Catalyst for preparing tetrahydronaphthalene and decahydronaphthalene from technical naphthalene through hydrogenation, preparation and application

A catalyst, a technology for tetralin, applied in the field of aromatic hydrocarbon hydrogenation catalysts, can solve problems such as unfavorable production of tetralin and decalin, complex catalyst manufacturing process, harsh operating conditions, etc., and achieves overcoming harsh raw material requirements, activity and stability The effect of good performance and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

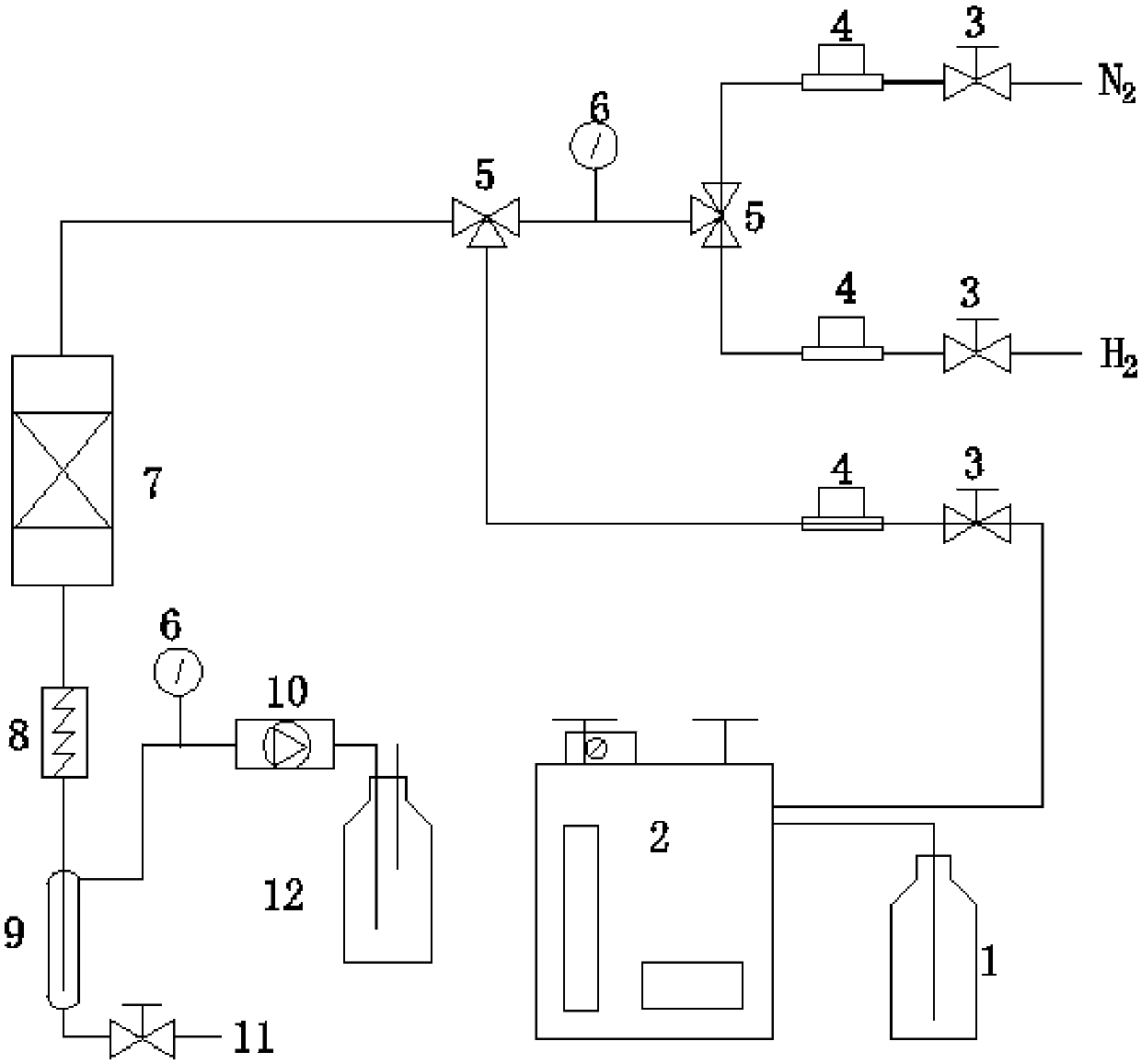

Method used

Image

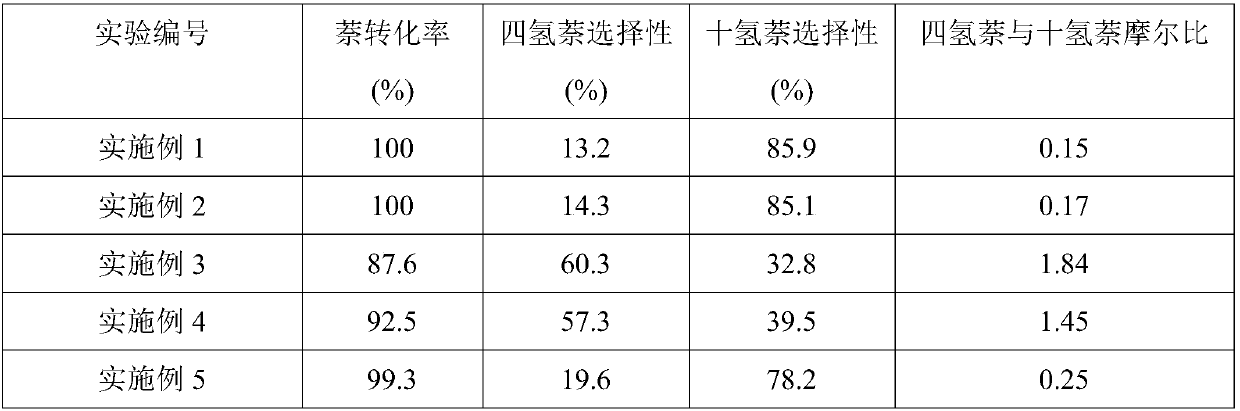

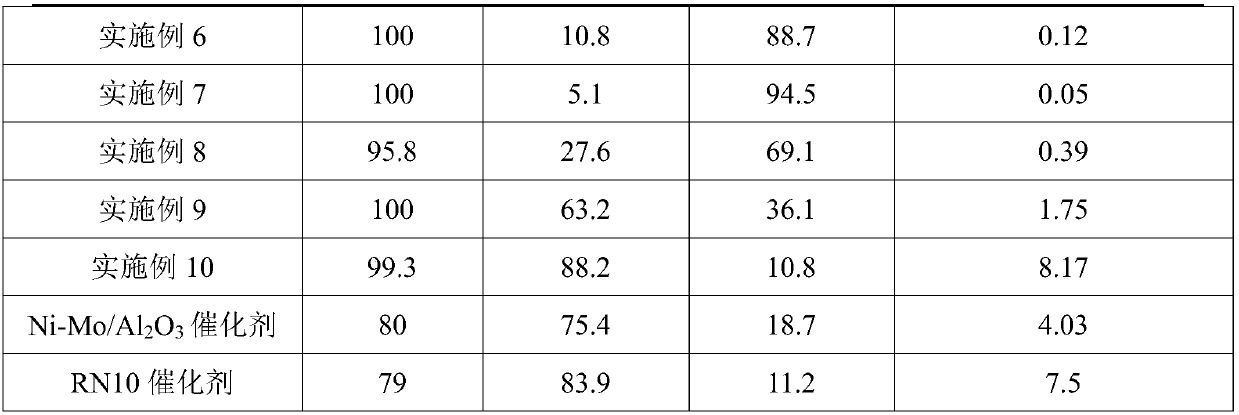

Examples

Embodiment 1

[0043] The preparation and application specific process of the present embodiment catalyst are as follows:

[0044] 1. Preparation of catalyst: Weigh 5.01g of basic nickel carbonate (3g of nickel oxide), 30.24g of ammonium metatungstate (26g of tungsten oxide), 100g of deionized water, and 0.2g of citric acid in an autoclave at 140°C Reaction 8h. The reaction product is taken out by filtration, washed with deionized water for 3-4 times, and then dried at 120°C. The dried metal oxide is ground into 150-200 mesh powder, then add 0.22g ammonium phosphate, 0.3gPEO (polyoxyethylene), 2gZSM-5 molecular sieve, and a certain amount of deionized water to knead the mud (the amount of deionized water According to the requirements of extrusion), the kneaded mud ball is aged for 2 hours and then extruded. The extrusion specification is ∮1.3×2-8mm clover type. After the extruded strips were dried at 120°C, they were finally calcined in a muffle furnace at 500°C for 4 hours to obtain a fin...

Embodiment 2

[0049] The preparation and application specific process of the present embodiment catalyst are as follows:

