Internal tooth milling and internal tooth rolling conversion knife rest device

A technology of internal gears and tool holders, which is applied in the direction of gear tooth manufacturing devices, gear teeth, gear cutting machines, etc., can solve the problems of workpiece precision tolerance and low processing efficiency, and achieve the solution of workpiece precision tolerance, strong versatility, and solution The effect of low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

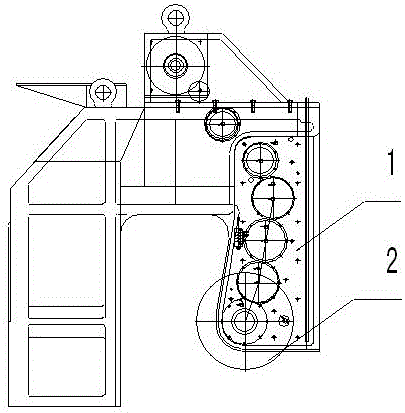

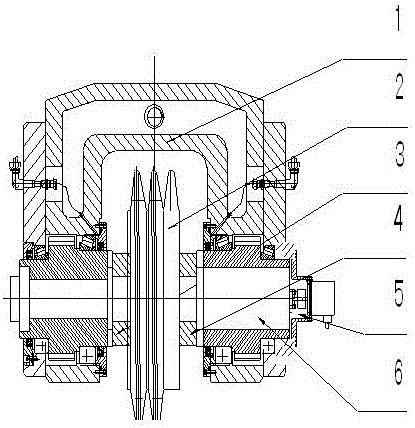

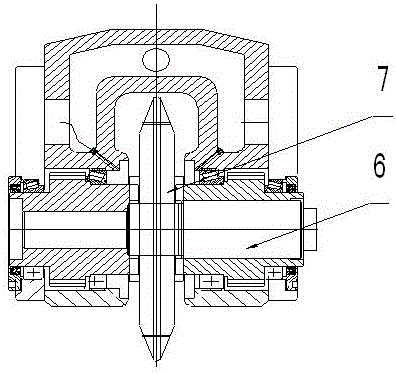

[0011] See figure 1 — figure 2 , an internal tooth milling and internal tooth hobbing switching tool holder device, which consists of a tool holder body 1, an internal tooth hob 2, a left knife pad 3, a right knife pad 4, a tightening nut 5, a mandrel 6, an internal tooth milling Knives 7 are formed; the tool holder body 1 is the main frame of the device, and the inner gear hob 2 is positioned in the tool holder body 1 through the mandrel 6 to perform rotary motion. The pad 4 is connected with the transmission gears at both ends to realize torque transmission; the right cutter pad 4 is pre-tightened by the tightening nut 5 at the right end to eliminate the gap between the right cutter pad 4 and the internal tooth hob 2, thereby ensuring the stability of the rotary motion of the internal tooth hob 2; When the tooth milling cutter 7 is switched to use, remove the left cutter pad 3, right cutter pad 4, mandrel 6, and inner tooth hob 2, install the inner tooth milling cutter 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com