Patents

Literature

38results about How to "Strong crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

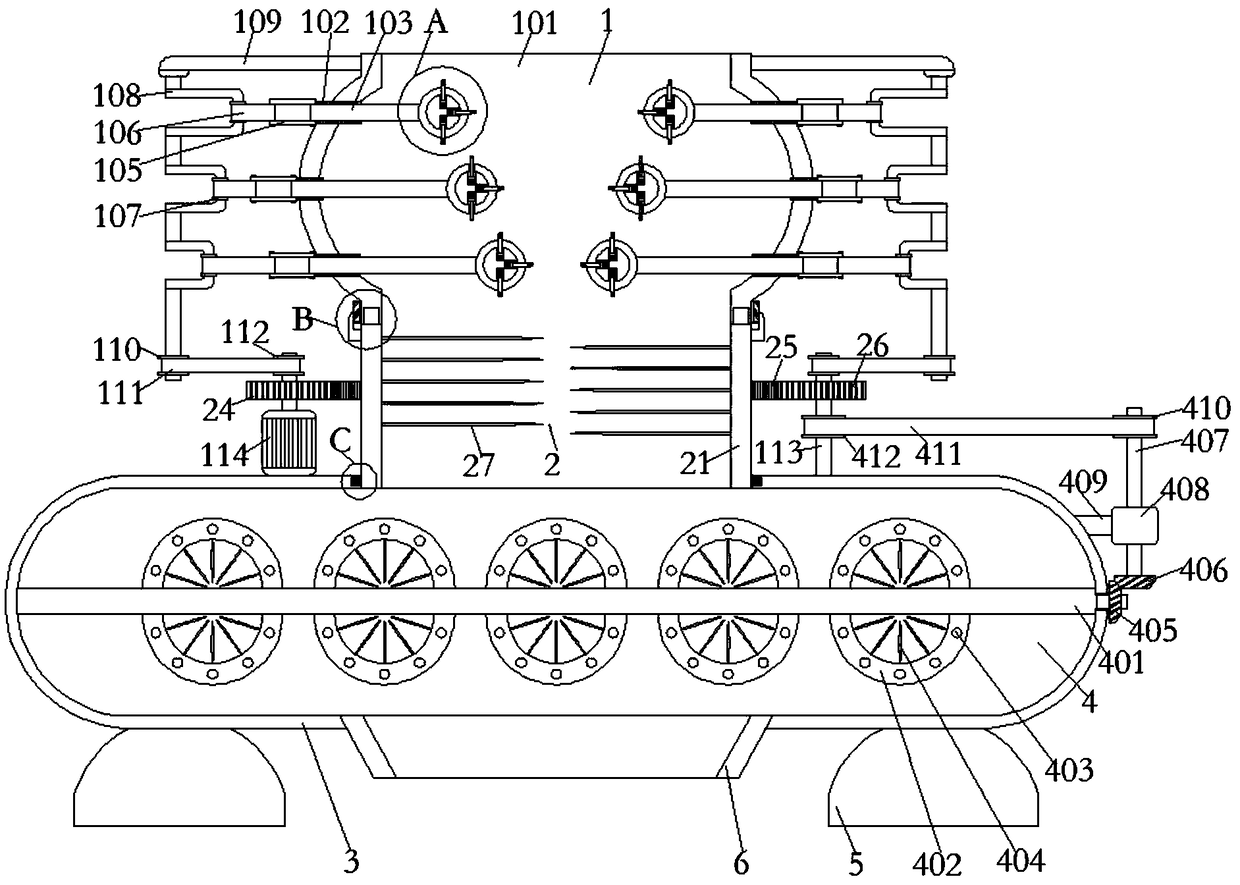

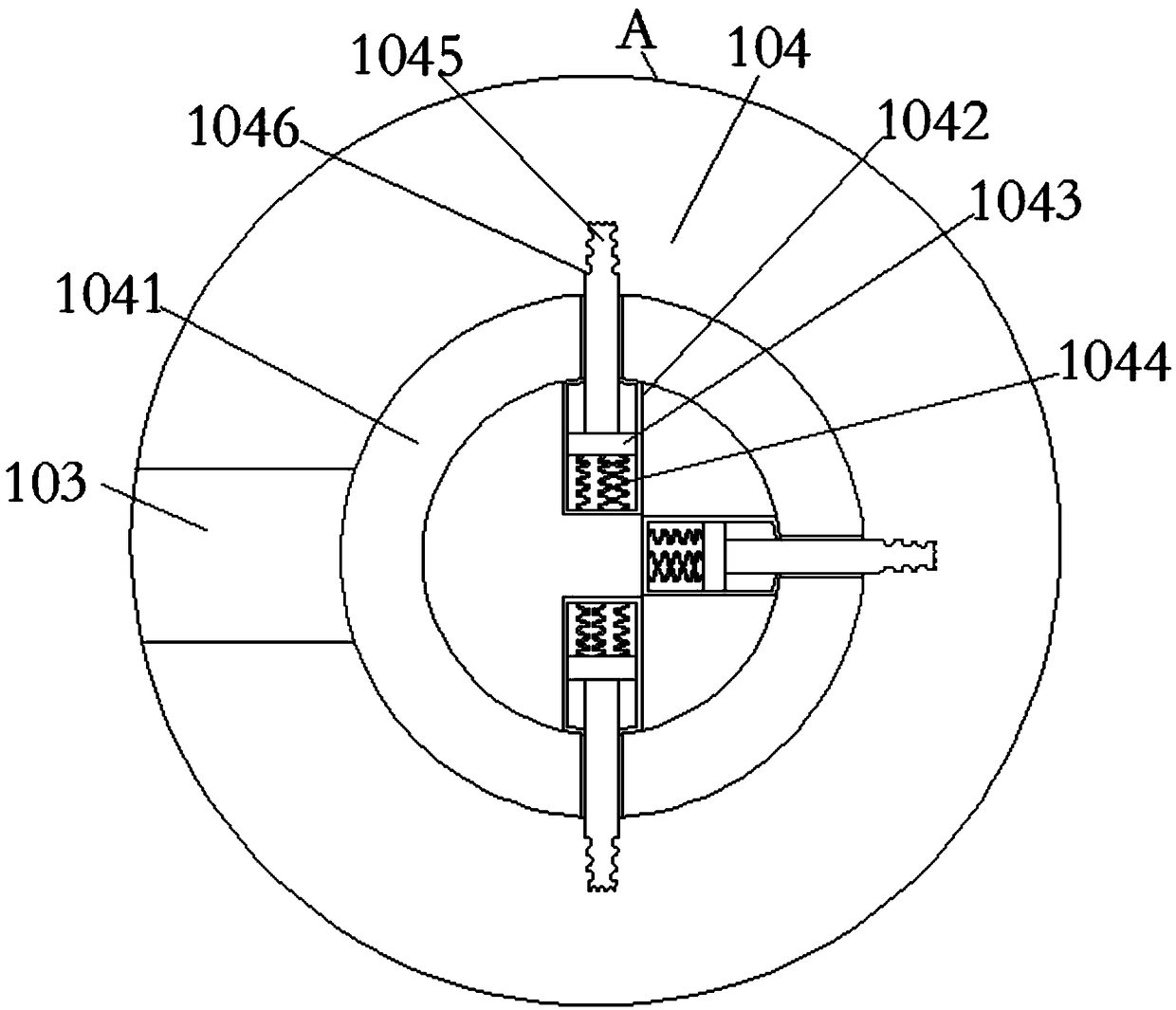

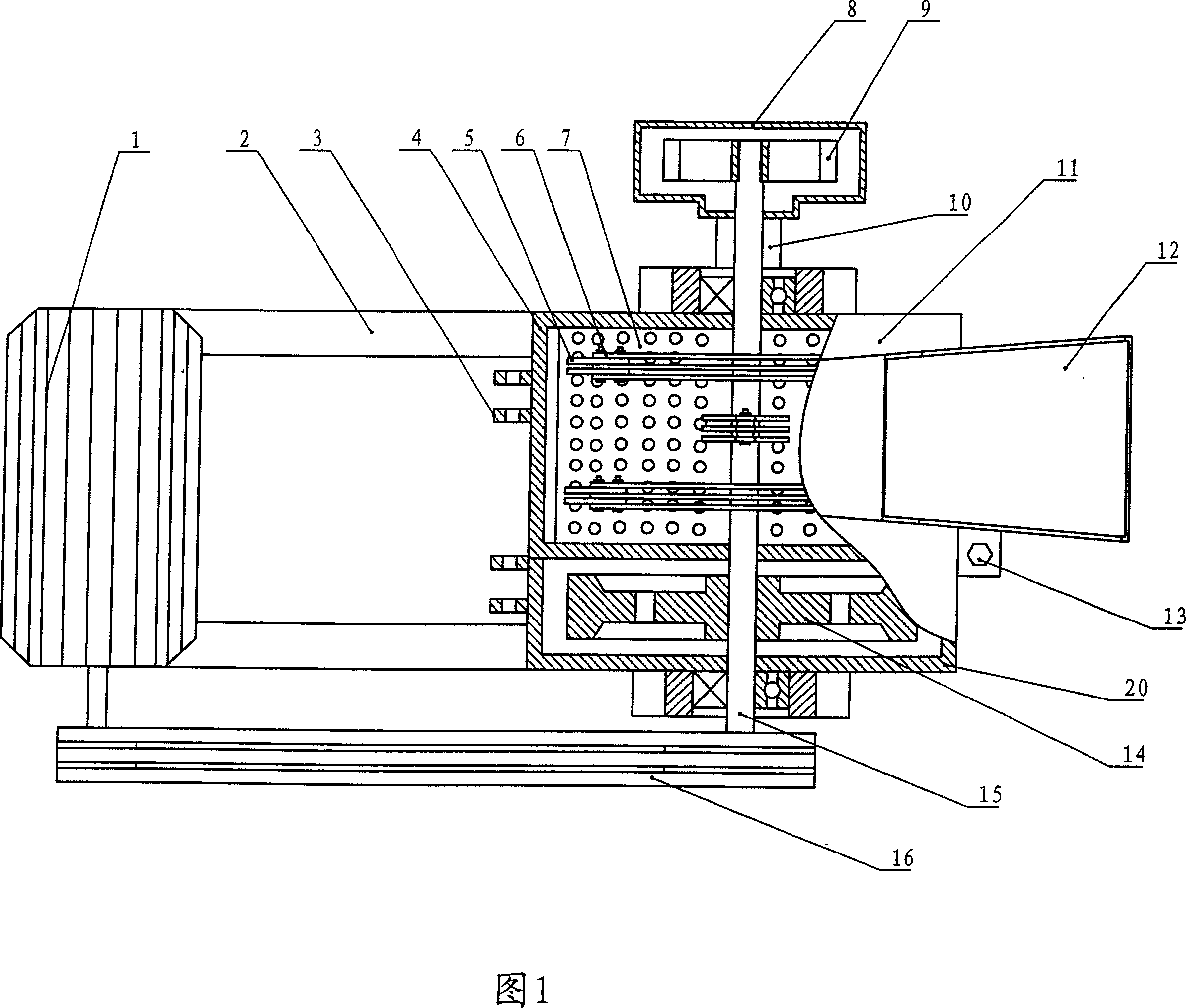

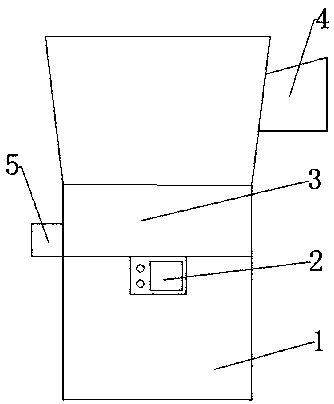

High-frequency breaking hammer

ActiveCN103706451AStrong crushingHigh crushing precisionSoil-shifting machines/dredgersGrain treatmentsDrive shaftEngineering

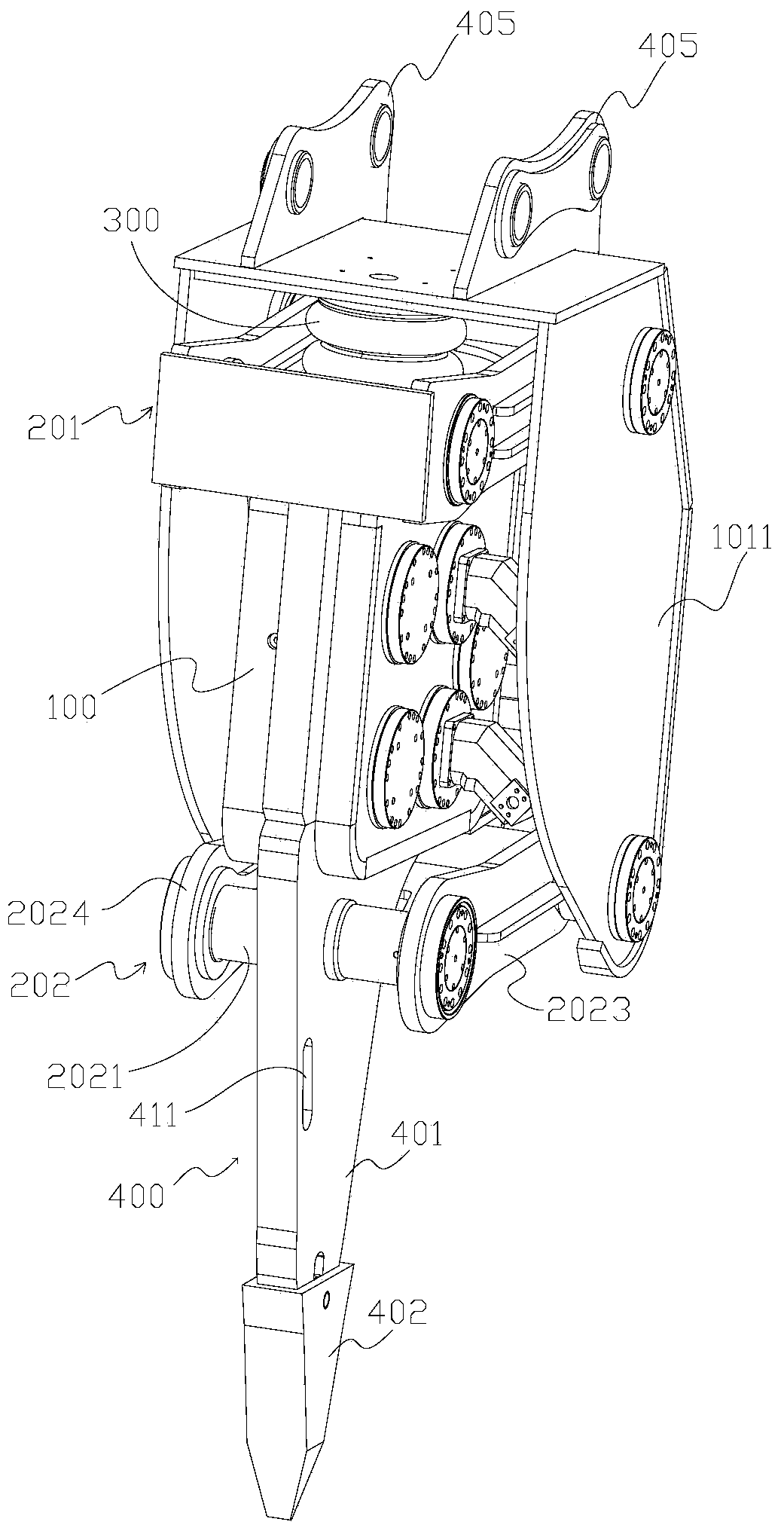

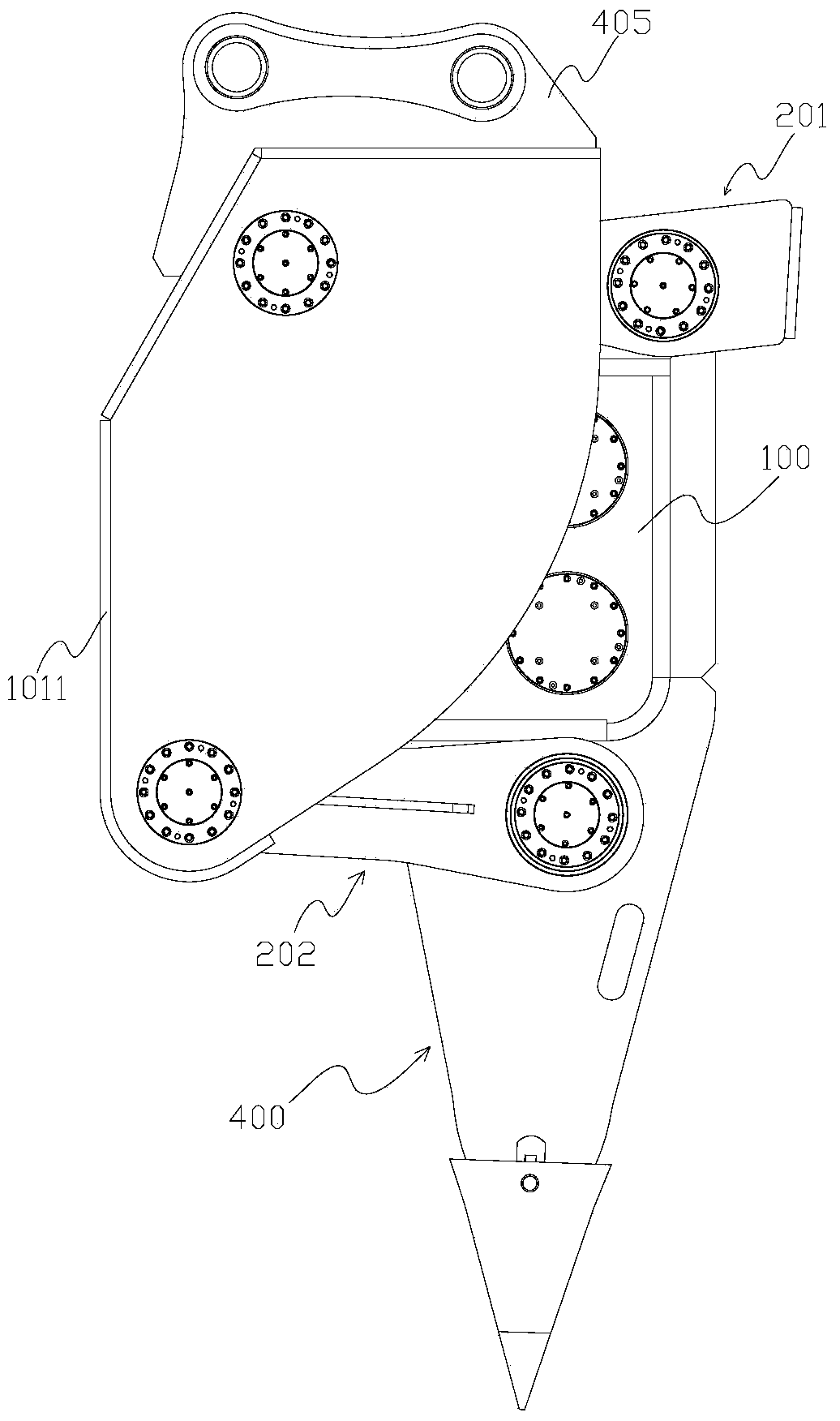

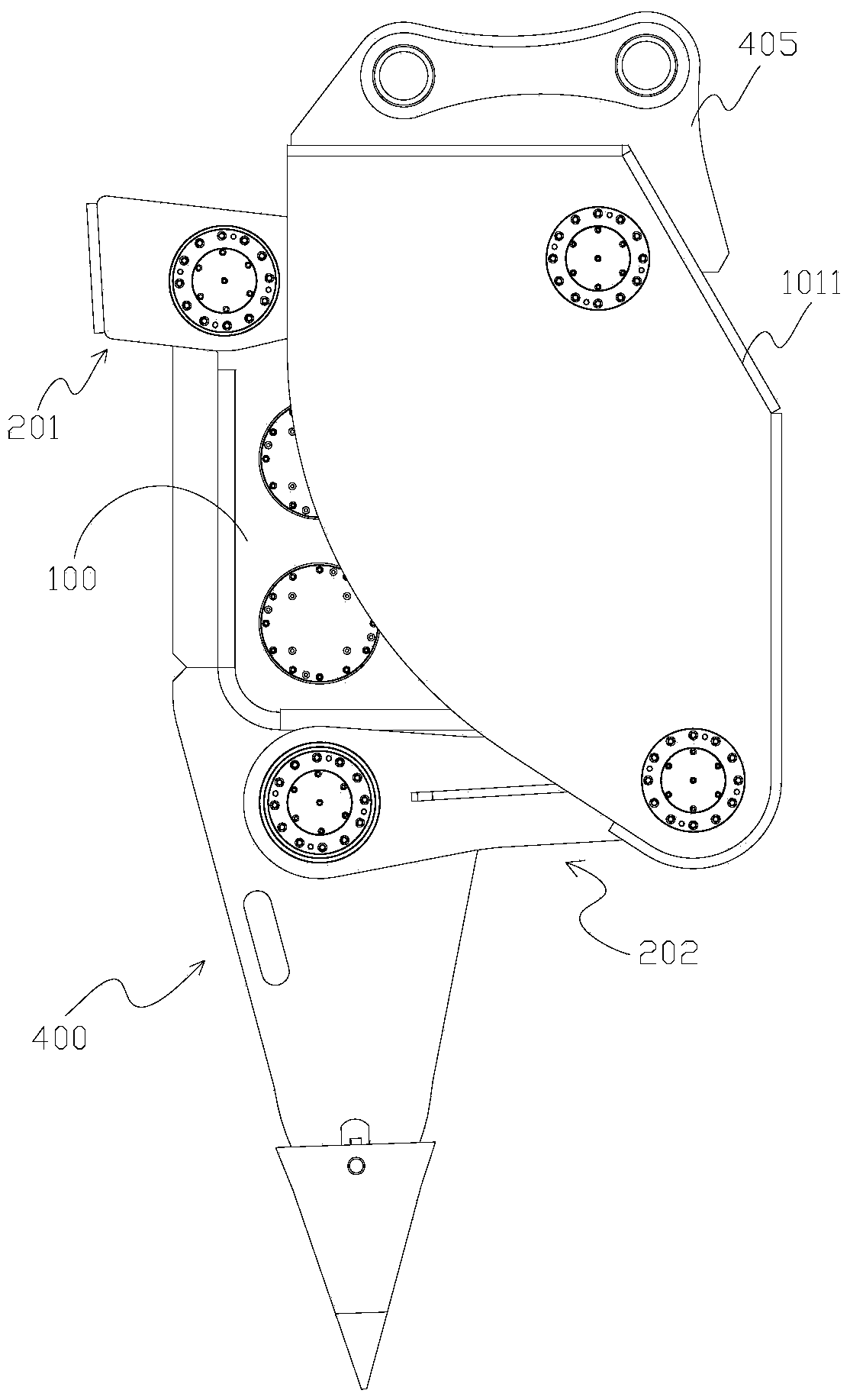

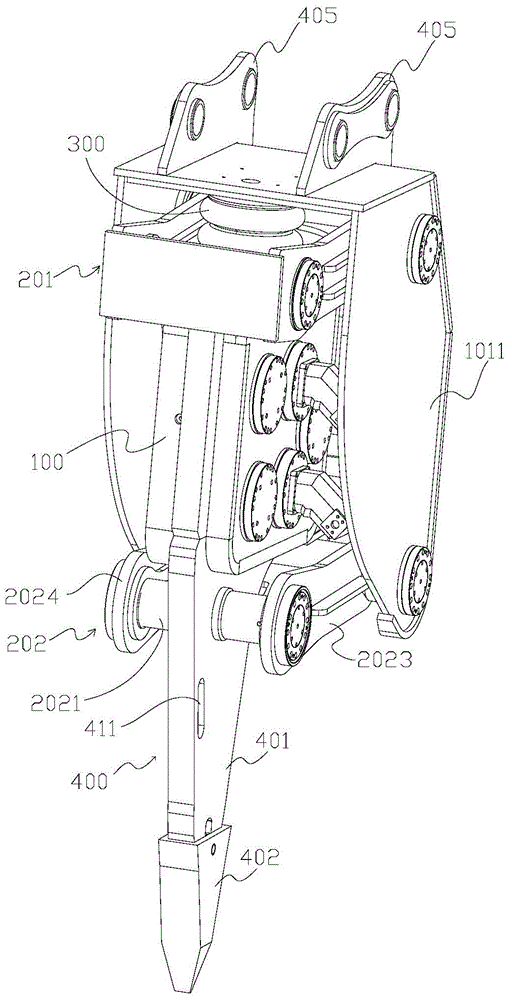

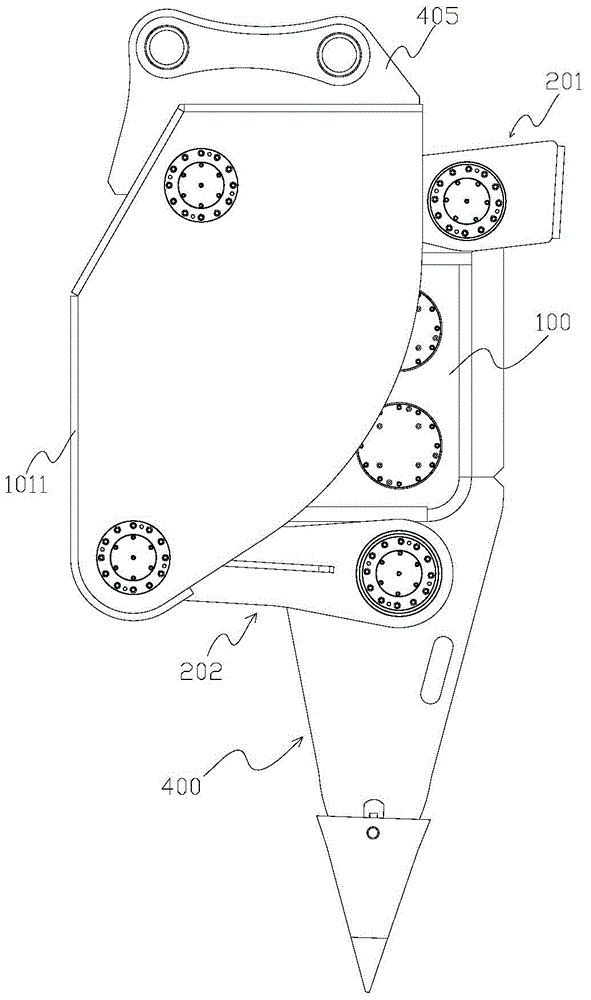

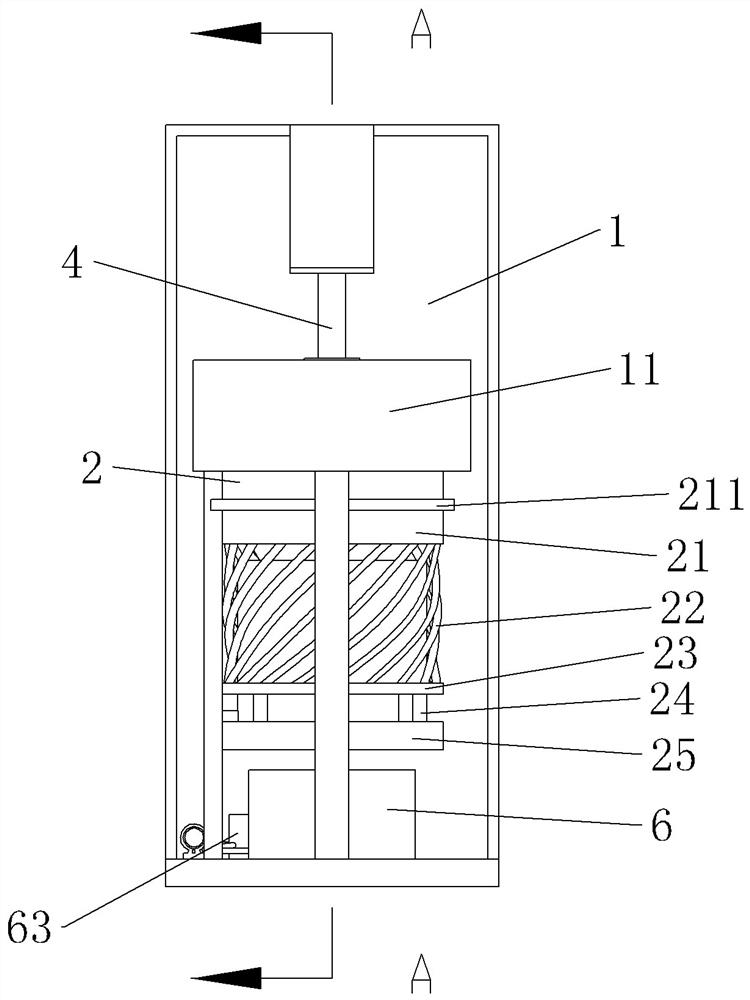

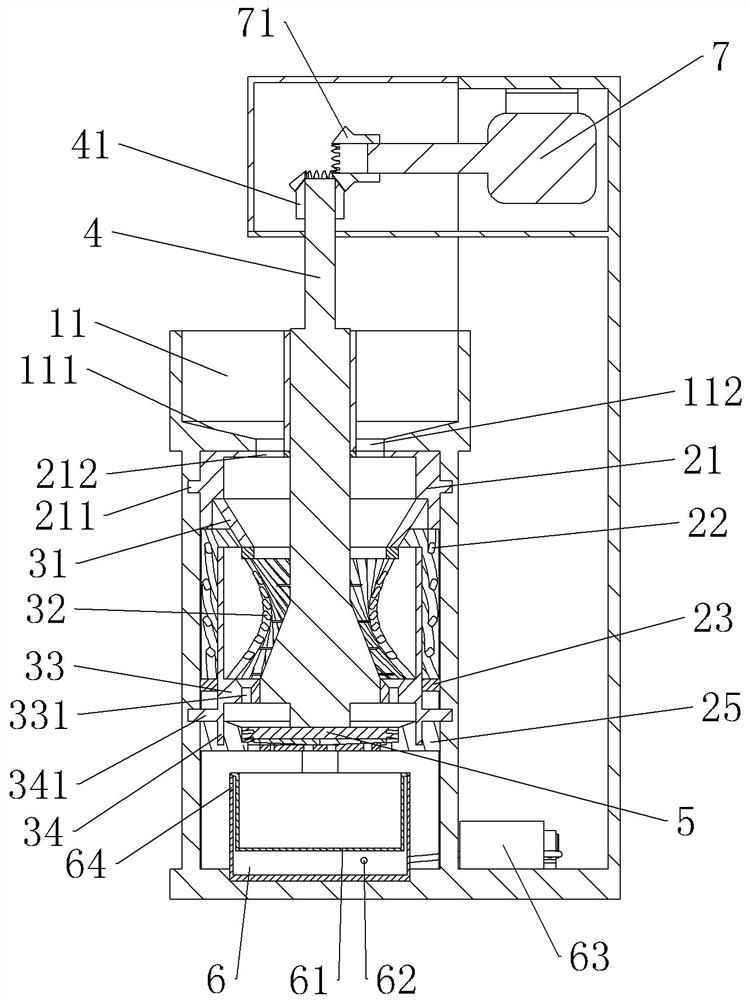

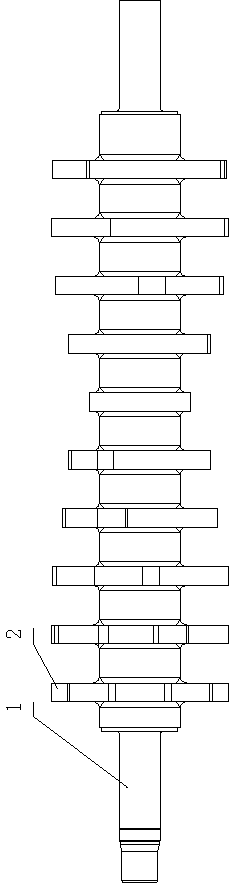

The invention discloses a high-frequency breaking hammer which comprises an installation shell, a vibration exciter, a four-bar mechanism and a vibration knife bar, wherein the vibration exciter comprises a shell, a first drive shaft arranged in the shell, a first driven shaft mutually meshed with the first drive shaft through a gear, a second drive shaft, a second driven shaft mutually meshed with the second drive shaft through a gear, and a bridging shaft arranged between the first drive shaft and the second drive shaft, wherein a first drive motor and a second drive motor are respectively arranged at one ends of the first drive shaft and the second drive shaft; central axes of the first drive shaft and the second drive shaft are positioned on the same vertical surface; and the first drive shaft, the first driven shaft, the second drive shaft and the second driven shaft are positioned on the same horizontal plane. According to the high-frequency breaking hammer, two groups of drive shafts are adopted and are matched with two drive motors; and compared with a breaking hammer driven by one motor, the high-frequency breaking hammer has the advantages of large breaking force, high breaking precision, small noise and strong breaking capability, thereby prolonging the working time of the breaking hammer and increasing the breaking efficiency.

