Strong crusher

A pulverizer, powerful technology, applied in grain processing, etc., can solve problems such as unstable speed, affecting the motor, and easy to produce strong impact, so as to improve safety and reduce injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

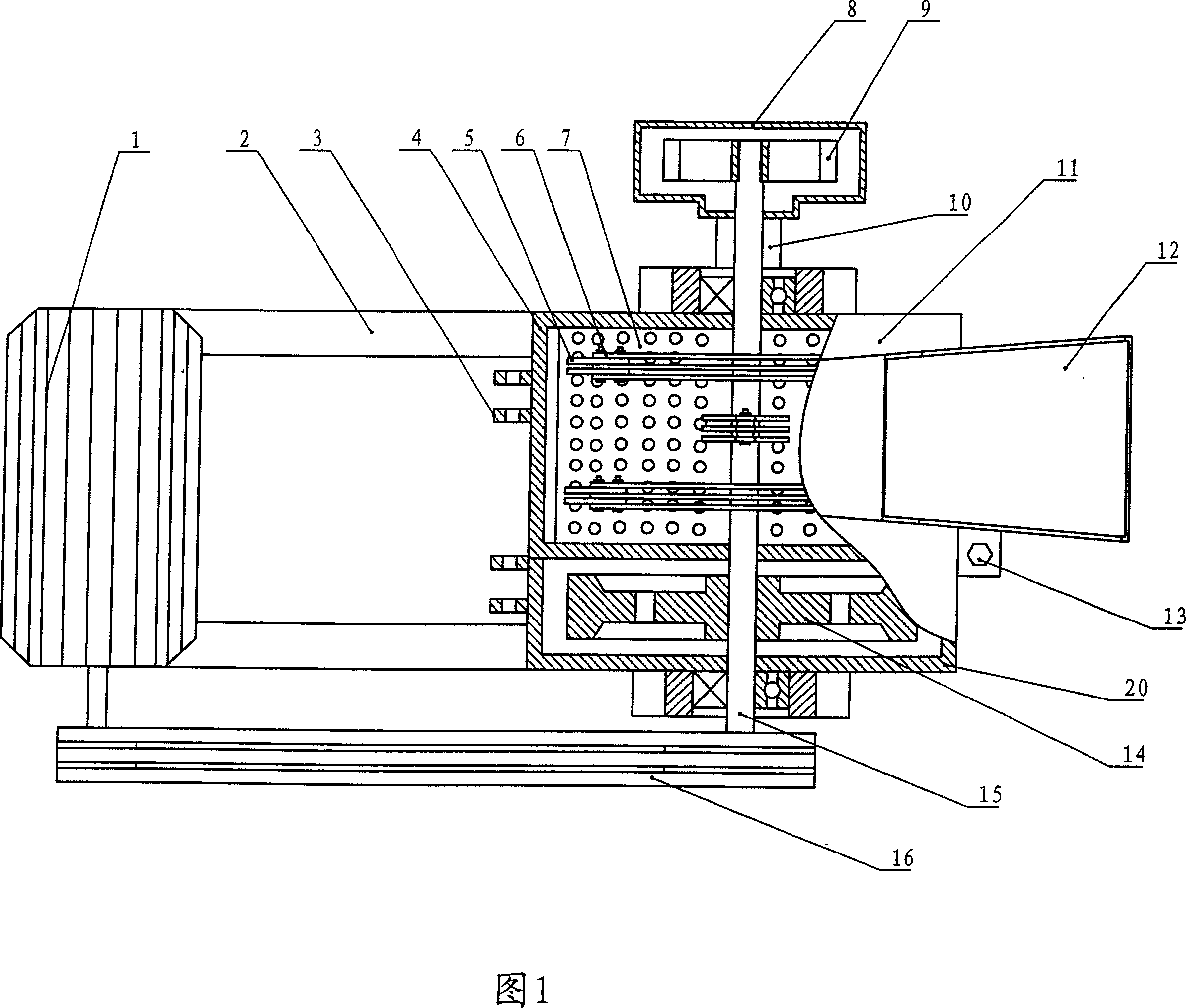

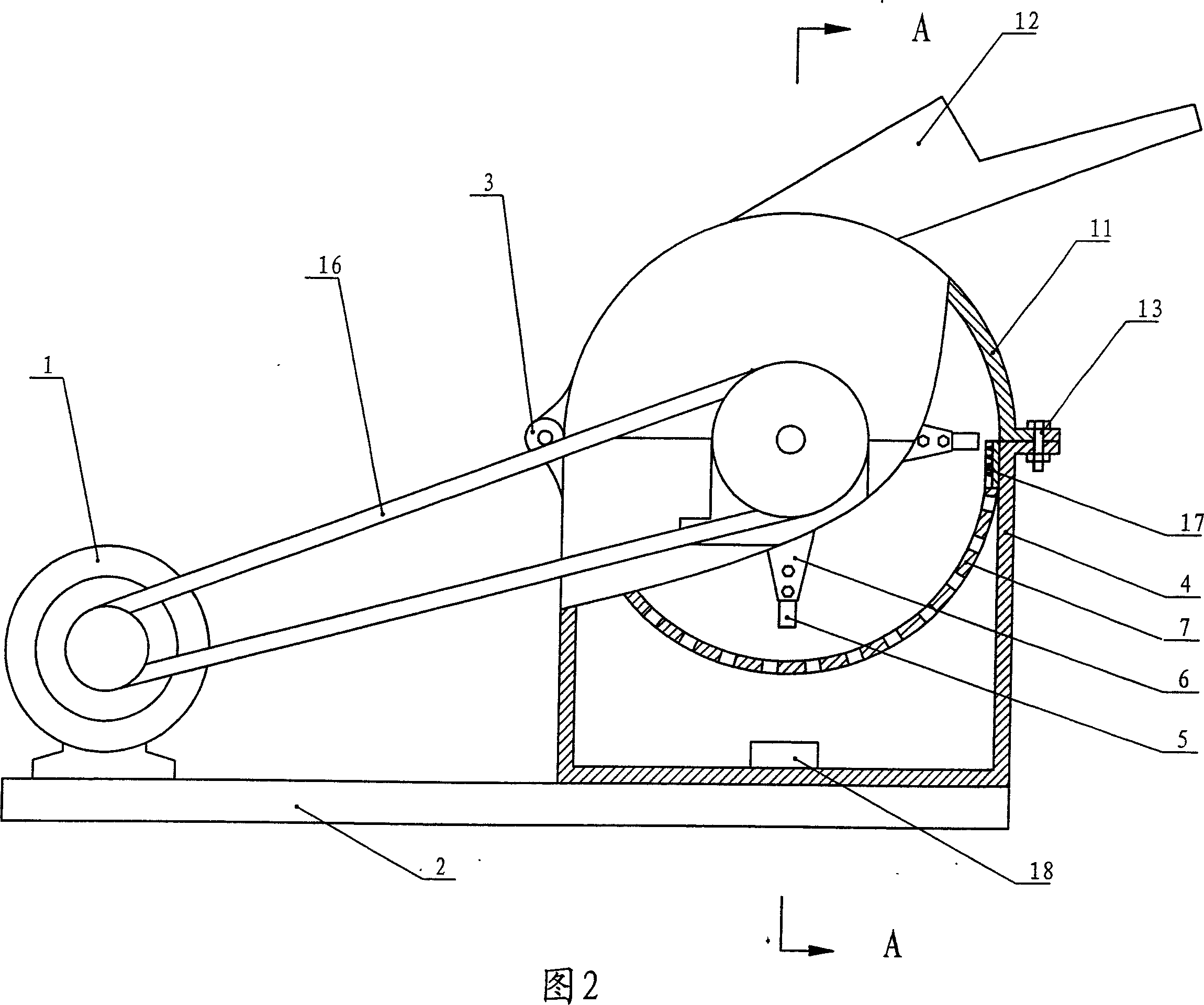

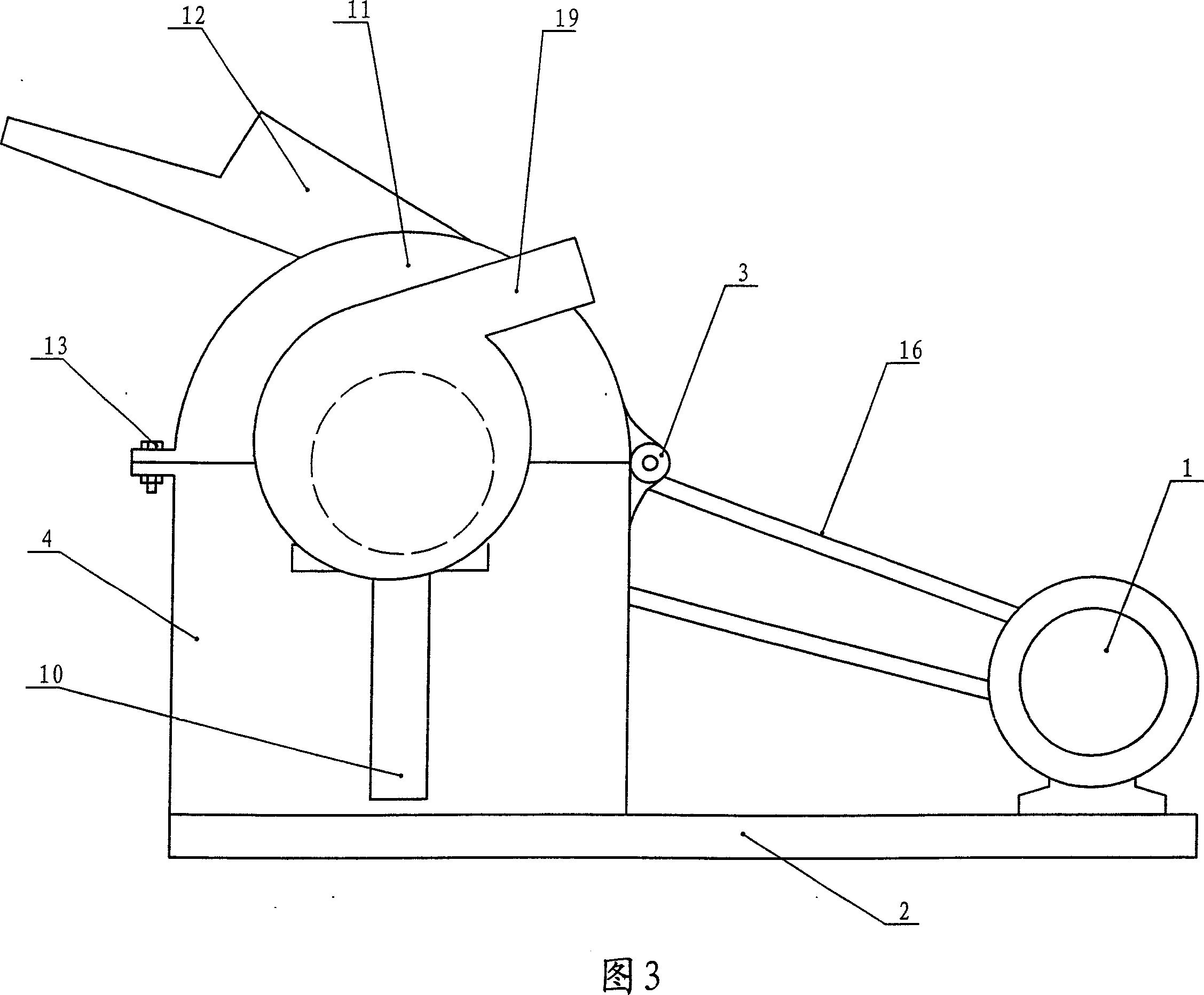

[0029] Embodiment 1: Referring to Fig. 1, Fig. 2, Fig. 3, Fig. 4 and Fig. 5, a powerful pulverizer includes a crushing device and a power machine 1 installed on the frame, and the output shaft of the power machine 1 is connected to the pulverizer through a transmission mechanism 16 The input shaft 15 of the device is connected, and the housings 4 and 11 of the pulverizing device are installed on the frame 2, and the input shaft 15 is installed in the housings 4 and 11 through the bearings, and a certain number of approximate shuttle-shaped shafts are installed and fixed on the input shaft 15. The flat plate crushing cutters 5 and 6 are connected and fixed with a feed port 12 in the tangential direction above the outer rotation circle of the crushing cutters 5 and 6 above the housing, and an arc-shaped screen is installed and fixed below the cutters 5 and 6. 7. A pulverized material storage chamber is formed between the screen 7 and the housing 4, 11; the input shaft 15 of the p...

Embodiment 2

[0030] Embodiment two: accompanying drawing is not drawn, and embodiment two is basically the same as embodiment one, and difference is that the cutter in embodiment two is four.

Embodiment 3

[0031] Embodiment three: accompanying drawing is not drawn, and embodiment three is basically the same as embodiment one, and difference is that the cutter in embodiment three is five.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com