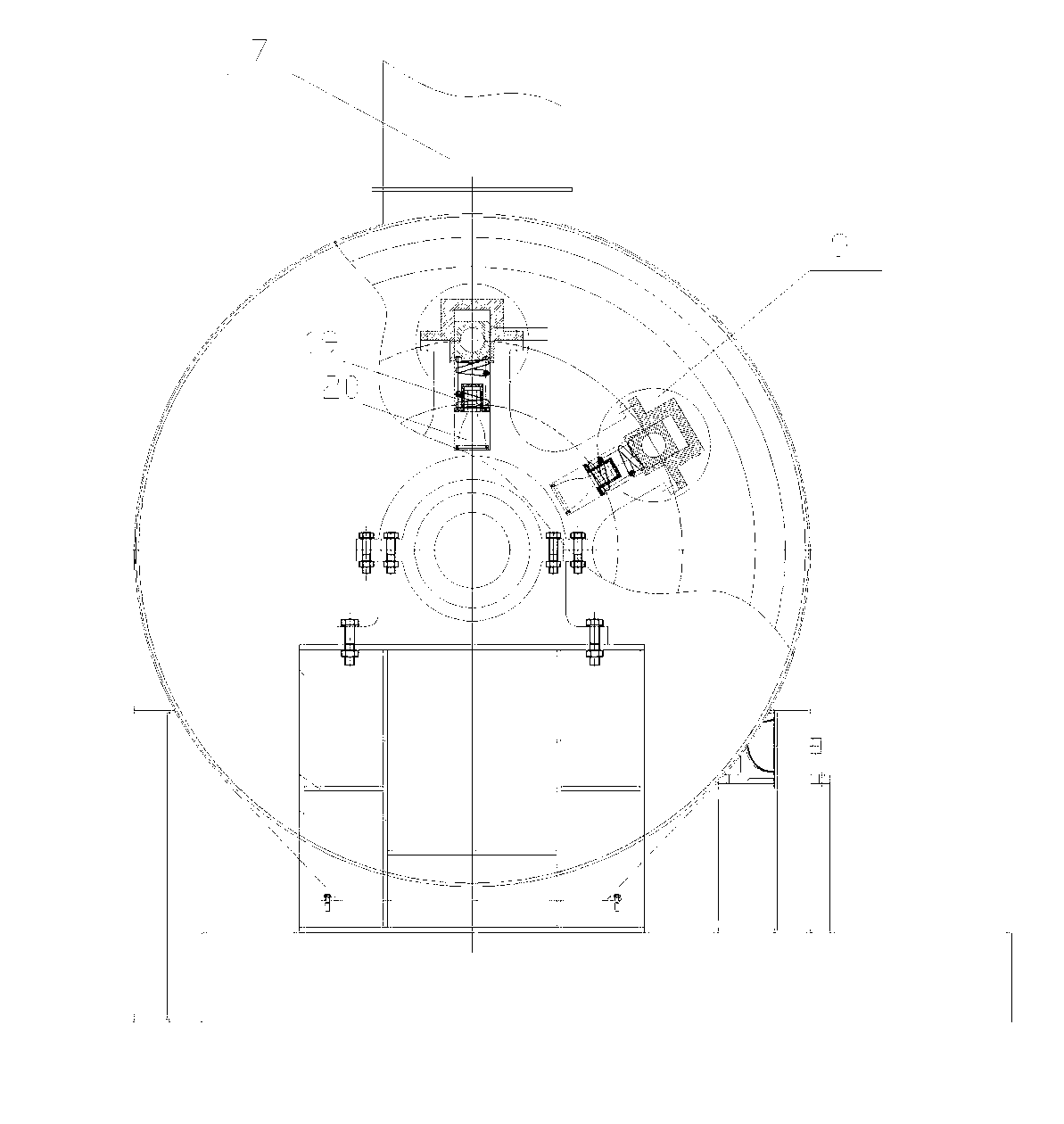

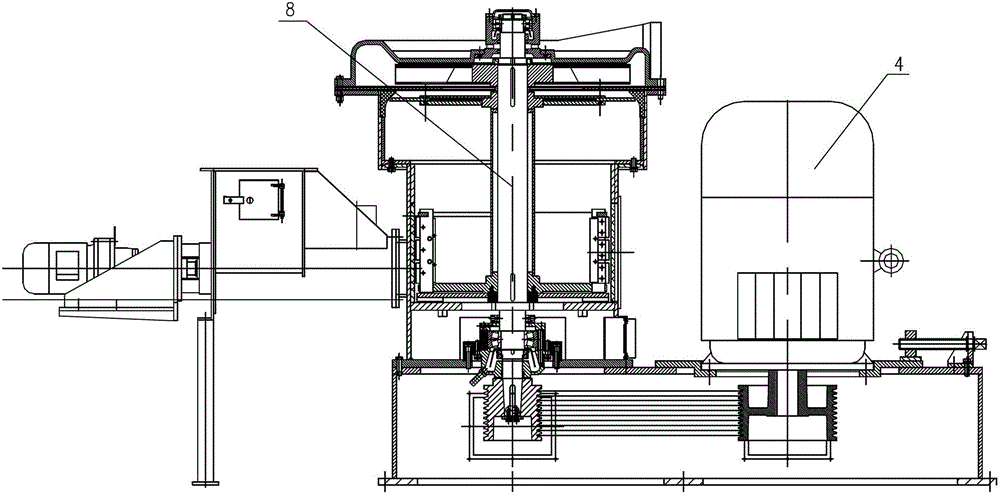

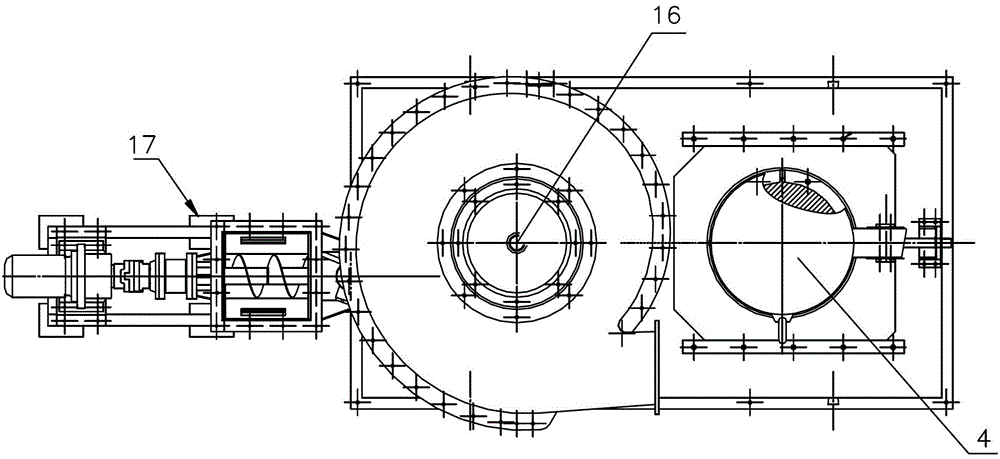

Planetary flour mill

InactiveCN102989554AReduce energy consumptionImprove grinding effectGrain treatmentsWear resistantReducer

The invention relates to a planetary flour mill. A mill pedal is provided with a cylinder assembly supported by hollow shafts, the inner wall of a cylinder is pasted with a wear-resistant lining plate, the cylinder is internally provided with a main shaft which is arranged in the hollow shafts at the two ends of the cylinder assembly, the periphery of a planetary rack fastened on the main shaft is provided with crushing rollers pressed on the wear-resistant lining plate on the inner wall of the cylinder, and the cylinder and the main shaft are respectively driven by a motor through a speed reducer. The planetary flour mill has the characteristics that the milling of thin materials can be realized, and the grinding effect on the thin materials is favorable when the cylinder moves relative to the crushing rollers on the periphery of the planetary rack. The planetary flour mill has the advantages of small occupation area, low energy consumption, strong grinding capability, low noise and the like.

Owner:长沙坚韧机械有限责任公司

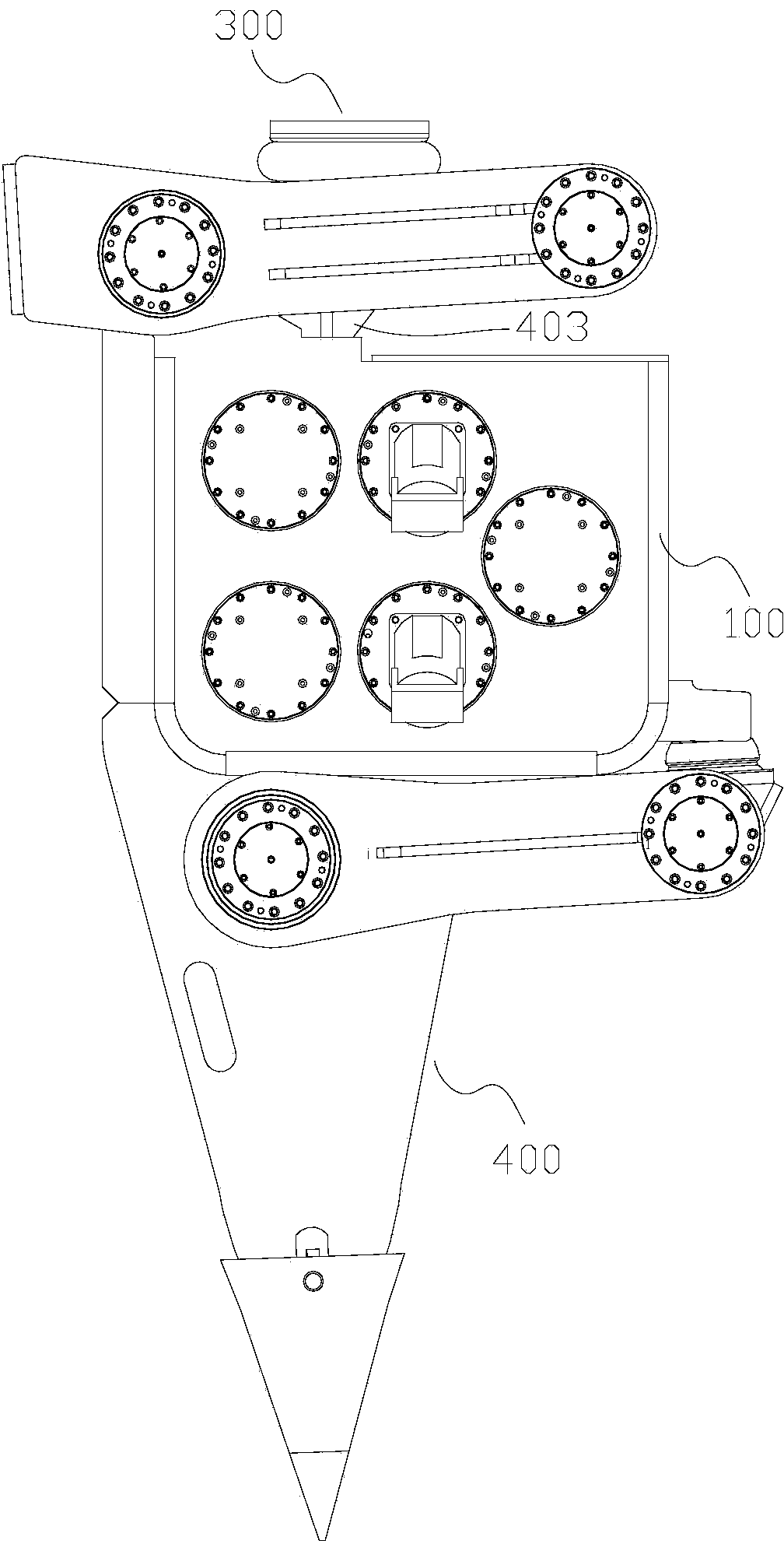

Hard rock crushing system

The invention discloses a hard rock crushing system. The hard rock crushing system comprises a triangular crawler walking part, a cutting part, a working arm, a power part and a hydraulic system, wherein a bottom frame is arranged on the upper part of the triangular crawler walking part; a rotating frame is connected with the bottom frame through a rotating bearing; a rotating device, a water tank, an operating room, a working arm base, the power part and the hydraulic system are arranged on the rotating frame; the working arm is hinged to the working arm base; the cutting part is hinged to the bottom frame. According to the hard rock crushing system, the width of a machine body is small; the triangular crawler walking part is adopted, the environmental adaptability is high, the traction force is high, the climbing capacity is high, the obstacle crossing ability is high, the structure of each part is simple and compact, and the hard rock crushing system is convenient to assemble and disassemble; a trench with fixed width, adjustable depth and the rock hardness f less than or equal to 16 can be dug; the trench is regular; the labor intensity of workers is alleviated; the work efficiency is improved.

Owner:CHINA UNIV OF MINING & TECH +1

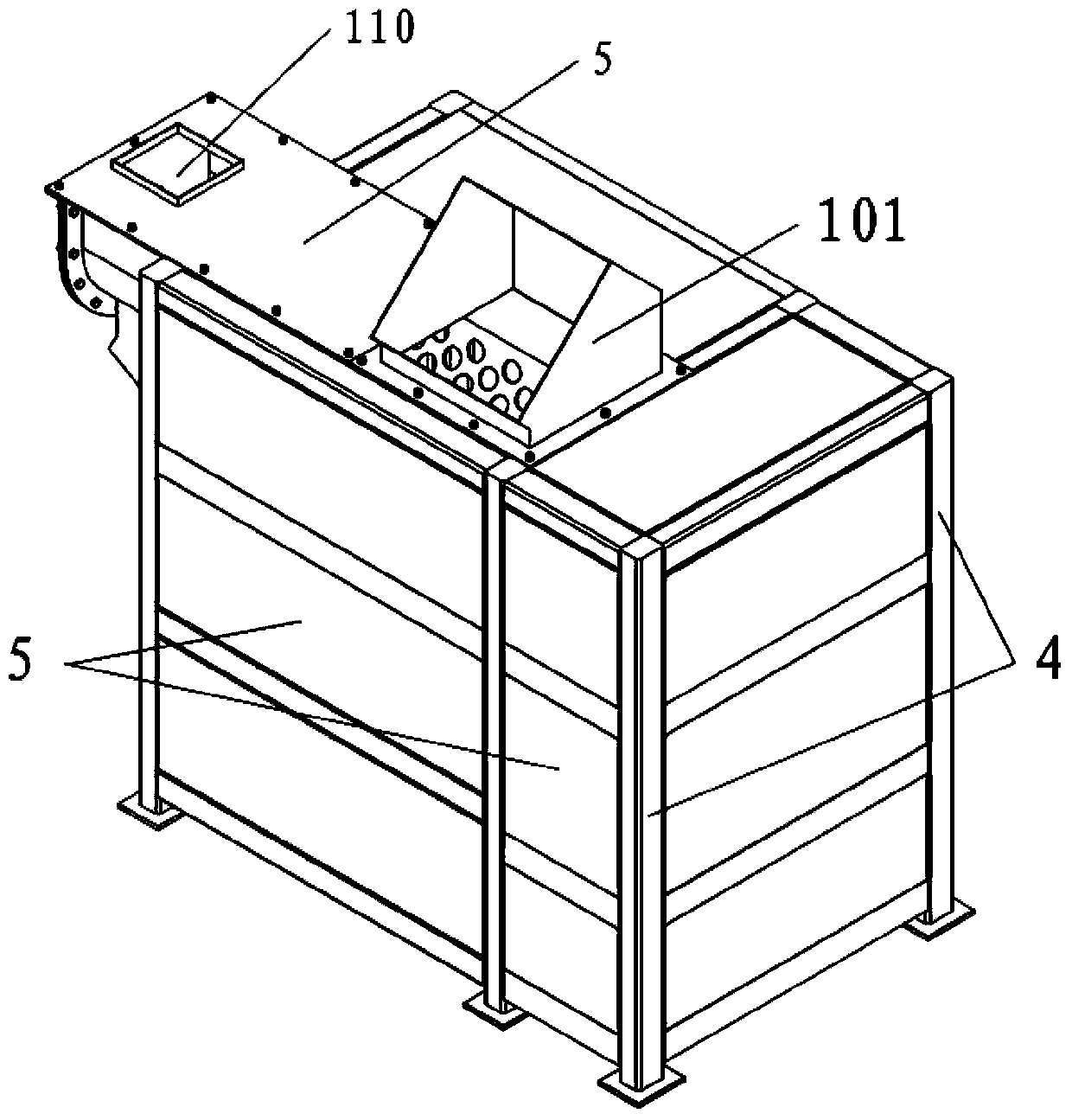

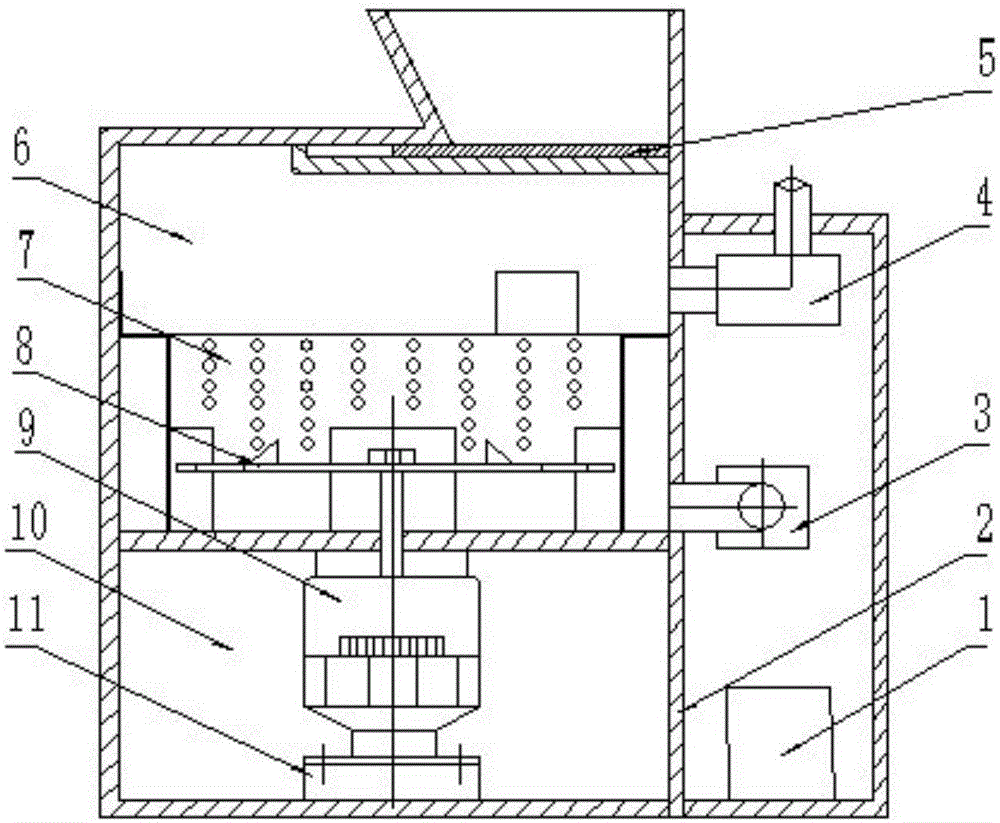

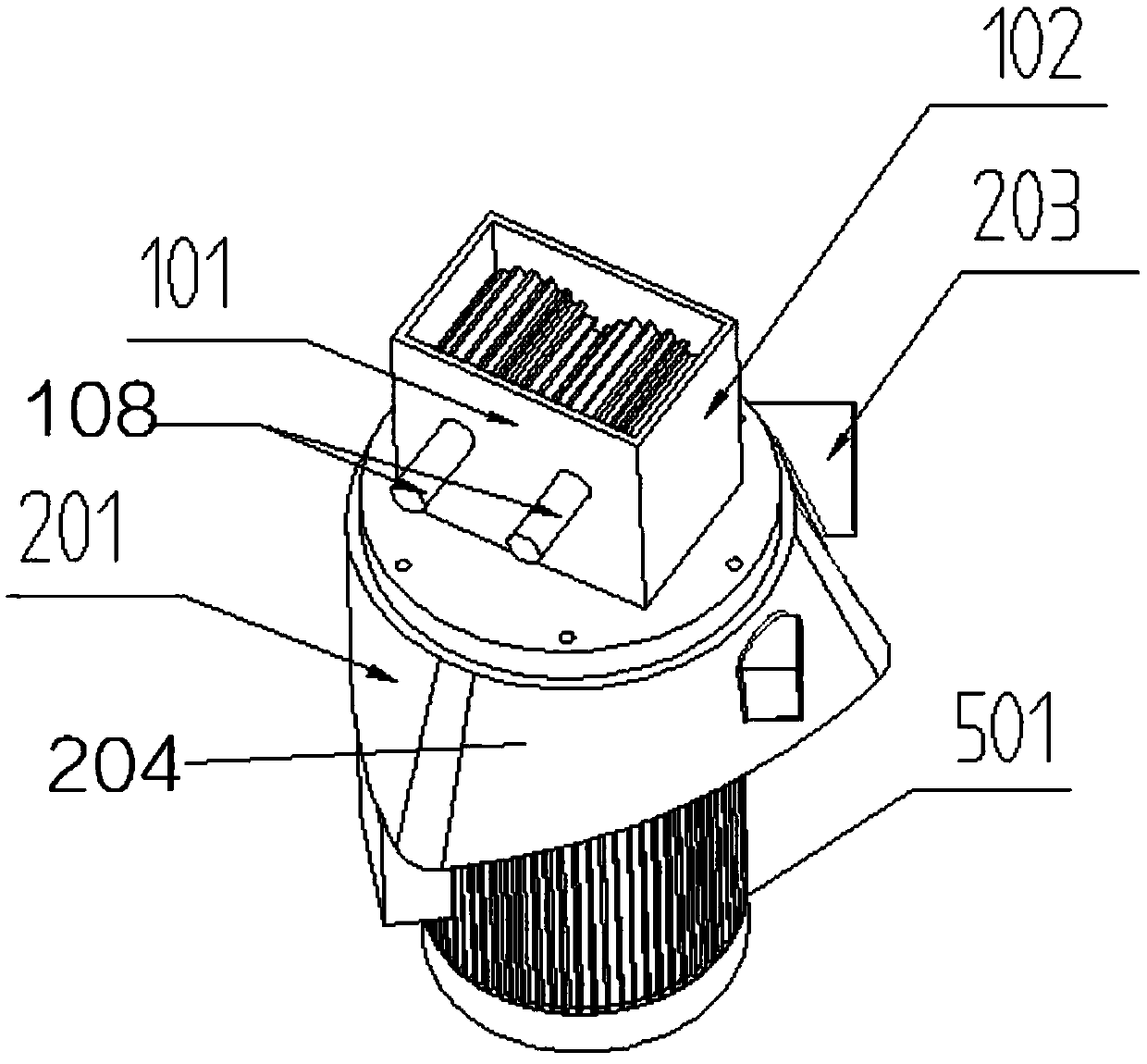

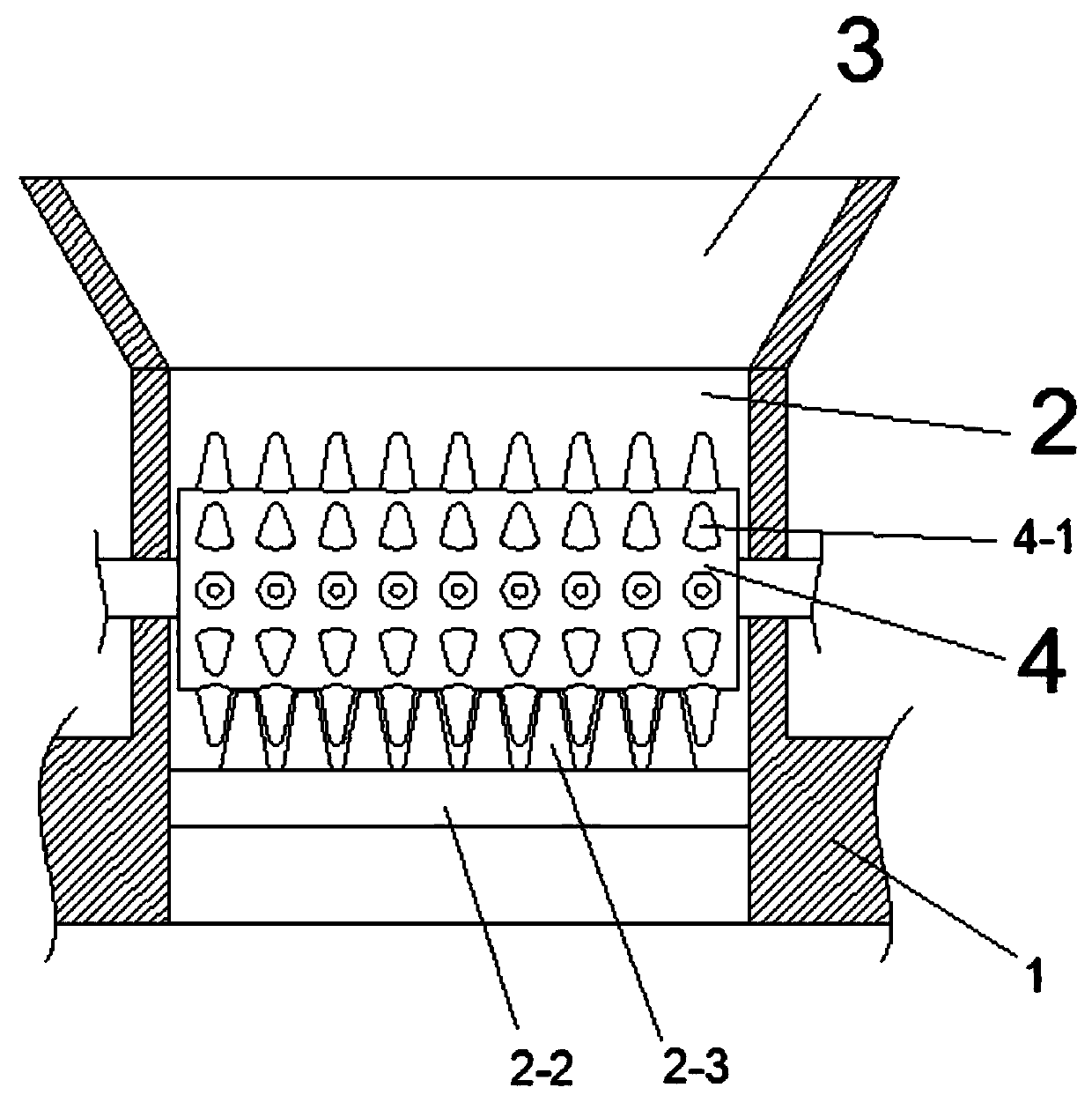

Integrated device for sorting, smashing and screening kitchen waste

ActiveCN103418601AShorten the length of the process routeImprove work efficiencySievingScreeningIntegrated devicesFiber

The invention relates to the field of environment-friendly devices and discloses an integrated device for sorting, smashing and screening kitchen waste. The integrated device for sorting, smashing and screening kitchen waste comprises a sorting device, a smashing device and a screening device, wherein the sorting device, the smashing device and the screening device are sequentially connected and installed on a machine frame from top to bottom. A shaft-less auger is adopted by the sorting device and waste such as fiber is prevented from being wound on the auger so that sorting can be thorough. Waste materials are cut and hammered by the smashing device through a hammer cutter assembly rotating at a high speed, so that the waste materials are thoroughly cut and dead angle positions which can not be cut do not exist. Meanwhile, the screening device is additionally arranged, the smashed waste materials can be further screened and a pipeline can be prevented from being blocked when a next disposal process is conducted.