Owner:苏州鸣尼克重工机械有限公司

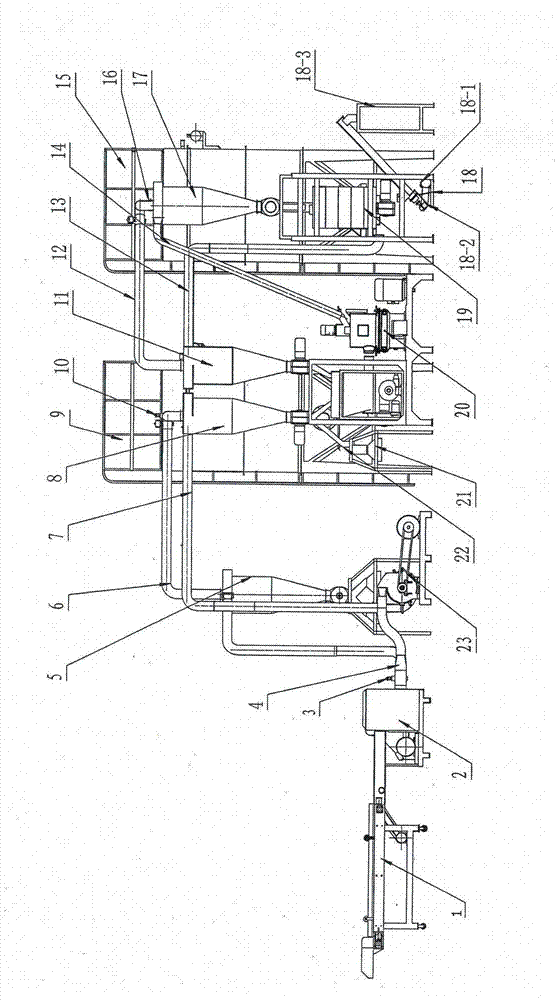

Carbon fiber smashing equipment

InactiveCN103567046AReduce the temperatureReduce the number of replacementsGrain treatmentsElectricityCarbon fibers

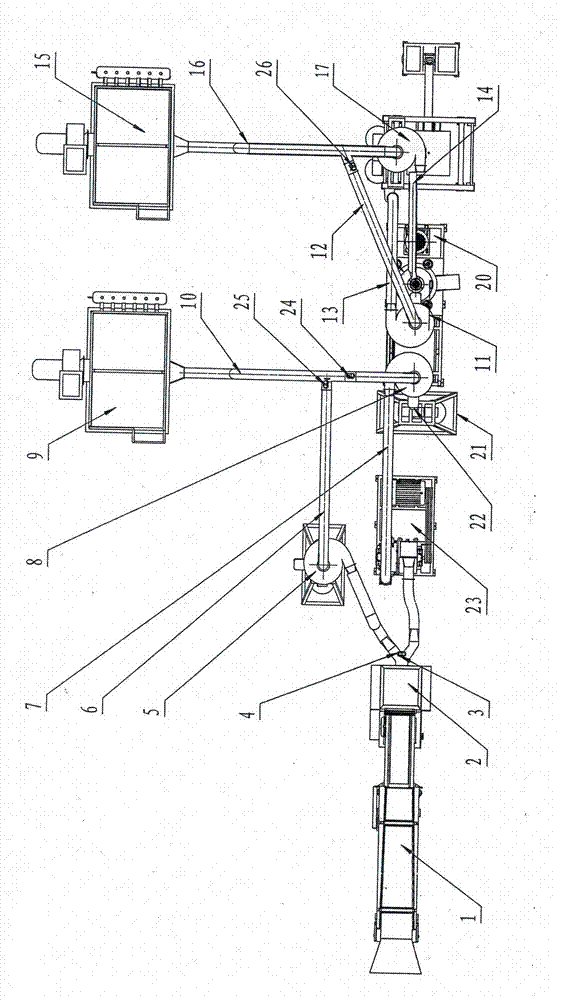

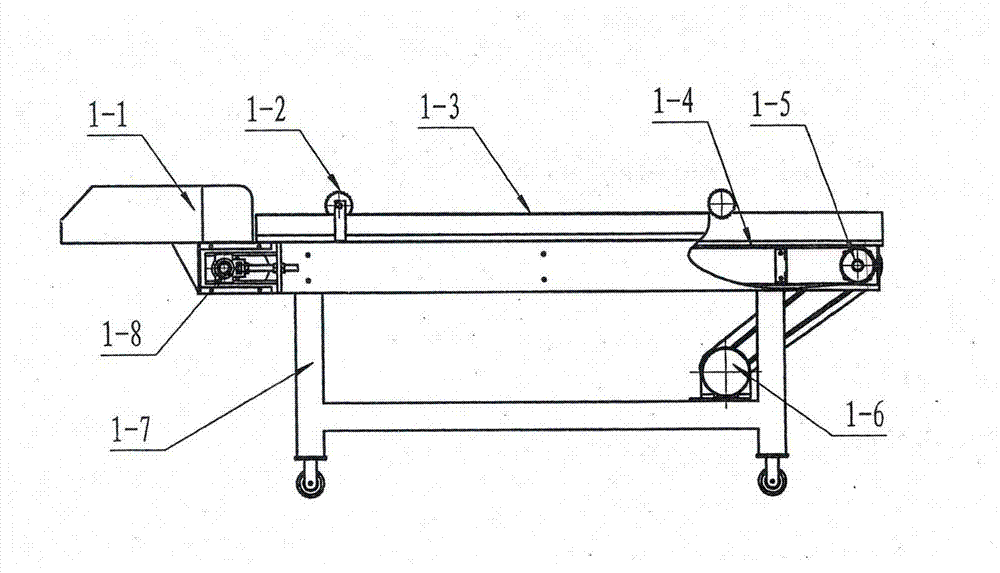

The invention discloses carbon fiber smashing equipment. The carbon fiber smashing equipment is mainly composed of a supplied material conveyor, a cut-off machine, a coarse pulverizer, an atomizer mill, a screening machine and a finished product conveyor as well as a cyclone separator and a pulse dust collector which are connected through a corresponding air conveying pipeline. The equipment can produce carbon fiber products with multiple lengths and finenesses, the highest fineness can achieve 300 meshes, the annual output can achieve 1000 tons, and the requirements of carbon fiber sections and thin powders of different specifications required by a carbon fiber production processing industry are fully achieved. The carbon fiber smashing equipment disclosed by the invention has the characteristics that the property is good, the efficiency is high, the structure is compact, the floor space is small, the yield is high, the operation is convenient, the smashing fineness is adjusted, the carbon fiber smashing equipment is wear-resisting and is easy to maintain, the labor is saved, the electricity is saved, and the environment can achieve the standard; the carbon fiber smashing equipment is ideal carbon fiber smashing equipment instead of imported equipment.

Owner:HENAN JIXING MACHINERY

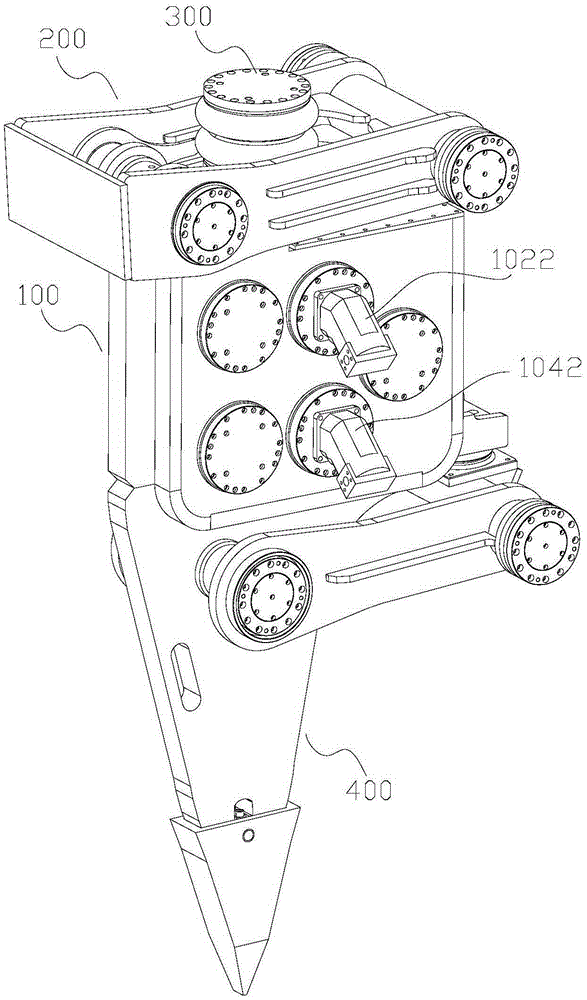

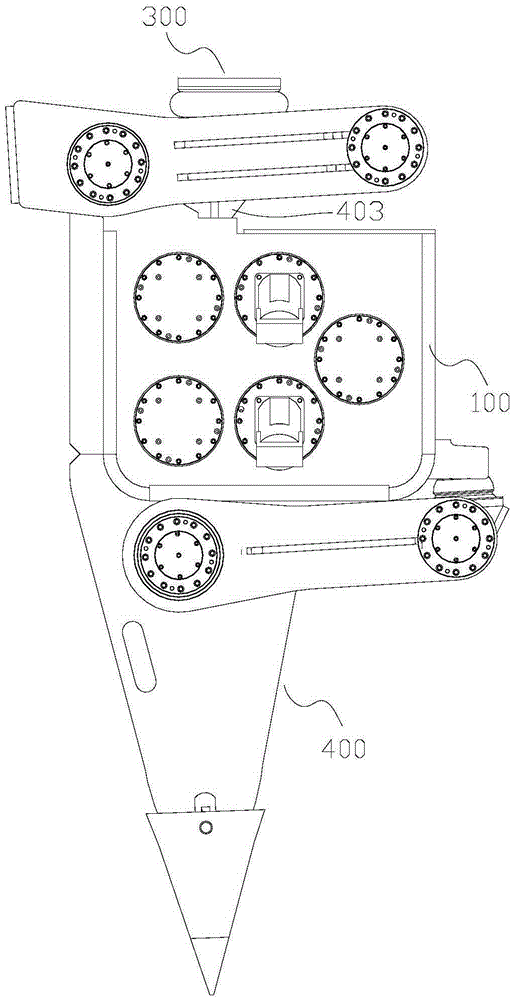

High frequency breaker

ActiveCN103706451BStrong crushingHigh crushing precisionSoil-shifting machines/dredgersDrive shaftEngineering

