Patents

Literature

54results about How to "Fully crushed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

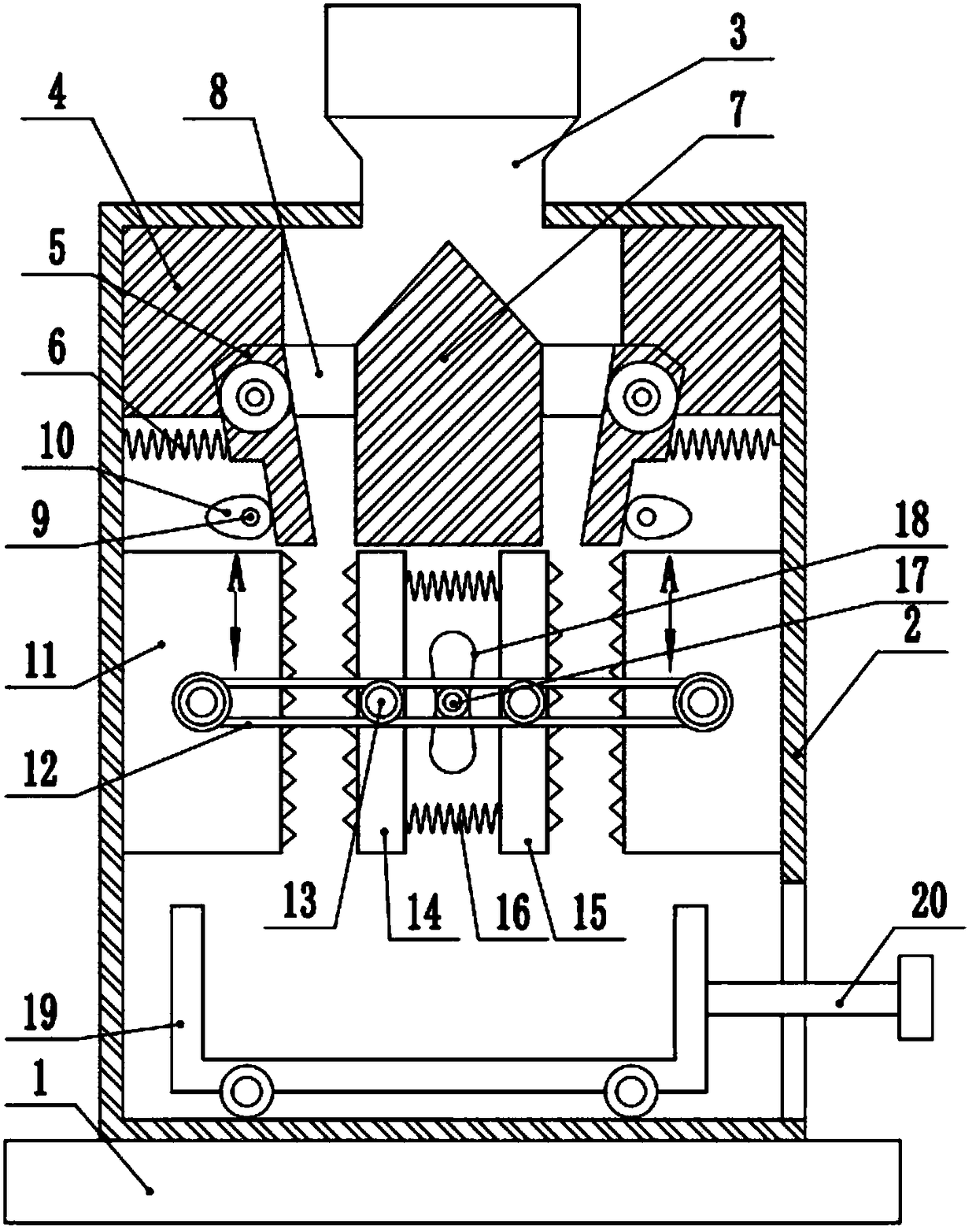

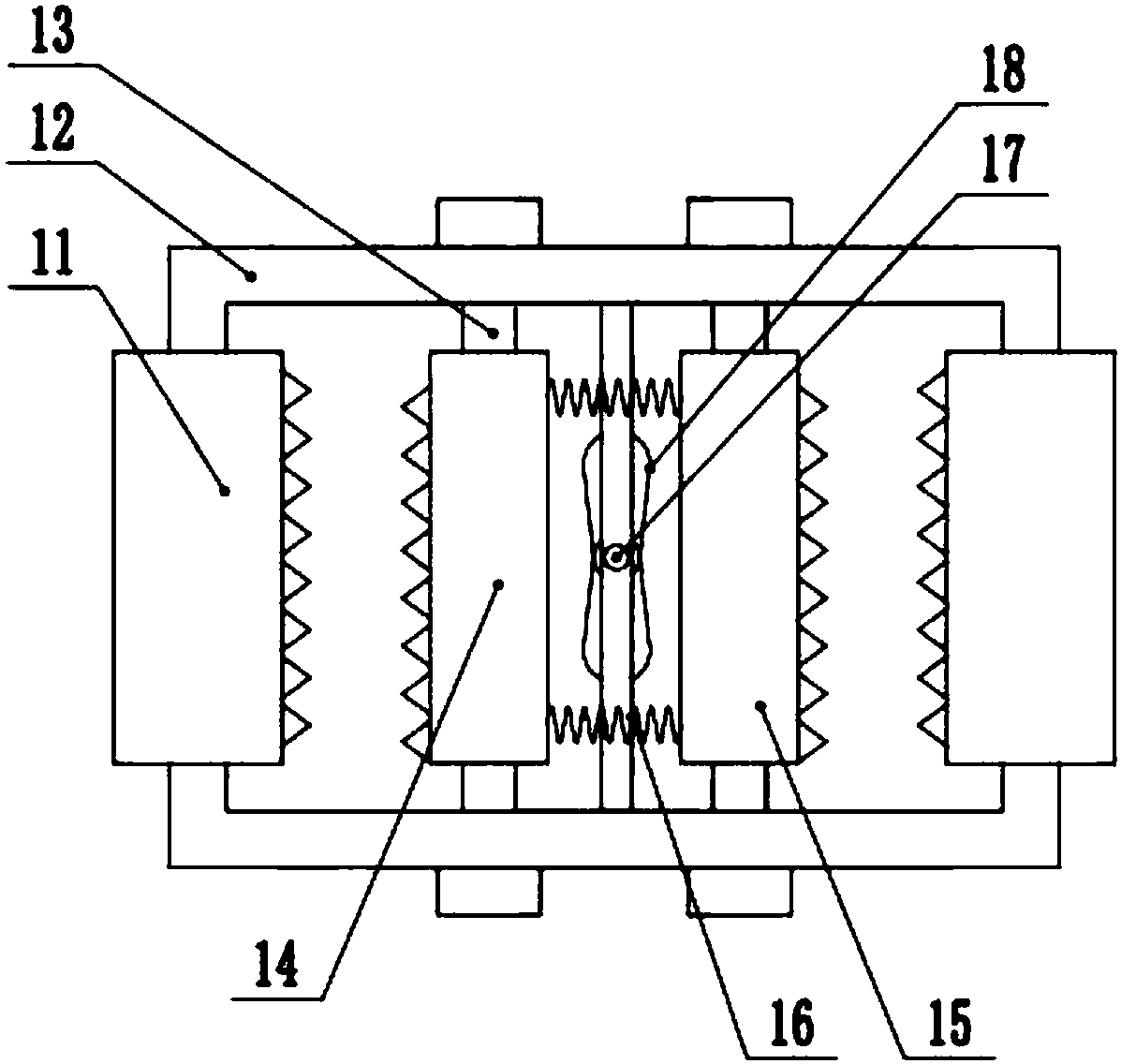

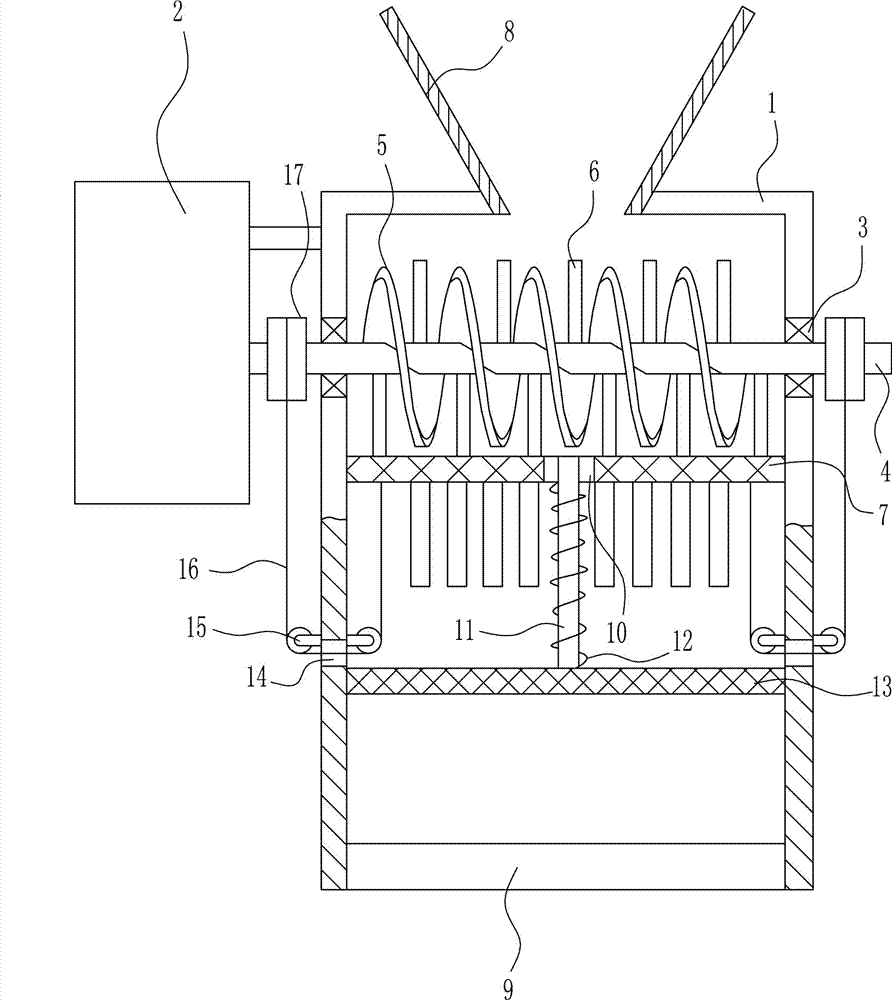

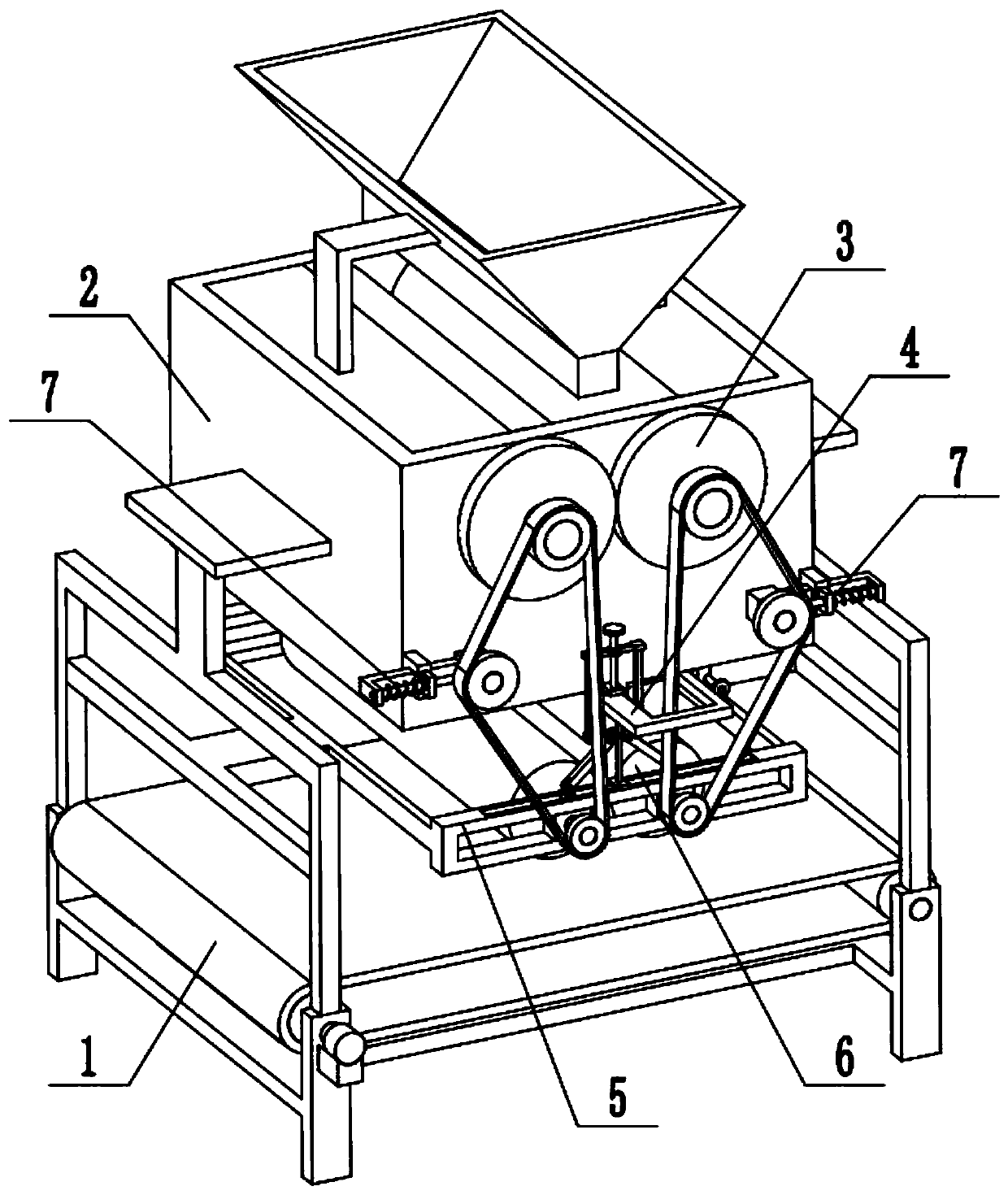

