Media-stirring pulverizer of internal classifier type

A stirring and classifying machine technology, applied in grain processing, etc., can solve problems such as insufficient air volume and impact on classification accuracy, and achieve the effect of easy ceramicization and easy sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

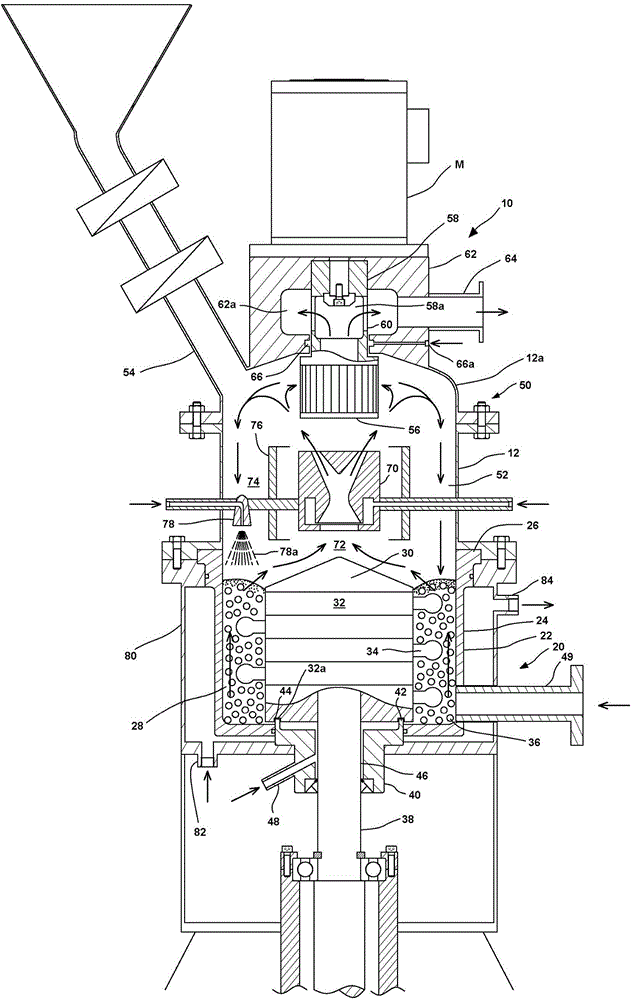

[0043] Below, refer to the attached figure 1 The medium agitation classifier built-in pulverizer according to the embodiment of the present invention will be described in detail.

[0044] The medium agitation classifier built-in pulverizer (hereinafter, simply referred to as the media agitation pulverizer) 10 according to the embodiment of the present invention is vertical and includes a cylindrical container 12 extending in the vertical direction.

[0045] The cylindrical container 12 is provided with a pulverizing part 20 at the lower part, and a classifying part 50 for classifying the wheel-rotating type product at the upper part.

[0046] In the above-mentioned crushing part 20, that is, the lower portion of the cylindrical container 12, a container 22 is accommodated. The container 22 has an annular flange 26 having a diameter larger than the container main body 24 at the top. The edge 26 is supported on the above-mentioned cylindrical container 12, and its lower part is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com