Carbon fiber smashing equipment

A crushing equipment and carbon fiber technology, applied in grain processing, etc., can solve the problems of high price, affecting production efficiency, production troubles, etc., and achieve the effect of adjustable crushing fineness, excellent performance and high efficiency, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

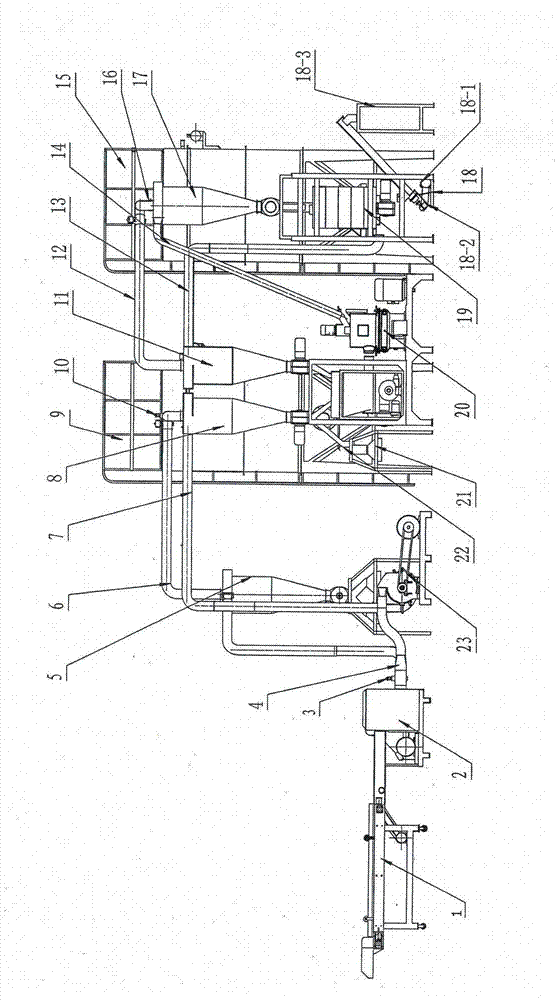

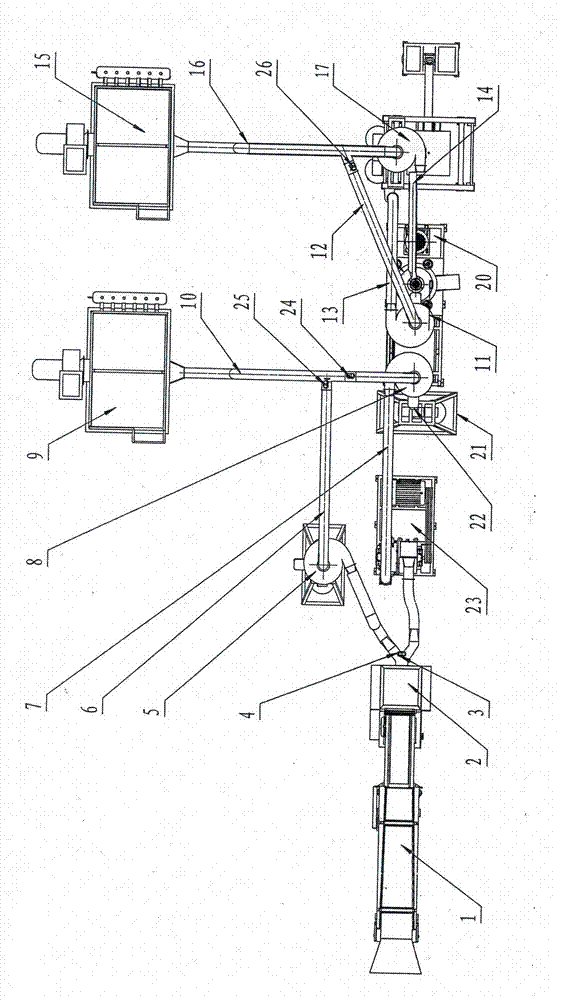

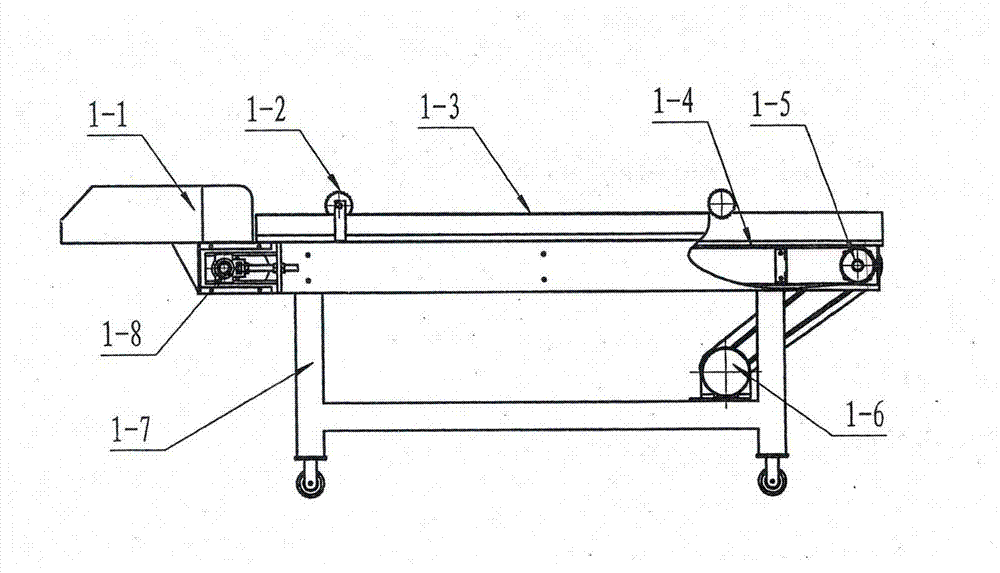

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] figure 1 , figure 2 Among them, the incoming material conveyor 1 and the cutting machine 2 are detachably plugged. Cutting machine 2 passes belt 1 # The first air delivery pipeline 4 of the pneumatic valve 3 communicates with the coarse pulverizer 23 and the first cyclone separator 5 respectively. The first cyclone separator 5 is provided with 2 # The first separation air delivery pipeline 6 of the pneumatic valve 25 and the belt 3 #The second separation air delivery pipeline 10 of the pneumatic valve 24 is communicated, and the second separation air delivery pipeline 10 is communicated with the second cyclone type separator 8 and communicated with the first air box type pulse dust collector 9, and the second cyclone separator 8 is also communicated with the coarse pulverizer 23 through the second air delivery pipeline 7, and comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com