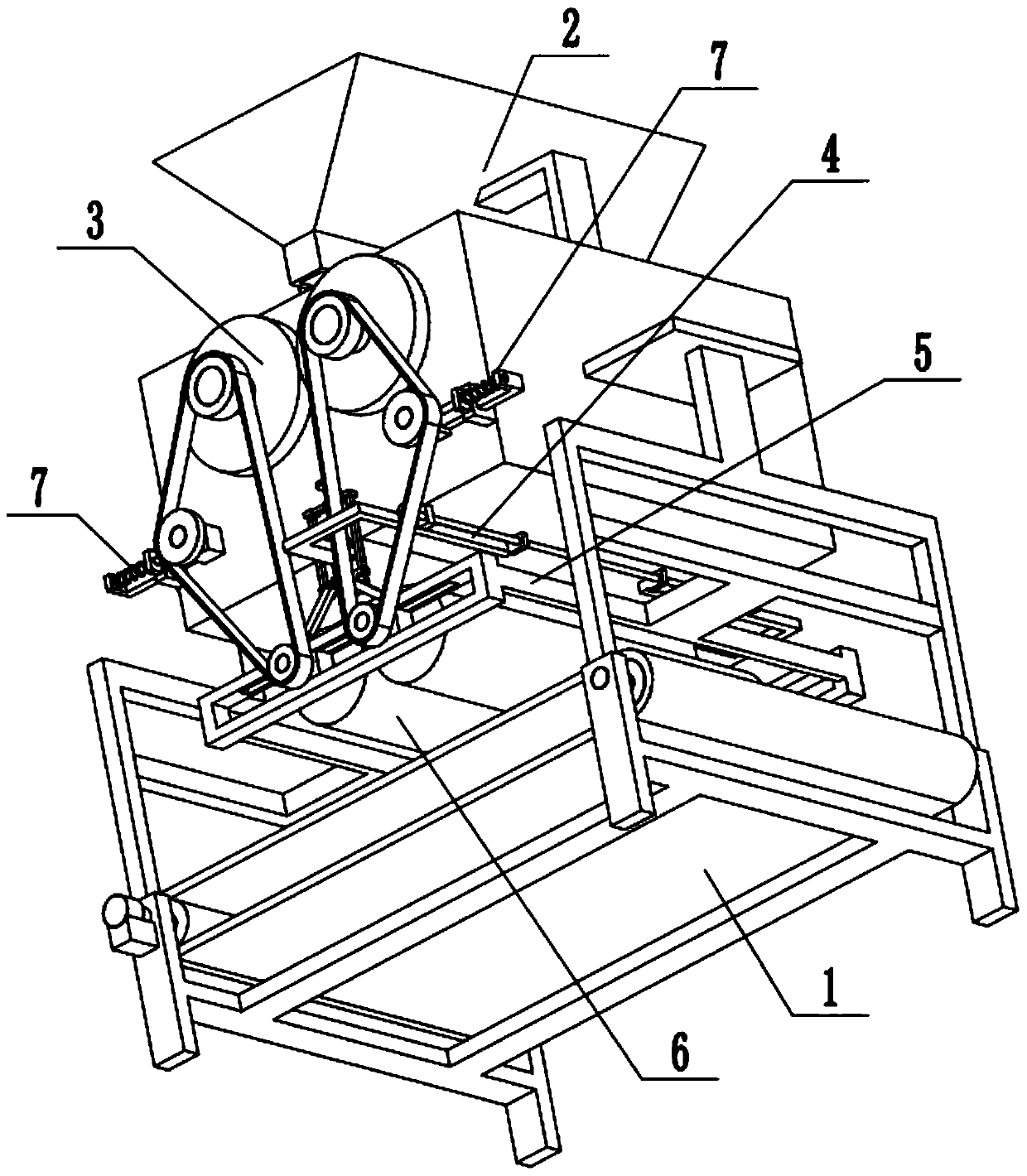

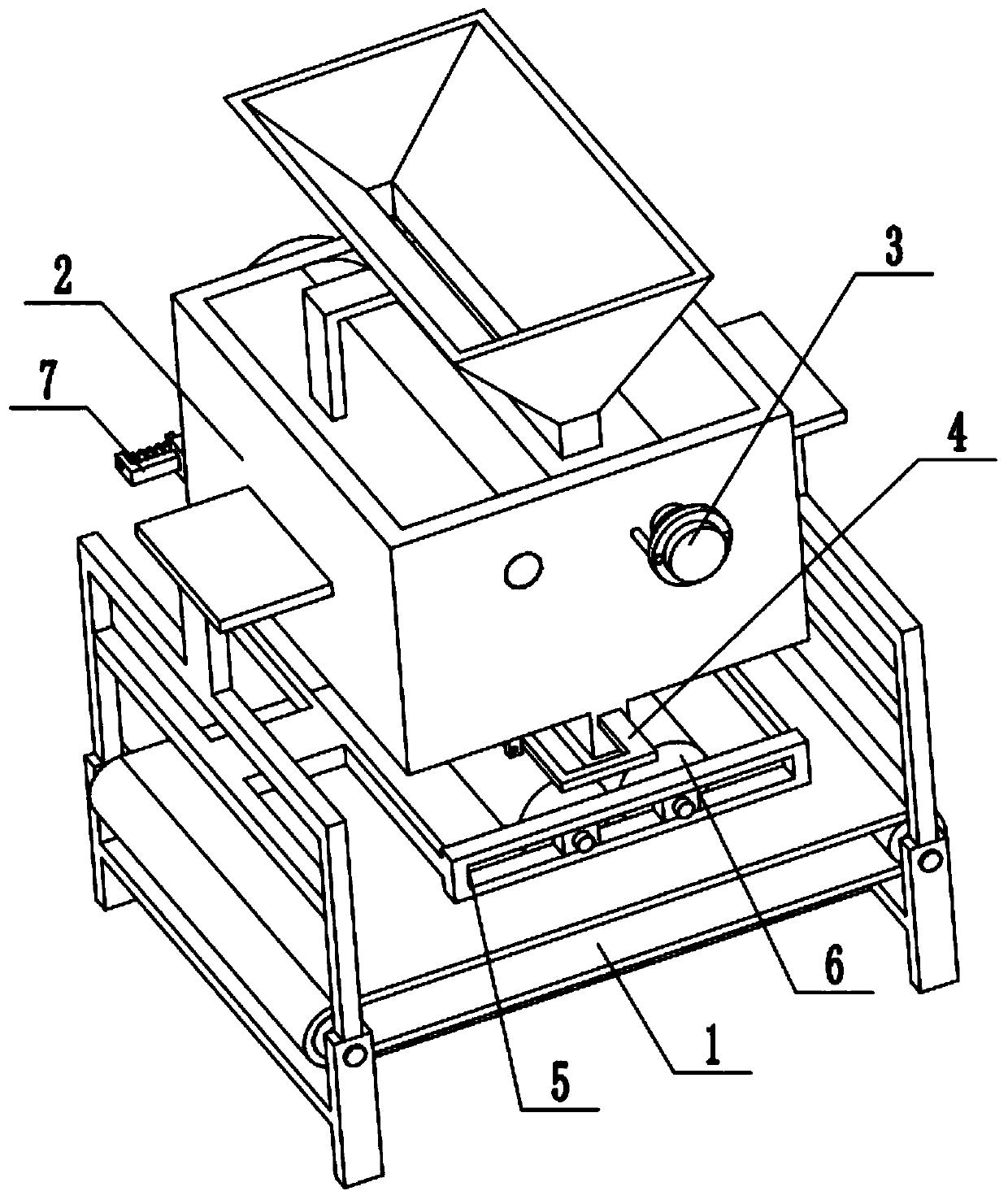

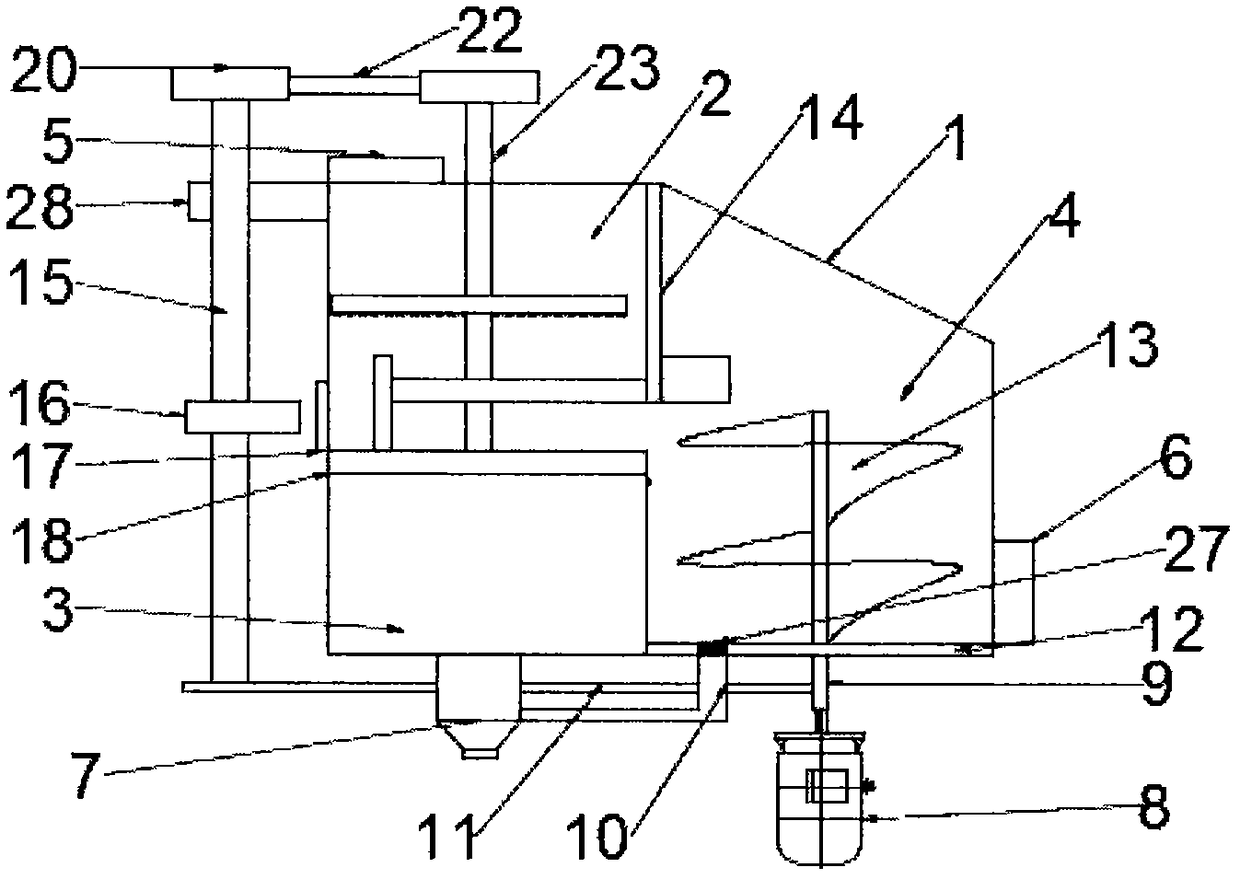

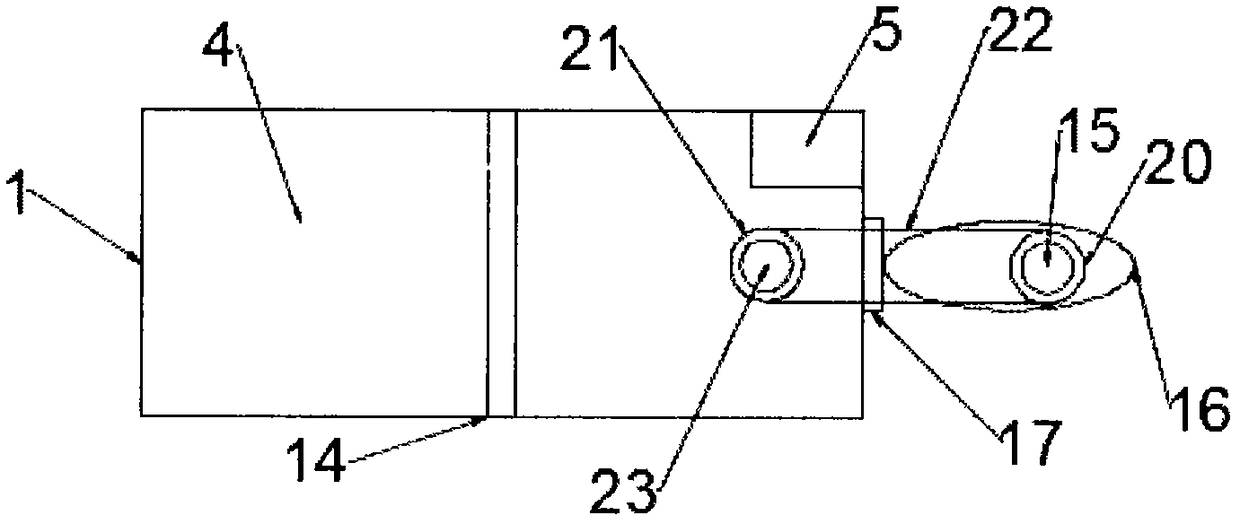

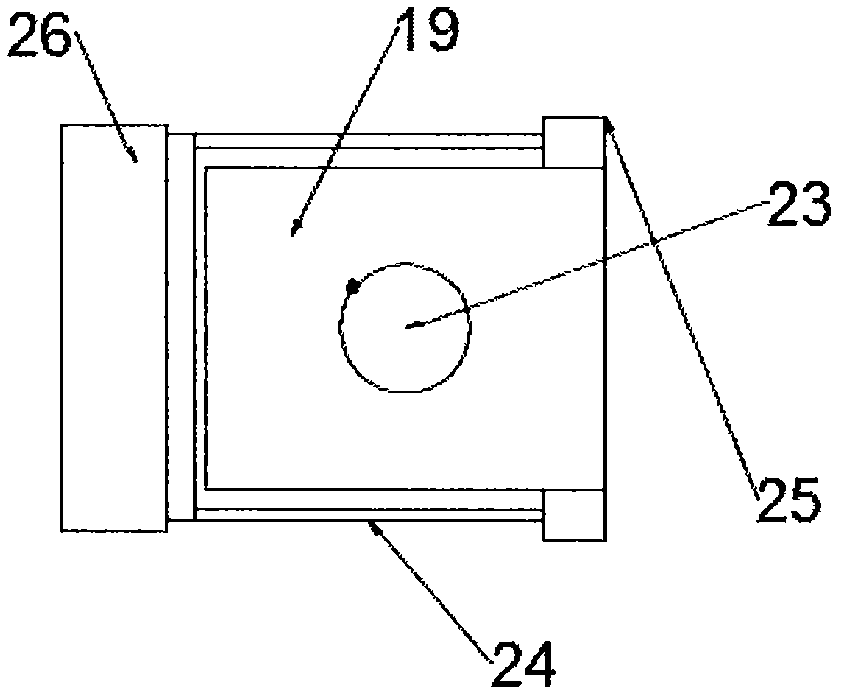

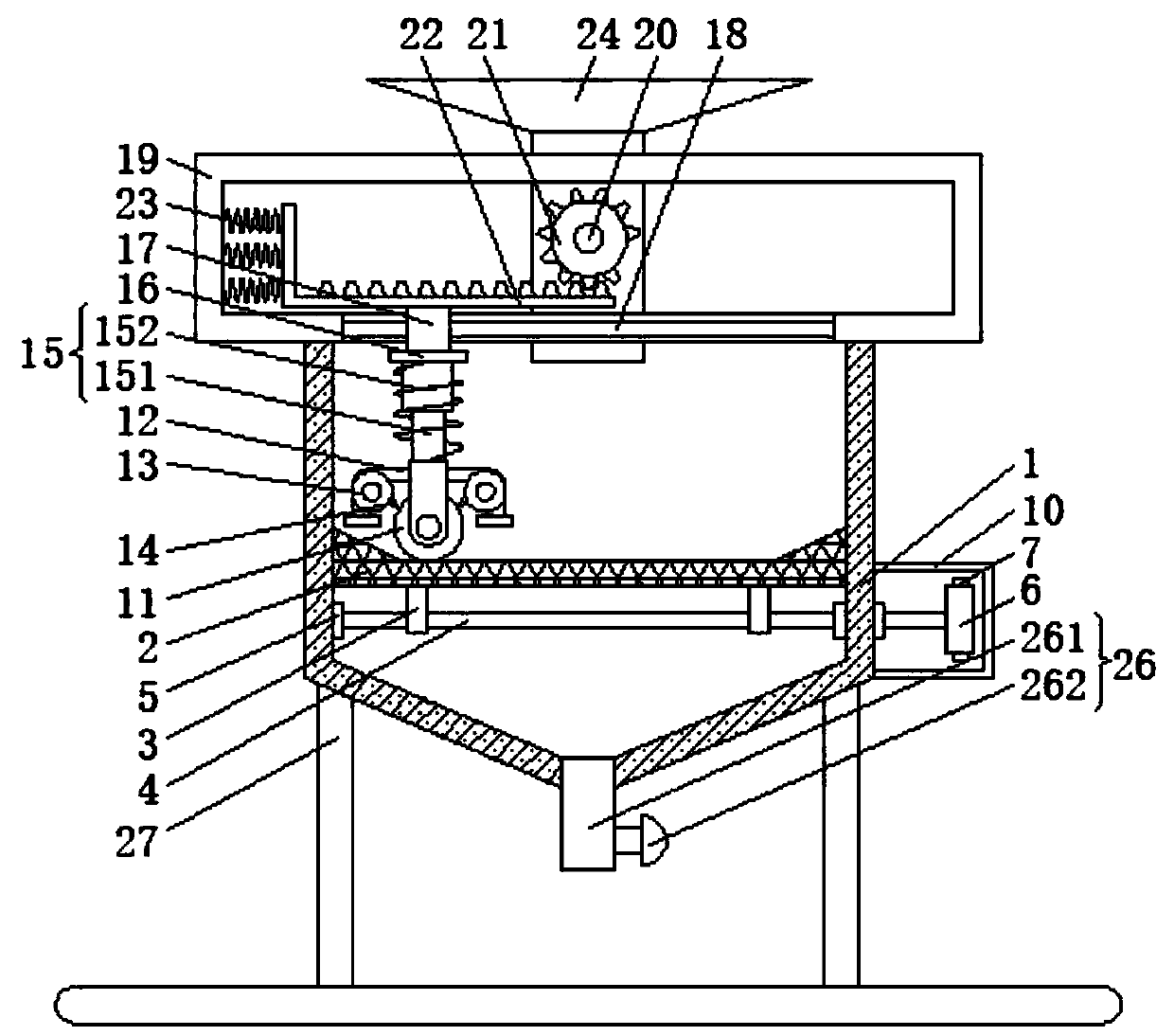

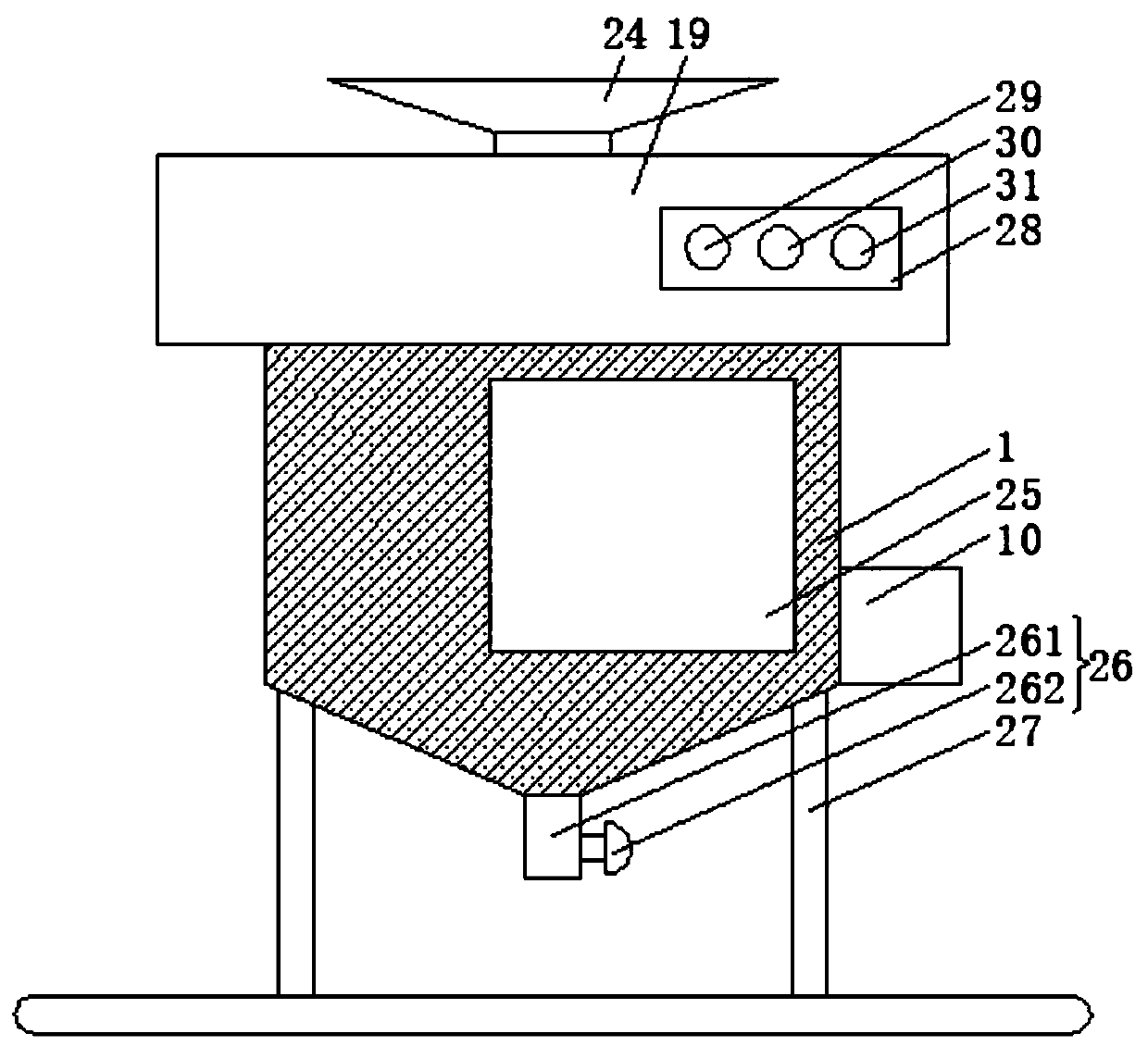