Owner:苏州鸣尼克重工机械有限公司

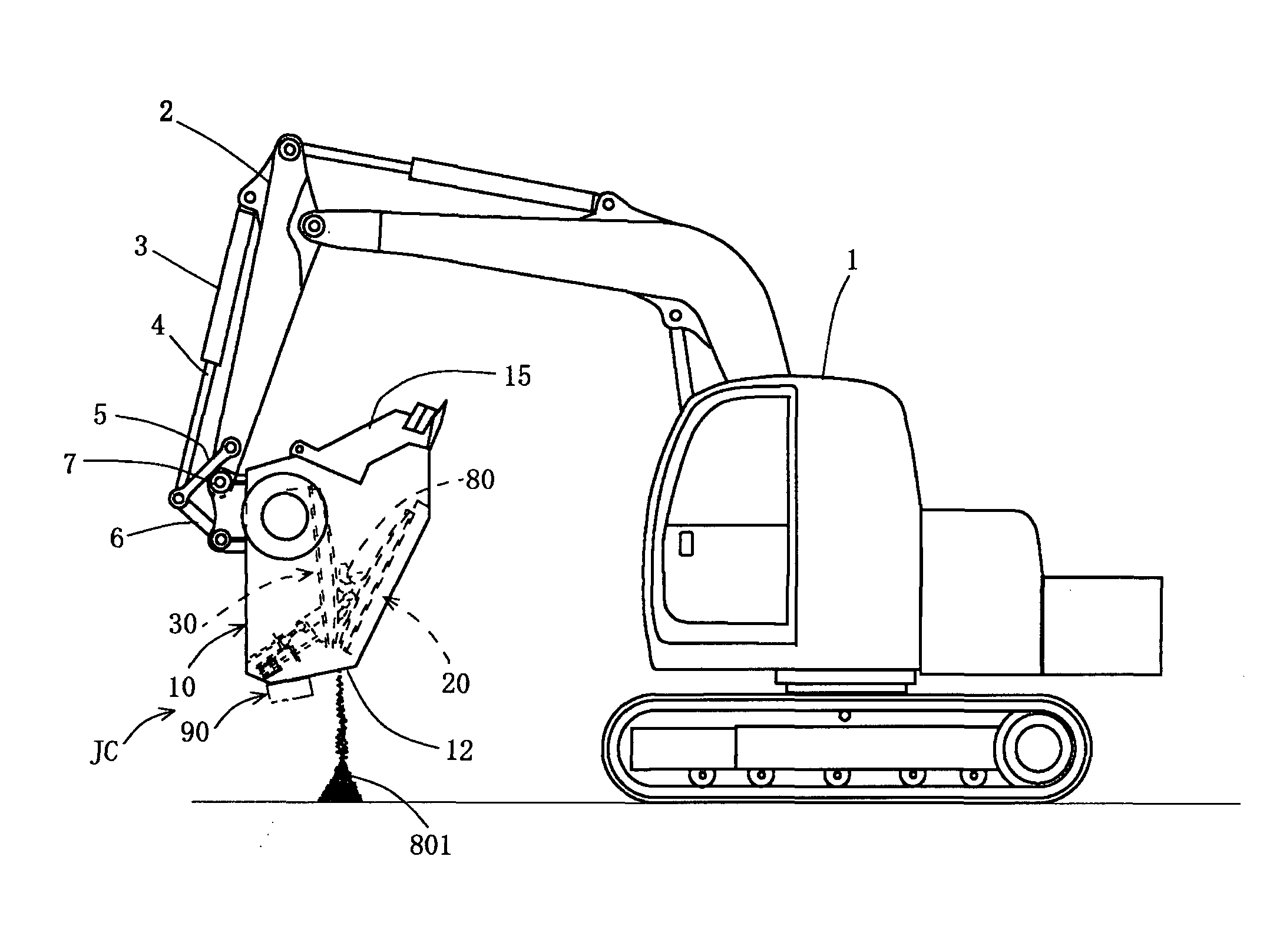

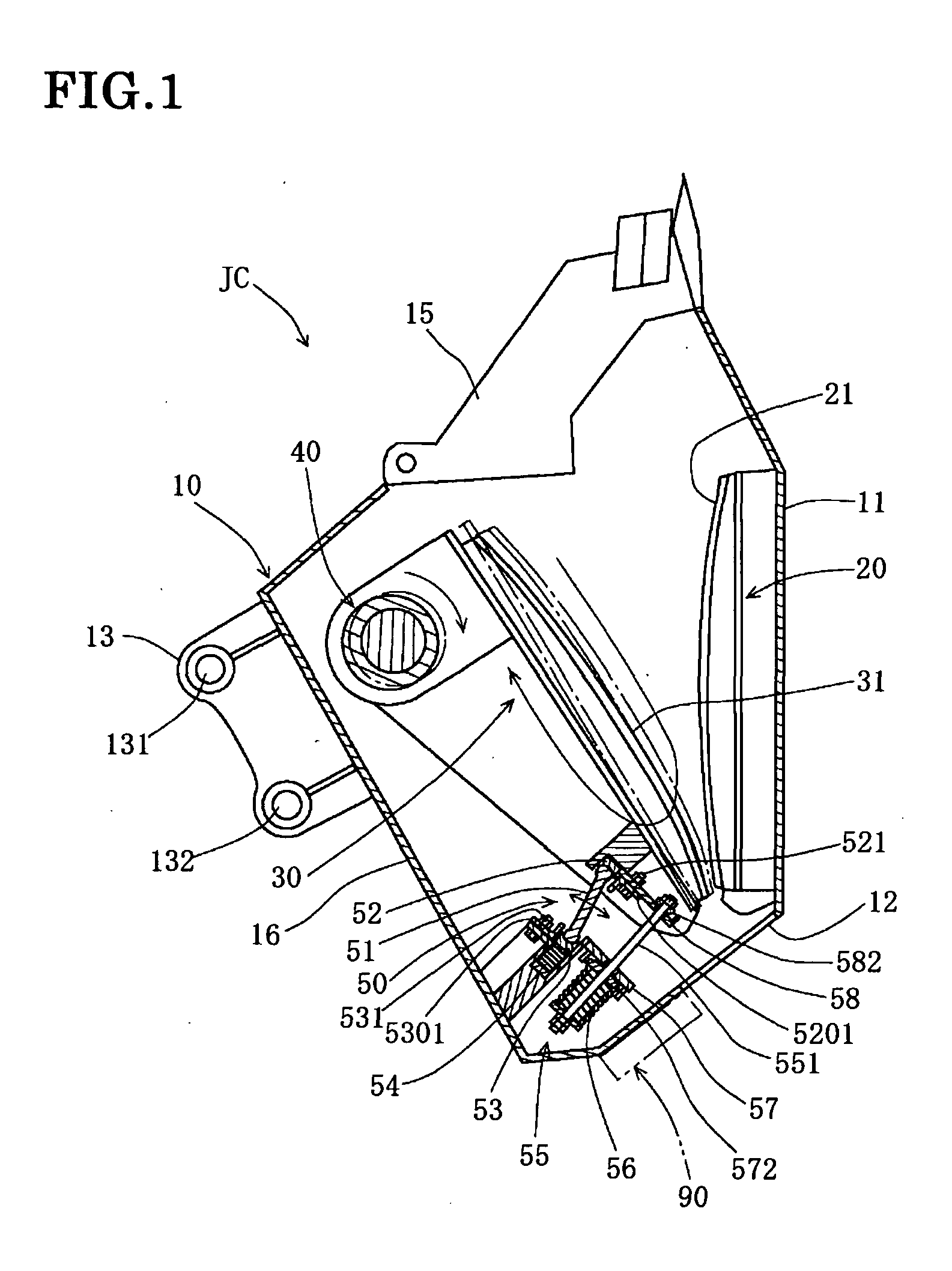

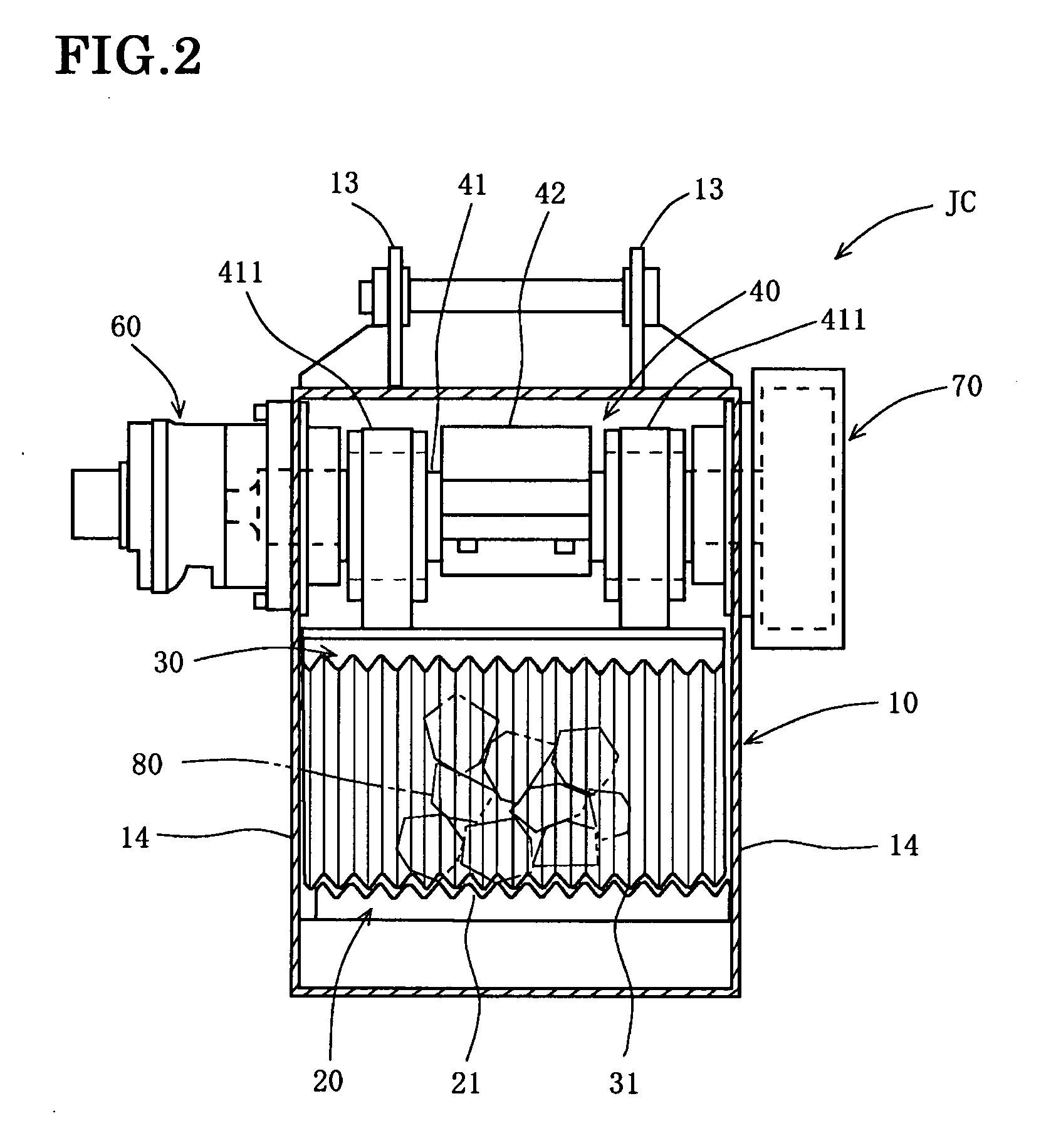

Bucket type jaw crusher

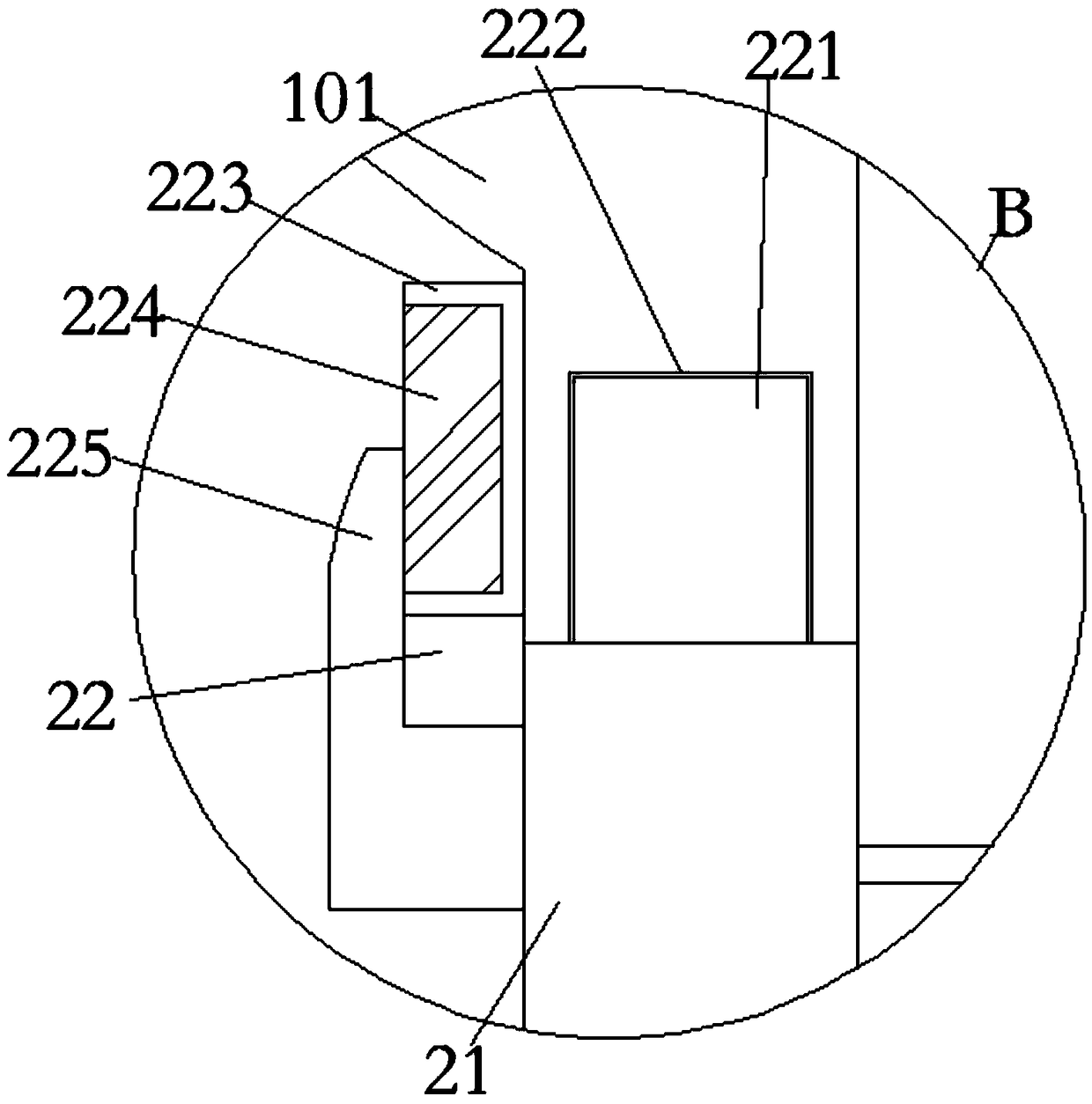

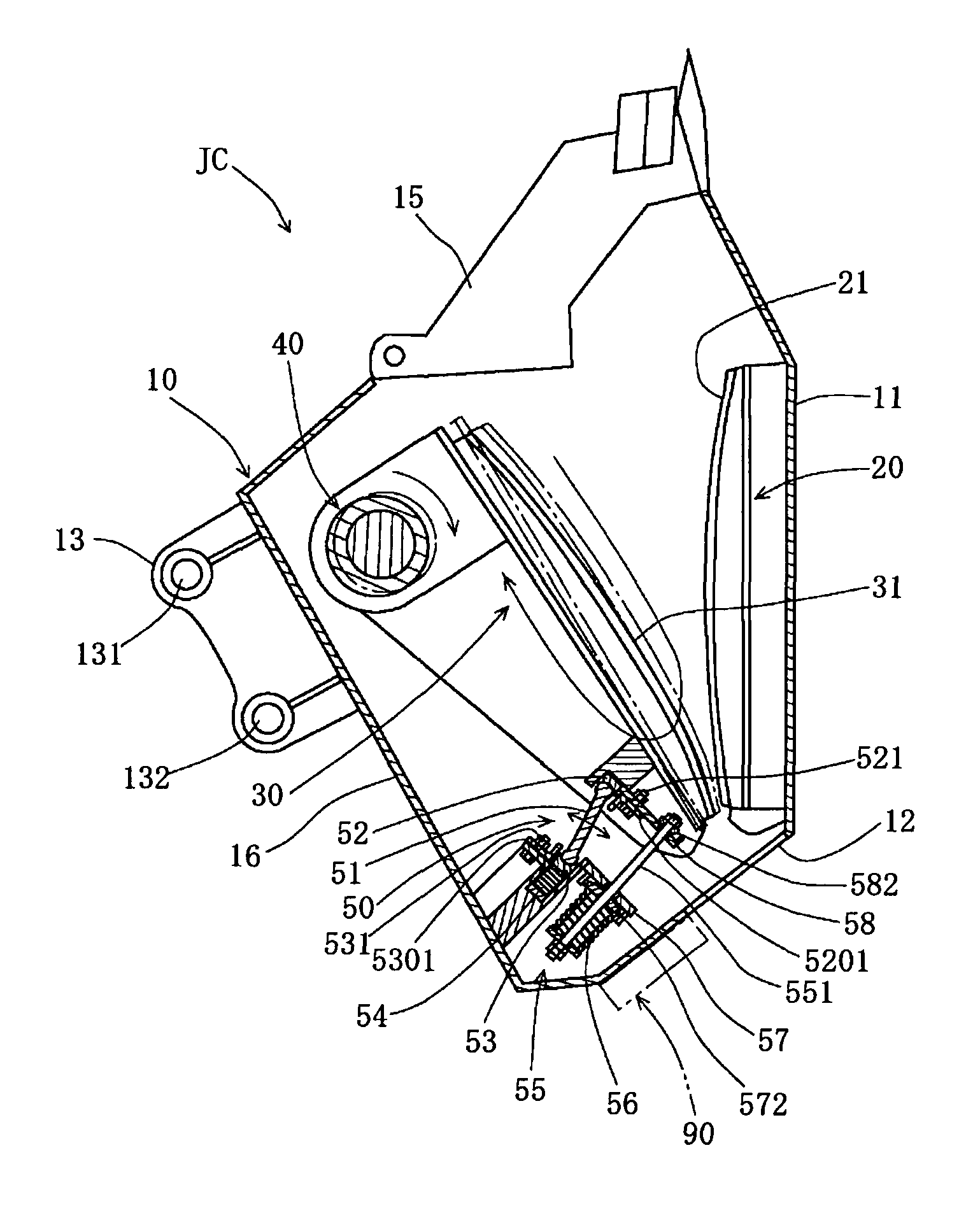

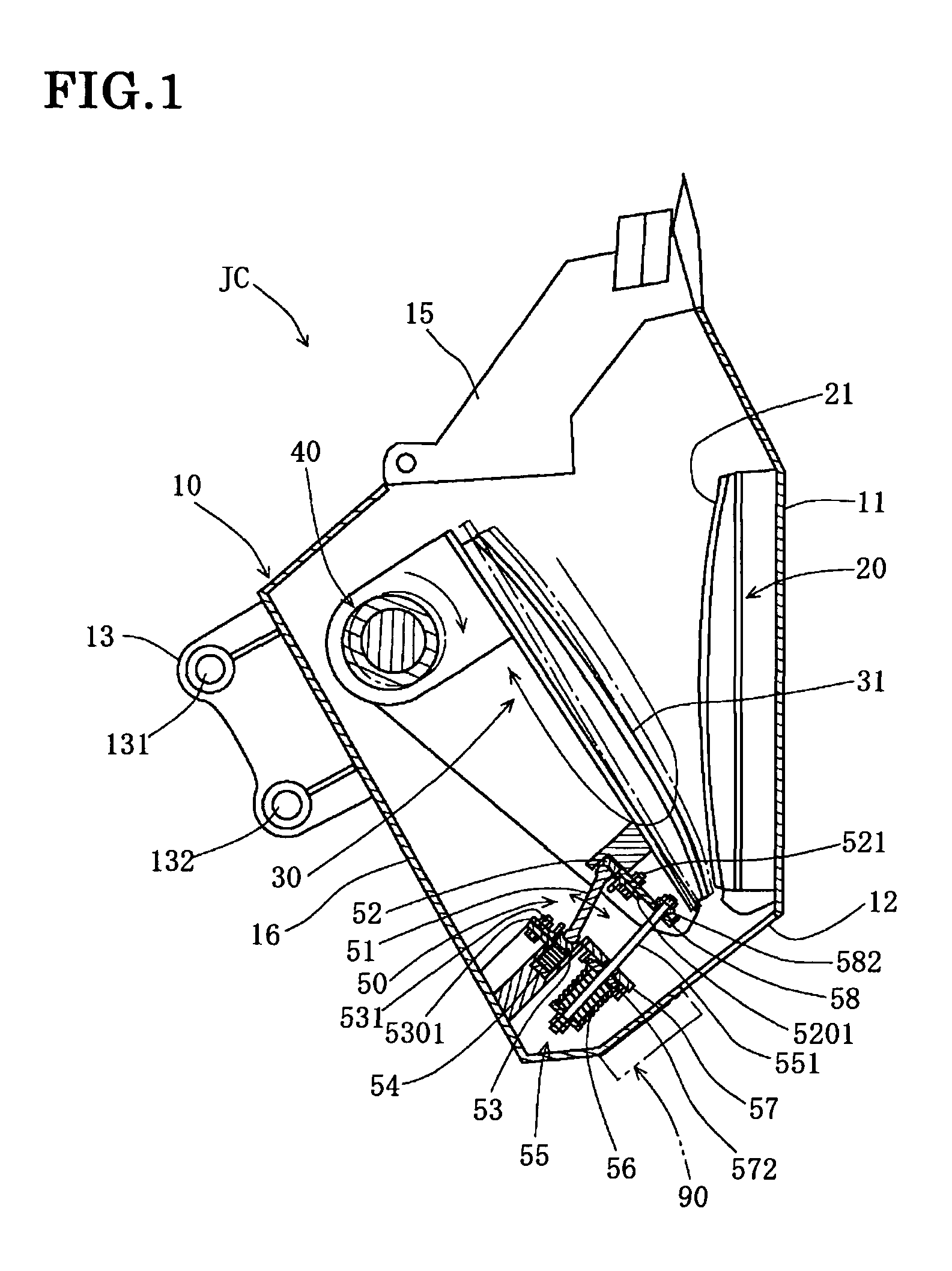

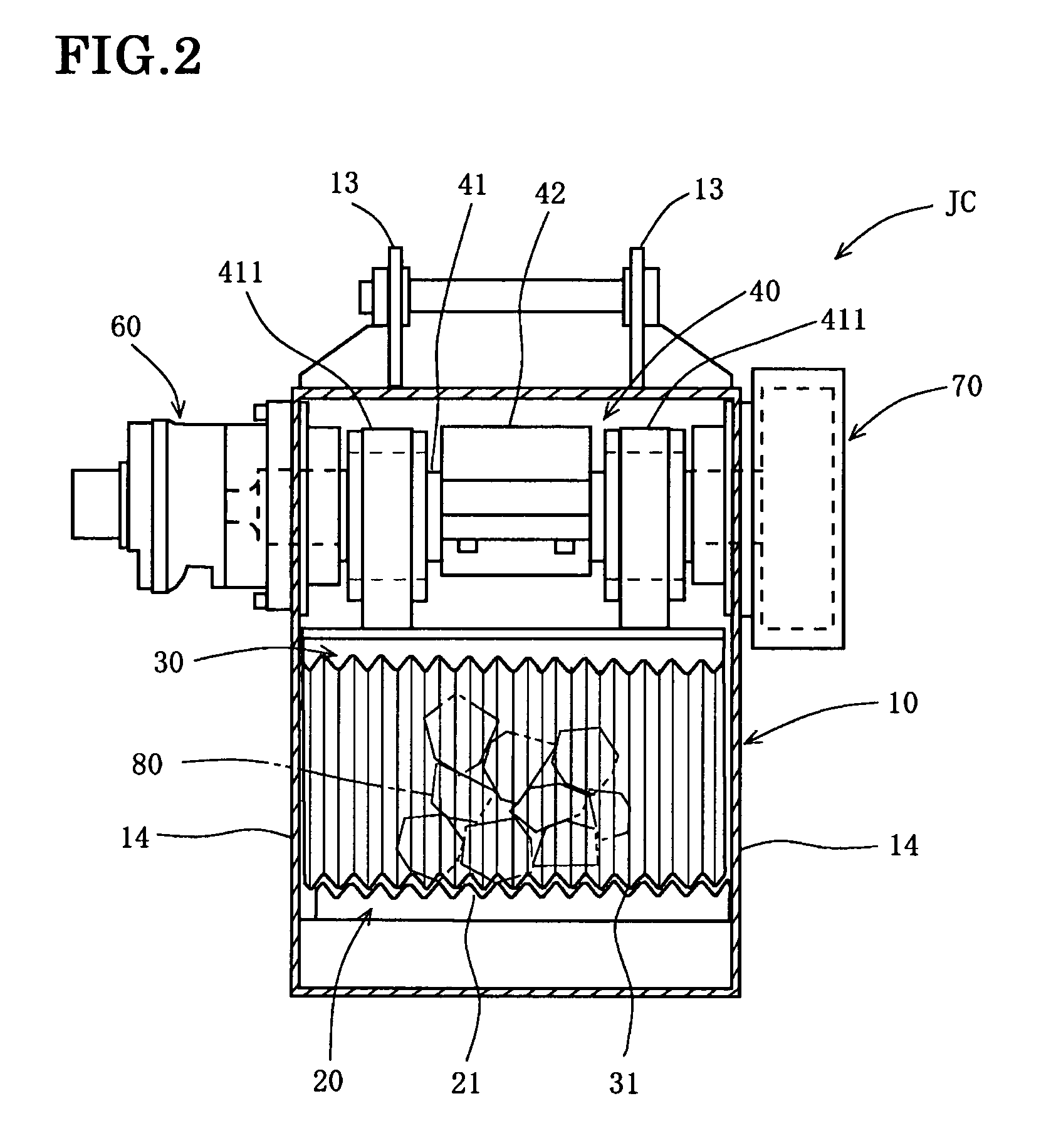

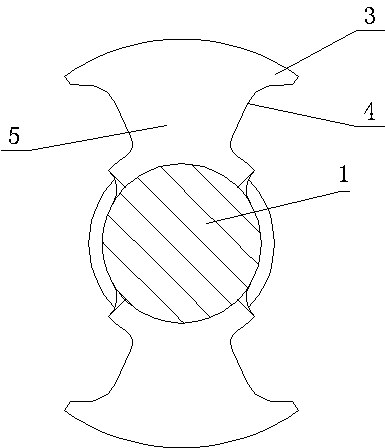

ActiveUS20100206975A1Short timeFor quick replacementMowersSoil-shifting machines/dredgersHydraulic motorReciprocating motion

A bucket type jaw crusher comprises a hydraulic motor connected to one end of an eccentric main shaft, a flywheel connected to the other end of the eccentric main shaft, and a counterweight for balance adjustment fitted at an intermediate section of the eccentric main shaft between the hydraulic motor and the flywheel. A movable jaw teeth side load receiving section of a toggle plate is placed at an upper position than a bucket side load receiving section of the toggle plate, and while movable jaw teeth are reciprocated by rotation of the eccentric shaft, an object to be crushed is pressed against stationary jaw teeth by the movable jaw teeth via rocking motion of the toggle plate.

Owner:UEDA IND

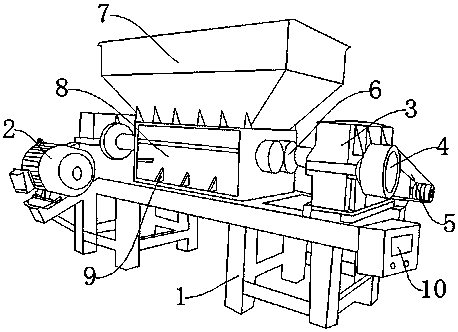

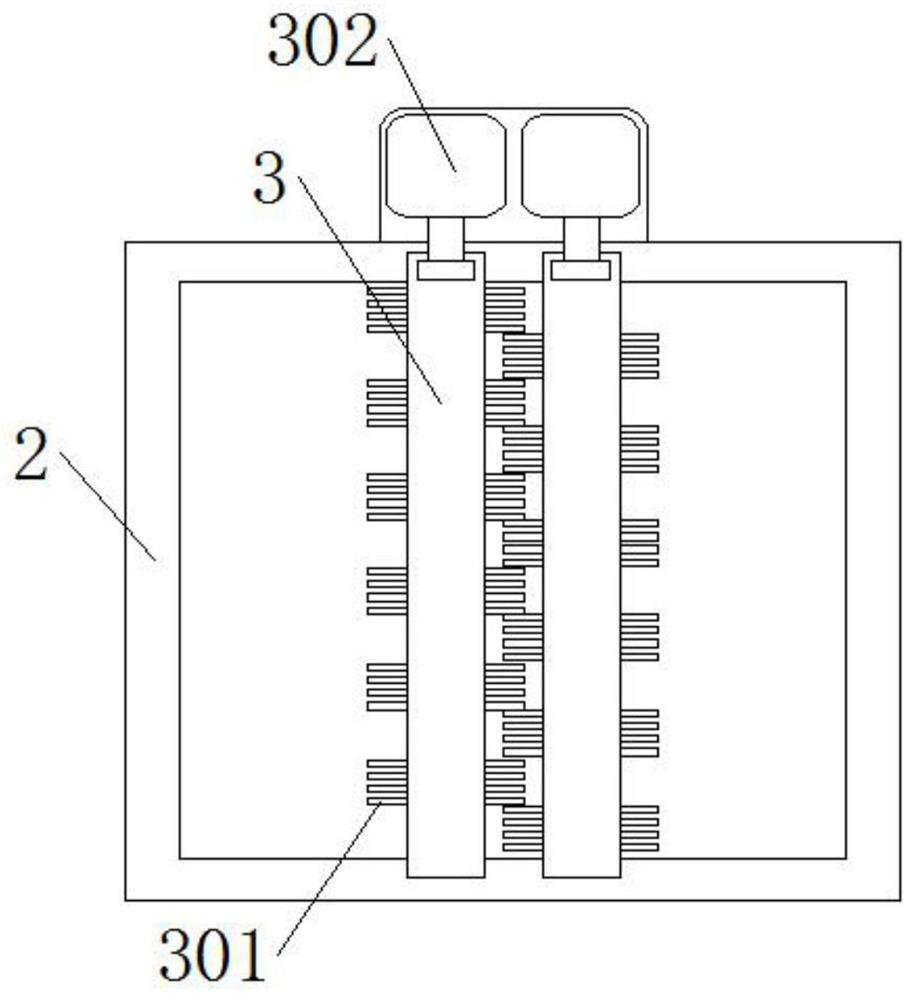

Crushing box of animal bone crusher

The invention discloses a crushing box of an animal bone crusher and relates to the field of collagen production equipment. The crushing box of the animal bone crusher comprises a crushing box outer shell. A crush roller is mounted in the crushing box outer shell, crush roller teeth are manufactured on roll surfaces of the crush roller, fixing teeth are arranged on the inner wall of the crushing box outer shell, and the fixing teeth and the crush roller teeth are arranged in a staggered manner. The crushing box of the animal bone crusher is simple in structure, convenient to use and maintain, low in manufacturing cost and equipment failure rate. In addition, the crush roller teeth of the crush roller and the fixing teeth are meshed in a staggered manner to break bones in a wringing manner crushing force and efficiency are high, and the service life of equipment is long.

Owner:安徽省淮河制胶有限公司

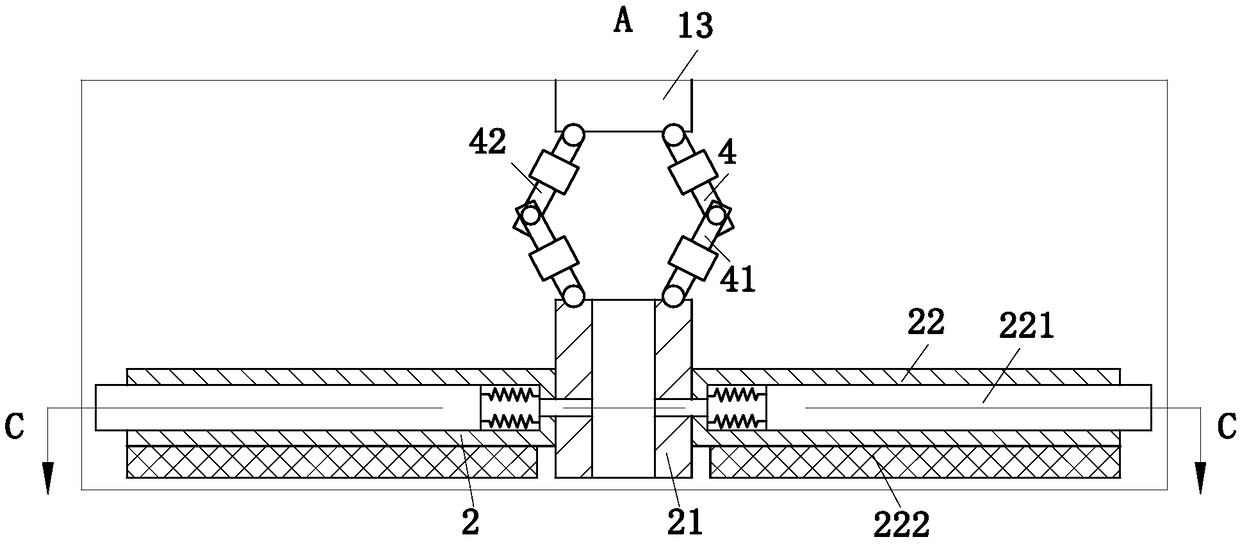

Powder breaking mechanism for secondary utilization of waste glass

The invention relates to the technical field of environmental protection equipment, in particular to a powder breaking mechanism for secondary utilization of waste glass. The powder breaking mechanismfor the secondary utilization of the waste glass solves the technical problems that the waste glass is not broken completely and the broken effect is not high. The powder breaking mechanism for the secondary utilization of the waste glass comprises a block breaking mechanism, a crushing cylinder mechanism is movably connected to the bottom of the block breaking mechanism, the bottom of the crushing cylinder mechanism is movably connected with an feed inlet of the top of a power stirring box, a power stirring mechanism is arranged in the power stirring box, support legs are separately and fixedly connected to four right angle positions of the bottom of the power stirring mechanism, and a discharge sleeve is connected to the interior of an opening of the bottom of the power stirring box ina sleeving mode. According to the powder breaking mechanism for the secondary utilization of the waste glass, when pushing rods push crushing heads to move, because the crushing heads on the two sidesare arranged in an inclined mode, when the glass enters a block breaking sleeve, the glass can be crushed into small pieces from large pieces by squeezing, and the farther down, the distance betweenthe two crushing heads is smaller, so that glass with large pieces is gradually broken.

Owner:安徽强钢钢化玻璃股份有限公司

Bucket type jaw crusher

ActiveUS7980501B2For quick replacementImprove the lubrication effectMowersSoil-shifting machines/dredgersHydraulic motorReciprocating motion