Owner:湖南普惠环境科技有限公司

High frequency breaker

ActiveCN103706451BStrong crushingHigh crushing precisionSoil-shifting machines/dredgersDrive shaftEngineering

Owner:苏州鸣尼克重工机械有限公司

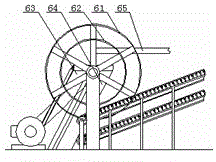

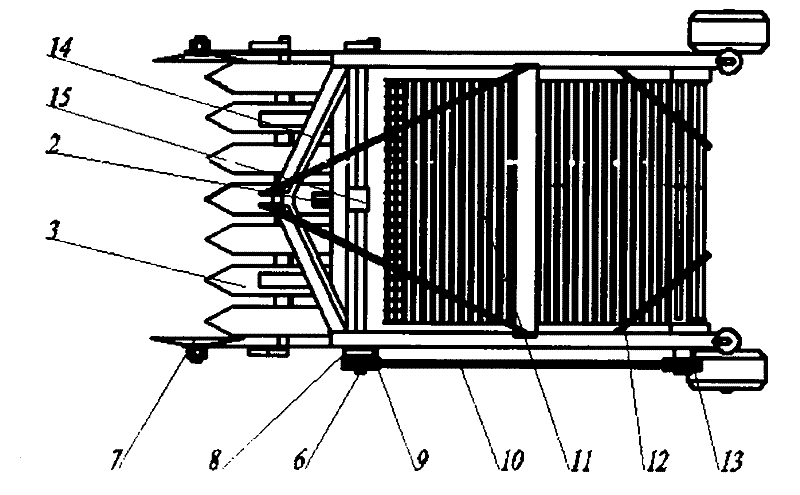

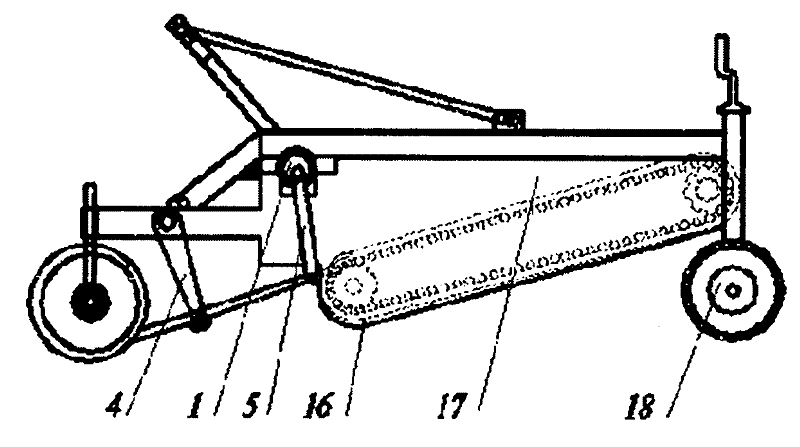

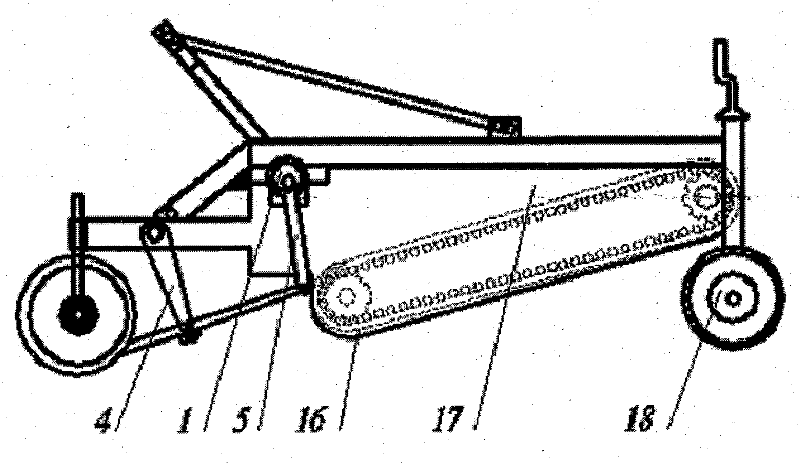

Movable shovel type potato excavator

InactiveCN102440112AIncreased ability to break down soilLow traction resistanceDiggersVibration amplitudeMechanical reliability

The invention relates to a potato excavator matched with a tractor for use, belonging to the field of agricultural machinery. The existing potato picker mainly adopts the fixed shovel excavating mode, thus having the problems of large consuming traction force, poor soil breaking property, serious blocking condition and poor soil and potato separating effect, and the like. A vibration type potato excavator is good in soil breaking property and small in traction resistance, but the vibration amplitude of the whole potato excavator is large, so that the potato damaging rate is high in the separating process, and the work reliability of the whole excavator is low. The movable shovel type potato excavator adopts a novel movable shovel type extracting mechanism, due to the reciprocating motion of an excavating shovel, the breakage capability of a soil-potato excavating object is enhanced, the traction resistance is reduced, the soil-potato separating effect is improved, and the mechanical reliability is high. A lifting chain screen type separating mechanism is adopted, the potato damaging rate in the separating process is reduced, and the work reliability of the whole excavator is high. The potato excavator is suitable for clay and clay loam with severer soil hardening, and is also widely applied to sand and loessial soil easy to cultivate.

Owner:GANSU AGRI UNIV

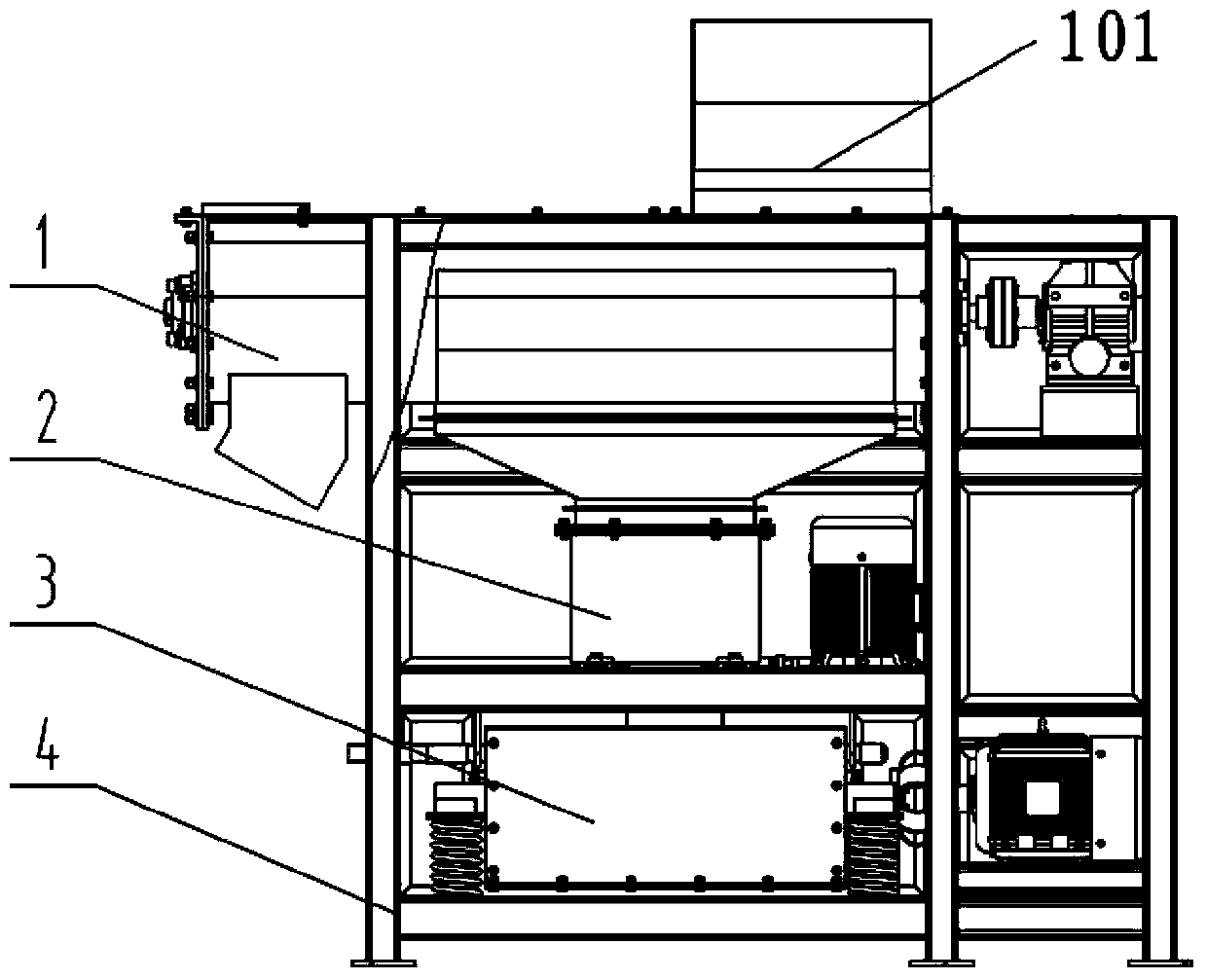

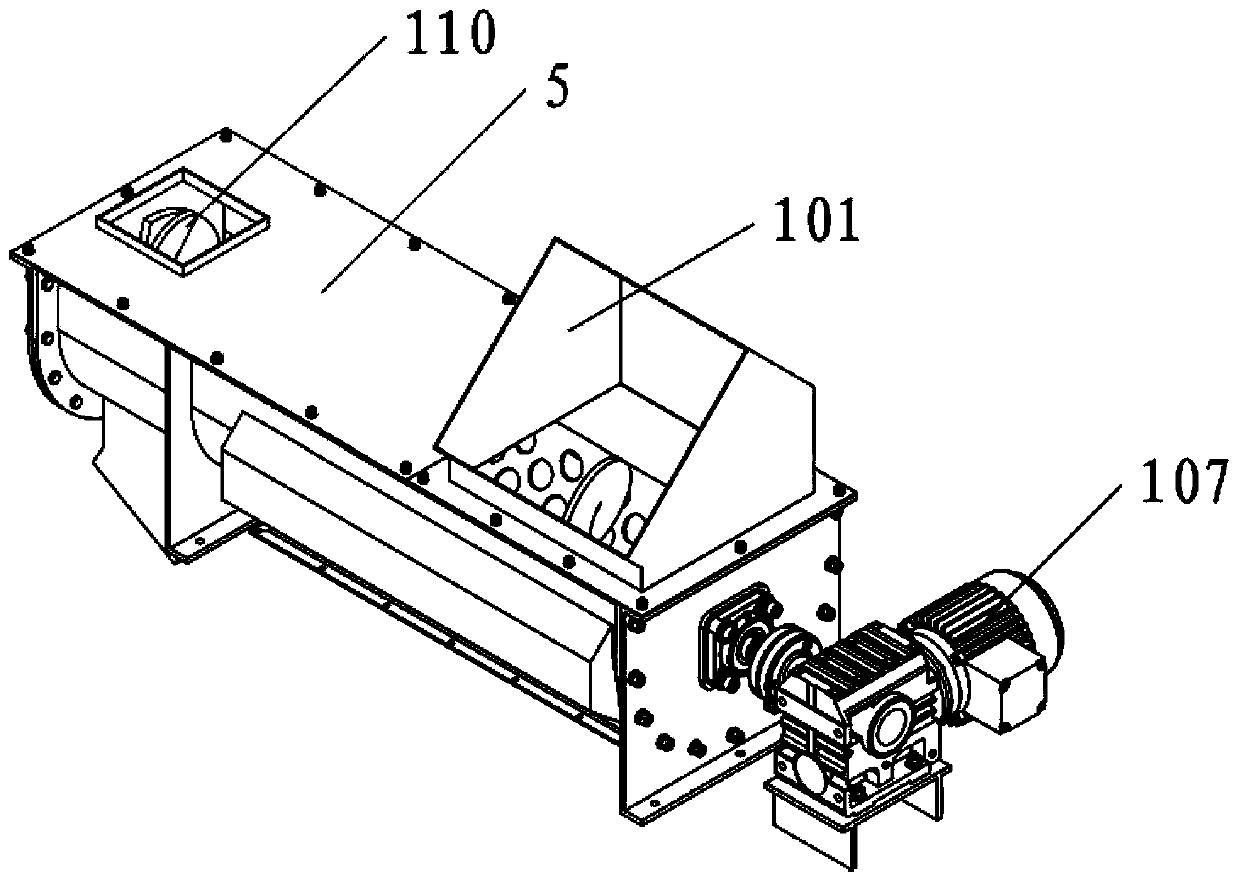

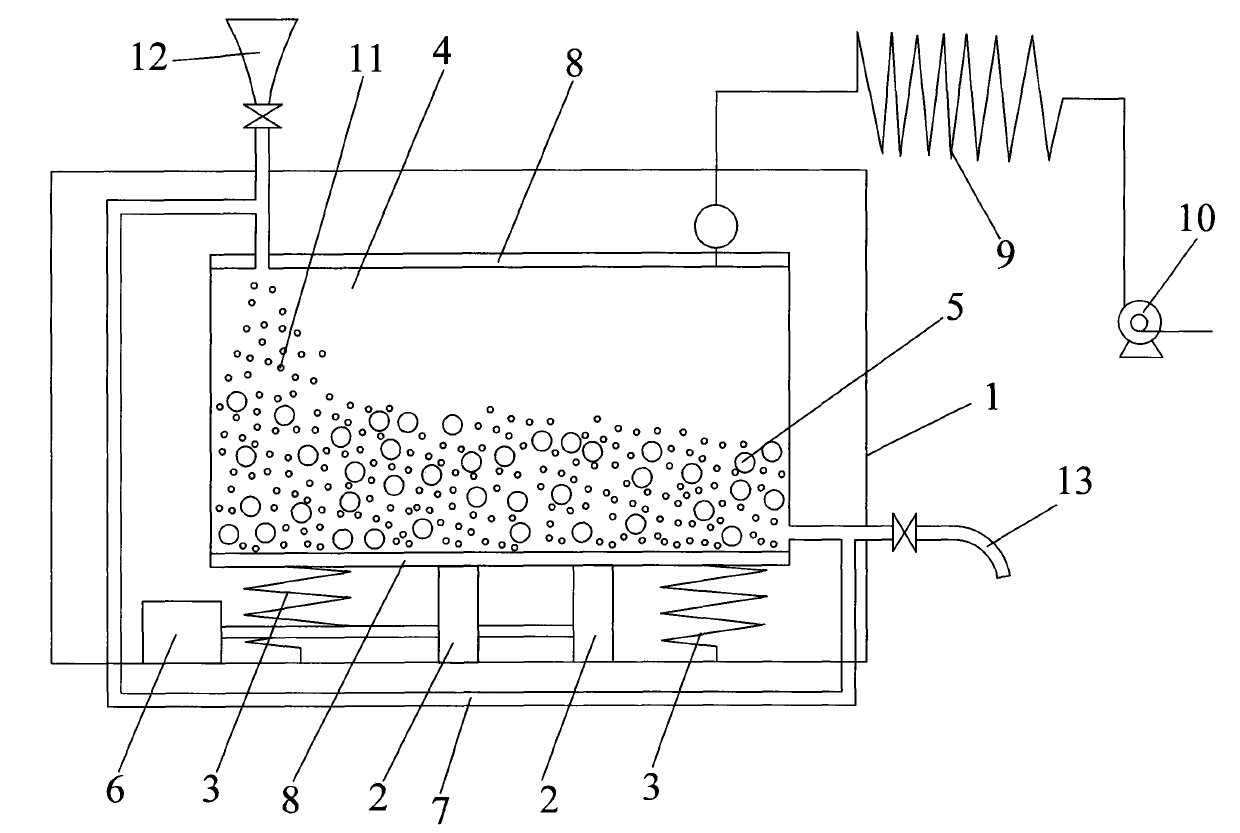

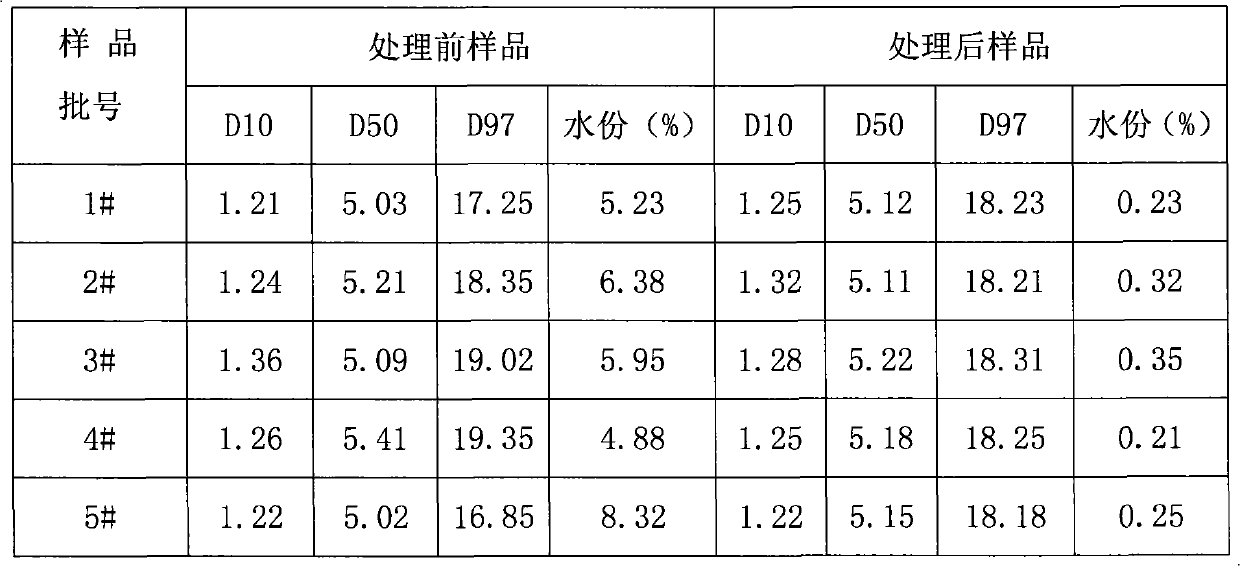

Dispersing, mixing and drying device

InactiveCN101816903AImprove the mixing effectFully dispersedShaking/oscillating/vibrating mixersGrain treatmentsEngineeringVibration exciter

The invention discloses a dispersing, mixing and drying device, comprising a stand, a vibration exciter mounted on a base of the stand, an electric motor driving the vibration exciter to operate, and a grinding barrel located inside the stand and mounted on the base of the stand via a vibration reduction spring. The grinding barrel is filled with grinding medium therein, the vibration exciter acts on the grinding barrel, the grinding barrel can be vacuumized or be used for heating and cooling the medium therein via a jacket arranged at the periphery of the grinding barrel. The materials at a discharging hole can be circularly fed into a feeding hole repeatedly via a material pipeline to be mixed and dispersed. The invention can enable the materials to be evenly dispersed and dried within a short time so that a desired crushing result is achieved.

