Patents

Literature

39results about How to "Increase crushing power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

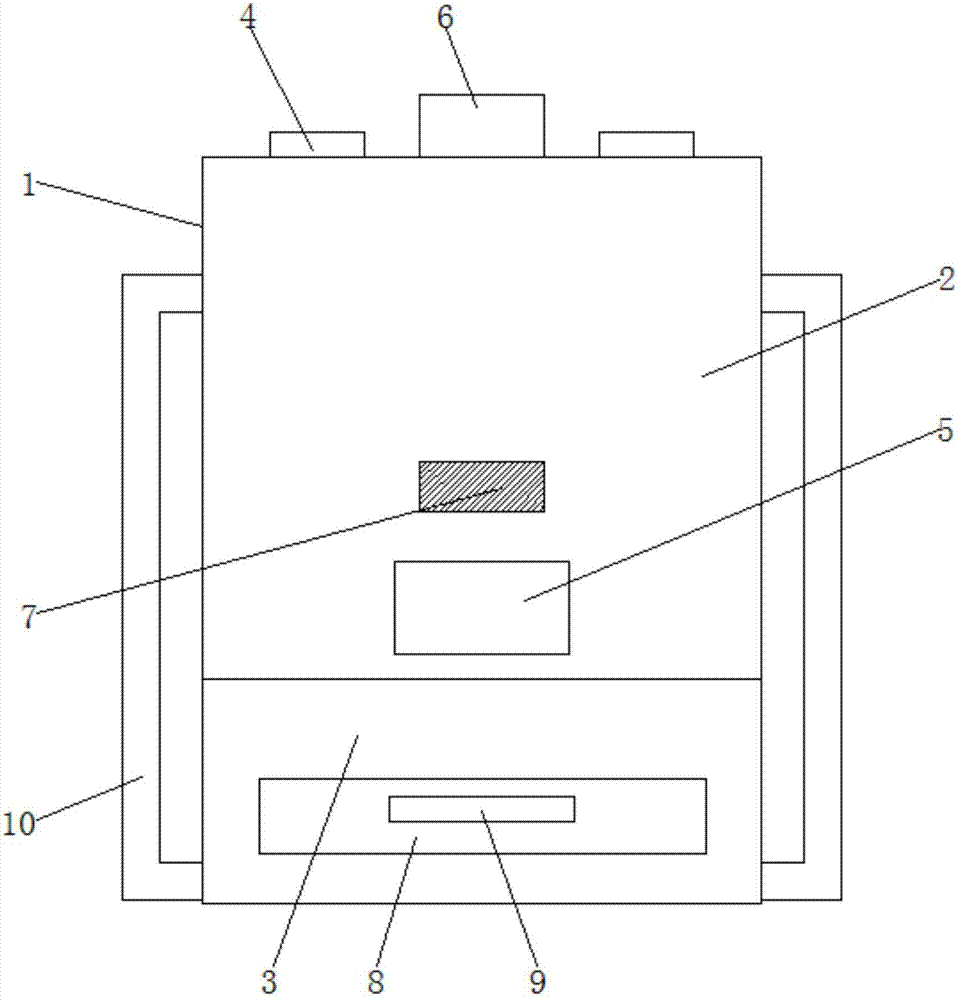

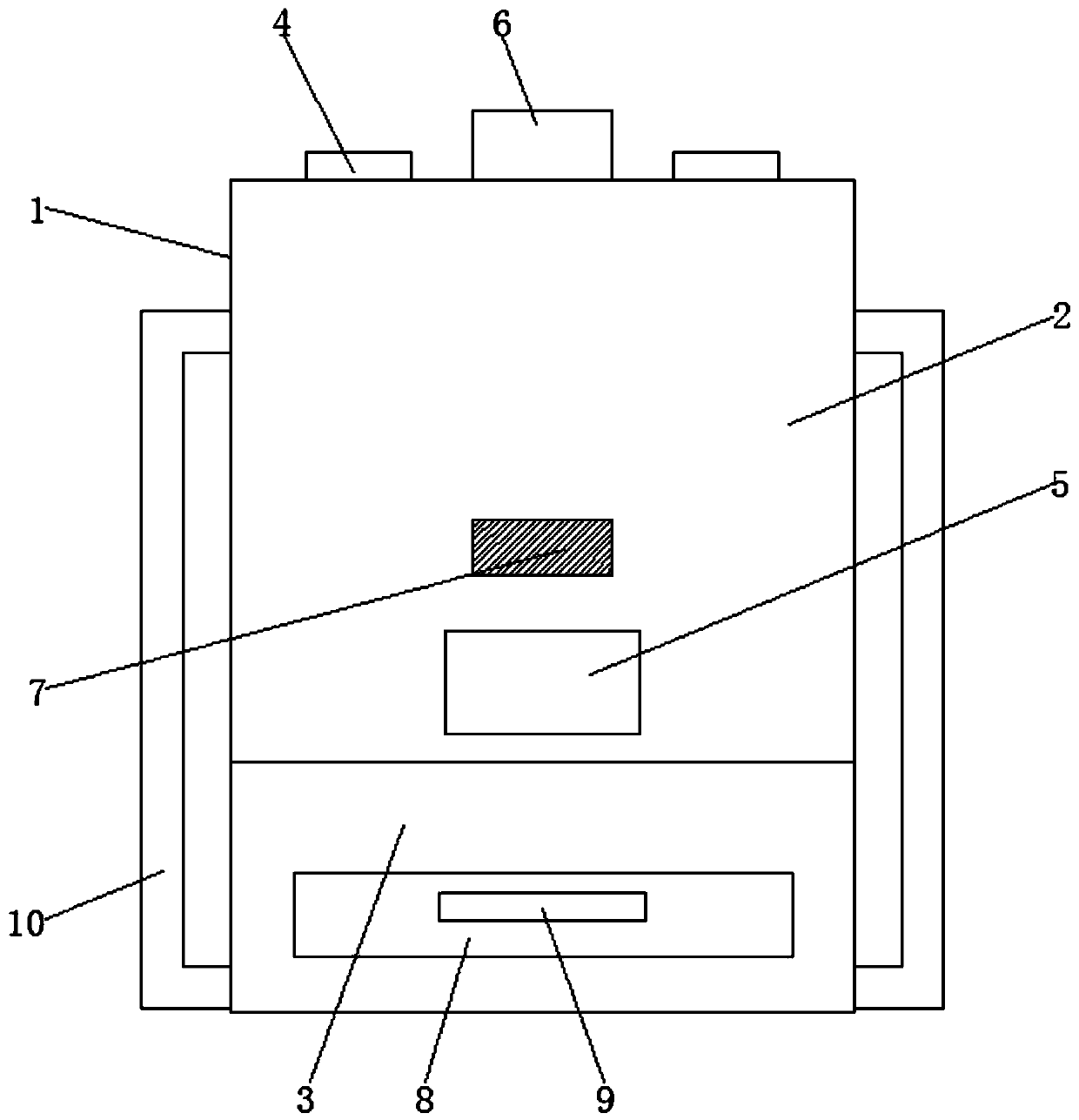

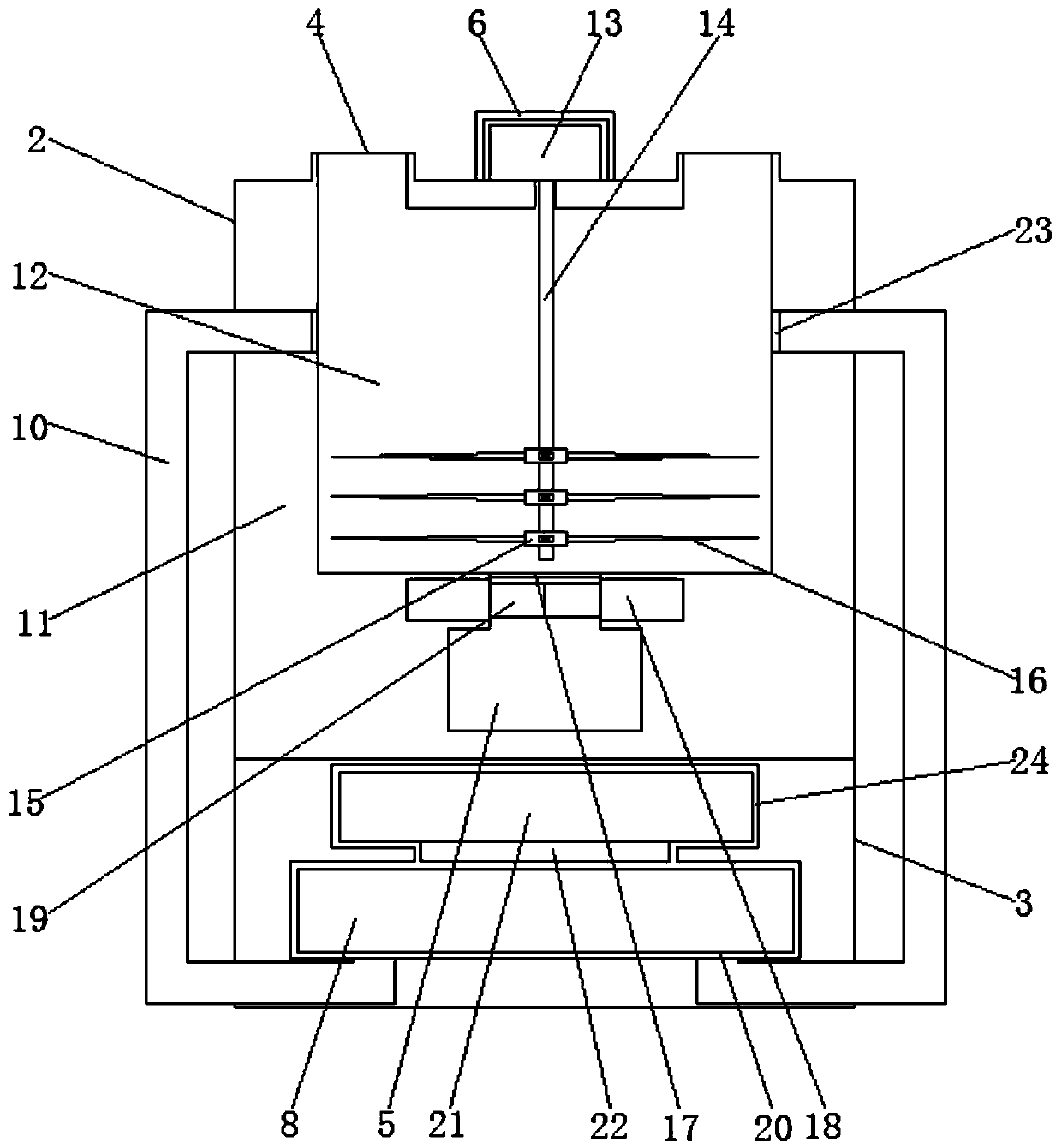

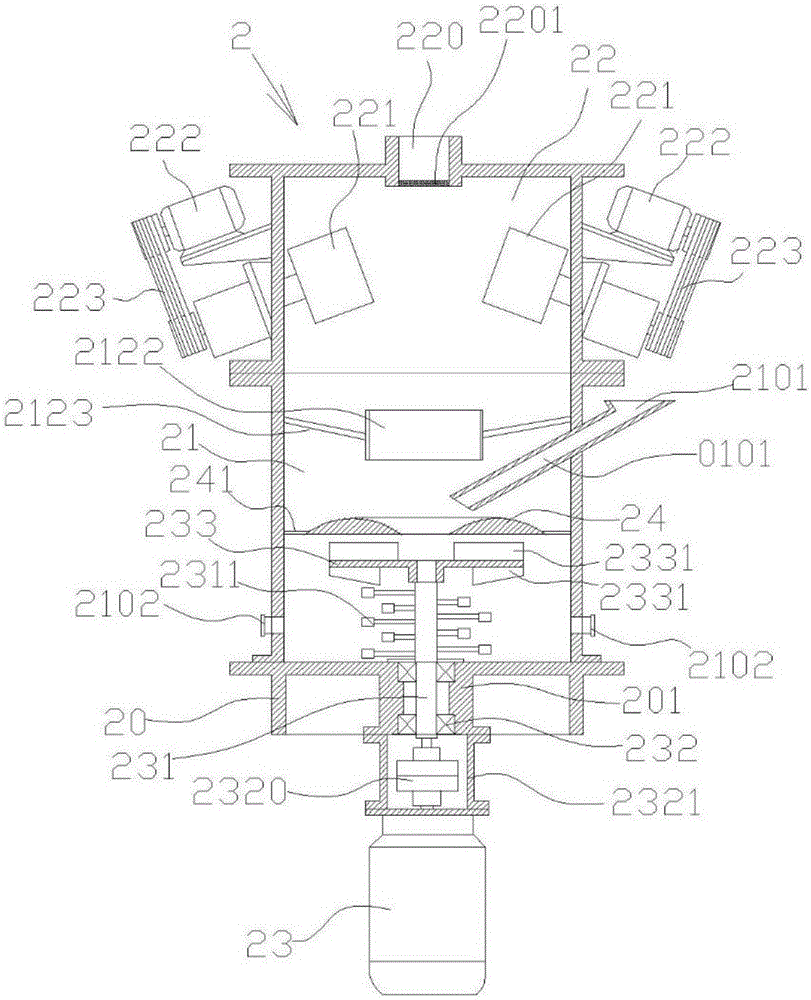

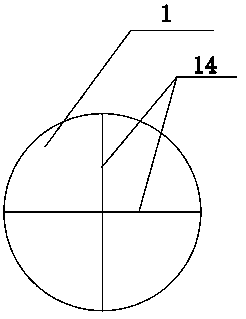

Traditional Chinese medicine crushing machine

ActiveCN107029841AEasy to controlConvenient crushing operationDrying gas arrangementsGrain treatmentsChinese drugMotor protection

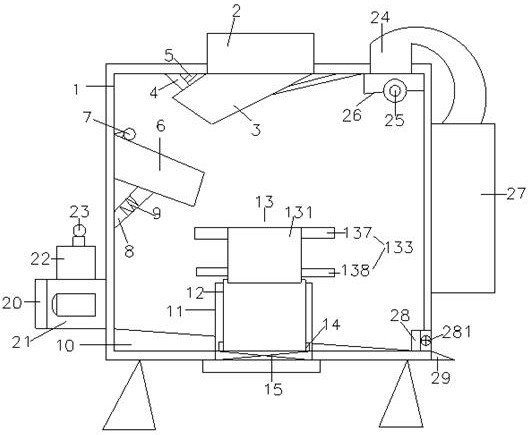

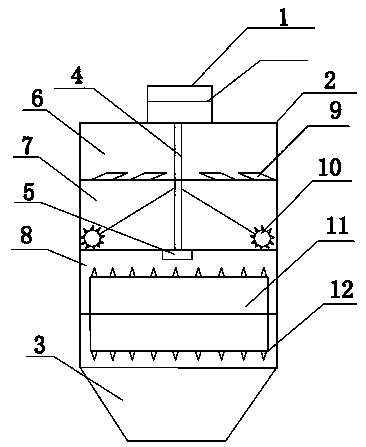

The invention discloses a traditional Chinese medicine crushing machine. The traditional Chinese medicine crushing machine comprises a traditional Chinese medicine crushing machine body, wherein the traditional Chinese medicine crushing machine body comprises a traditional Chinese medicine crushing device; a traditional Chinese medicine drying device is fixedly connected to the bottom of the traditional Chinese medicine crushing device; a traditional Chinese medicine charge pipe is fixedly communicated to the top of the traditional Chinese medicine crushing device; an inner shell is arranged in the traditional Chinese medicine crushing device; a traditional Chinese medicine crushing chamber is formed in the inner shell; the bottom of the traditional Chinese medicine charge pipe penetrates through the inner shell and communicates with the traditional Chinese medicine crushing chamber; and a motor protection cover is fixedly connected to the top of the traditional Chinese medicine crushing device. According to the traditional Chinese medicine crushing machine disclosed by the invention, traditional Chinese medicines in the traditional Chinese medicine crushing chamber are filtered through a filter plate, so that the crushing efficiency of the medicines is increased, only the crushed medicines can pass through the filter plate, the crushing force of the medicines is increased, uniform crushing for the traditional Chinese medicines is achieved, the crushing effect of the medicines is improved, the advantage of fine crushing is achieved, and then the problem of influence on a medicine manufacturing process due to the poor crushing effect of an existing traditional Chinese medicine crushing machine is effectively solved.

