Cutter shaft of garbage crusher

A crusher and cutter shaft technology, which is applied in grain processing, etc., can solve the problems that the cutter shaft cannot meet the high torque requirement, the blade wears fast, and the effect of crushing large garbage is not ideal, and achieves convenient installation and debugging, simple structure, The effect of high torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

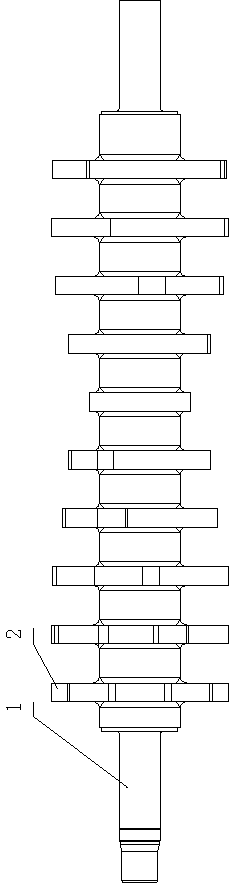

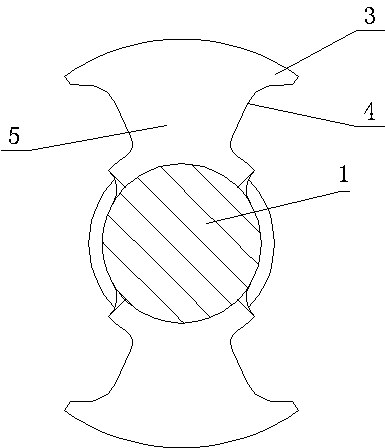

[0011] See figure 1 , figure 2 The cutter shaft of the garbage crusher in the embodiment of the present invention includes a shaft body 1 and a number of blades 2 uniformly distributed on the shaft body 1 at a certain angle (usually 15-40 degrees) in the axial direction. The blades 2 include a cutter head part. 3. Blade part 4 and blade body part 5. The number of blades 2 is preferably 8-20. Each blade 2 has two correspondingly distributed (symmetrically distributed, 180-degree distribution in the axial section) of the tip part 3, the blade part 4 and the blade body part 5, such as figure 2 Shown. This structure enables the cutter head to have only two symmetrical cutter teeth (the sharp part of the cutter head part 3) in a certain direction, and the distance between the two cutter teeth and the fixed blade is relatively large, which is conducive to the cutter teeth grasping and being broken Large objects and apply torque to tear and squeeze broken objects in time, while t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com