Owner:赛福能源科技(徐州)有限公司

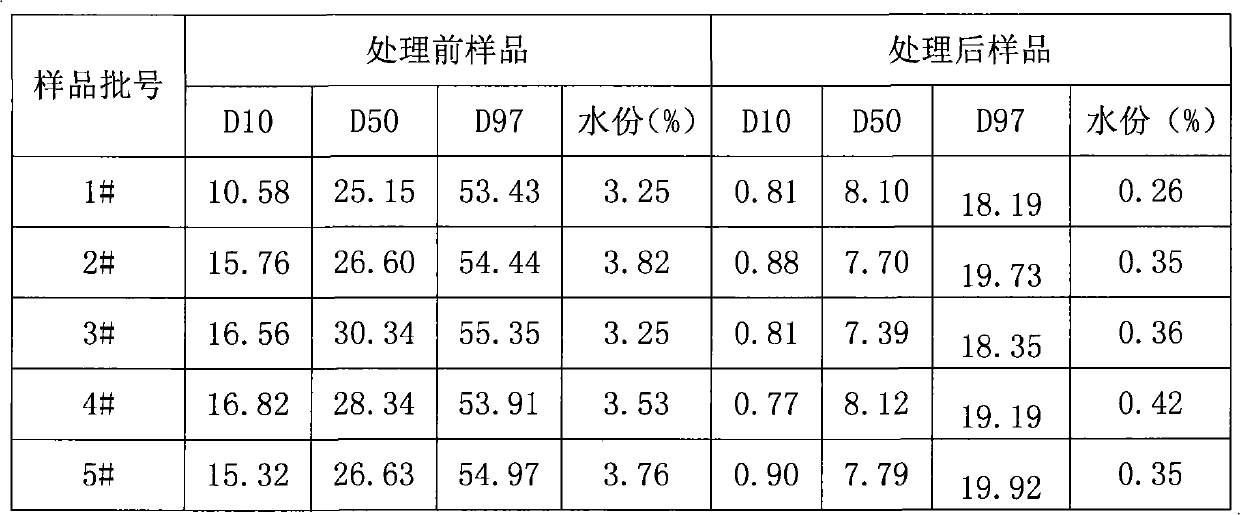

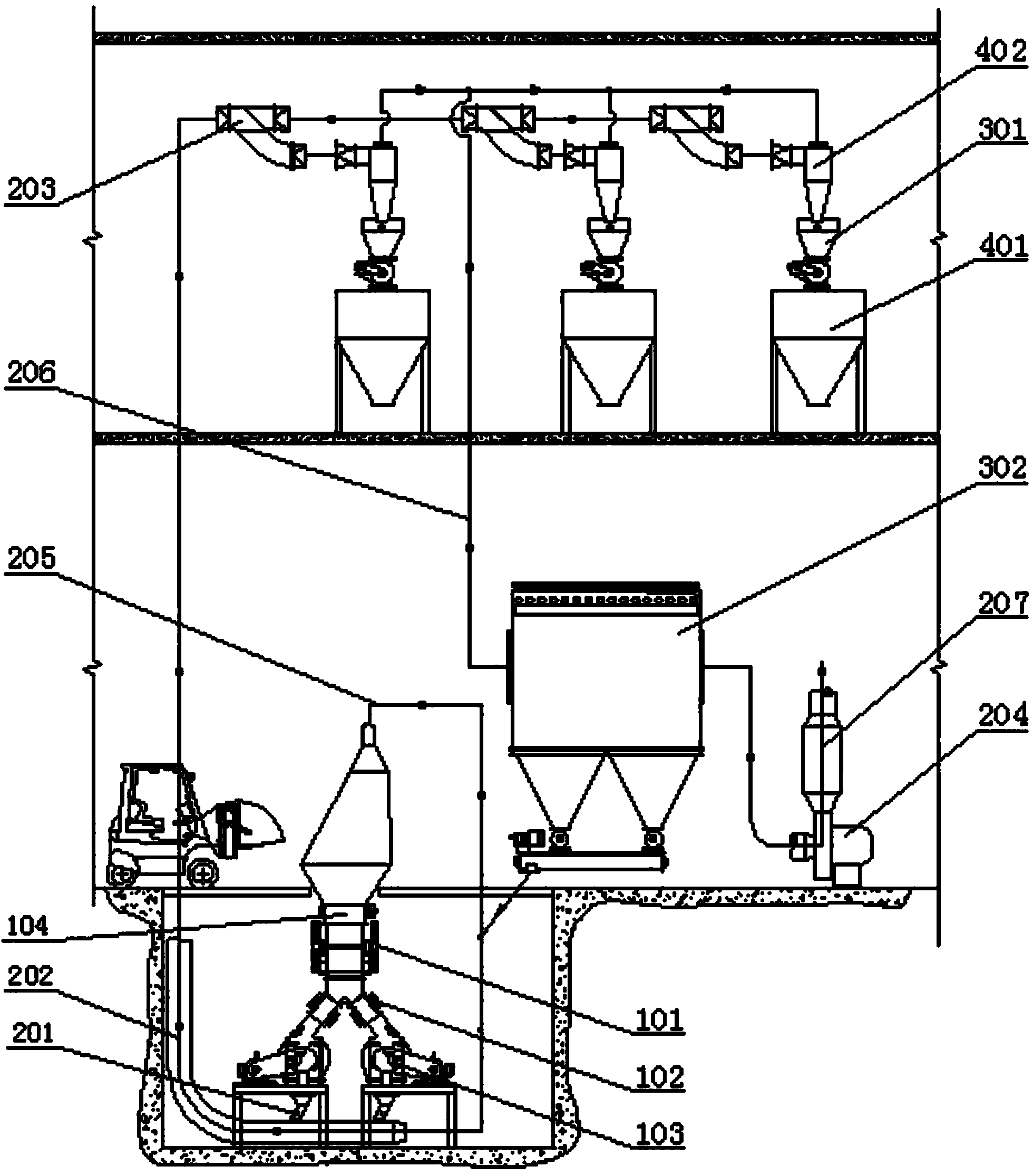

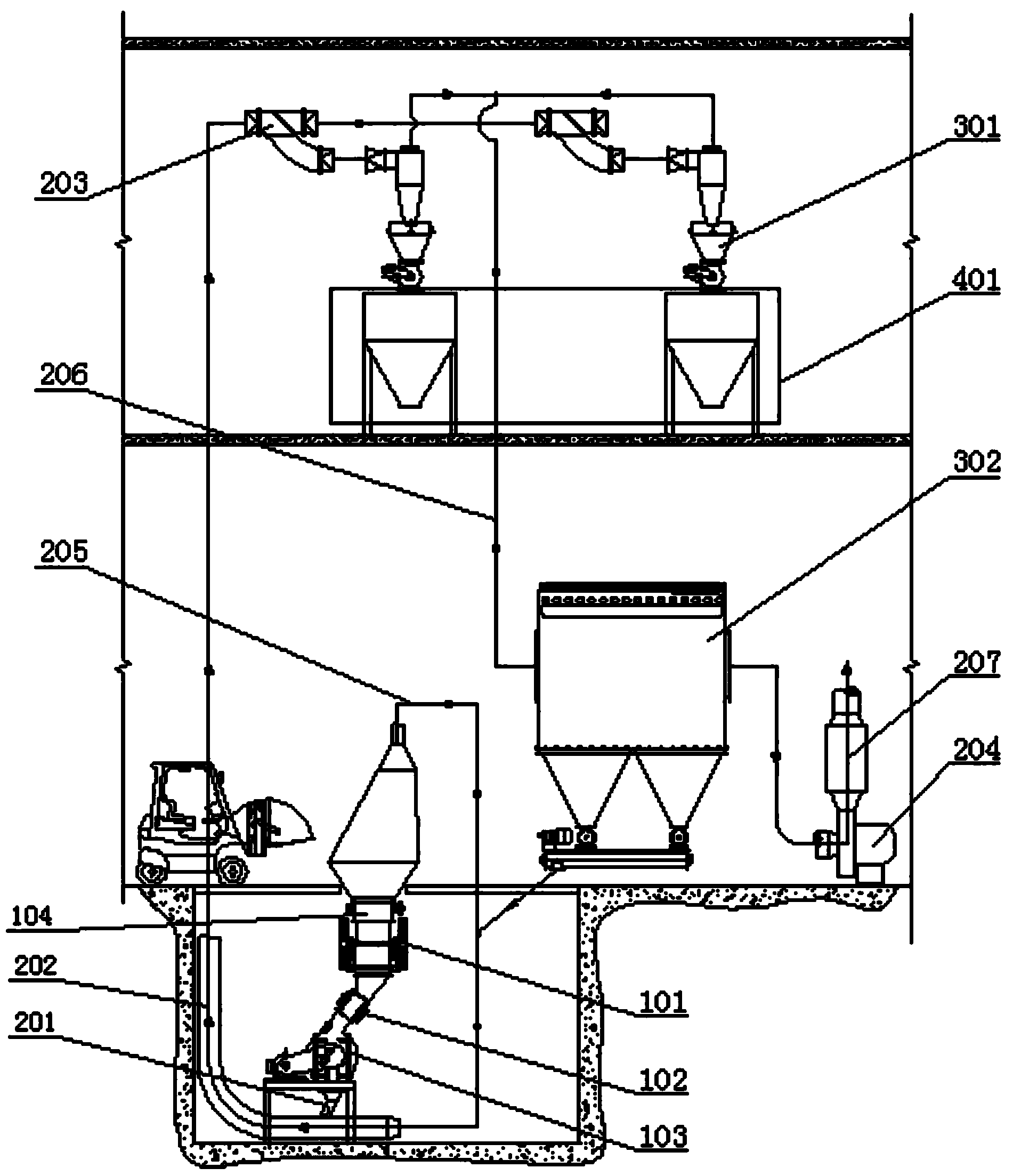

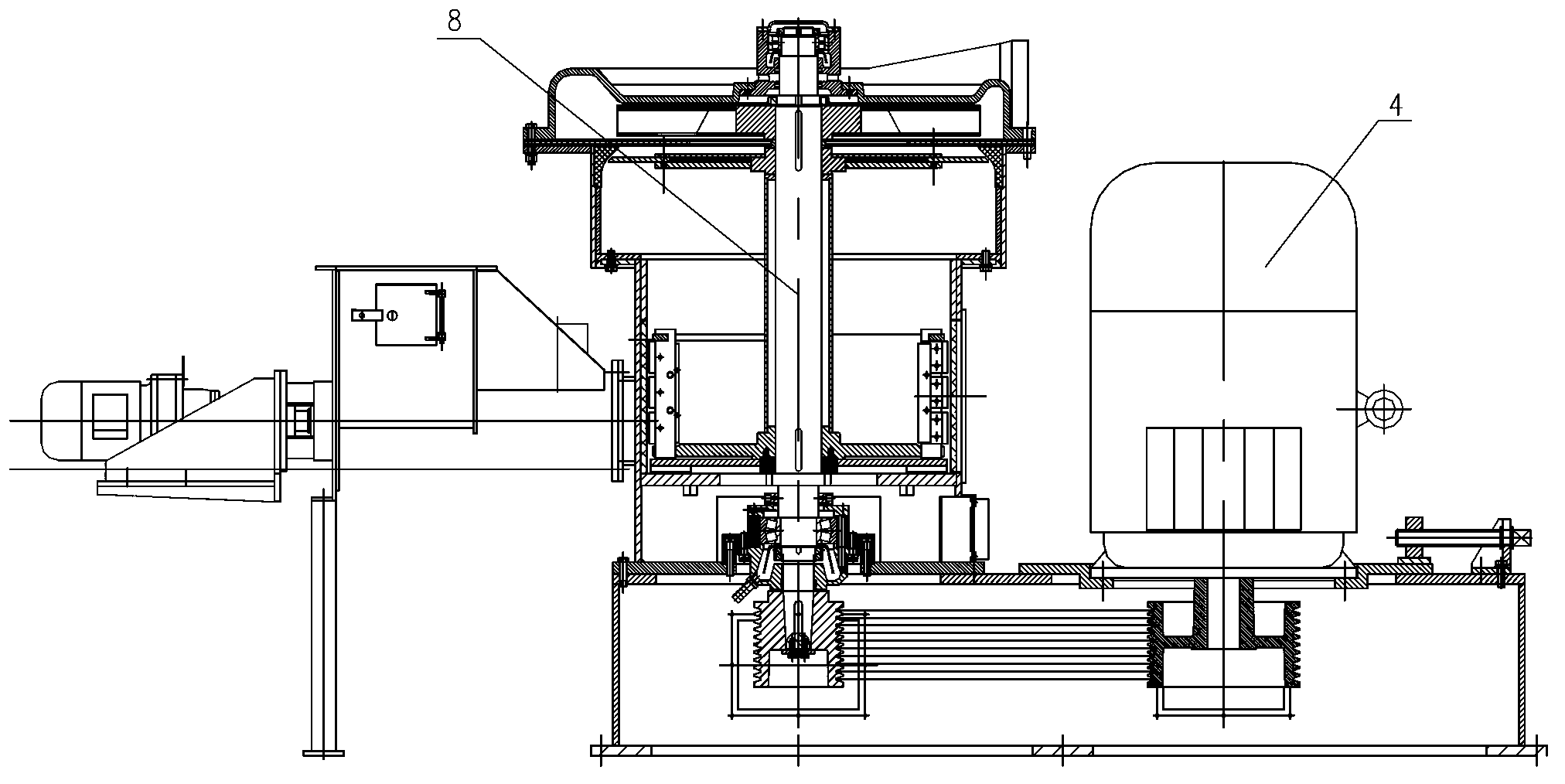

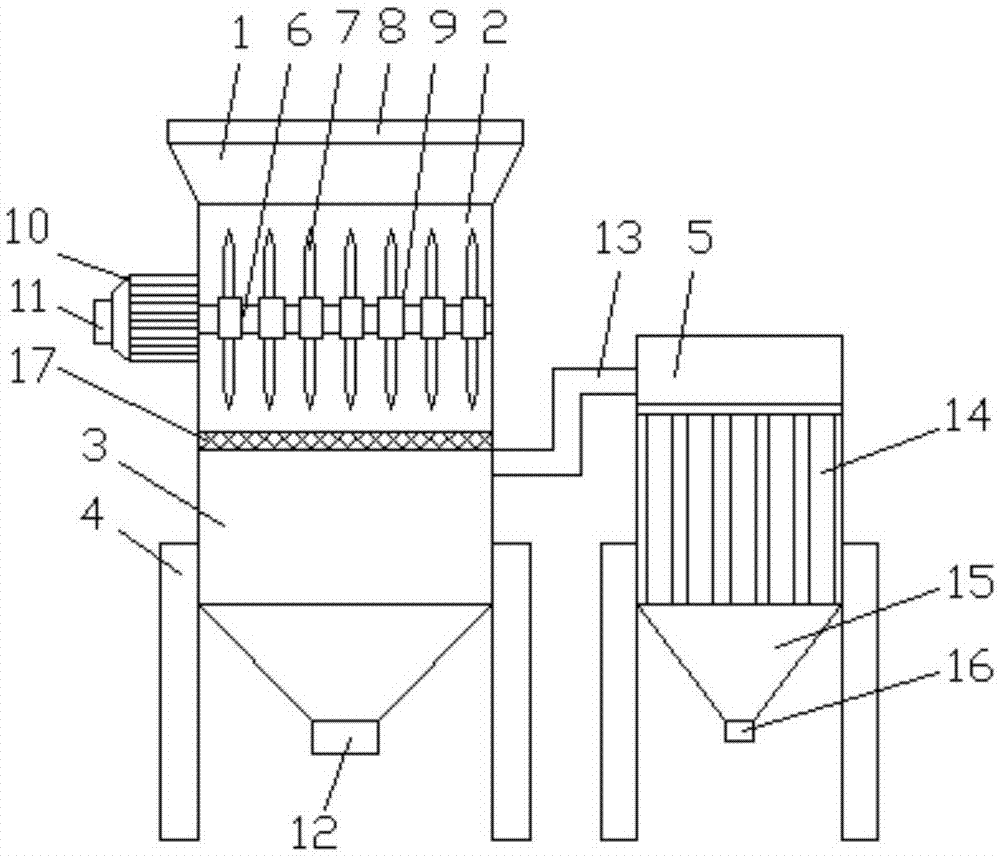

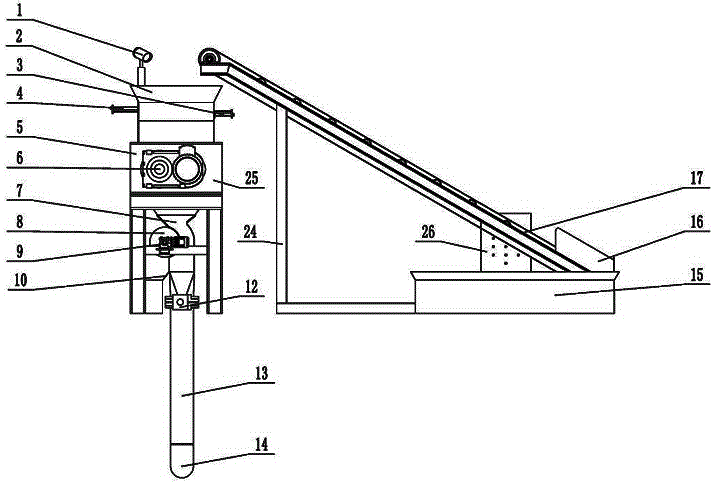

Yeast crushing equipment and method for preparing yeast powder

ActiveCN103894278AExtended service lifeControlled heatingBulk conveyorsGrain treatmentsYeastBaghouse

The invention discloses yeast crushing equipment and a method for preparing yeast powder. The powdery yeast equipment comprises an air conveying system, and a crushing mechanism, a yeast powder buffering cabin and a bag-type dust collector which are connected with the air conveying system, wherein the air conveying system comprises a draught fan, a feeding air pipe, a dust suction air pipe, a dust-air air pipe and a clean-air air pipe; one end of the feeding air pipe is connected with the crushing mechanism and the other end of the feeding air pipe is communicated with the yeast powder buffering cabin by a three-way switching valve; the upper end of the yeast powder buffering cabin is connected with the dust-air air pipe; the dust suction air pipe and the dust-air air pipe are connected in parallel and then are connected with the crushing mechanism to form a closed pipeline; the three-way switching valve is also provided with a comprehensive controller. The method for preparing the yeast powder comprises the following steps of yeast block crushing, air conveying of the yeast powder, yeast powder collection and environmental dust collection. According to the powdery yeast equipment and the method for preparing the yeast powder, a yeast block is crushed and the yeast powder is conveyed under a full-negative-pressure state; the crushing quality can be monitored in real time, the working temperature of a crusher is effectively controlled and the conveying efficiency is greatly improved.

Owner:KWEICHOW MOUTAI COMPANY

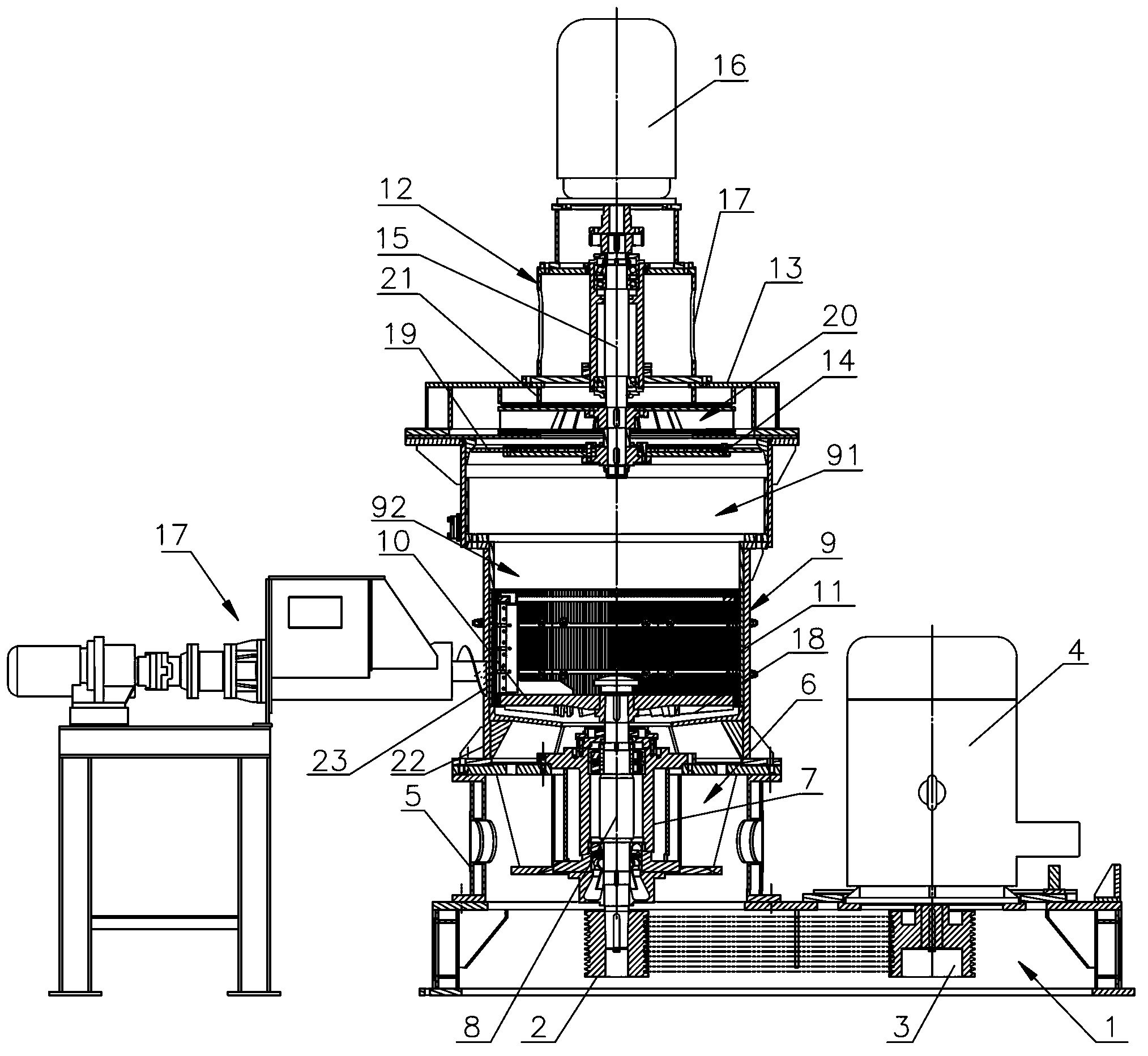

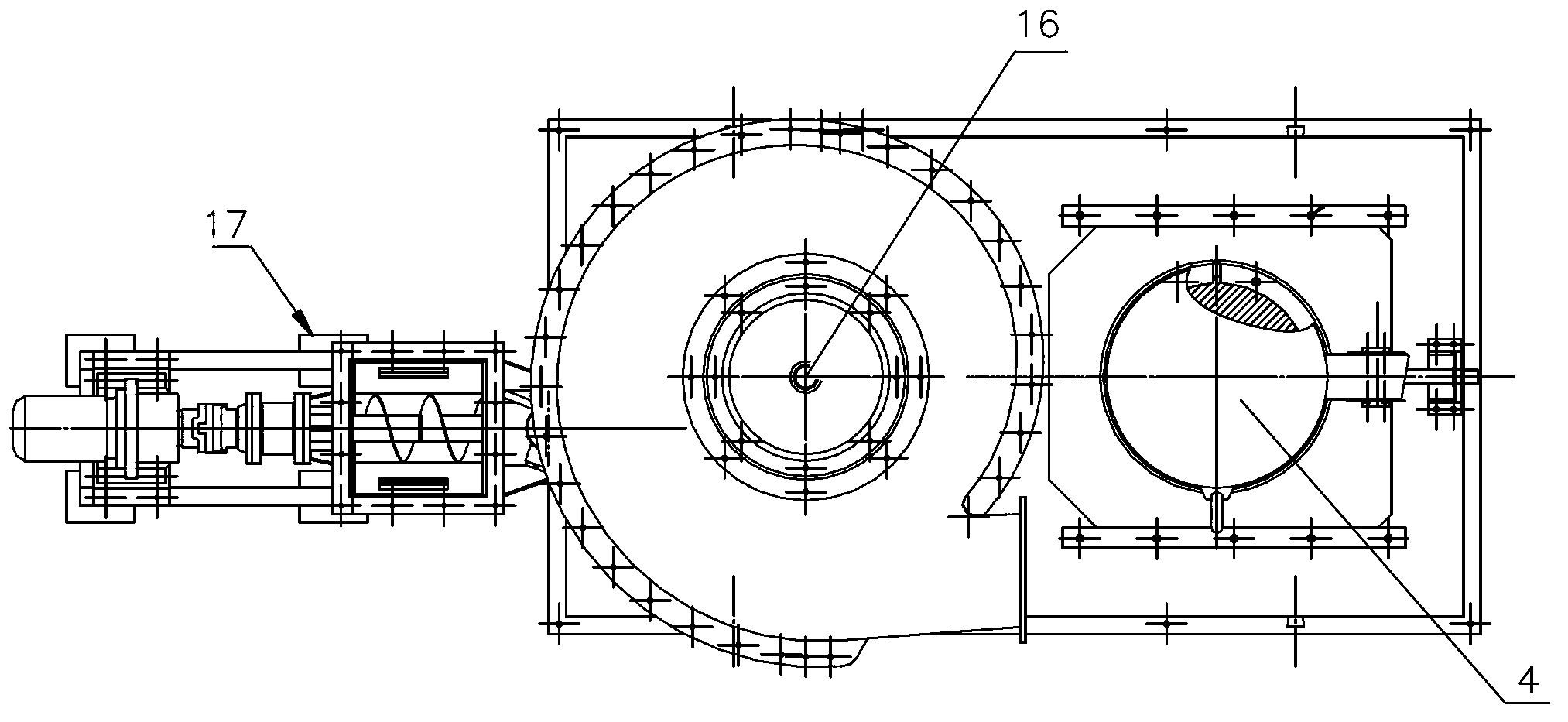

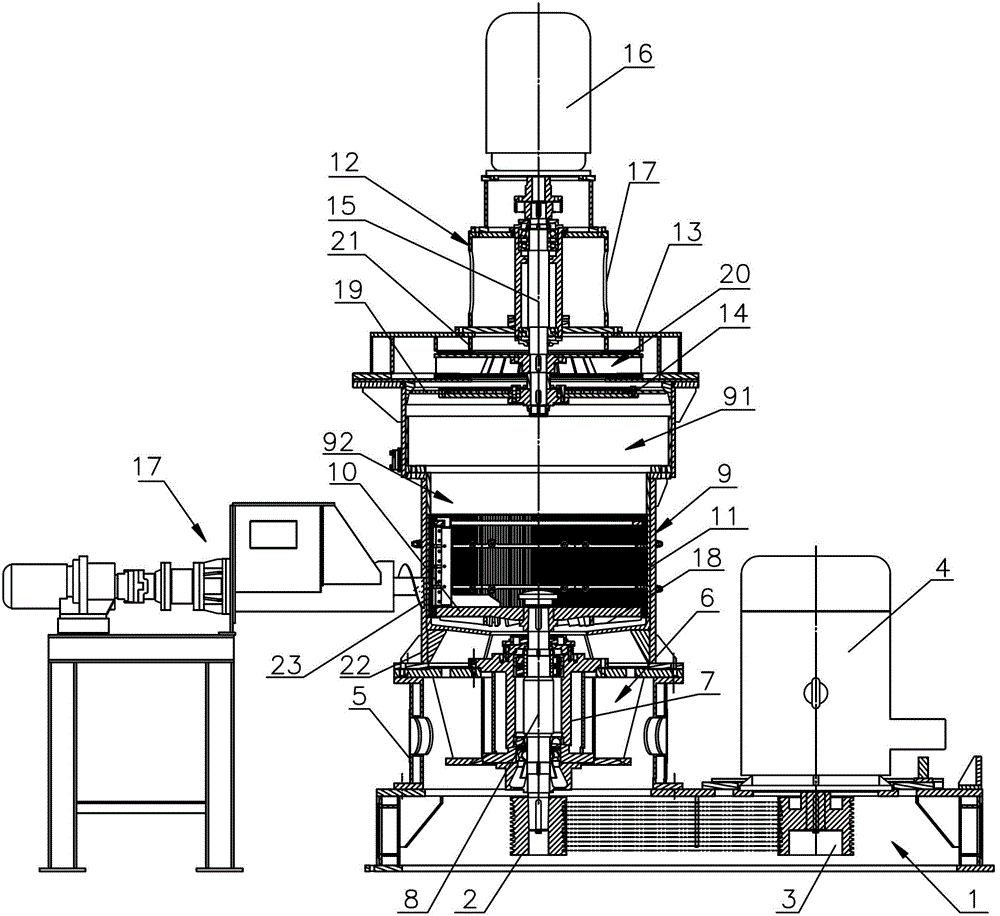

Powder depolymerization beater

ActiveCN103252284AReduce energy consumptionImprove versatilityGrain treatmentsDepolymerizationElectric machinery

The invention relates to a powder depolymerization beater. The powder depolymerization beater comprises a machine shell, wherein the machine shell comprises a classifying cavity and a beating cavity which are distributed from top to bottom, wherein the beating cavity is provided with a crushing mechanism which is used for crushing materials and utilizes a crushing main shaft as a rotating center; and the classifying cavity is provided with a classifying mechanism which can discharge material after crushing and utilizes a classifying main shaft as a rotating center, the crushing mechanism is driven by a crushing motor, and the classifying mechanism is driven by a classifying motor. The powder depolymerization beater provided by the invention can autonomously regulate a crushing process and a particle guiding process, the rotating speeds of a main shaft and the classifying main shaft are also controlled to be different, and thus, the purposes that the material is fully crushed and crushed particles are not rapidly guided can be achieved.