Owner:DAYA PHARMA HUIZHOU

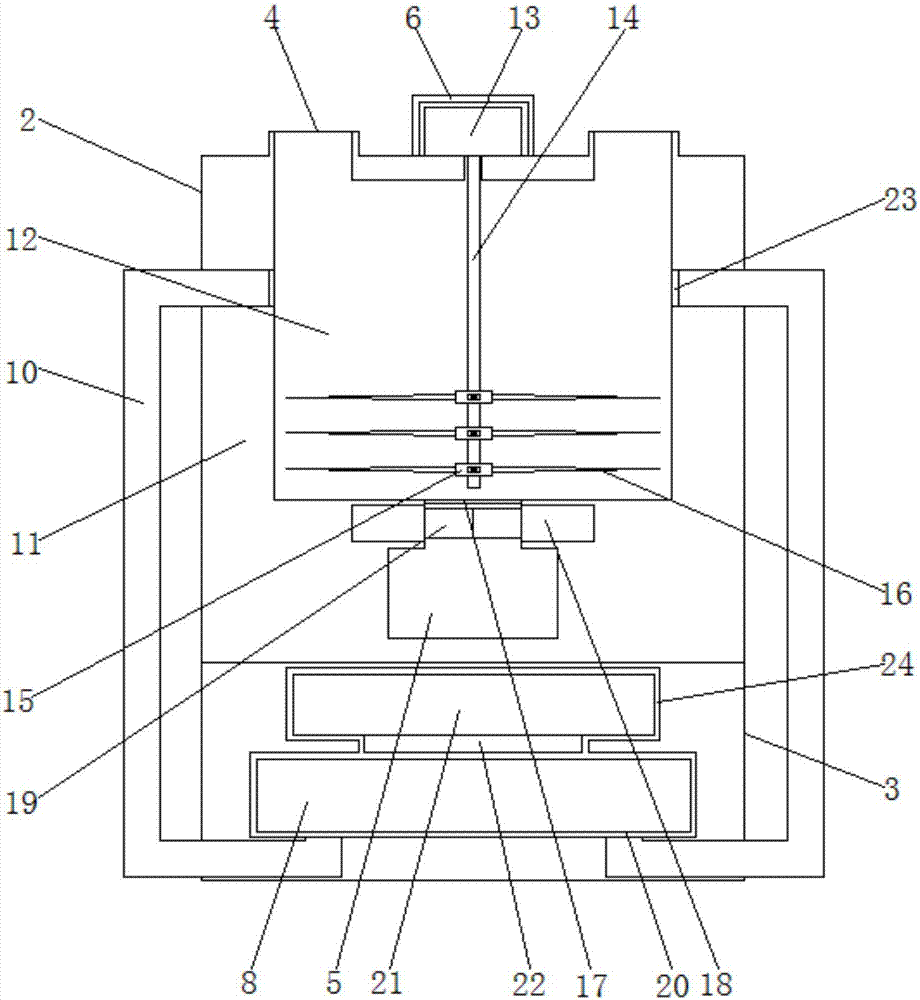

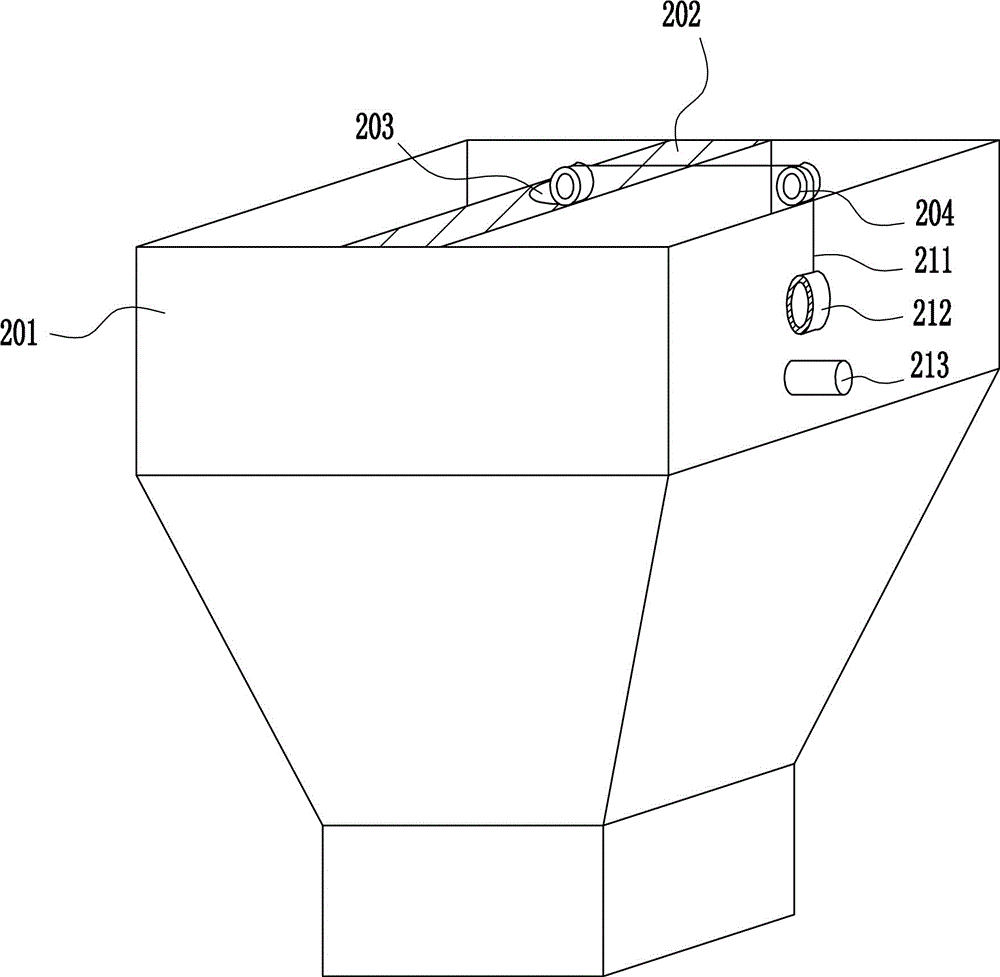

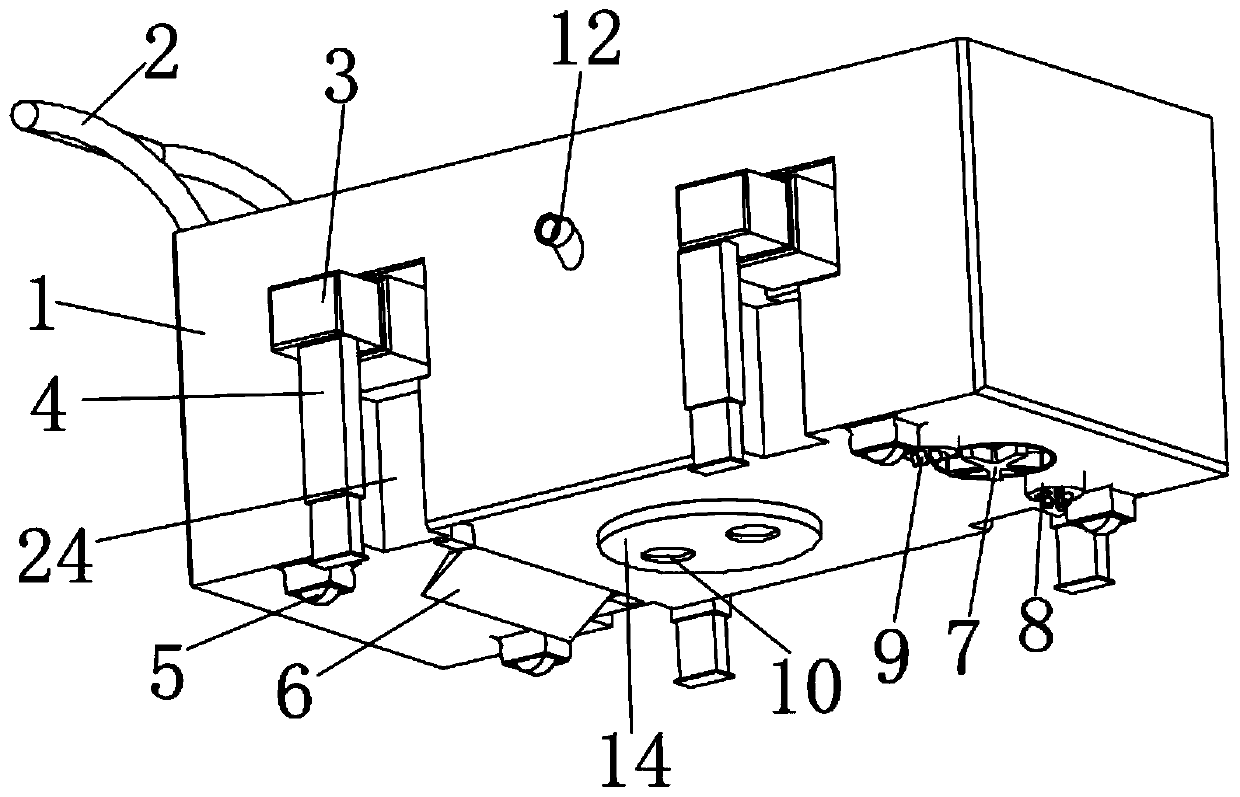

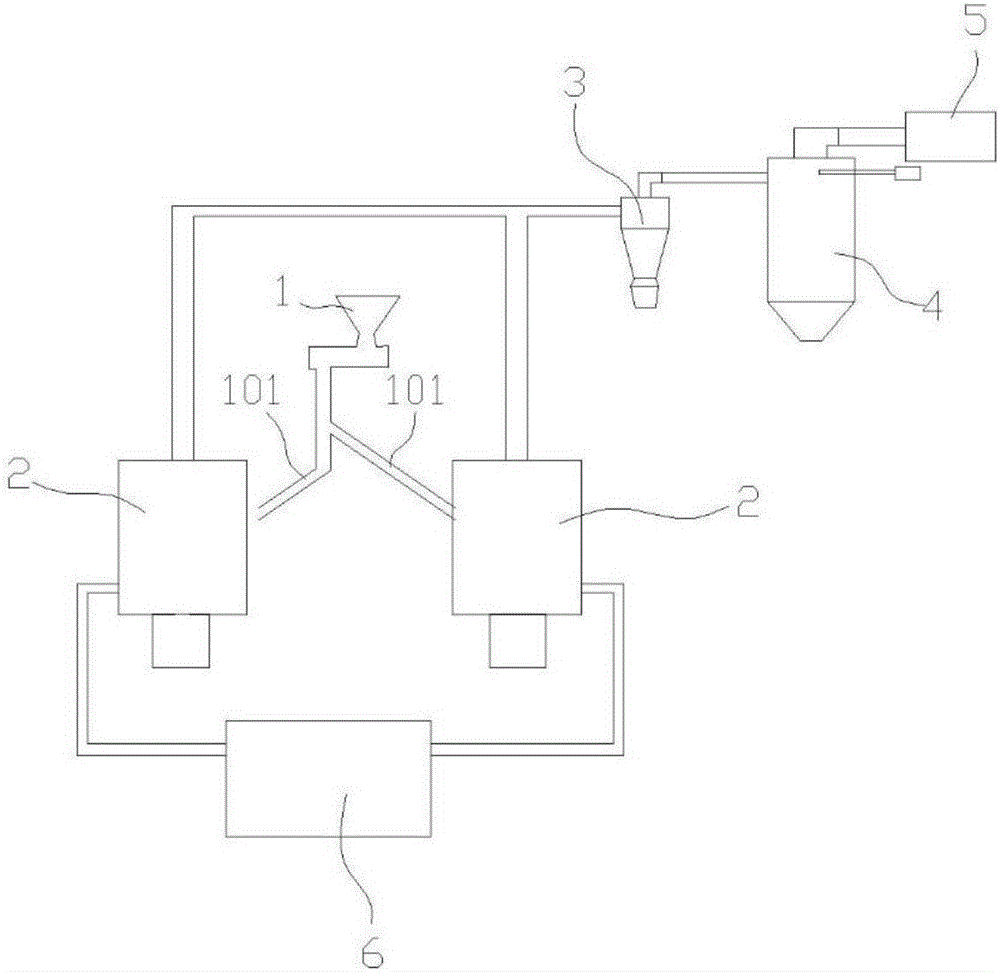

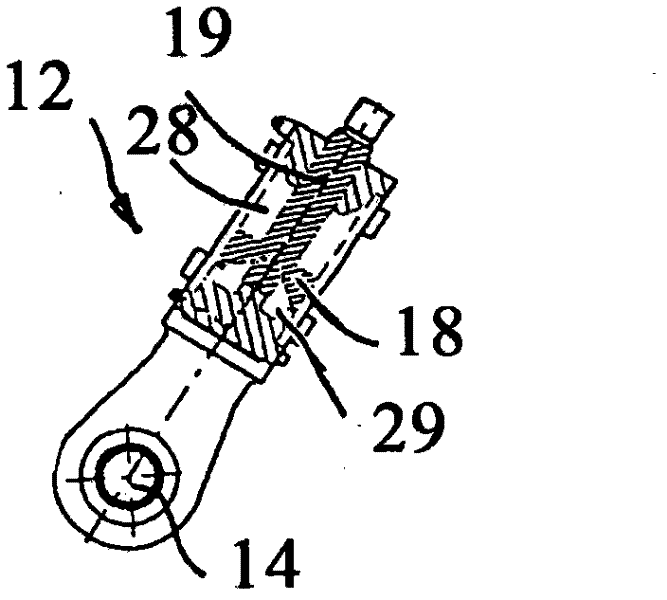

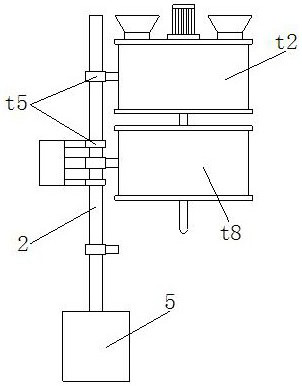

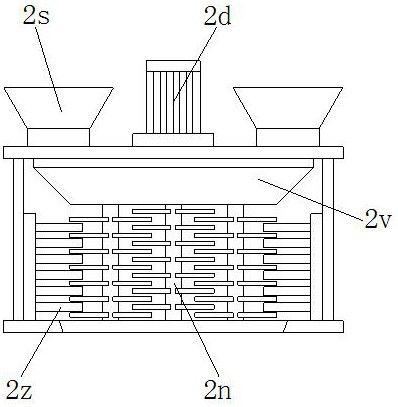

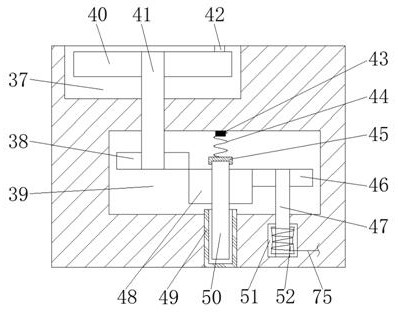

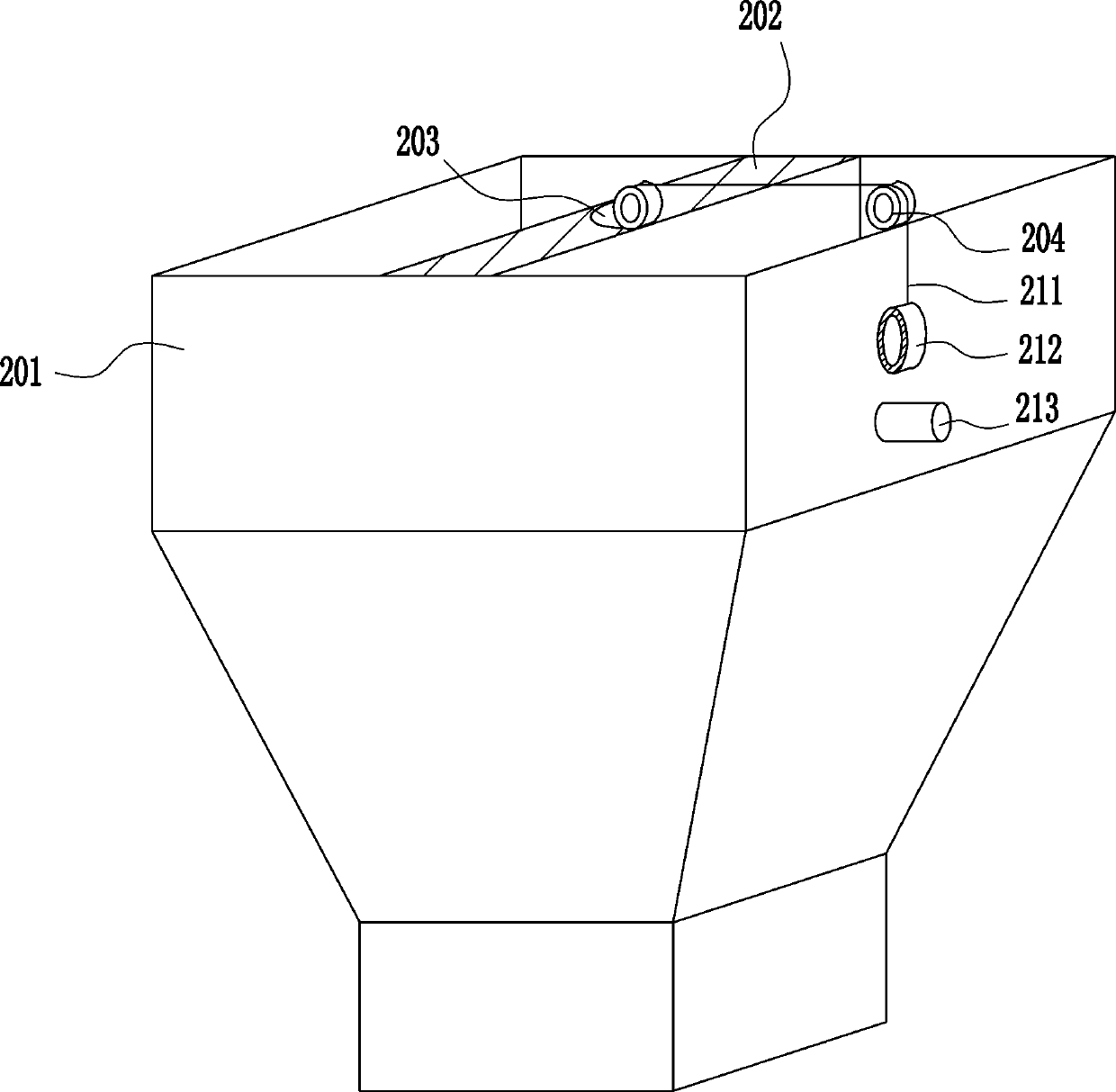

Material rubbing and squeezing smashing mechanical device

ActiveCN105618226APrevent material from leaking into the feeding pipelineGood crushing effectGrain treatmentsRubbingShovel

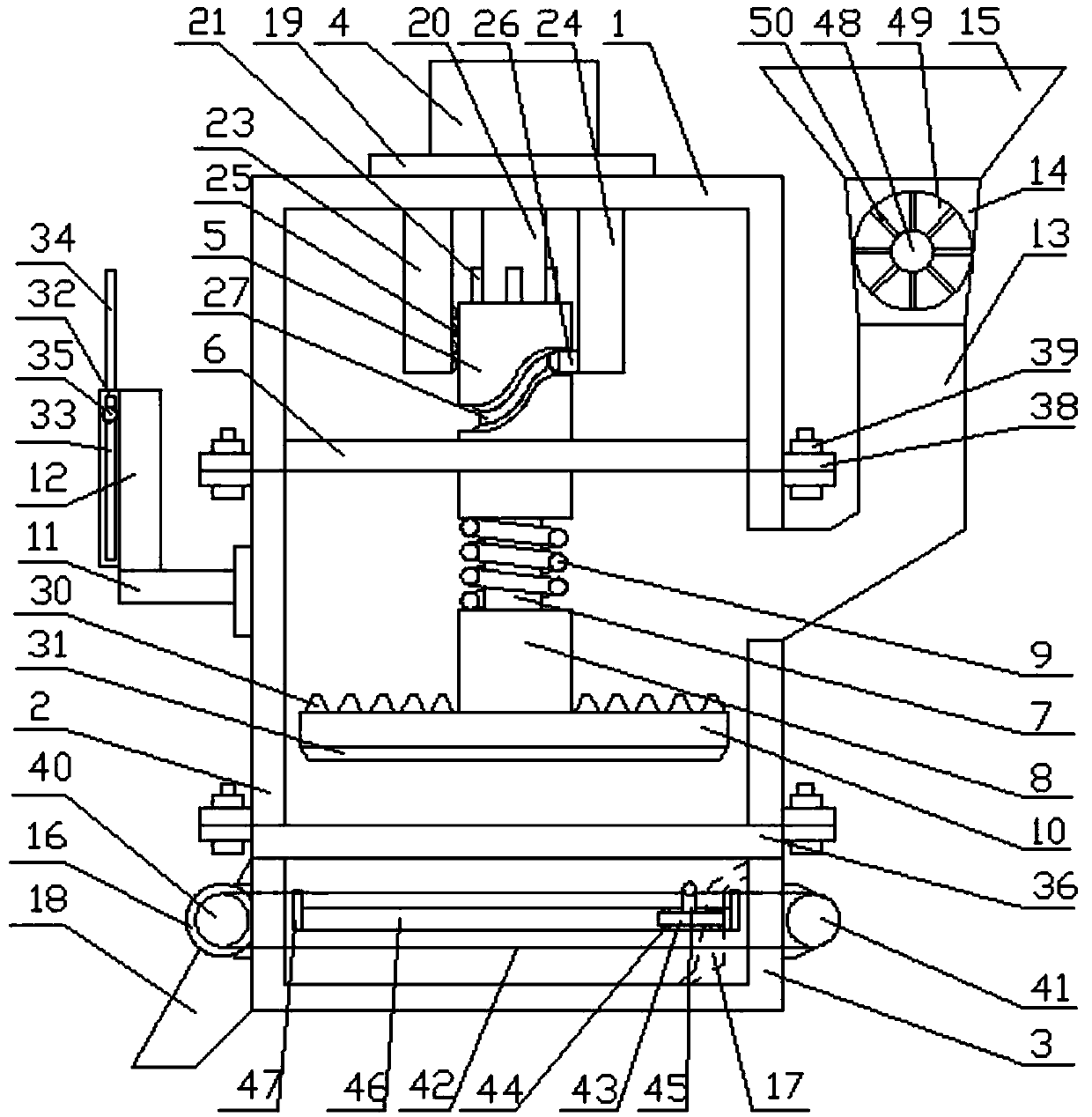

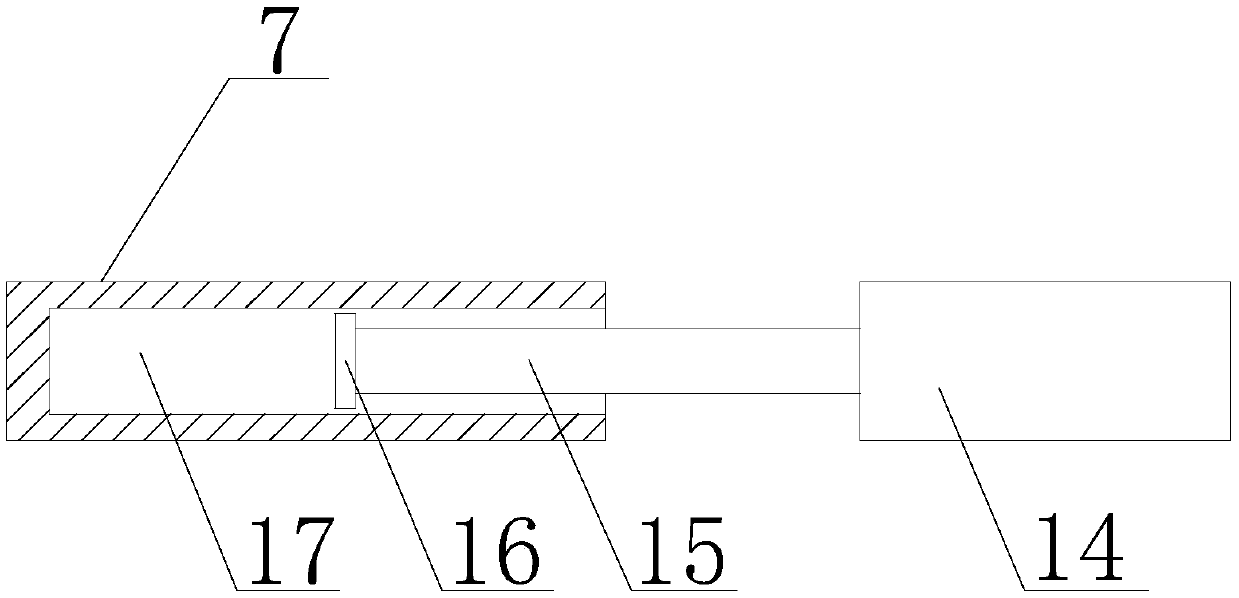

The invention discloses a material rubbing and squeezing smashing mechanical device which comprises an upper device shell, a middle device shell and a lower device shell. A smashing motor is arranged on the upper portion of the upper device shell and matched with a rotating shaft. An ash damper is arranged in the upper device shell. The rotating shaft is matched with a connector through a telescopic rod which is sleeved with a spring. The end of the connector is connected with a rotating pulverizing disc. One side of the middle device shell is connected with a controller through a connecting frame, and the other side of the middle device shell is connected with a feeding pipeline. A feeding device is arranged at the end of the feeding pipeline and communicates with a feeding hopper. One side of the lower device shell is provided with a material clearing motor and a discharge port, and the material clearing motor is matched with a material clearing shovel through a transmission device. When the material rubbing and squeezing smashing mechanical device is used, materials can be smashed under the combined action of downward pressure and rubbing force, the smashing intensity is high, and the smashing effect is good; and in addition, the material clearing device is arranged, so that material clearing is convenient and rapid, and working efficiency is high.

Owner:滁州爱沃富光电科技有限公司

Efficient garbage crushing equipment

InactiveCN105728126AImprove working environmentGood environmental effectGrain treatmentsLow speedEngineering

The invention discloses efficient garbage crushing equipment which comprises a machine body. A main shaft is rotatably mounted in the machine body, and crushing blades extending outwards are evenly distributed on the circumferential face of the main shaft. Adjusting toothed plates of an annular structure are arranged outside the main shaft and fixed to the machine body in the mode that the adjusting toothed plates can stretch to the center and retract through oil cylinders. Crushing blades are evenly distributed on the inner wall of each adjusting toothed plate. A feed hopper is mounted at the top end of the machine body, materials needing to be processed enter the machine body from the feed hopper, the main shaft rotates at a low speed under the action of a main motor, and the main motor is fixedly mounted outside the machine body. A discharging cavity is formed in the bottom of the machine body, the side wall of the discharging cavity communicates with a pipeline, and the far end of the pipeline is connected with a dust collecting device.