Owner:UEDA IND

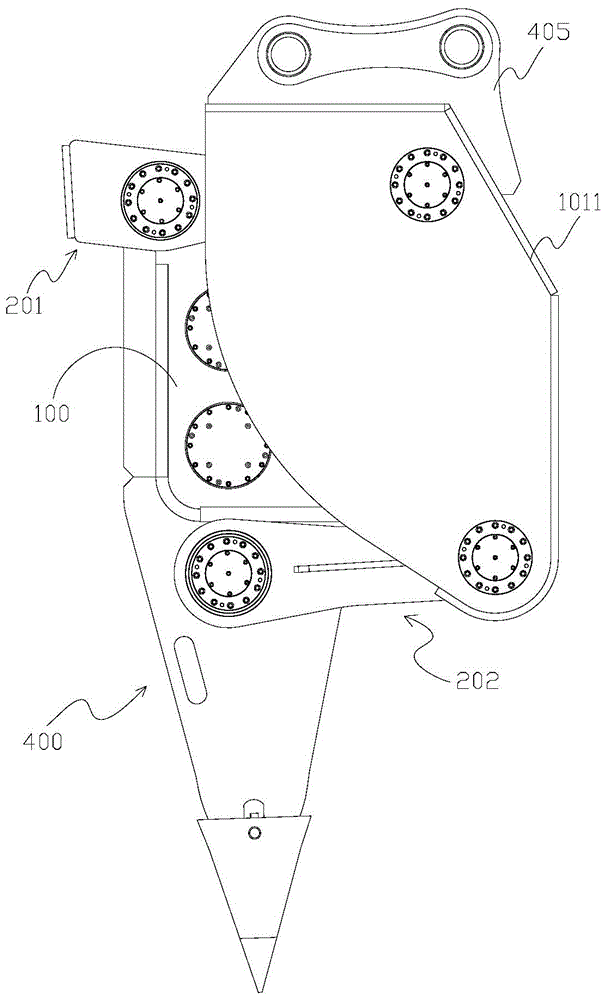

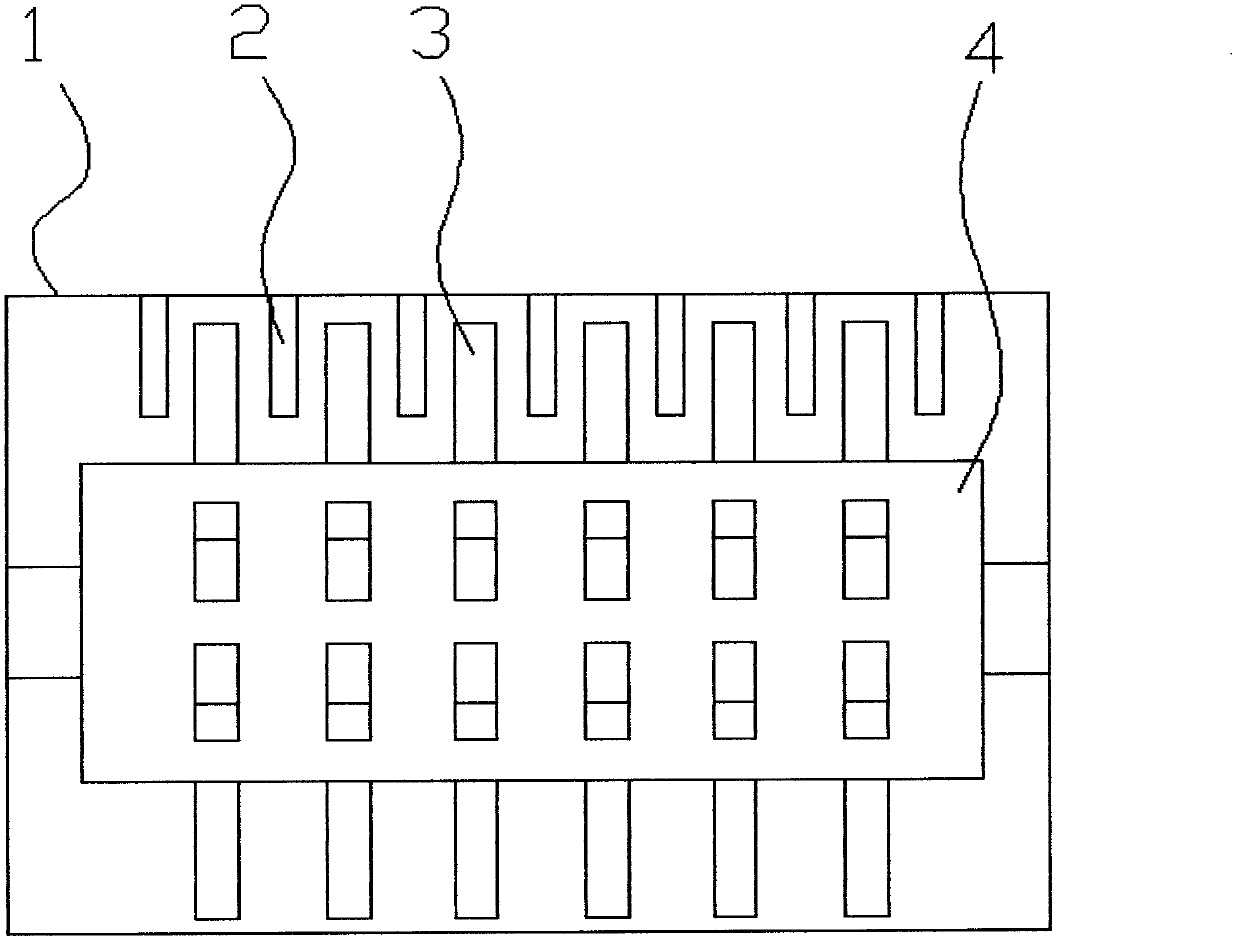

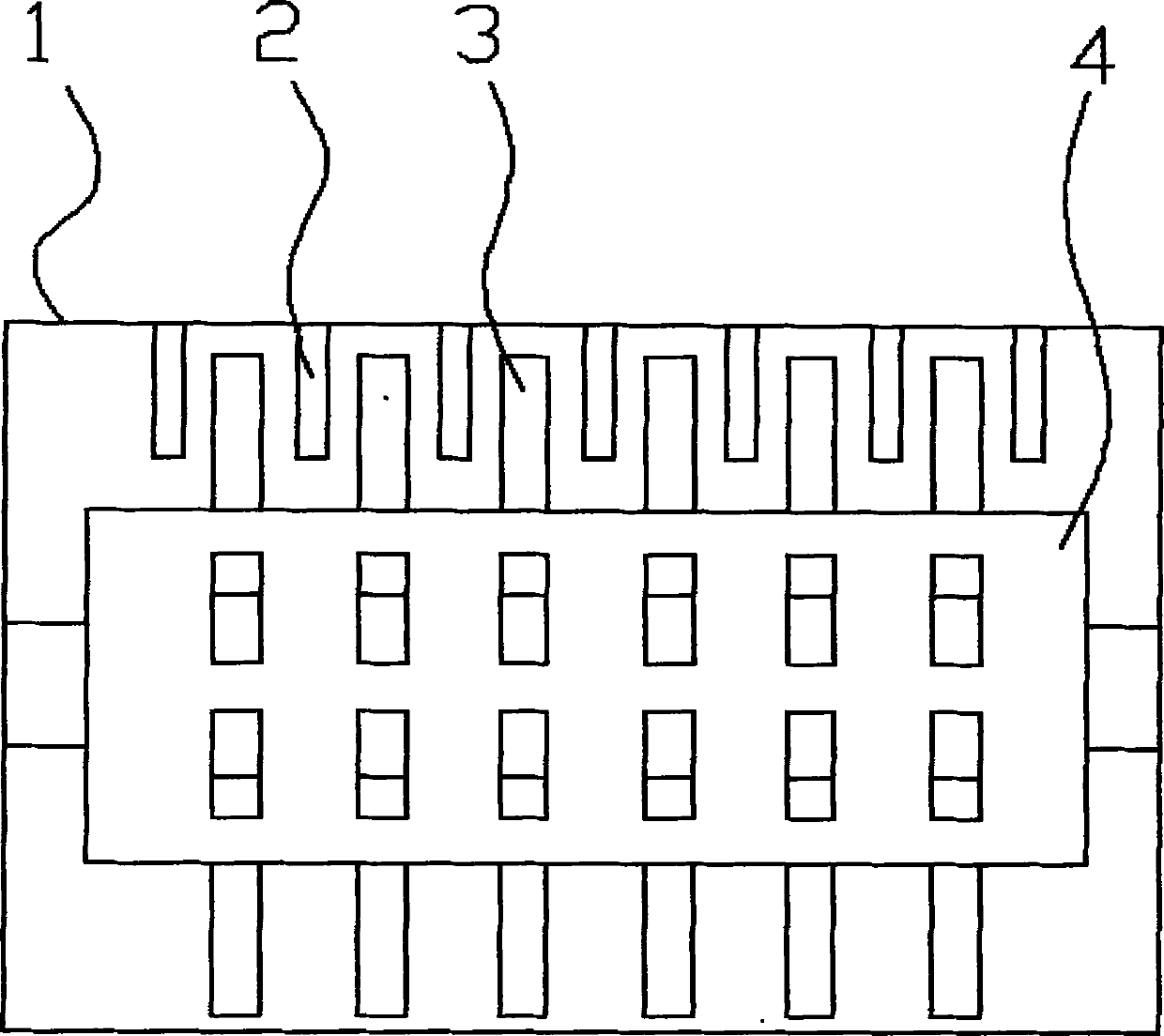

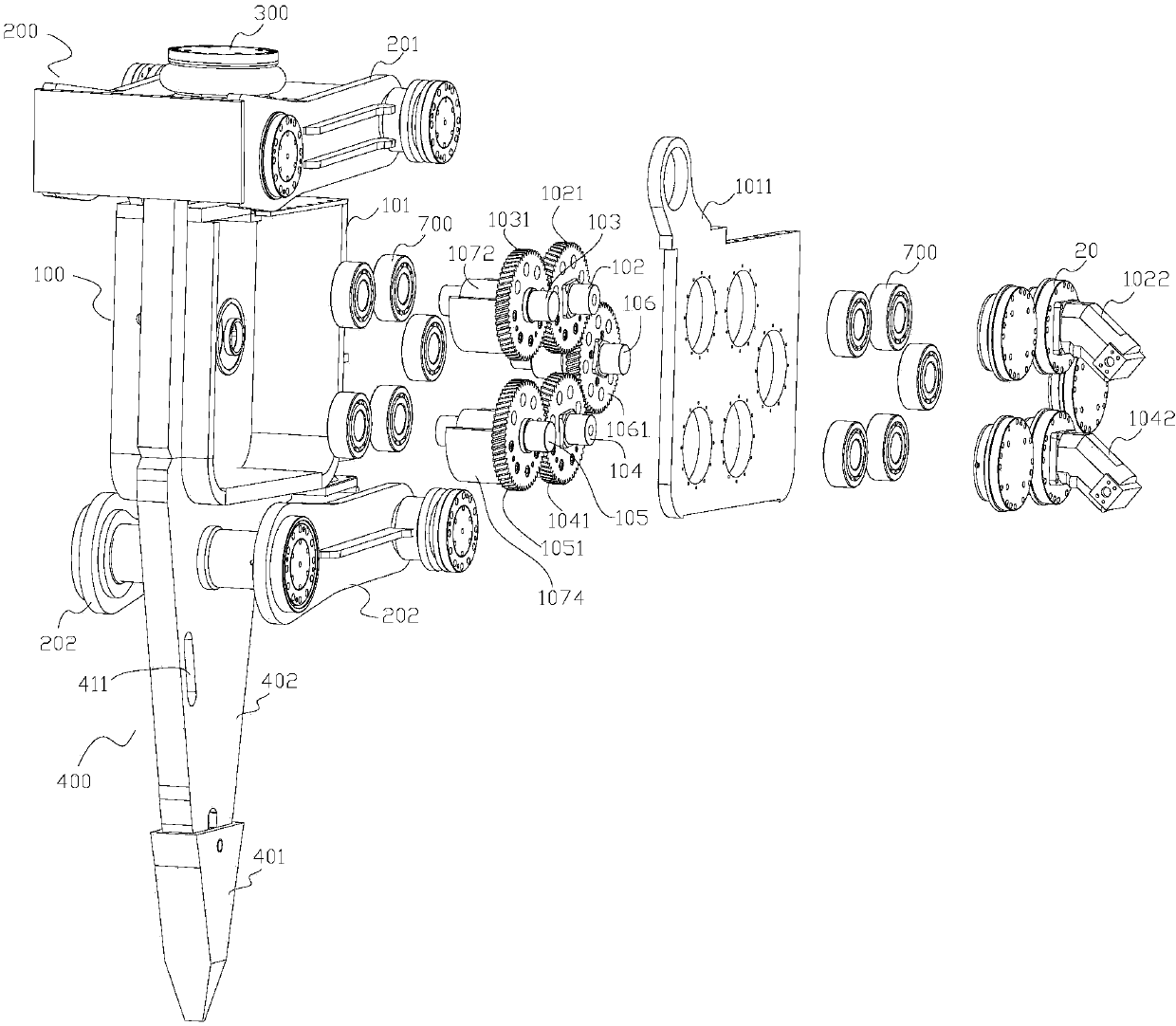

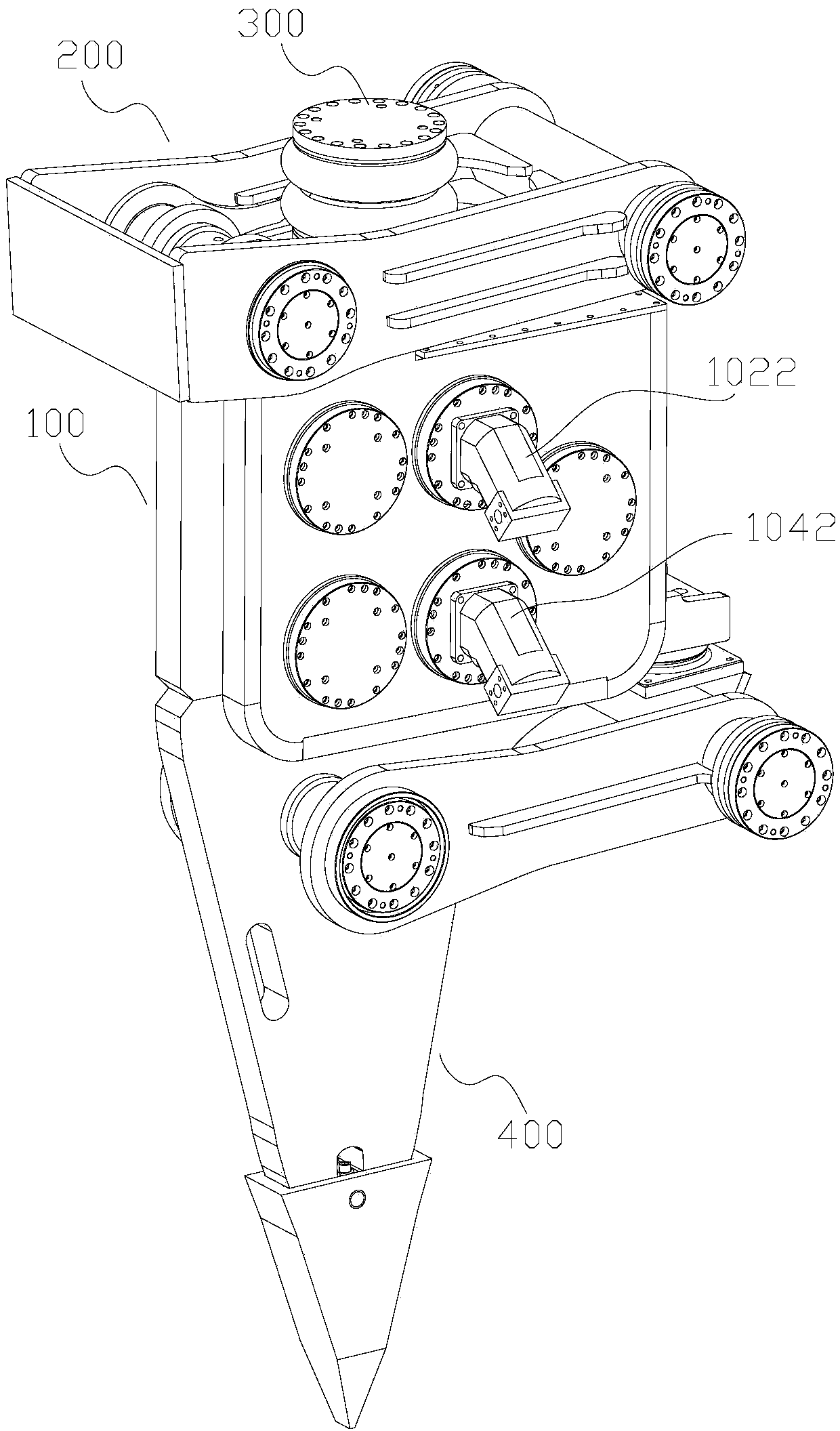

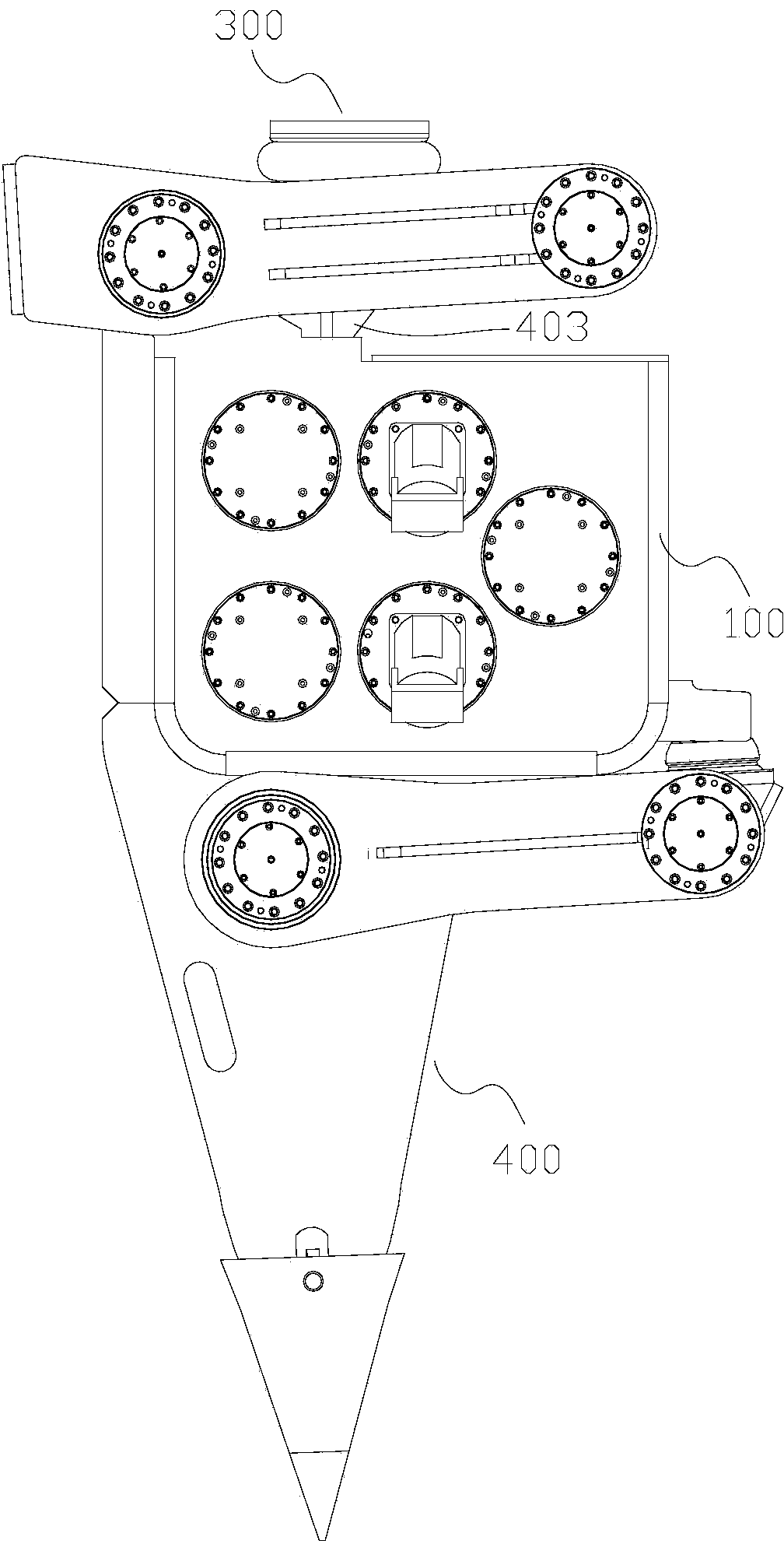

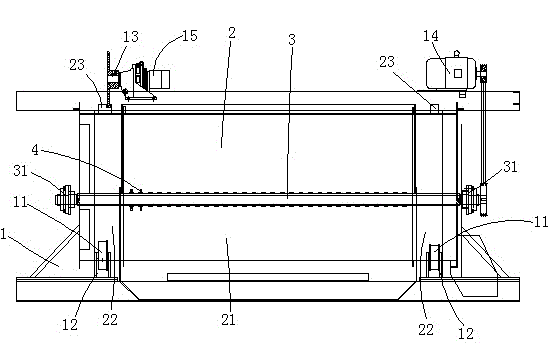

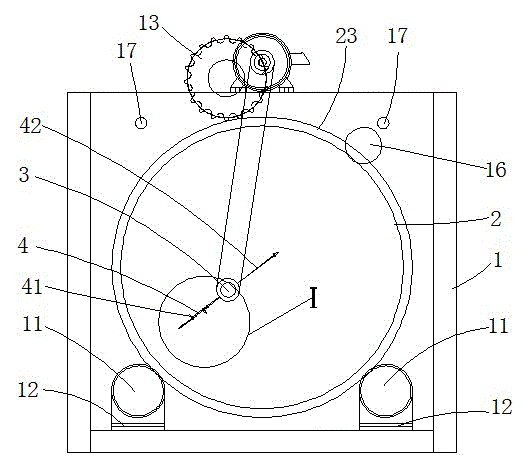

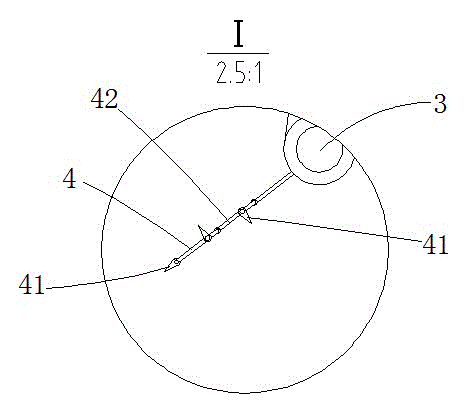

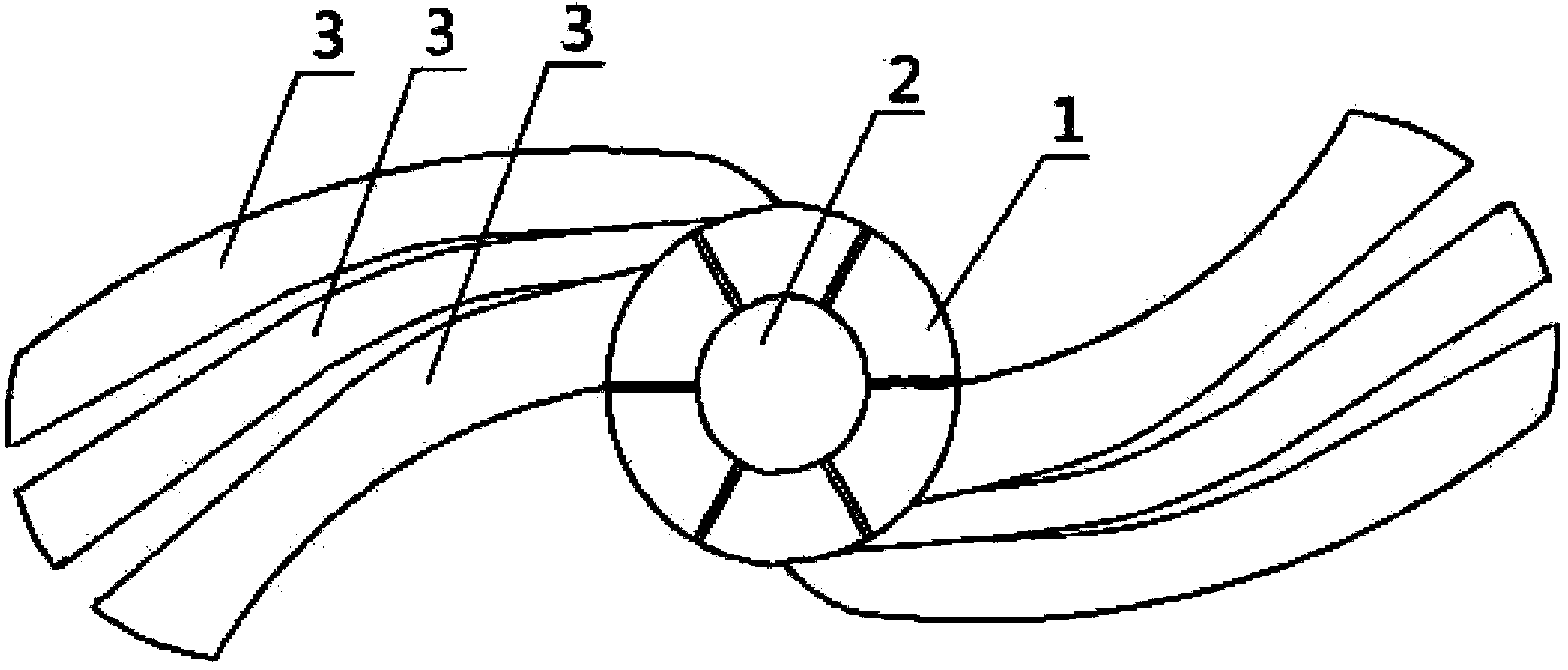

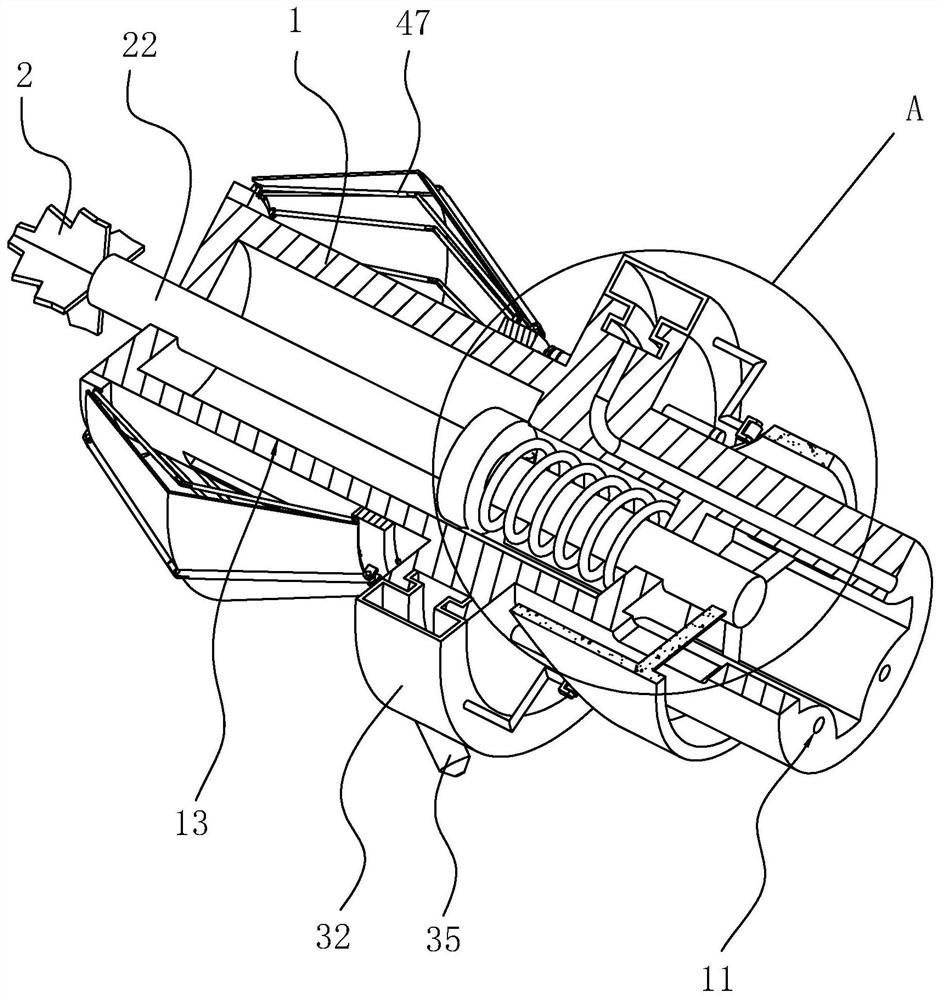

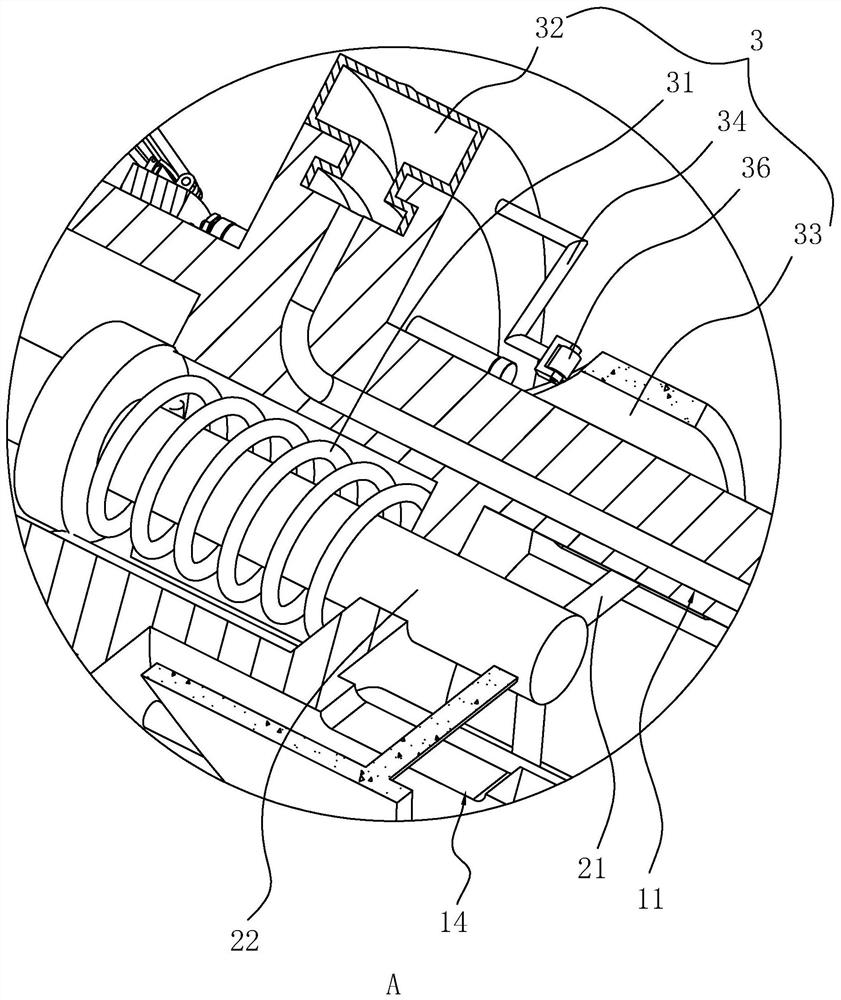

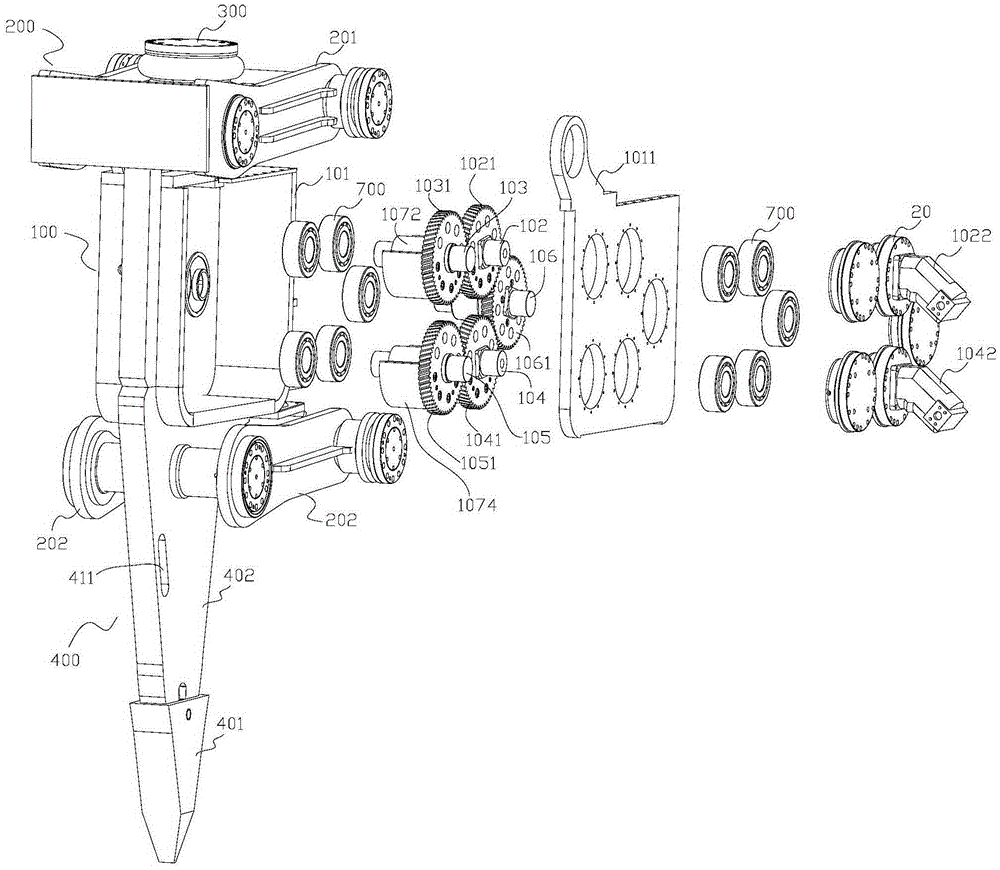

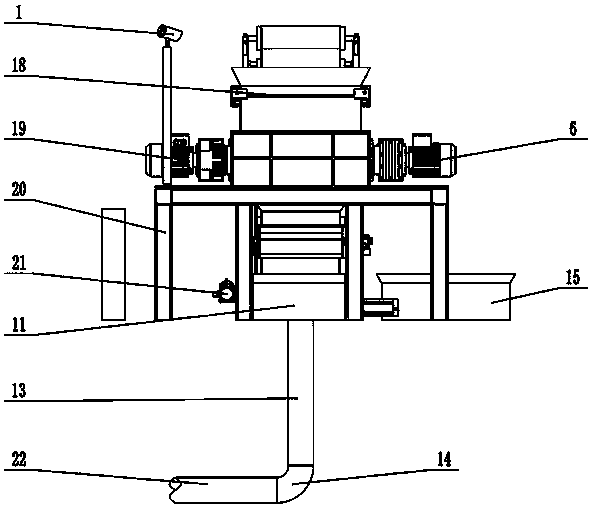

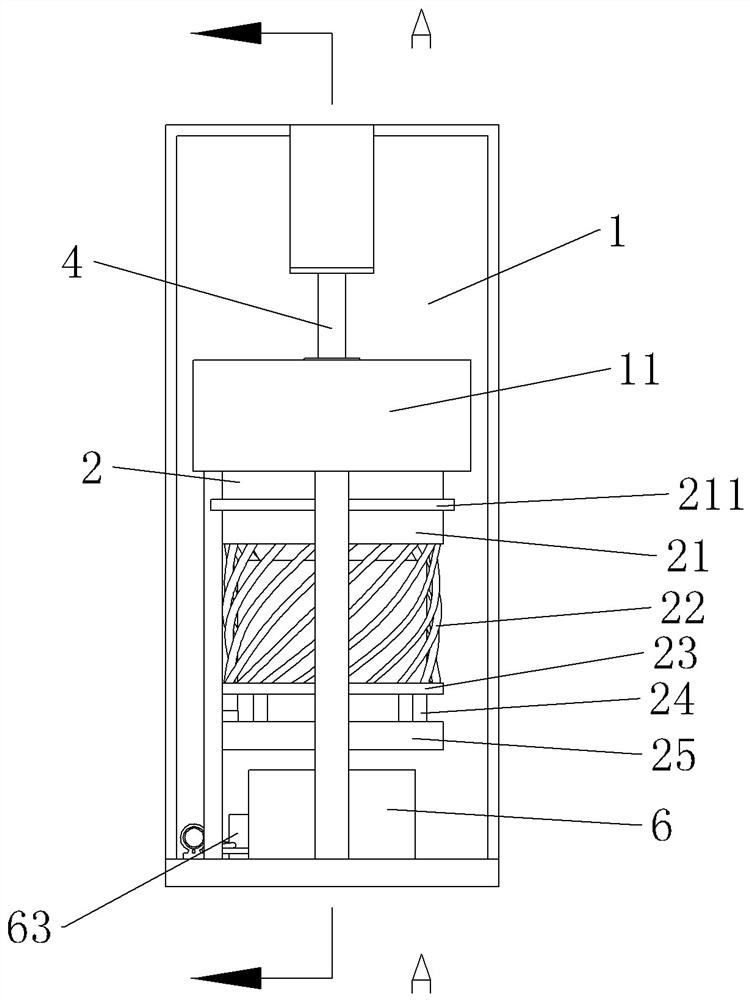

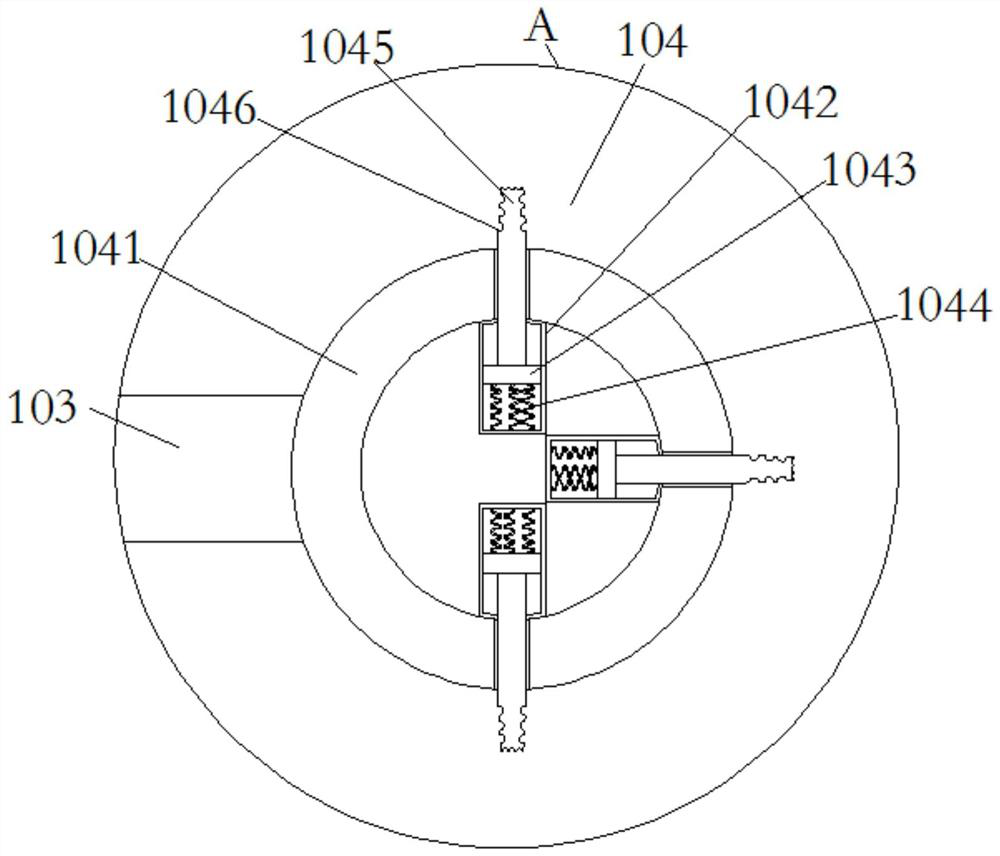

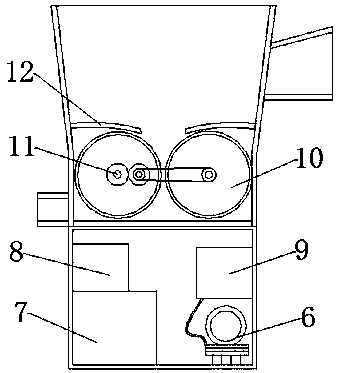

Double-motor crushing device of high frequency crushing hammer

ActiveCN103736545AStrong crushingHigh crushing precisionNon-rotating vibration suppressionGrain treatmentsDrive shaftOperation time

The invention discloses a double-motor crushing device of a high frequency crushing hammer. The double-motor crushing device comprises a vibration generator, a four connecting rod mechanism and a shaking knife row, wherein the vibration generator comprises a shell, a first driving shaft arranged in the shell, a first driven shaft which is mutually meshed with the first driving shaft through gears, a second driving shaft, a second driven shaft which is mutually meshed with the second driving shaft through gears as well as a bridge crossing shaft arranged between the first driving shaft and the second driving shaft; the bridge crossing shaft is mutually meshed with the first driving shaft and the second driving shaft gears, the first driving shaft, the first driven shaft, the second driving shaft and the second driven shaft are all provided with eccentric wheels and gears. The double-motor crushing device disclosed by the invention has the advantages that as two groups of actuating shafts are adopted and matched with two actuating motors, the crushing force of the crushing hammer actuated by the two actuating motors is large relative to that of the crushing hammer actuated by the single motor, the crushing accuracy is high, the noises are small, and the crushing capacity is strong, thus the operation time of the crushing hammer is prolonged, and the crushing efficiency is improved.

Owner:苏州鸣尼克重工机械有限公司

Strong crusher

A high-power pulverizer is composed of a machine frame, a pulverizing unit consisting of casing, input axle, several plate-type cutters fixed to input, sieving net under said cutters and powder storage chamber, and a power unit with an output axle coupled to input axle of pulverizing unit via drive mechanism.

