Preparation method of ultrafine ferrite powder

A technology of ferrite and ferrite, which is applied in the field of preparation of ultrafine ferrite powder, can solve the problems of reduced particle size of ferrite powder, insufficient magnetic force of blank, sintering and adhesion, etc., and achieves improvement of initial magnetic permeability. and resistivity, improving magnetic properties, and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

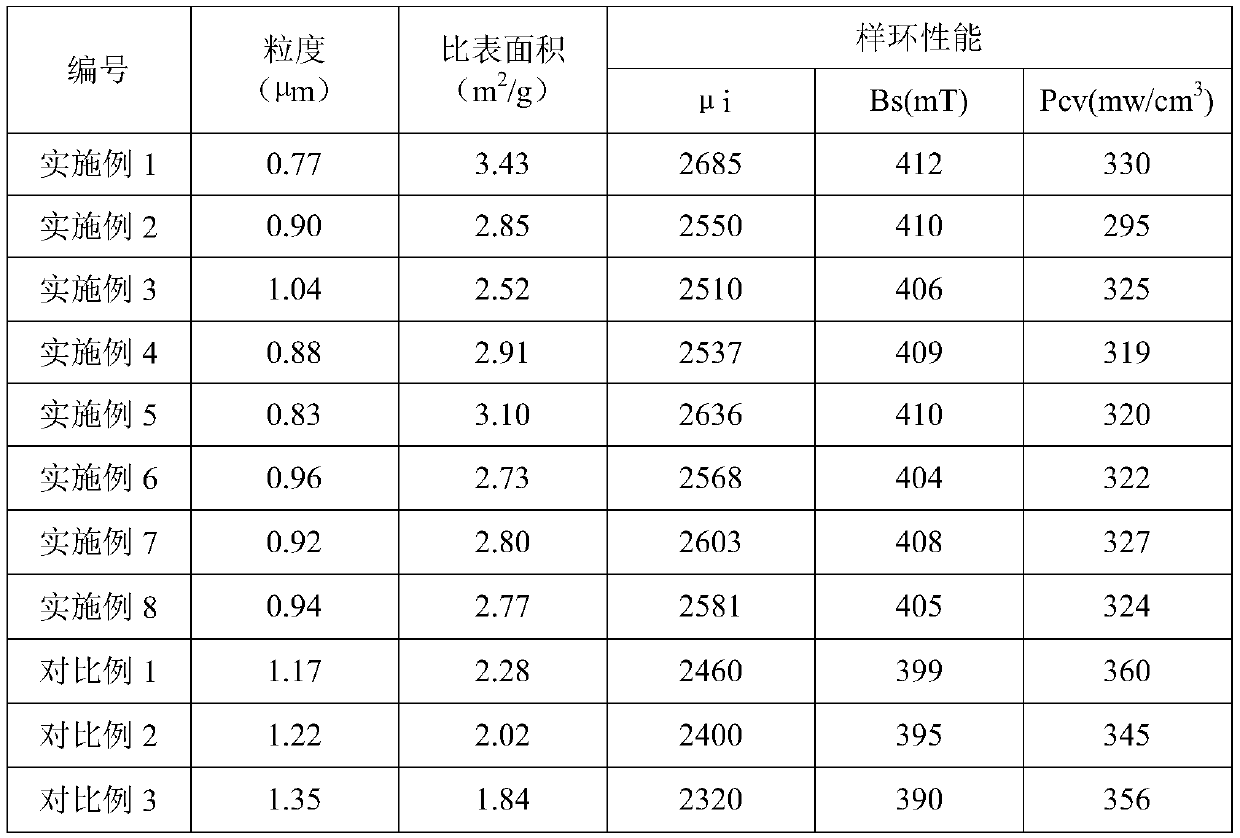

Embodiment 1

[0060] A preparation method of ultrafine ferrite powder, comprising the steps of:

[0061] (1) 69.75% Fe by weight 2 o 3 , 23% Mn 3 o 4 , 7.25% ZnO to prepare 400kg MnZn power ferrite DMR44 raw material, after mixing evenly, put the raw material into the rotary kiln and pre-fire at 980°C for 3 hours to obtain high-temperature pre-fired material;

[0062] (2) The high-temperature calcined material is directly dropped into 320kg of cooling medium (concentration is 0.06wt% lime water) for rapid cooling, and after cooling for 5min, coarse pulverized slurry is obtained;

[0063] (3) Coarse crushing slurry and auxiliary material SiO 2 and Nb 2 o 5 Pour into sand mill together and carry out secondary grinding 90 minutes (material: ball=1:6), obtain ferrite slurry, wherein SiO 2 and Nb 2 o 5 The concentration in the ferrite slurry is 0.003wt% and 0.03wt%;

[0064] (4) The ferrite slurry is spray-dried to obtain superfine ferrite powder.

Embodiment 2

[0066] A preparation method of ultrafine ferrite powder, comprising the steps of:

[0067] (1) 69.75% Fe by weight 2 o 3 , 23% Mn 3 o 4 , 7.25% ZnO to prepare 400kg MnZn power ferrite DMR44 raw material, after mixing evenly, put the raw material into the rotary kiln and pre-fire at 950°C for 4 hours to obtain high-temperature pre-fired material;

[0068] (2) The high-temperature calcined material is directly dropped into 320kg of cooling medium (concentration is 0.06wt% lime water) for rapid cooling, and after cooling for 3min, coarse pulverized slurry is obtained;

[0069] (3) Coarse crushing slurry and auxiliary material SiO 2 , Nb 2 o 5 and ZrO 2Pour into sand mill together and carry out secondary grinding 90 minutes (material: ball=1:6), obtain ferrite slurry, wherein SiO 2 , Nb 2 o 5 and ZrO 2 The concentration in the ferrite slurry is 0.003wt%, 0.03wt% and 0.03wt%;

[0070] (4) The ferrite slurry is spray-dried to obtain superfine ferrite powder.

Embodiment 3

[0072] A preparation method of ultrafine ferrite powder, comprising the steps of:

[0073] (1) 69.75% Fe by weight 2 o 3 , 23% Mn 3 o 4 , 7.25% ZnO to prepare 400kg MnZn power ferrite DMR44 raw material, after mixing evenly, put the raw material into the rotary kiln and pre-fire at 1050°C for 2 hours to obtain high-temperature pre-fired material;

[0074] (2) The high-temperature pre-fired material is directly dropped into 320kg of cooling medium (concentration is 0.06wt% lime water) for rapid cooling, and after cooling for 10min, coarse pulverized slurry is obtained;

[0075] (3) Coarse crushing slurry and auxiliary material SiO 2 , Nb 2 o 5 and ZrO 2 Pour into sand mill together and carry out secondary grinding 90 minutes (material: ball=1:6), obtain ferrite slurry, wherein SiO 2 , Nb 2 o 5 and ZrO 2 The concentration in the ferrite slurry is 0.005wt%, 0.02wt% and 0.02wt%;

[0076] (4) The ferrite slurry is spray-dried to obtain superfine ferrite powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com