Owner:XIAN ALL SAFE SCI & TECH

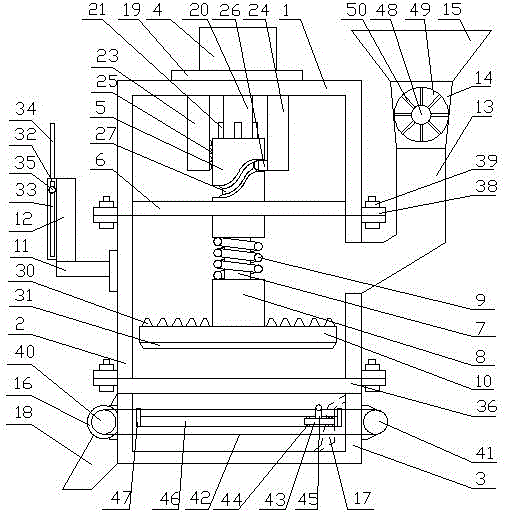

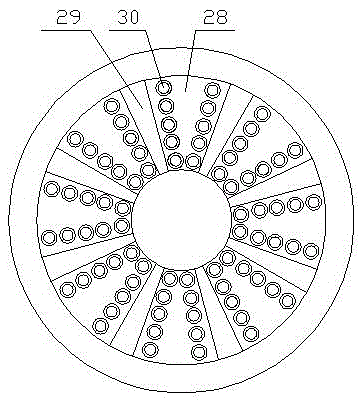

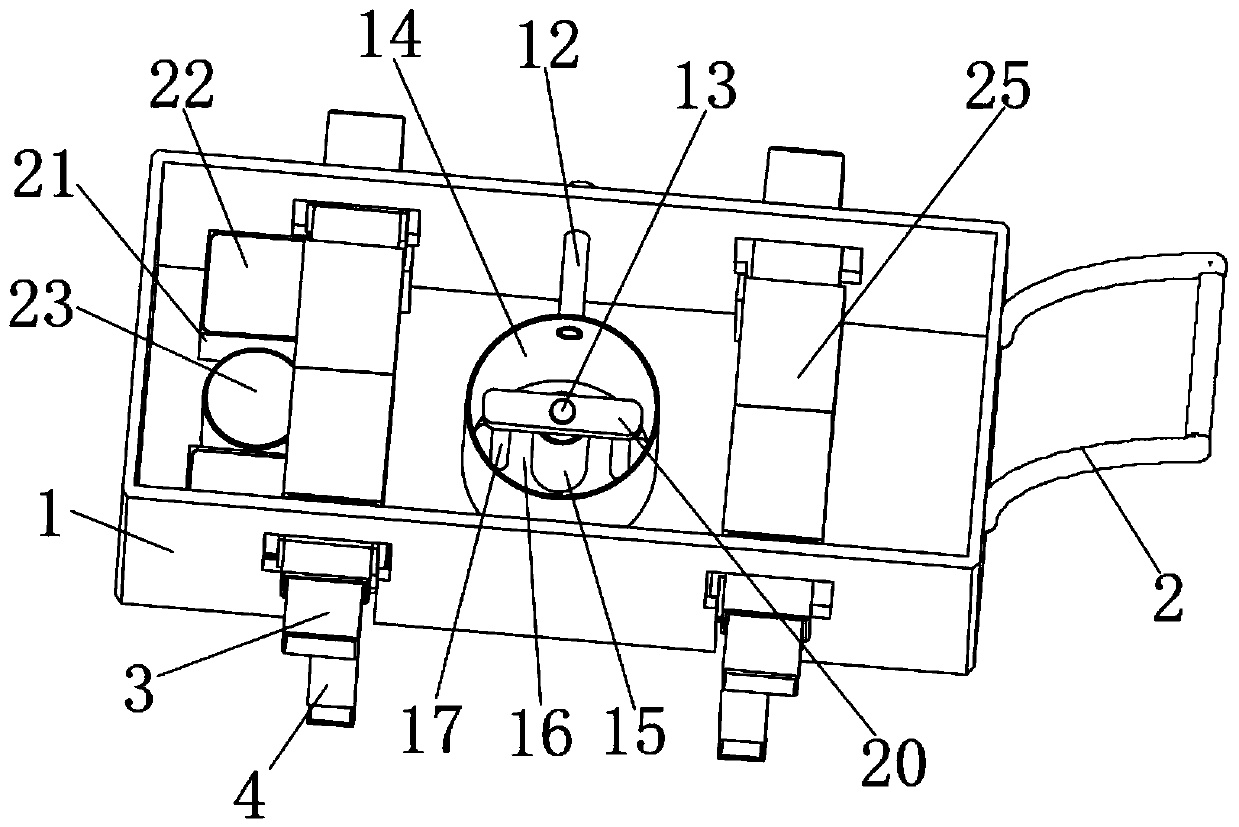

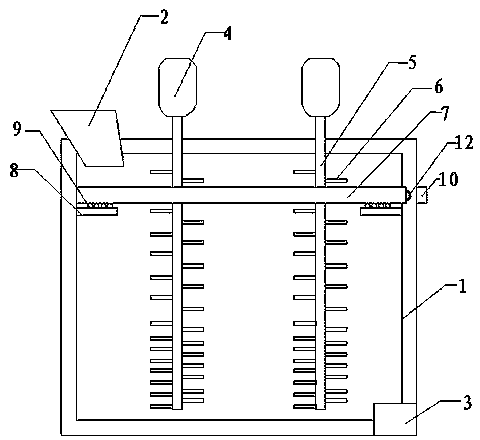

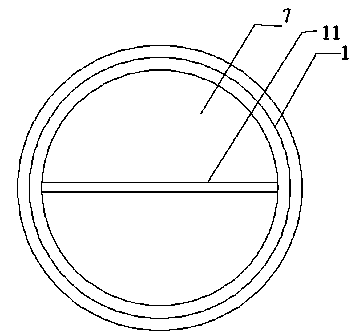

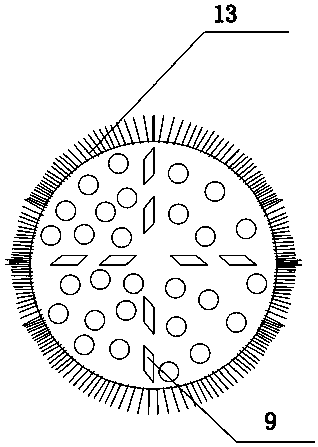

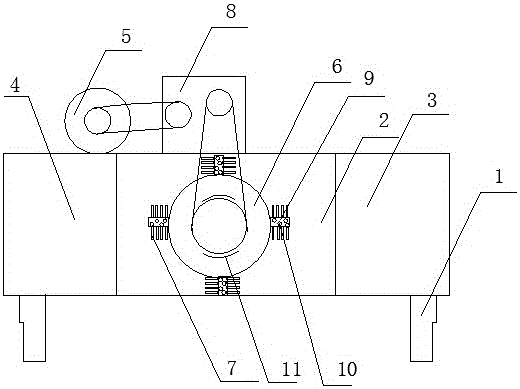

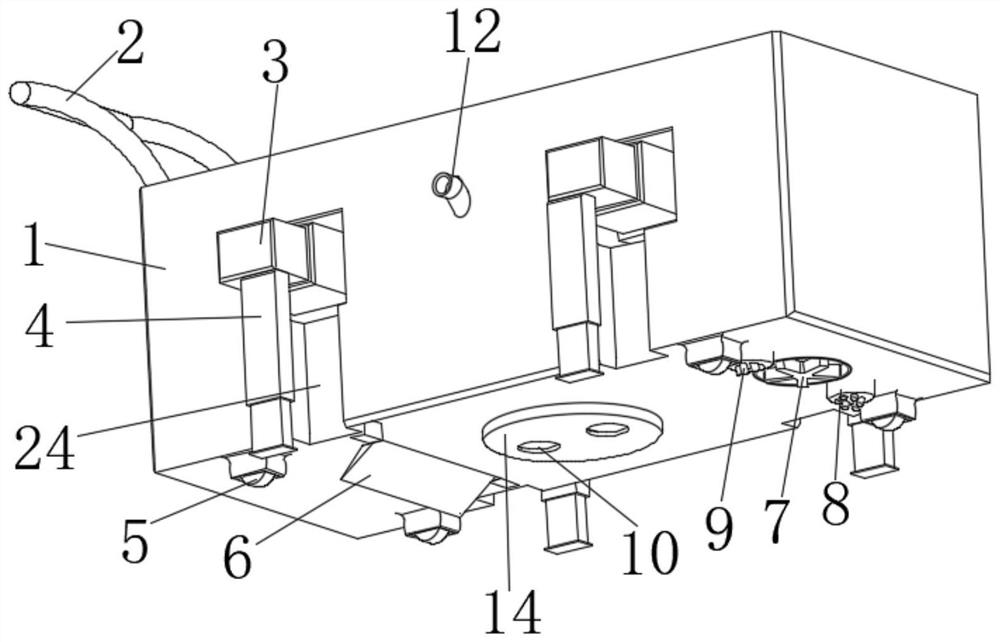

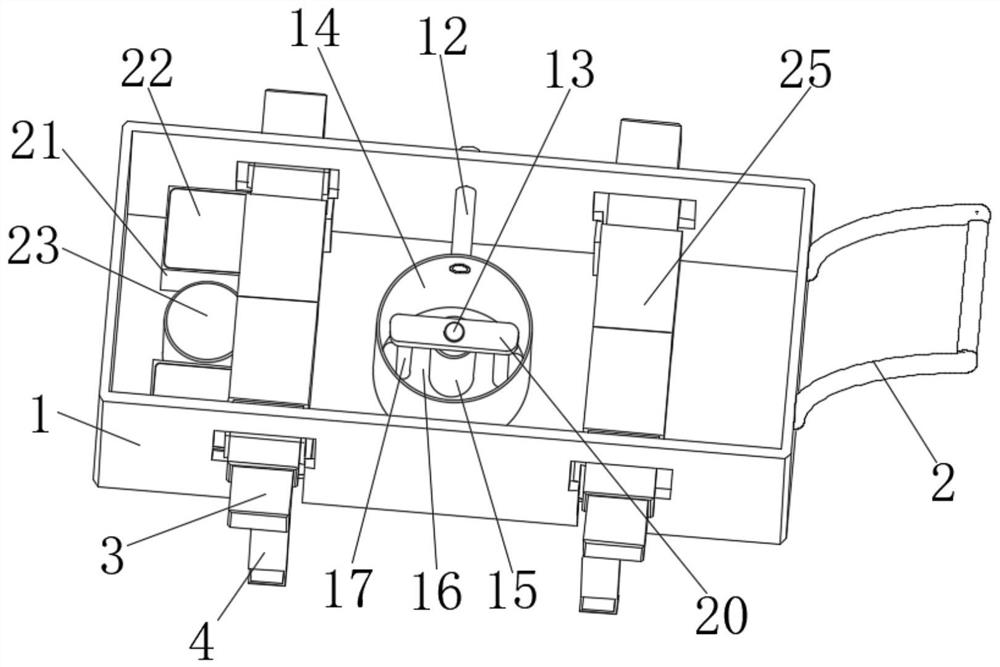

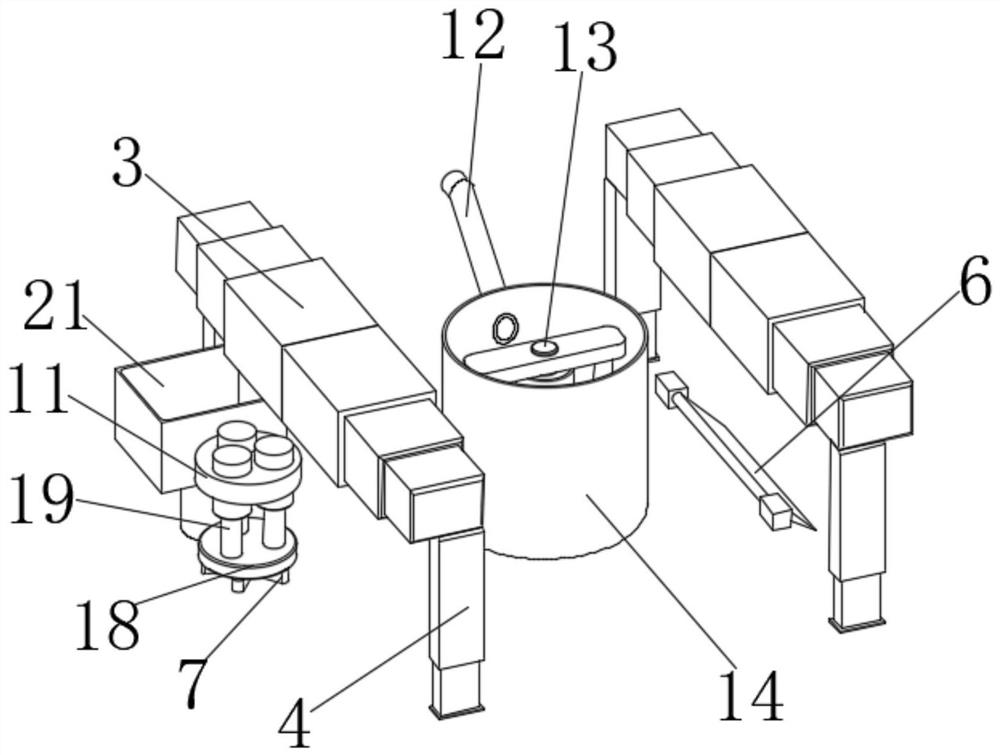

Rubbish disposer for home kitchen and bathroom

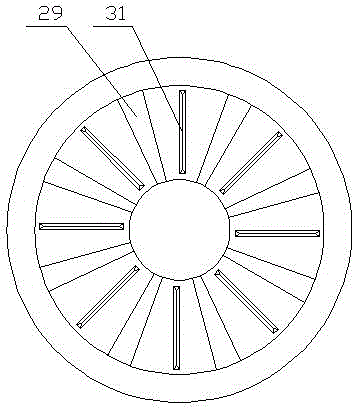

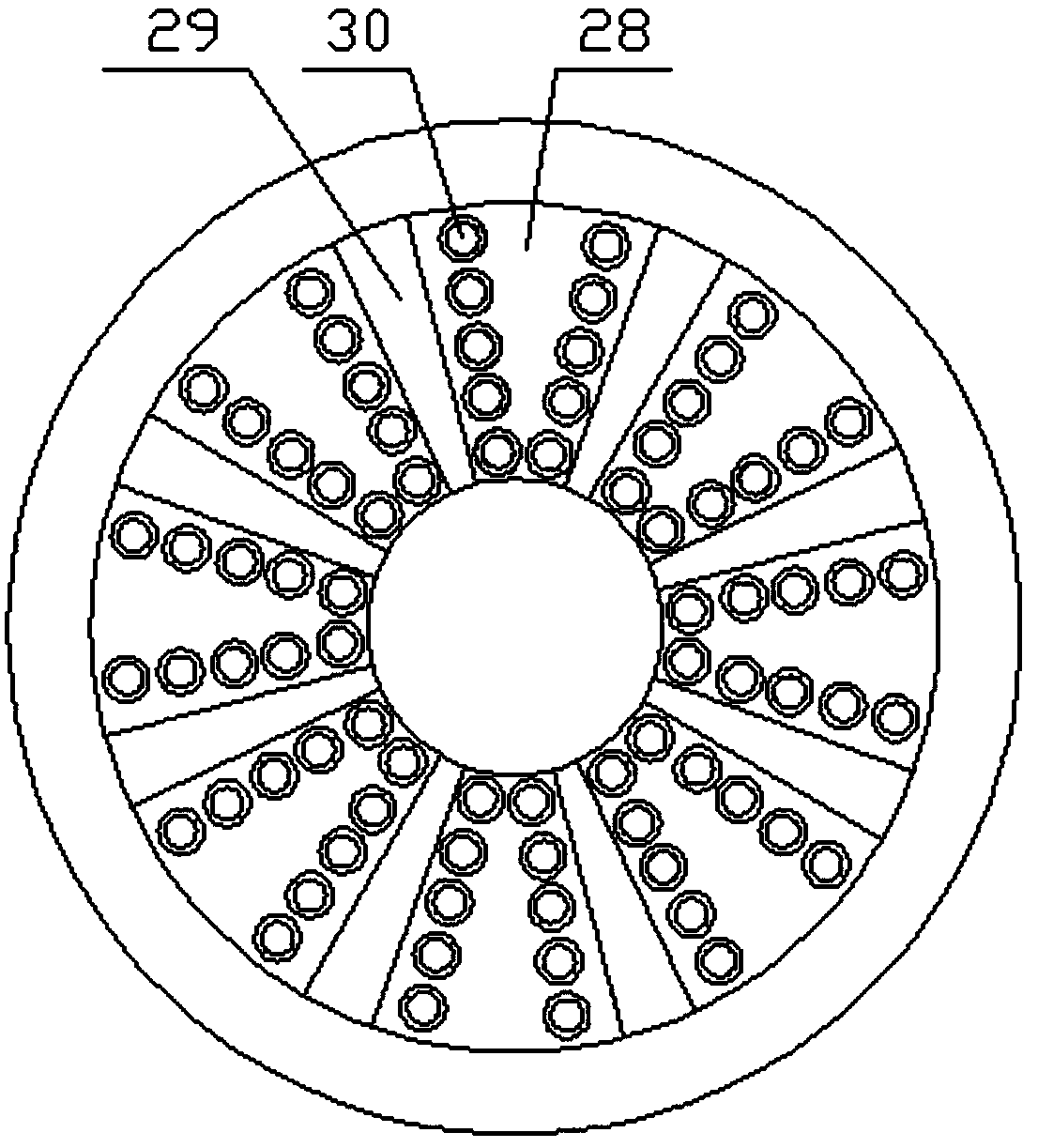

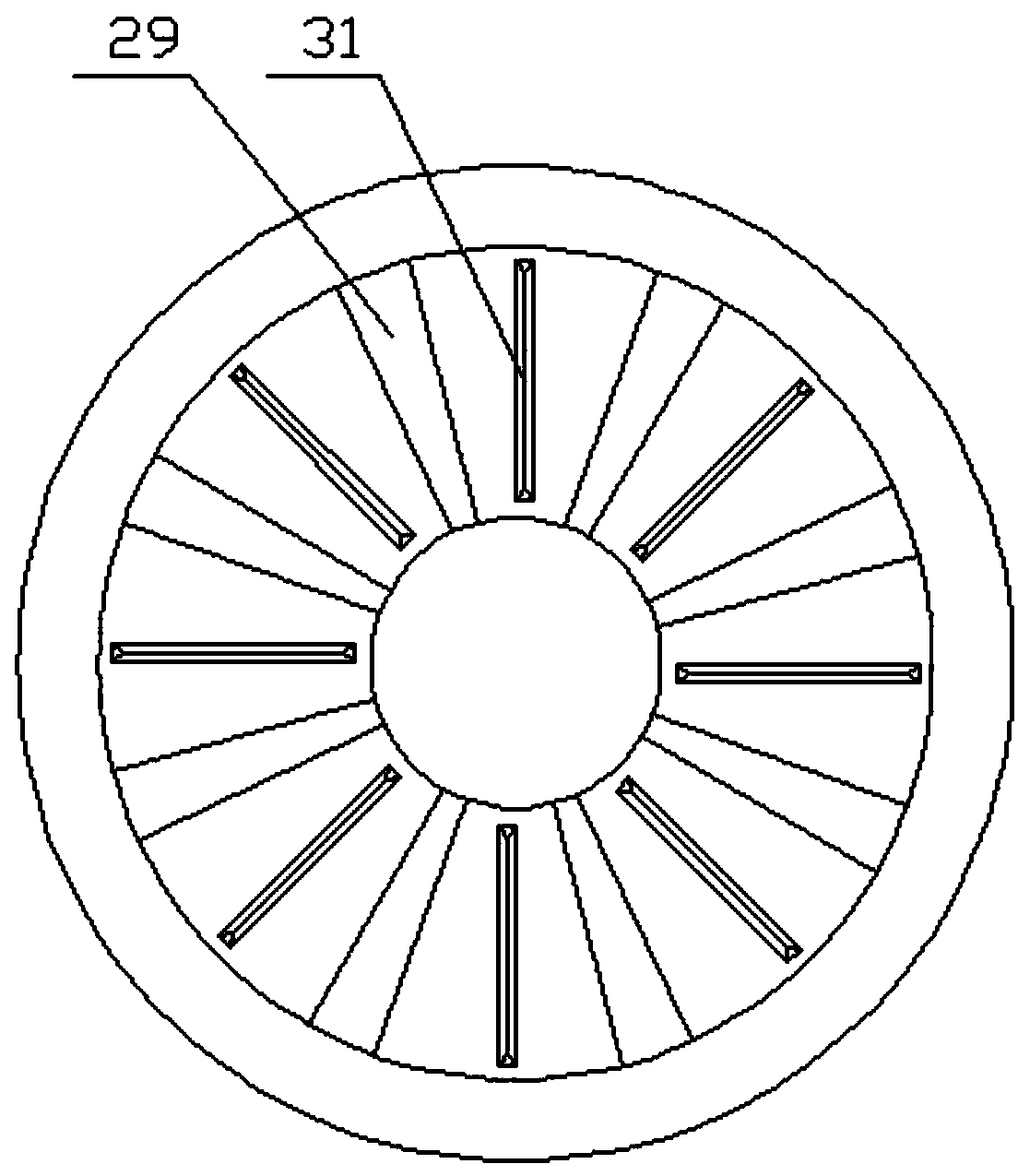

ActiveCN105312130AImprove crushing abilityIncrease crushing powerGrain treatmentsFiberHome environment

The invention discloses a rubbish disposer for a home kitchen and bathroom. The kitchen and bathroom rubbish disposer is composed of a convenient feeding mechanism, a cutter disk and inner ring smashing system and a water inlet-outlet system which is electrically controlled by a single chip microcomputer. After feeding, the whole process is completed automatically. After a foot plate is stepped on, a separation plate is pulled to be opened through a steel wire, and rubbish is put into a cavity of an upper box body from a feed inlet. The foot plate is loosened, and the separation plate is reset. The feed inlet is closed, and an electric control program is started. Flowing-in and flowing-out of water are controlled through electromagnetic valves. A cutter disk is driven through a motor to rotate while the water inlet electromagnetic valve is opened. The cutter disk is provided with 3-6 cutter blades through which the rubbish can be smashed. An inner ring is provided with a multi-hole cutting edge. Fibrous matter which is difficult to smash is shredded under the combined action of the multi-hole cutting edge and the cutter blades on the cutter disk. The lower end of the inner ring is provided with a groove, and an annular cavity is formed by the inner ring and the inner wall of a box body, so that up-down circulation of water flow is facilitated and the rubbish is smashed multiple times. After smashing, the water outlet electromagnetic valve is opened, and the rubbish is discharged from a water outlet. The rubbish disposer can be used for disposing kitchen waste vegetable leaves, plastic bags, baby diapers, sanitary pads and other rubbish containing fibers, and the problems that sewers of the kitchen, the bathroom and a toilet are blocked due to the rubbish are solved, so that the home environment is improved.

Owner:XIANGTAN UNIV

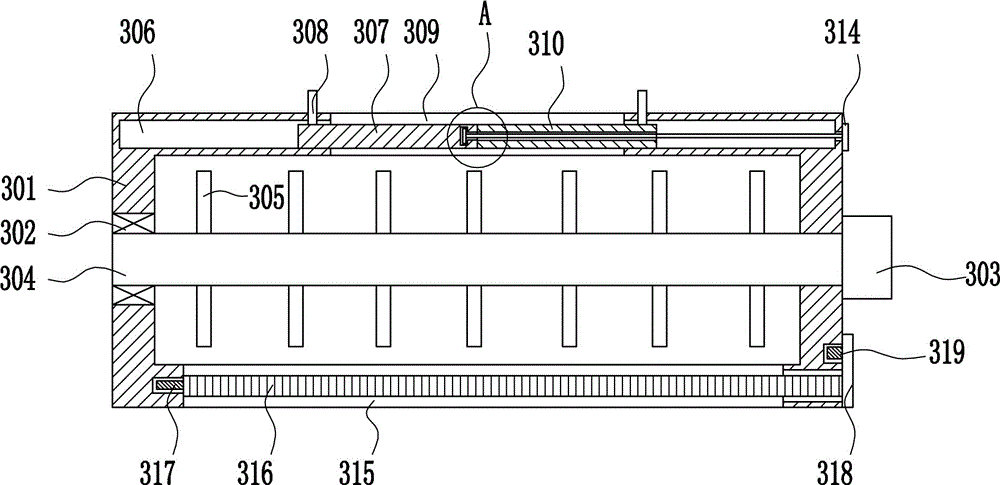

Novel waste accumulator fully crushing equipment

ActiveCN106733033ATo achieve the purpose of stopping feedingEasy to dredgeGrain treatmentsWaste management

Owner:烟台金潮宇科蓄电池有限公司

A traditional Chinese medicine grinder

ActiveCN107029841BEasy to controlConvenient crushing operationDrying gas arrangementsGrain treatmentsCrusherTraditional medicine

The invention discloses a traditional Chinese medicine crushing machine. The traditional Chinese medicine crushing machine comprises a traditional Chinese medicine crushing machine body, wherein the traditional Chinese medicine crushing machine body comprises a traditional Chinese medicine crushing device; a traditional Chinese medicine drying device is fixedly connected to the bottom of the traditional Chinese medicine crushing device; a traditional Chinese medicine charge pipe is fixedly communicated to the top of the traditional Chinese medicine crushing device; an inner shell is arranged in the traditional Chinese medicine crushing device; a traditional Chinese medicine crushing chamber is formed in the inner shell; the bottom of the traditional Chinese medicine charge pipe penetrates through the inner shell and communicates with the traditional Chinese medicine crushing chamber; and a motor protection cover is fixedly connected to the top of the traditional Chinese medicine crushing device. According to the traditional Chinese medicine crushing machine disclosed by the invention, traditional Chinese medicines in the traditional Chinese medicine crushing chamber are filtered through a filter plate, so that the crushing efficiency of the medicines is increased, only the crushed medicines can pass through the filter plate, the crushing force of the medicines is increased, uniform crushing for the traditional Chinese medicines is achieved, the crushing effect of the medicines is improved, the advantage of fine crushing is achieved, and then the problem of influence on a medicine manufacturing process due to the poor crushing effect of an existing traditional Chinese medicine crushing machine is effectively solved.

Owner:DAYA PHARMA HUIZHOU

Road depression rapid repairing device

ActiveCN111270595APromote repairRepair firmRoads maintainenceElectric machineryStructural engineering

The invention discloses a road depression rapid repairing device, and relates to the technical field of road maintenance. The road depression rapid repairing device comprises a vehicle body, a hydraulic rod cylinder is arranged on one side in the vehicle body, a first hydraulic rod with a downward output end and extending to the lower portion of the vehicle body is arranged in the hydraulic rod cylinder, the output end of the first hydraulic rod is connected with a second motor, and the output end of the second motor is connected with a brush. The brush driven by the second motor is arranged at the front end of the bottom of the vehicle body, water pipes and water spraying heads are arranged on the two sides, the concave to-be-repaired part of the road can be cleaned and wetted, and this is more conducive to road repair; and the two hydraulic sets are arranged at the two ends of the vehicle body correspondingly, the supporting legs are arranged at the bottoms of the tail ends of the hydraulic sets correspondingly, the ground can be fixed through the hydraulic devices, the repairing process is more stable, the scraping plate is arranged at the bottom of the vehicle body and can scrape the vehicle body flat, and repairing operation is convenient.