Owner:王建中

Vacuum-wrapped aluminum slag separation system for electrolytic aluminum

ActiveCN109482280AStrong crushingSolve pollutionDispersed particle filtrationGrain treatmentsSlagAluminium

The invention belongs to the technical field of electrolytic aluminum, and particularly relates to a vacuum-wrapped aluminum slag separation system for electrolytic aluminum. The vacuum-wrapped aluminum slag separation system comprises a grinding and smashing sieving machine, and further comprises a box body, a first grinding and smashing unit, a second grinding and smashing unit, a telescopic unit, a grinding plate, a double-head motor, a first motor and a controller. The first motor drives the box body to rotate, thus the first grinding and smashing unit rotates in the vertical direction, and a grinding ball rotates inside the box body, and meanwhile, the double-head motor drives thesecond grinding and smashing unit to rotate in the horizontal direction; and through mutual cooperation between the first grinding and smashing unit, the second grinding and smashing unit and the grinding ball, aluminum slag is thoroughly grinded, thus electrolyte and alumina powder wrapped in the aluminum slag are fully separated, and thus the separation efficiency of the aluminum slag is improved.

Owner:江苏复容科技创业孵化管理有限公司

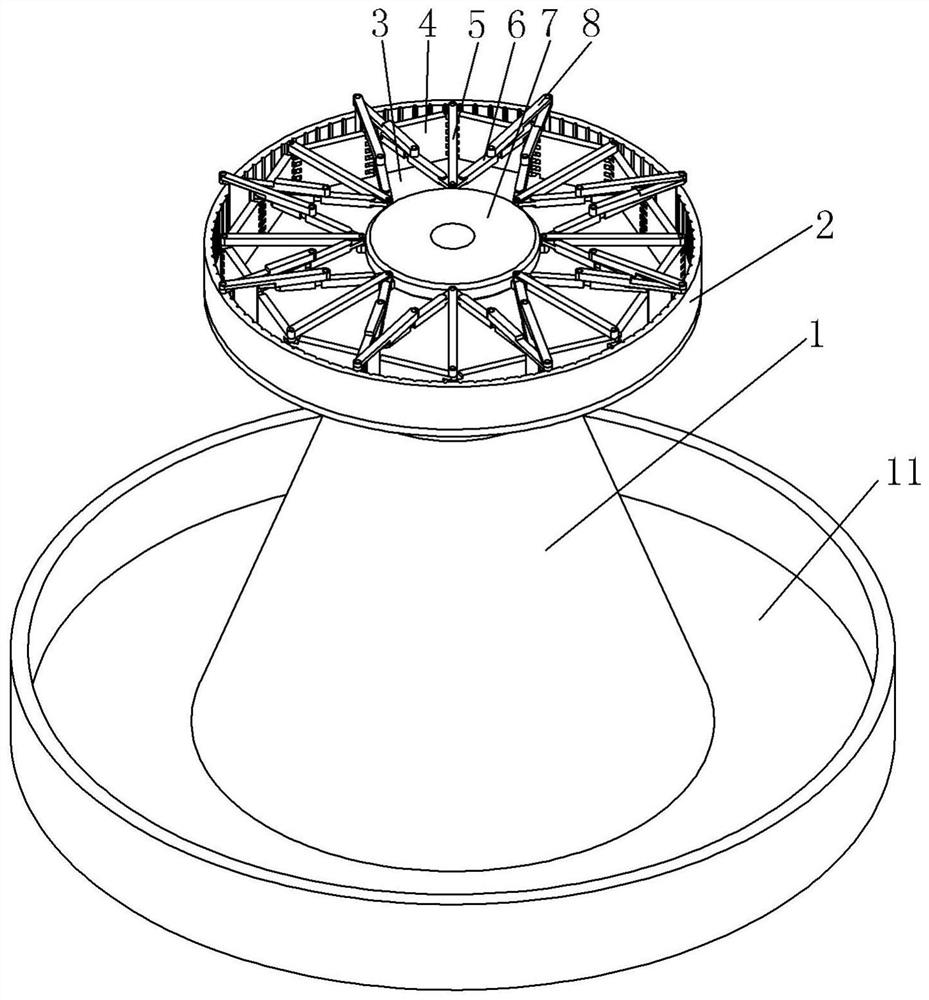

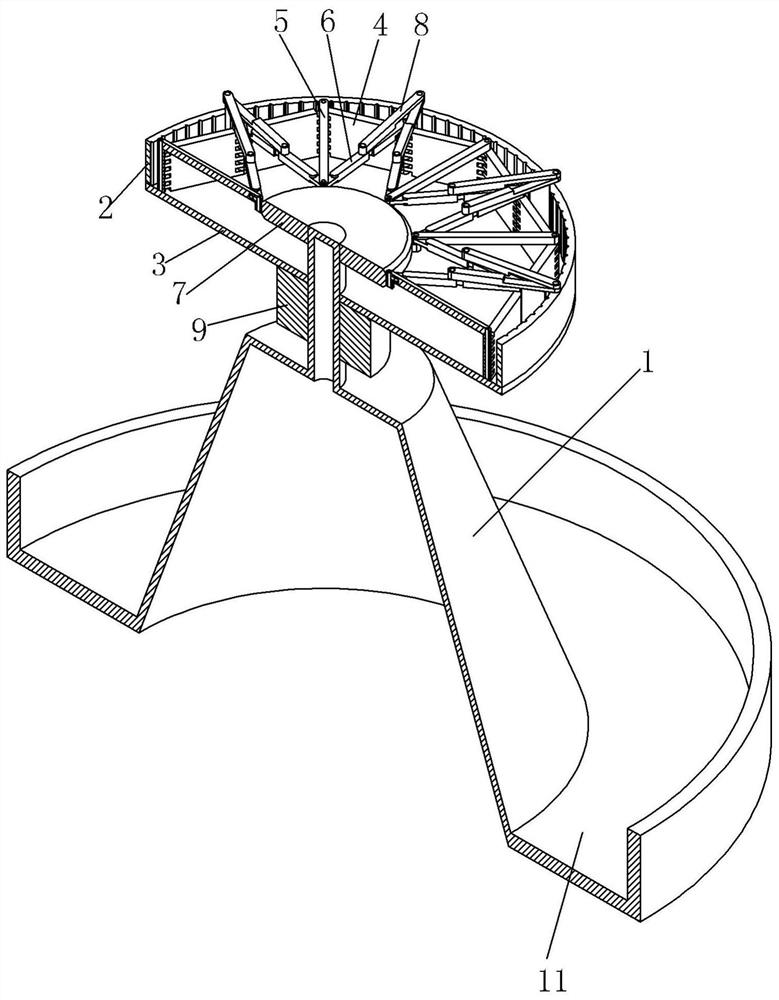

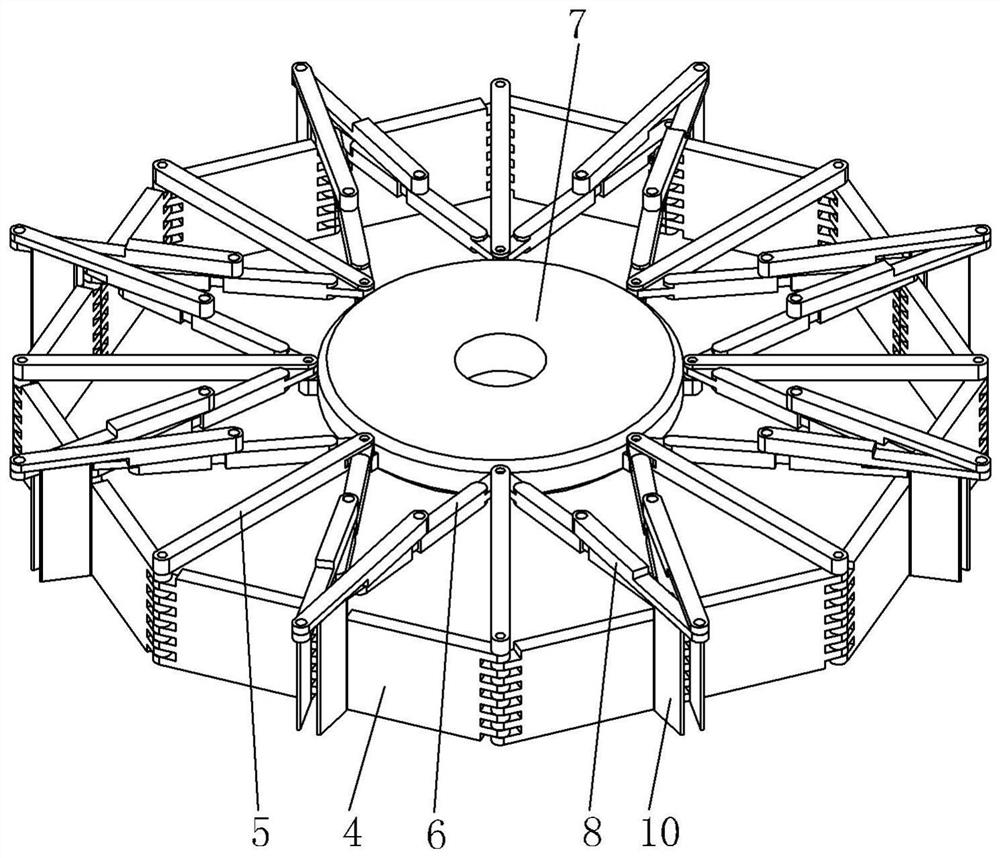

Decoration garbage sorting and crushing device

ActiveCN113769862AStrong crushingEasy to grind and breakGrain treatmentsStructural engineeringRefuse Disposals

The invention relates to the technical field of garbage treatment, in particular to a decoration garbage sorting and crushing device. The decoration garbage sorting and crushing device comprises a rack and a crushing assembly, wherein the rack comprises a tray and a crushing ring, the crushing assembly comprises a connecting plate, a plurality of crushing boards, a plurality of connecting rods, a plurality of stretchable driving rods arranged in pairs, a plurality of pushing rods and baffles, the crushing boards are connected end to end and connected to one another in a hinged mode to define a polygon, the connecting rods and the stretchable driving rods are connected to the connecting plates and the crushing boards, the pushing rods are installed on the stretchable driving rods, and the baffles are installed on the pushing rods. According to the decoration garbage sorting and crushing device, in the process that the stretchable driving rods drive the crushing boards to rotate in one direction, the pushing rods move in the opposite direction and drive the baffles to push and extrude garbage in the opposite direction, so that the garbage is tighter, the crushing force is increased, grinding and crushing are facilitated, and the crushing effect is improved.

Owner:SUZHOU CONSTR MATERIAL RECYCLING APPL

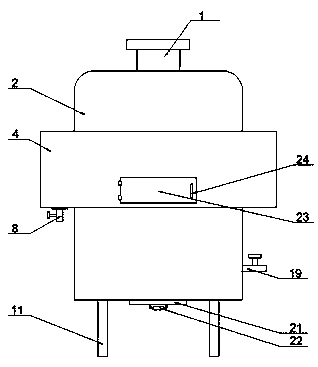

Garbage screening machine with flail knife crushing function

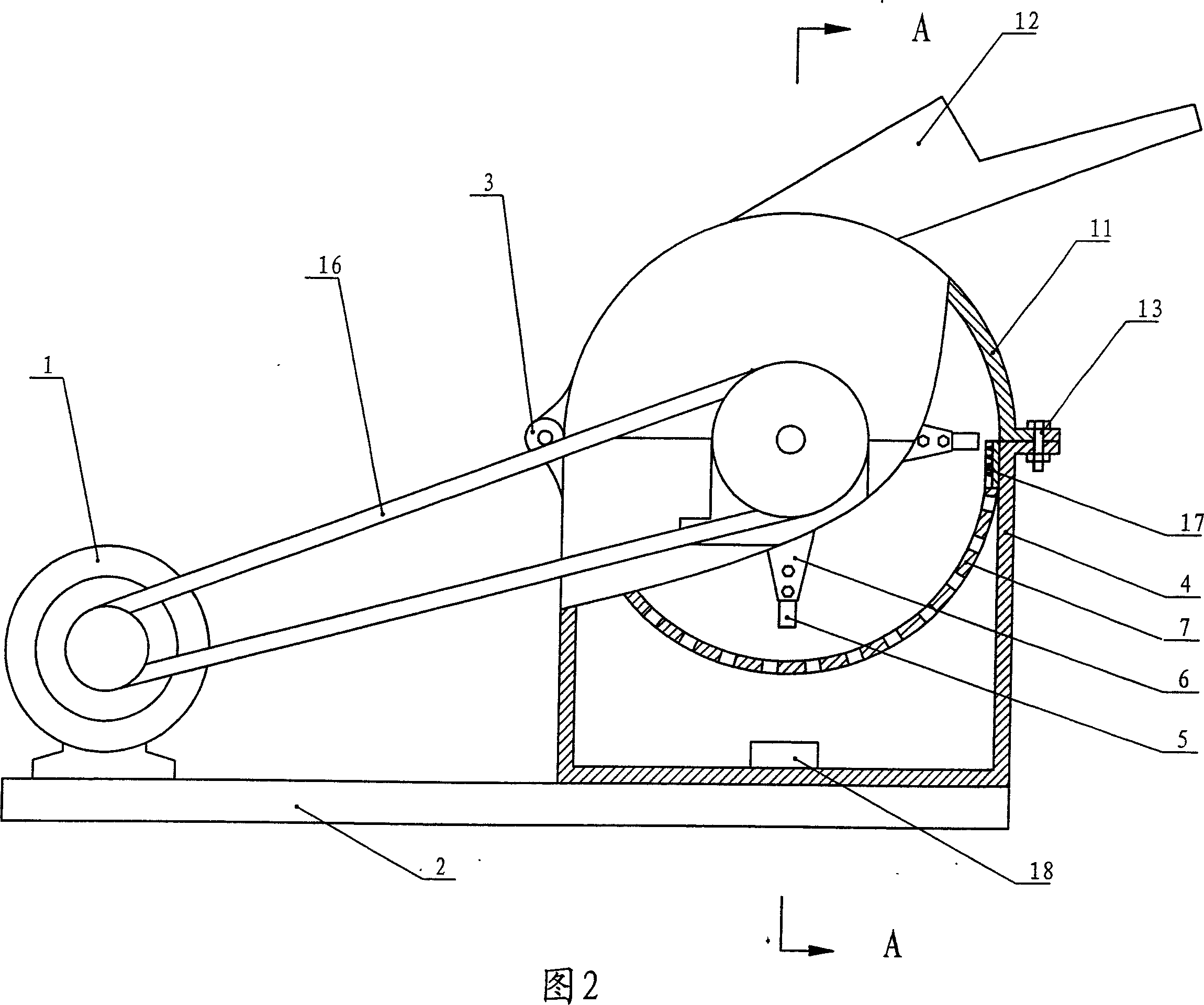

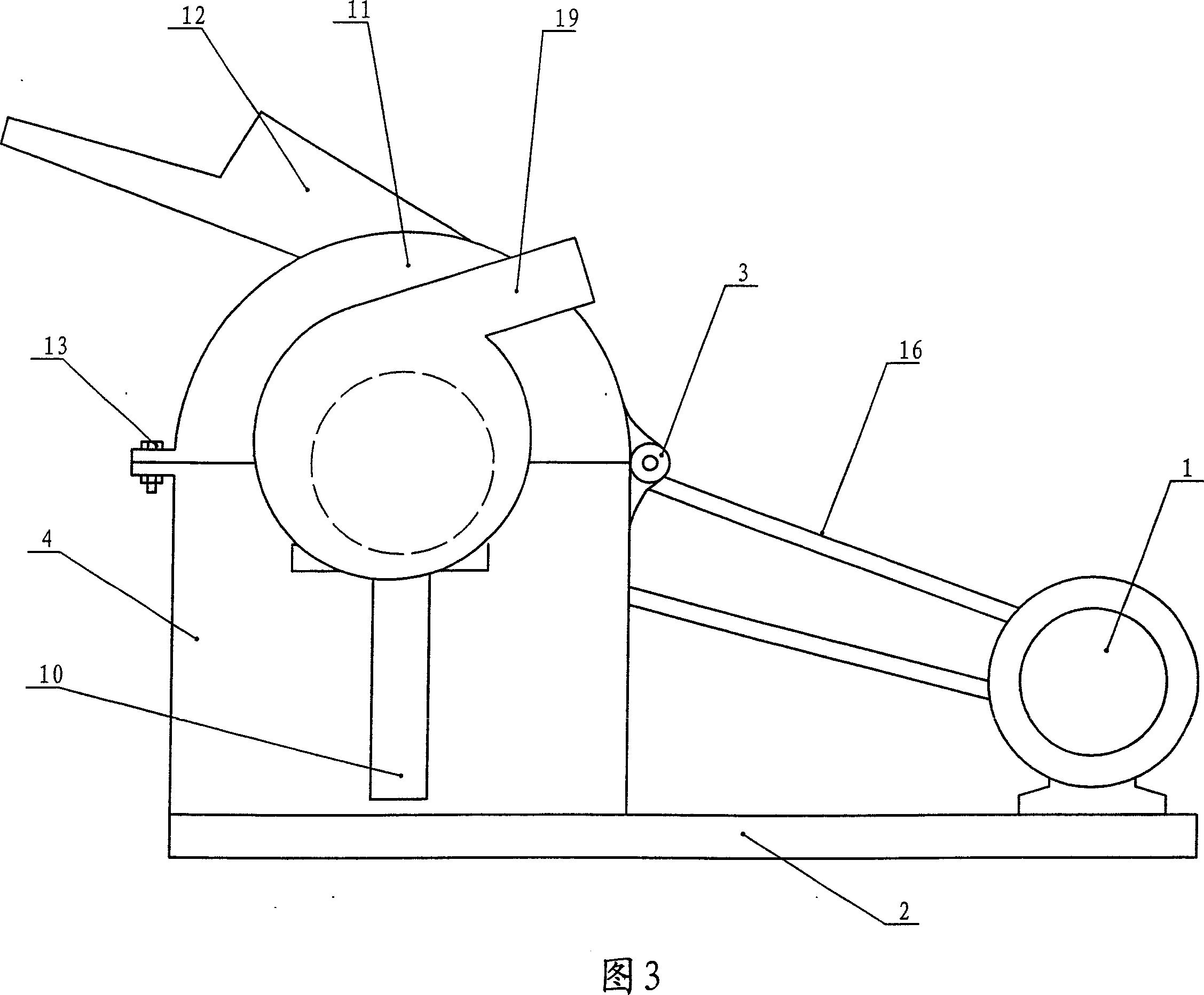

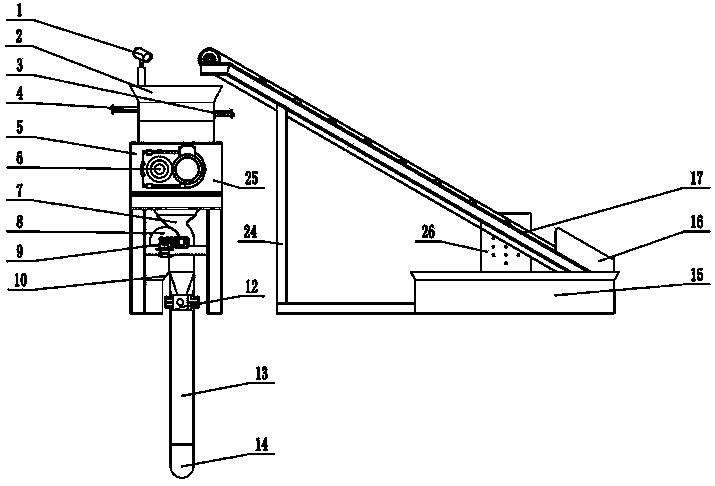

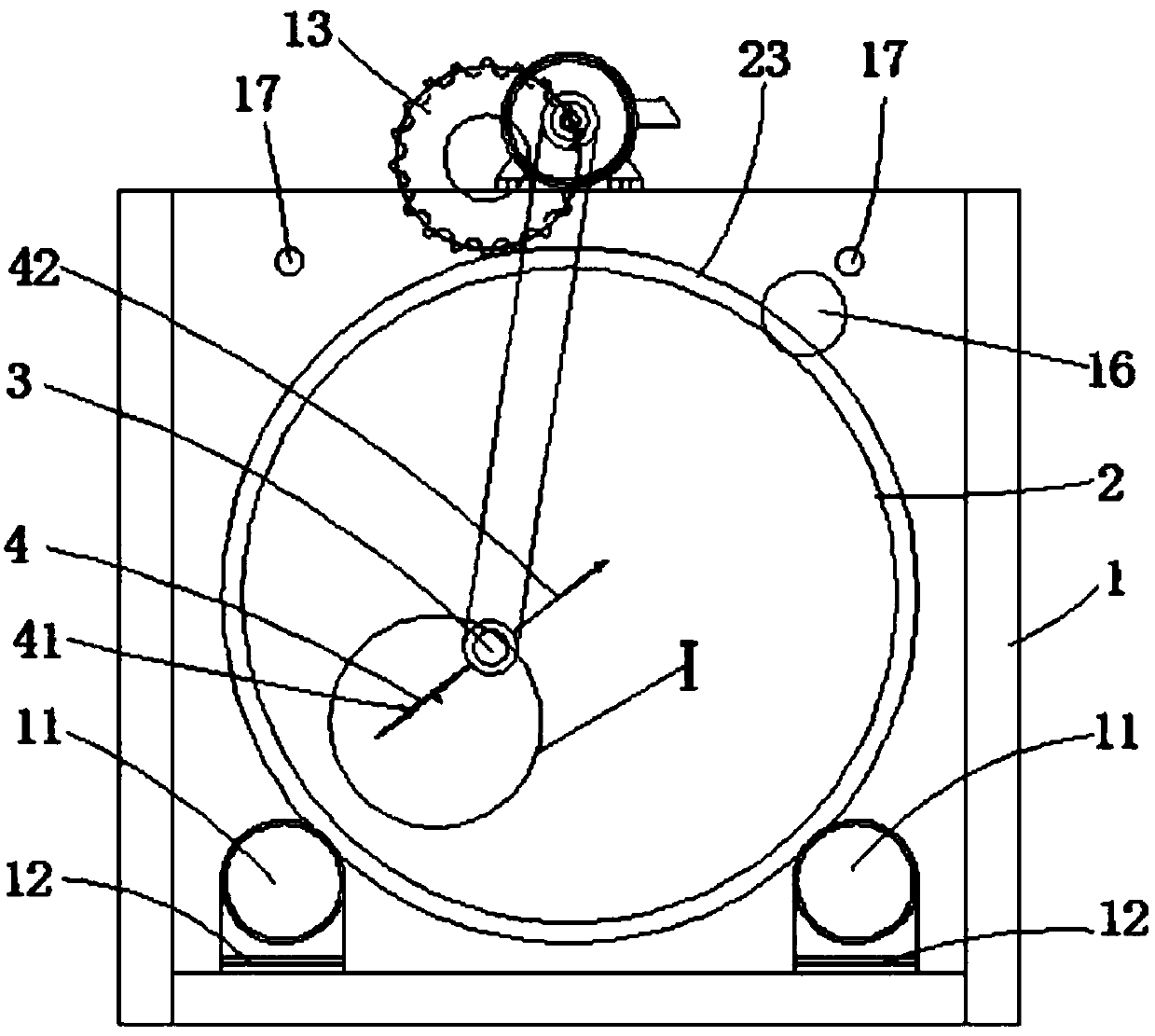

ActiveCN103551368AImprove crushing effectStrong crushingSievingSolid waste disposalRotational axisKinematics

The invention discloses a garbage screening machine with a flail knife crushing function. The garbage screening machine comprises a rack body, a rotary roller screen and a crushing rotary shaft, wherein supporting wheels are arranged on a bottom side plate of the rack body; the rotary roller screen is placed above the supporting wheels; a working cavity is formed in the middle of the rotary roller screen; the crushing rotary shaft penetrates into the working cavity of the rotary roller screen; the rotation direction of the crushing rotary shaft is opposite to that of the rotary roller screen; a flail knife assembly is arranged on the crushing rotary shaft; crushing blades are arranged on the flail knife assembly; two ends of the crushing rotary shaft are respectively provided with a rotary shaft seat; the rotary shaft seats are assembled on the rack body. The garbage screening machine adopts a dual-action mode of opposite shaft screen rotation, is high in material crushing capacity and good in crushing effect, adopts a flail knife crushing mode and adopts a principle of inertial kinematics in physics; the rotary roller screen is independently adopted, and screen holes in the rotary roller screen can be prevented from being blocked; by arranging a water spraying pipe, double effects of cleaning the wall surface of the rotary roller screen and cleaning materials are achieved; the viscosity of the materials is reduced, and the materials are convenient to crush.

Owner:NINGBO KASEEN ECOLOGY TECHNOLOGY CO LTD

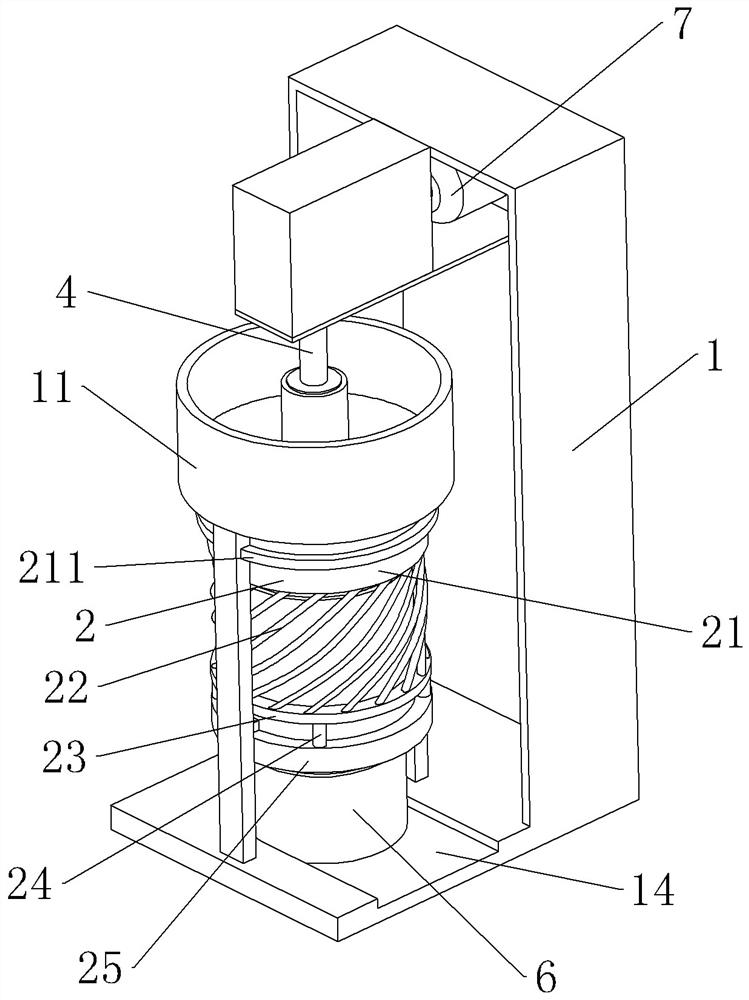

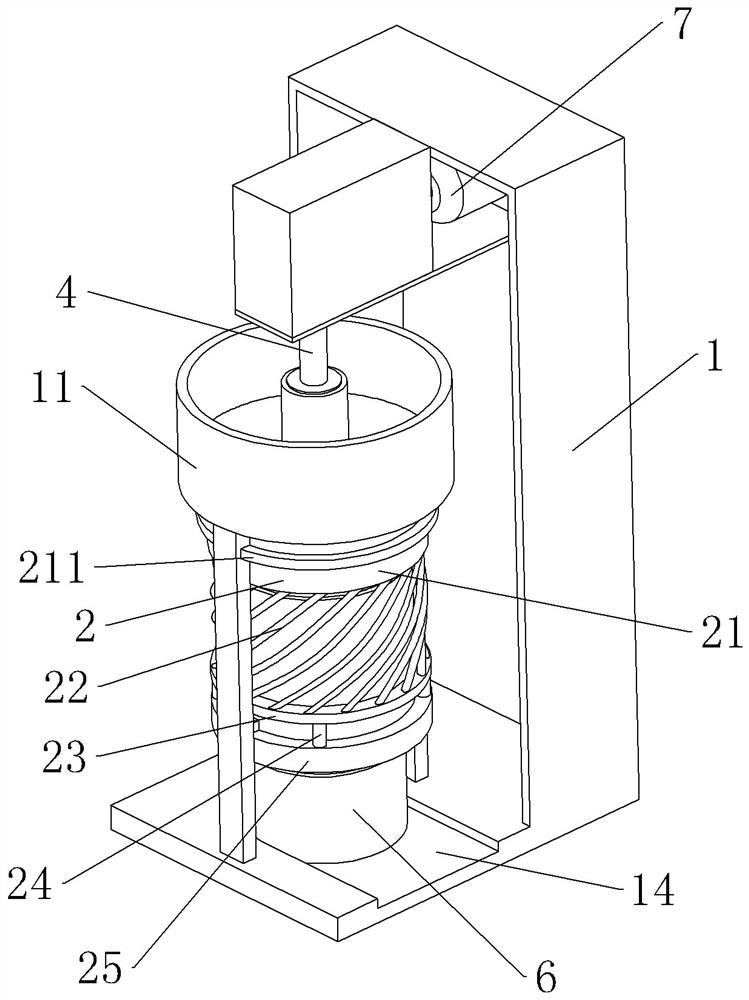

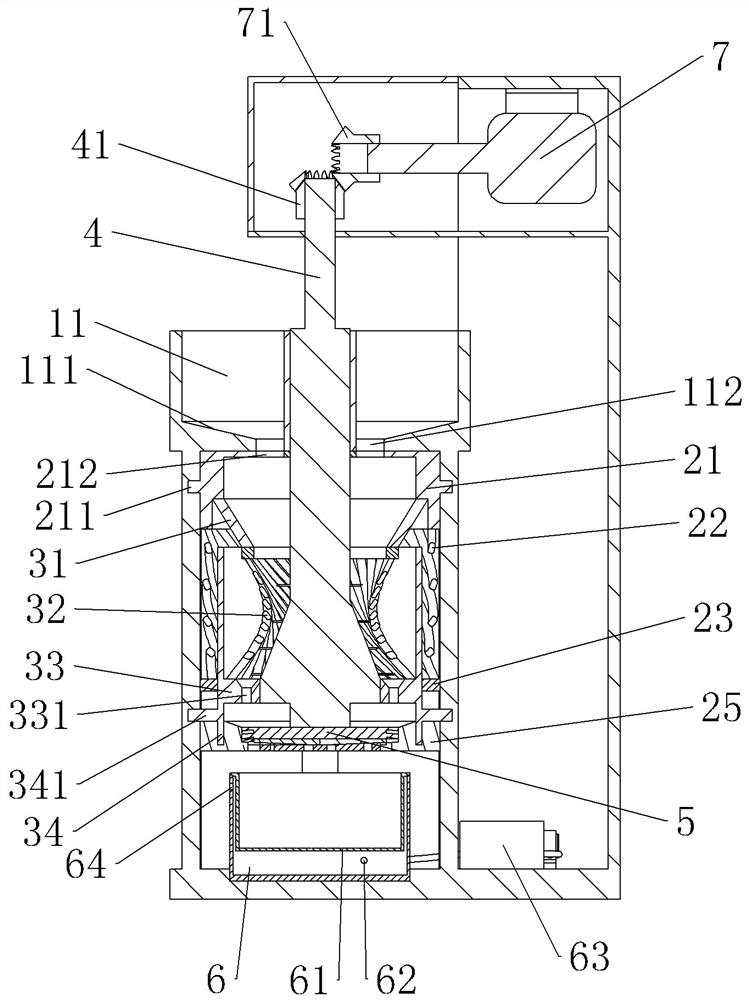

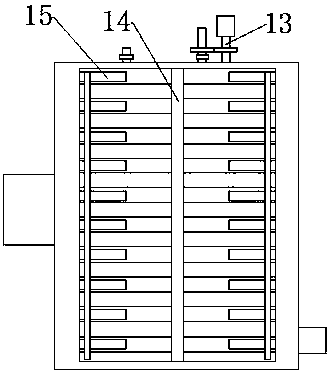

Energy-saving sodium acetate rapid drying equipment and drying process thereof

ActiveCN113559993ASmall particle sizeReduce gapGrain treatmentsHeating arrangementSodium acetateStructural engineering

The invention relates to the field of chemical product drying, in particular to energy-saving sodium acetate rapid drying equipment and a drying process thereof. The drying equipment comprises a rack, a crushing and grinding device and a drying device, the drying device dries crushed and ground materials, the crushing and grinding device comprises a material bin, a rotating shaft, an inner elastic frame and an outer elastic frame, the inner elastic frame comprises an upper ring, a lower ring and an inner elastic strip, the outer elastic frame comprises an upper plate, a lower ring and an outer elastic strip, a discharging port is formed in the material bin, and a feeding port is formed in the upper plate. When ground materials are increased to enable the lower ring to move downwards or grinding resistance is increased to enable the lower ring to rotate, the upper plate can rotate, the discharging port and the feeding port are staggered, the feeding amount is reduced, meanwhile, the upper plate rotates to drive the upper ring to rotate, the inner elastic strip contracts inwards, the gap between the inner elastic strip and the rotating shaft is reduced, the crushing strength is increased, and therefore through cooperation of the inner elastic frame and the outer elastic frame, the feeding amount and the crushing strength are automatically controlled according to the grinding condition, the crushing effect is improved, and the drying effect is guaranteed.