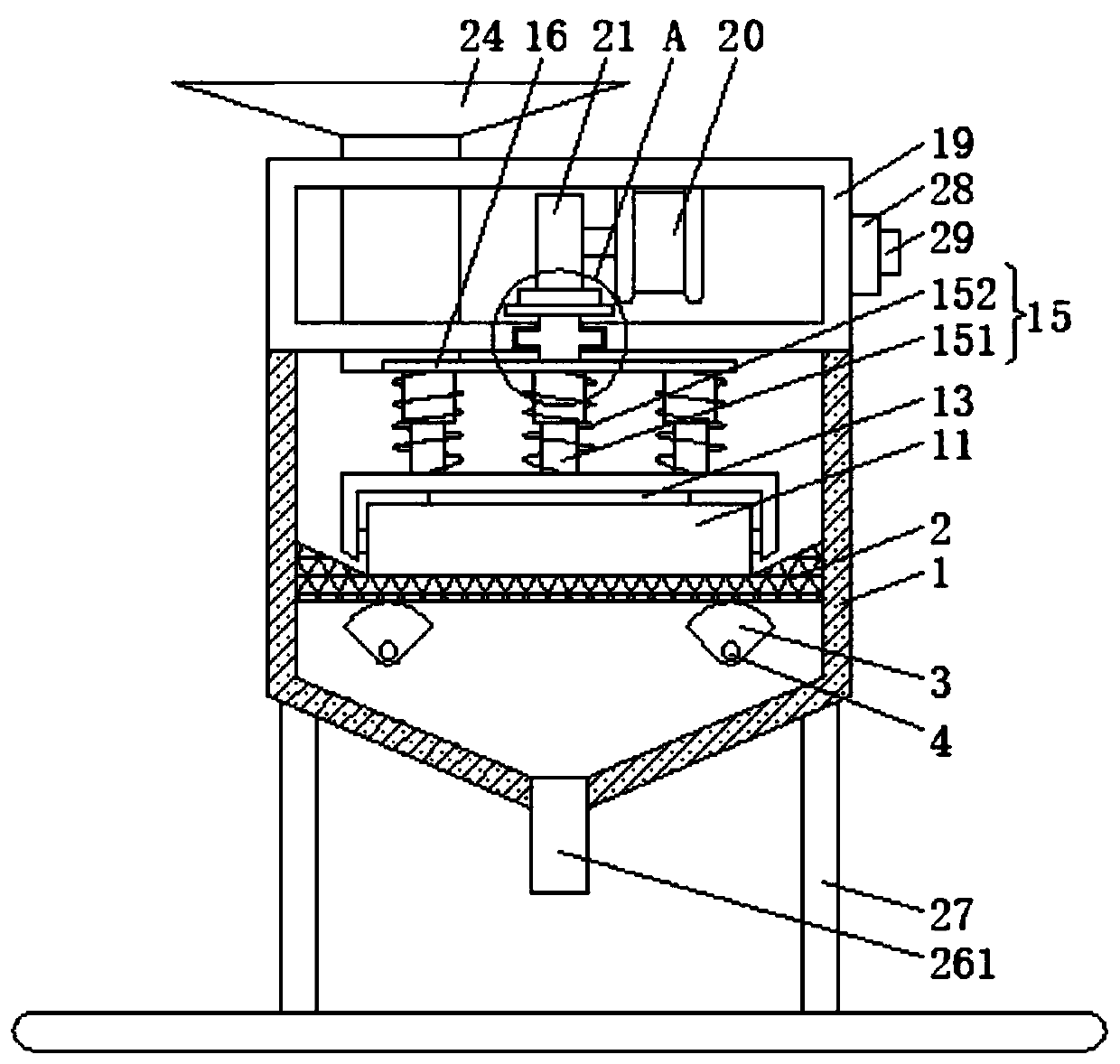

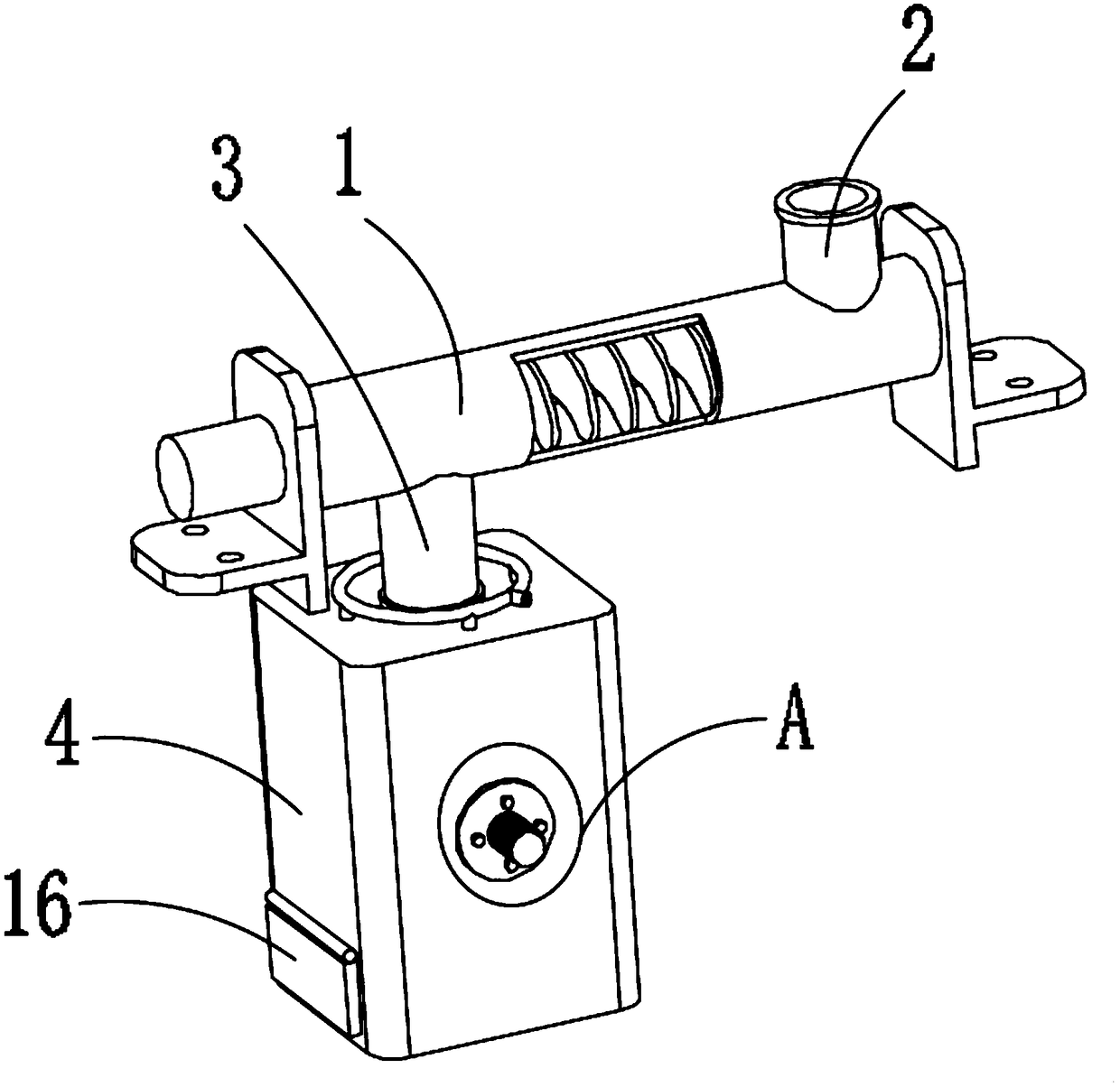

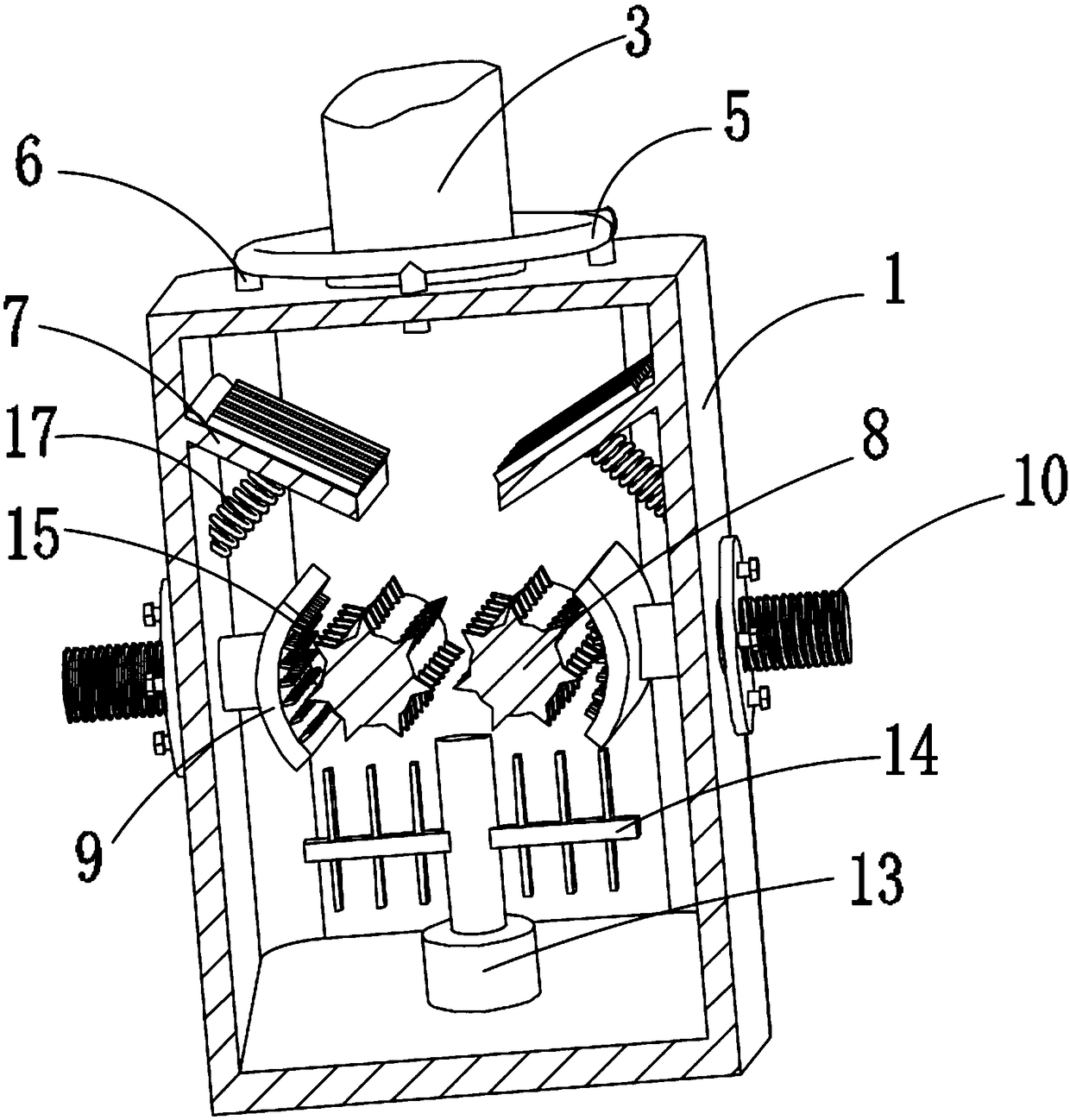

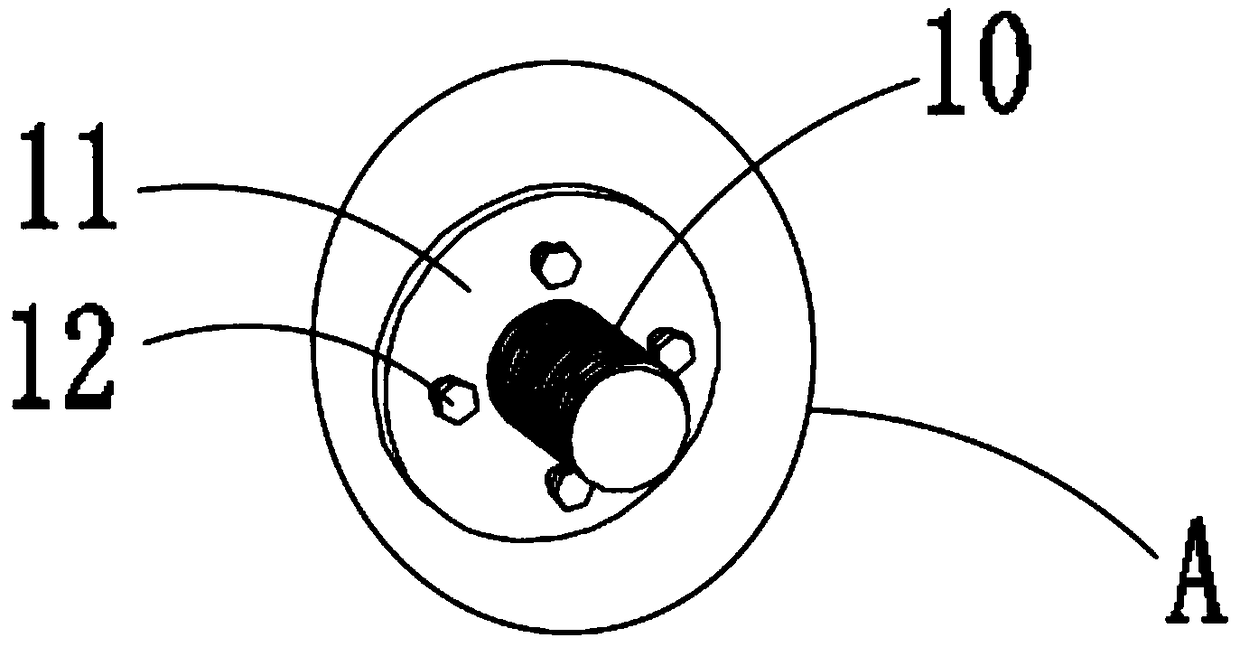

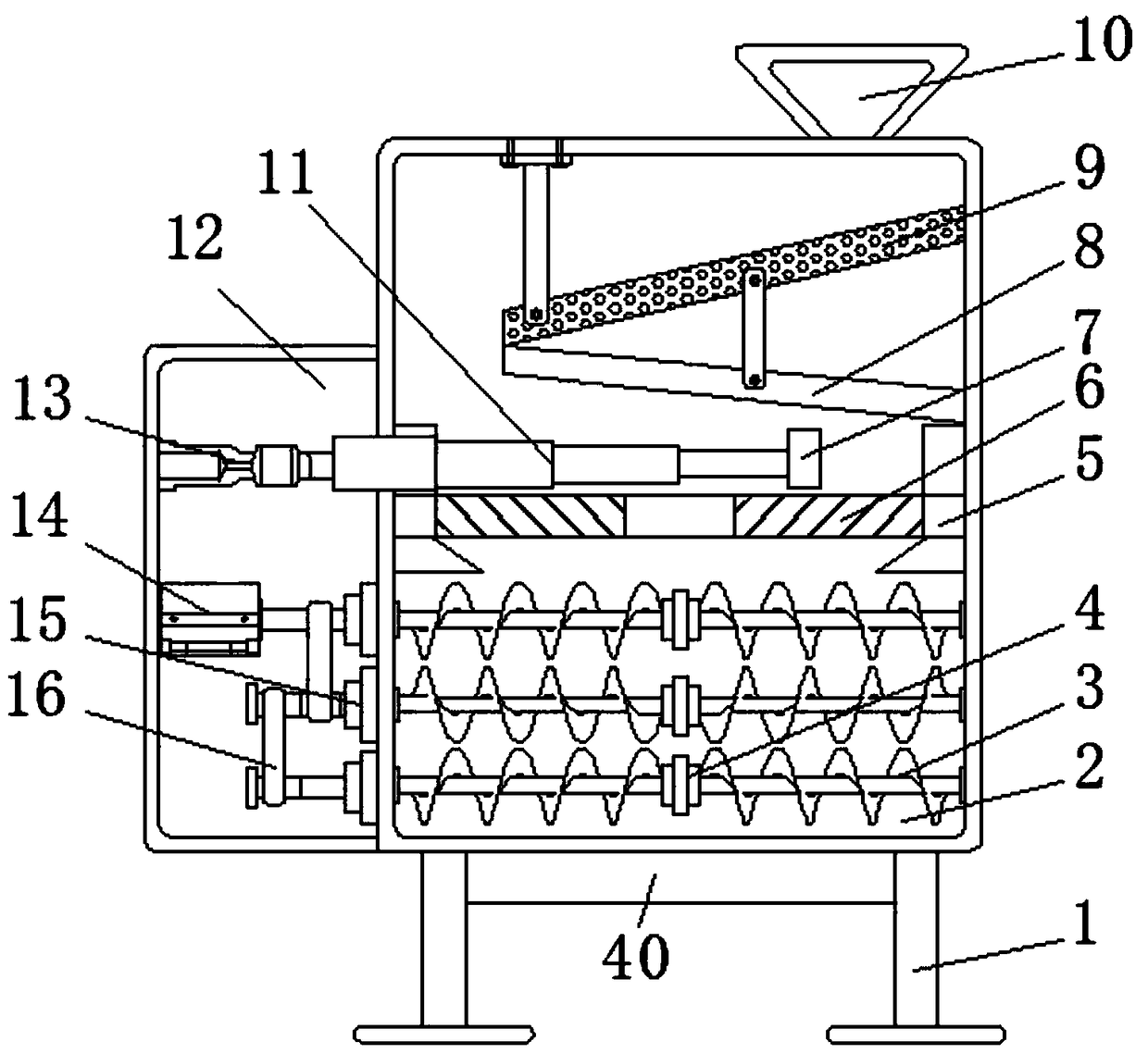

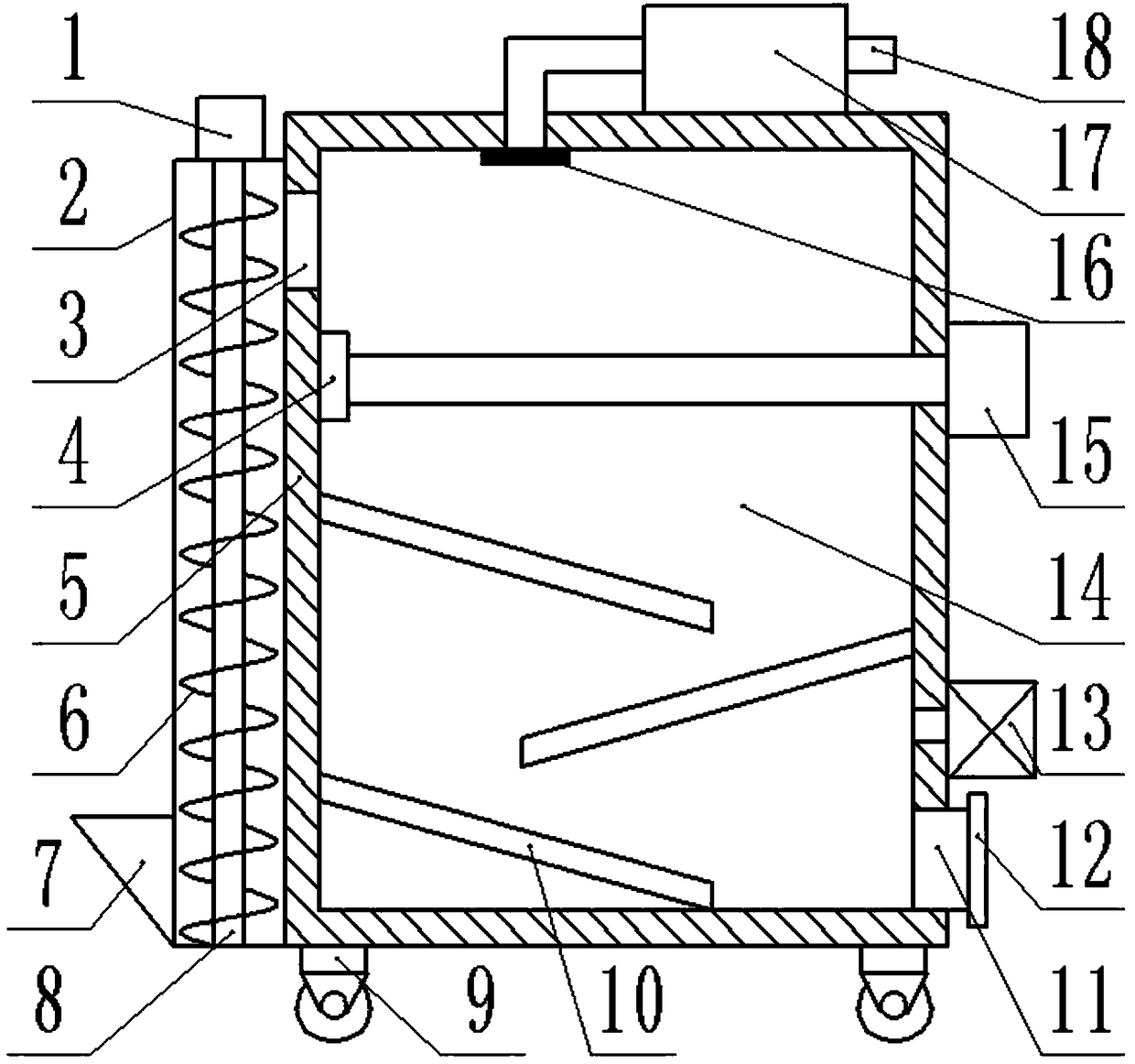