Owner:郑州市公路工程公司

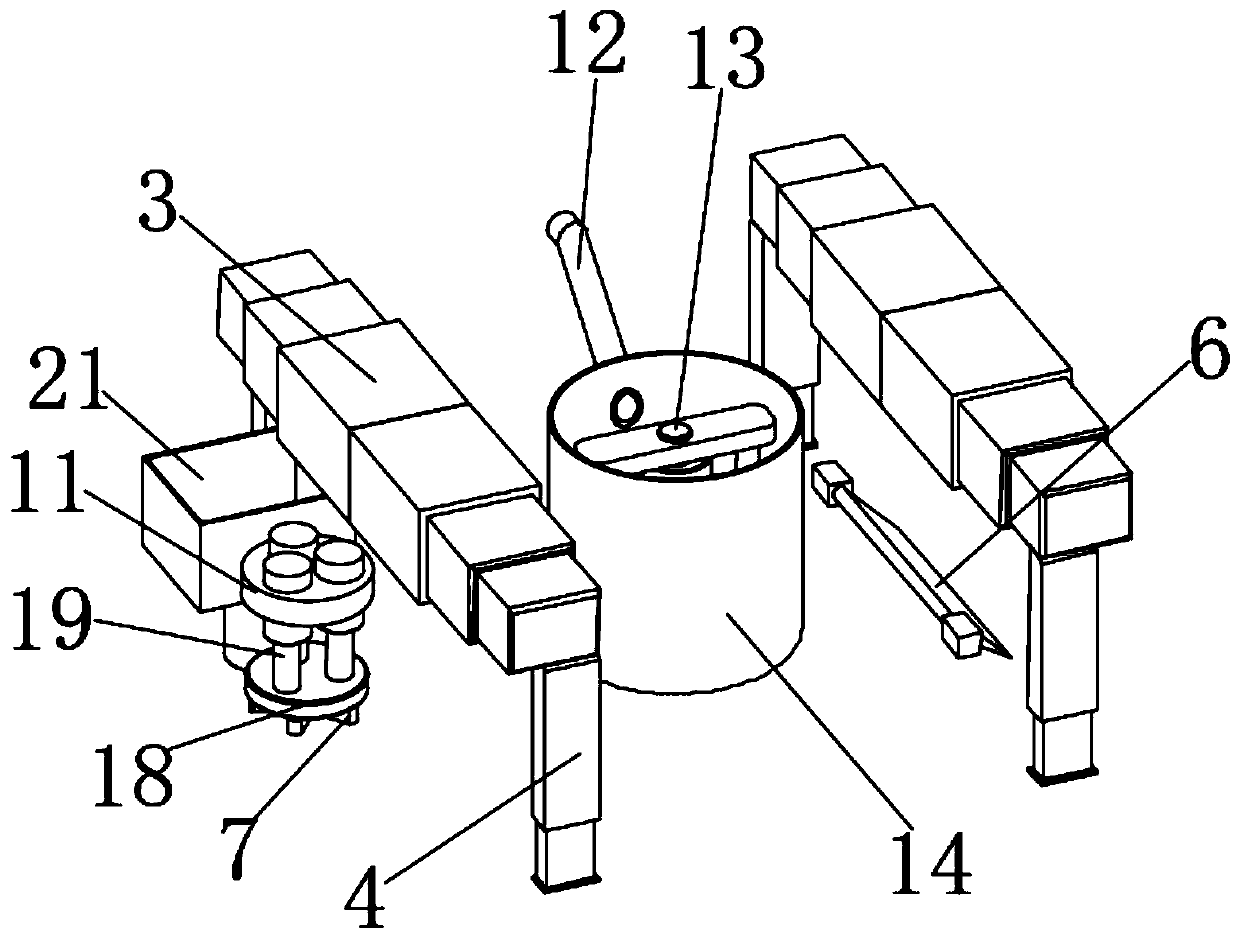

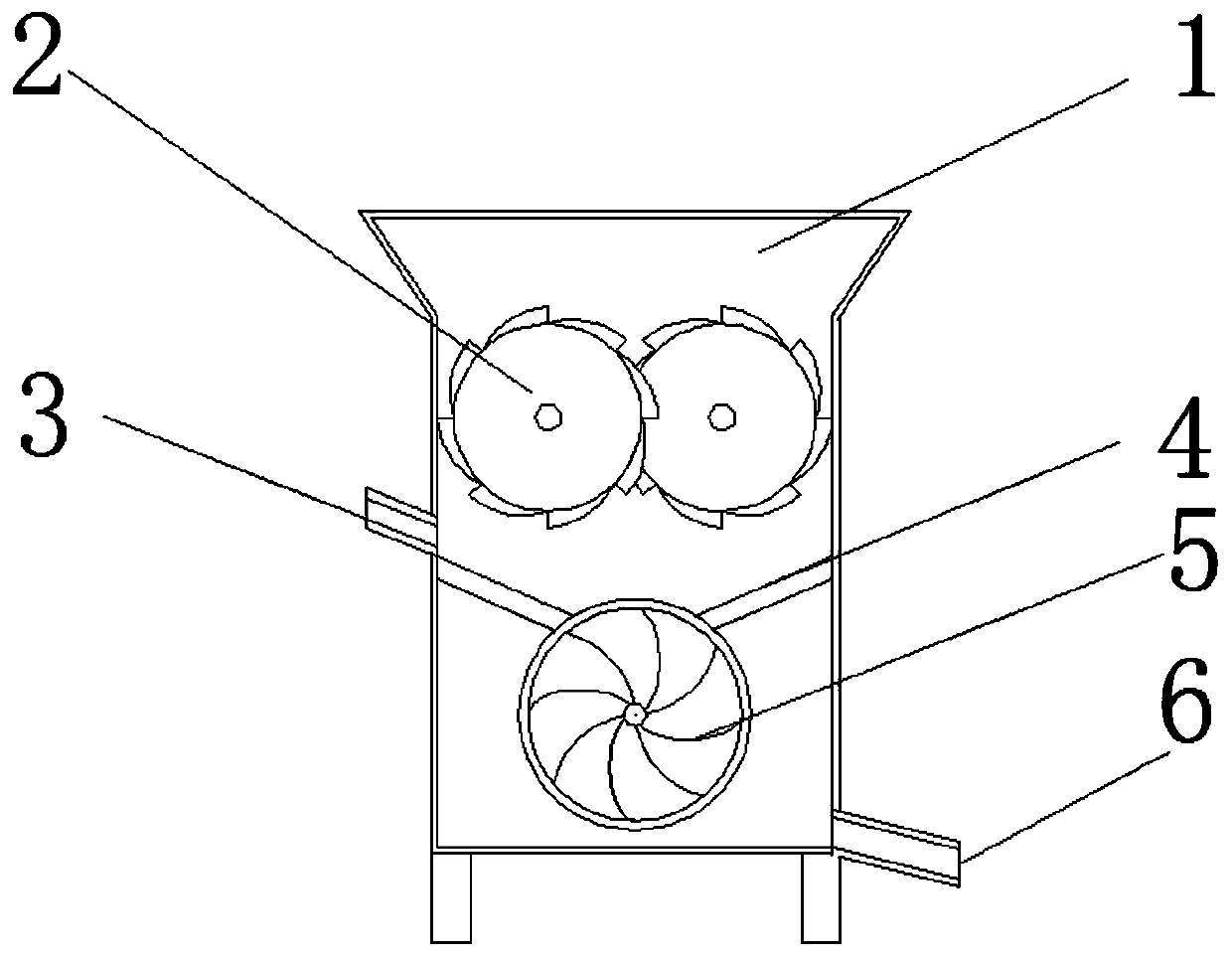

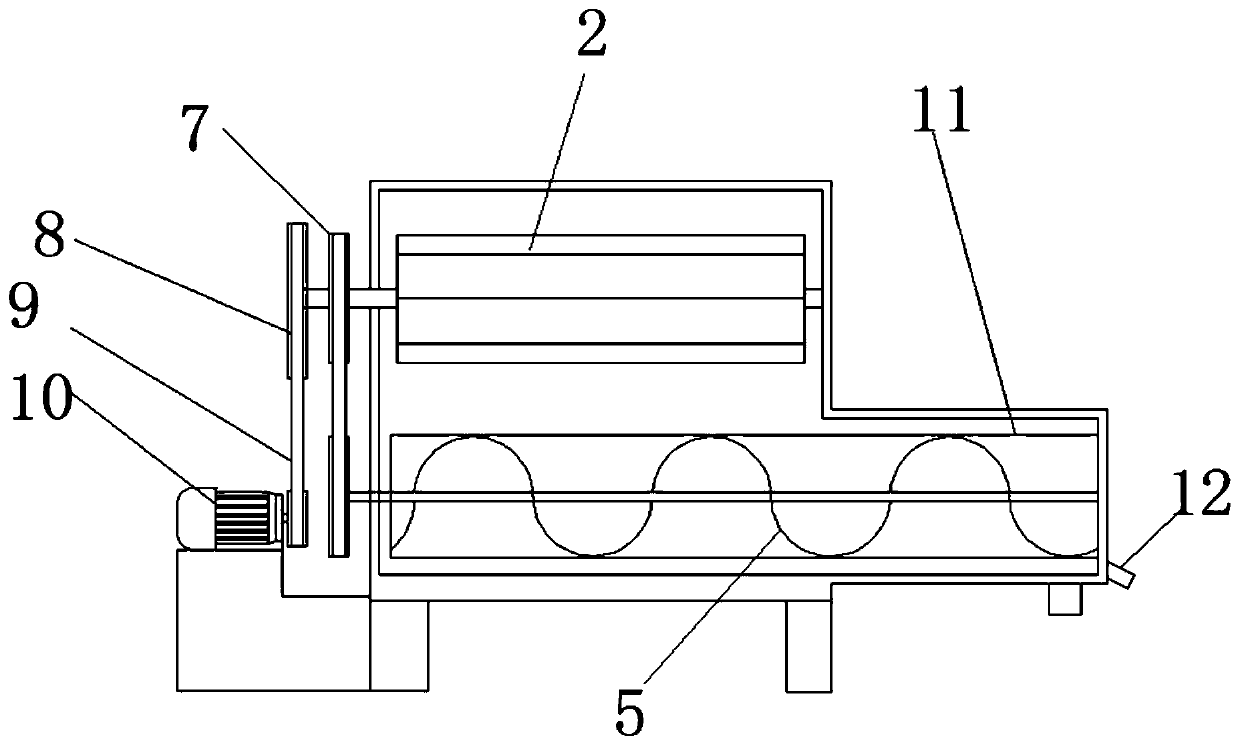

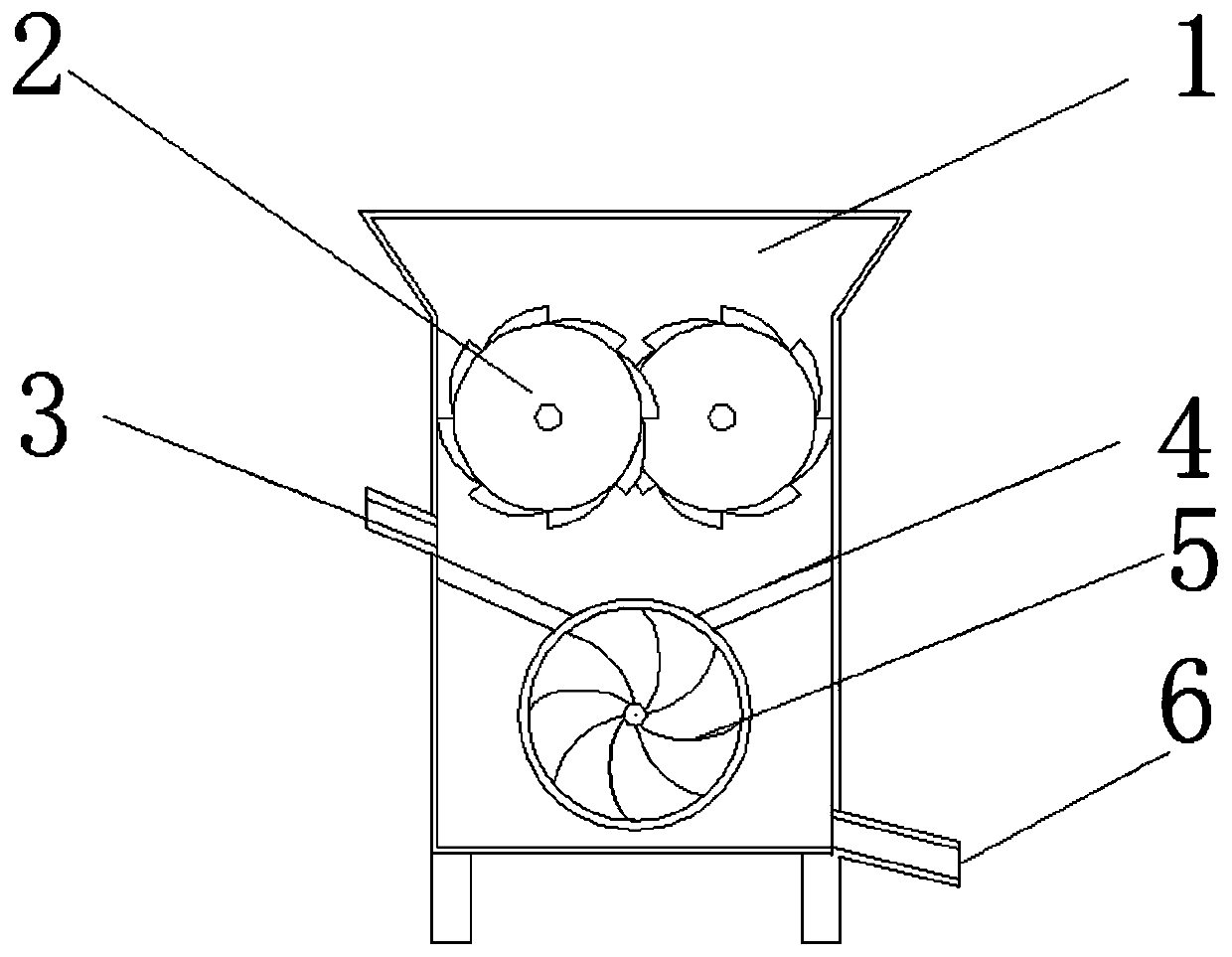

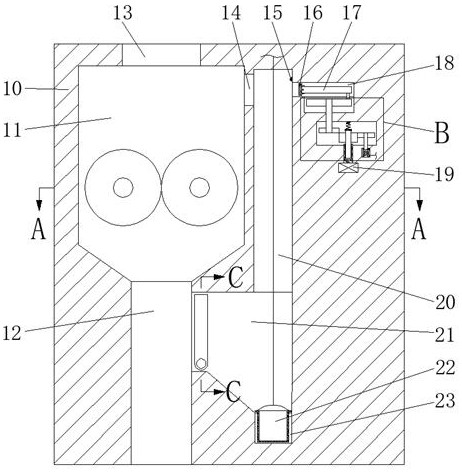

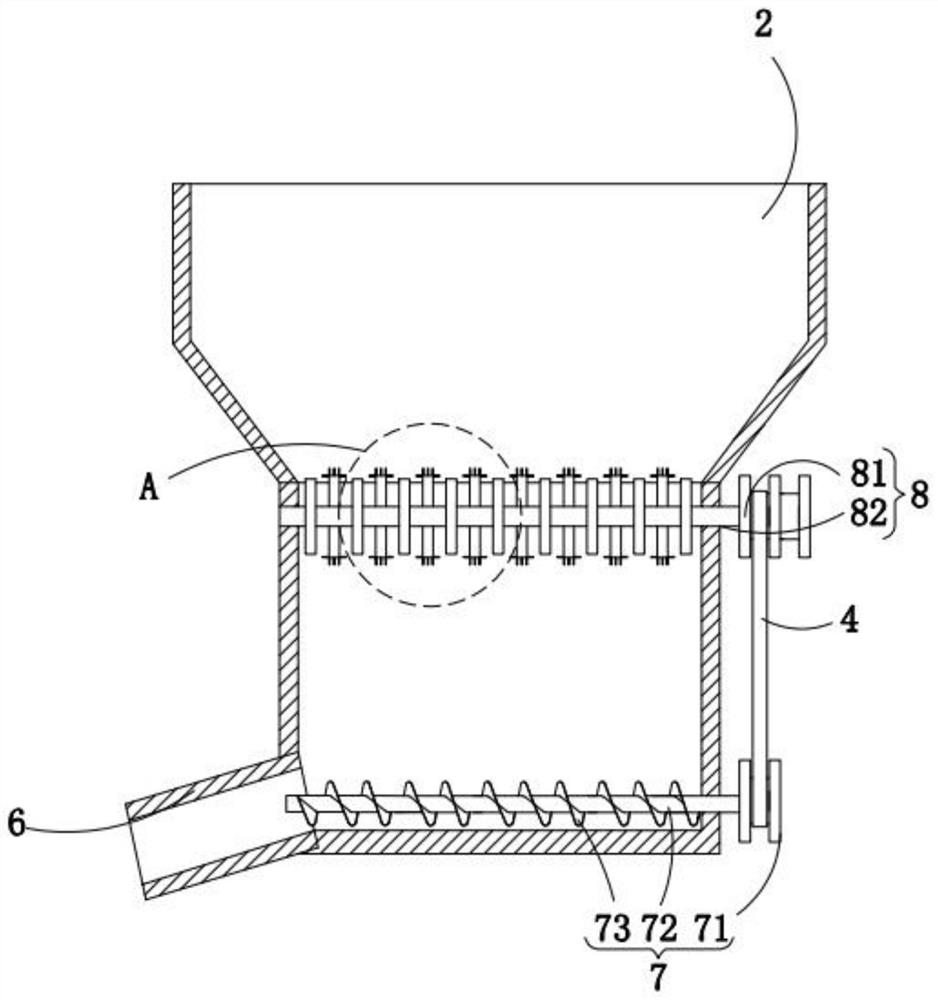

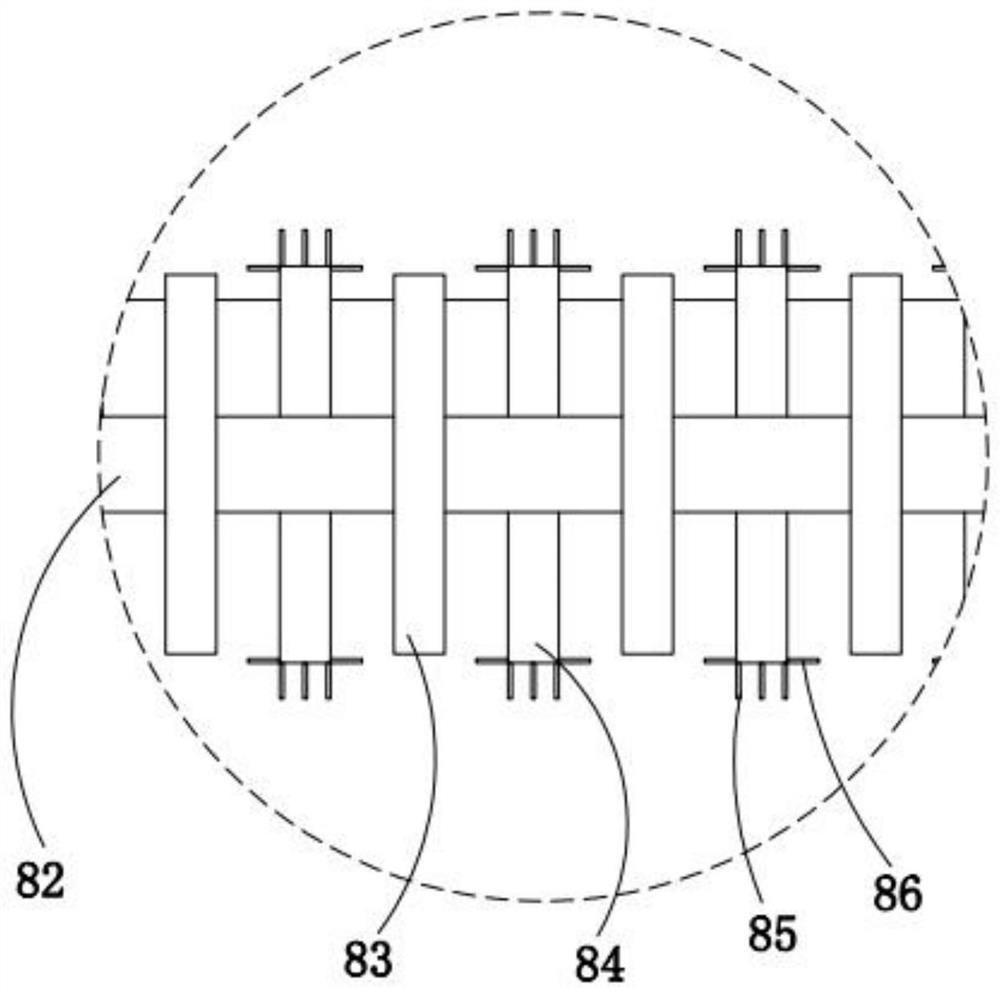

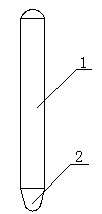

Double-gear type lobed kudzuvine root processing machine

InactiveCN110038674AImprove crushing effectIncrease crushing powerGrain treatmentsPressesPulp and paper industryEnergy conservation

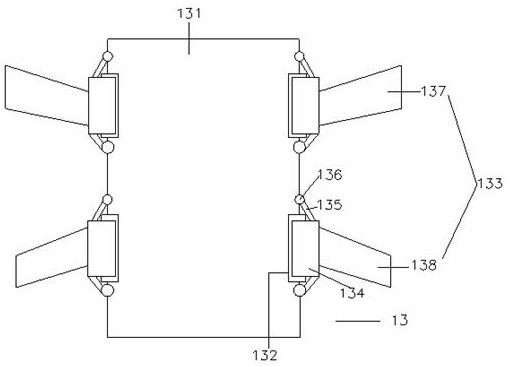

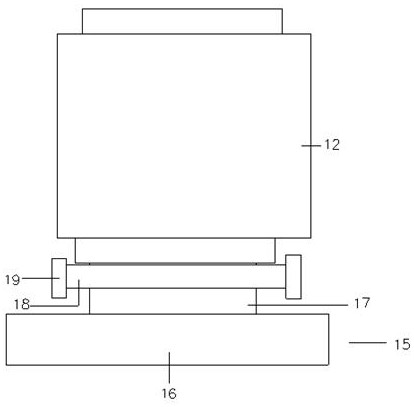

The invention discloses a double-gear type lobed kudzuvine root processing machine. The double-gear type lobed kudzuvine root processing machine comprises an electric motor (10) and a processing machine body. The interior of the processing machine body is divided into a pulverization mechanism and a pulp separation mechanism from top to bottom. The electric motor (10) is connected with the pulverization mechanism and the pulp separation mechanism to drive the pulverization mechanism and the pulp separation mechanism to run. A discharging outlet of the pulverization mechanism communicates witha feeding inlet of the pulp separation mechanism so that lobed kudzuvine roots can fall into the pulp separation mechanism to be subjected to pulp separation treatment after the lobed kudzuvine rootsare pulverized. The double-gear type lobed kudzuvine root processing machine is high in pulverization force, good in pulverization effect, simple in structure and easy to maintain, saves time and labor and can also save energy.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

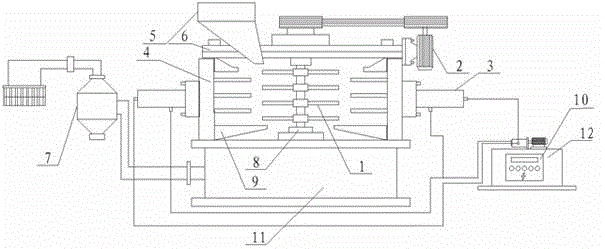

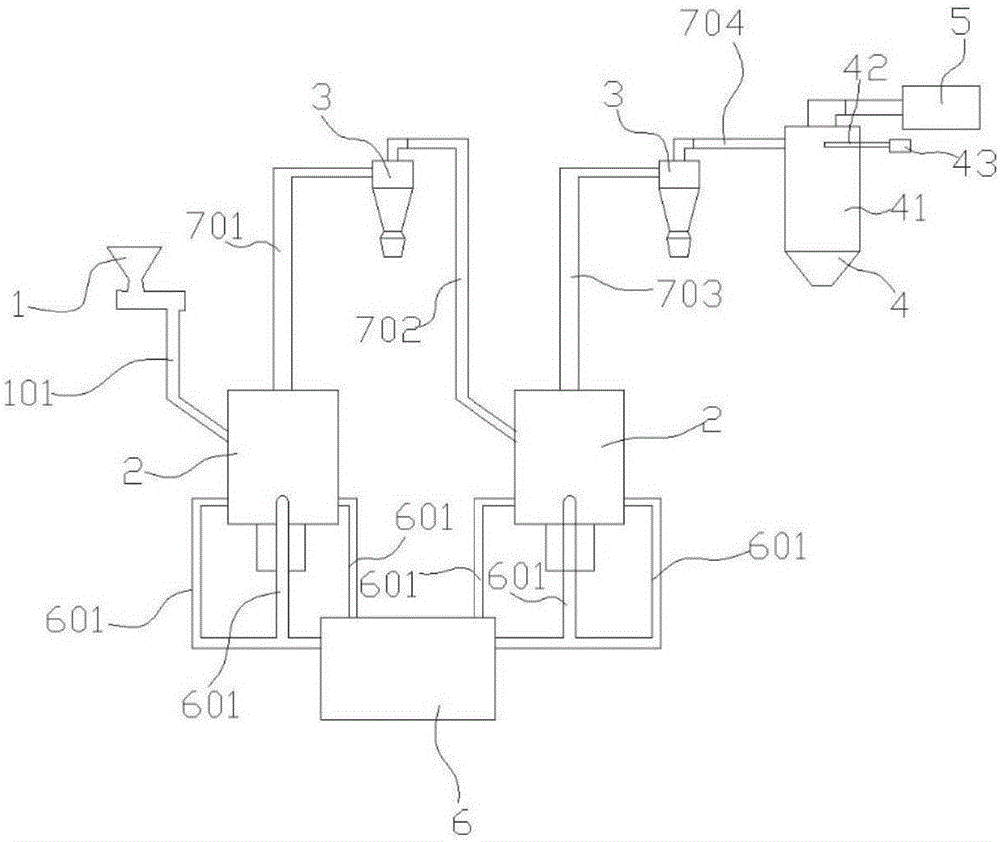

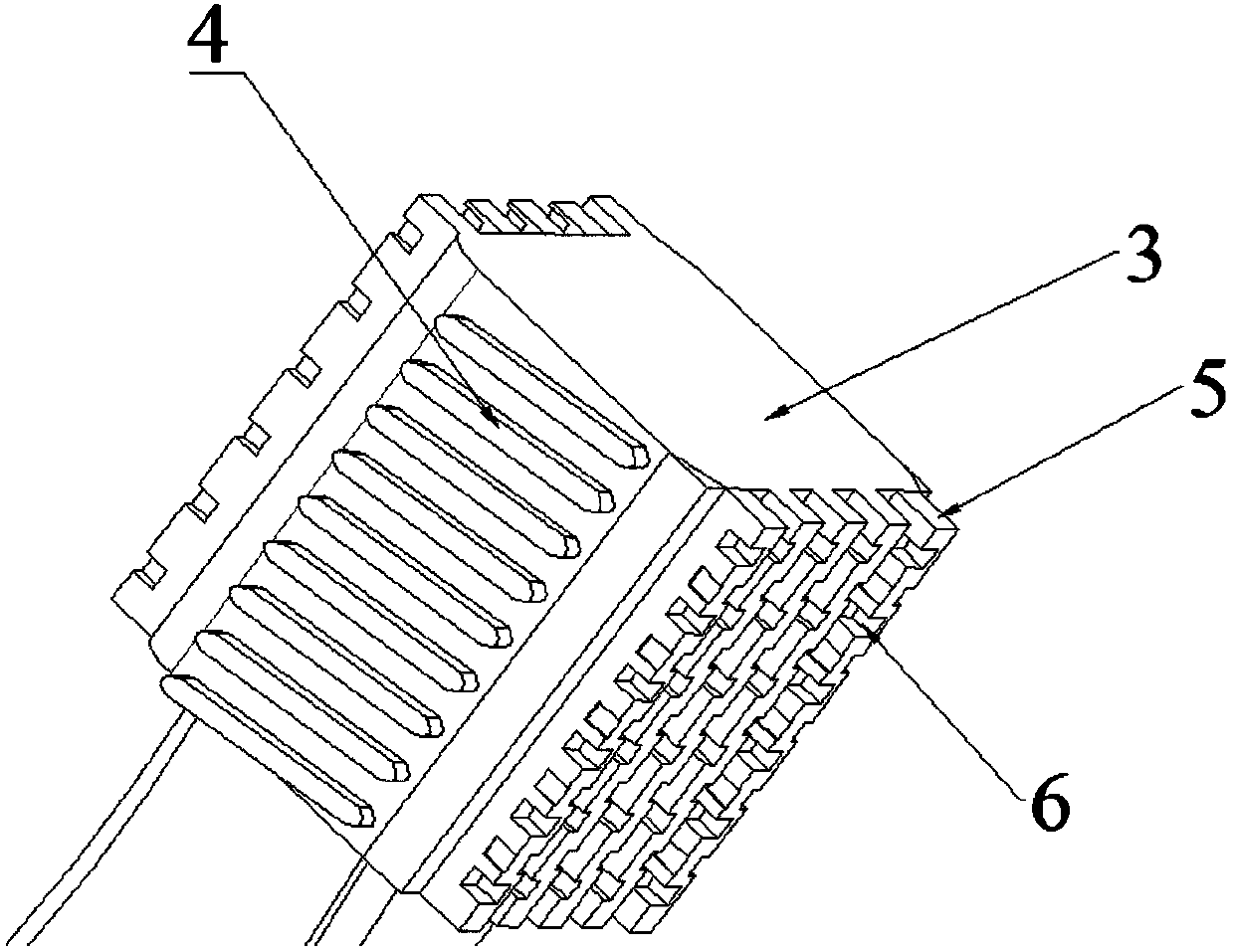

Device for manufacturing magnetic powder particles

InactiveCN105964376AImprove uniformityImprove crushing efficiencyGrain treatmentsMechanical engineeringDust collector