Owner:SUZHOU ZHONGYUAN MACHINERY EQUIP MFG

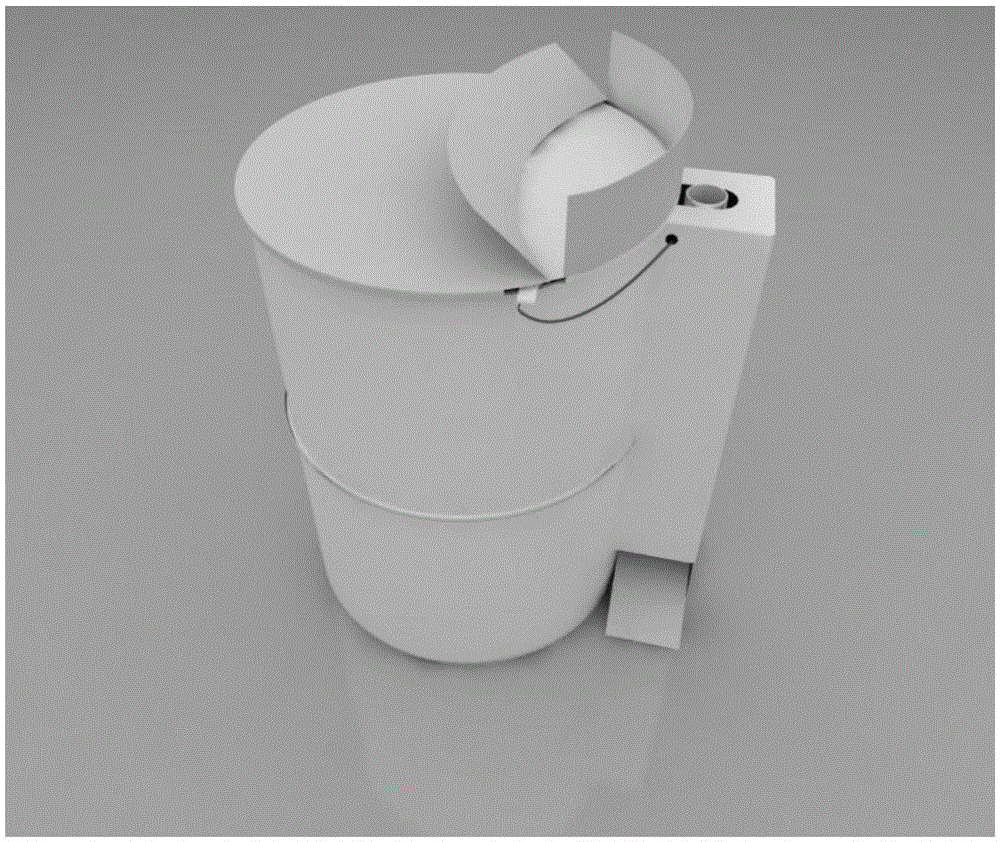

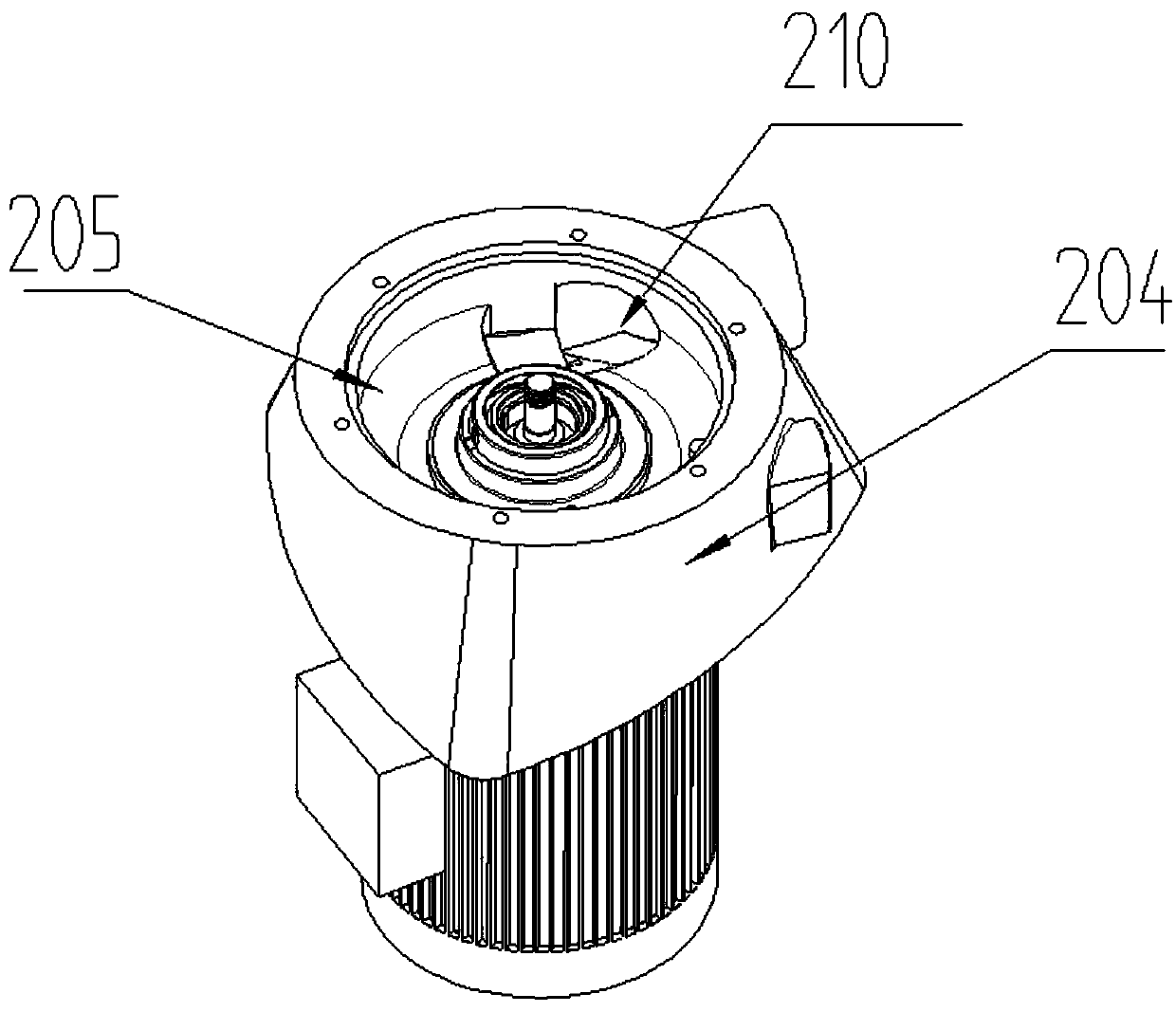

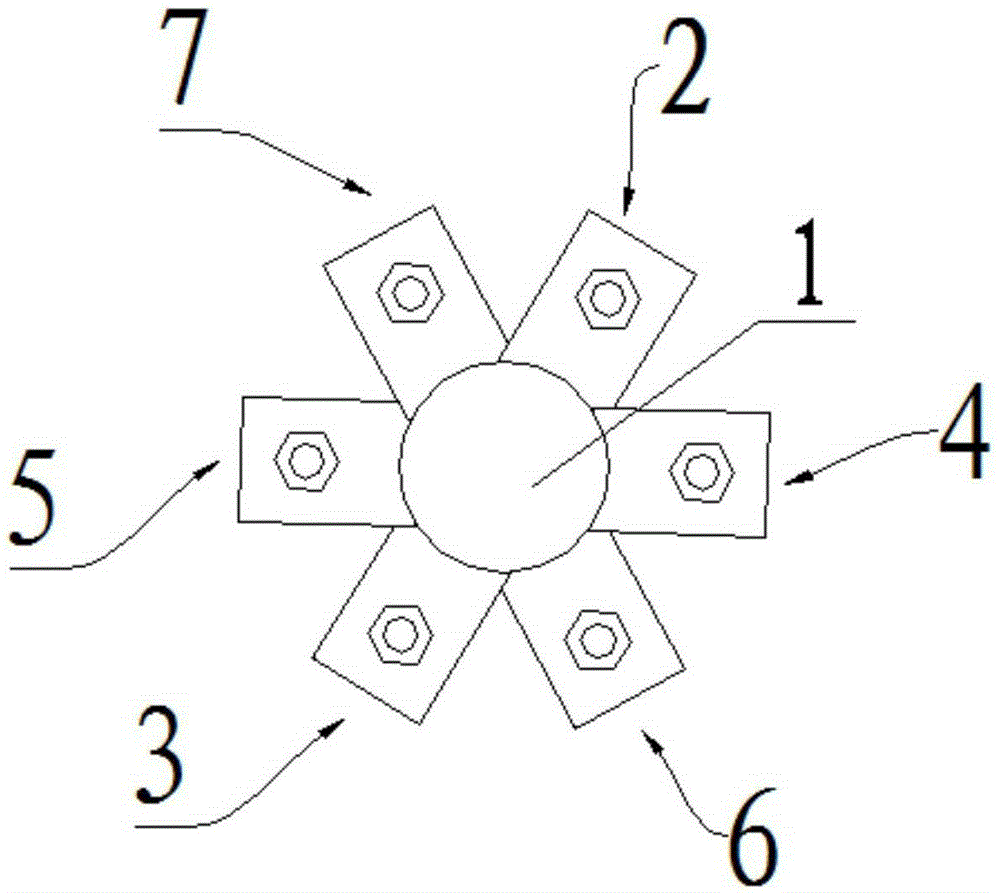

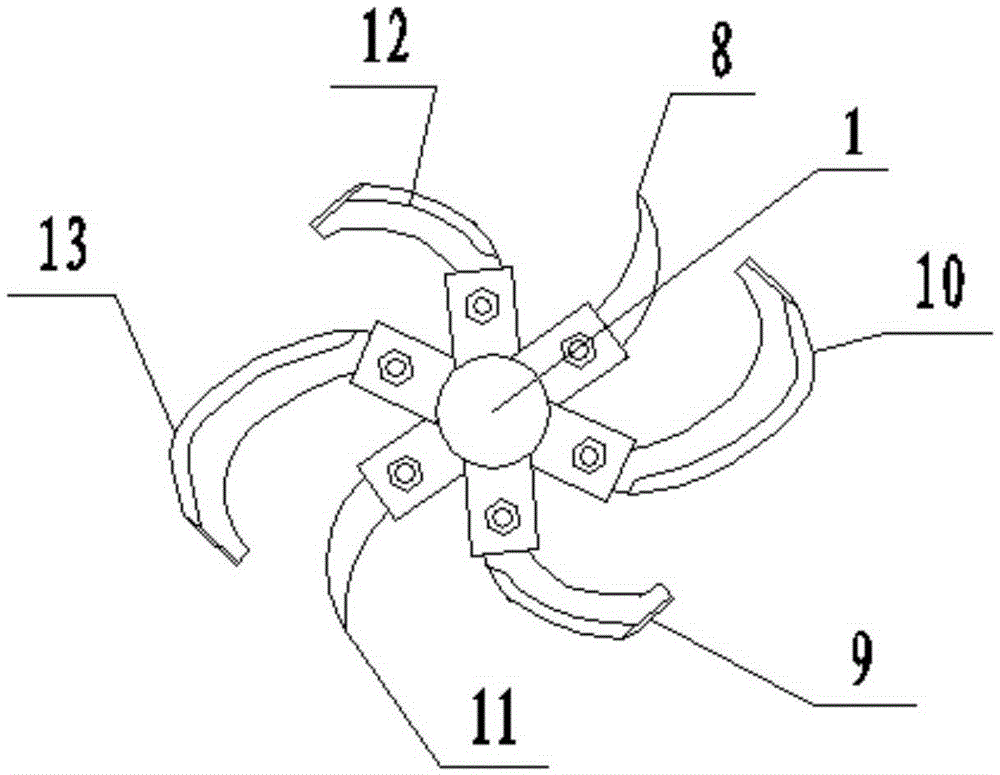

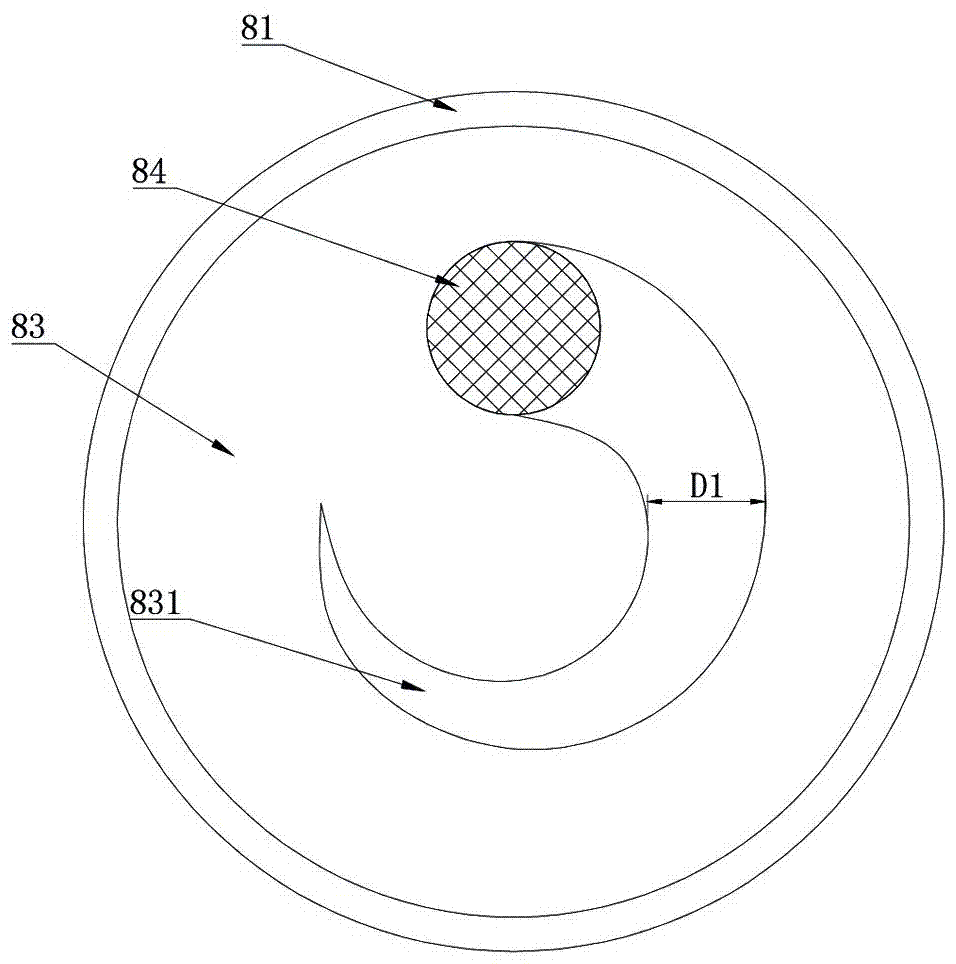

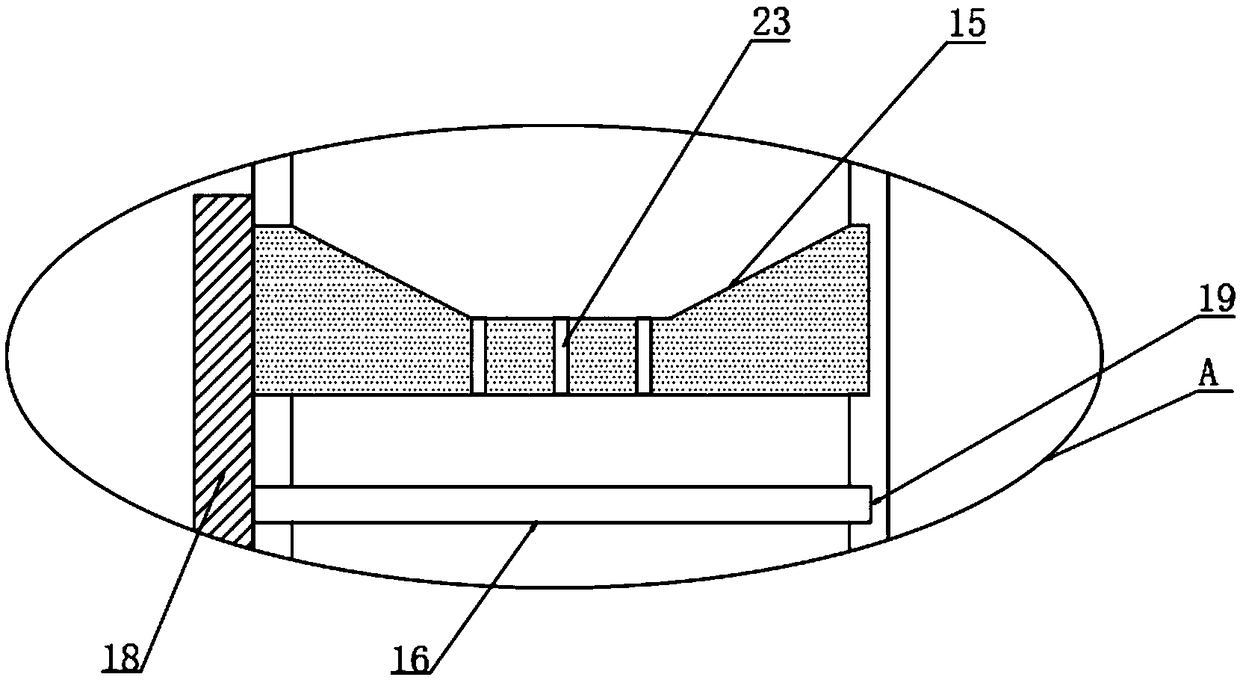

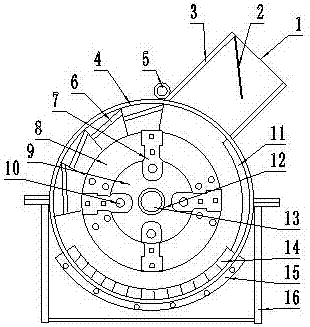

Rubbish disposer for home kitchen and bathroom

ActiveCN105312130AImprove crushing abilityIncrease crushing powerGrain treatmentsFiberHome environment

The invention discloses a rubbish disposer for a home kitchen and bathroom. The kitchen and bathroom rubbish disposer is composed of a convenient feeding mechanism, a cutter disk and inner ring smashing system and a water inlet-outlet system which is electrically controlled by a single chip microcomputer. After feeding, the whole process is completed automatically. After a foot plate is stepped on, a separation plate is pulled to be opened through a steel wire, and rubbish is put into a cavity of an upper box body from a feed inlet. The foot plate is loosened, and the separation plate is reset. The feed inlet is closed, and an electric control program is started. Flowing-in and flowing-out of water are controlled through electromagnetic valves. A cutter disk is driven through a motor to rotate while the water inlet electromagnetic valve is opened. The cutter disk is provided with 3-6 cutter blades through which the rubbish can be smashed. An inner ring is provided with a multi-hole cutting edge. Fibrous matter which is difficult to smash is shredded under the combined action of the multi-hole cutting edge and the cutter blades on the cutter disk. The lower end of the inner ring is provided with a groove, and an annular cavity is formed by the inner ring and the inner wall of a box body, so that up-down circulation of water flow is facilitated and the rubbish is smashed multiple times. After smashing, the water outlet electromagnetic valve is opened, and the rubbish is discharged from a water outlet. The rubbish disposer can be used for disposing kitchen waste vegetable leaves, plastic bags, baby diapers, sanitary pads and other rubbish containing fibers, and the problems that sewers of the kitchen, the bathroom and a toilet are blocked due to the rubbish are solved, so that the home environment is improved.

Owner:XIANGTAN UNIV

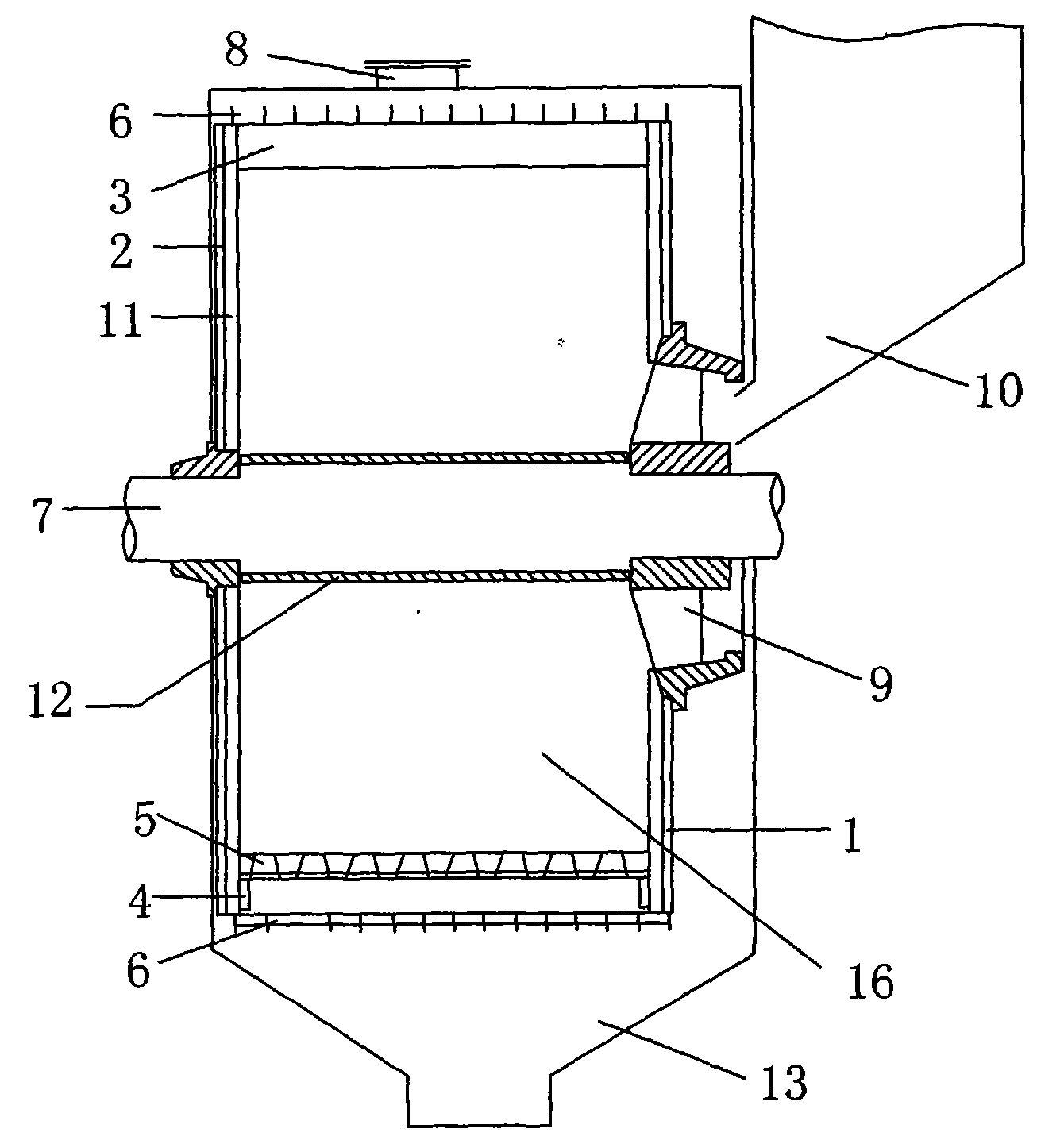

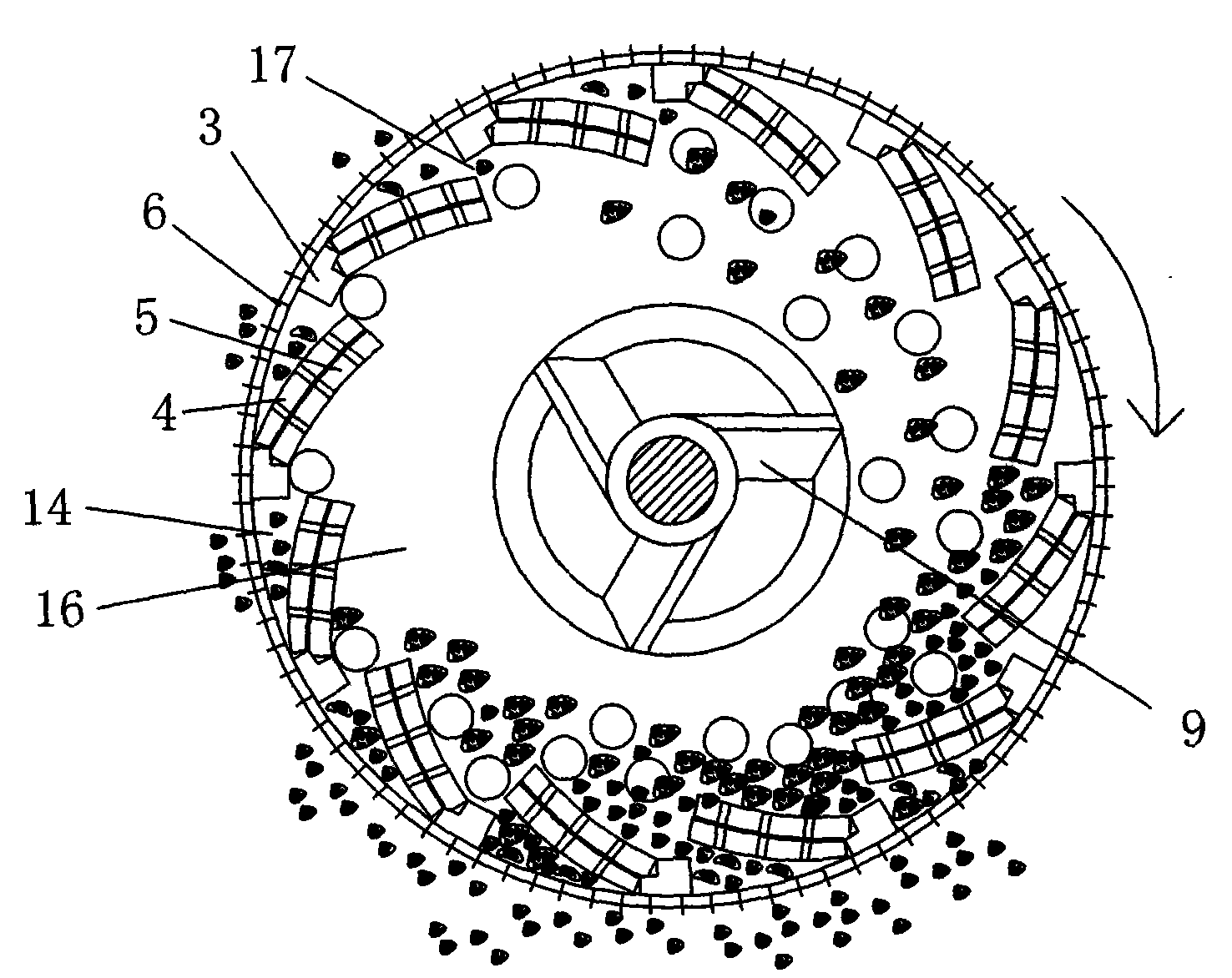

Roller crusher

The invention discloses a roller crusher. The prior crusher mainly performs single-stage crushing by an impact or extrusion mode, so that the crusher has large equipment attrition and large power consumption, cannot perform sieving in time, is difficult to control the granularity of materials, and cannot feed back alone. The invention provides the roller crusher in order to solve the problems, wherein one end of a driving shaft (7) is firmly fixed on a central hole of a back end plate (2), and the other end of the driving shaft (7) is firmly fixed on a central hole of a helical guide plate (9); the outer edge of the helical guide plate is firmly fixed on a front end plate (1) which is connected with the back end plate (2) through a lashing strip (3); one end of a sieve plate (4) is firmly fixed on the lashing strip and forms steps for accommodating and lifting the materials; a screen mesh (6) is coated on the outside of the lashing strip and the sieve plate to form a cylinder; and an outer cover which is taken as a receiving bin (13) is arranged outside a secondary sieve. The roller crusher has reasonable design, simple structure and low maintenance and management cost, can sieve qualified materials in time, and is energy-saving and environment-friendly.