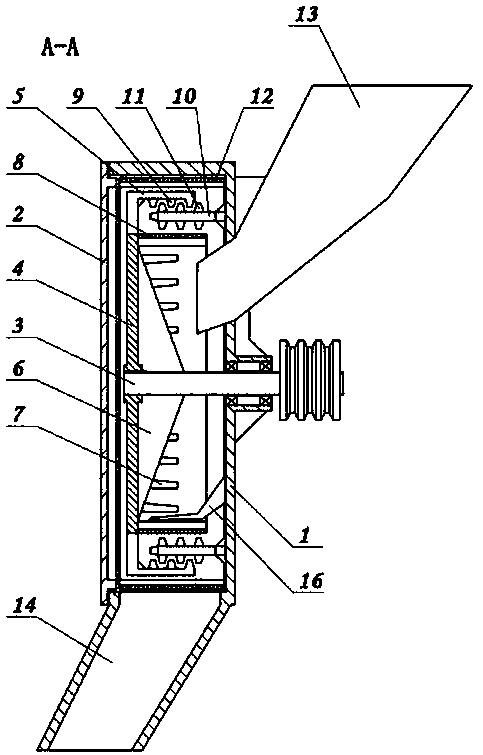

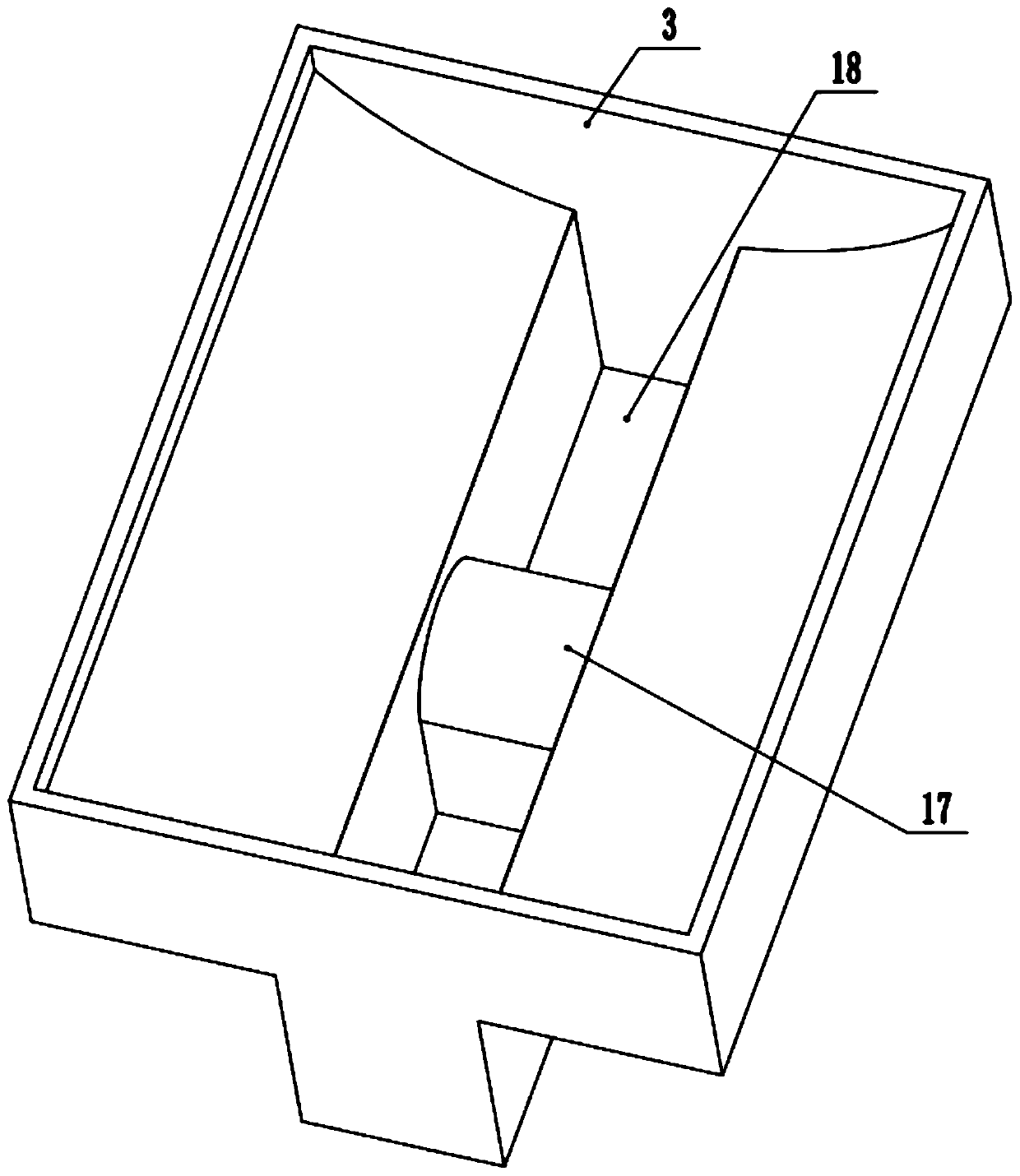

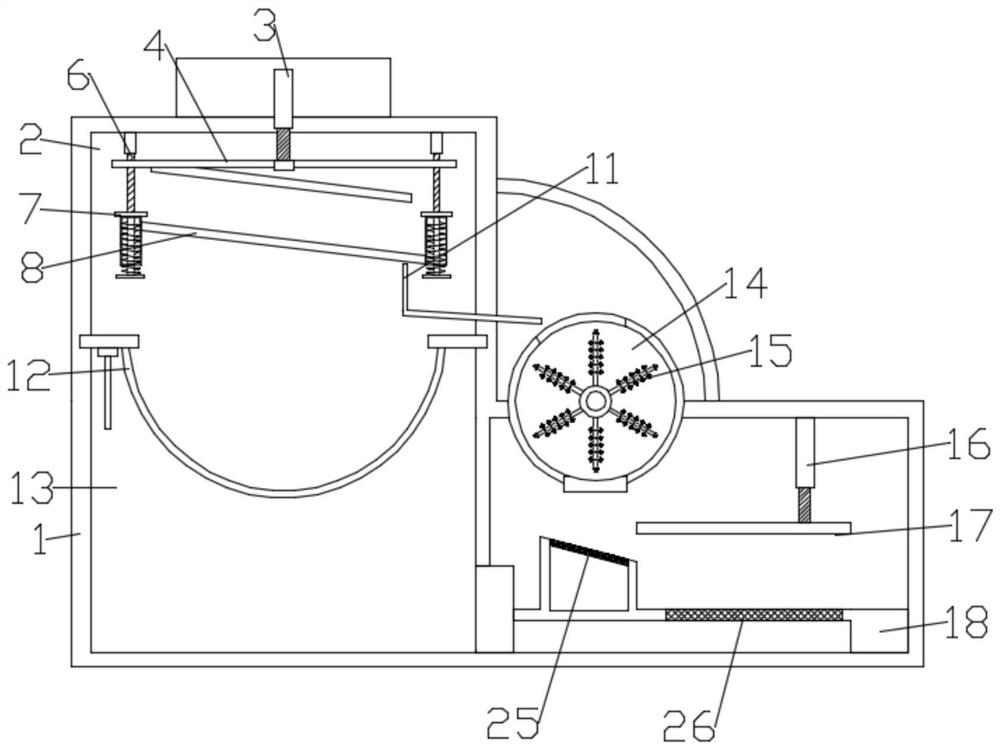

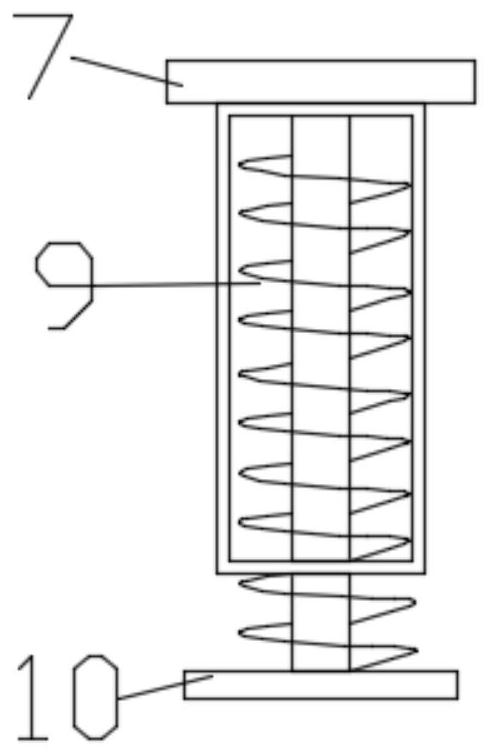

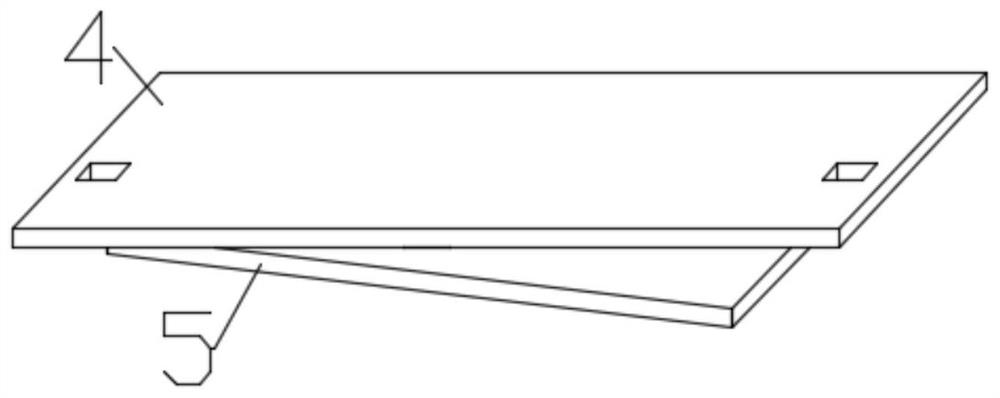

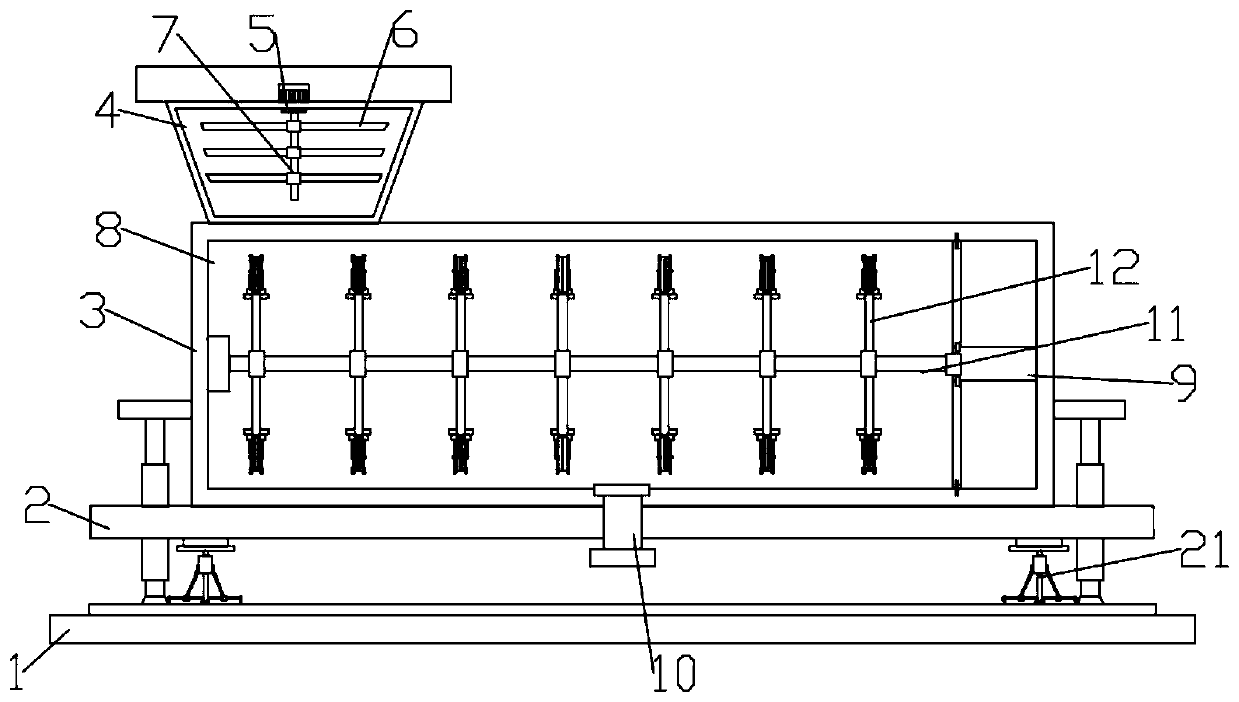

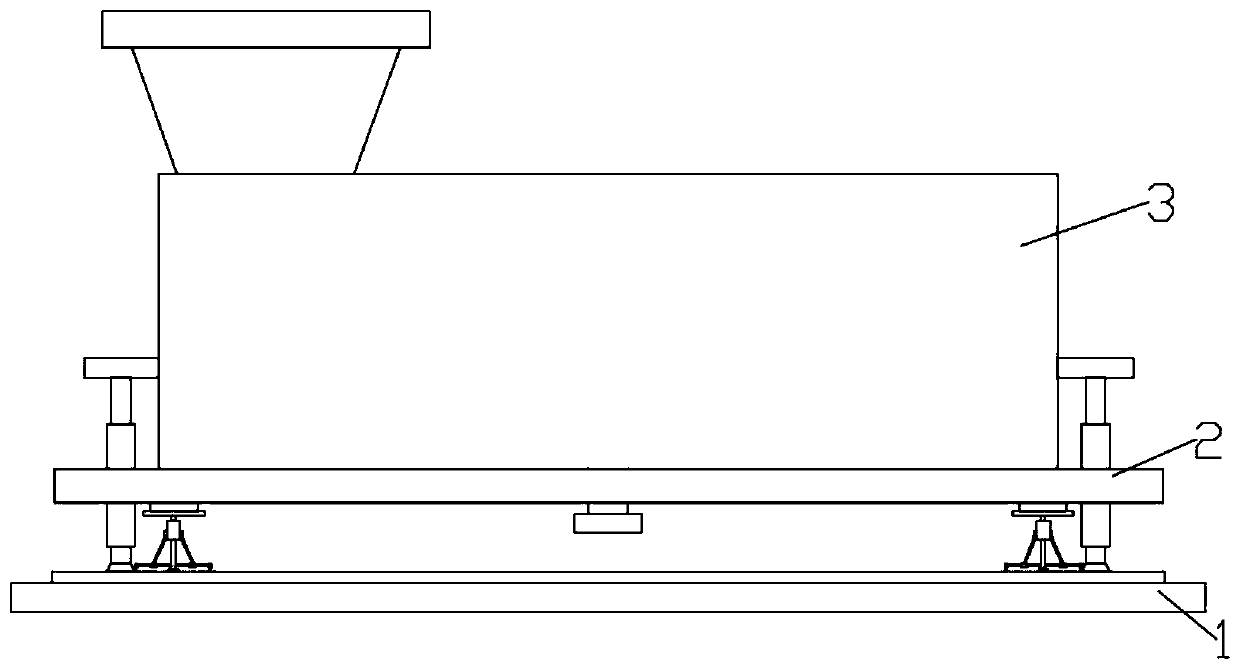