The invention provides a device for manufacturing magnetic powder particles. The device comprises an automatic feeder, at least one crushing mechanism and at least one separating and collecting mechanism, wherein the crushing mechanism is connected with the automatic feeder; the separating and collecting mechanism is connected with the crushing mechanism; the rear portion of the separating and collecting mechanism is also connected with a filtering and collecting mechanism; a dust collector is arranged at a tail gas output end of the filtering and collecting mechanism, wherein the crushing mechanism comprises a crushing chamber, a first motor which is positioned at the lower portion of the crushing chamber, and an air sorting chamber which is positioned at the upper portion of the crushing chamber; the crushing chamber communicates with the air sorting chamber; a feeding hole connected with the automatic feeder is formed in the upper portion of the crushing chamber; an air inlet is formed in the circumferential surface of the crushing chamber; a discharging hole is formed in the top of the air sorting chamber and is connected with the separating and collecting mechanism. The device for manufacturing the magnetic powder particles, provided by the invention, has the advantages of improving the uniformity of the magnetic powder particles, increasing the crushing force, also improving the crushing efficiency and preventing environmental pollution.

Owner:JIANGSU PULONG MAGNETIC ELECTRICITY CO LTD

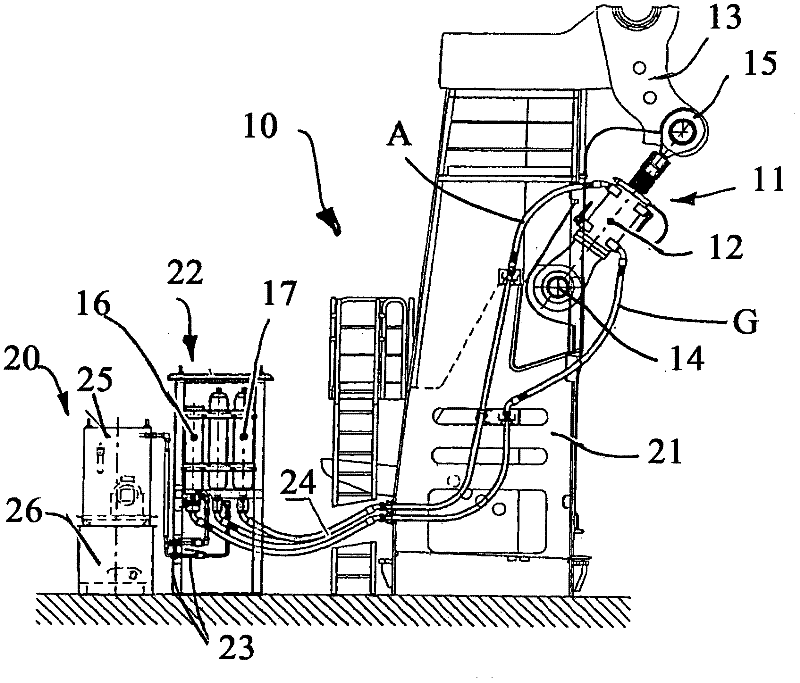

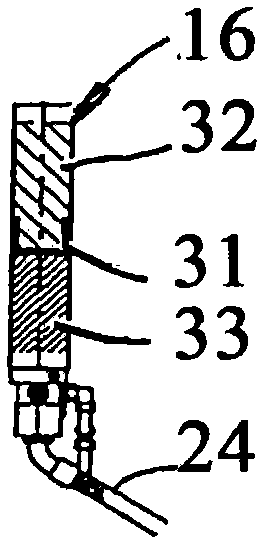

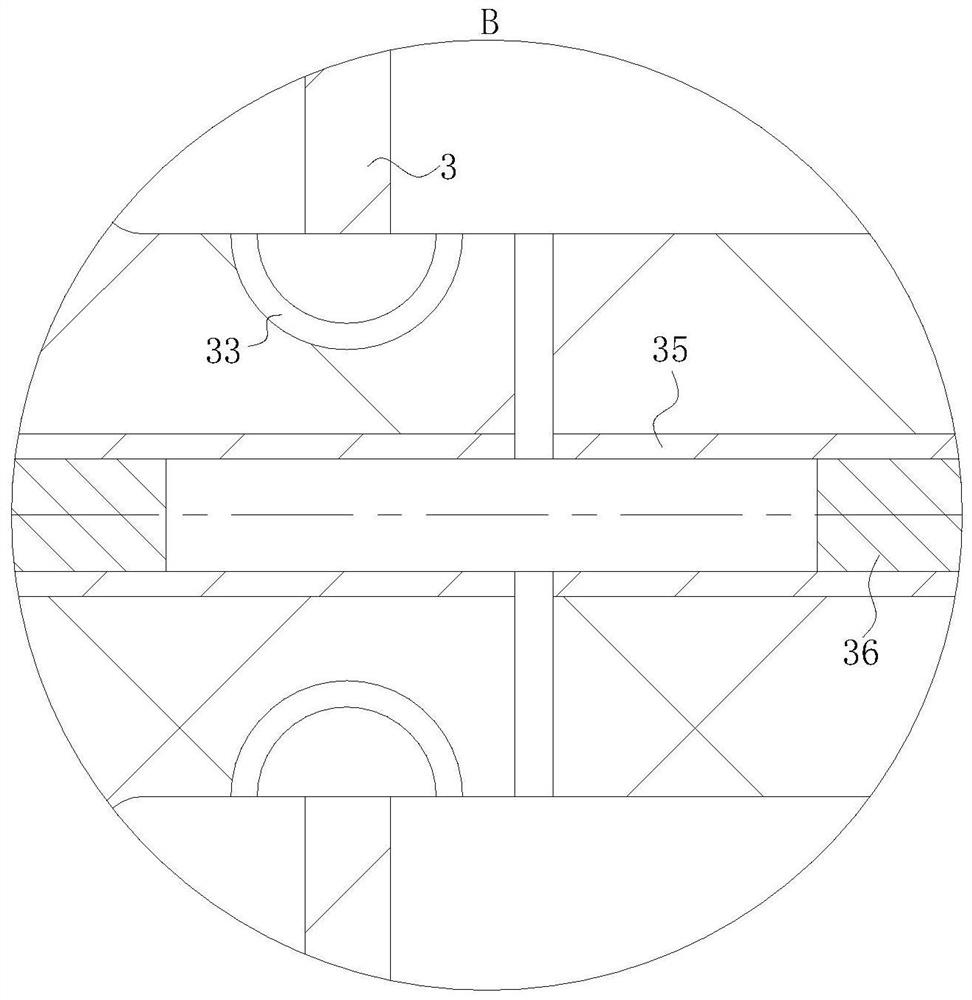

Hydraulic array for roller mills

The invention relates to a hydraulic array for roller mills, having a spring unit (11) for each grinding roll, a gas / oil reservoir (16, 17) and hydraulic supply systems for changing the operation states of the spring units or grinding rolls. In order to ensure an almost constant crushing power and a uniform contact pressure of the grinding rolls and at the same time reduce the production and assembly costs and the risk of failure of the components of the hydraulic system and to improve the exchange of components or the entire system, each spring unit of a grinding roll is associated, in its proximity, with its proper hydraulic supply unit (20) as a compact hydraulic system and a reservoir station (22) so that the necessary connections can be realized by means of relatively short conduits (23) and high-pressure lines (24). Every hydraulic supply unit can be pre-assembled under dust-free ambient conditions and accommodated for example in a hydraulic cabinet (25) and only needs to be connected on site.

Owner:LOESCHE GMBH

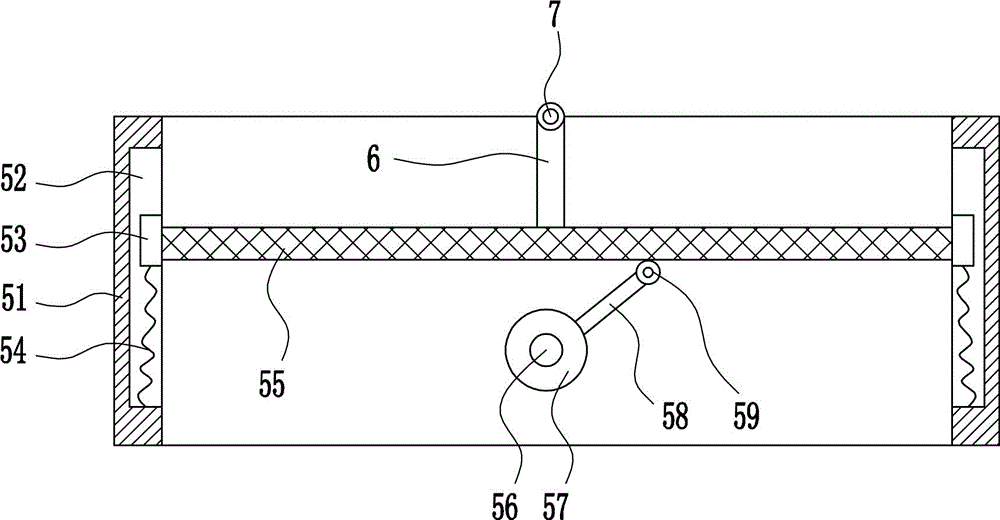

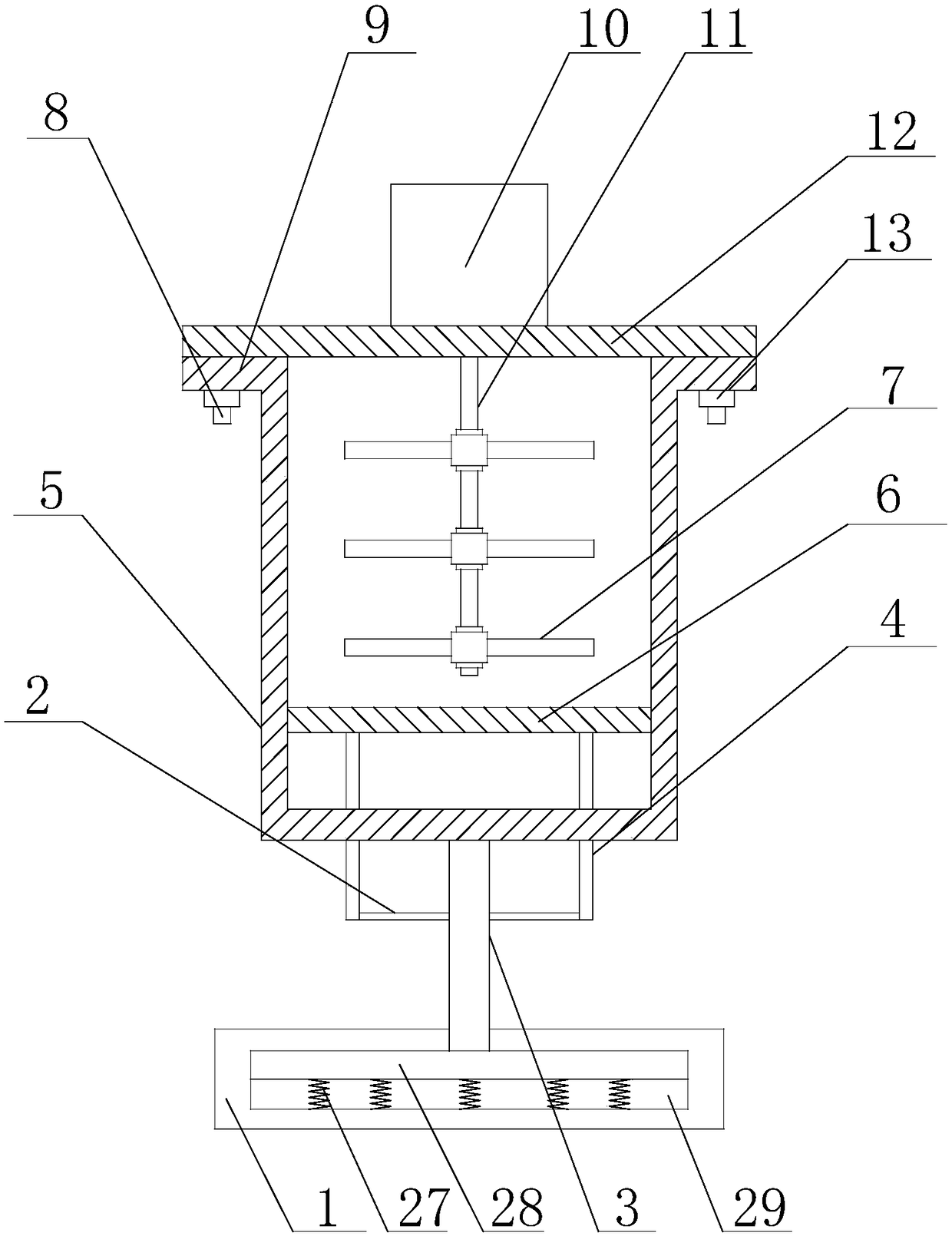

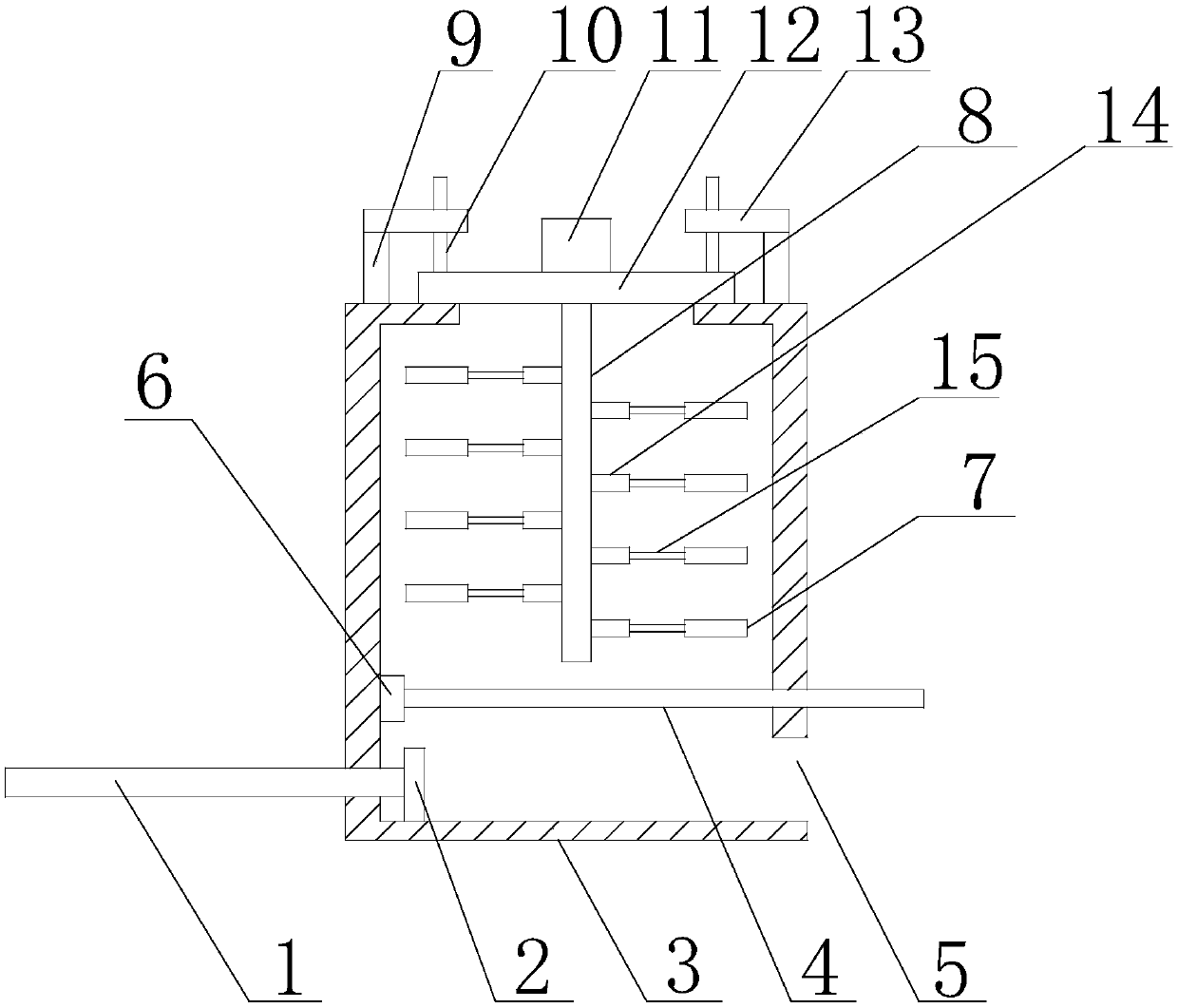

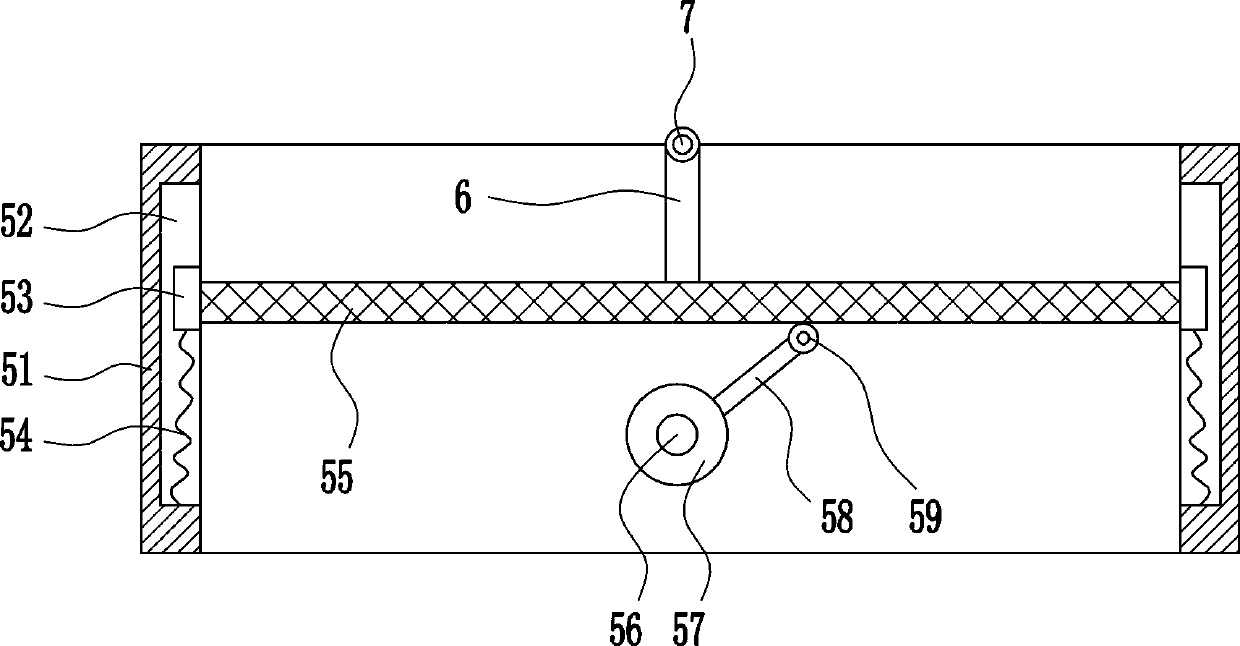

Machining equipment applied to biological straw fertilizers

The invention discloses machining equipment applied to biological straw fertilizers, The equipment comprises a base, a damping element is arranged in the base, and a supporting plate is arranged on the top of the base; a box body is arranged on the top of the supporting plate, a box cover matched with the box body is arranged on the top of the box body, and a motor is arranged on the top of the box cover and comprises an output shaft; the output shaft is inserted in the box cover, located in the box body, and further provided with several fixed blocks, the fixed blocks all sleeve the output shaft, and the output shaft is further provided with several second fixing rings; the second fixing rings are all in threaded connection with the output shaft and can fix the fixed blocks to the outputshaft, the two ends of each fixed block are both provided with smashing blades, and a filtering screen is further arranged in the box body; the filtering screen can move in the box body in the vertical direction, two vertical rods are arranged on the top of the filtering screen, and transverse rods are both arranged on the two sides of the supporting plate, can move on the supporting plate in thevertical direction, and are connected with the vertical rods.