Owner:曾发明 +1

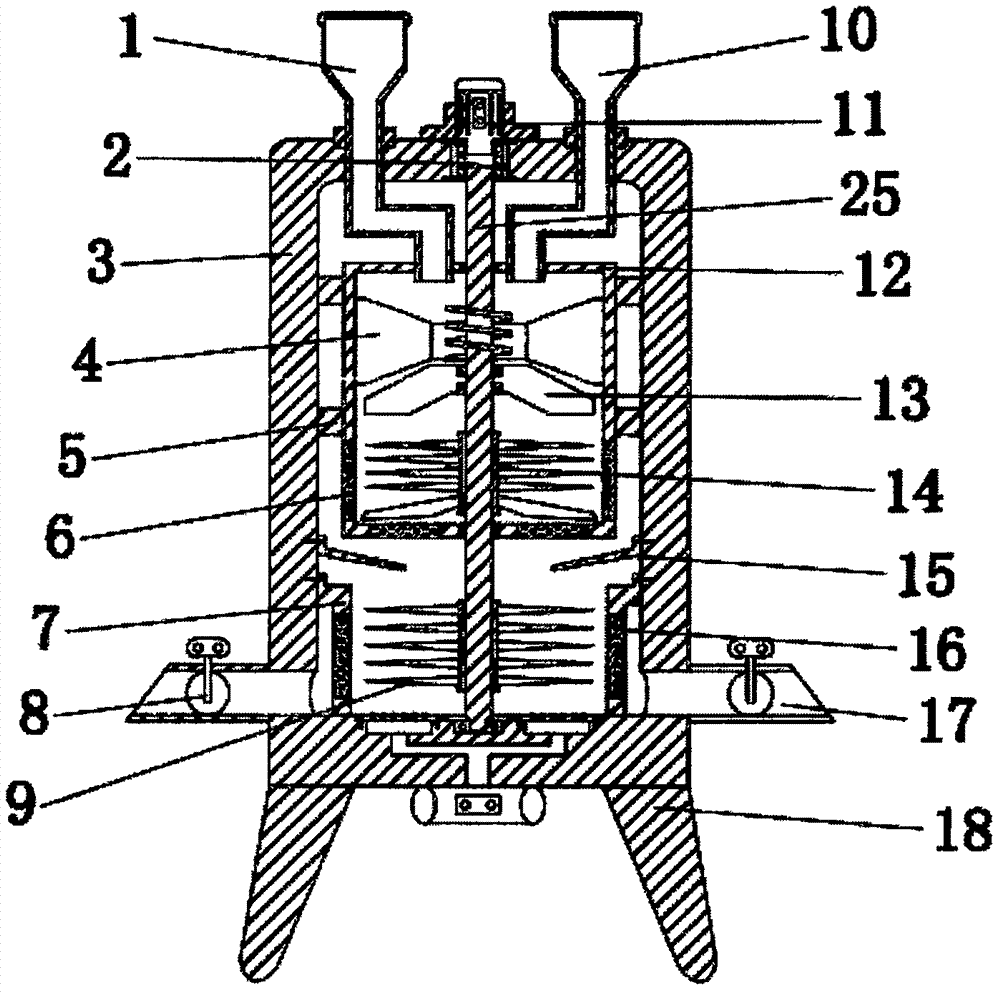

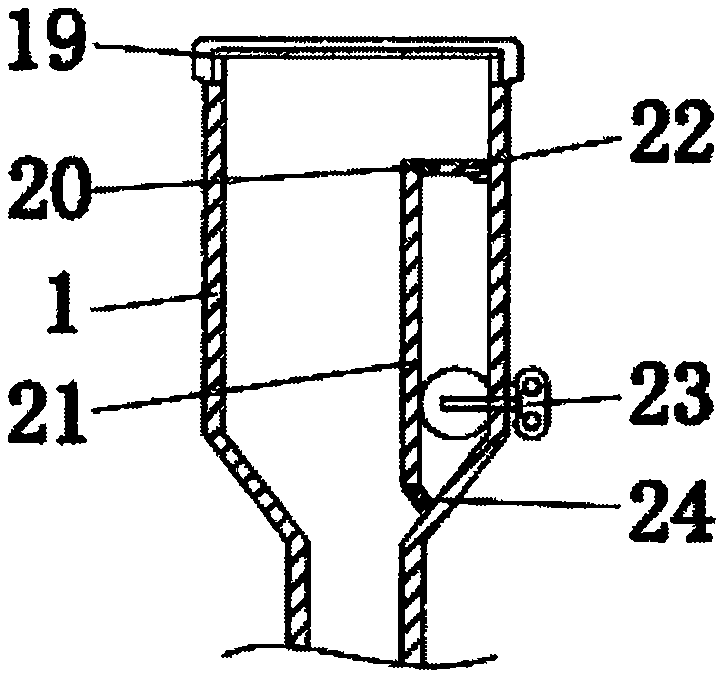

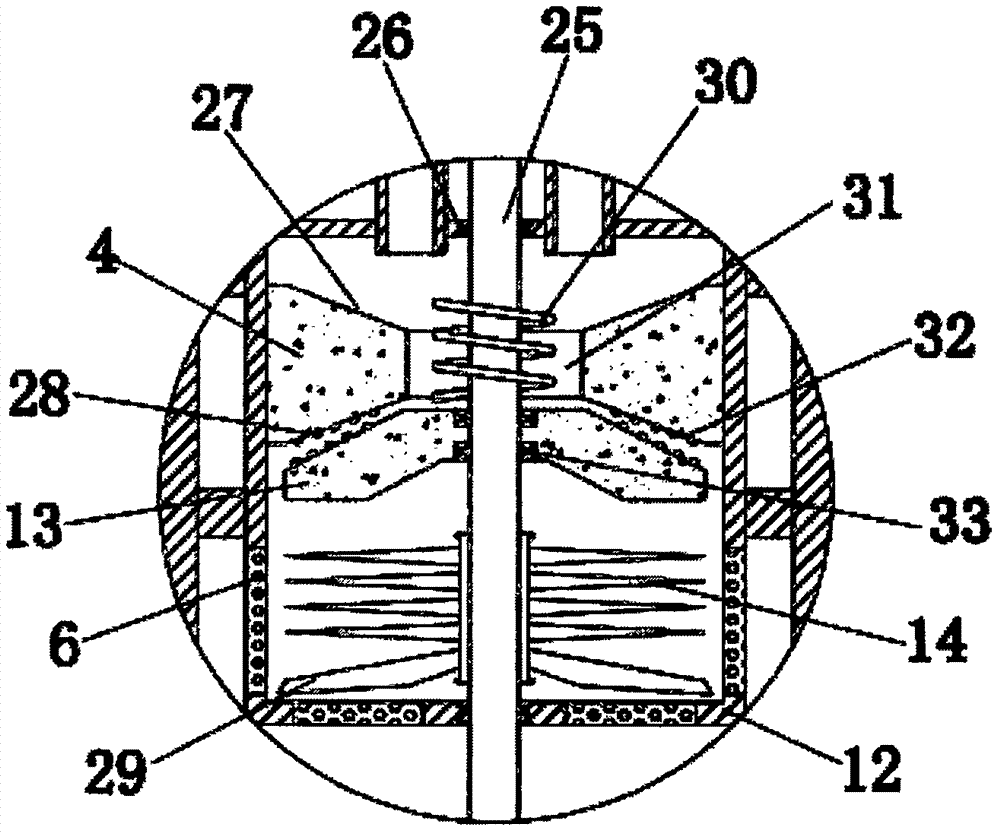

Biotechnological material ultrafine-crushing device

The invention discloses a biotechnological material ultrafine pulverization device, which comprises a casing, the left and right sides of the top of the casing are respectively connected with a first feeding hopper and a second feeding hopper, and the inner top of the casing is provided with As for the top cylinder, an upper pulverizing knife is installed on the top of the outer wall of the main shaft rod, and a bottom pulverizing knife is installed on the outside of the bottom end of the main shaft rod. The ultra-fine pulverization device for biotechnology materials, through the cooperation of the first metal mesh and the second metal mesh with the bottom pulverizer and the upper pulverizer, drives the upper pulverizer to rotate when the main shaft rotates, and the pulverized material passes through the first metal The net falls into the shell, and the unqualified material stays in the top cylinder and continues to be crushed by the rotation of the upper crushing knife. When the material is floating, the tiny particles of the material pass through the second metal mesh on the inner wall of the bottom ring cylinder and then fall to the discharge pipe. The material with a larger specific gravity falls back to the inside and is continuously crushed by the bottom crushing knife, which meets the actual use requirements.

Owner:张志通

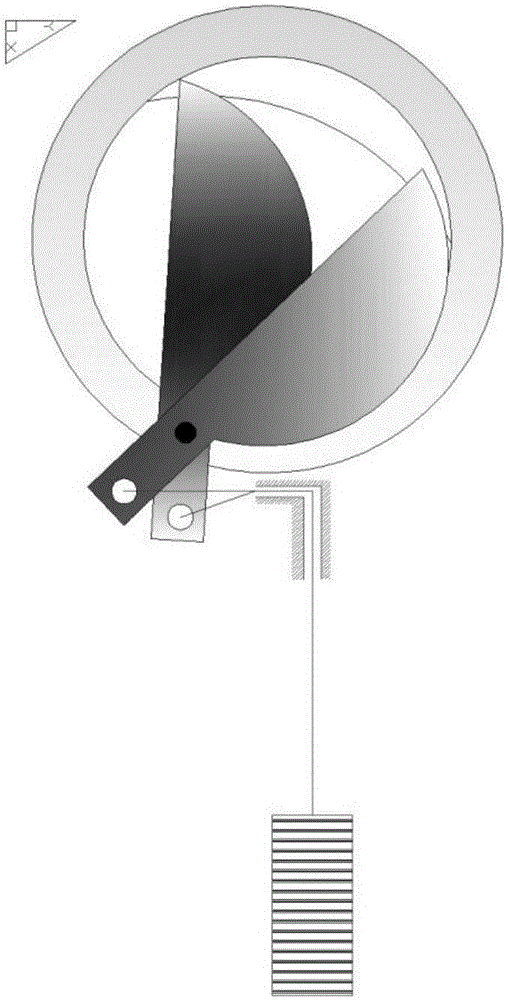

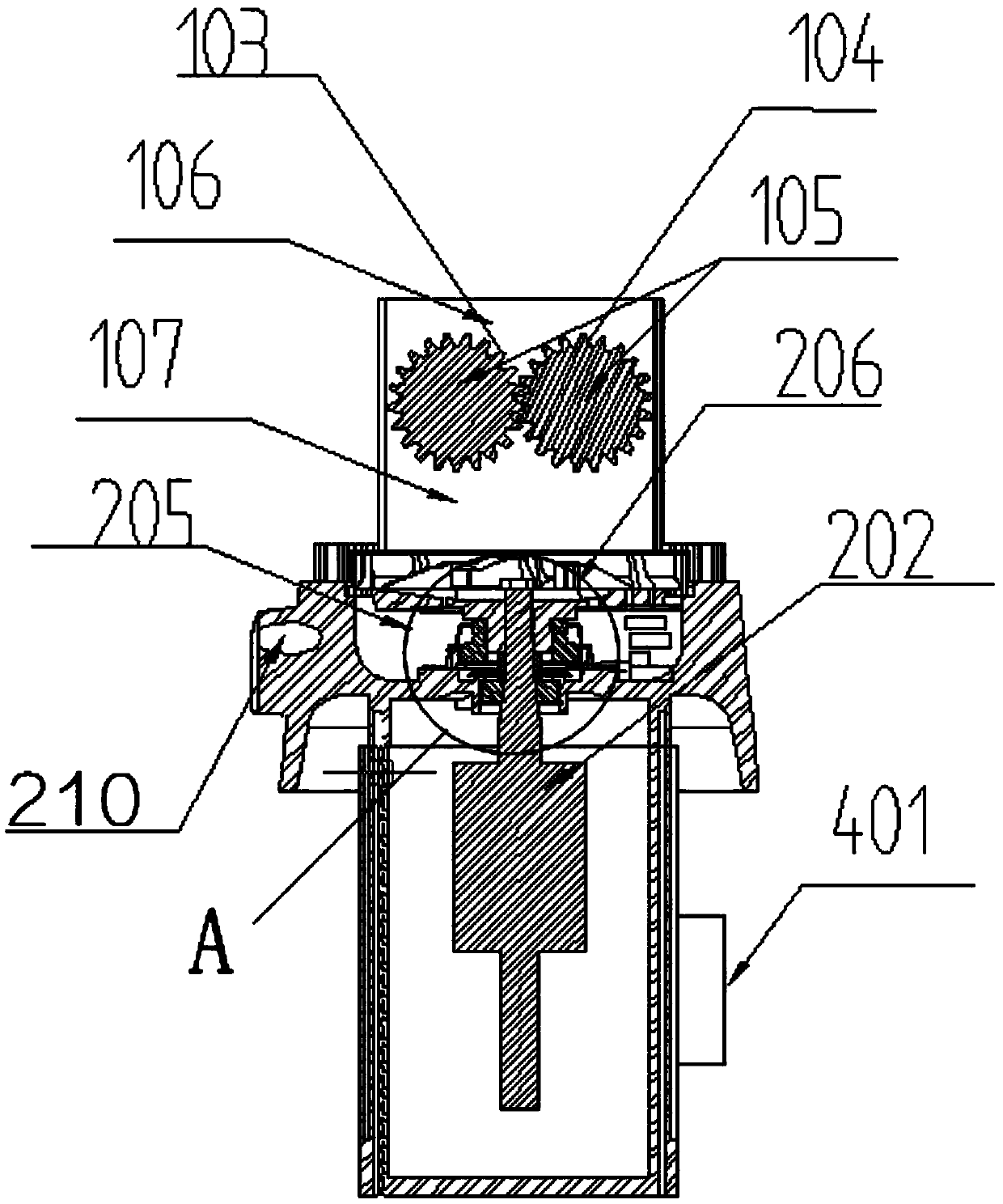

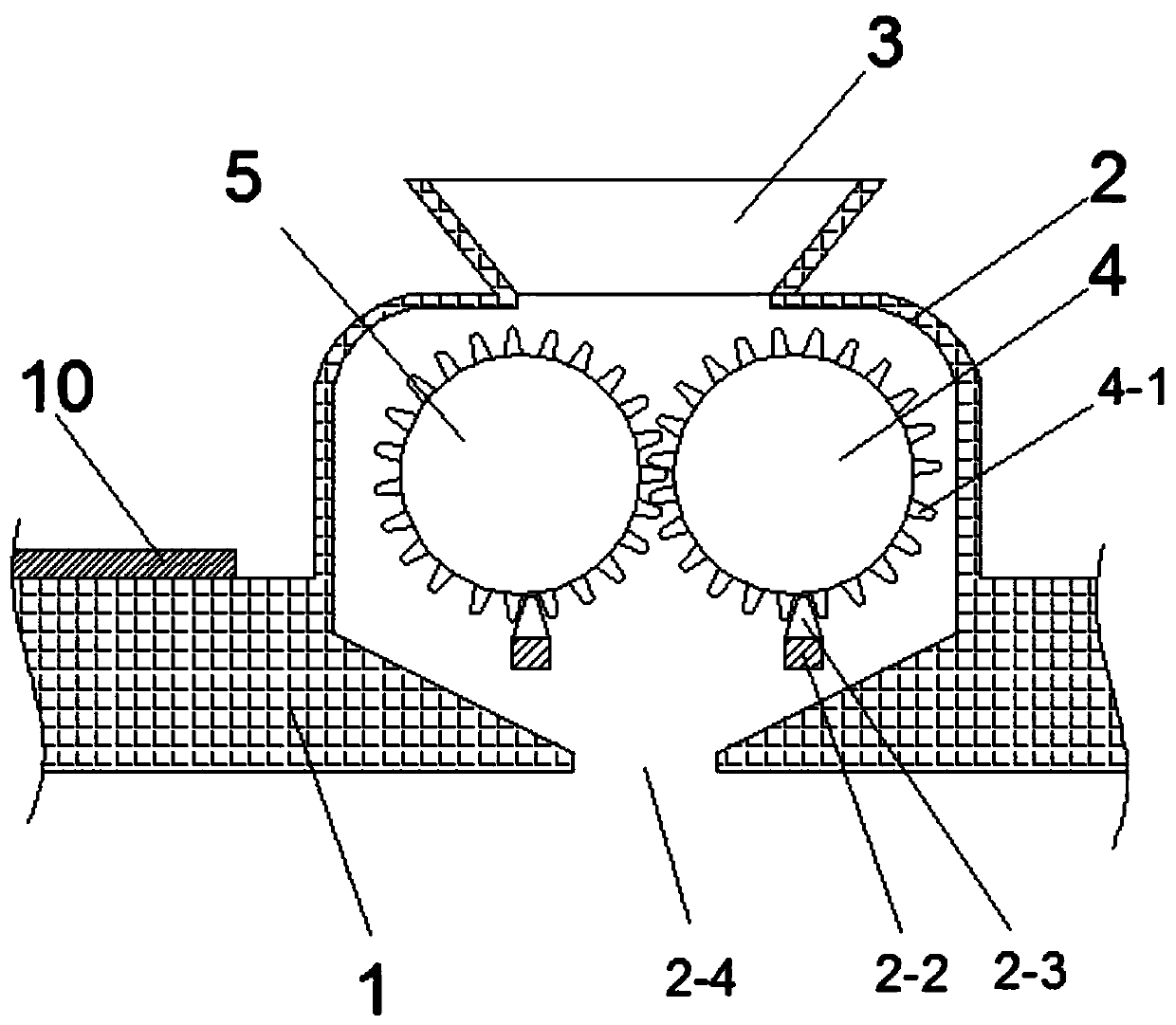

Crushing conduction enhanced kitchen waste disposal plant

InactiveCN109622134AImprove crushing abilityEnhanced handling and crushing capabilitiesDomestic plumbingGrain treatmentsHigh frequencyWaste disposal

The invention discloses a crushing conduction enhanced kitchen waste disposal plant. The crushing conduction enhanced kitchen waste disposal plant comprises a first-stage crushing body and a second-stage crushing body, wherein the first-stage crushing body comprises a first-stage shell and a first-stage crushing component, waste is crushed and extruded by a gear by virtue of the rotation of the first-stage crushing body, bones are extruded and crushed to enter a first-stage crushing lower cavity, a second-stage crushing component is arranged on the second-stage crushing body, a crushing hammerand a crushing wall are arranged on the upper surface of the second-stage crushing component, a pressure reinforcing piece and a cutting knife are arranged on the lower surface of the second-stage crushing component, a second-stage crushing power shaft rotates so as to drive the second-stage crushing component to rotate, kitchen waste is stricken at high frequency between the crushing hammer andthe crushing wall so as to be crushed, and then the kitchen waste is cut and crushed by virtue of the rotation of a cutting ring and the cutting knife and then is discharged. The device has the characteristics of rapidity, reliability, low cost and practicability, and the problems of no thoroughness in crushing the kitchen waste, poor universality, difficulty in discharging the waste, easiness inblockage and the like in the prior art can be solved.

Owner:泰州首创环保科技有限公司

Stubble-cleaning soil-crushing rotary tillage apparatus

The invention provides a stubble-cleaning soil-crushing rotary tillage apparatus. A handle unit A, a handle unit C, a handle unit E, a handle unit B, a handle unit D and a handle unit F are successively uniformly arranged at the outer periphery of a cutter shaft along a spiral direction. The handle unit A is successively provided with a right stubble-cleaning knife, a right soil-crushing knife and a right rotary tillage knife from the left to the right; the handle unit C is successively provided with a right rotary tillage knife, a right stubble-cleaning knife and a right soil-crushing knife from the left to the right; the handle unit E is successively provided with a right soil-crushing knife, a right rotary tillage knife and a right stubble-cleaning knife from the left to the right; the handle unit B is successively provided with a left stubble-cleaning knife, a left soil-crushing knife and a left rotary tillage knife from the left to the right; the handle unit D is successively provided with a left rotary tillage knife, a left stubble-cleaning knife and a left soil-crushing knife from the left to the right; and the handle unit F is successively provided with a left soil-crushing knife, a left rotary tillage knife and a left stubble-cleaning knife from the left to the right. The apparatus provided by the invention can simultaneously realize stubble-cleaning, soil-crushing and rotary tillage functions, and is simple in overall structure, small in land occupation and convenient to operate.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