[0050] 1. Preparation of catalyst: Weigh 8.35g of basic nickel carbonate (5g of nickel oxide), 26.97g of ammonium molybdate (22g of molybdenum oxide), 100g of deionized water, and 0.4g of urea in an autoclave, and react at 180°C 12h. The reaction product is taken out by filtration, washed with deionized water for 3-4 times, and then dried at 120°C. Grind the dried metal oxide into 150-200 mesh powder, then add 5.5g phosphoric acid (concentration 85%), 0.03g PEG (polyvinyl alcohol), 65g pseudo-boehmite (400°C loss rate about 20%), and a certain amount of deionized water to knead the mud. The kneaded mud ball is aged for 2 hours and then extruded. The extrusion size is ∮1.3×2-8mm clover. After the extruded strips were dried at 120°C, they were finally calcined in a muffle furnace at 350°C for 4 hours to obtain a finished clover-type catalyst with a total mass of 76.8g. ...

Embodiment 3

[0055] This example is a comparative example of Example 2. On the basis of Example 2, no inorganic additive phosphoric acid and organic additive PEG are added. Other operations are completely consistent with Example 2. The influence of organic and inorganic additives on catalyst performance is investigated. .

[0056] The preparation and application specific process of the present embodiment catalyst are as follows:

[0057] 1. Preparation of catalyst: Weigh 8.35g of basic nickel carbonate (5g of nickel oxide), 26.97g of ammonium molybdate (22g of molybdenum oxide), 100g of deionized water, and 0.4g of urea in an autoclave, and react at 180°C 12h. The reaction product is taken out by filtration, washed with deionized water for 3-4 times, and then dried at 120°C. Grind the dried metal oxides into 150-200 mesh powders, knead the mud after adding 65g of pseudoboehmite (about 20% loss on ignition at 400°C) and a certain amount of deionized water, and knead the kneaded mud. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com