Owner:陈统宪

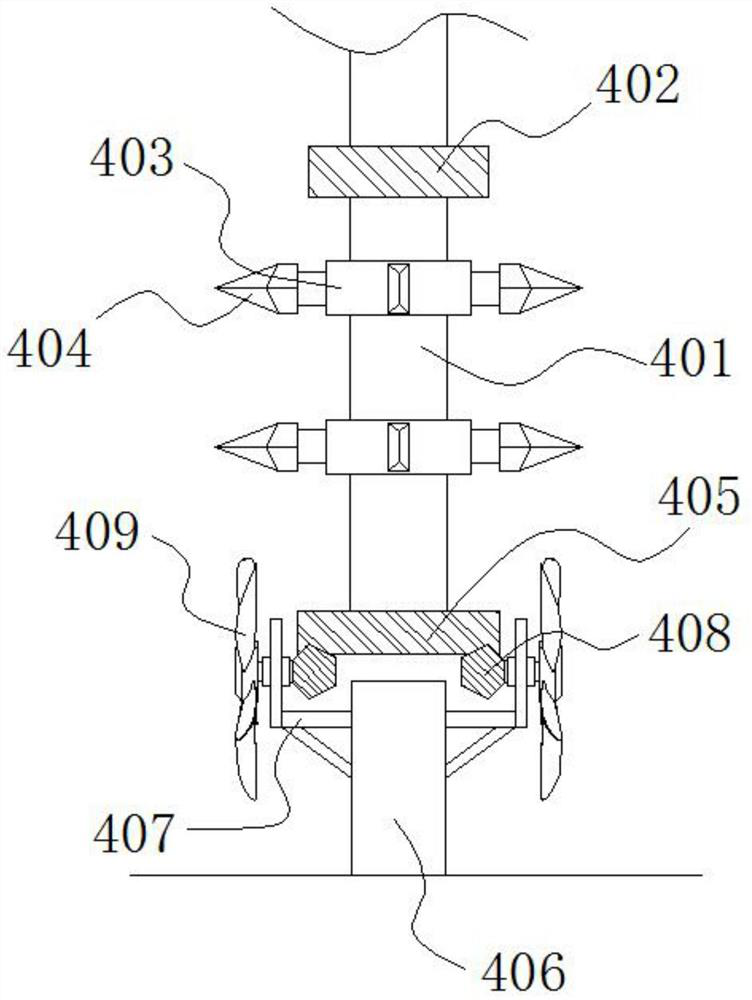

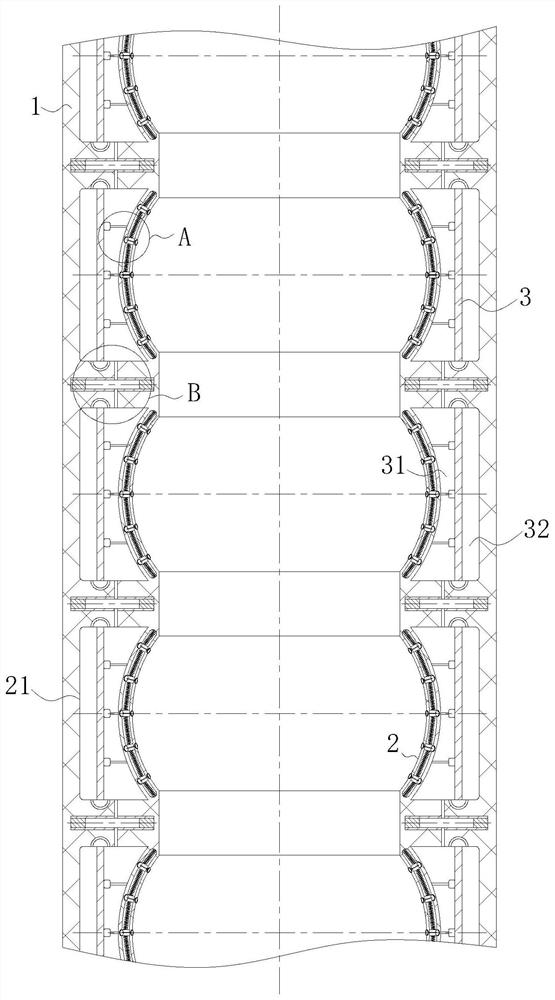

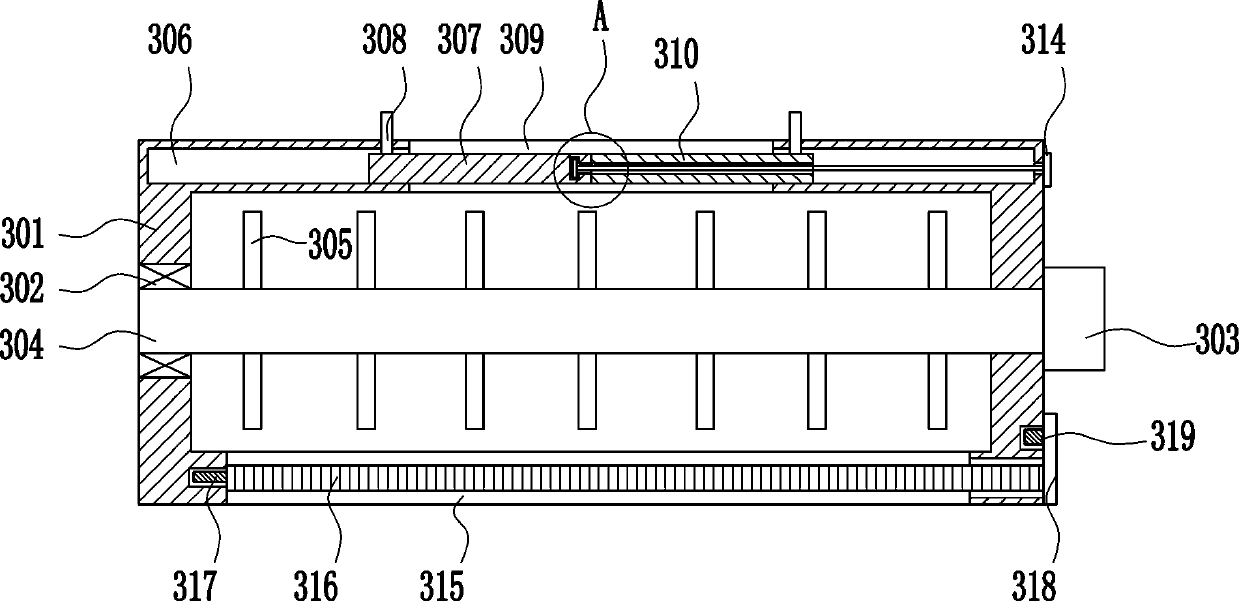

Vertical double-shaft coal crushing machine

ActiveCN103861690AIncrease crushing powerReduce crushing timeGrain treatmentsEngineeringMechanical engineering

The present invention relates to a vertical double-shaft cola crushing machine, which comprises a machine body, wherein one side on the upper end of the machine body is provided with a material inlet, the one side on the lower end of the machine body is provided with a material outlet, rotation shafts with rotation driven respectively by a motor are arranged in the machine body in an insertion manner, each rotation shaft is provided with a plurality of hammers, a horizontally-arranged material receiving plate is inserted in the machine body, material receiving plate supporting frames are arranged on both sides inside the machine body and the lower end of the material receiving plate, the position on one side of the machine body and corresponding to the material receiving plate in a parallel manner is provided with an opening door for pulling into / pulling out the material receiving plate, the middle of the material receiving plate is provided with a slot, each rotation shaft is arranged in a manner of penetrating-through of the slot, a plurality of rolling balls are respectively arranged on the two material receiving plate supporting frames, the material receiving plate moves on the rolling balls, and one end of the material receiving plate is further provided with a handle. According to the present invention, the structure is simple, the design is reasonable, the crushing efficiency per unit of time can be effectively improved, the crushing is uniform, and the crushing difficulty is relatively reduced.

Owner:蒋小华

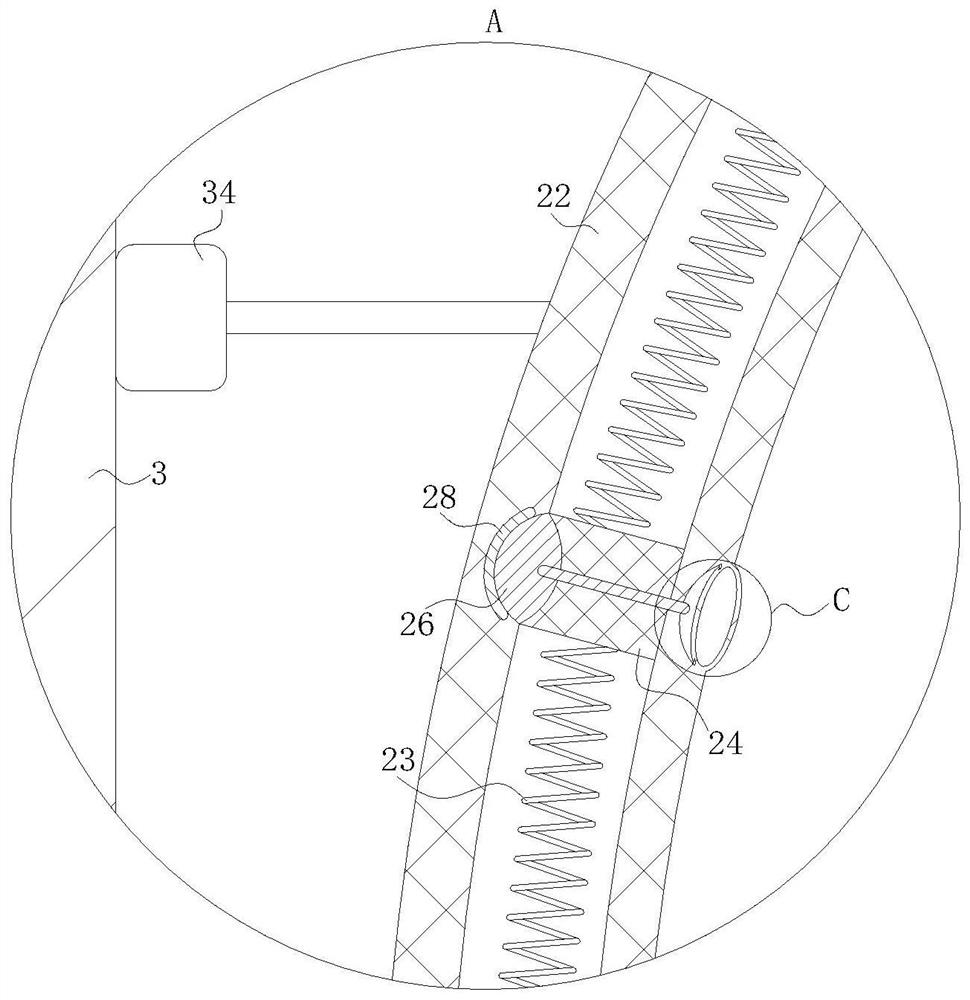

Environment-friendly breaker

InactiveCN107754984AExtended service lifeReduce replacement frequencyUsing liquid separation agentGrain treatmentsGear wheelDrive shaft

The invention relates to an environment-friendly breaker. The environment-friendly breaker comprises a breaking assembly, a power assembly, a dust removing assembly and a filtering assembly, wherein the dust removing assembly is partially arranged at the top end of the breaking assembly, and the filtering assembly is arranged at the lower end and on the right side of the breaking assembly; the power assembly is arranged on the right side of the breaking assembly and is connected with the breaking assembly through a transmission shaft and a bevel gear, and the breaking assembly comprises a feeding opening, a supporting rod, a movable cone, a movable cone bushing, a fixed cone, a fixed cone bushing, an eccentric sleeve, a discharging opening and a conveying belt; the movable cone bushing isarranged on the surface of the movable cone, the eccentric sleeve is arranged in the movable cone, the feeding opening is arranged at the upper part of the movable cone and fixed to the fixed cone bythe support rod, the discharging opening is arranged at the lower end of the left side of the fixed cone, and the conveying belt is arranged under the discharging opening; the power assembly comprisesa motor, a transmission shaft and a bevel gear, the motor is connected with the bevel gear through the transmission shaft, and the bevel gear is partially connected with the movable cone.

Owner:盐城市大丰匀力机械制造厂

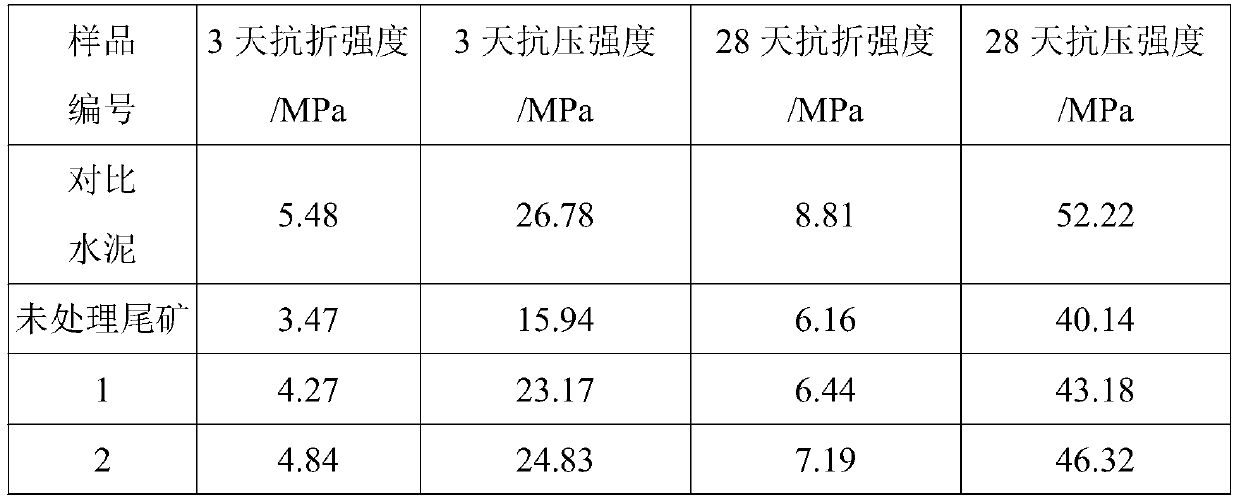

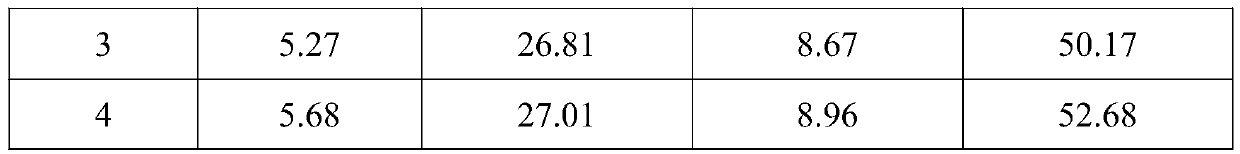

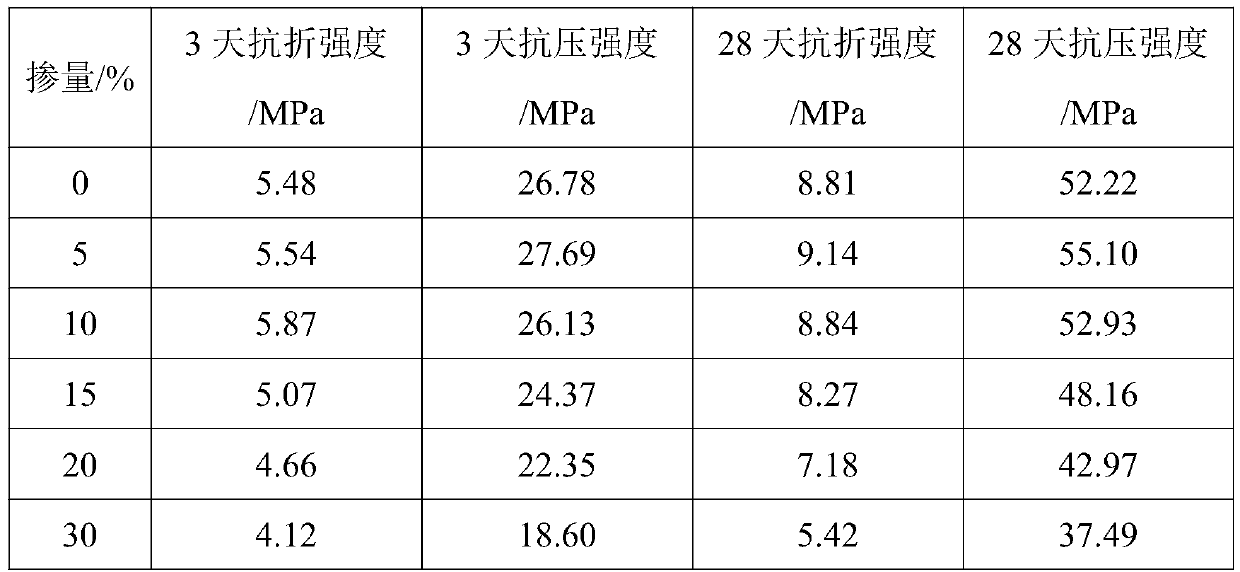

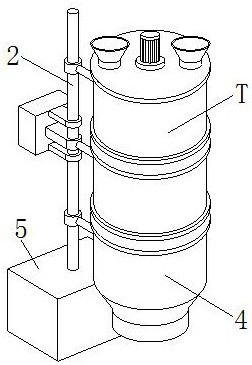

Cement admixture containing vanadium titano-magnetite tailings and preparation method and application of cement admixture

ActiveCN111302679AReduce processing costsIncrease crushing powerCement productionPhysical chemistrySodium silicate

The invention belongs to the technical field of comprehensive utilization of mineral resources, and particularly relates to a cement admixture containing vanadium titano-magnetite tailings and a preparation method and application of the cement admixture. The cement admixture comprises the following components: vanadium titano-magnetite tailings, lime, sodium silicate, triethanolamine and water. The preparation method comprises the following steps: mixing and curing vanadium titano-magnetite tailings, lime, sodium silicate, triethanolamine and water according to a certain ratio, carrying out ultrafine processing through a steam kinetic energy mill, and carrying out grading treatment to complete the preparation of the cement admixture. The method has the advantages of short technological process, small environmental pollution, easily available raw materials, high operability and the like, a new method is provided for efficient utilization of the vanadium titano-magnetite tailings, the problem of low utilization efficiency of the vanadium titano-magnetite tailings for a long time is solved, the environmental pressure of stacking of the vanadium titano-magnetite tailings can be relieved, and economic benefits can be created.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI +1

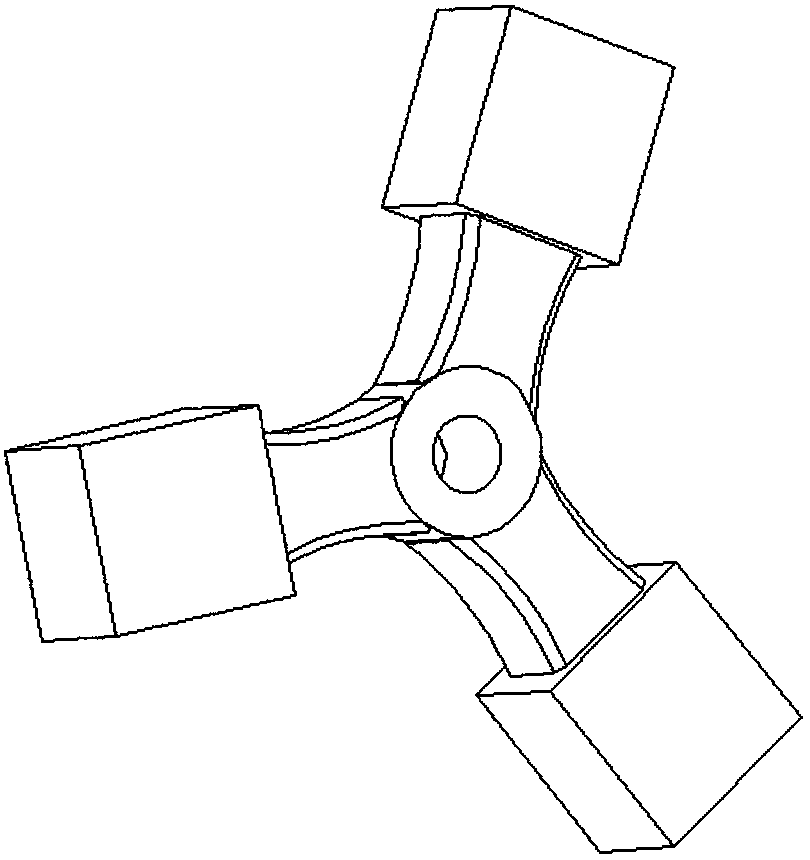

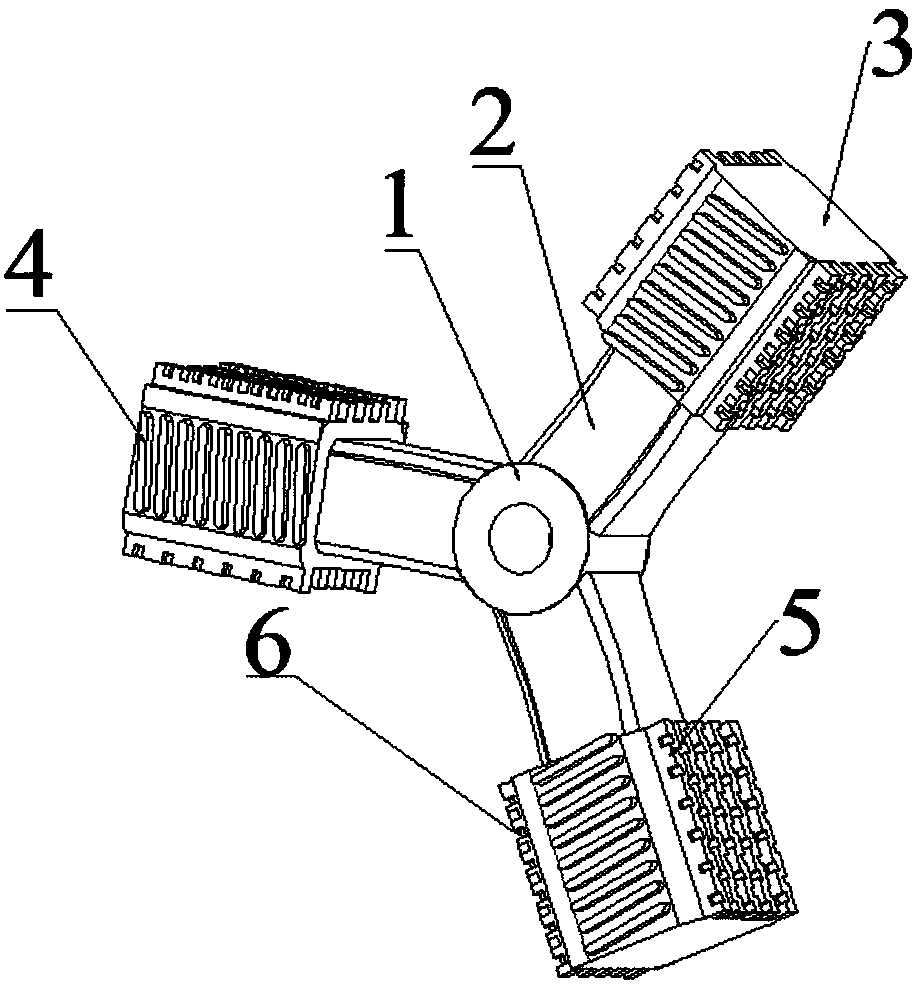

Straw recovery device for green agricultural development

ActiveCN114600651AIncrease crushing powerPrevent jumpingSievingScreeningGear wheelAgricultural engineering

The invention discloses a green agriculture development straw recovery device which structurally comprises a base, a supporting rod, a recovery mechanism and a collecting box, the middle of the upper end of the base is welded to the lower end of the supporting rod, the recovery mechanism is installed at the upper end of the supporting rod, and a smashing cutter at the middle end rotates to enable a guide gear ring to synchronously rotate through connection of a connecting rod; a movable gear on the inner side is driven to rotate around the interior of a guide rotating groove, three smashing cutters rotate and rotate to cut and smash straw, a certain gap exists between the three smashing cutters, the straw is prevented from jumping, swing pieces at the middle end of the outer side of the screening box body elastically slide on spring rods in an arc mode, and therefore the straw can be smashed. And the sliding block drives the scraping plate to slide left and right in the sliding rail, the lower end of the scraping plate scrapes left and right on the upper end face of the sieving plate, large particles in straw powder are prevented from blocking the upper end face of the sieving plate, and the fine degree of the straw powder is improved.

