Dispersing, mixing and drying device

A drying equipment and dispersion technology, which is applied in mixers, lighting and heating equipment, shaking/oscillating/vibrating mixers, etc., can solve the problems of low mixing efficiency, high labor intensity, poor mixing effect, etc., and achieve drying ability and effect Enhanced, high-productivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

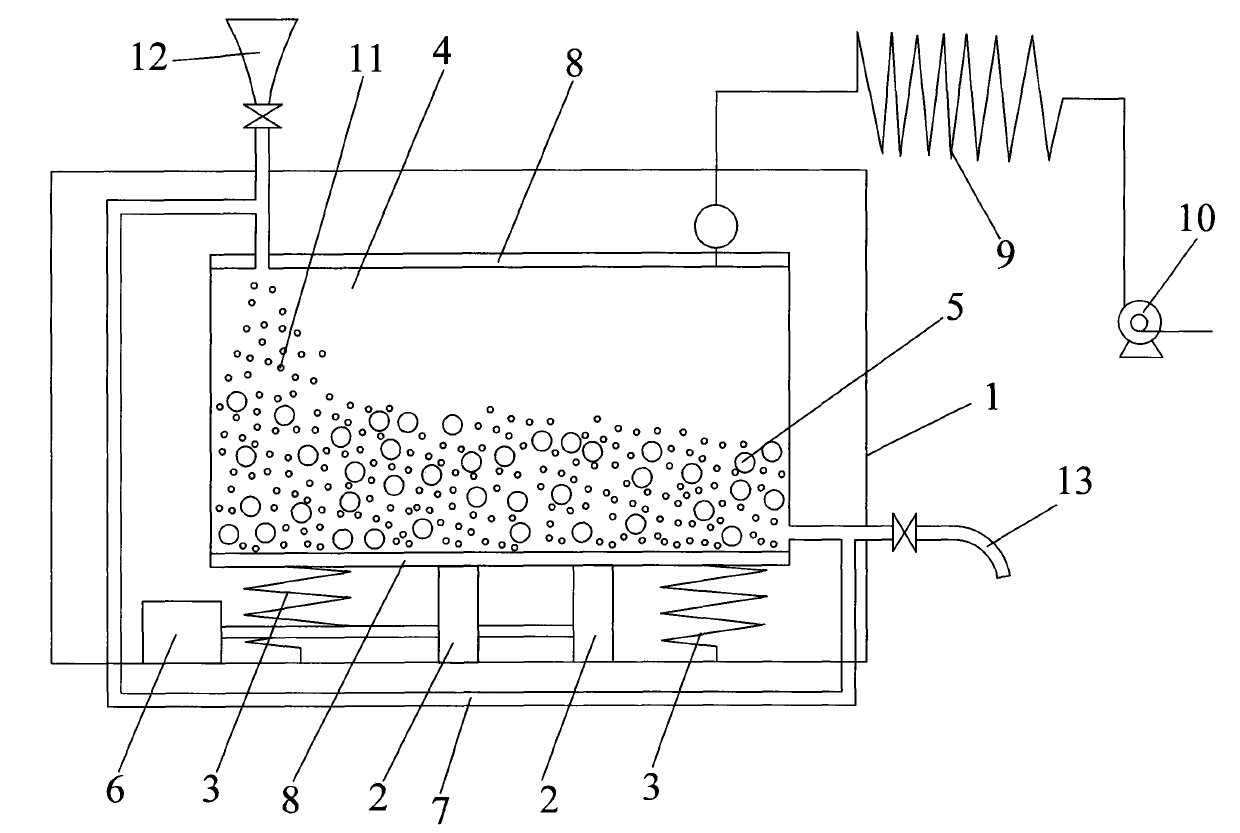

[0023] A kind of dispersing and mixing drying equipment, including a frame 1, a vibrator 2 installed on the base of the frame 1, a motor 6 for driving the vibrator 2, and a motor 6 located in the frame 1 and installed on the frame through a vibration damping spring 3 1. A grinding barrel 4 on the base, the grinding barrel 4 has a grinding medium 5 inside, and the vibration exciter 2 acts on the grinding barrel 4.

[0024] A material circulation pipeline 7 is connected between the discharge port 13 and the feed port 12 of the mill barrel 4. After the material 11 enters the mill barrel 4 from the feed port 12, it interacts with the grinding medium under the action of excitation and is dispersed. And pulverize, then come out from the discharge port 13, the qualified ones are sent to the next production step, and those that need to be further dispersed and crushed will enter the grinding barrel 4 again from the above-mentioned material circulation pipeline 7 through the feed port 1...

