Agitating vane structure of soybean milk machine

A technology of mixing blades and soybean milk machines, which is applied in milk substitutes, beverage preparation devices, household appliances, etc., can solve the problems of single blades and low work efficiency, achieve strong crushing performance, high work efficiency, and overcome the effects of single blades

Inactive Publication Date: 2014-01-15

XUZHOU LONGTAI COAL MINING EQUIP MFG

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a stirring blade structure of a soybean milk maker, which overcomes the defect of low working efficiency of the existing stirring blades of a soybean milk maker, and brings convenience to people

[0005] Beneficial effects are: because the present invention adopts the structural mode of adding multi-blades on one side of the edge of the hub, the structure of the present invention has the advantages of high working efficiency, strong crushing performance, and rapid stirring, and effectively overcomes the disadvantages of existing soymilk machines. The defects of single blade and low working efficiency in the structure of stirring blade

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

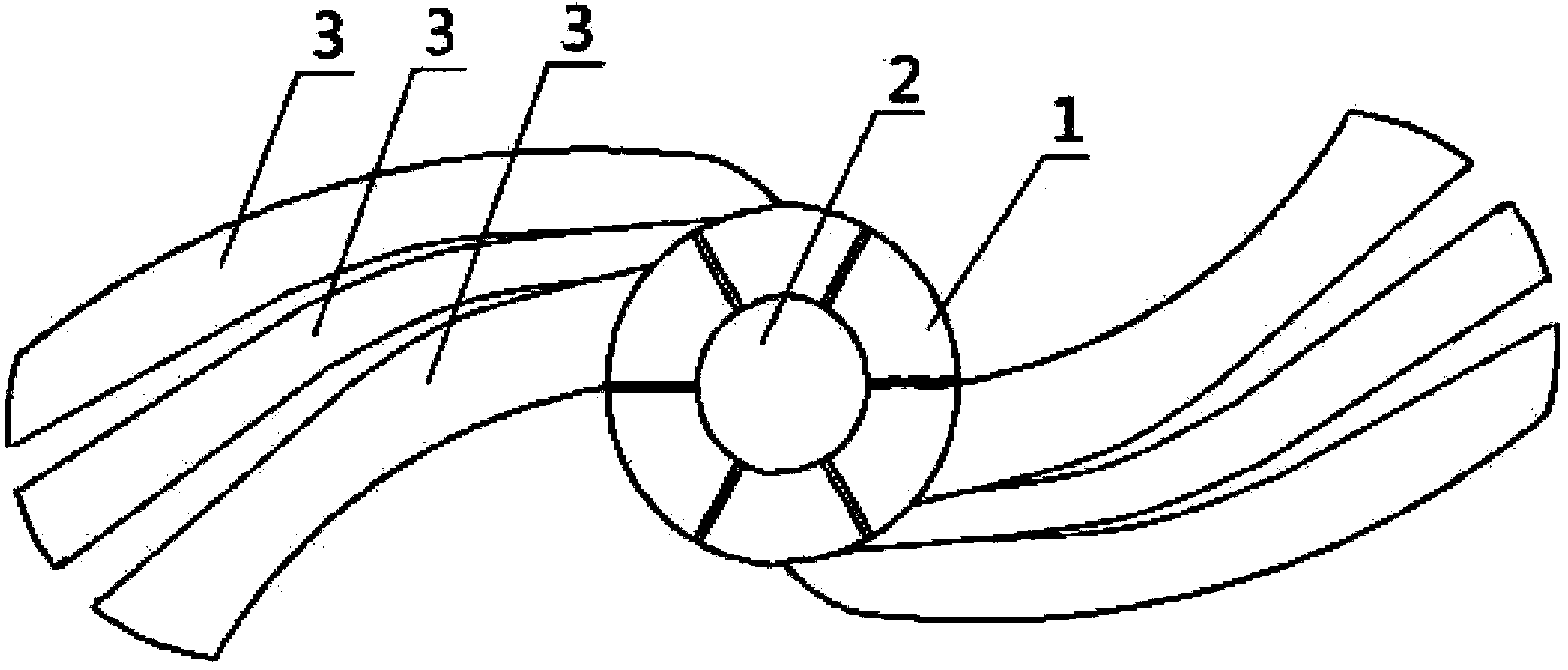

[0009] A stirring blade structure of a soybean milk machine, which is composed of a wheel base (1), a stirring shaft hole (2), and a multi-blade stirring blade (3); a stirring shaft hole (2) is arranged in the middle of the wheel base (1), Multi-blade stirring blades (3) are arranged on opposite sides of the edge of the wheel (1), and the multi-blade stirring blades (3) are fixed on the wheel (1).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an agitating vane structure of a soybean milk machine. A plurality of agitating vanes are installed on opposite sides of the edge of a hub, and the agitating vanes are fixed on the hub. The agitating vane structure has the advantages that the structural manner that the agitating vanes are additionally installed on each single side of the edge of the hub is adopted. The agitating vane structure has the advantages of being high in work efficiency, strong in crushing performance and high in agitating speed, and effectively overcomes the defects that an agitating vane structure of an existing soybean milk machine has a single vane and is low in work efficiency.

Description

technical field [0001] The invention relates to a stirring blade structure, in particular to a stirring blade structure of a soybean milk maker, and belongs to the technical field of agitator structures. Background technique [0002] At present, the mixing blades of soybean milk mixers are mostly provided with a blade on the opposite side of the edge of the hub of the mixing blade, and specifically, the opposite sides of the edge of the hub are each provided with a relative single piece like the shape of an airplane wing. The blade also has a blade with a relatively cross-shaped single side on its wheel hub; like this, the mixer blade with a blade on one side of the wheel hub edge has a lower working efficiency, which is easy to bring people To use the passive. Contents of the invention [0003] The object of the present invention is to provide a stirring blade structure of a soymilk maker, which overcomes the defect of low working efficiency of the existing stirring blad...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A47J31/44A23C11/10A23L11/60

Inventor 王桂荣

Owner XUZHOU LONGTAI COAL MINING EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com