Owner:SUZHOU UNIV OF SCI & TECH

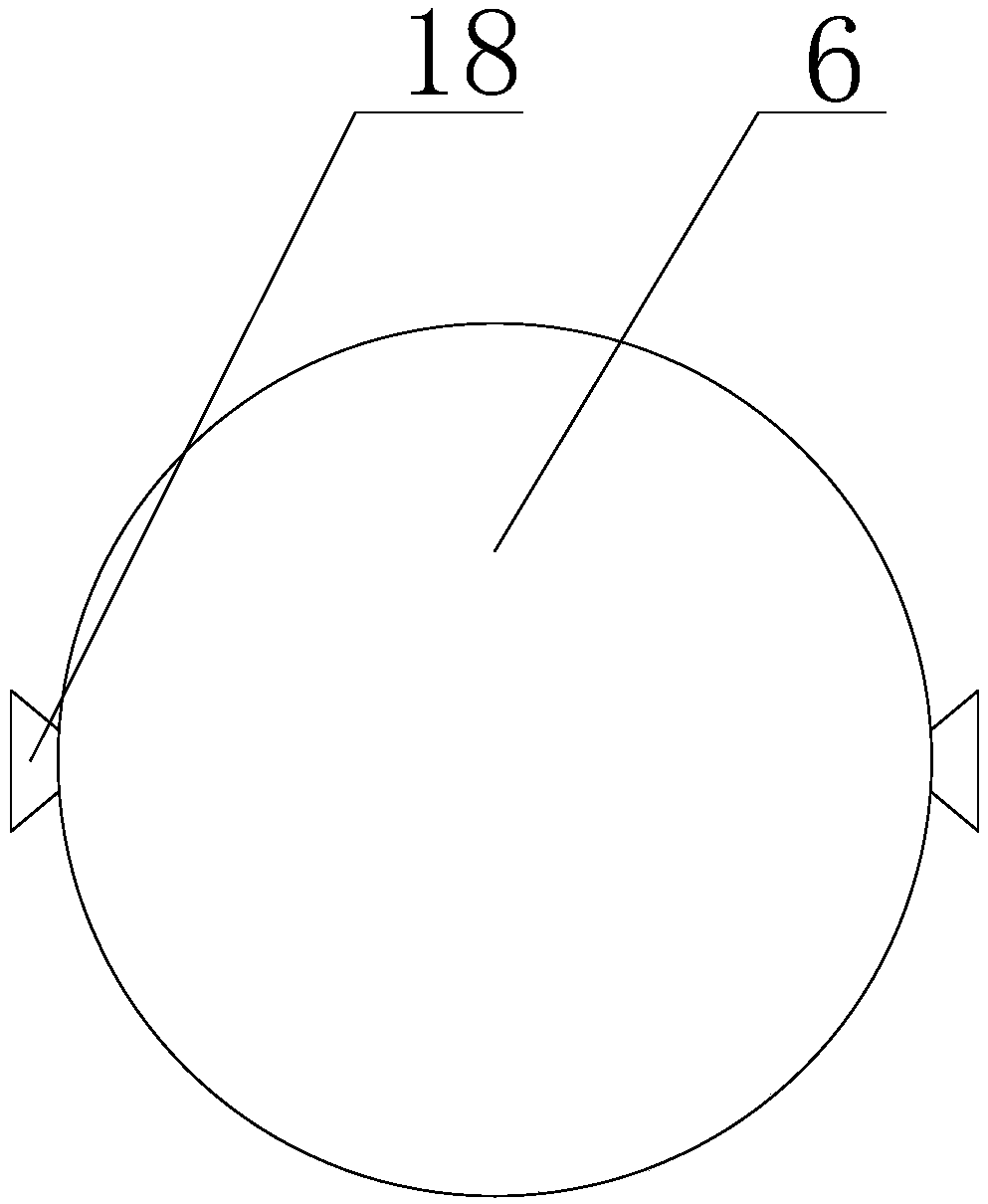

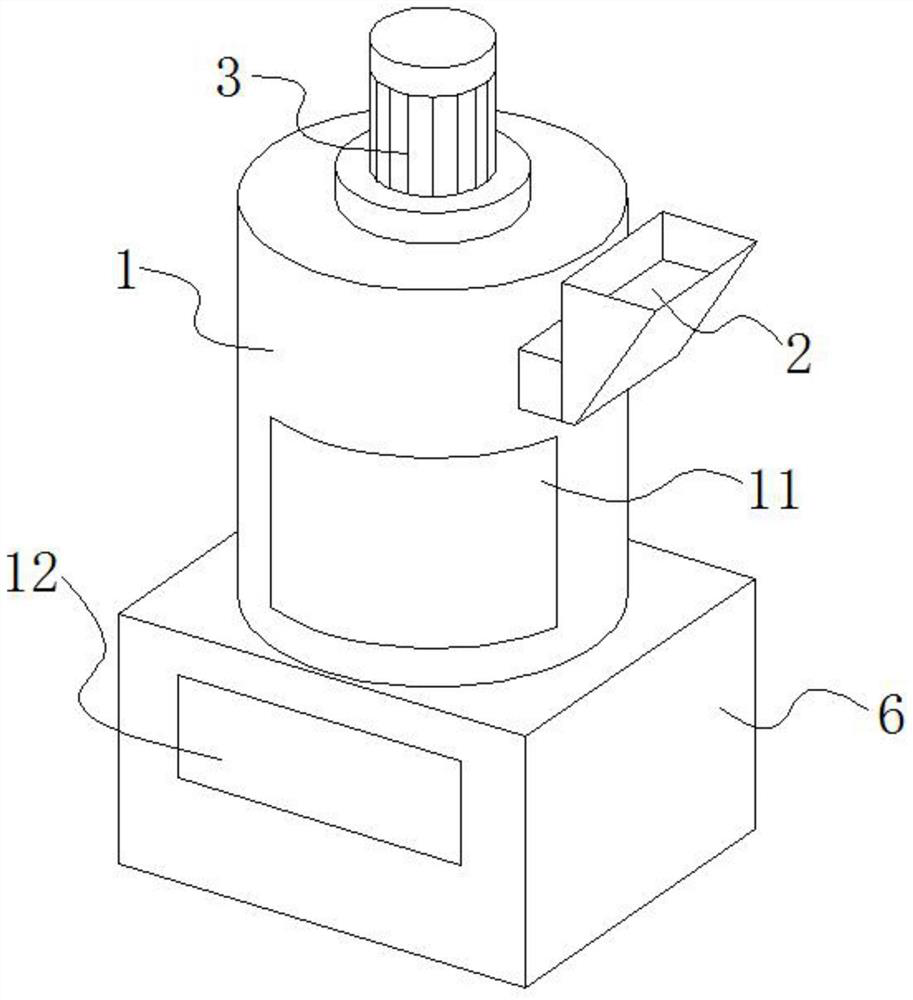

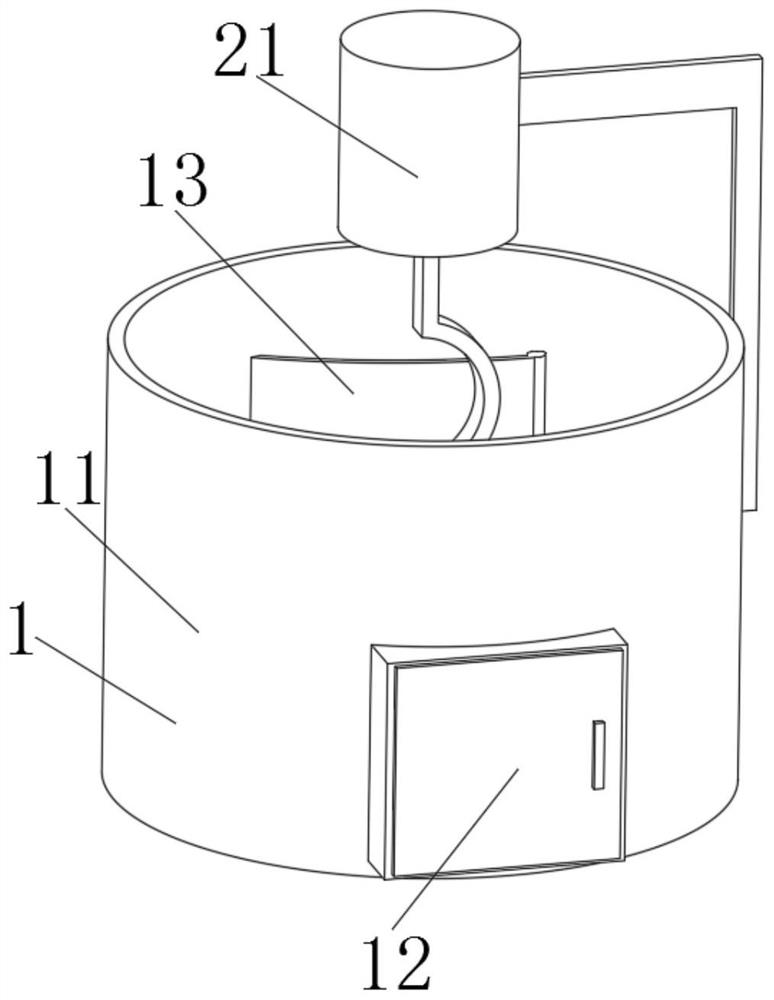

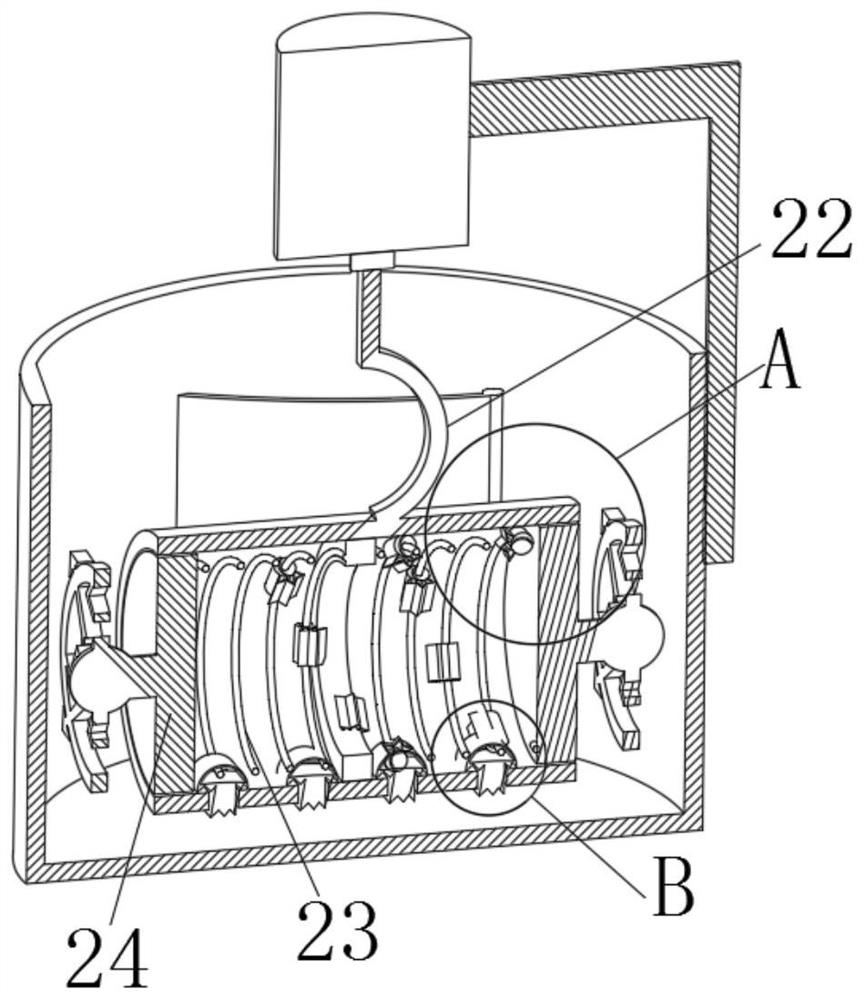

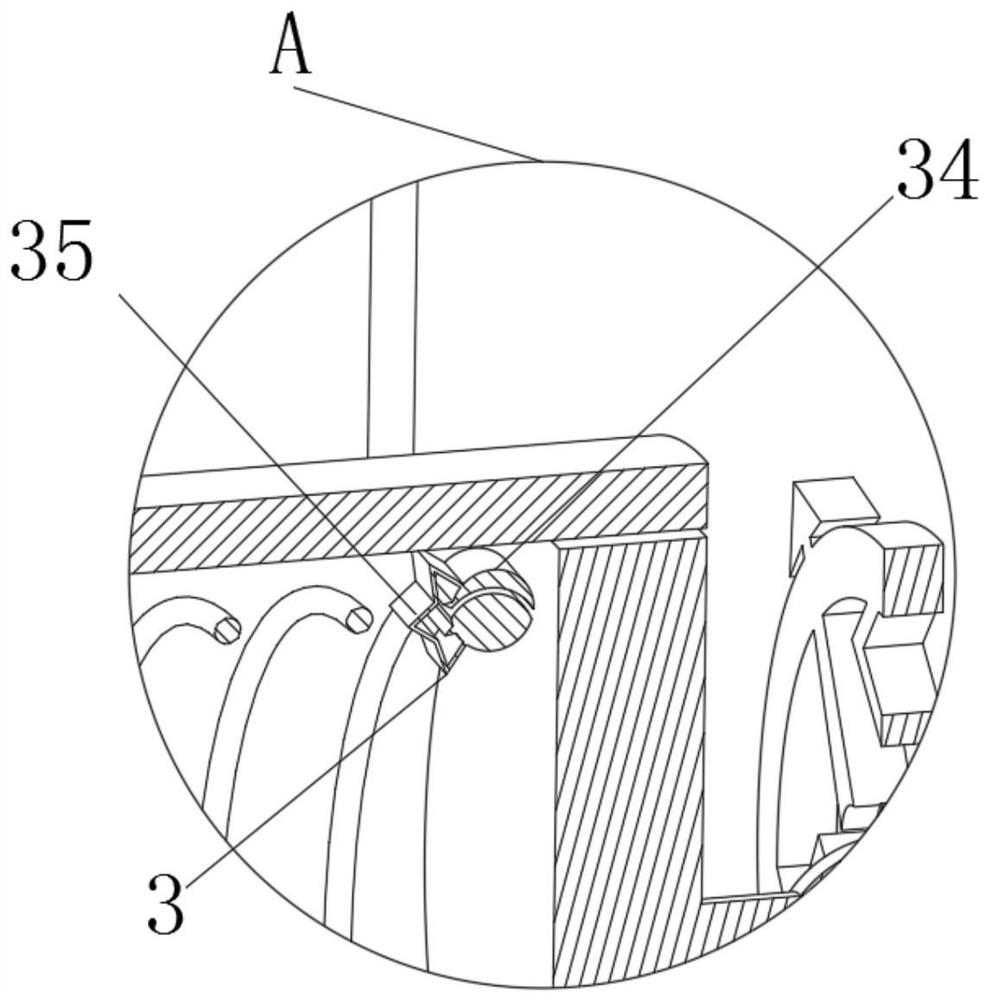

Raw material crushing and filtering device for aluminum oxide ceramic production and processing

ActiveCN112892762AIncrease crushing powerImprove crushing qualityGrain treatmentsComposite materialOxide ceramic

The invention relates to the technical field of aluminum oxide ceramic production, in particular to a raw material crushing and filtering device for aluminum oxide ceramic production and processing. The crushing and filtering device comprises a first shell, a first servo motor, a crushing assembly and a filtering assembly; the first shell is of a cylinder structure, the first servo motor is fixedly arranged on the top of the first shell, and the central axis of the first servo motor coincides with the central axis of the first shell; and the crushing assembly comprises a first crushing mechanism and a second crushing mechanism, wherin a rotating part of the first crushing mechanism is in transmission connection with the output end of the first servo motor, a shell of the filtering assembly is fixedly arranged at the bottom of the first shell, and a feeding mechanism of the filtering assembly communicates with a discharging part of the first shell. The device can increase the crushing strength, improve the crushing quality and save the energy consumption, and the compatibility of the crushing and filtering device is improved.

Owner:子夏科技(佛山)有限公司

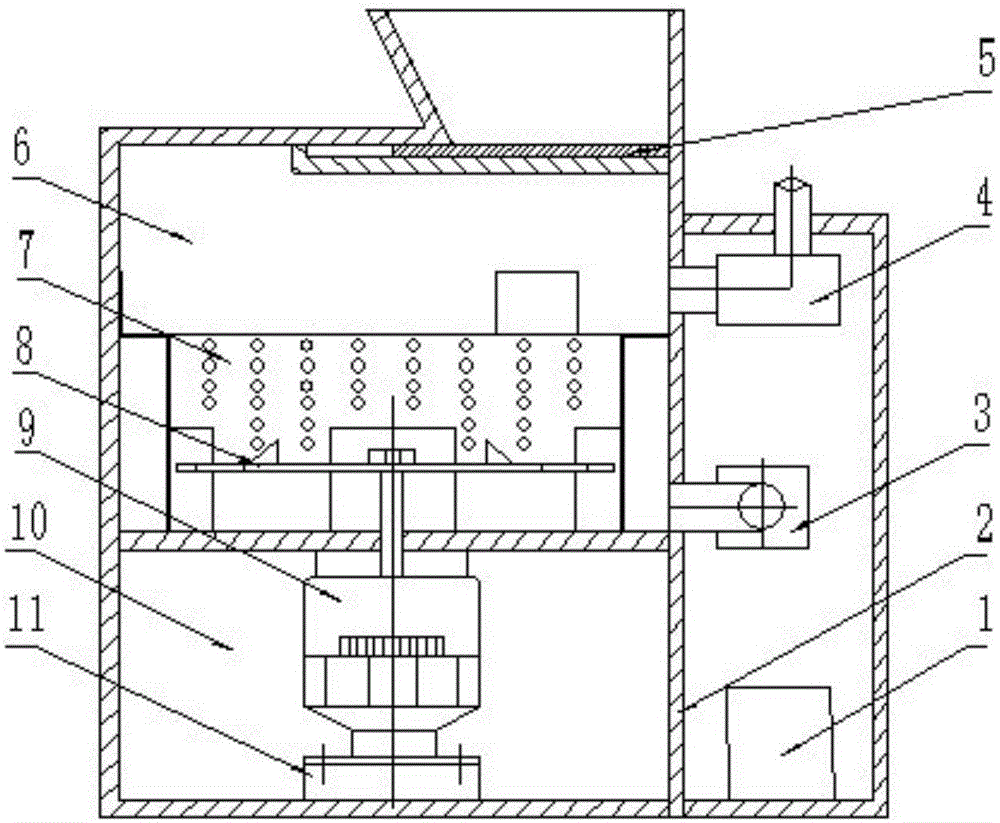

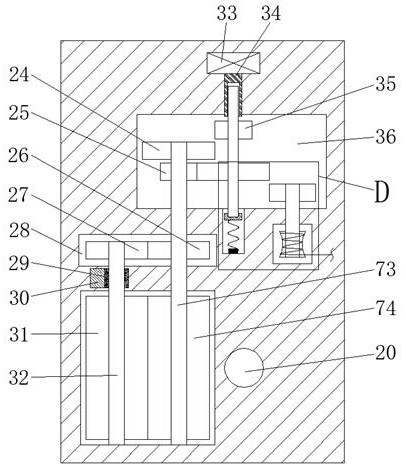

Material twisting and squeezing crushing mechanical device

InactiveCN107597285APrevent leakagePrevent leaks from enteringCocoaGrain treatmentsEngineeringShovel

The invention discloses a material twisting and squeezing crushing mechanical device. The device comprises a device upper shell, a device middle shell and a device lower shell, a material crushing motor is arranged at the upper part of the device upper shell, and the crushing motor is matched with a rotating shaft; an ash blocking plate is arranged inside the device upper shell, the rotating shaftis matched with a connecting head through a telescopic rod, a spring is arranged on the telescopic rod in a sleeving mode, and the end part of the connecting head is connected with a rotating crushing disc; one side of the device middle shell is connected with a controller through a connecting frame, the other side of the device middle shell is connected with a feeding pipeline, a feeding deviceis arranged at the end part of the feeding pipeline, and the feeding device communicates with a feeding hopper; and one side of the device lower shell is provided with a material clearing motor and adischarging opening, and the material clearing machine is matched with a material clearing shovel through a transmission device. When the material twisting and squeezing crushing mechanical device isused, materials can be crushed under the combined actions of the downward pressure and the twisting force, the crushing force is large, and the effect is good; and the material clearing device is arranged, the material clearing is convenient and fast, and the working efficiency is high.

Owner:何敏

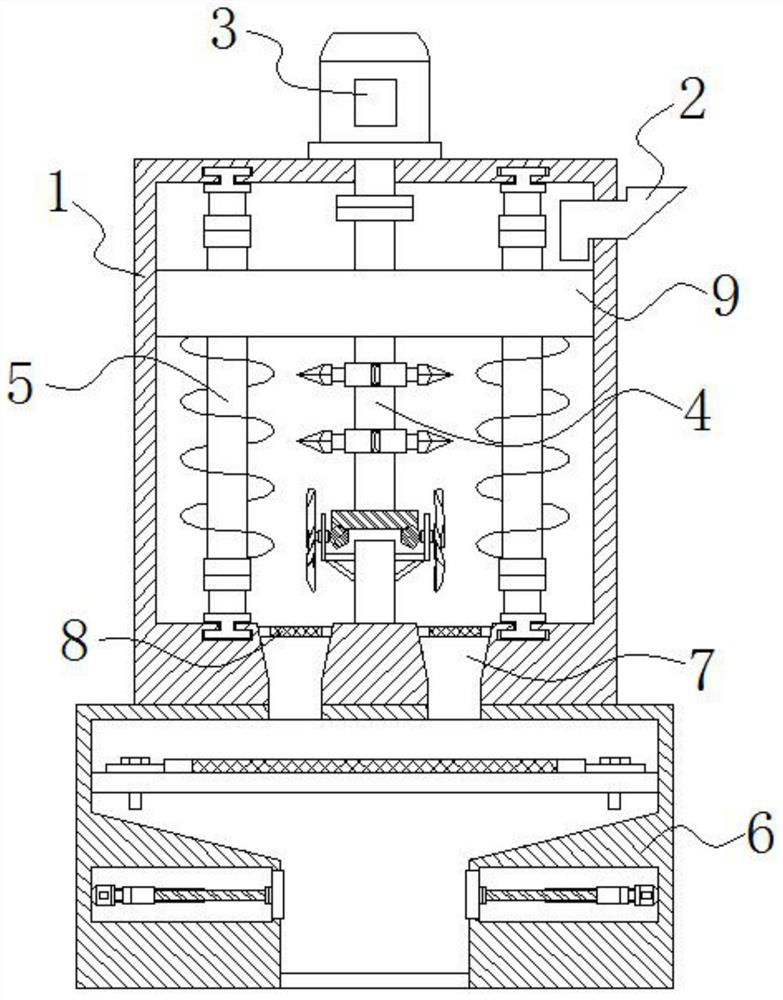

A solid waste crushing device

ActiveCN109433352BShock mitigationImprove securityCleaning using gasesGrain treatmentsStructural engineeringIndustrial engineering

The invention relates to a solid waste crushing device. The solid waste crushing device comprises a shell, wherein a feeding hopper is arranged at the top of the shell, the feeding hopper is connectedwith a first fixing plate, the first fixing plate is arranged in 30-45 degrees with the horizontal plane, the first fixing plate is fixed to the inner wall of the shell through a reinforcing rib, thereinforcing rib is connected with a damping rod, the first fixing plate is connected with a second fixing plate, the second fixing plate is arranged in 30 degrees with the horizontal plane, the inclined directions of the first fixing plate and the second fixing plate are opposite, the second fixing plate is fixed to the inner wall of the shell through bolts, a reinforcing plate is fixed between the second fixing plate and the shell, a damping spring is arranged on the reinforcing plate, an inclined plate is arranged at the bottom of the shell, the inclined plate is arranged in 10 degrees withthe horizontal plane, the end, located on the lower side, of the inclined plate is connected with an outlet, the outlet is provided with a valve, the middle of the inclined plate is connected with asupporting shaft perpendicular to the bottom of the shell, a rotating shaft is arranged in the supporting shaft, the rotating shaft is connected with a crushing mechanism and is fixed through a connecting piece, and the other end of the rotating shaft is connected with a fixing device. The solid waste crushing device has high working efficiency, high precision, short crushing time, stability and firmness, good impact resistance effect and long service life.

Owner:重庆太富环保科技集团有限公司

Crusher high in crushing efficiency

The invention relates to the field of crushers, in particular to a crusher high in crushing efficiency. The crusher high in crushing efficiency comprises a feed inlet, a crushing cavity and a discharge hopper. The crushing cavity internally comprises a spindle. A motor is arranged at the bottom of the spindle and drives the spindle to rotate. The crushing cavity comprises a cutting cavity body, acrushing cavity body and a pulverizing cavity body. A cutter is arranged at the bottom of the cutting cavity body. The bottom of the cutting cavity body is fixed to the spindle and rotates along withrotation of the spindle. A hammer-milling cavity is formed below the cutting cavity body. Two heavy hammers are arranged in the position, in the hammer-milling cavity, of the spindle. The pulverizingcavity body is formed at the bottom of the hammer-milling cavity. A pulverizing roller is arranged in the pulverizing cavity body and is arranged in the crushing cavity body in the horizontal direction. The discharge hopper is arranged at the bottom of the pulverizing cavity body. The crusher has the characteristics that various crushing modes are combined, and crushing efficiency is high.