specific Embodiment 2

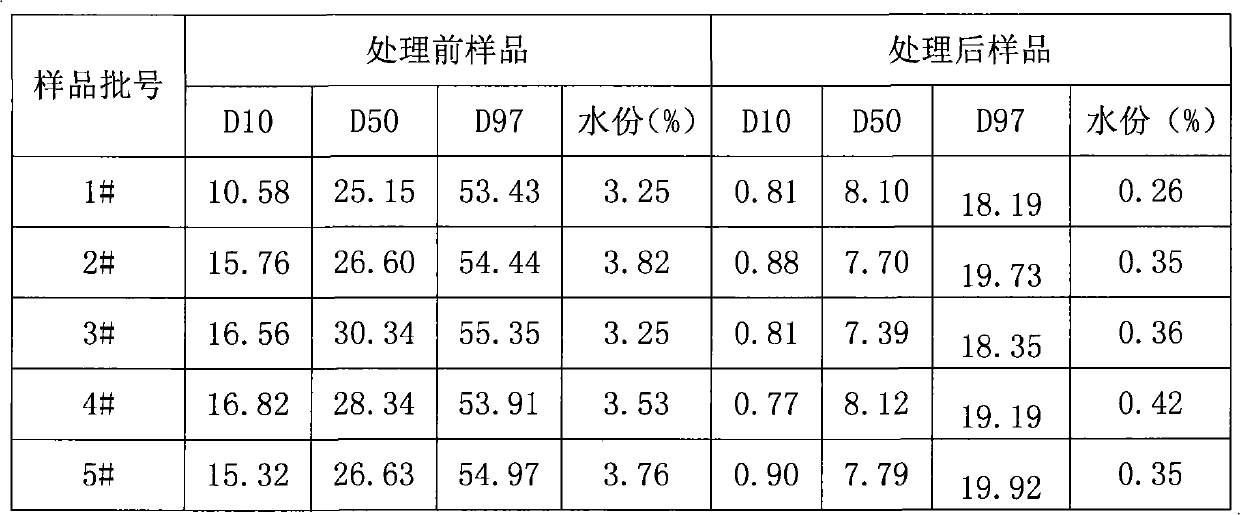

[0029] Start the equipment in specific embodiment 1, adjust the equipment parameters, add 100Kg of material with uneven thickness and particles no greater than 30um from the feed port 12, start vacuum pumping and excitation, and after 30 minutes of vibration, the discharge port 13 start discharging, the sample is taken as a sample every 20Kg, and 5 samples are taken for testing, and the results are as follows:

[0030] Table I:

[0031]

specific Embodiment 3

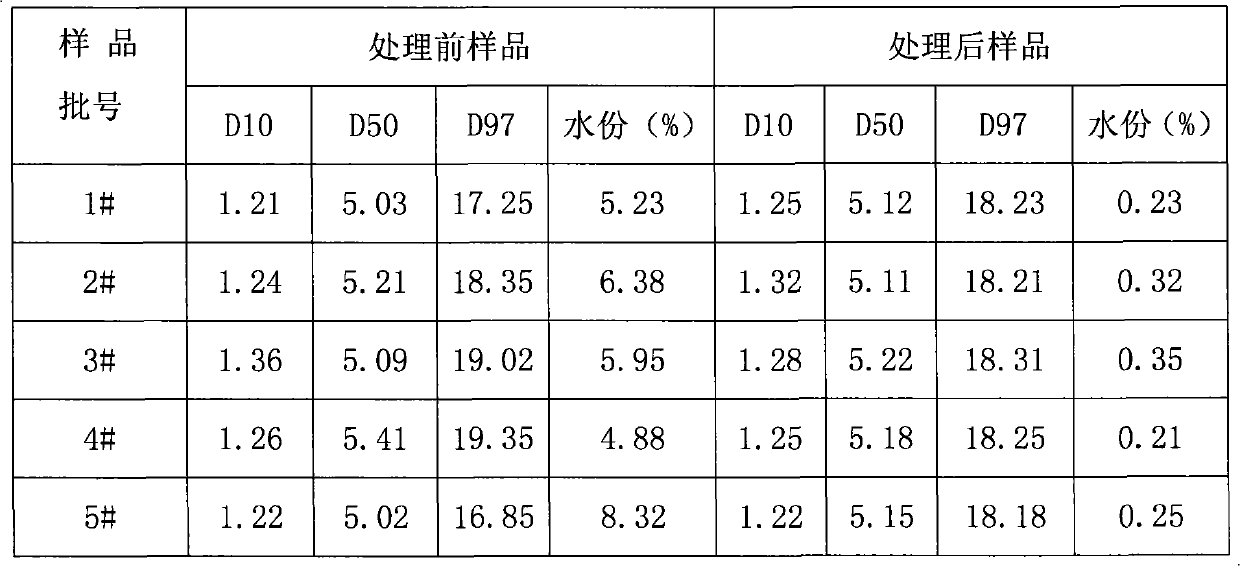

[0032] Start the equipment described in the specific embodiment 1, adjust the equipment parameters, add grinding media to the equipment, then add 100Kg of materials with uneven thickness and particles no greater than 100um into the equipment from the feed port 12, start vacuum pumping and exciting Vibrate, after 30 minutes of vibration, the discharge port 13 starts to discharge, and the sample is tested by 20Kg to get a sample, and the results are as follows:

[0033] Table II:

[0034]

[0035] It can be seen from Table 1 and Table 2 that this equipment has obvious mixing and dispersing effect, good crushing ability and strong drying ability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com