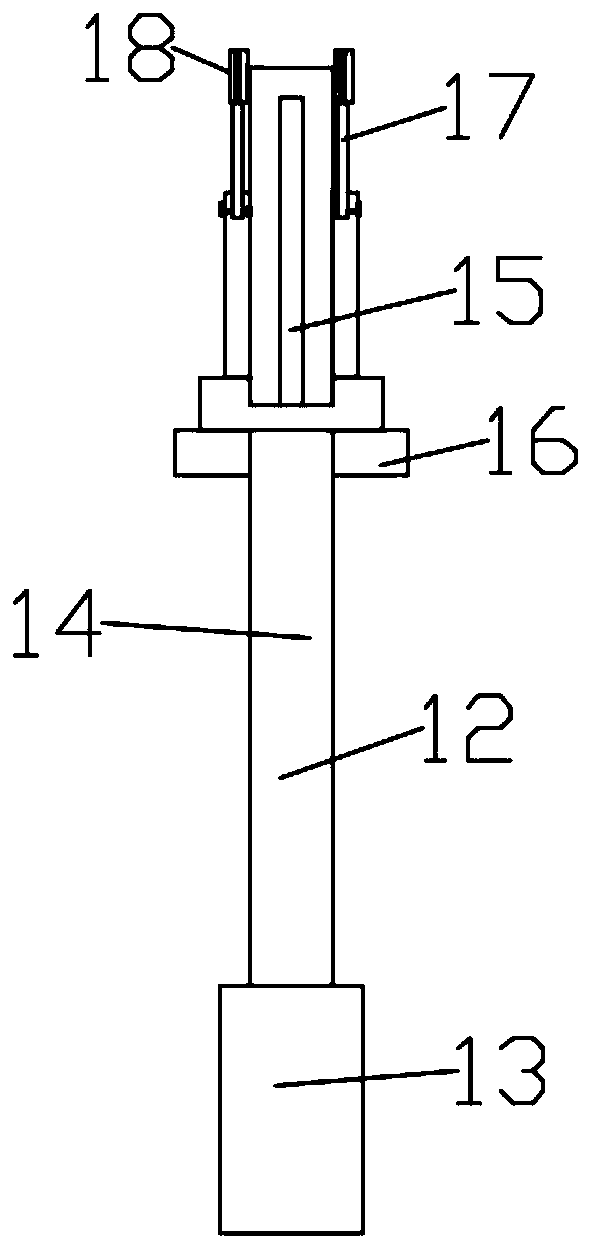

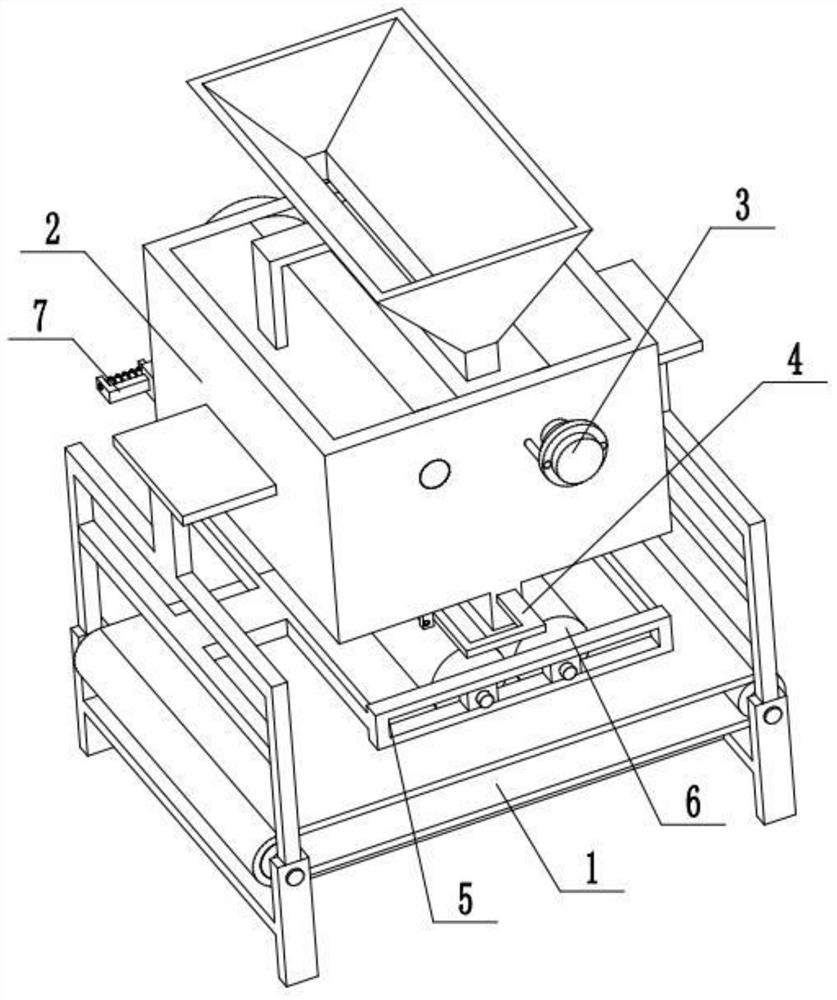

Cam-driven type intermittent feeding fodder smashing device

InactiveCN108160156ACrushed fullyRealize the effect of continuous extrusion and crushingFeeding-stuffGrain treatmentsInterference fitDrive motor