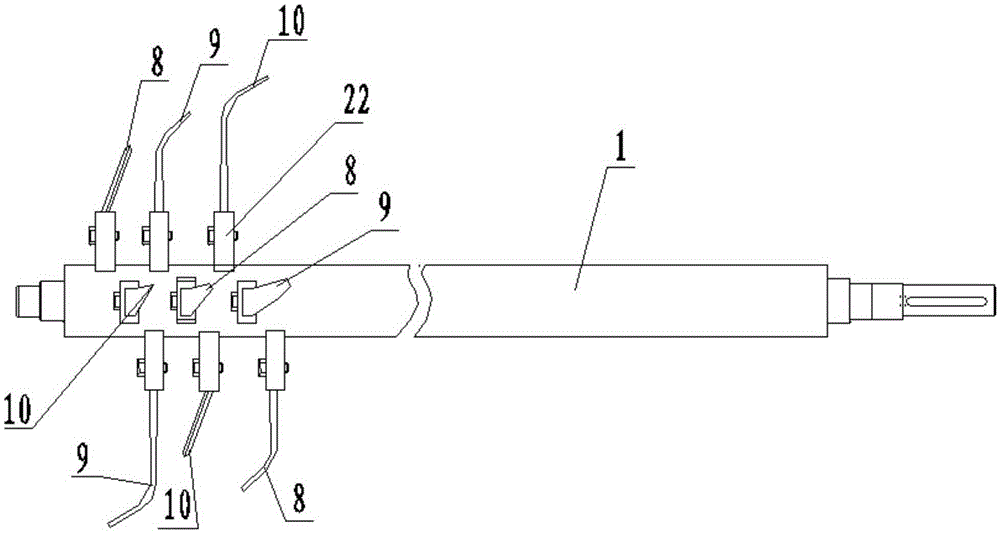

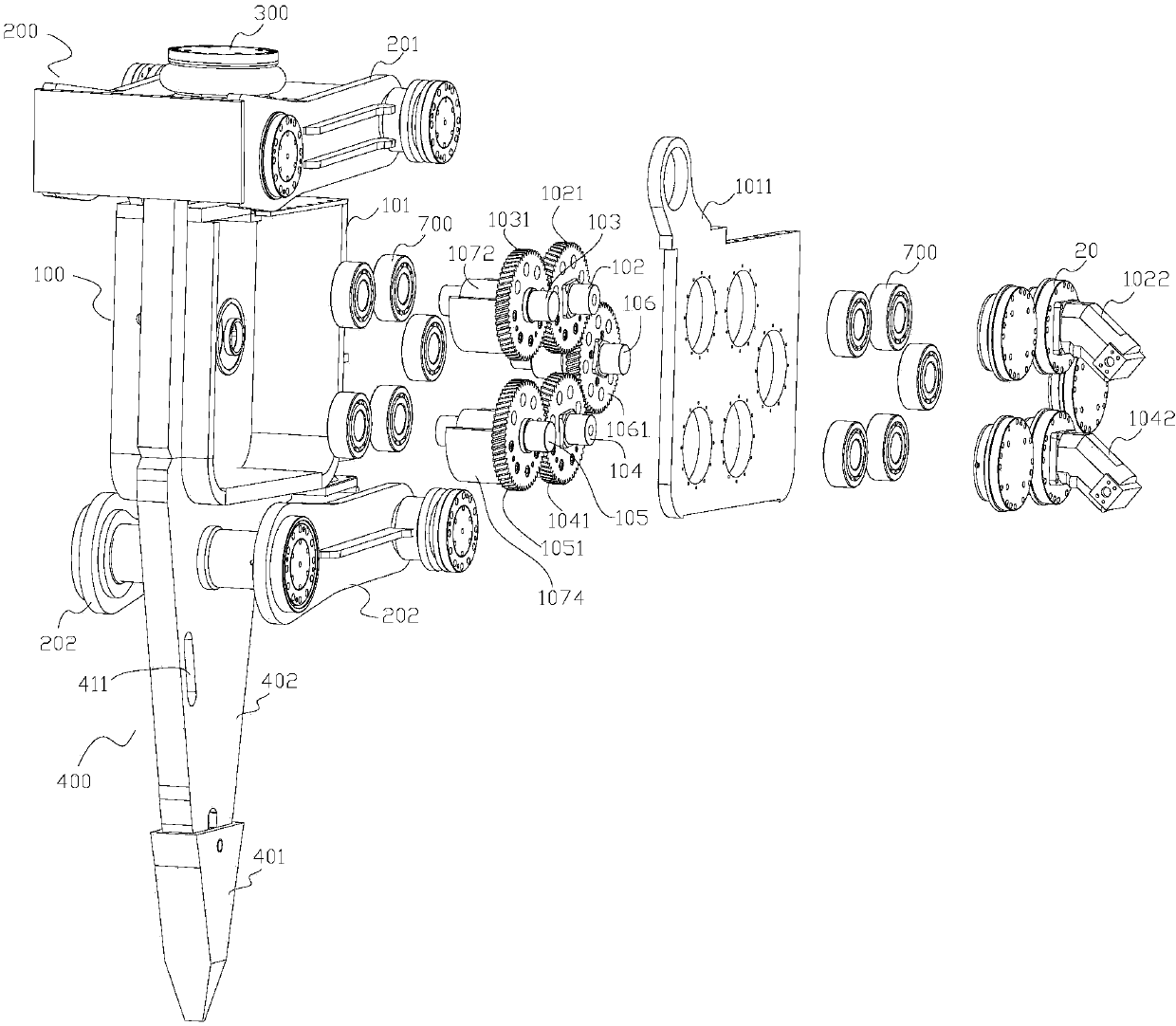

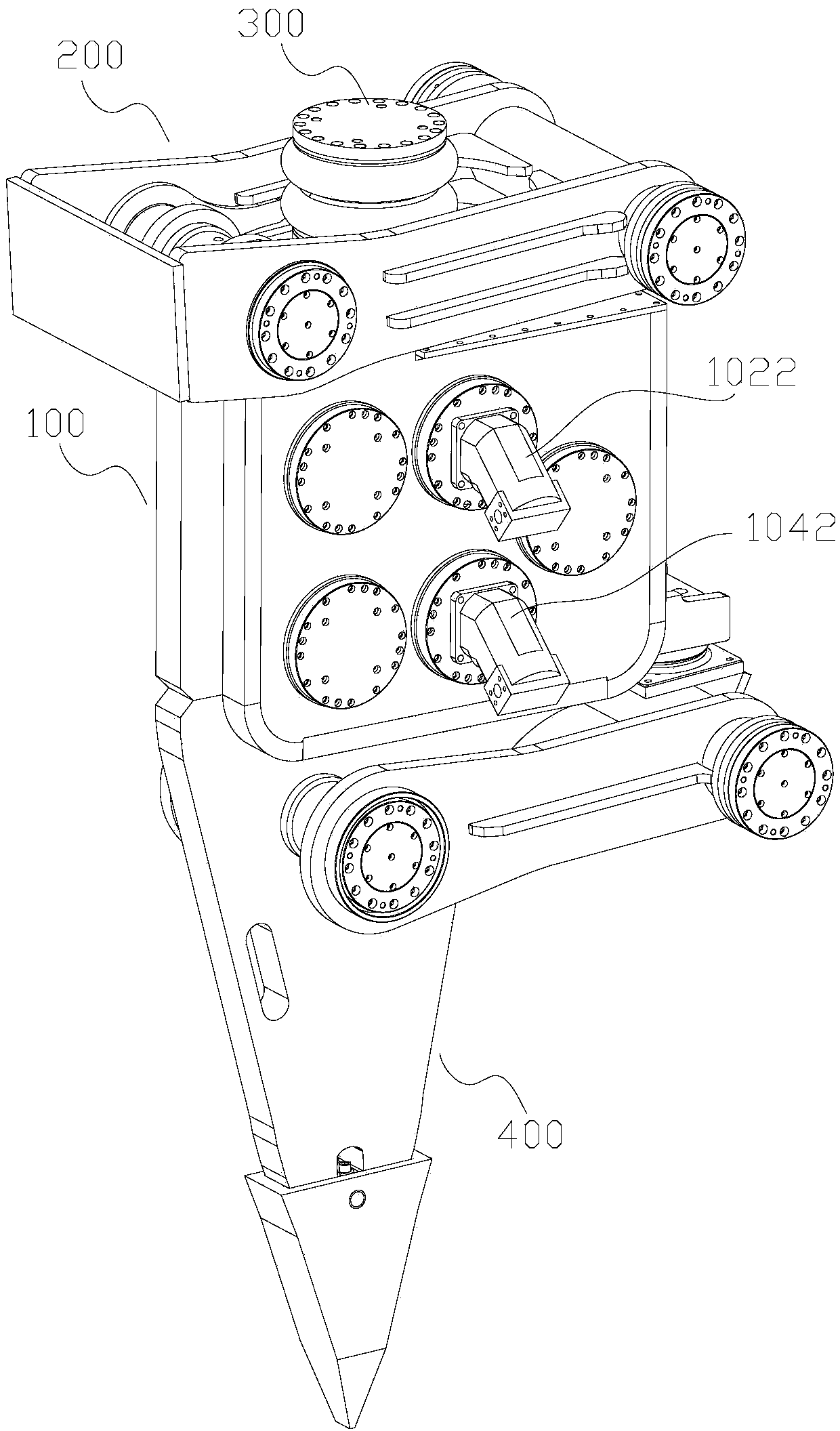

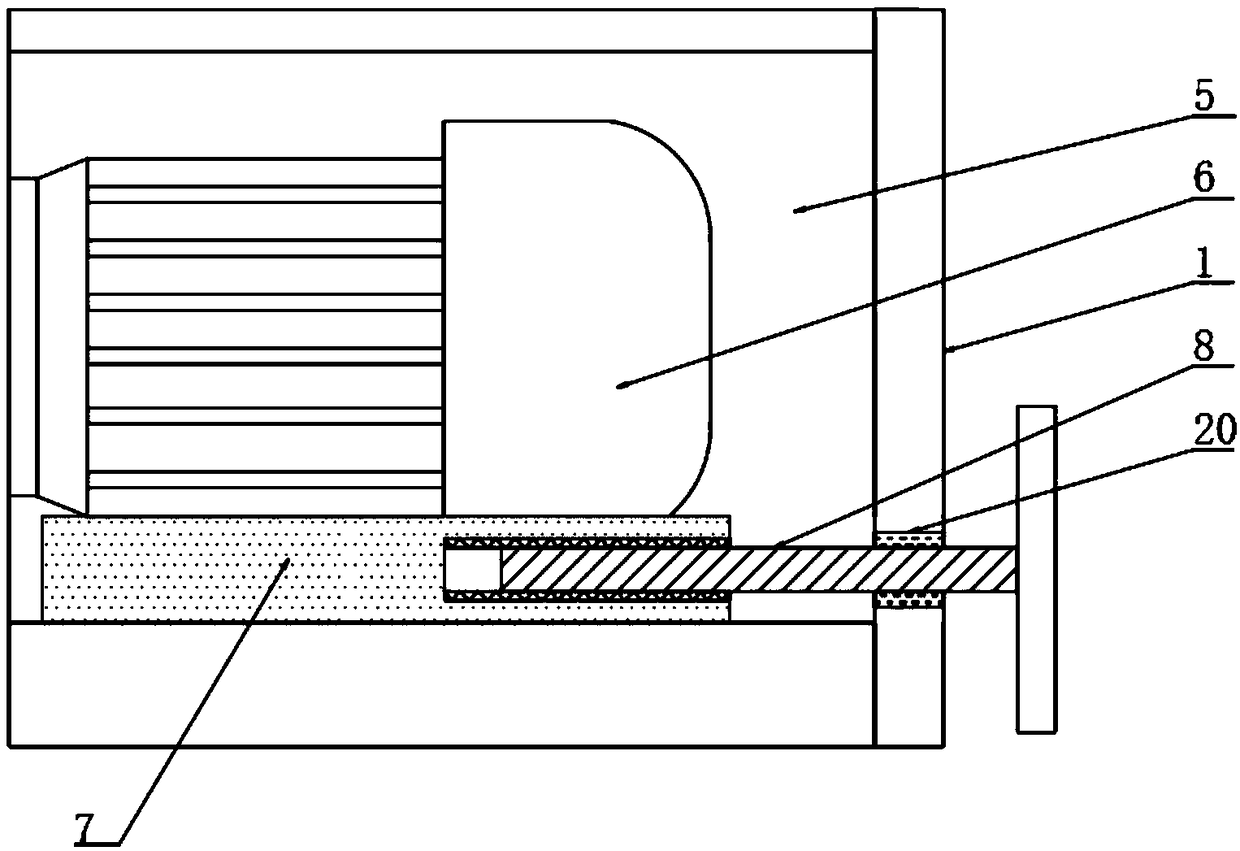

Double-motor crushing device of high frequency crushing hammer

ActiveCN103736545AStrong crushingHigh crushing precisionNon-rotating vibration suppressionGrain treatmentsDrive shaftOperation time

The invention discloses a double-motor crushing device of a high frequency crushing hammer. The double-motor crushing device comprises a vibration generator, a four connecting rod mechanism and a shaking knife row, wherein the vibration generator comprises a shell, a first driving shaft arranged in the shell, a first driven shaft which is mutually meshed with the first driving shaft through gears, a second driving shaft, a second driven shaft which is mutually meshed with the second driving shaft through gears as well as a bridge crossing shaft arranged between the first driving shaft and the second driving shaft; the bridge crossing shaft is mutually meshed with the first driving shaft and the second driving shaft gears, the first driving shaft, the first driven shaft, the second driving shaft and the second driven shaft are all provided with eccentric wheels and gears. The double-motor crushing device disclosed by the invention has the advantages that as two groups of actuating shafts are adopted and matched with two actuating motors, the crushing force of the crushing hammer actuated by the two actuating motors is large relative to that of the crushing hammer actuated by the single motor, the crushing accuracy is high, the noises are small, and the crushing capacity is strong, thus the operation time of the crushing hammer is prolonged, and the crushing efficiency is improved.

Owner:苏州鸣尼克重工机械有限公司

Material pulverizer with dust removal function

InactiveCN106861842AStrong incomeIncrease incomeDirt cleaningGrain treatmentsEngineeringExhaust pipe

The invention belongs to the technical field of crushing machinery and discloses a dust-removable material grinder, which includes a crushing chamber, a separation chamber, a dust removal chamber, a crushing shaft, a feeding cover, a crushing motor, a dust removal bag and a vibrating screen. The upper side of the crushing chamber is A feed hopper is provided, and a crushing shaft is arranged inside the crushing chamber, and the crushing shaft axially penetrates the crushing chamber, and a crushing motor is fixedly installed at one end of the crushing shaft, and the crushing motor is arranged on the wall of the crushing chamber. The lower side of the chamber is provided with a separation chamber, the lower side of the separation chamber is provided with a separation outlet, the upper side of the separation chamber is provided with a dust discharge pipe, and the other end of the dust discharge pipe is connected with a dust removal chamber. The lower side of the chamber is fixedly provided with support frames. The invention has good pulverization and dust removal effects, high powder forming rate, can effectively improve production efficiency and product quality, not only can make the product quality meet the ministerial standard, but also can make the dust emission reach the qualified standard required by the state for environmental protection.

Owner:CHONGQING SHANGSHANG SCI & TECH CO LTD

Flexible crushing equipment for waste asphalt mixture

PendingCN109731633AImprove crushing effectImprove crushing abilityGrain treatmentsSurface cleaningEngineering

The invention discloses flexible crushing equipment for a waste asphalt mixture. The flexible crushing equipment comprises a fixed base, a crushing cavity, a charge hole, a fixed crushing roller, a movable crushing roller, a first transmission motor, a fixed belt wheel, a first transmission motor belt, a movable base rail, a movable base, a hydraulic rod supporting base, a hydraulic rod, a secondtransmission motor, a movable belt wheel, a second transmission motor belt, a fixed block, a supporting rod, a slide block and a locking bolt, wherein the fixed crushing roller is arranged at one sideof the crushing roller; the movable crushing roller is arranged at the other side of the crushing cavity; the bottom ends of the two sides of the crushing cavity are equipped with comb tooth bracketrods; comb teeth are arranged on the top surface of each comb tooth bracket; and the movable base roller is embedded into the movable base rail, so that the movable base is in sliding connection to the fixed base. The flexible crushing equipment can perform differential-speed control over rotation speed of the crushing rollers, is strong in crushing performance, can adjust spacing of the crushingrollers, is high in material crushing and recycling efficiency, is firm in system structure, and can clean the roller tooth surfaces of the crushing rollers.

Owner:镇江路机重工科技有限公司

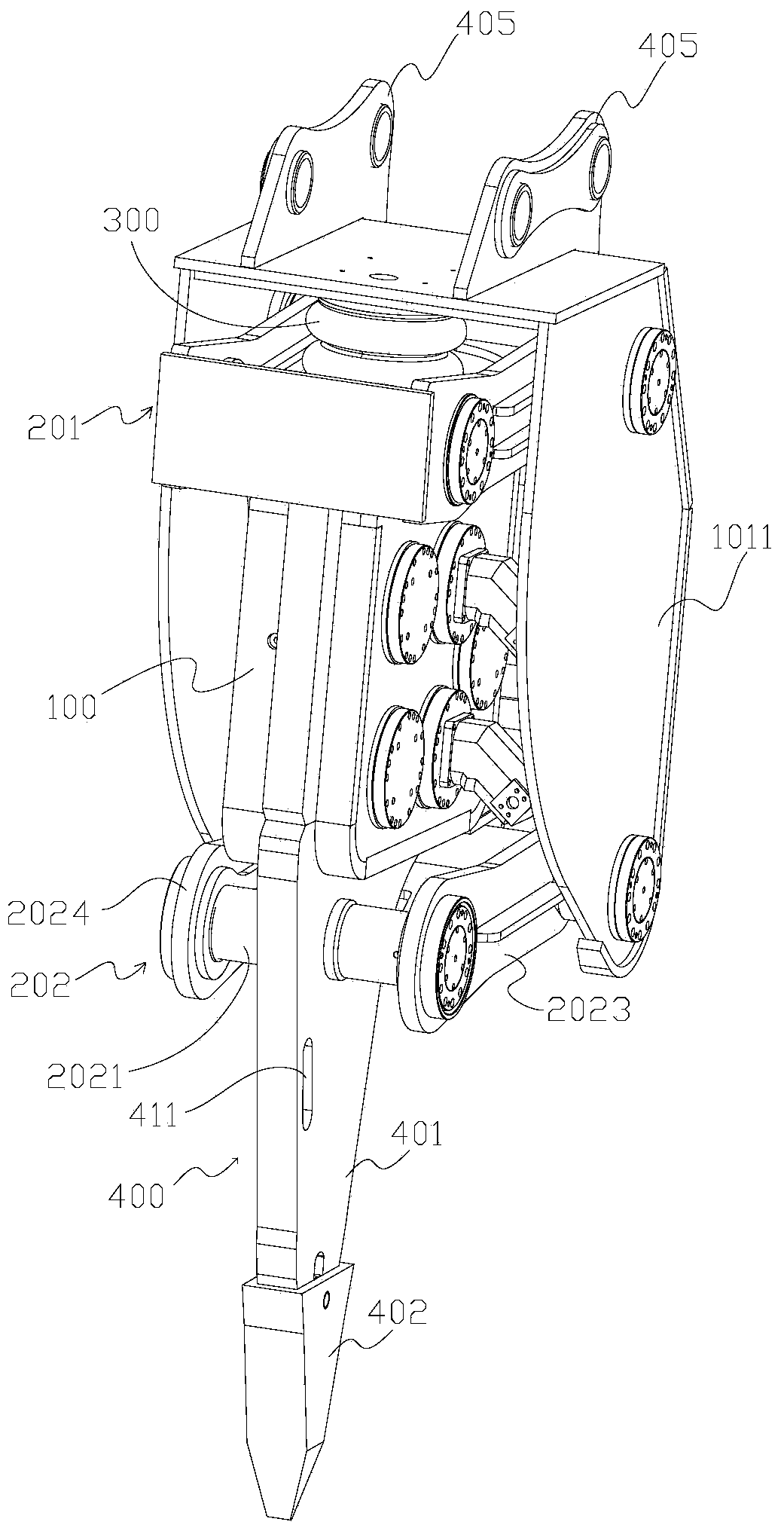

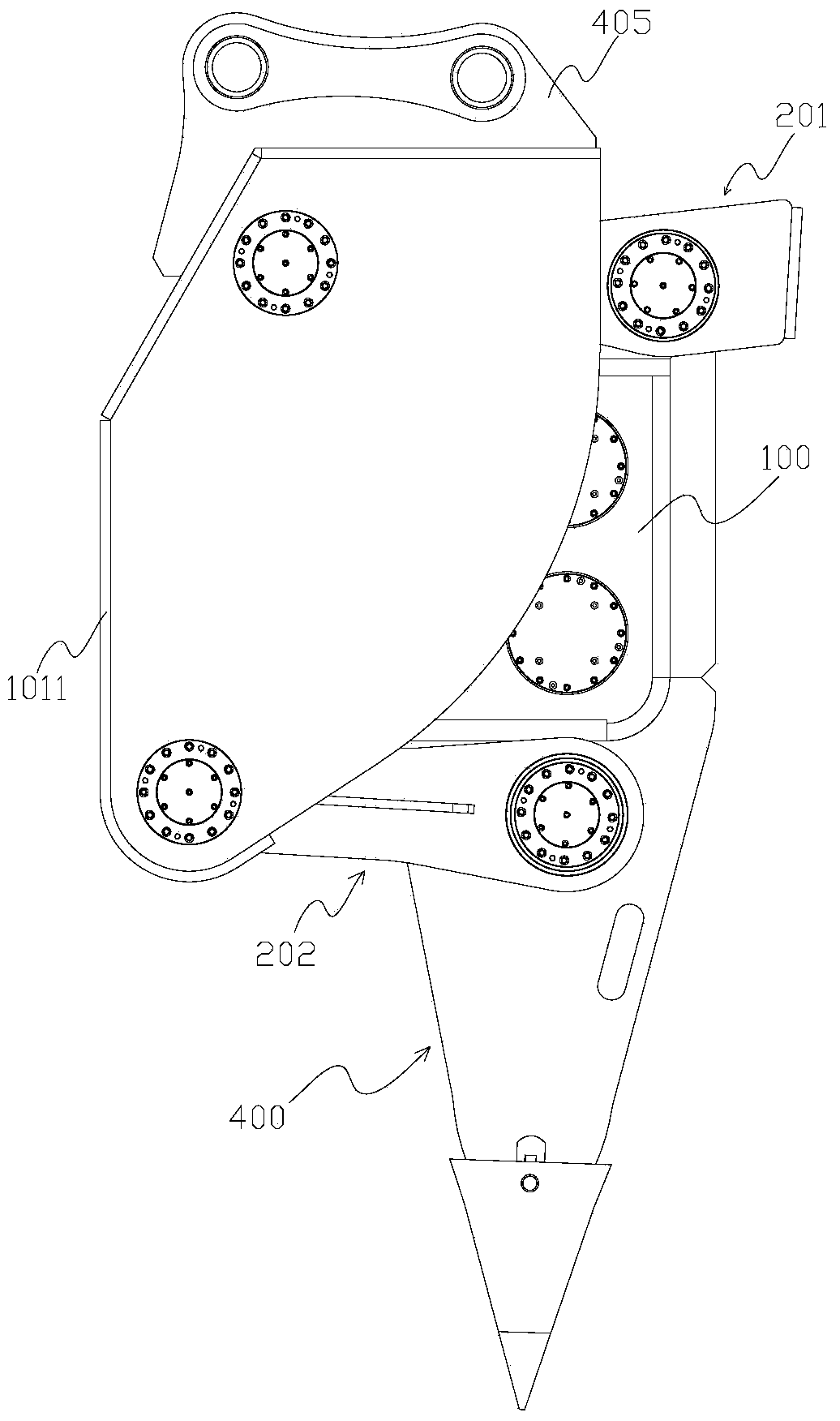

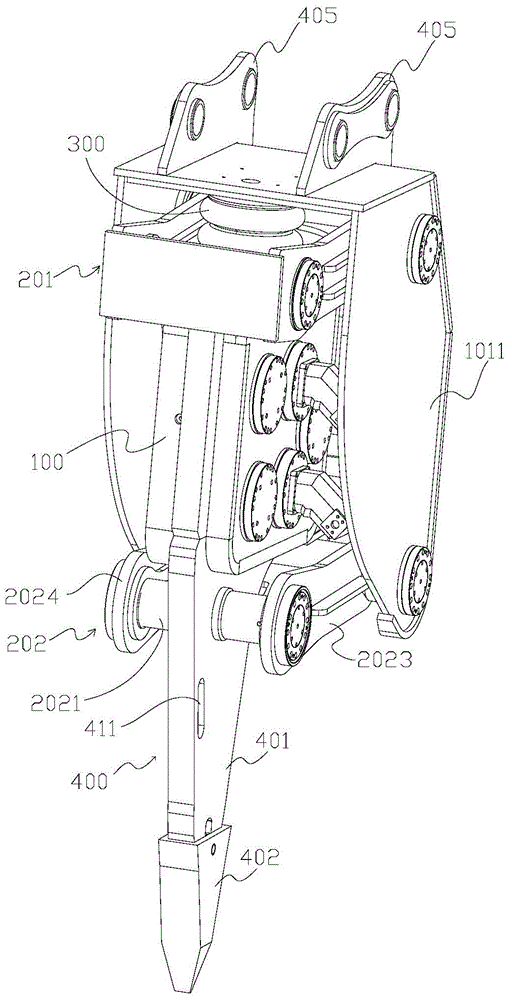

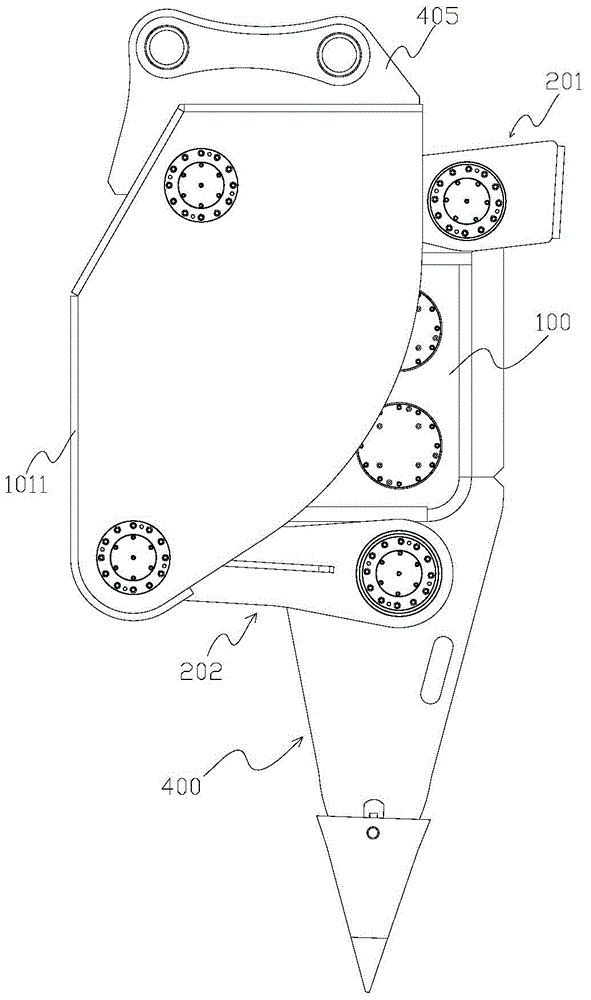

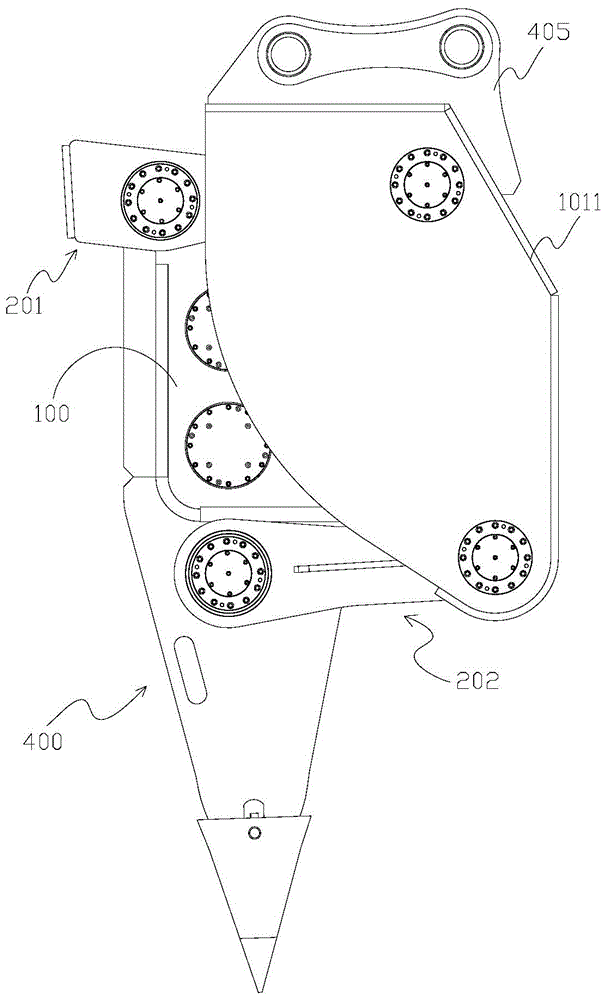

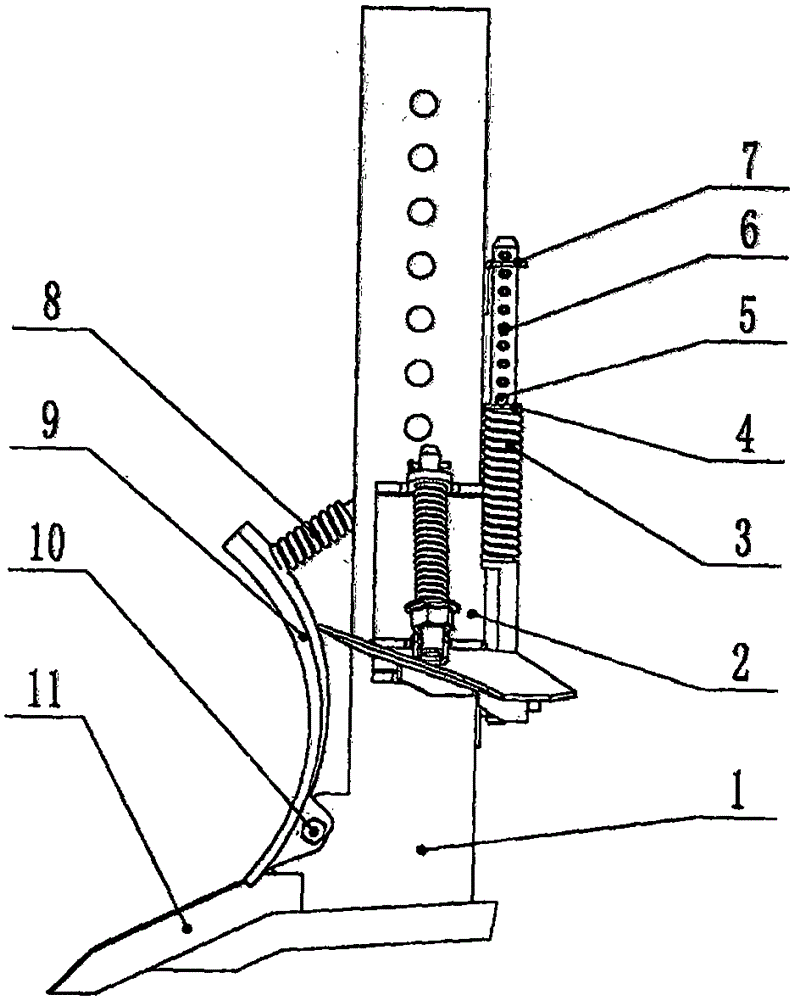

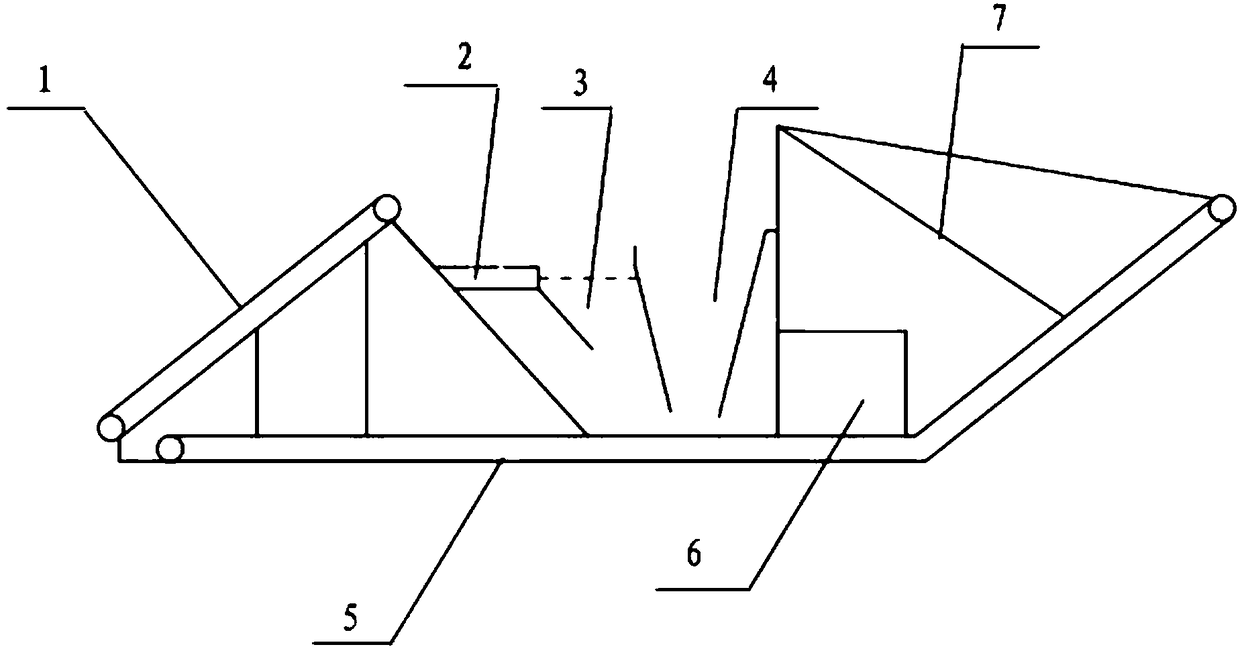

Vibrating subsoiler

ActiveCN105103671AImprove crushing abilityReduce and avoid clogging and winding failuresPloughsAgricultural engineeringSubsoiler

The invention relates to a vibrating subsoiler, and belongs to agricultural machines. A curved surface ploughshare body is installed at the front end of a subsoiler body through a front pin shaft and a ploughshare body pressure spring, hanging lugs are fixedly installed on the rear side portion of the subsoiler body, a vertical shaft is fixedly installed on the hanging lugs, the vertical shaft is sleeved with a shaft sleeve in a matched mode, the shaft sleeve can axially move on the vertical shaft, and the vertical shaft is sleeved with a gasket and a main pressure spring; base plates are fixedly arranged on the portions, located at the left side and the right side of the subsoiler body, of the shaft sleeve respectively, a wing plate is hinged to each base plate through a side pin shaft, a U-type base is fixedly installed on each wing plate, the bottom end of a threaded pin shaft sleeved with an adjusting nut and an auxiliary pressure spring is hinged to each U-type base, and the upper portion of each threaded pin shaft is axially movably inserted into the corresponding base plate. The soil hacking capacity of the vibrating subsoiler during subsoiling operation is substantially improved, faults that the subsoiler body is blocked and wound by weed and the like are reduced, and the range of influence on soil by the subsoiling operation is expanded; the vibrating subsoiler is reasonable in structure, high in operation quality and efficiency, convenient to adjust and wide in application range and has few faults.