Owner:南通泰如美术设计服务有限公司

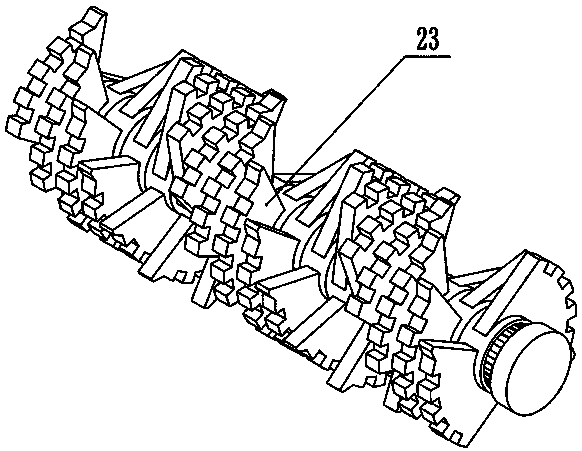

Cutter shaft of garbage crusher

InactiveCN104209171AAchieve coarse crushingSimple structureGrain treatmentsHigh resistanceMaximum torque

The invention discloses a cutter shaft of a garbage crusher. The cutter shaft comprises a shaft body and blades, wherein the blades are fixedly connected with the shaft body. The cutter shaft is characterized in that the blades consist of cutter head parts, cutter edge parts and cutter body parts; the blades are spirally and evenly distributed in the axial direction of the shaft body; each of the blades has two cutter head parts, cutter edge parts and cutter body parts correspondingly arranged; included angles of the adjacent blades in the axial direction are within 15-40 degrees; 8-20 blades are provided; and the cutter edge parts are U-shaped. The material of the shaft body is high-strength alloy steel; and the materials of the blades are materials with high wear resistance. The cutter shaft of the garbage crusher has such characteristics as simple structure, convenience for mounting and debugging, high torque and high reliability; the maximum torque of the cutter shaft can bear 80 kN.m; and the cutter shaft is uniform in crushing, and can realize rough crushing of garbage.

Owner:HANGZHOU HANGZHONG CONSTR MACHINERY

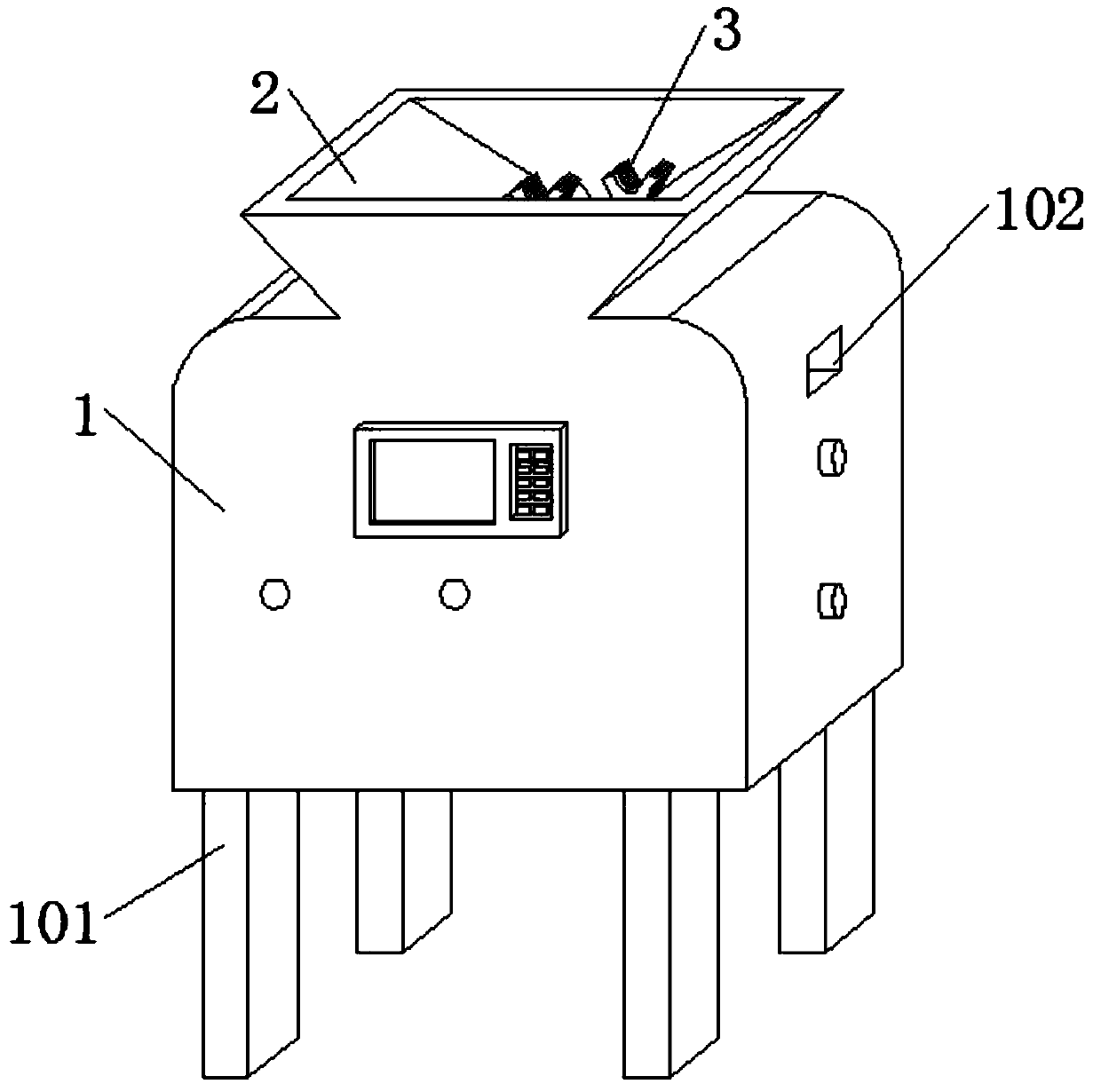

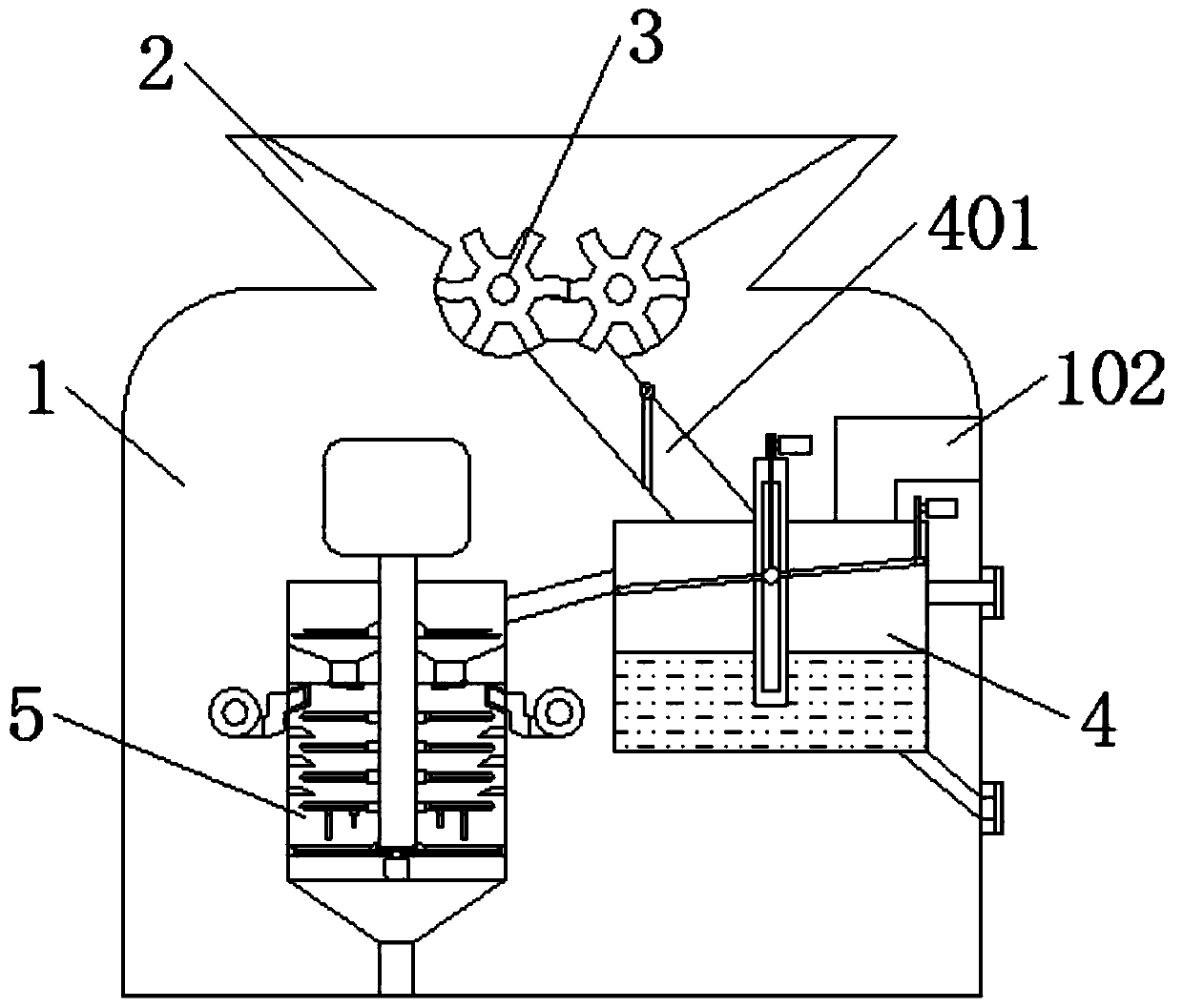

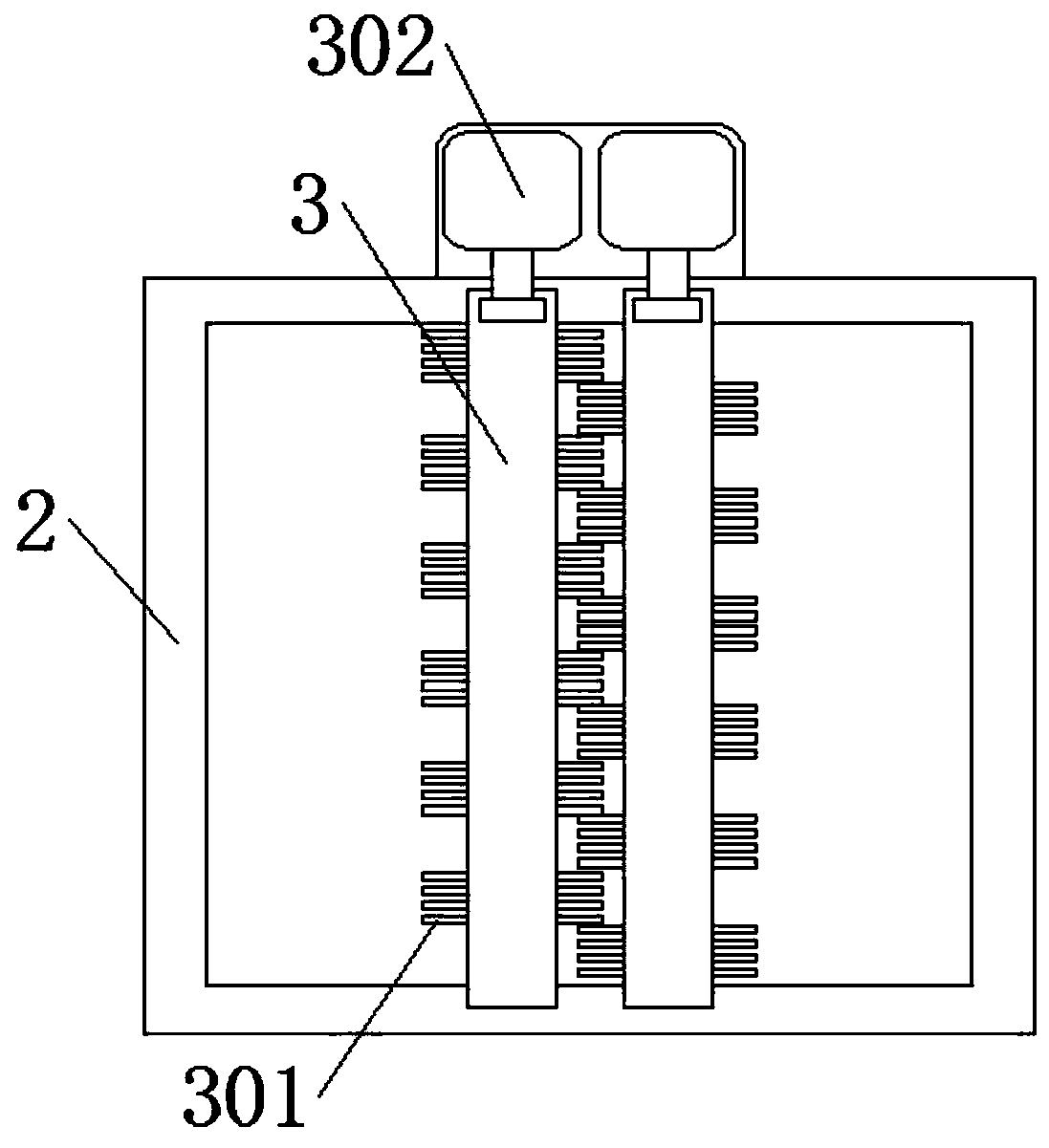

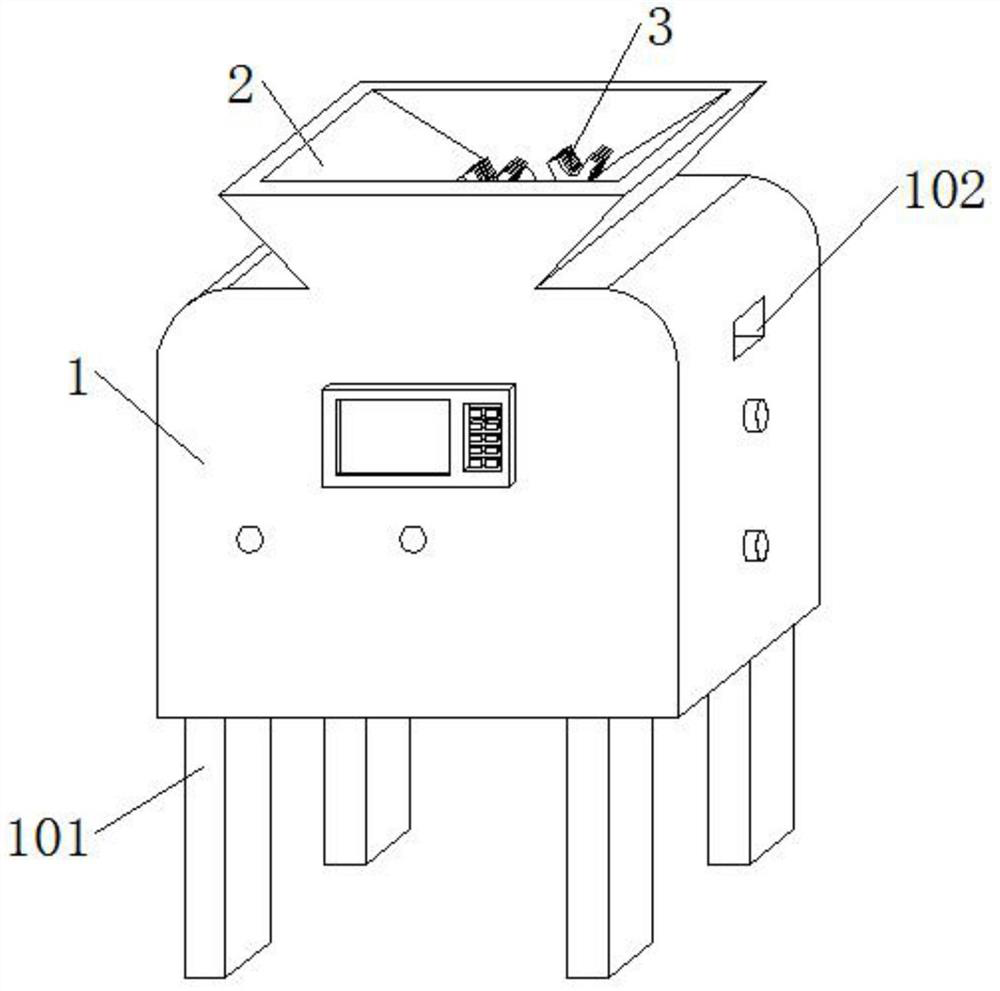

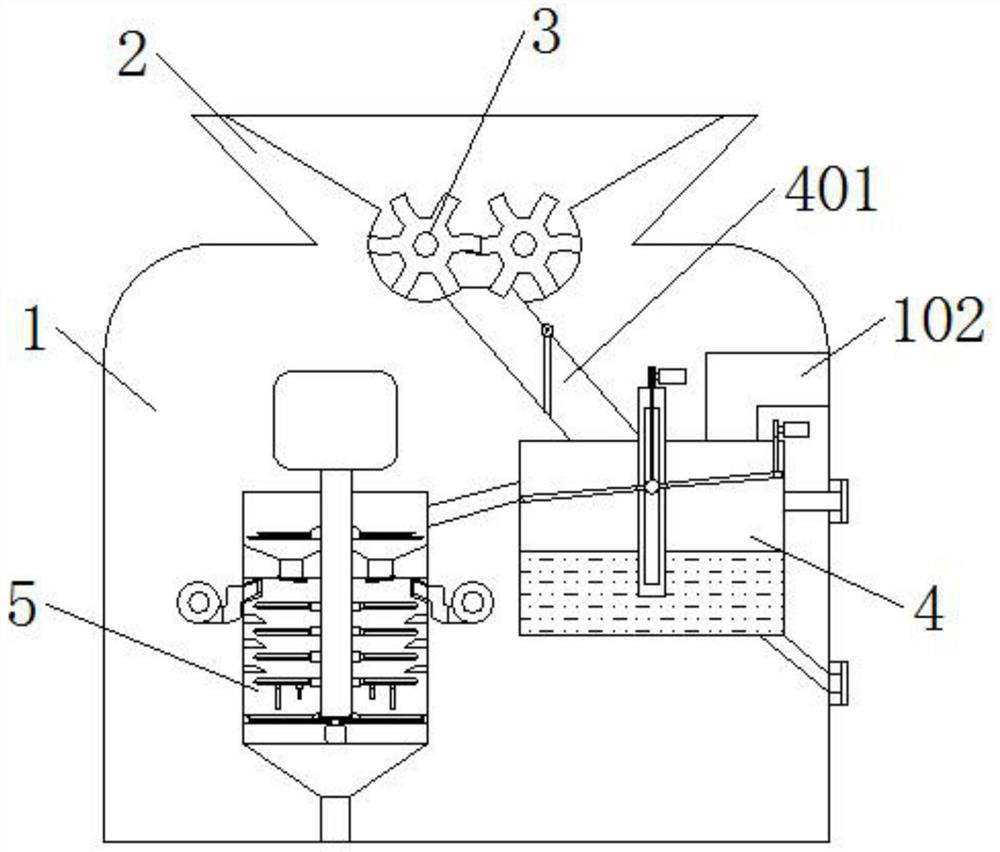

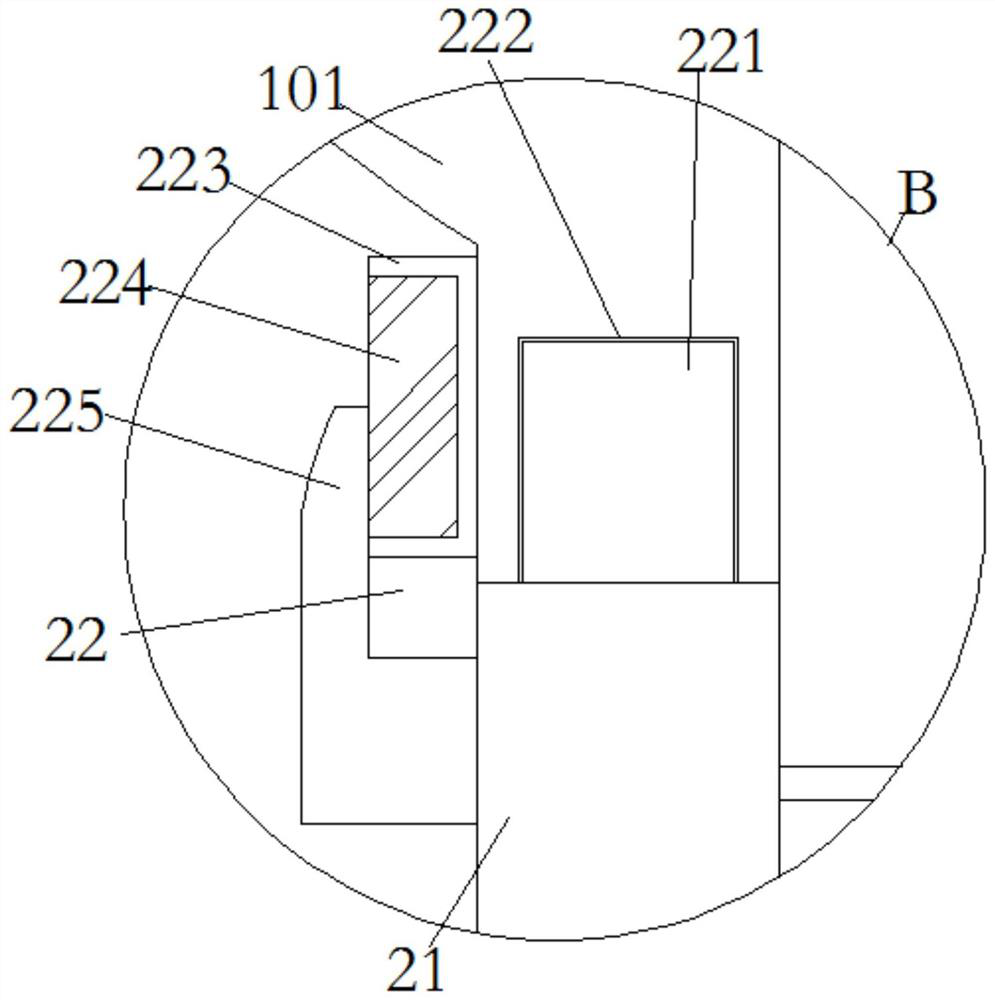

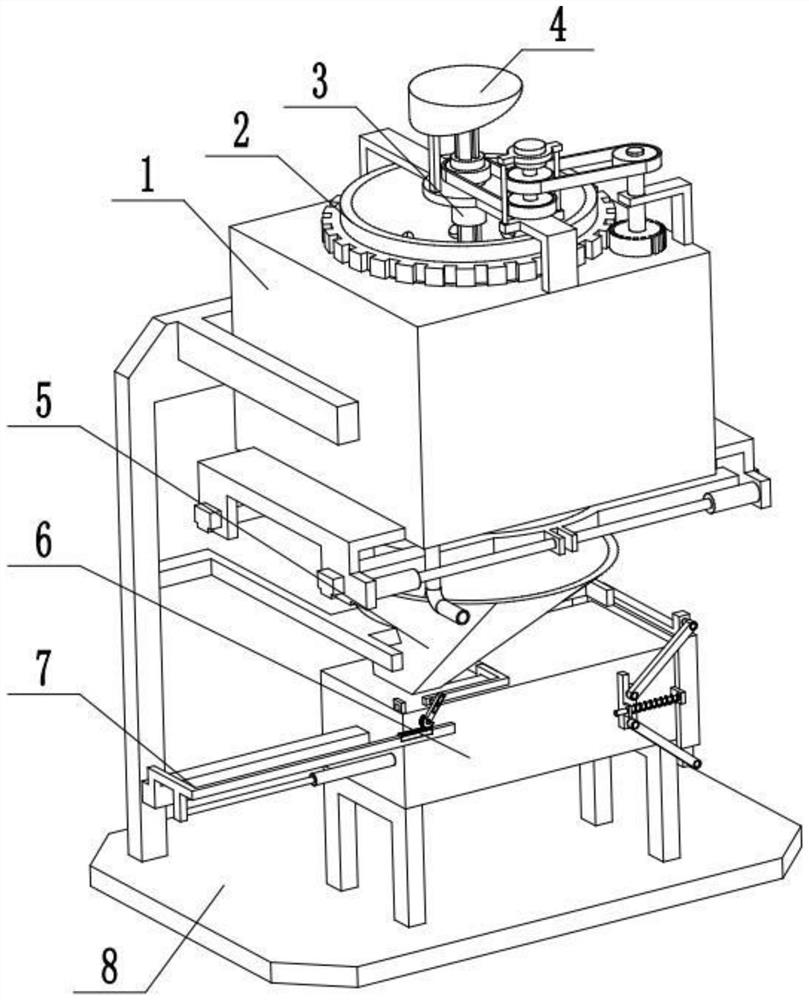

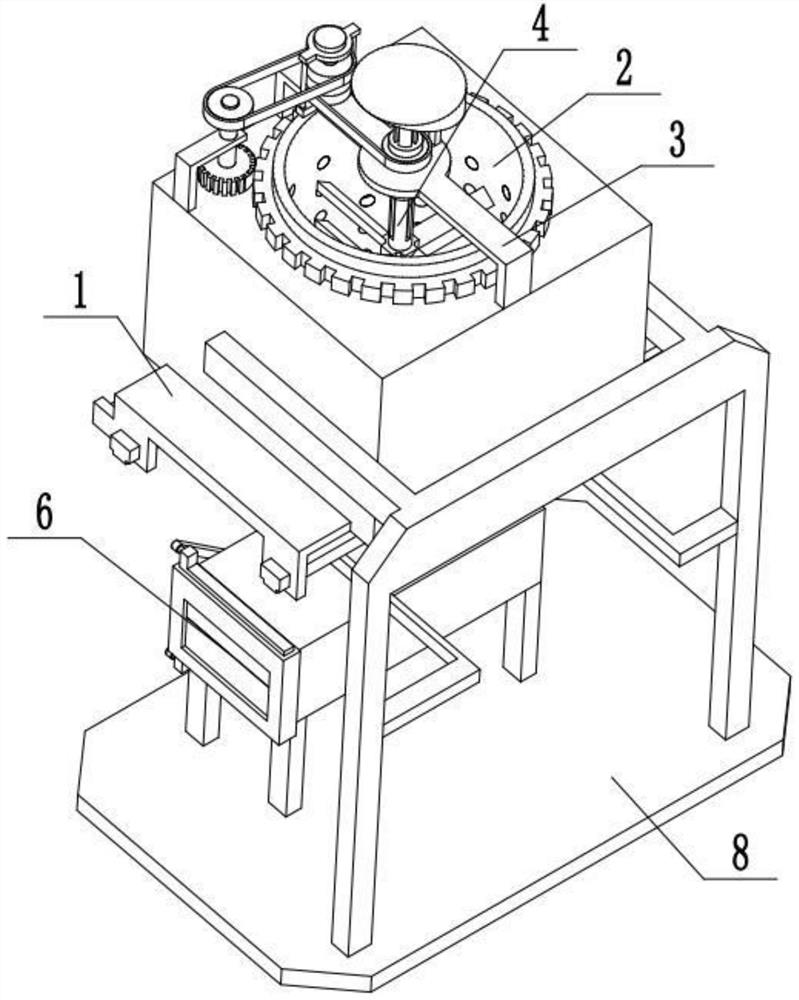

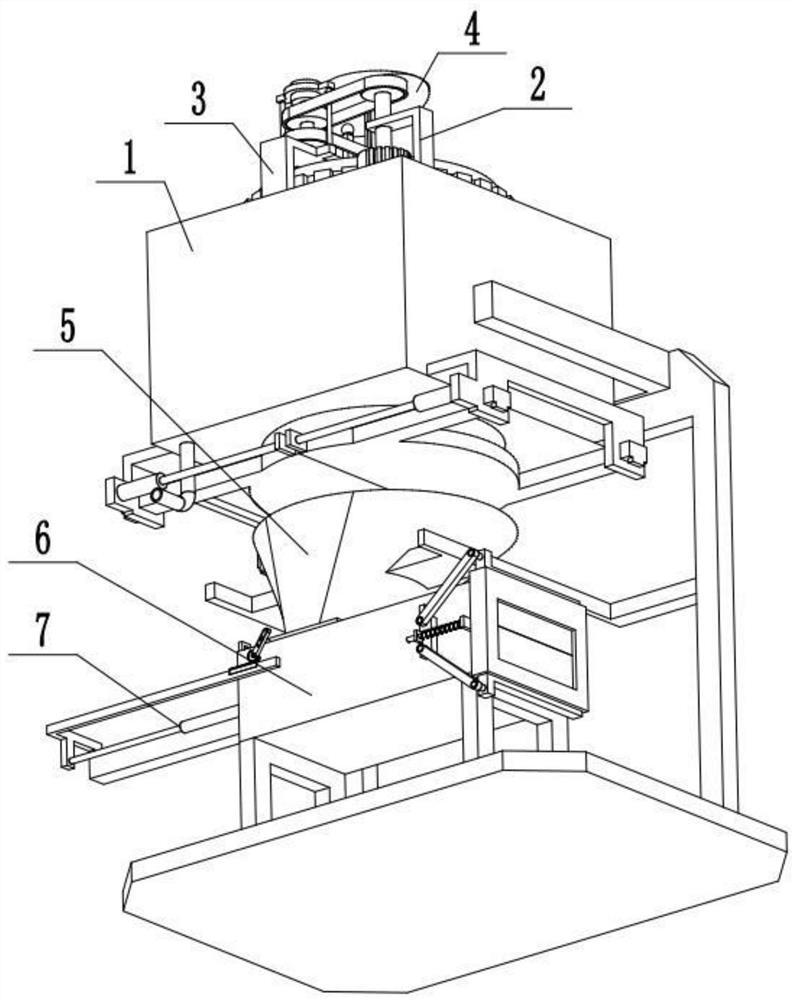

Flow line operating cycle operation-based semi-automatic crushing device for traditional Chinese medicine cooked pseudo-ginseng

ActiveCN110394217AStrong crushingEfficient crushingPharmaceutical product form changeGrain treatmentsSemi automaticEngineering

The invention provides a flow line operating cycle operation-based semi-automatic crushing device for traditional Chinese medicine cooked pseudo-ginseng. The device comprises a shell, bottom columns,a funnel, a cutting wheel, a frying chamber and a crushing chamber, wherein the bottom columns are integrally arranged on the periphery of the bottom end of the shell, the funnel is integrally arranged in the middle of the top end of the shell, the cutting wheel is arranged in the middle of the bottom end of the funnel, the frying chamber is embedded in the right side of the middle of the inner wall of the shell, and the crushing chamber is embedded in the left side of the inner wall of the shell. The whole device is stable in structure, rapid and convenient to use and operate, time-saving andlabor-saving, capable of effectively improving the production efficiency and good in crushing efficiency.