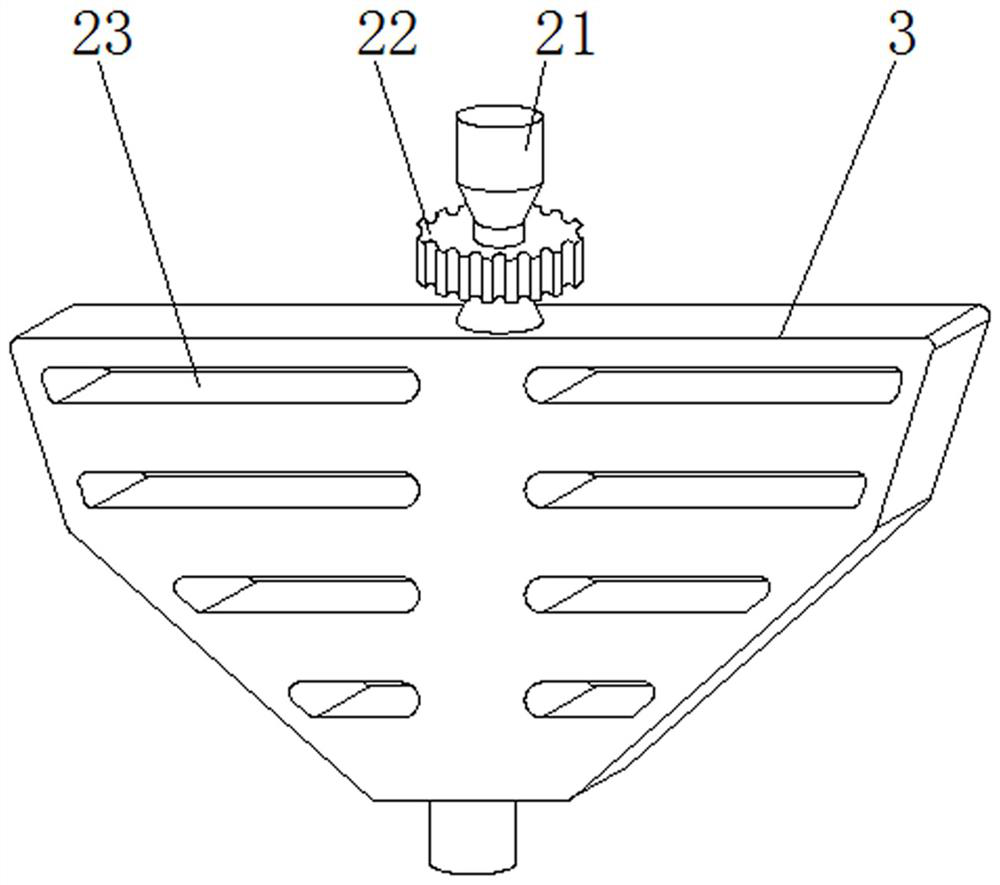

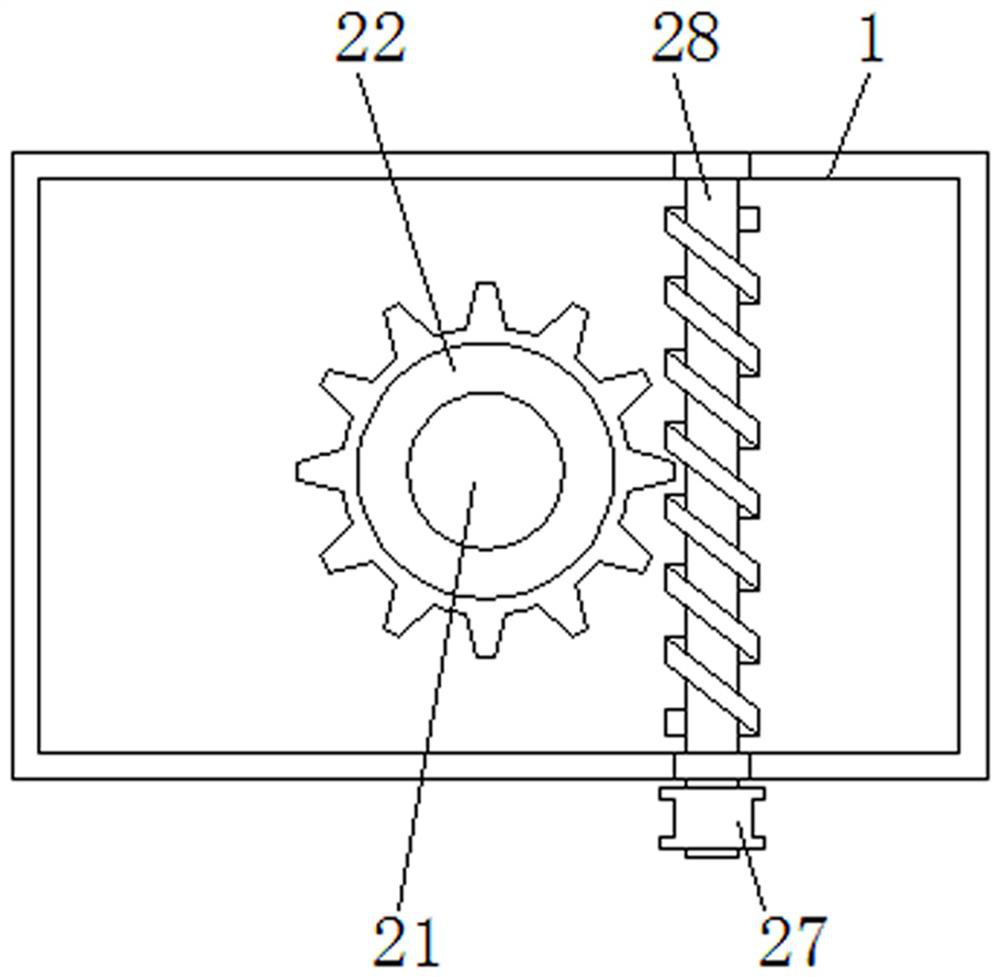

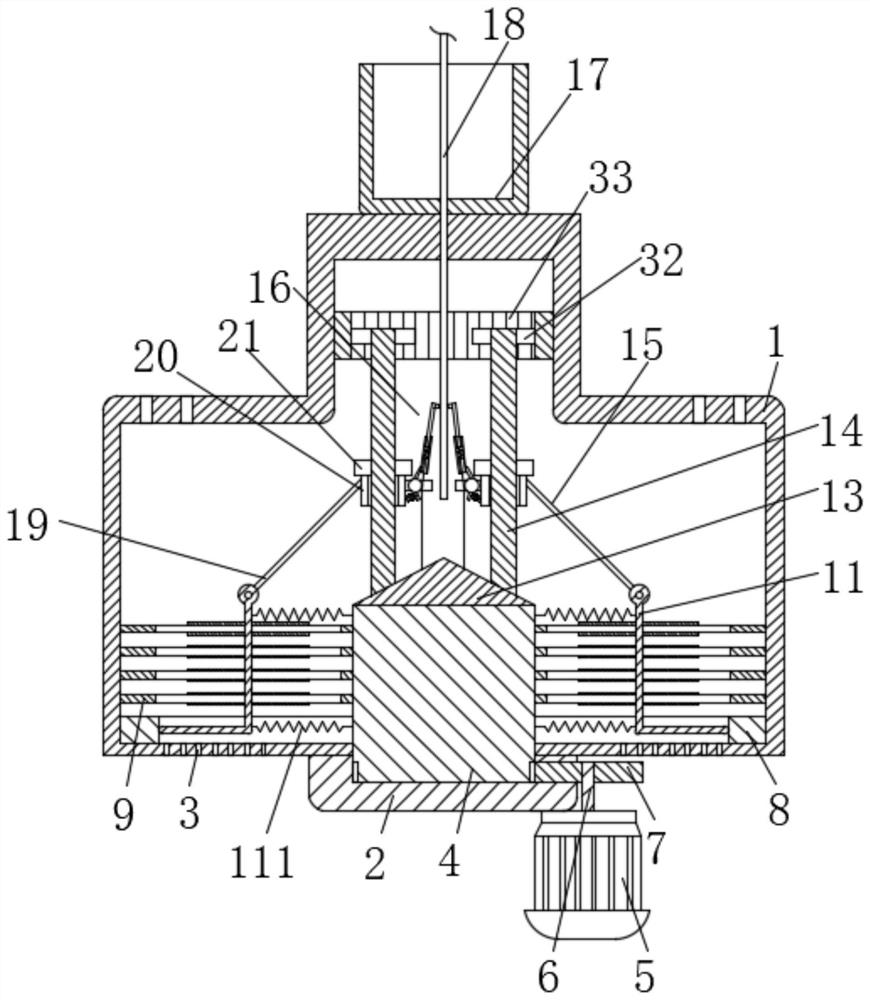

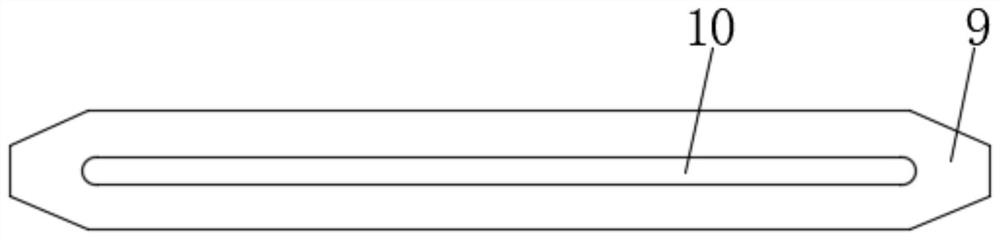

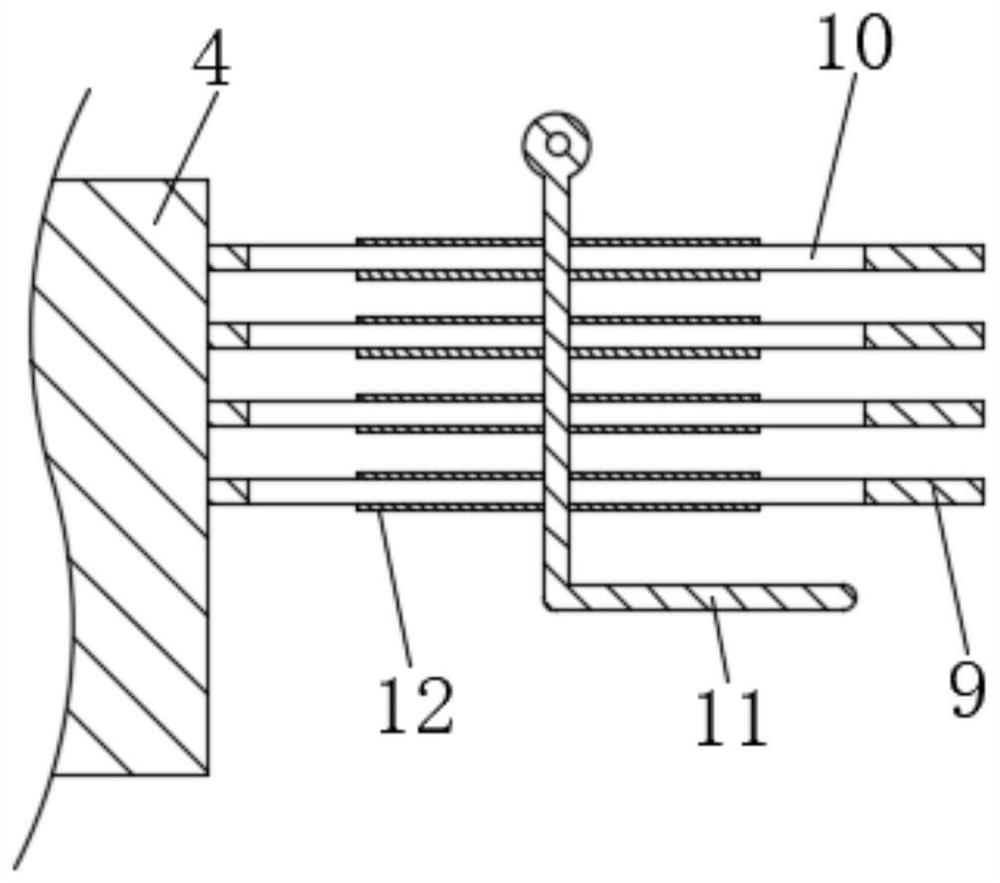

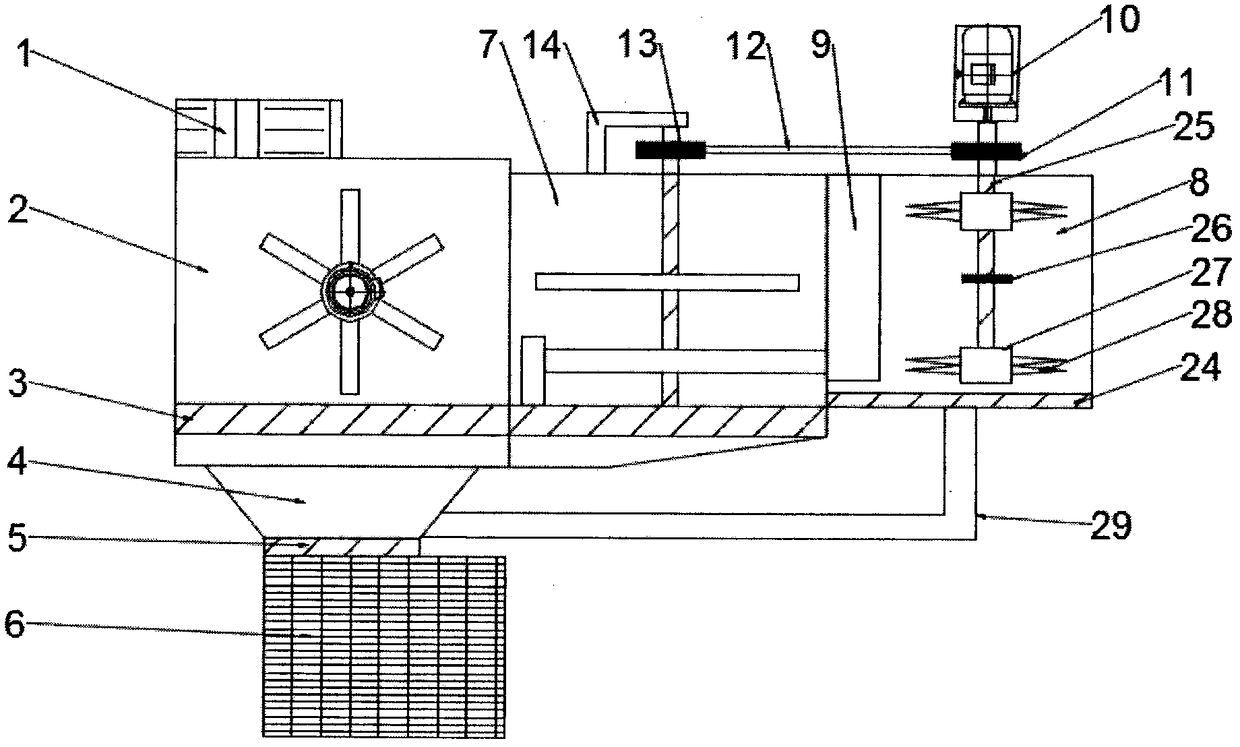

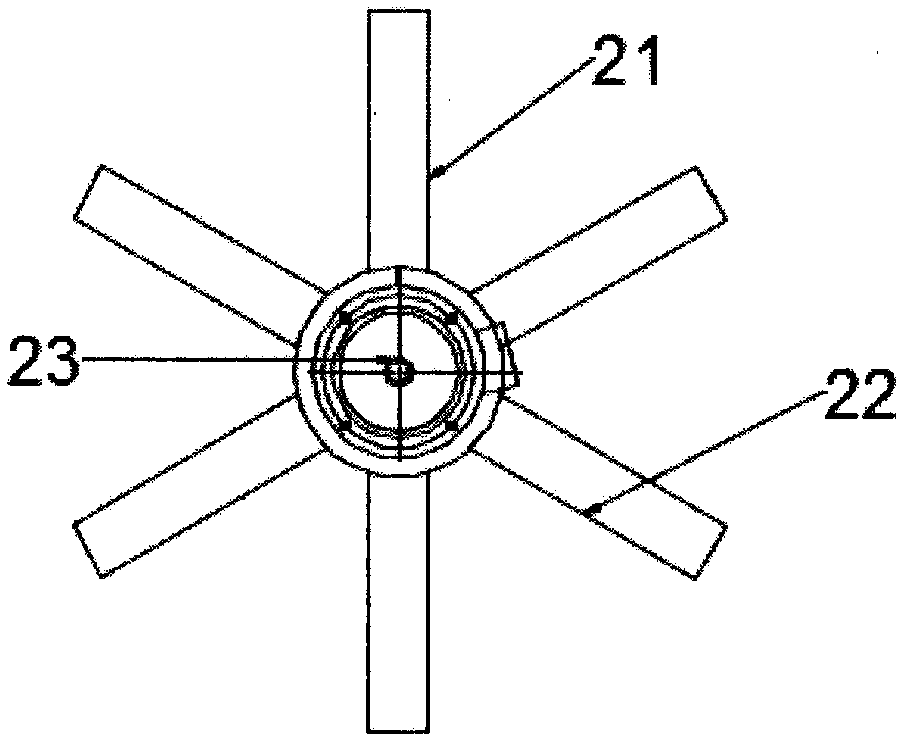

A cam-driven type intermittent feeding fodder smashing device comprises a base, a smashing tank, a rotating baffle, a first drive motor, a first cam, fixed smashing plates, a left smashing plate and aright smashing plate; the smashing tank is arranged on the base; the rotating baffle is rotationally installed on a fixed baffle through a rotating shaft; the fixed smashing plates are fixedly installed on the inner walls of the left side and the right side in the smashing tank through screws; and the left smashing plate and the right smashing plate are installed on a sliding shaft in an interference fit mode. The cam-driven type intermittent feeding fodder smashing device can achieve intermittent feeding, at the same time, the left smashing plate and the right smashing plate move towards thefixed smashing plates intermittently, accordingly continuous squeezing and smashing effects are achieved, discharging and smashing are conducted at the same time, and the situation that fodder is notsufficiently smashed as being discharged too much at a time is effectively avoided; and meanwhile, continuous pressing and squeezing can greatly improve the fodder smashing effect, the fodder can besmashed more sufficiently, and compared with manual grinding, more time and labor are saved, the structure is simple, and practicability is high.