Owner:HARBIN CITY ACAD OF AGRI SCI

Pulverizer structure with secondary pulverizing function and pulverizer

ActiveCN107225023AControl dwell timeImprove uniformityFeeding-stuffGrain treatmentsLow noiseEngineering

The invention discloses a pulverizer structure with a secondary pulverizing function. The pulverizer structure comprises more than two rotors. Each rotor comprises a main shaft and more than two hammer carriers. The main shafts of the adjacent rotors are arranged in parallel. The hammer carriers are vertically and fixedly mounted on the corresponding main shafts. Hammers are mounted on the circumferences of the hammer carriers. An included angle alpha between a horizontal line and a line for connecting projective points of the center lines of the main shafts of the adjacent rotors on a plane perpendicular to the main shafts is greater than or equal to 35 degrees and is smaller than or equal to 45 degrees. Correspondingly, the invention further provides a pulverizer provided with the pulverizer structure. The pulverizer structure with the secondary pulverizing function and the pulverizer have the advantages of high pulverizing ability, small vibration, low noise, low energy consumption, high production efficiency and the like.

Owner:HUNAN UNIV OF SCI & TECH

Device and method for separating and extracting active components from plant

InactiveCN109177276AIncrease concentrationReduce sizeGrain treatmentsPressesActive componentEngineering

The invention discloses a device and method for separating and extracting active components from a plant. The device comprises a box body. The box body is internally provided with a feeding cavity. The feeding cavity is internally provided with a first electric push rod. A push block is arranged at the output end of the first electric push rod. A cavity is formed in one side of the feeding cavity.A motor is arranged in the cavity. A sliding block is arranged at the bottom of the motor. A rotating shaft is arranged on one side of the sliding block. A smashing cavity is formed between the cavity and the feeding cavity. A cutting blade is arranged in the smashing cavity. A material conveying pipe is arranged at the bottom of the smashing cavity. An extruding cavity is formed in the other side of the material conveying pipe. Through arrangement of the smashing cavity, the feeding cavity and an extruding head, the first electric push rod pushes the plant by the push block, the plant entersthe smashing cavity, and the cutting blade cuts and smashes the plant. The first electric push rod slowly pushes the plane to slide, and therefore the cutting blade can fully smash the plant. The structure is simple and operation is convenient.

Owner:大连侨李网络科技有限公司

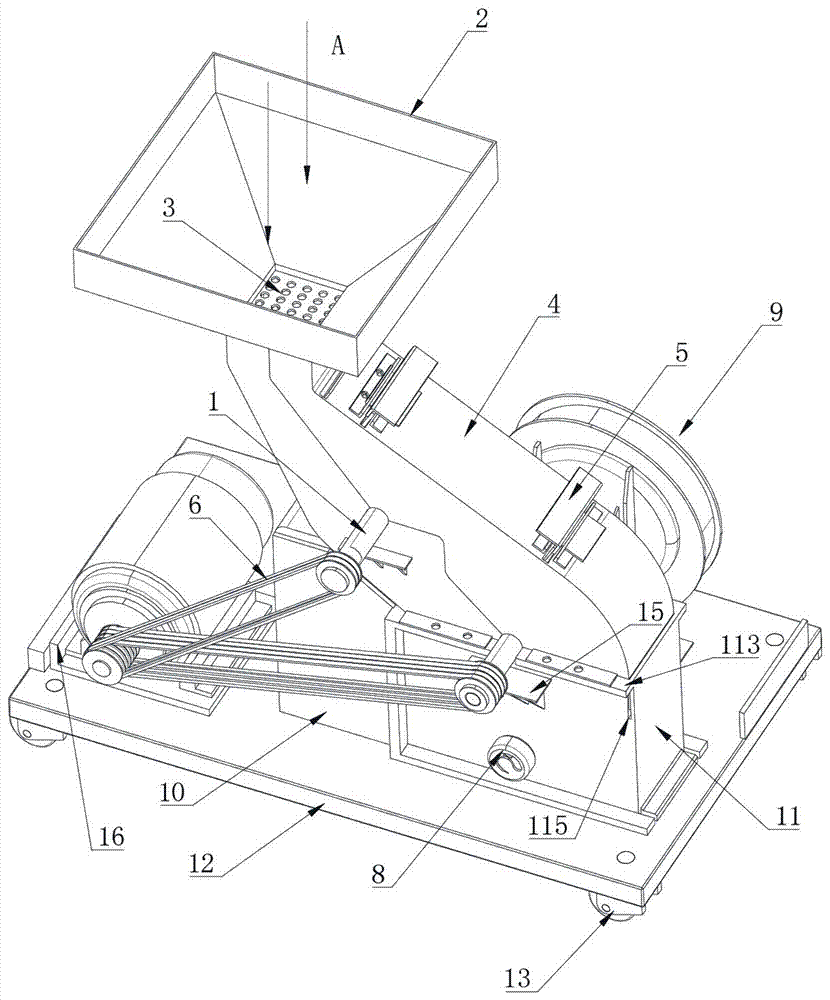

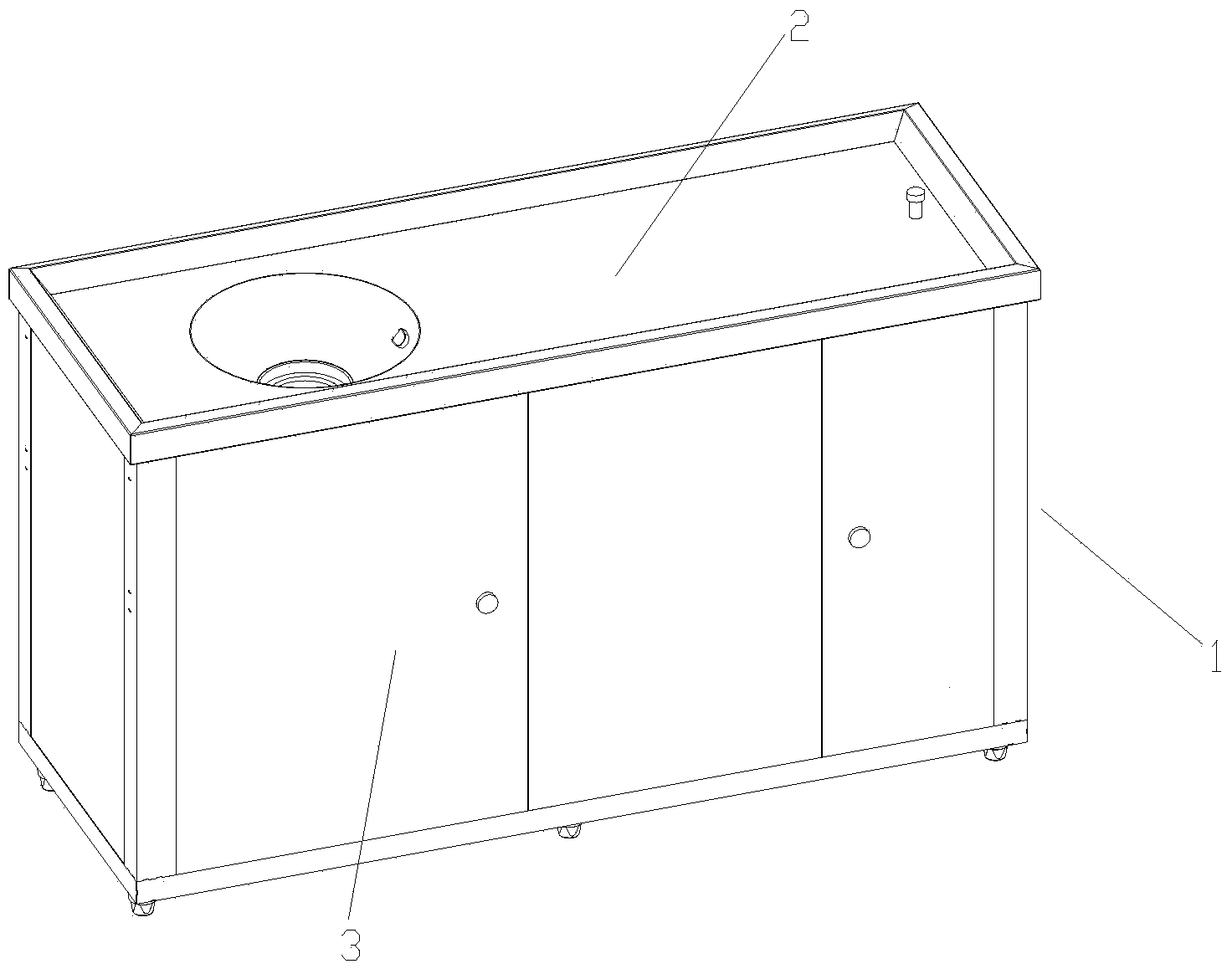

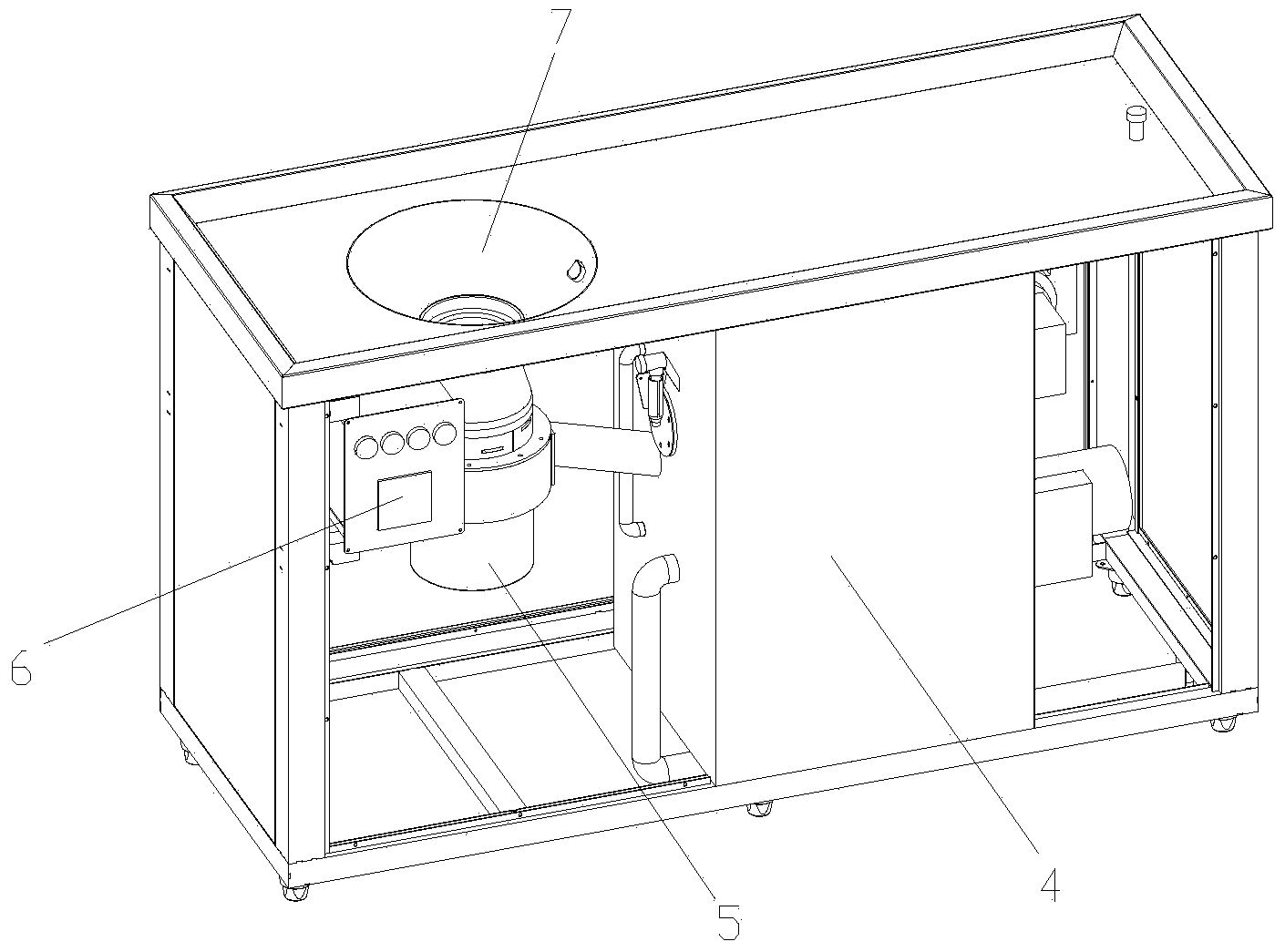

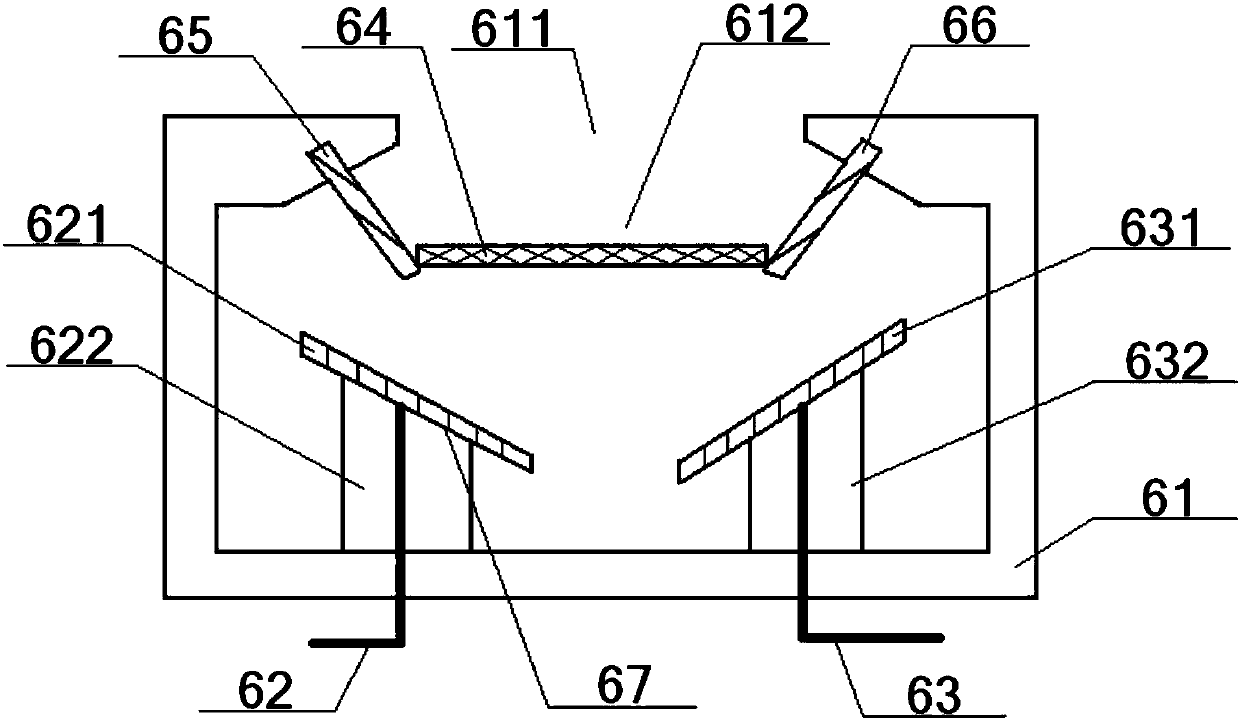

High-quality integrated biochemical garbage treatment machine

ActiveCN104259184AImprove crushing abilityImprove the effectSolid waste disposalDomestic plumbingWall plateThree-phase

The invention discloses a high-quality integrated biochemical garbage treatment machine. The high-quality integrated biochemical garbage treatment machine comprises a workbench, a garbage back-flushing treatment box and a garbage crusher, wherein the garbage back-flushing treatment box and the garbage crusher are positioned inside the workbench; the garbage crusher comprises a hollow grinding cavity and a grinding cutter; the grinding cutter is coaxially mounted in a grinding chamber in a clearance fit manner and comprises a cutter disk, a cutter block, a scraper plate and a coupling sleeve; one end of the cutter block is aligned with the radial edge of the cutter disk, and the other end of the cutter block extends to a central hole; the scraper plate is further arranged on the lower end surface of the cutter disk; one end of the scraper plate is connected with the coupling sleeve, and the other end of the scraper plate is aligned with the radial edge of the cutter disk; the garbage back-flushing treatment box comprises a sewage collecting box, a strain injection mechanism, a three-phase motor, a back-flushing pipe, a sewage draining pipe, a filter pipe and a liquid back-flushing mechanism; the filter pipe and the liquid back-flushing mechanism are positioned inside the sewage collecting box; the filter pipe is driven by the three-phase motor; a garbage inlet and a strain inlet leading to the end part of the filter pipe are formed in the wall plate of the sewage collecting box; the strain inlet is externally connected with the strain injection mechanism; the liquid back-flushing mechanism is positioned below the filter pipe and is connected to the filter pipe through the back-flushing pipe.

Owner:SUZHOU MEISHENG ENVIRONMENTAL PROTECTION TECH

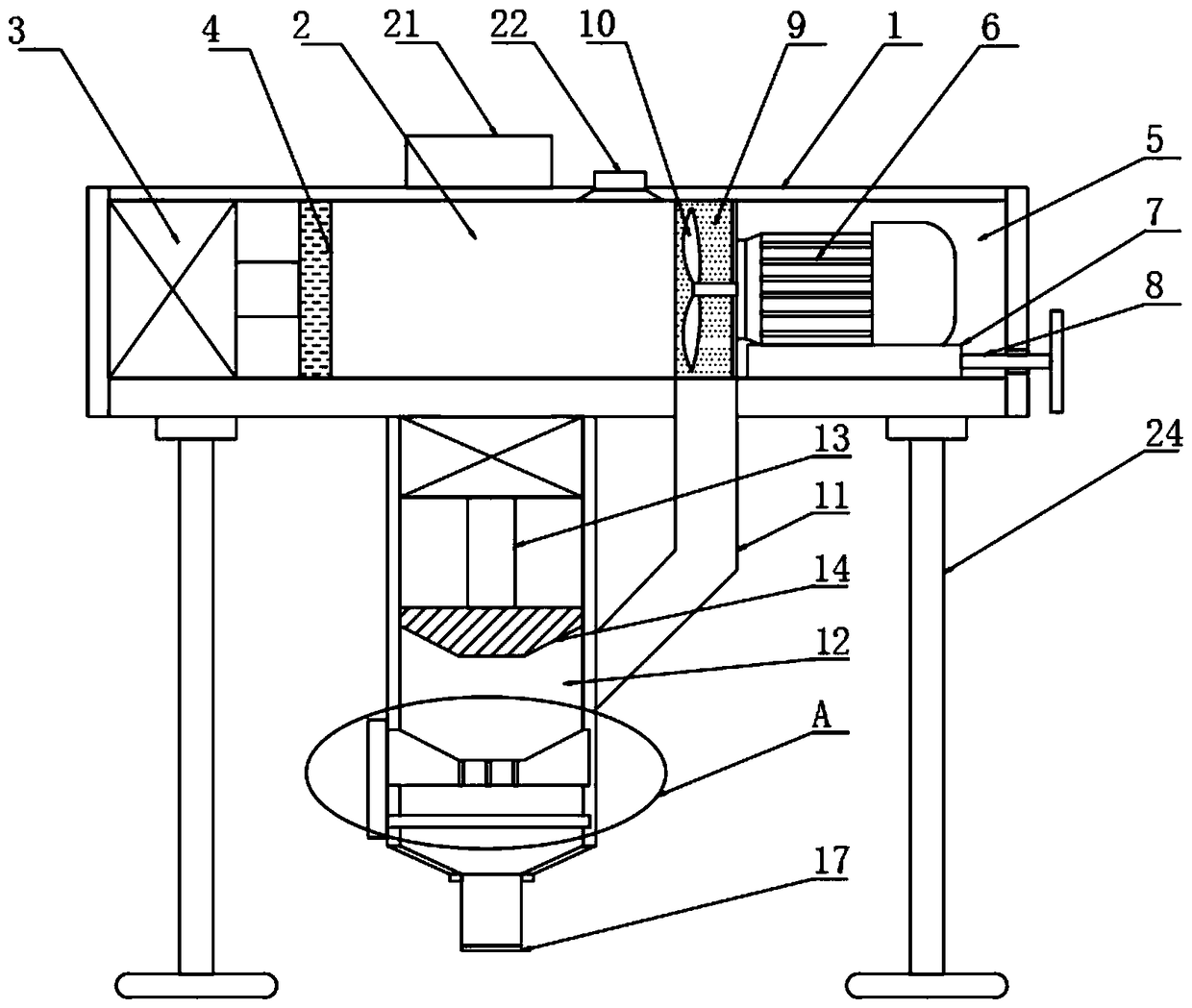

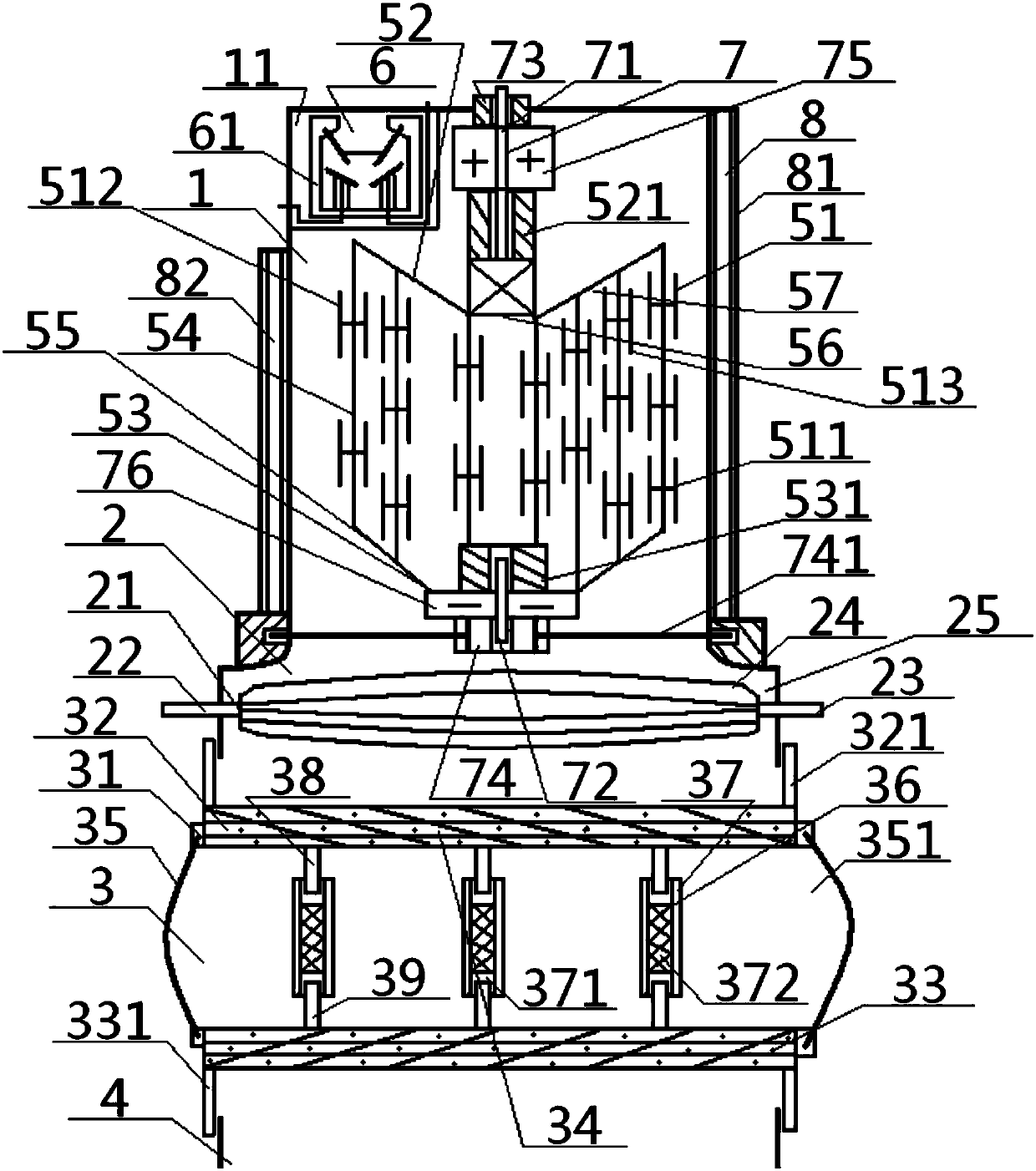

Biogas fermentation pretreatment system

InactiveCN107723217AIncrease temperatureReduce volumeBioreactor/fermenter combinationsBiological substance pretreatmentsDrive shaftFiltration

The invention discloses a biogas fermentation pretreatment system. The biogas fermentation pretreatment system has the advantages that an upper bent plate, a lower bent plate, stirring rods and stirring hooks can be driven by a driving shaft to destroy and smash to-be-treated straw in a main treatment bin, so that the volume of the straw can be reduced, and the straw and moisture mixing uniformitycan be improved; particularly, clockwise and anticlockwise switching rotation can be intermittently carried out during operation when the top of an upper spindle is connected with a clockwise drivingmotor and the top of a lower spindle is connected with an anticlockwise motor, the internal temperature of the main treatment bin can be increased by a heating device and can be monitored by a temperature measuring sensor, and accordingly smashing effects can be guaranteed; the good smashing effects can be realized by the biogas fermentation pretreatment system, the smashing directions can be switched over, and accordingly the biogas fermentation pretreatment system is favorable for follow-up fermentation; the filter efficiency can be improved, and the biogas fermentation pretreatment systemis high in controllability and excellent in environmental friendliness.