Owner:HENAN MEDICAL COLLEGE

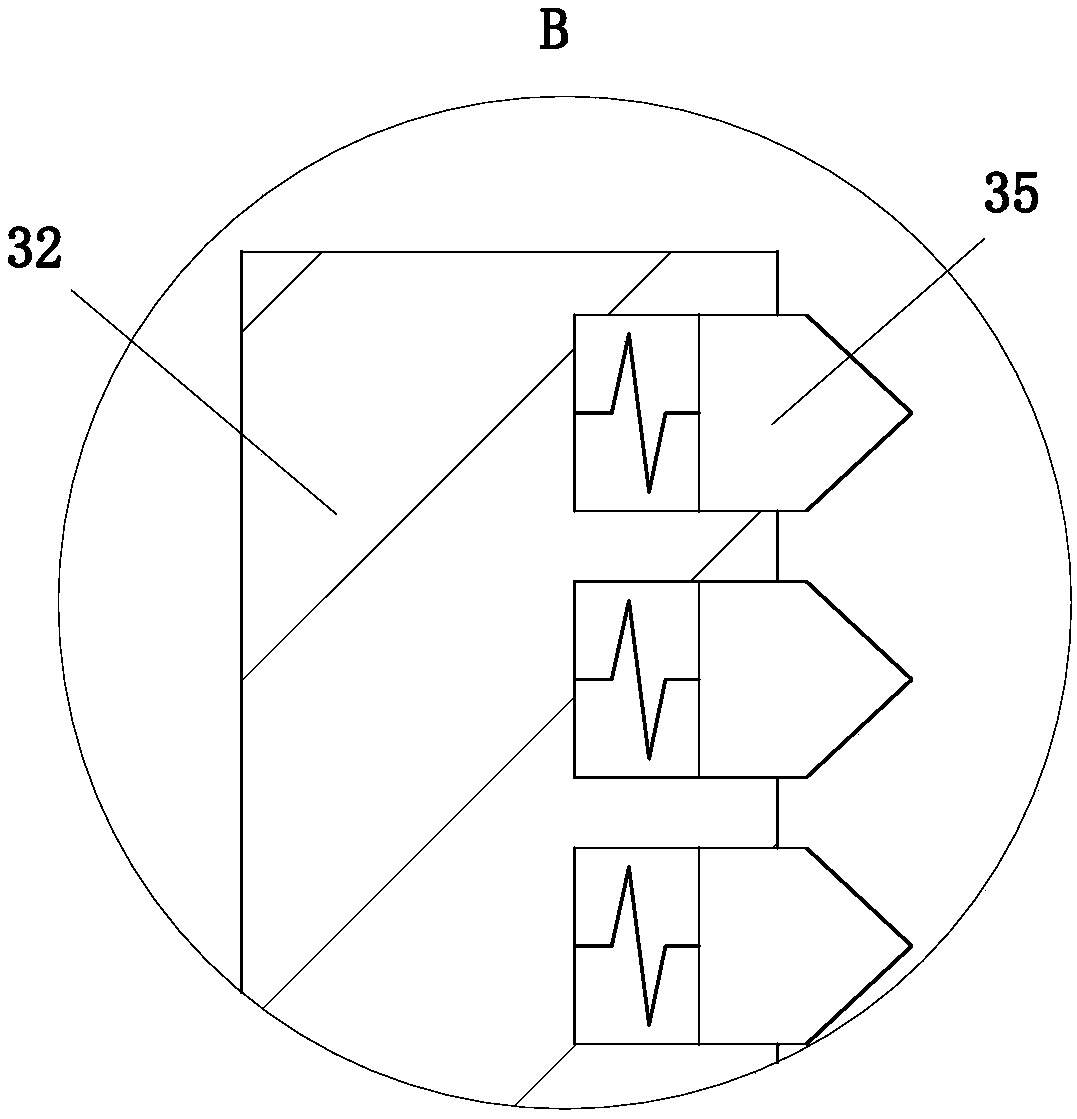

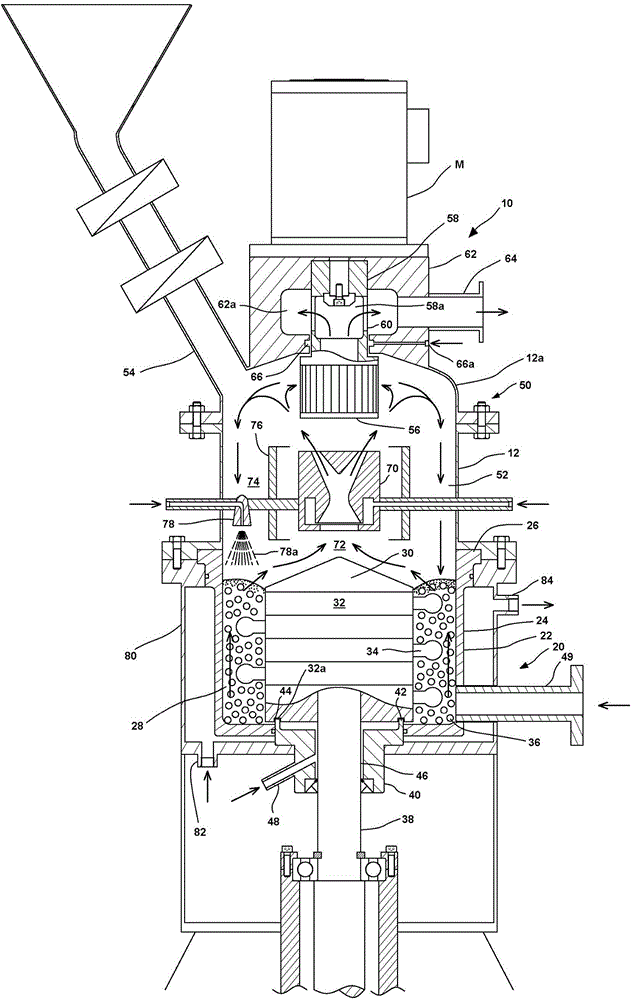

Media-stirring pulverizer of internal classifier type

InactiveCN104039456AIncrease flow rateImprove grading effectGrain treatmentsEngineeringCoarse particle

In this media-stirring pulverizer of internal classifier type (10), a stirring member (30) is provided with a rotating cylindrical base (32) extending in the vertical direction within a vessel (22) and capable of rotation, forming an annular pulverization chamber (28) between the outside periphery of the rotating cylindrical base (32) and the inside periphery of the vessel (22). Between a pulverization section (20) and a classification section (50) is situated a circulating mechanism (70) for promoting flow of a carrier gas accompanied by pulverized particles, from the pulverization section (20) to the classification section (50). A descent passage (74) for returning coarse particles from the classification section (50) to the pulverization section (20) is furnished with a pulverization aid addition means (78) for adding a pulverization aid to the coarse particles.

Owner:ASHIZAWA FINETECH

Industrial-waste processing device

The invention discloses an industrial-waste processing device. The industrial-waste processing device comprises an over-fixing bracket, an electric motor, a transmission, a driving wheel and a drivingbelt, wherein the electric motor is arranged above the over-fixing bracket; the transmission is arranged at the rear of the electric motor; the driving wheel is arranged at one side of the transmission; the driving belt is arranged above the driving wheel; a coupling is arranged at one side of the driving belt; a feeding hopper is arranged at one side of the coupling; a crushing box is arranged below the feeding hopper; a reinforcing plate is arranged at one side of the crushing box; anda control box is arranged at one side of the reinforcing plate. The industrial-waste processing device hasthe advantages that the design is reasonable, the work efficiency is high, the crushing noise is small, the crushing performance is good, the control operation is convenient, the corrosion resistanceis good, and the service life is long.

Owner:成都北辰航易工程设备有限公司

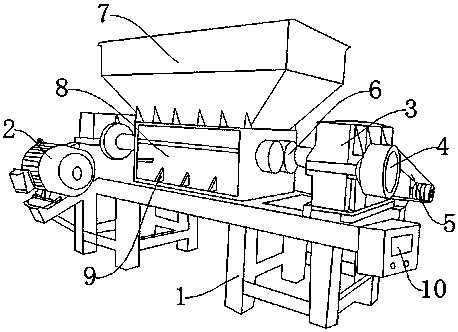

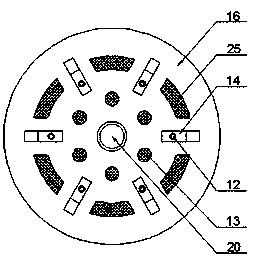

Agitating vane structure of soybean milk machine

InactiveCN103505051AOvercome singleOvercome efficiencyBeverage vesselsMilk substitutesMechanical engineeringEngineering

The invention discloses an agitating vane structure of a soybean milk machine. A plurality of agitating vanes are installed on opposite sides of the edge of a hub, and the agitating vanes are fixed on the hub. The agitating vane structure has the advantages that the structural manner that the agitating vanes are additionally installed on each single side of the edge of the hub is adopted. The agitating vane structure has the advantages of being high in work efficiency, strong in crushing performance and high in agitating speed, and effectively overcomes the defects that an agitating vane structure of an existing soybean milk machine has a single vane and is low in work efficiency.

Owner:XUZHOU LONGTAI COAL MINING EQUIP MFG

Municipal drainage pipeline dredging device

ActiveCN113266070AImprove cleaning effectStrong crushingSewer cleaningClimate change adaptationWater pipeMechanical engineering

The invention relates to a municipal drainage pipeline dredging device, and belongs to the technical field of municipal pipeline cleaning. The municipal drainage pipeline dredging device comprises a shell, wherein a water inlet is formed in one end of the shell; jet orifices inclined to one side of the water inlet are formed in the outer wall of the shell; the water inlet communicates with the jet orifices; the jet orifices are uniformly formed in the circumferential direction of the shell at intervals; an impact head is slidably connected to the end, away from the water inlet, of the shell in the axial direction of the shell; and a driving mechanism used for driving the impact head to move on the shell in a reciprocating mode is arranged in the shell. A worker connects a water pipe to the water inlet of the shell, water is introduced into the shell, the water is jetted from the jet orifices and flushes the inner wall of a pipeline, so that the shell moves forwards, then the impact head is driven to move in front of the shell in a reciprocating mode, and when the impact head impacts an obstacle, the forward force of the impact head and the forward force applied to the shell by the water flow act together. The municipal drainage pipeline dredging device has the effect of improving the cleaning effect on the pipeline.

Owner:浙江易承环境科研有限公司

A semi-automatic crushing device for traditional Chinese medicine cooked Panax notoginseng based on flow direction line operation cycle operation

ActiveCN110394217BStrong crushingEfficient crushingPharmaceutical product form changeGrain treatmentsSemi automaticProcess engineering

The invention provides a semi-automatic pulverizing device for cooked Chinese medicine notoginseng based on flow line operation cycle operation, which includes a shell, a bottom column, a funnel, a cutting wheel, a frying chamber and a crushing chamber, and a bottom is uniformly arranged around the bottom of the shell. The column is provided with a funnel in the middle part of the top end of the housing, a cutting wheel is provided in the middle part of the bottom end of the funnel, a frying chamber is embedded in the middle part of the inner wall of the housing, and a crushing chamber is embedded in the left side of the inner wall of the housing. The structure of the whole device of the present invention is stable, quick and convenient to use and operate, saves time and effort, can effectively improve production efficiency, and has good crushing efficiency.

Owner:HENAN MEDICAL COLLEGE

High Frequency Hammer Dual Motor Crushing Device

ActiveCN103736545BStrong crushingHigh crushing precisionSoil-shifting machines/dredgersDual frequencyDrive shaft

The invention discloses a double-motor crushing device of a high frequency crushing hammer. The double-motor crushing device comprises a vibration generator, a four connecting rod mechanism and a shaking knife row, wherein the vibration generator comprises a shell, a first driving shaft arranged in the shell, a first driven shaft which is mutually meshed with the first driving shaft through gears, a second driving shaft, a second driven shaft which is mutually meshed with the second driving shaft through gears as well as a bridge crossing shaft arranged between the first driving shaft and the second driving shaft; the bridge crossing shaft is mutually meshed with the first driving shaft and the second driving shaft gears, the first driving shaft, the first driven shaft, the second driving shaft and the second driven shaft are all provided with eccentric wheels and gears. The double-motor crushing device disclosed by the invention has the advantages that as two groups of actuating shafts are adopted and matched with two actuating motors, the crushing force of the crushing hammer actuated by the two actuating motors is large relative to that of the crushing hammer actuated by the single motor, the crushing accuracy is high, the noises are small, and the crushing capacity is strong, thus the operation time of the crushing hammer is prolonged, and the crushing efficiency is improved.

Owner:苏州京海智能装备制造有限公司

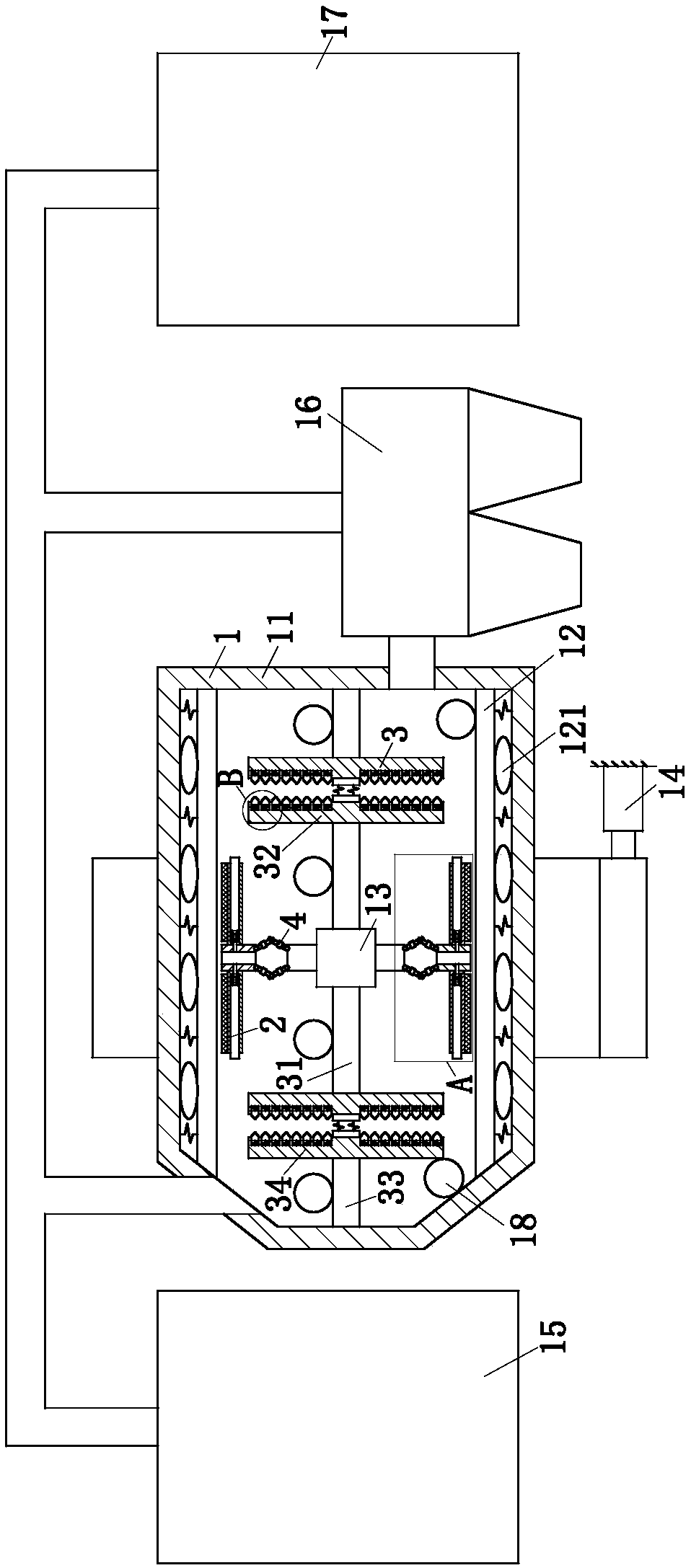

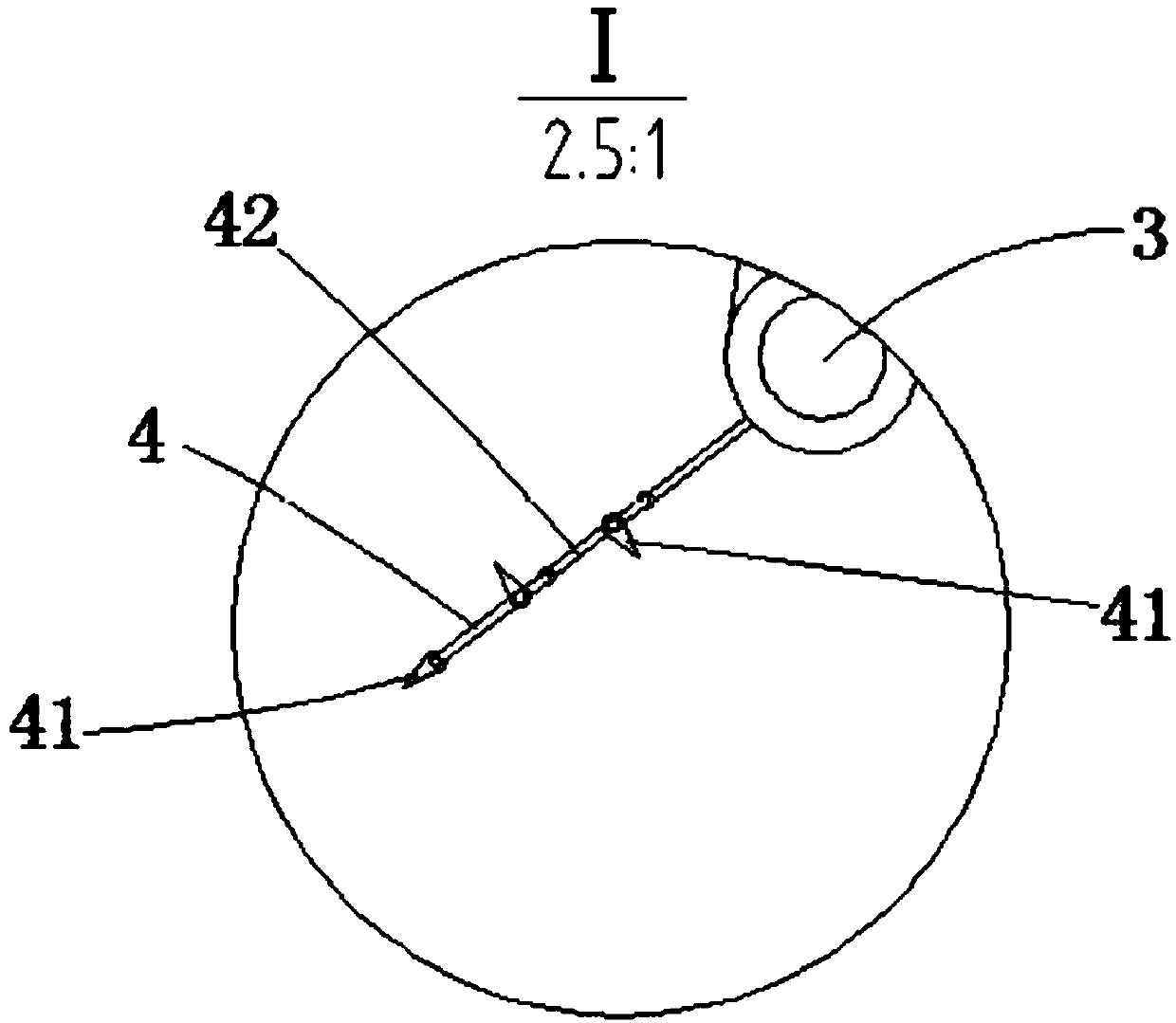

Solid waste and domestic waste pipeline transportation ground bulky processing device and control method thereof

ActiveCN106076538BRealize shredding and recyclingRealize energy collectionMagnetic separationGrain treatmentsPasswordIdentity recognition

The invention relates to a treatment device for a solid waste and household garbage pipeline to transport large ground pieces. The treatment device comprises a first rack sealed through four side plates, a crushing device fixed to the first rack, a vertical garage pipe connected with the lower end of the crushing device, a conveyor fixedly arranged on a second rack, a large piece containing box used for temporally storing large garbage, and a control device arranged on one side of the lower end of the conveyor. The upper end of the conveyor is arranged on the top of the crushing device, the lower end of the conveyor is arranged on the ground, and the large piece containing box is arranged on the other side of the lower end of the conveyor. When garbage in the large piece containing box reaches the designed volume, the garbage is treated through a specially-assigned person, and collection is controlled manually after password unlocking and identity recognition are conducted. The treatment device has the beneficial effects that crushing and recycling of large packaging boxes, waste furniture, garden waste and other large garbage are achieved, the crushing capability is high, the iron ware sorting efficiency is high, and pneumatic collecting of various kinds of garbage is achieved.

Owner:张子宇

A kind of energy-saving sodium acetate fast drying equipment and its drying process

ActiveCN113559993BSmall particle sizeReduce gapGrain treatmentsHeating arrangementSodium acetateChemical products

The invention relates to the field of chemical product drying, in particular to energy-saving sodium acetate rapid drying equipment and a drying process thereof. The drying equipment includes a frame, a crushing and grinding device and a drying device. The drying device dries the crushed and ground materials. The crushing and grinding device includes a silo, a rotating shaft, an inner elastic frame and an outer elastic frame. The inner elastic frame includes an upper ring, The lower ring and the inner elastic bar, the outer elastic frame includes the upper plate, the lower ring and the outer elastic bar, the material bin is provided with a material outlet, and the upper plate has a material inlet. In the present invention, when the grinding material increases and the lower ring moves down, or the grinding resistance increases and the lower ring rotates, the upper plate can be rotated, the discharge port and the feed port are dislocated, and the feeding amount is reduced. At the same time, the upper plate rotates to drive the upper ring. Rotate, so that the inner elastic strip shrinks inward and the gap between the rotating shaft is reduced, and the crushing force is increased. Through the cooperation of the inner elastic frame and the outer elastic frame, the feeding amount and crushing force are automatically controlled according to the grinding situation, and the crushing effect and crushing effect are improved. effect, to ensure the drying effect.

Owner:南通泰如美术设计服务有限公司

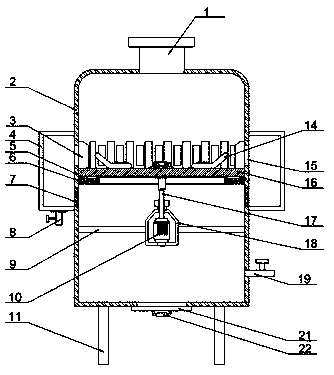

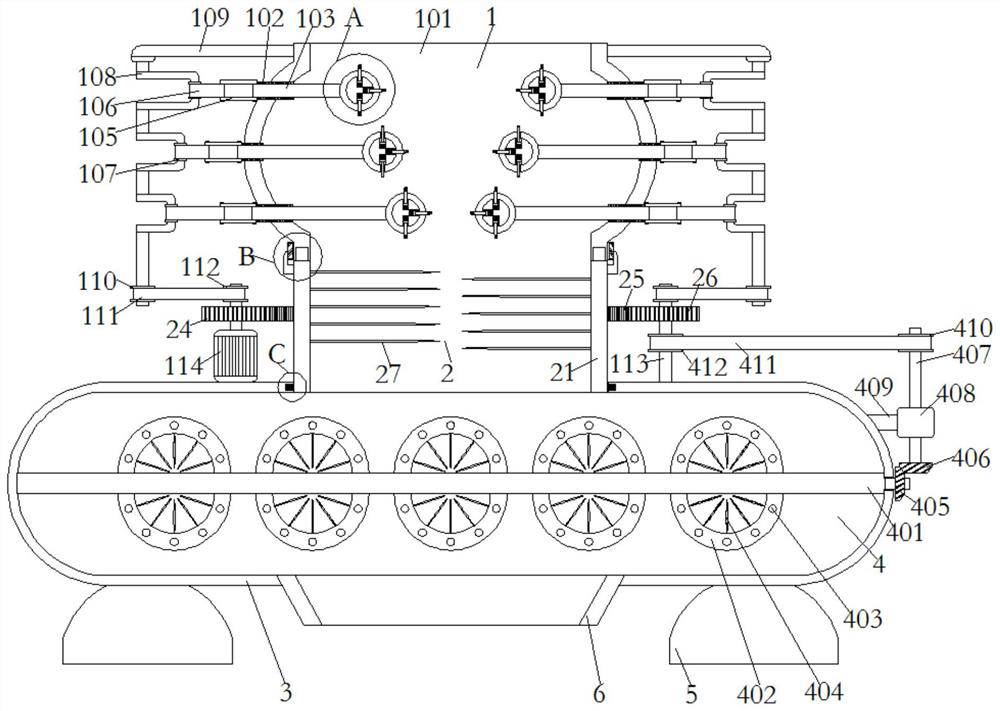

Garbage treatment equipment for primary purification of sewage

PendingCN109224553ANovel structureScientific and reasonable designGrain treatmentsStationary filtering element filtersEngineeringSewage

The invention belongs to the technical field of sewage purification and in particular relates to garbage treatment equipment for primary purification of sewage. The garbage treatment equipment comprises a treatment box, wherein a water inlet is formed in the top of the treatment box; a supporting cushion disc is fixedly mounted in the treatment box; a bottom disc is arranged at the top of the supporting cushion disc in a rotary manner; the bottom disc is provided with a plurality of filtering screens and filtering holes; the filtering screens and the filtering holes are distributed in an annular shape; a machine case is fixedly welded with the inner part of the treatment box through a bracket; the machine case is internally provided with a motor; a rotary shaft is fixedly connected with anoutput shaft of the motor; the upper end of the rotary shaft is fixedly connected with the bottom disc; a plurality of rotary propelling devices, which are distributed in the annular shape, are fixedly arranged at the top of the bottom disc through screws; a plurality of grinding rings, which are distributed in the annular shape, are fixedly mounted on an inner wall of the treatment box; throughholes are formed among the grinding rings. The garbage treatment equipment provided by the invention is novel in structure and scientific and reasonable in design; floating matters in the sewage are sufficiently filtered and the purification effect of a purifier is further improved.