Owner:ZHENGZHOU HAOEN ELECTRONICS INFORMATION TECH CO LTD

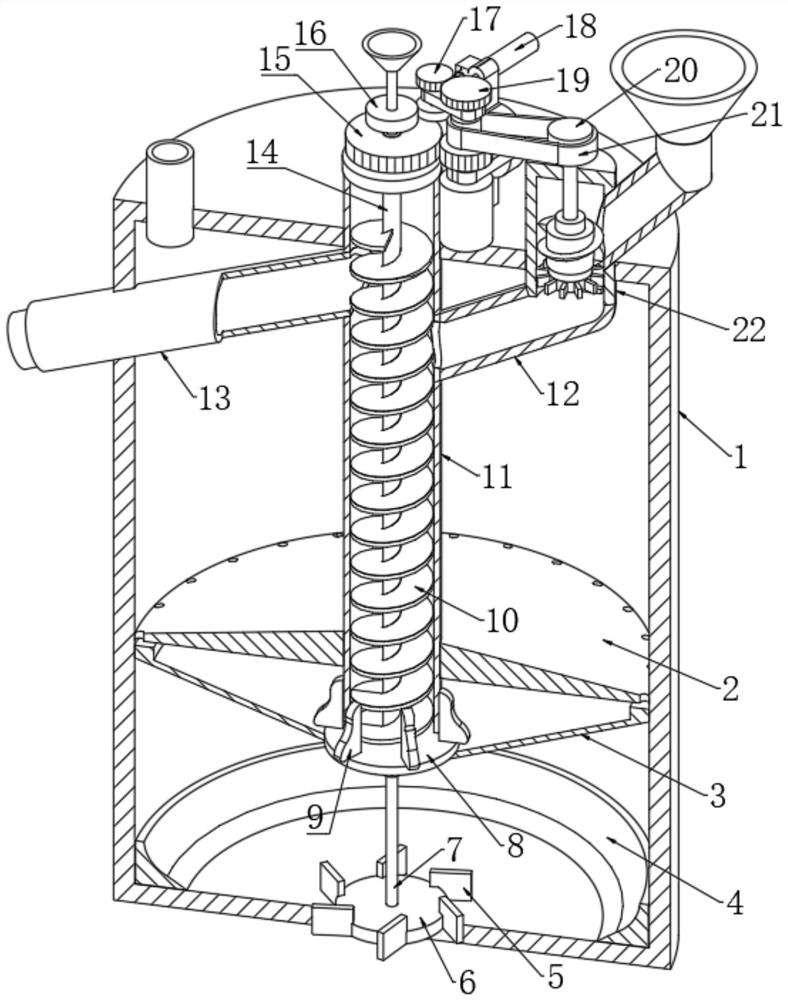

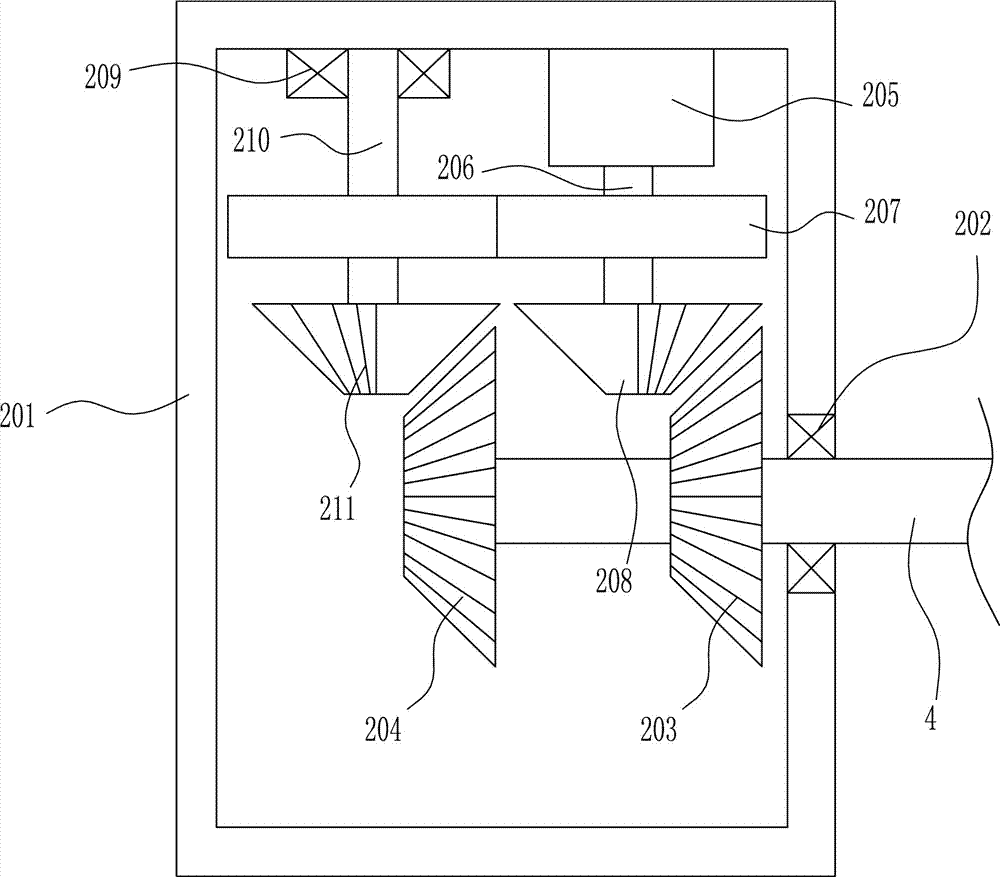

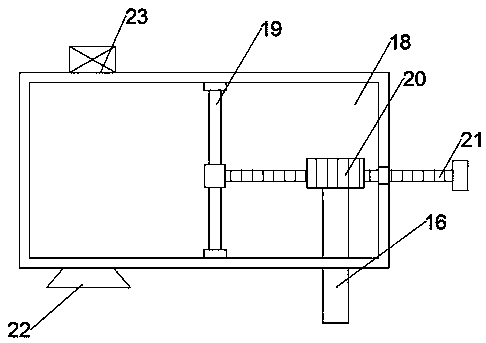

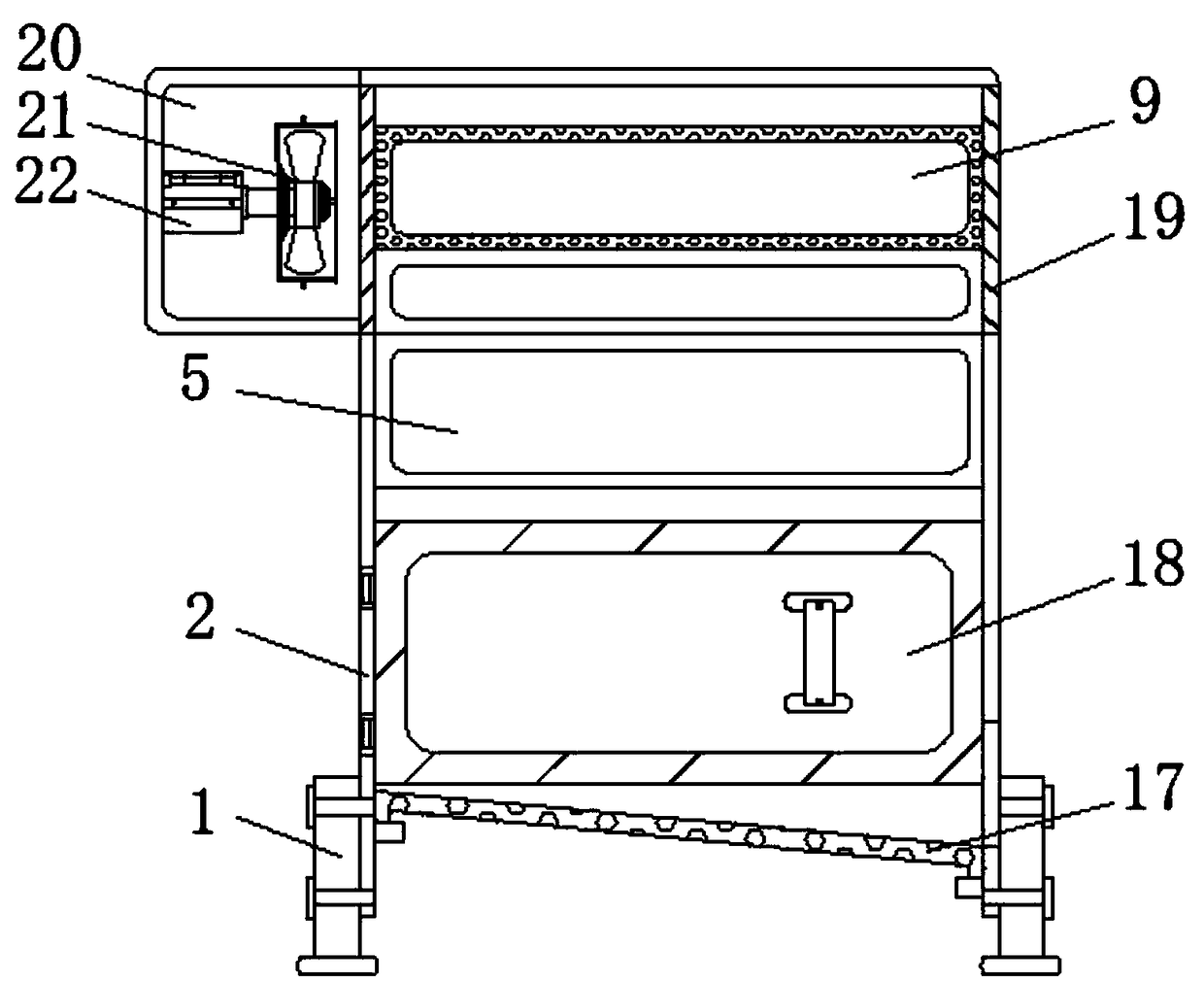

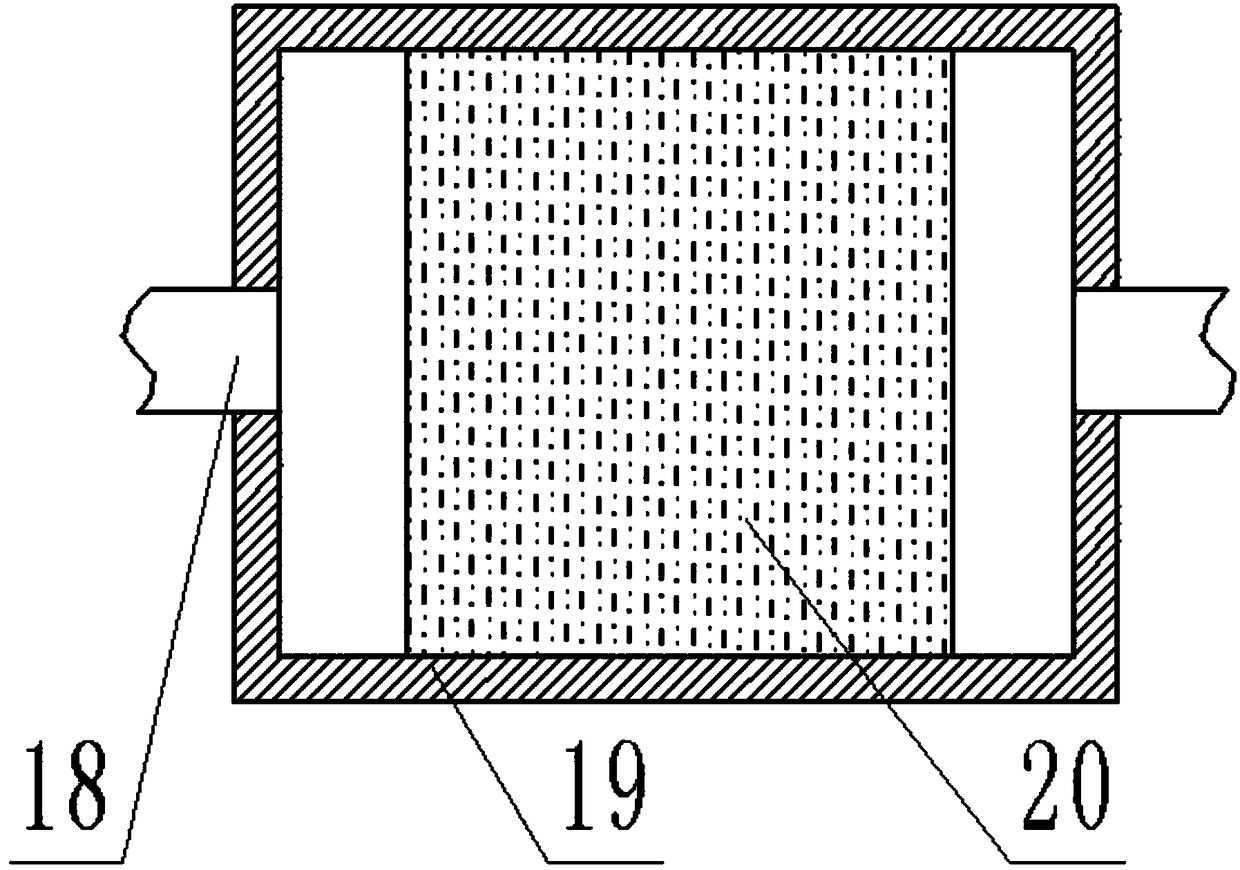

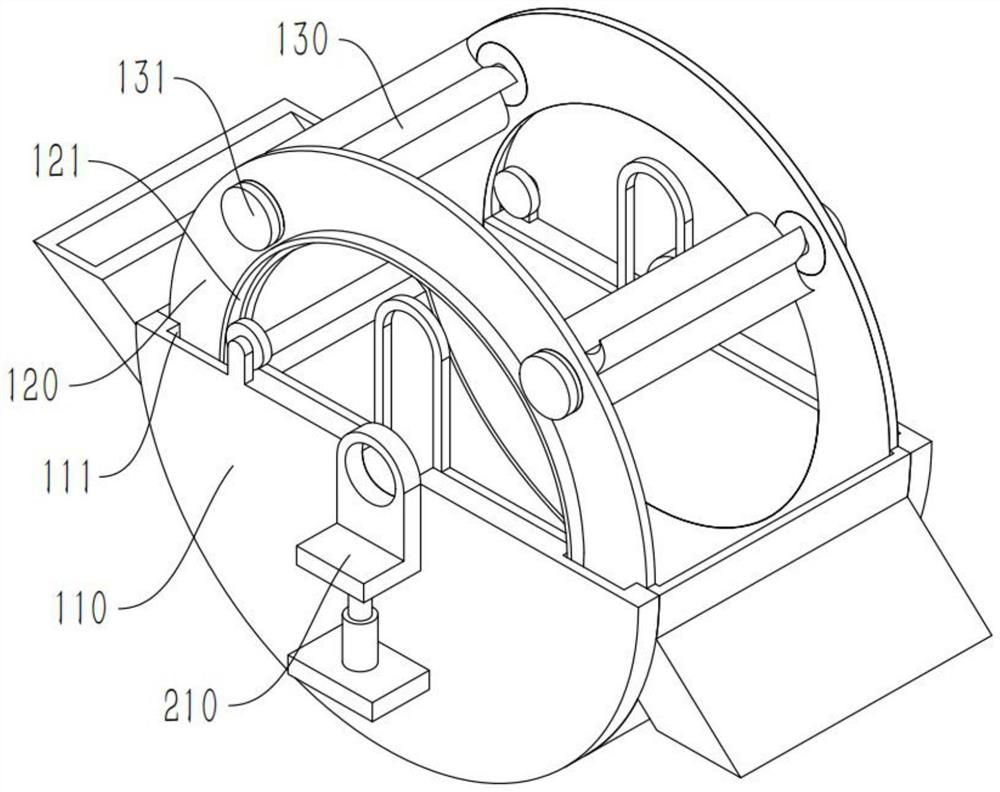

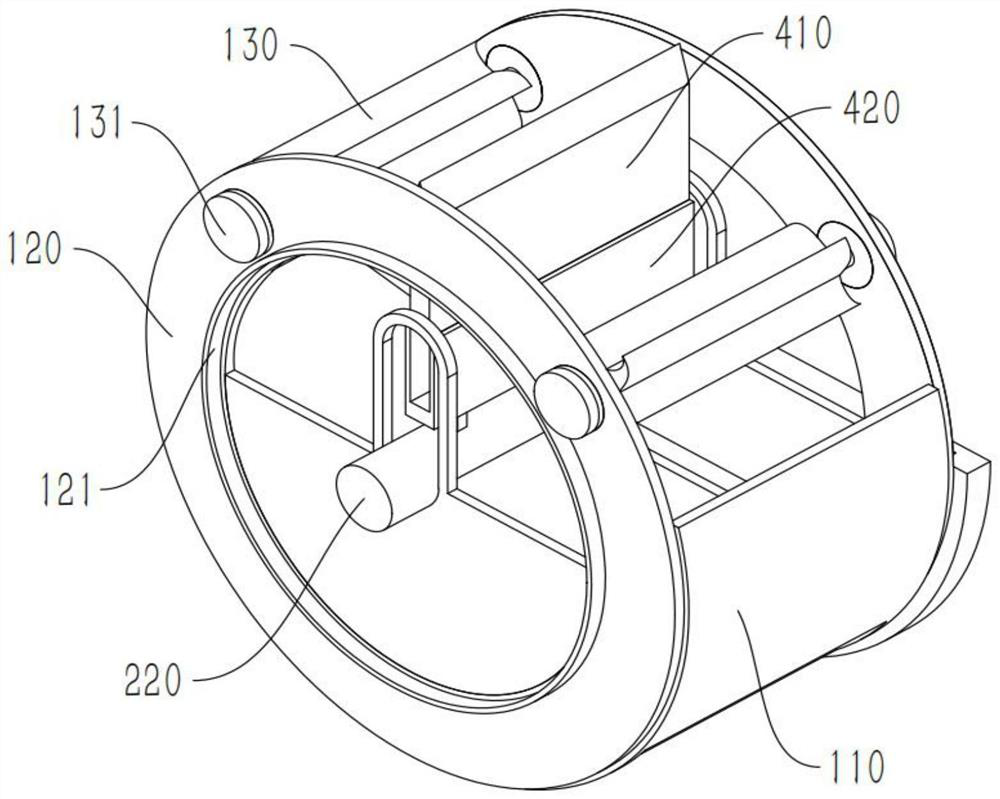

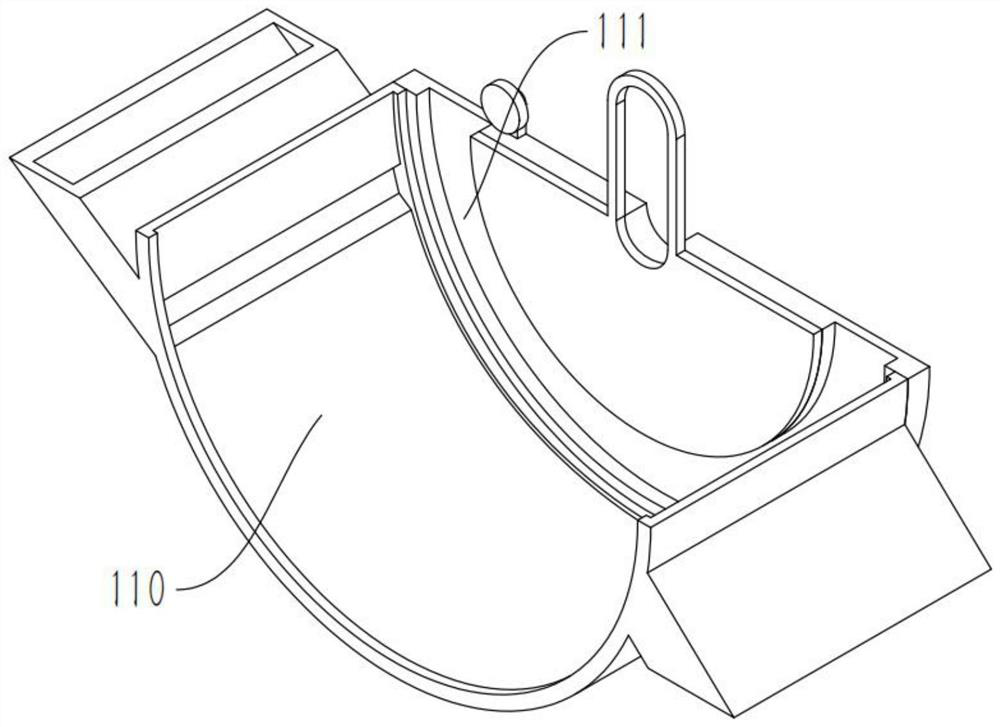

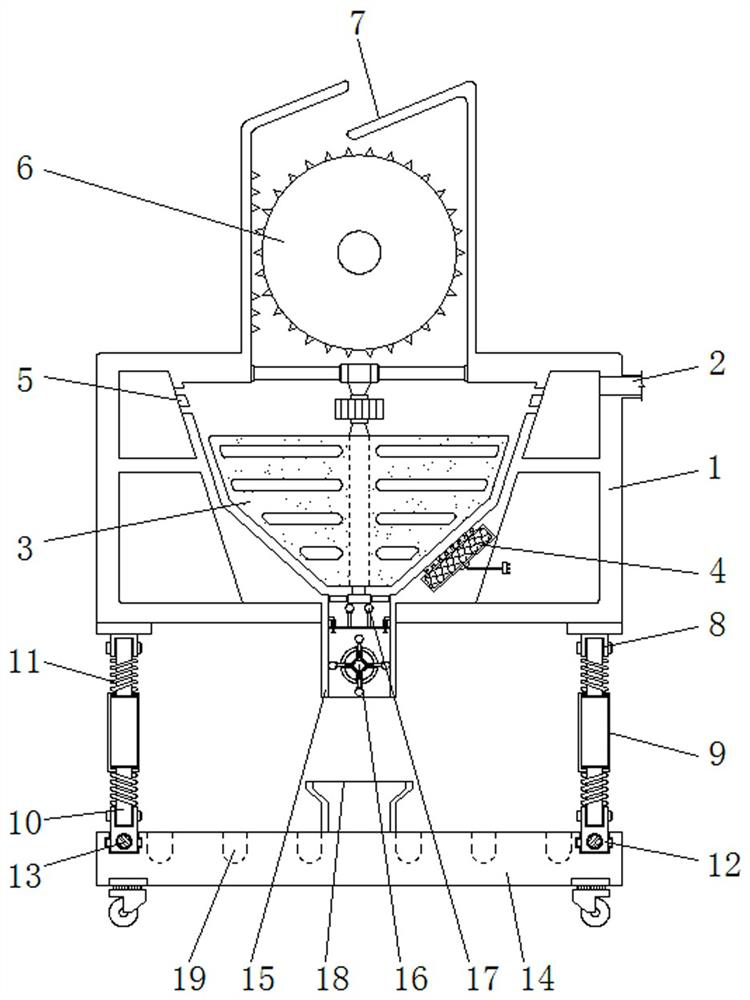

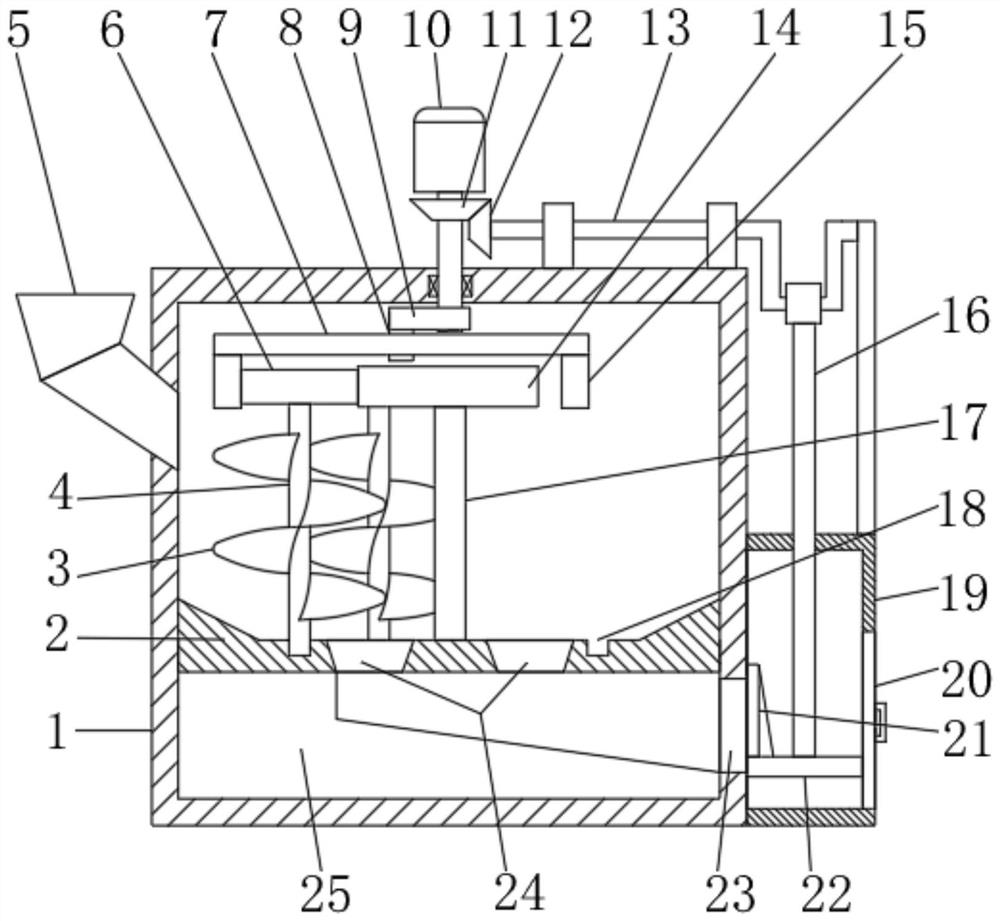

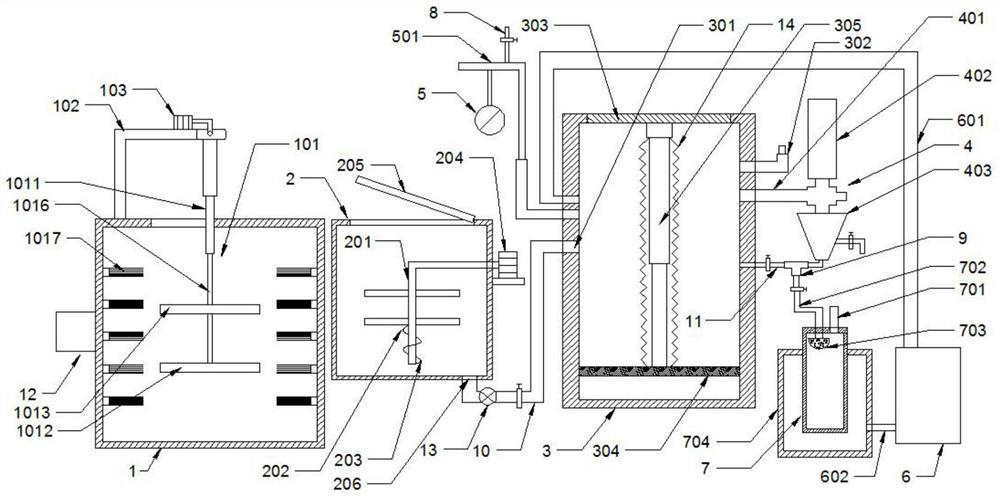

Agricultural wastewater treatment device

ActiveCN112607909AFully absorbedRapid solid-liquid separationWaste water treatment from animal husbandryTreatment involving filtrationSludgeSpiral blade

The invention relates to the technical field of wastewater treatment, and discloses an agricultural wastewater treatment device which comprises a tank body, a sleeve is fixedly connected to the center of the upper end of the tank body through a round opening, a sealing plate is fixedly connected to the