Owner:李秀青

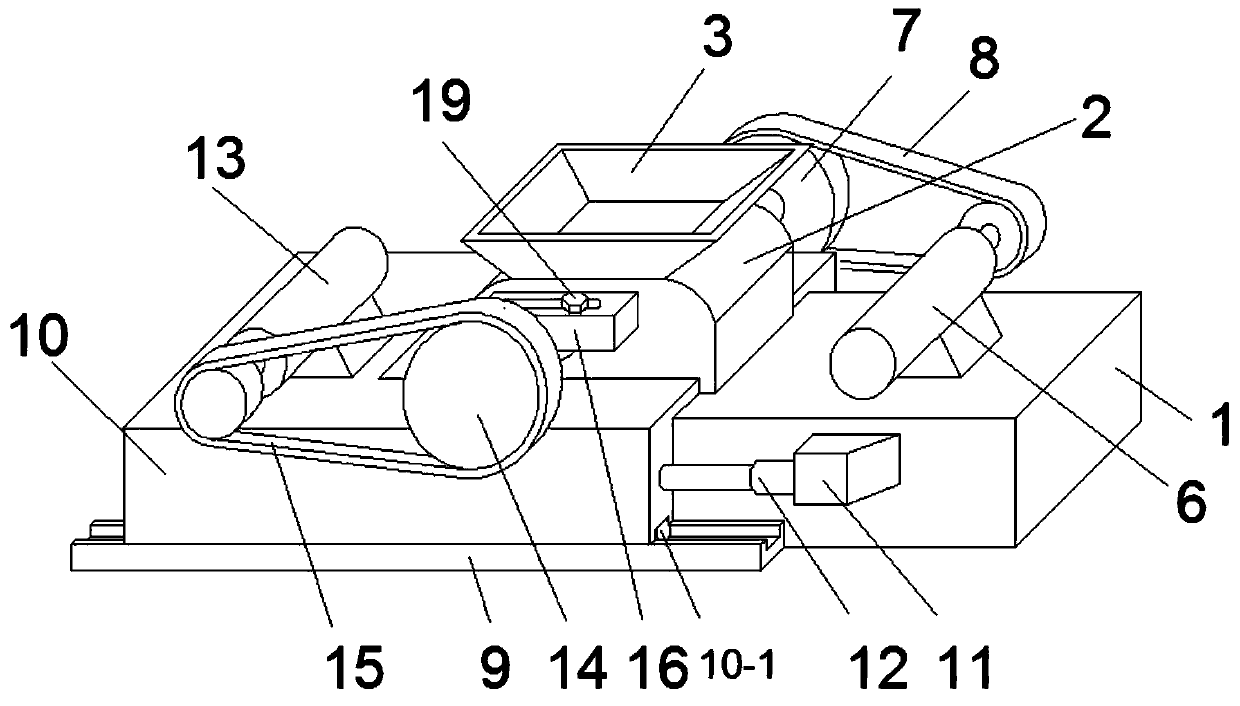

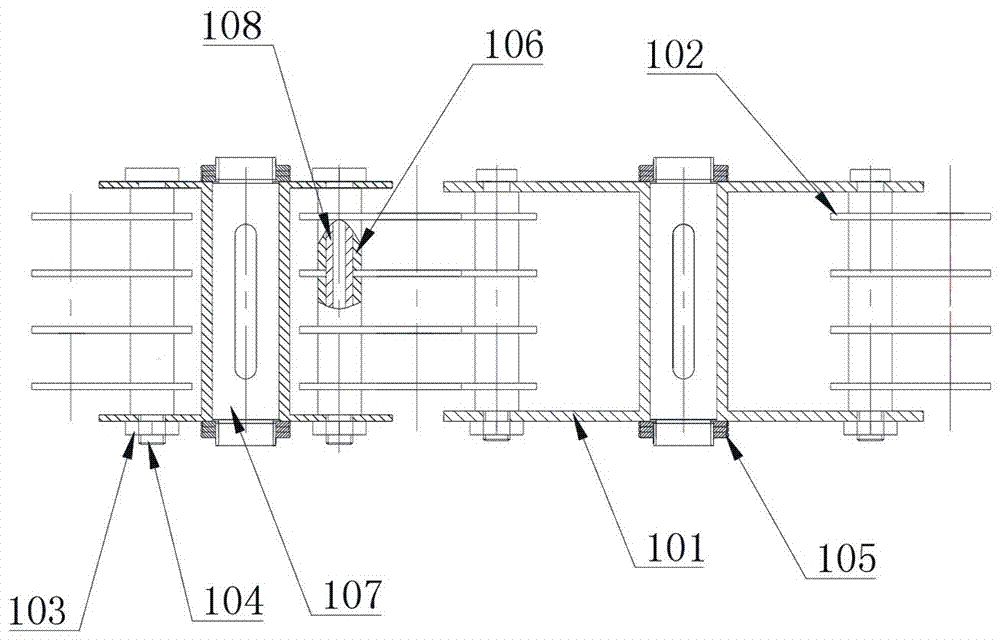

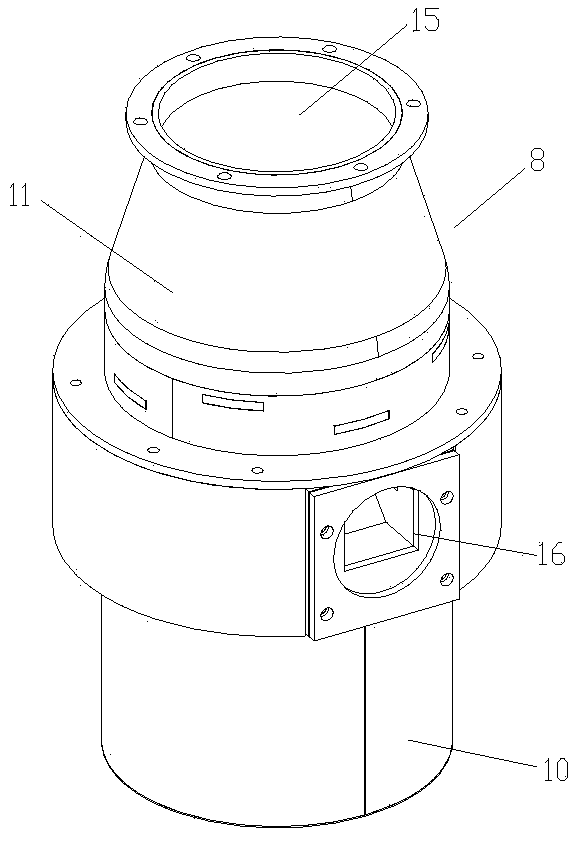

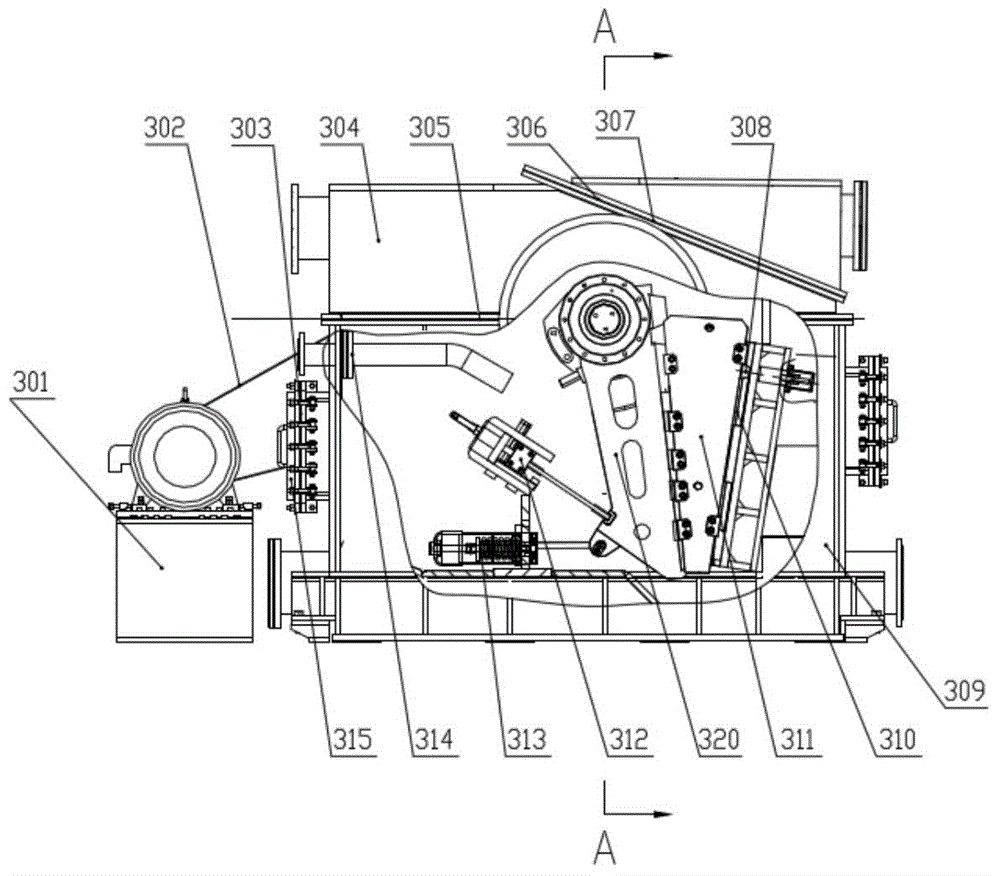

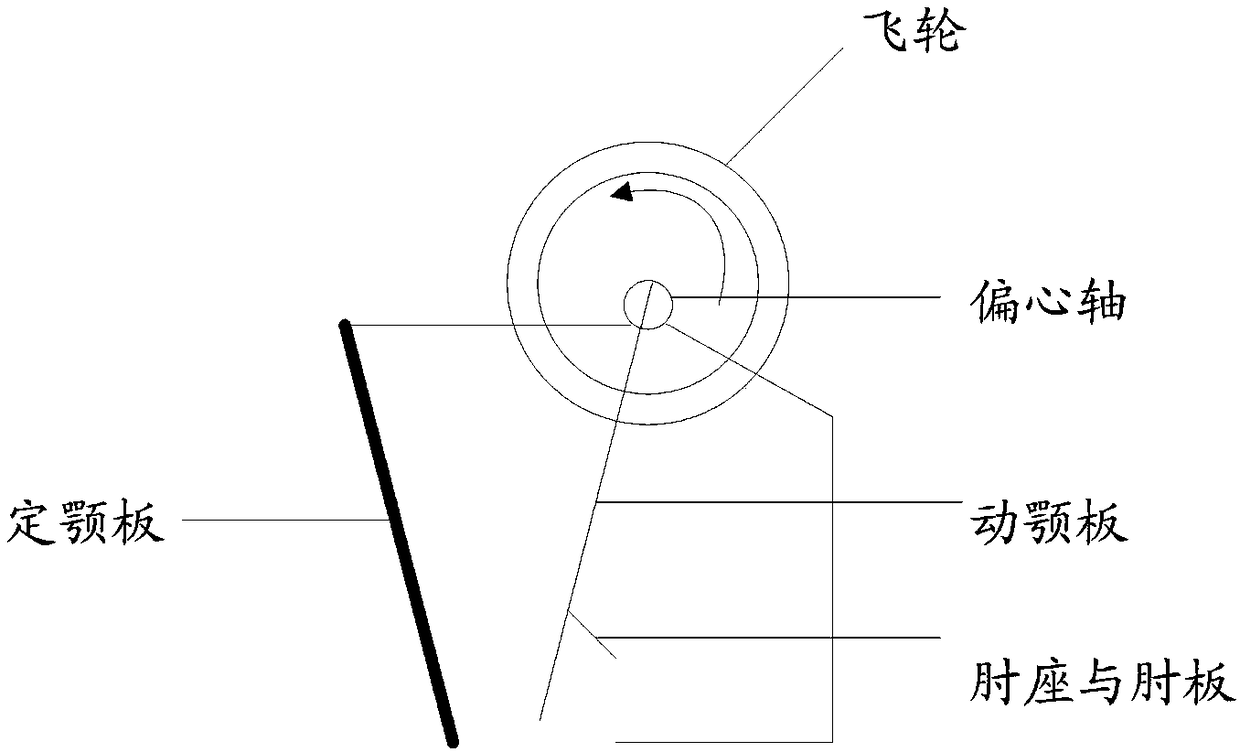

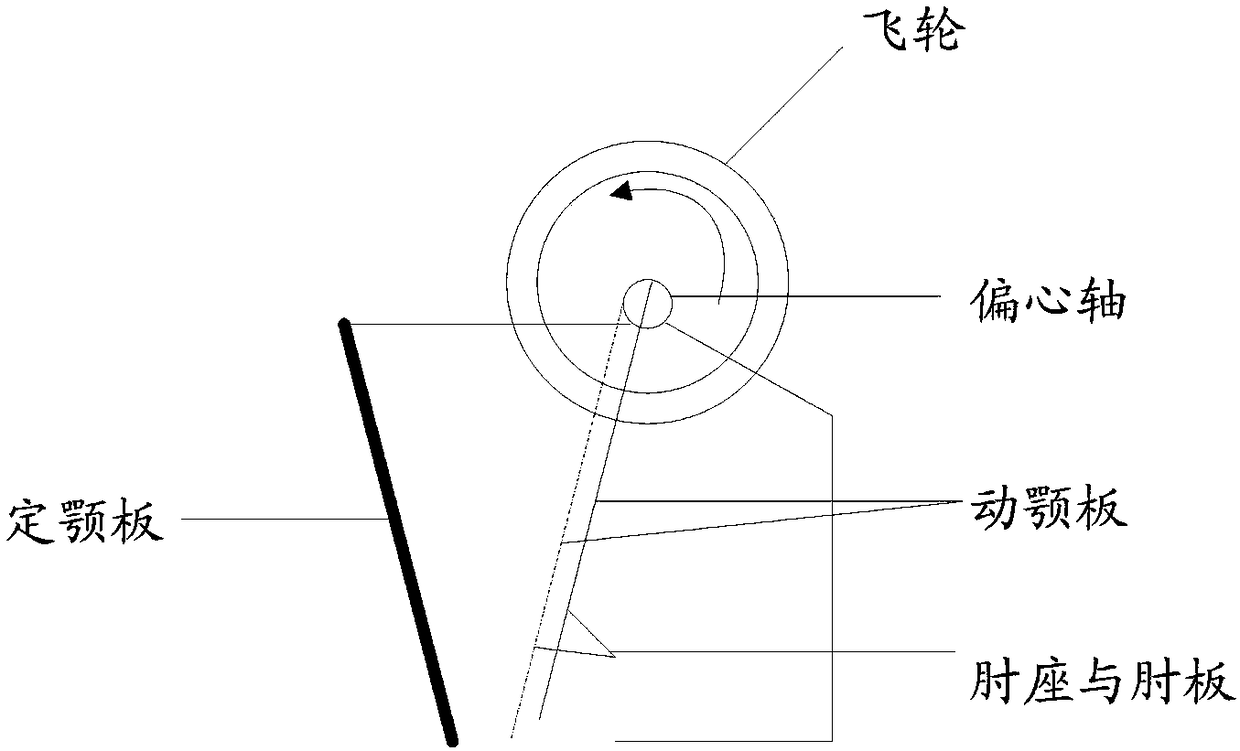

Slurry pipeline crusher used in shield machine

The invention provides a slurry pipeline crusher used in a shield machine. The slurry pipeline crusher is a closed slurry fluid jaw crusher with the inside having a sealed pressure reaching above 0.5MPa, and the slurry pipeline crusher comprises a frame, a movable jaw assembly, sealing gaskets, a fixed jaw plate positioned in the frame, and a motor driving assembly and a belt positioned outside the frame, wherein the frame, the movable jaw assembly and the sealing gaskets form an internal sealing space; the motor driving assembly and the belt are used for driving the movable jaw assembly to carry out compound pendulum extruding motion relative to the fixed jaw plate in order to extrude and crush bones between the movable jaw assembly and the fixed jaw plate; and the movable jaw assembly comprises an eccentric shaft arranged on the frame and a movable jaw plate positioned in the frame, and a rotation seal is formed between the movable jaw assembly and the frame. The slurry pipeline crusher has strong crushing ability and good maintainability, and can provide high-pressure crushing sealing environment.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Hammer type crushing mill

The invention discloses a hammer crusher, which is composed of a material inlet, a baffle plate, a mouth guard plate, a casing, a suspension ring, an impact plate, a hammer head, a side guard plate, a rotor disk, a rotor shaft, a front guard plate, and a spacer ring. Sleeve, drive shaft, sieve bar, support sieve plate and bracket, the material inlet is located on the upper right of the casing, the baffle is connected to the inside of the material inlet, the mouth guard is connected to the inner wall of the material inlet, and the lifting ring is connected to the top of the casing , the counterattack plate is connected to the inner wall of the casing, the transmission shaft is connected to the center of the casing, a spacer sleeve is arranged around the transmission shaft, the rotor disc is connected to the spacer sleeve, the side guard plate is connected to the rotor disc, and the four hammer heads are evenly connected to the rotor disc. On the side guard plate, the four hammerheads are respectively connected to the rotor shaft, the front guard plate is connected to the right side of the inside of the casing, the screen bars are connected to the bottom of the inside of the casing, the supporting screen plate is connected to the bottom of the outside of the casing, and the brackets are connected to both sides of the outside of the casing . The invention has the advantages of simple structure, convenient use and reasonable technology.

Owner:李颂

Treatment device for solid waste and household garbage pipeline to transport large ground pieces and control method of treatment device

ActiveCN106076538AStrong crushing abilityIron sorting efficiency is highMagnetic separationGrain treatmentsDomestic wastePassword

The invention relates to a treatment device for a solid waste and household garbage pipeline to transport large ground pieces. The treatment device comprises a first rack sealed through four side plates, a crushing device fixed to the first rack, a vertical garage pipe connected with the lower end of the crushing device, a conveyor fixedly arranged on a second rack, a large piece containing box used for temporally storing large garbage, and a control device arranged on one side of the lower end of the conveyor. The upper end of the conveyor is arranged on the top of the crushing device, the lower end of the conveyor is arranged on the ground, and the large piece containing box is arranged on the other side of the lower end of the conveyor. When garbage in the large piece containing box reaches the designed volume, the garbage is treated through a specially-assigned person, and collection is controlled manually after password unlocking and identity recognition are conducted. The treatment device has the beneficial effects that crushing and recycling of large packaging boxes, waste furniture, garden waste and other large garbage are achieved, the crushing capability is high, the iron ware sorting efficiency is high, and pneumatic collecting of various kinds of garbage is achieved.

Owner:张子宇

Powder depolymerization and dispersing machine

ActiveCN103252284BReduce energy consumptionImprove versatilityGrain treatmentsDepolymerizationEngineering

The invention relates to a powder depolymerization beater. The powder depolymerization beater comprises a machine shell, wherein the machine shell comprises a classifying cavity and a beating cavity which are distributed from top to bottom, wherein the beating cavity is provided with a crushing mechanism which is used for crushing materials and utilizes a crushing main shaft as a rotating center; and the classifying cavity is provided with a classifying mechanism which can discharge material after crushing and utilizes a classifying main shaft as a rotating center, the crushing mechanism is driven by a crushing motor, and the classifying mechanism is driven by a classifying motor. The powder depolymerization beater provided by the invention can autonomously regulate a crushing process and a particle guiding process, the rotating speeds of a main shaft and the classifying main shaft are also controlled to be different, and thus, the purposes that the material is fully crushed and crushed particles are not rapidly guided can be achieved.

Owner:SUZHOU ZHONGYUAN MACHINERY EQUIP MFG

Environment-friendly civil engineering building waste treatment equipment

ActiveCN109772506ARealize classification and crushingReduce manufacturing costGrain treatmentsGradingEnvironmental resistanceWaste treatment

Owner:CHUZHOU VOCATIONAL & TECHN COLLEGE

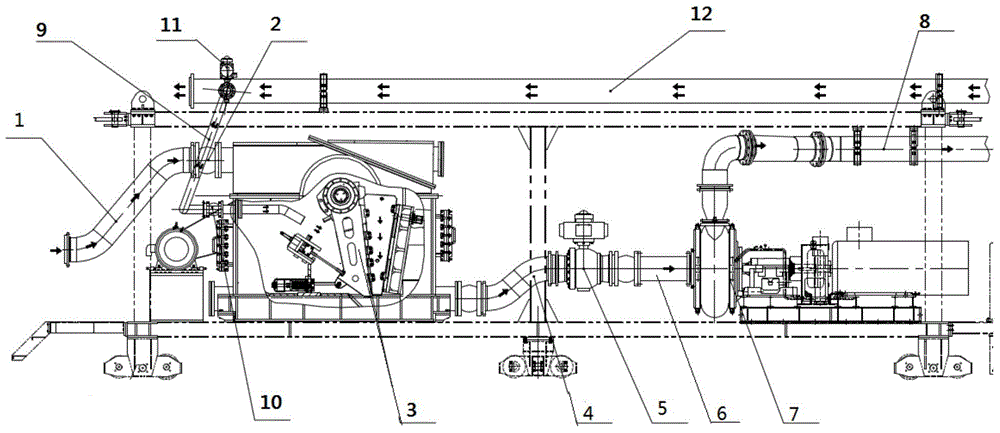

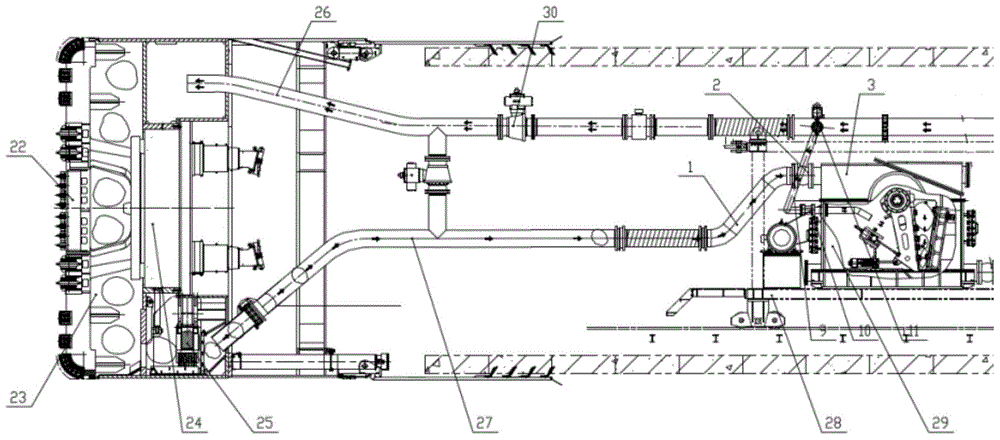

Hydraulic jaw crusher unit

The invention discloses a hydraulic jaw crusher unit. The hydraulic jaw crusher unit comprises a feeding device, a screening device, a jaw crusher, a conveying device, a hydraulic station and an integrated frame, wherein the feeding device, the screening device, the jaw crusher, the conveying device and the hydraulic station are arranged in the integrated frame; the jaw crusher adopts a crusher jaw plate structure adopting deep cavity as a double-curved cavity form; the hydraulic station is used for supplying working oil pressure to the feeding device, the screening device, the jaw crusher andthe conveying device; materials enter the screening device through the feeding device and enter the jaw crusher for being crushed after passing through the screening device; the crushed materials enter the conveying device. In-factory pre-installing debugging can be realized by all parts of equipment of the whole unit, integrated transportation is realized, assembling is not required during a production site, and civil construction is not required.

Owner:北京博岳恒科技发展有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com