Owner:宜兴市申生催化剂有限公司

Hammer type crushing equipment part

PendingCN107774392AIncrease pressureIncrease crushing powerGrain treatmentsStructural engineeringMechanical engineering

The invention provides a hammer type crushing equipment part, which comprises an installing part, a hammer handle and a hammer head, wherein the hammer handle is fixedly connected onto the installingpart; the hammer head is fixedly connected onto the hammer handle; a plurality of projected parts are arranged on the upper and lower beating surfaces of the hammer head in the axis direction of the hammer handle; a rectangular groove is formed in each projected part in the length direction of the projected part; a convex block projected out of the surface of the hammer head is arranged on the inner and outer side surface of the hammer head. The crushing intensity of the beating surfaces on materials can be improved through the arrangement of the plurality of projected parts and the grooves inthe beating surfaces; the bulges arranged at the inner and outer side of the hammer head are favorable for guiding the airflow trends; the influence of the air resistance on the rotating speed duringthe rotation is reduced; the crushing intensity of the hammer head is enhanced.

Owner:TIANJIN HONGYA LUBRICATION POWDER MFG

a pe tube

ActiveCN110274096BIncrease the flow diameterReduced durabilityPipe elementsRigid pipesWater dischargePipe

The invention belongs to the technical field of pipes and particularly relates to a PE (polyethylene) pipe. The PE pipe comprises a pipe body and a rebound mechanism; the rebound mechanism is arranged in the pipe body; the rebound mechanism comprises extruding cavities, elastic layers, springs and supporting rods; the extruding cavities are arranged in the wall of the pipe body uniformly; the elastic layer is arranged on the inner side of each extruding cavity; the elastic layer and the inner wall of the pipe body are connected integrally; each elastic layer has a certain degree of flexibility; the supporting rods are fixedly arranged in the elastic layers horizontally and uniformly; and the supporting rods are connected through the springs. The PE pipe is mainly used for solving the problems in the prior art that a PE water discharging pipe is blocked because the PE water discharging pipe is liable to enable stone to enter the pipe when a filtering net is not mounted and the PE water discharging pipe is used in a mine as well as the inner wall of the pipe is scratched continuously and the durable degree of the PE water discharging pipe is greatly reduced because the stone is liable to generate relative friction with the inner wall of the PE water discharging pipe when the stone is conveyed in water and in the pipe.

Owner:山东博大管业有限公司

A rapid crushing device for agricultural fertilizer

ActiveCN112354645BIncrease crushing powerPromote absorptionGrain treatmentsAgricultural scienceTransmission belt

Owner:金莱福(山东)化肥进出口有限公司

Crushing device capable of automatically adjusting strength

The invention relates to the related field of garbage crushing, and discloses a crushing device capable of automatically adjusting strength. The crushing device comprises a main body box, a feeding power cavity is arranged in the main body box, a feeding wheel cavity is arranged on the lower side of the feeding power cavity, a feeding gear cavity is arranged on the upper side of the feeding power cavity, and a push block cavity communicates with the upper side of the feeding gear cavity; and the left side of the push block cavity communicates with a feeding cavity, and the lower side of the feeding cavity communicates with a baffle cavity. The crushing device has the beneficial effects that the crushing torsion is detected through a pressure sensor, so that when thick branches which are difficult to crush exist in the crushing cavity, a sliding cover electromagnet is electrified to enable a low-speed driven wheel to be meshed with a low-speed driving wheel, the crushing speed is reduced, the crushing strength is improved, and thus energy is saved; and meanwhile, crushed materials are collected through a collecting barrel, and the crushed materials are put into the crushing cavity to be subjected to secondary crushing, so that the crushed materials finally entering collecting equipment are consistent in particle size, and subsequent utilization is convenient.

Owner:湖南银粉世家建材科技有限公司

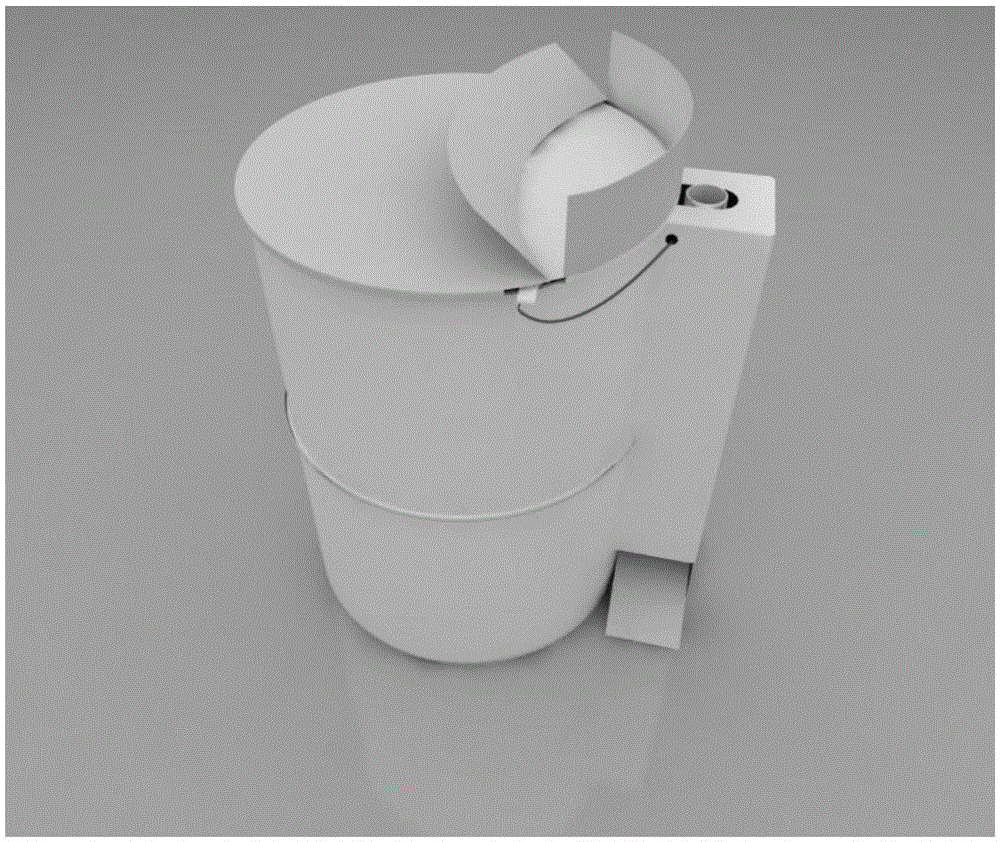

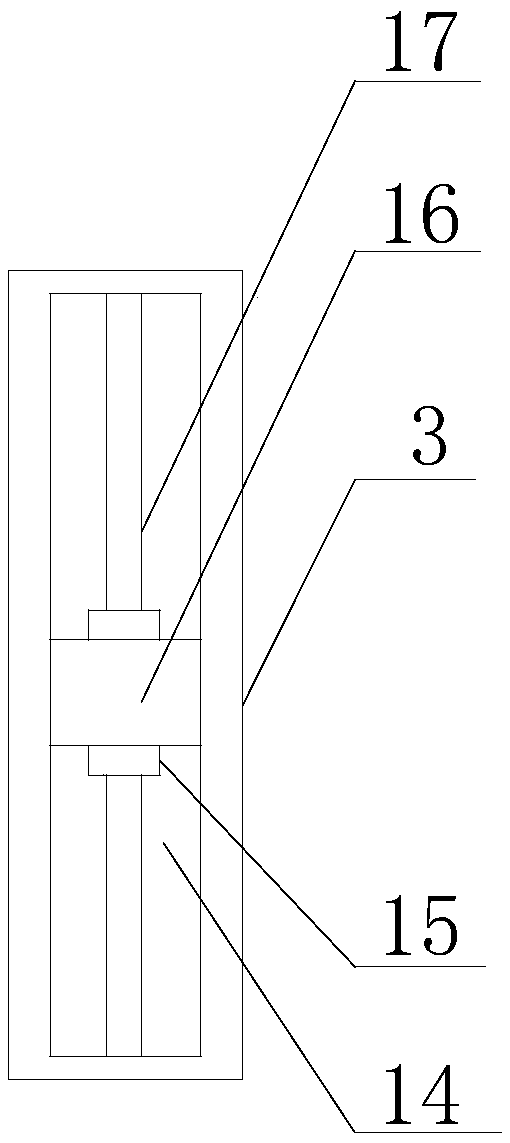

Pulp-separating machine with adjustable rotating speed

InactiveCN105887542ASimple and reasonable structureEasy to manufacturePulp beating methodsDesign technologyElectric machine

The invention relates to a separating machine, specifically relates to a pulp-separating machine with an adjustable rotating speed and belongs to the technical field of design of the separating machine. The pulp-separating machine comprises a rack, a separating chamber, a feeding port, a discharging port and a motor, wherein a separating shaft is arranged in the separating chamber; a grid net baffle plate is arranged on the feeding port; a stick thorn is arranged on the separating shaft; an embossment is arranged on the separating shaft; a through hole is formed on the embossment; the stick thorn is arranged on the part with through holes at intervals on the embossment; the pulp-separating machine is characterized in that a gearbox is arranged; a power output shaft of the motor is connected with a power input shaft of the gearbox through a chain; the power output shaft of the gearbox is connected with the separating shaft through the chain; an overload protection device is arranged on the motor; a fuse is arranged as the overload protection device; a quick shutdown device is arranged on an axial external circle of the separating shaft. Through the pulp-separating machine with the adjustable rotating speed, in the specific operation, we can realize the adjustment for the rotating speed of the separating shaft by adjusting the gearbox, and the overload protection device is arranged for protecting the motor.

Owner:DANYANG ZHENGLIAN INTPROP OPERATIONS MANAGEMENT CO LTD

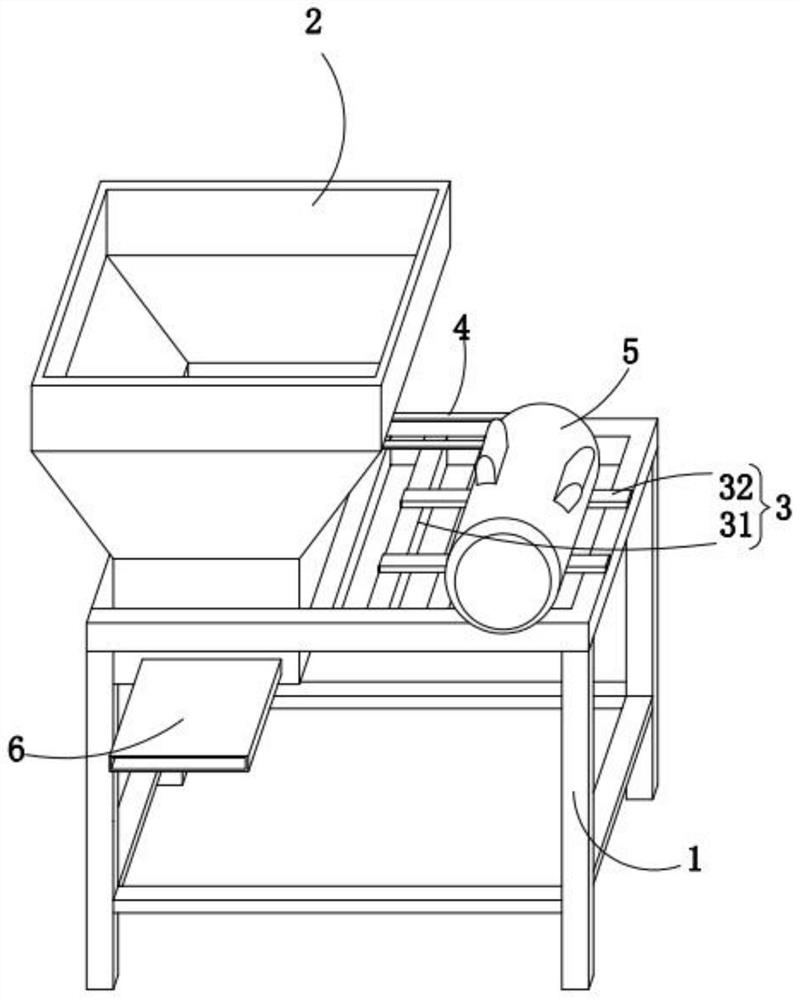

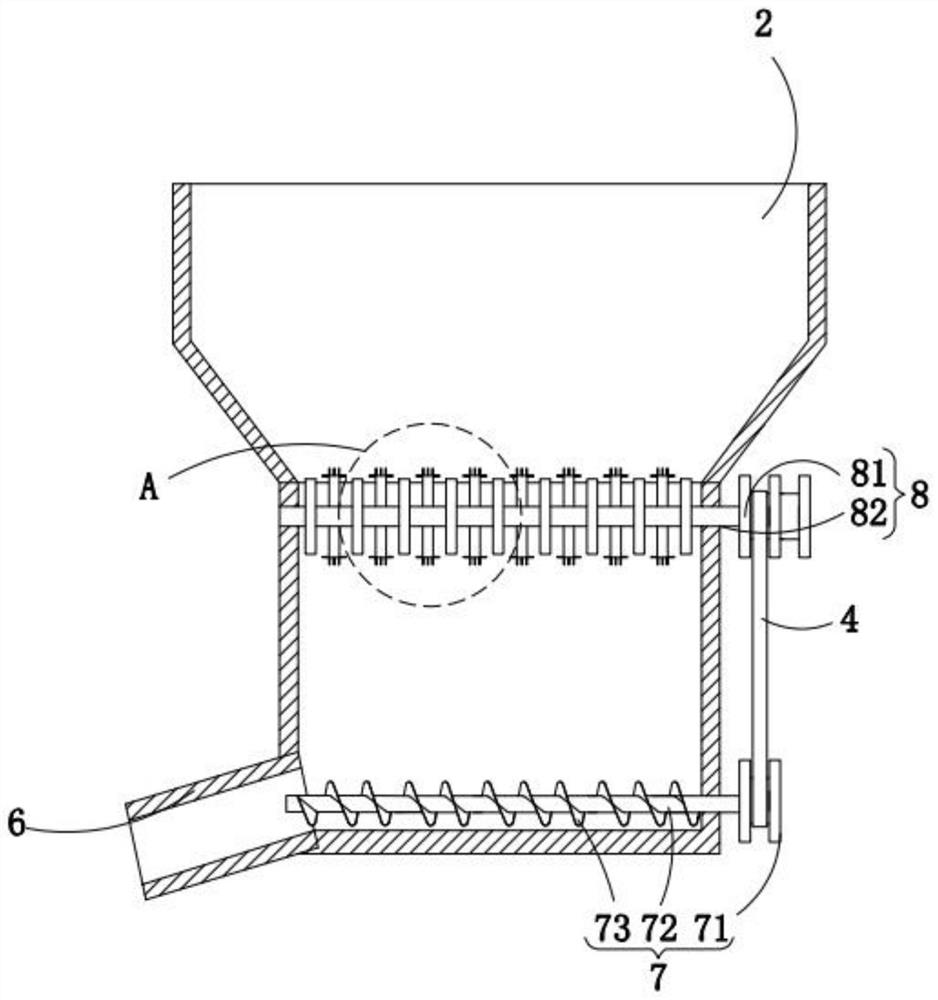

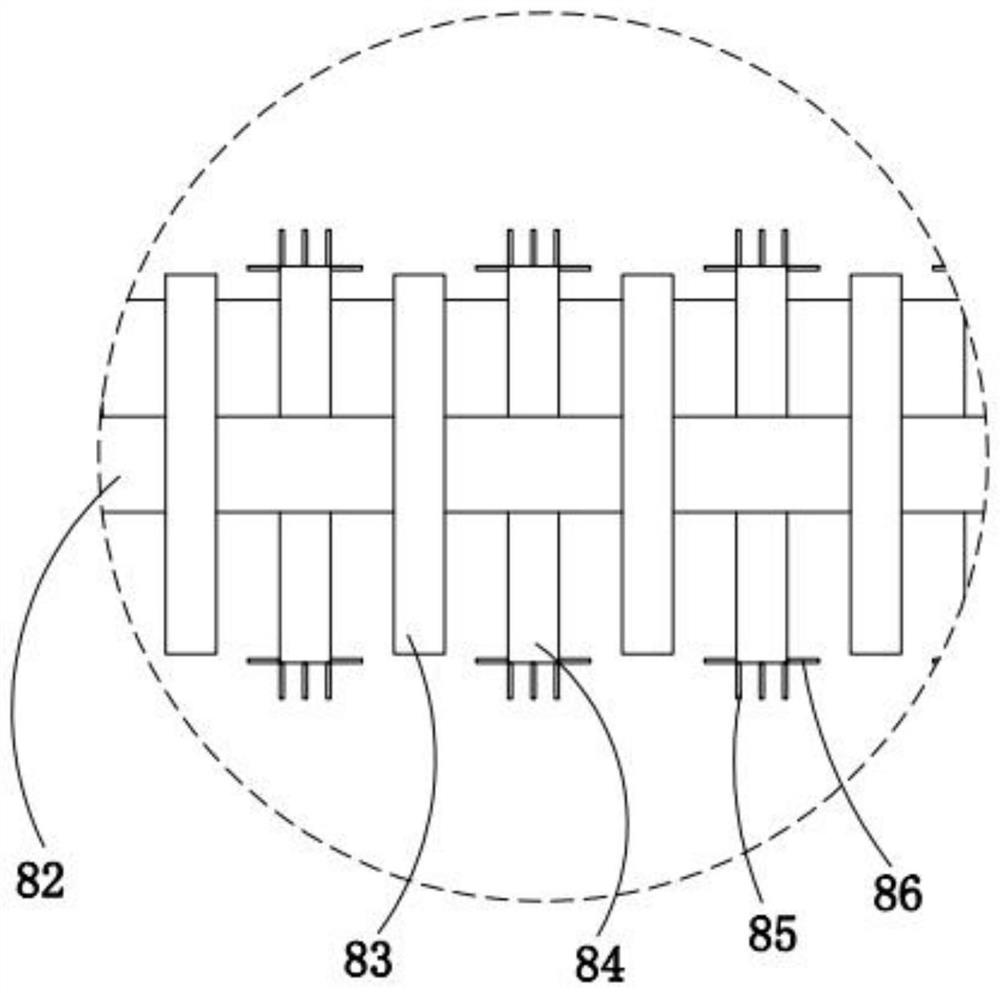

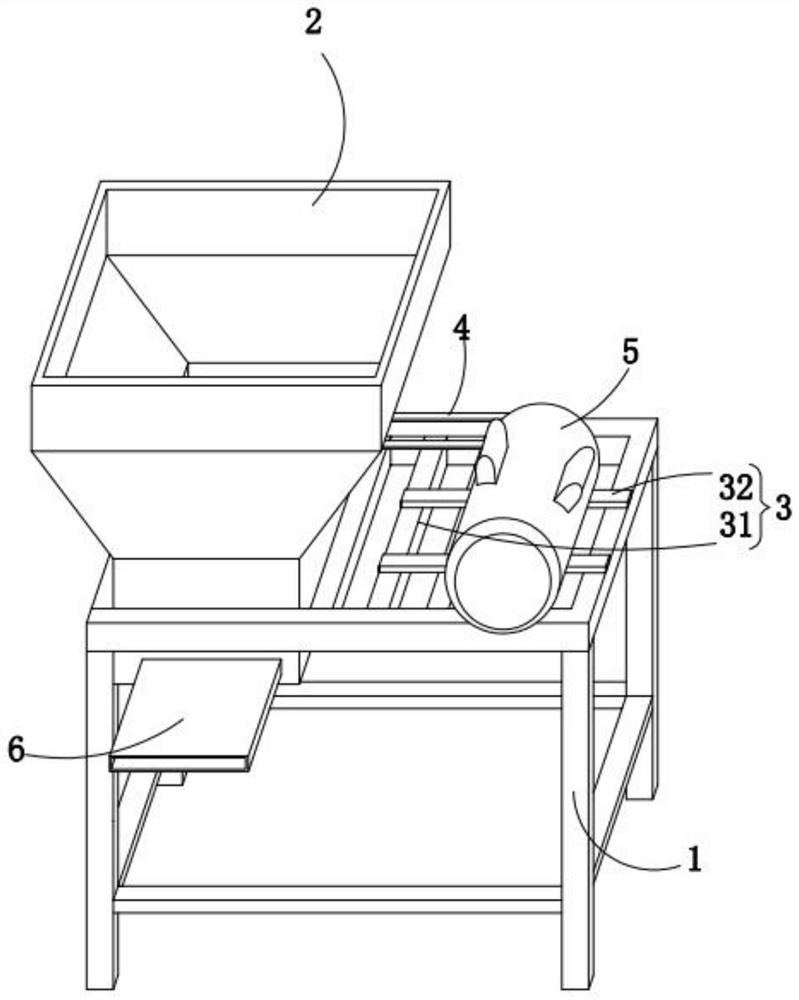

Rapid crushing device for agricultural fertilizer

ActiveCN112354645AIncrease crushing powerPromote absorptionGrain treatmentsAgricultural scienceTransmission belt

The invention provides a rapid crushing device for an agricultural fertilizer. The rapid crushing device structurally comprises a supporting frame, a funnel structure, a supporting structure, a motor,a discharging port, a crushing structure, a discharging structure and transmission belts. The funnel structure is fixed to one end of the supporting frame. The supporting structure is fixed to one end of the top face of the supporting frame. The motor is mounted on the surface of the supporting structure; the discharging port is fixed to the side wall of the bottom end of a funnel; the crushing structure is mounted in the funnel; the discharging structure is mounted at the bottom end of the funnel; and the two transmission belts are provided, and rotatably connected with the motor, double pulleys and a single pulley separately. The rapid crushing device for the agricultural fertilizer has the advantages that the fertilizer crushing force is increased, so that the powder is stirred and crushed more finely, and the absorption of crops is facilitated.

Owner:金莱福(山东)化肥进出口有限公司

A rapid repair device for road depressions

ActiveCN111270595BPromote repairRepair firmRoads maintainenceElectric machineryStructural engineering

Owner:郑州市公路工程公司

Notch crushing blade

InactiveCN103567034AIncrease crushing powerImprove work performanceGrain treatmentsPulp and paper industryKnife blades

The invention relates to the technical field of coating production equipment, especially to a notch crushing blade, which comprises a blade and a mounting head. The bottom of the blade is provided with the mounting head, the narrow side of the blade is provided with at least 2 notches. A plurality of notches are designed laterally on the notch crushing blade, when the blade rotates, the notches rotate along the blade, thus increasing the crushing strength on coating, improving the work efficiency, and achieving a good use effect.

Owner:余正忠

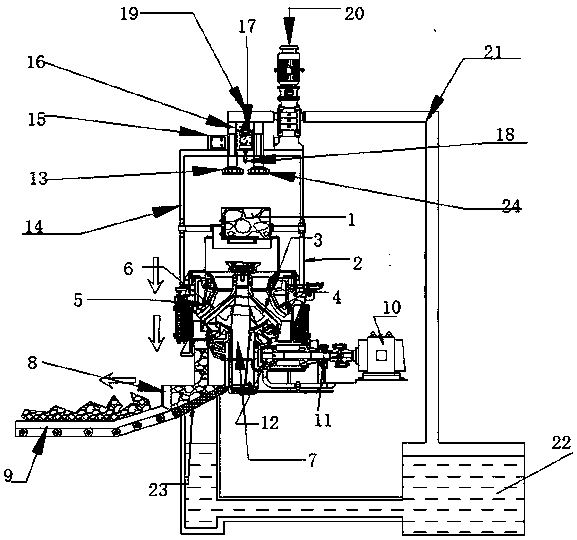

Equipment and method for recycling aggregate from waste concrete

InactiveCN114534856AIncrease the impact frequencyIncrease crushing powerSolid waste managementGrain treatmentsEnvironmental engineeringCrusher

The invention discloses equipment and a method for recycling aggregate from waste concrete, and relates to the technical field of waste concrete recycling. The equipment comprises a concrete crushing mechanism, the concrete crushing mechanism is provided with a shell, the top of the shell is fixedly connected with a rotary stirring mechanism, the concrete crushing mechanism is fixedly connected with the rotary stirring mechanism, the rotary stirring mechanism is provided with an extrusion block, and the extrusion block is fixedly connected with the shell. The outer wall of the extrusion block is fixedly connected with a crushing mechanism, and the rotary stirring mechanism is fixedly connected with the crushing mechanism. According to the equipment and the method for recycling the aggregate from the waste concrete, the extrusion block impacts on the inner wall of the shell, so that the extrusion block extrudes gas in the cylinder, blowing-out of airflow is accelerated, the airflow can blow up dust in the cylinder, and the influence of dust accumulation on concrete smashing is avoided; and the molecular spacing in the gas is reduced.

Owner:金敏

A new type of fully crushing equipment for waste batteries

Owner:烟台金潮宇科蓄电池有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com