Owner:湖州欧汇再生资源科技有限公司

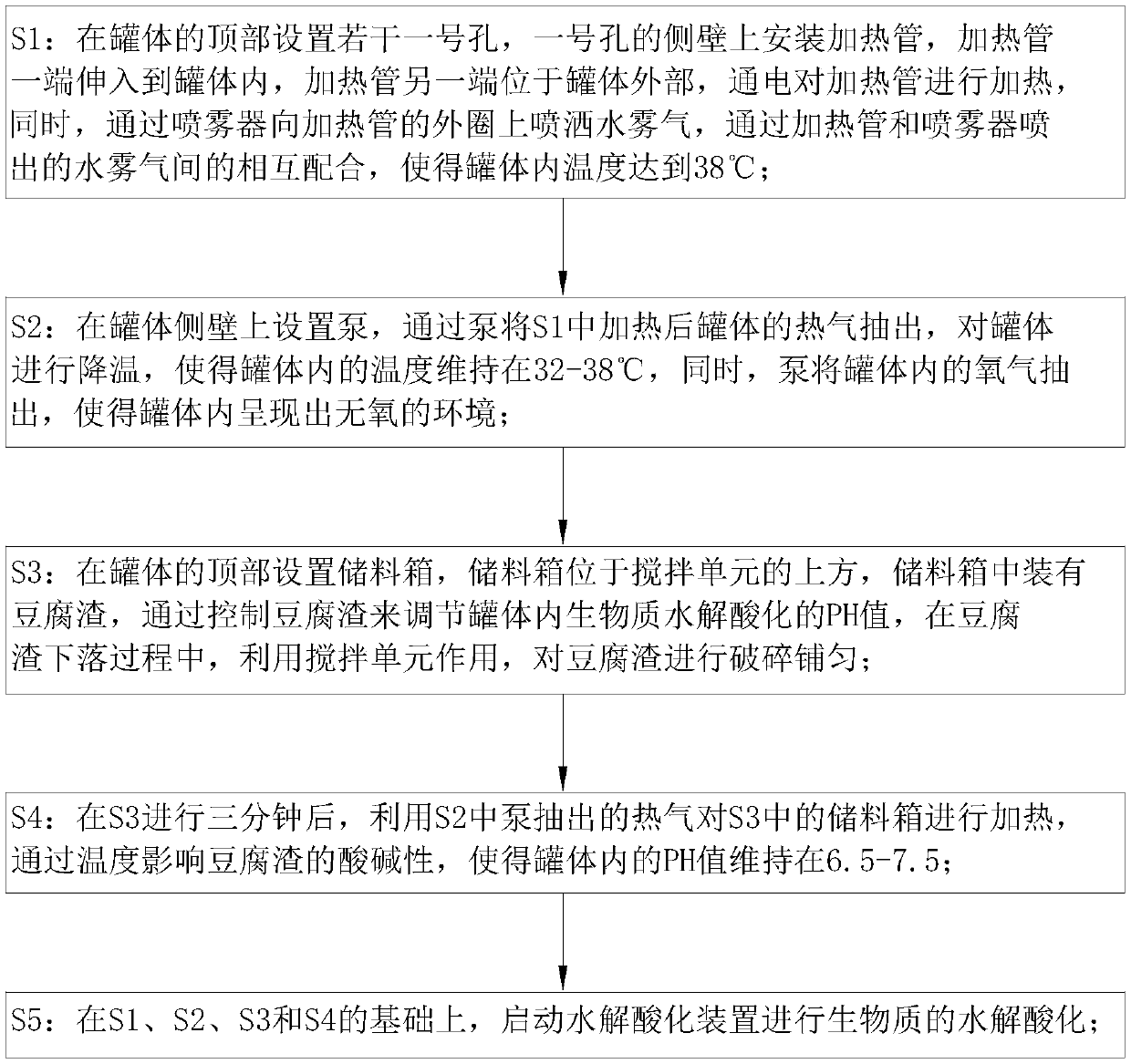

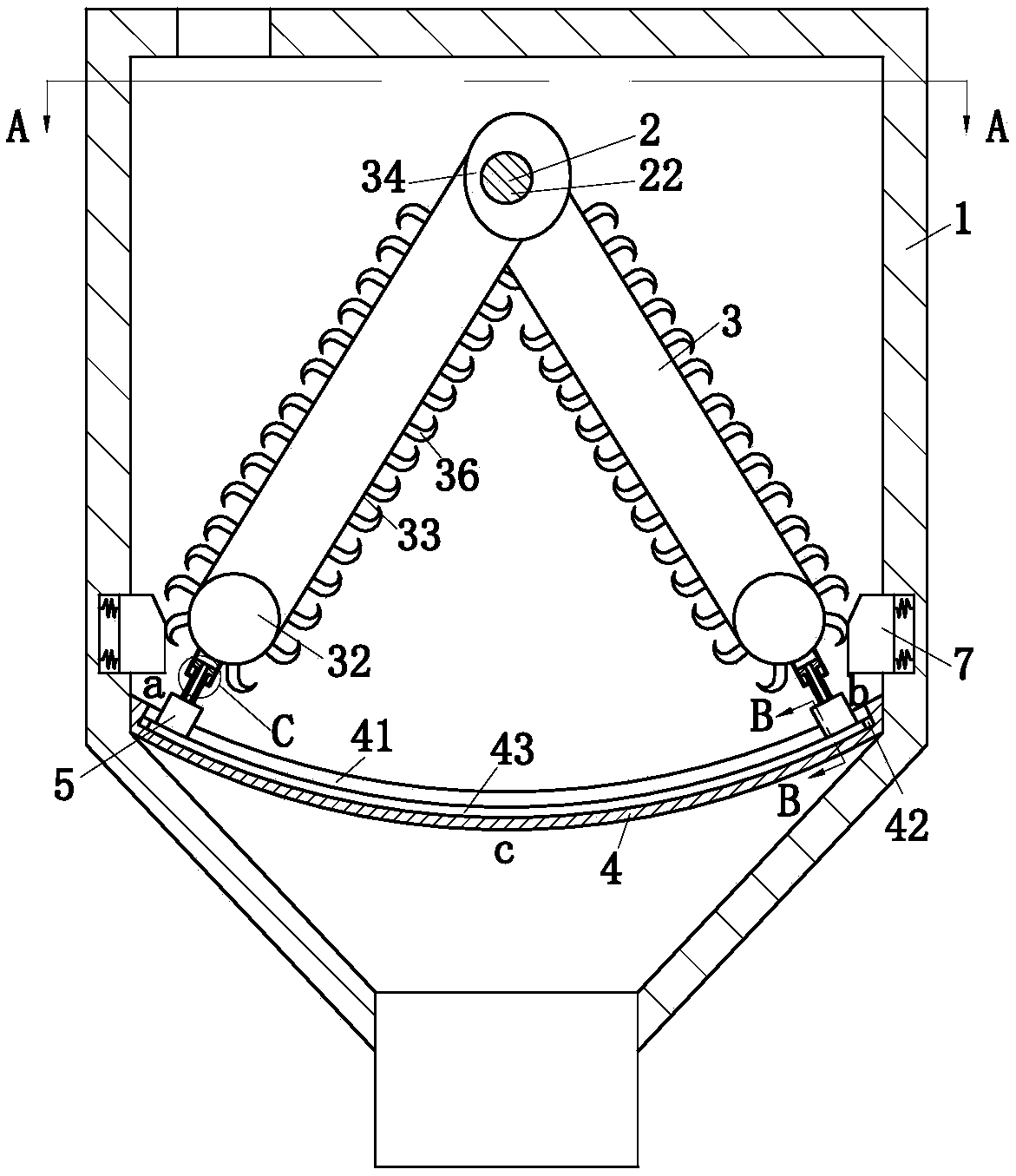

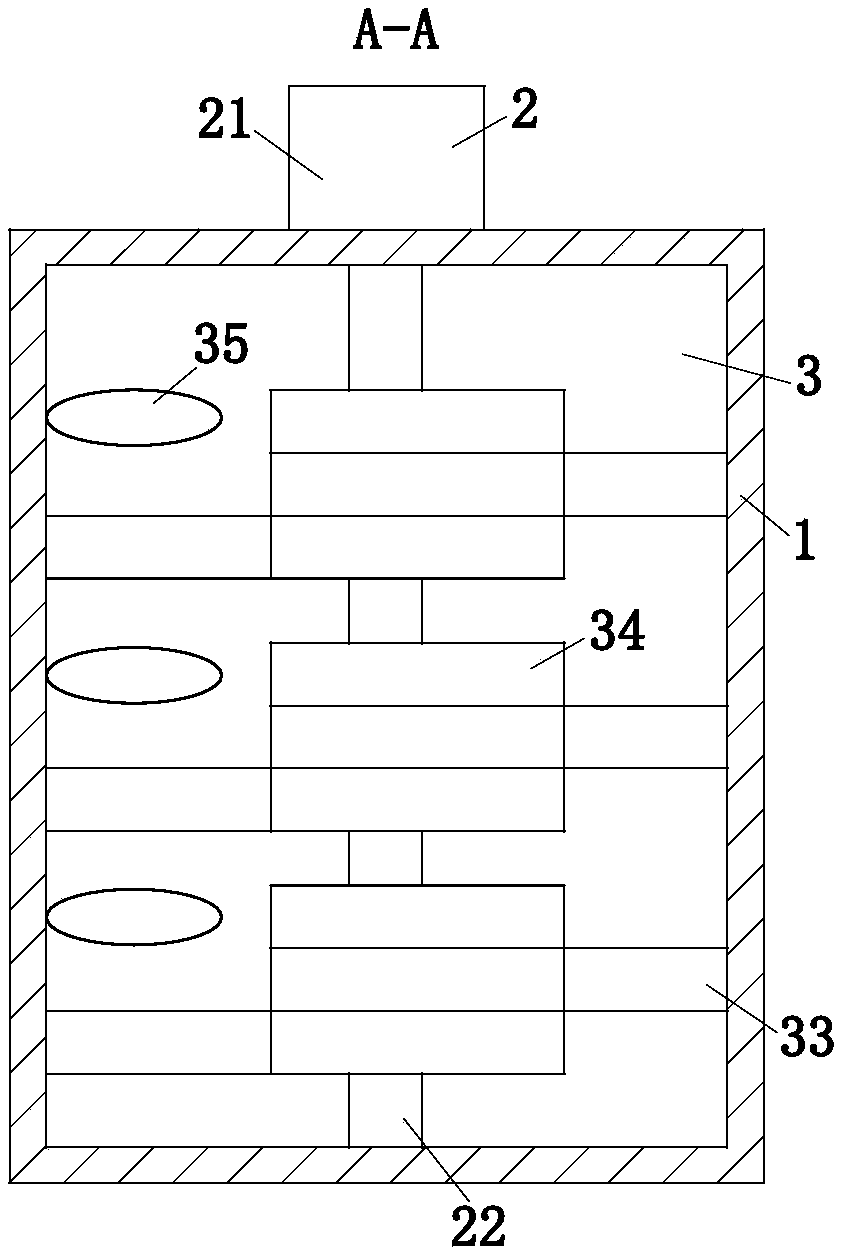

Biomass hydrolytic acidification process

InactiveCN109536536AStrong crushingHydrolytic acidification effectWaste based fuelFermentationBiomassCrop

The invention belongs to the technical field of hydrolytic acidification of biomass, and in particular, relates to a biomass hydrolytic acidification process; a hydrolytic acidification device adoptedin the process includes a tank body, a driving unit, a stirring unit, an arc-shaped plate, a No.1 sliding block, a No.1 gas cylinder and a controller. According to the process, on one hand, with interaction of a heating pipe, a pump and a sprayer, the hydrolytic acidification temperature of crop straw in the tank body is maintained at 32-38 DEG C; on the other hand, through interaction of the pump, bean curd residue and the stirring unit, the pH value in the tank body can be adjusted, so that the hydrolytic acidification pH value of the crop straw in the tank body can be maintained at 6.5-7.5; through adjustment of the temperature and the pH value, the influence on hydrolytic acidification of the crop straw due to the temperature and the pH value can be avoided, the hydrolytic acidification of the crop straw is allowed to be fast, and thus the hydrolytic acidification efficiency of the crop straw is improved.

Owner:孙勇

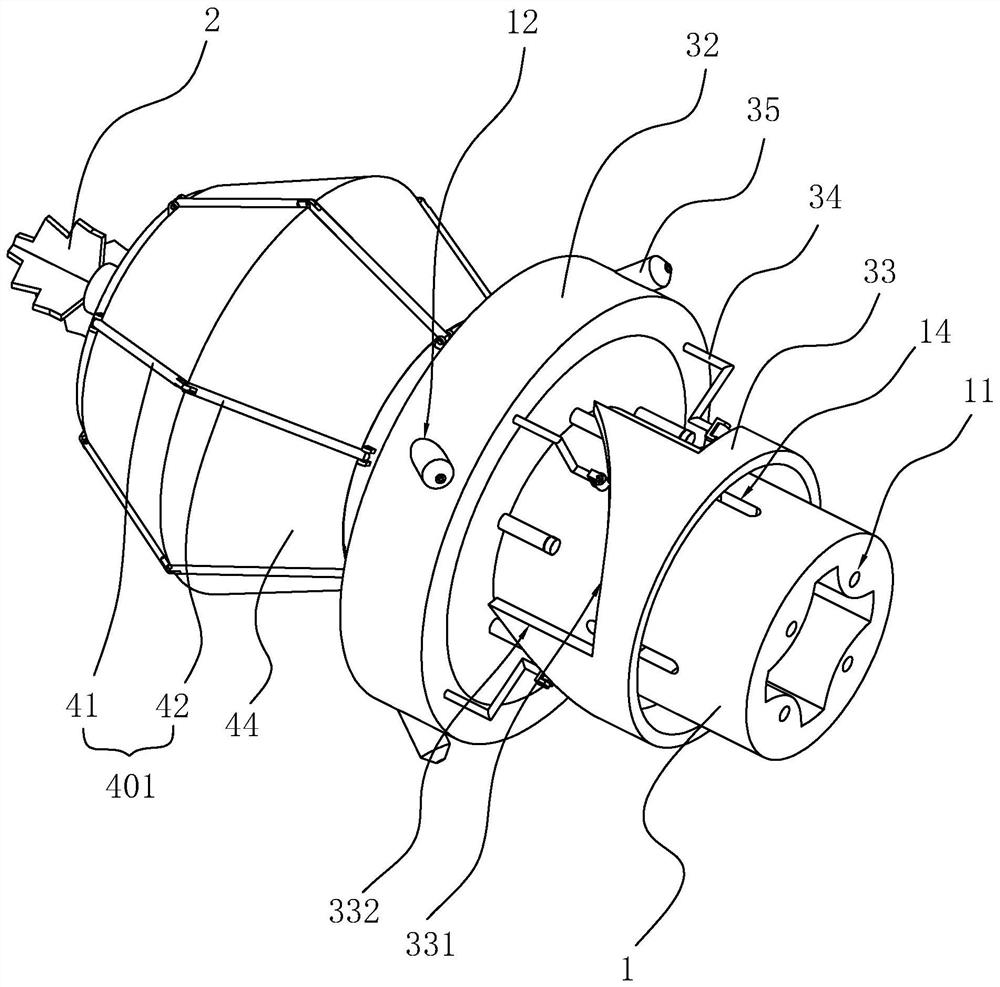

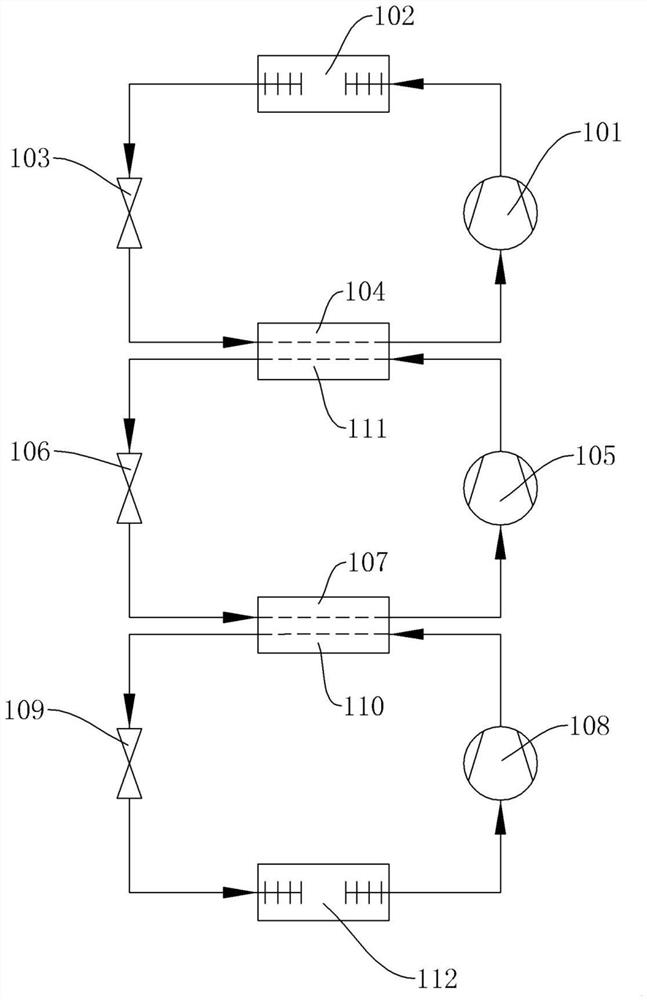

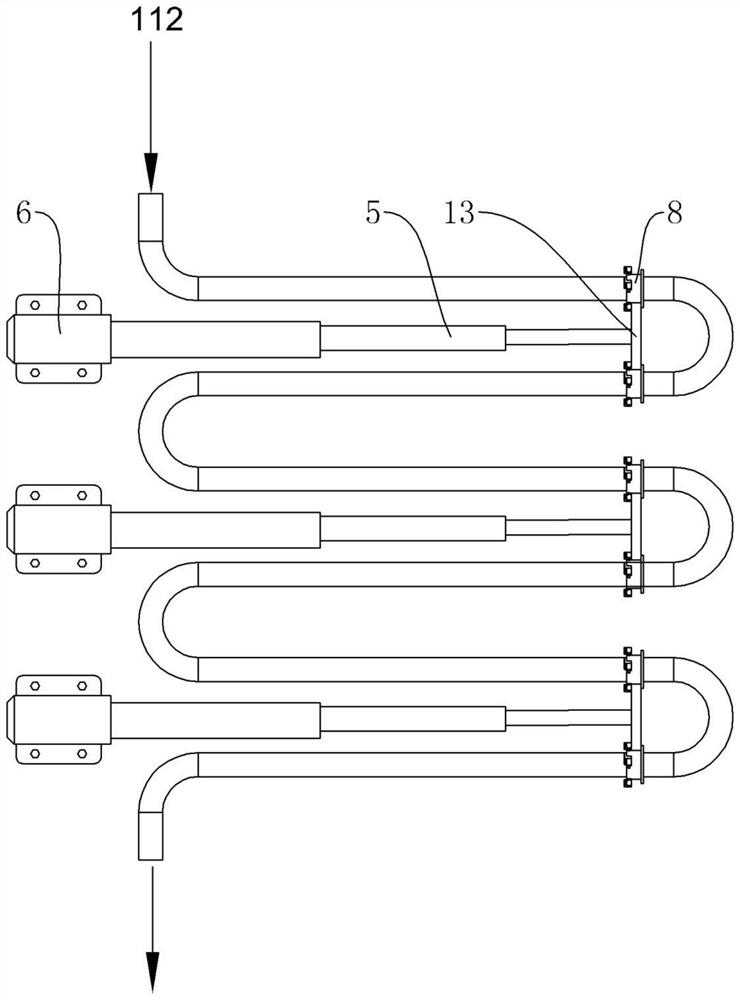

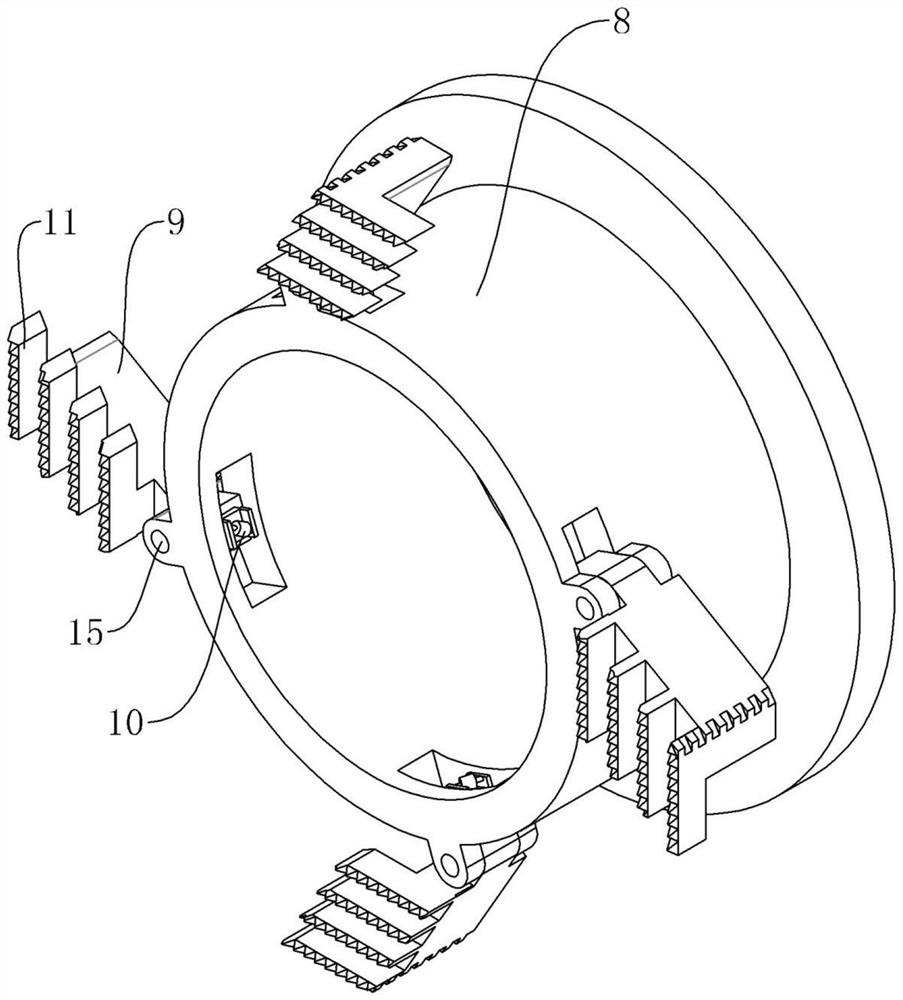

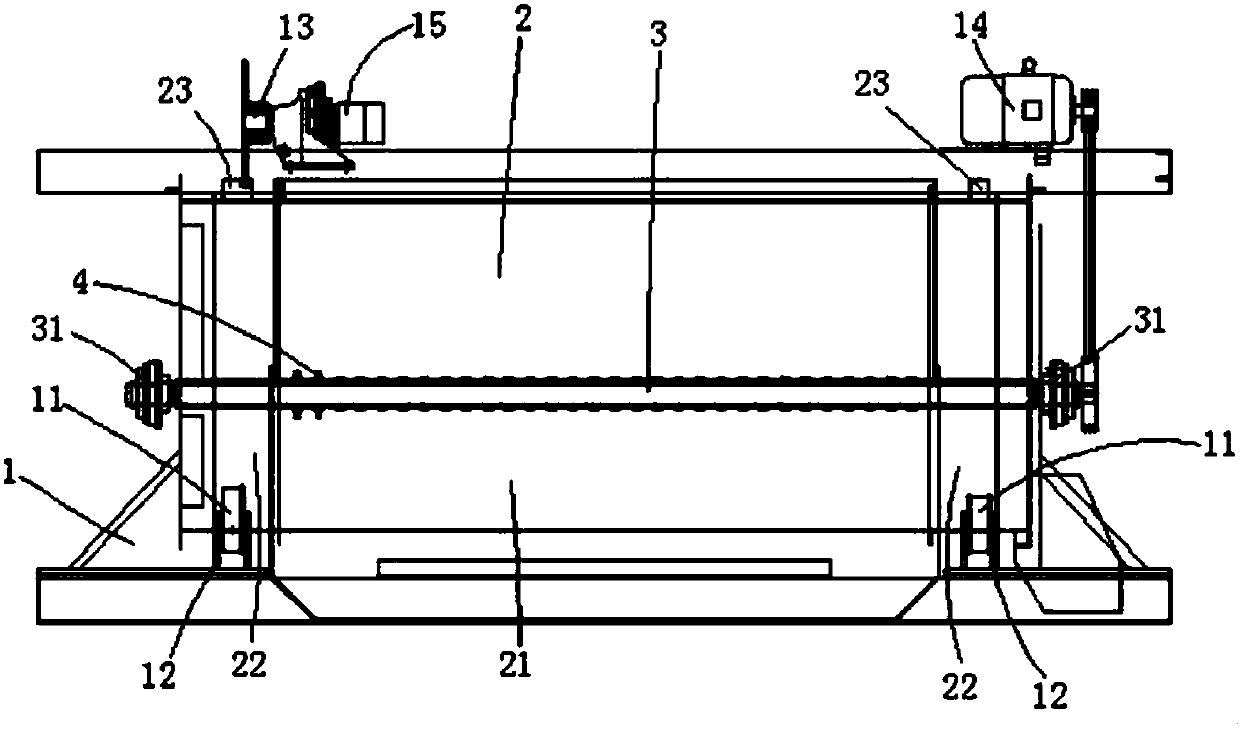

Intelligent, efficient, energy-saving and environment-friendly Freon, ammonia and carbon dioxide cascade refrigeration system

ActiveCN114111077AWalk fastAvoid affecting the heat transfer effectCorrosion preventionCompression machines with cascade operationProcess engineeringFreon

The invention relates to the technical field of cascade refrigeration systems, in particular to an intelligent, efficient, energy-saving and environment-friendly Freon, ammonia and carbon dioxide cascade refrigeration system. An intelligent, efficient, energy-saving and environment-friendly Freon, ammonia and carbon dioxide cascade refrigeration system comprises a first-stage refrigeration system, a second-stage refrigeration system and a third-stage refrigeration system which are sequentially connected in an overlapped mode. The intelligent, efficient, energy-saving and environment-friendly Freon, ammonia and carbon dioxide cascade refrigerating system further comprises a deicing device. The deicing device comprises a rotating ring, a plurality of cutting boards, a plurality of crushing cutter sets, a driving mechanism and a plurality of advancing wheels. By arranging the deicing device, when the outer surface of the evaporator is iced, the cutting mode is adjusted in a self-adaptive mode according to different frost hardness, under the condition that the frost hardness is low, the rotating ring of the deicing device is high in walking speed and high in crushing efficiency, and under the condition that the frost hardness is high, the frost crushing force is increased; and frost with high hardness can be cut and crushed.

Owner:ZHENGZHOU KAIXUE COLD CHAIN CO LTD

Rubbish screening machine with flail knife crushing function

InactiveCN110339922AImprove crushing effectStrong crushingSievingScreeningPulp and paper industryWater spray

The invention discloses a rubbish screening machine with a flail knife crushing function. The rubbish screening machine comprises a machine frame body, a rotating roller screen and a crushing rotary shaft, wherein supporting wheels are arranged on a bottom side plate of the machine frame body, and the rotating roller screen is arranged above the supporting wheels; the middle of the rotating rollerscreen is a working cavity, the crushing rotary shaft is arranged in the working cavity of the rotating roller screen in a penetrating manner, and the rotating direction of a rotating shaft for crushing and the rotating direction of the rotating roller screen are opposite; and the rotating shaft is provided with a flail knife assembly, crushing blades are arranged on the flail knife assembly in amatched manner, rotating shaft bases are arranged at the two ends of the rotating shaft for crushing, and the rotating shaft bases are assembled on the machine frame body. A double-action mode of opposite rotation of a shaft screen is high in the material crushing capacity, and the flail knife crushing mode adopts the principle of inertia operation in physics, so that the crushing effect is good;the rotating roller screen is independently arranged, and screen holes in the rotating roller screen can be prevented from being blocked; a water spraying pipe is arranged, and has a double effects of cleaning a wall surface of the rotating roller screen and cleaning materials, so that the viscosity of the materials is reduced, and the crushing is facilitated.

Owner:长兴睿锋科技有限公司

A powder breaking mechanism for secondary utilization of waste glass

ActiveCN109092512BEvenly brokenAvoid jammingGrain treatmentsEnvironmental engineeringMechanical engineering

The invention relates to the technical field of environmental protection equipment, in particular to a powder breaking mechanism for secondary utilization of waste glass. The powder breaking mechanismfor the secondary utilization of the waste glass solves the technical problems that the waste glass is not broken completely and the broken effect is not high. The powder breaking mechanism for the secondary utilization of the waste glass comprises a block breaking mechanism, a crushing cylinder mechanism is movably connected to the bottom of the block breaking mechanism, the bottom of the crushing cylinder mechanism is movably connected with an feed inlet of the top of a power stirring box, a power stirring mechanism is arranged in the power stirring box, support legs are separately and fixedly connected to four right angle positions of the bottom of the power stirring mechanism, and a discharge sleeve is connected to the interior of an opening of the bottom of the power stirring box ina sleeving mode. According to the powder breaking mechanism for the secondary utilization of the waste glass, when pushing rods push crushing heads to move, because the crushing heads on the two sidesare arranged in an inclined mode, when the glass enters a block breaking sleeve, the glass can be crushed into small pieces from large pieces by squeezing, and the farther down, the distance betweenthe two crushing heads is smaller, so that glass with large pieces is gradually broken.

Owner:安徽强钢钢化玻璃股份有限公司

A pollution-free crushing device for medical waste

ActiveCN110882773BReduce volumeBroken comprehensiveDrying solid materials without heatDrying chambers/containersMedical wasteRefuse Disposals

Owner:QINGDAO MUNICIPAL HOSPITAL

Solid waste crusher for environmental protection

InactiveCN109926157AReasonable designImprove work efficiencyGrain treatmentsEnvironmental resistanceCoupling

The invention discloses a solid waste crusher for environmental protection. The solid waste crusher for environmental protection comprises a crusher body, a control panel, a crushing box body and a water inlet pipe. The crushing box body is arranged above the crusher body, one side of the crushing box body is connected with the waste inlet pipe, and a crushed material discharge pipe is arranged onthe other side of the crushing box body. An electric motor is installed in the crusher body, a transmission is installed above the electric motor, a hydraulic tank is arranged on one side of the transmission, an electrical appliance cabinet is arranged above the hydraulic tank, and one side of the electrical appliance cabinet is connected with the control panel. A feeding wheel is installed abovethe electrical appliance cabinet, a transmission gear is arranged on one side of the feeding wheel, a coupler is installed on one side of the transmission gear, and one side of the coupler is connected with a transmission shaft. The solid waste crusher for environmental protection has the beneficial effects of being reasonable in design, high in working efficiency, low in crushing noise, high incrushing performance, convenient to control and operate, high in corrosion resistance, wide in application range and long in service life.

Owner:GUILIN SHIHUAN WASTE GAS TREATMENT EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com