Double-motor crushing device of high frequency crushing hammer

A technology of crushing device and hammer, which is used in the lubrication of engines, rigid supports of bearing components, mechanical equipment, etc., can solve the problems of reducing vibration energy in the crushing direction, reducing crushing efficiency, and breaking hammer fatigue, and achieves optimal vibration reduction and performance. Energy-saving effect, increased crushing capacity, and the effect of large crushing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, technical features, invention objectives and technical effects realized by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

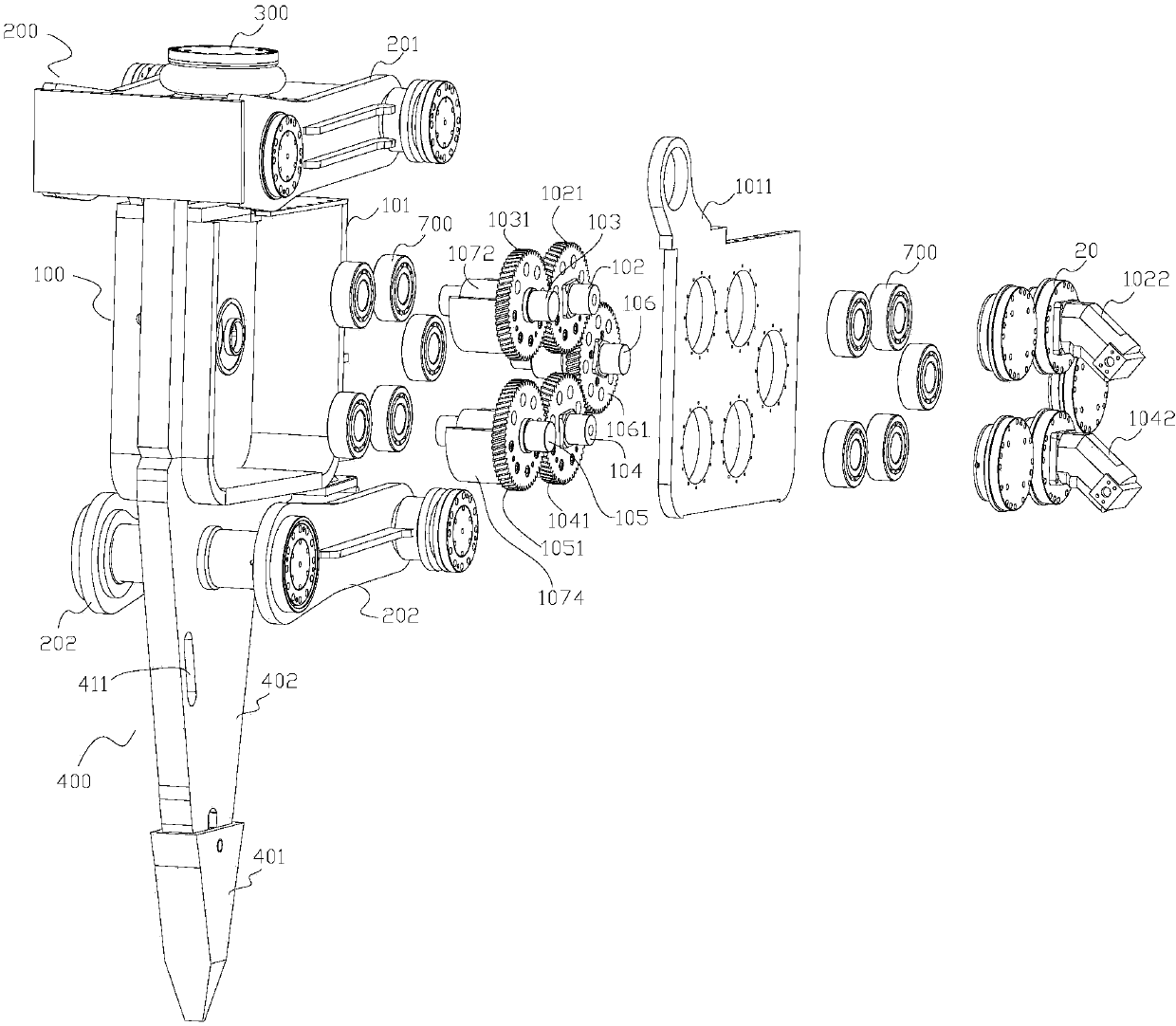

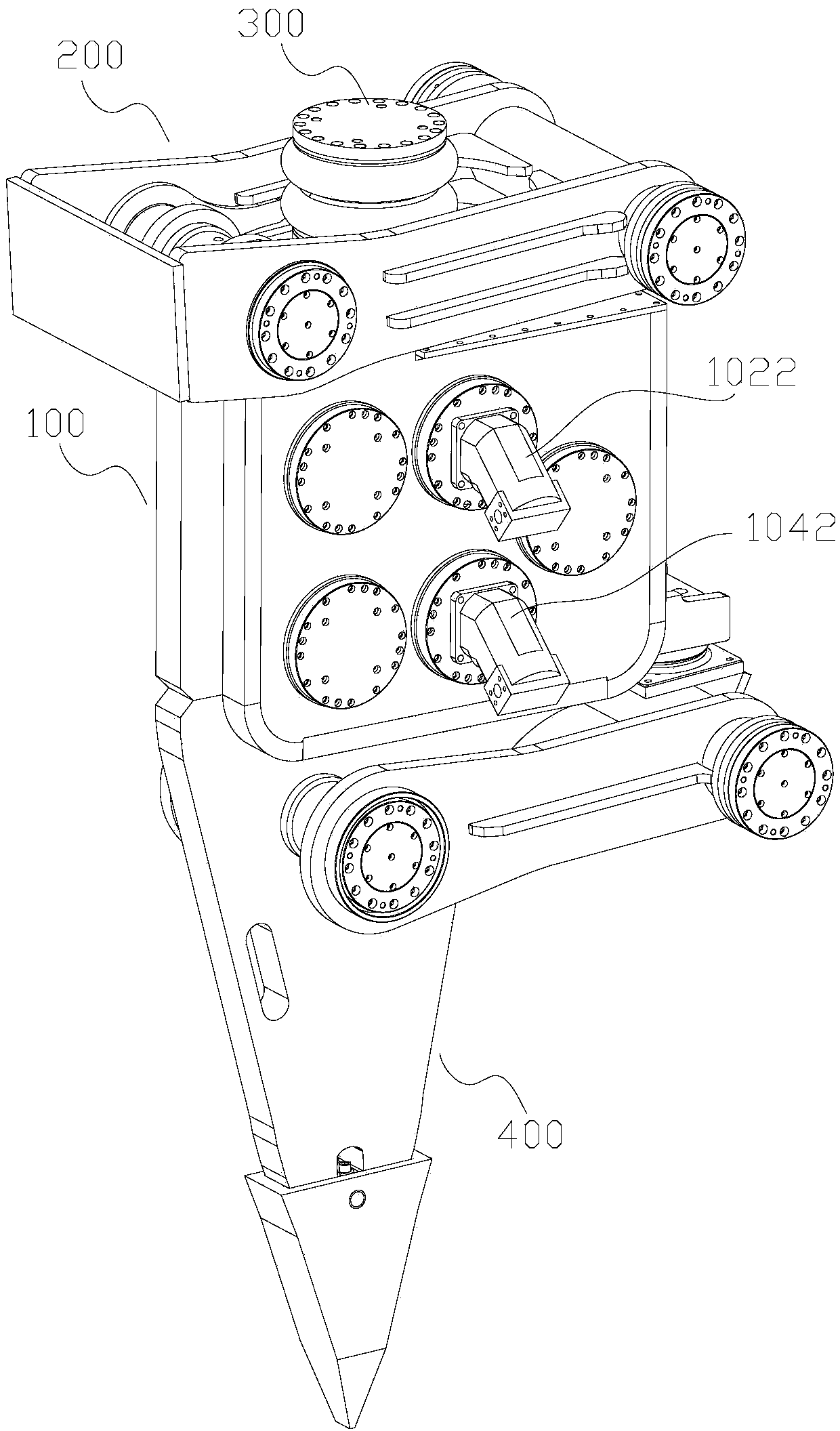

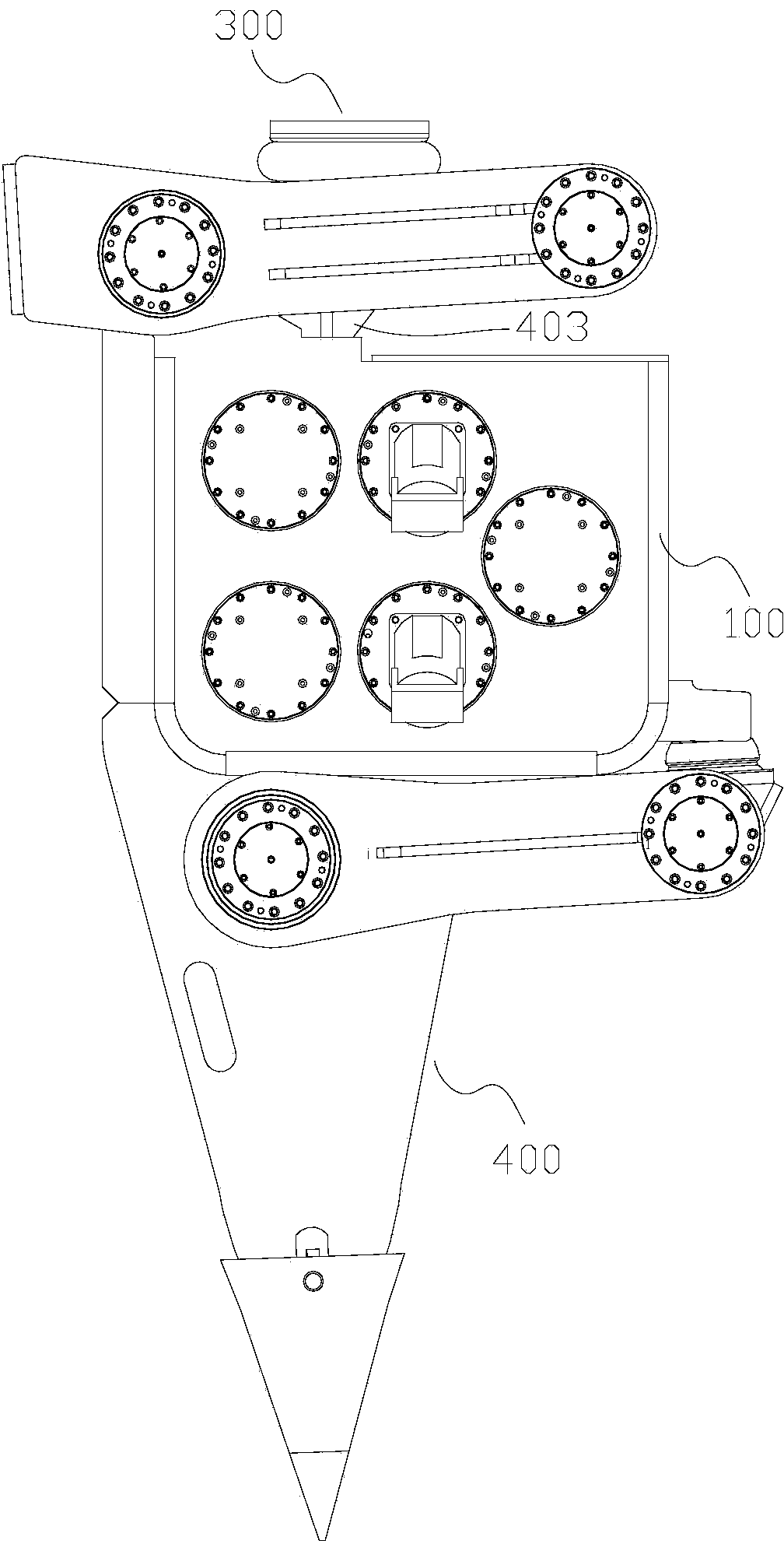

[0026] Such as figure 1 Shown: is a high-frequency hammer dual-motor crushing device of the present invention, including a vibrator 100, a four-bar linkage mechanism 200, a vibration damping device 300, and a vibrating knife row 400 composed of a knife row 401 and bucket teeth 402, The vibrator 100 is arranged above the vibrating knife row 400, and the two are integrally formed by welding. The vibrating knife row 400 is a crushing hammer head, and the crushing hammer head has a conical structure or an inverted triangular pointed structure in its cross section. The shape of the vibrating knife row 400 is not limited to the types mentioned above, and can also be conical or plate-shaped. and other corresponding shapes; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com