upper end of the sleeve, a rotating shaft is rotatably connected to the center of the sealing plate through a first rolling bearing, a gear ring is fixedly connected to the shaft wall of the rotating shaft, the lower end of the rotating shaft penetrates through the first sealing bearing, extends into the sleeve and is fixedly connected with a spiral blade, a conical plate is arranged in the tank body, and the center of the conical plate is slidably sleeved with the wall of the sleeve through a circular hole. According to the agricultural wastewater treatment device, straw feed waste generated in the breeding process can be used as a filter material to effectively filter excrement residues and sludge in agricultural wastewater, the generated filter residues are convenient to clear and transport for secondary processing production, filtered sewage can be effectively stirred and flocculated, and the sewage treatment steps are effectively simplified.

Owner:安徽建筑大学城市建设学院

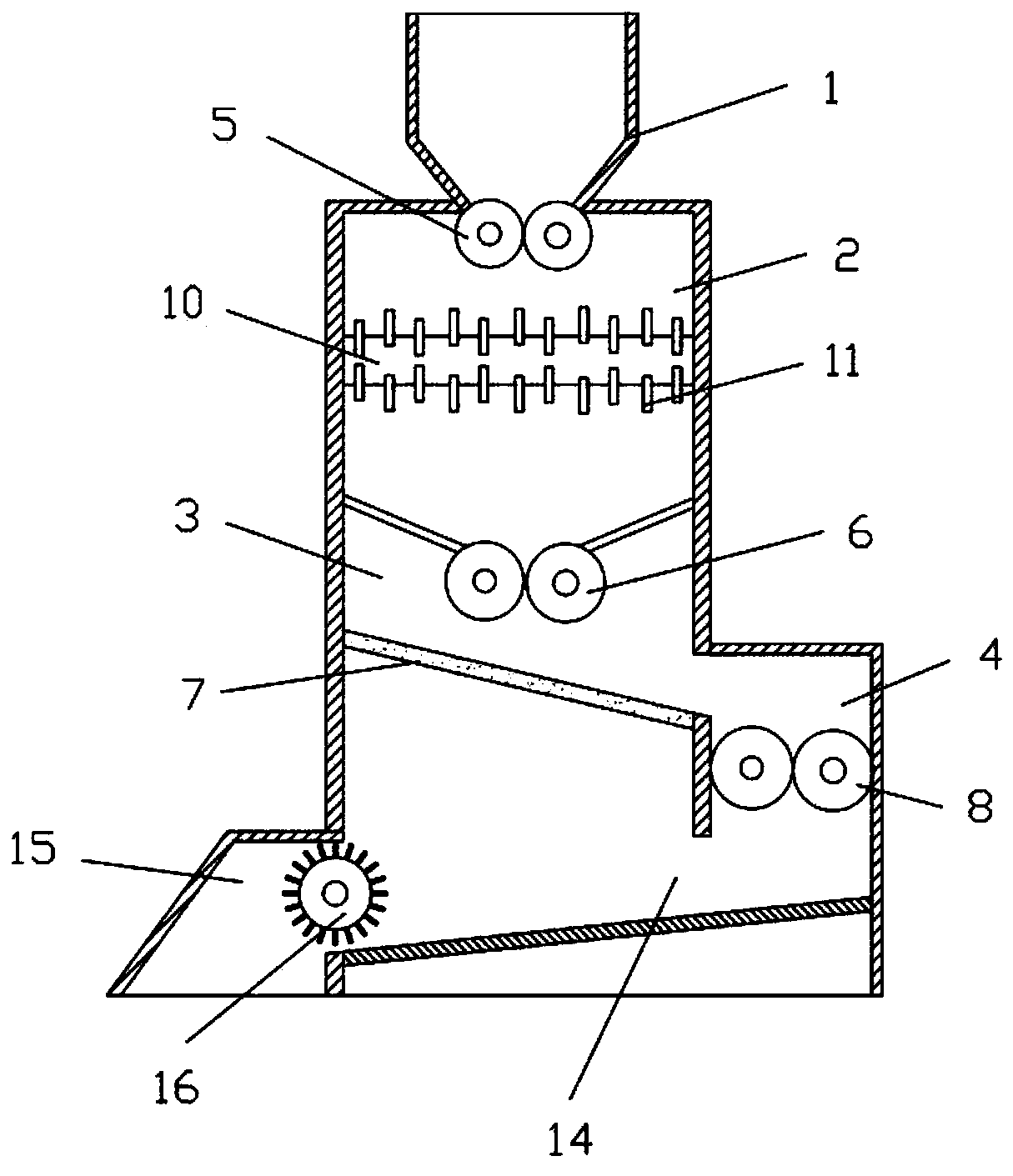

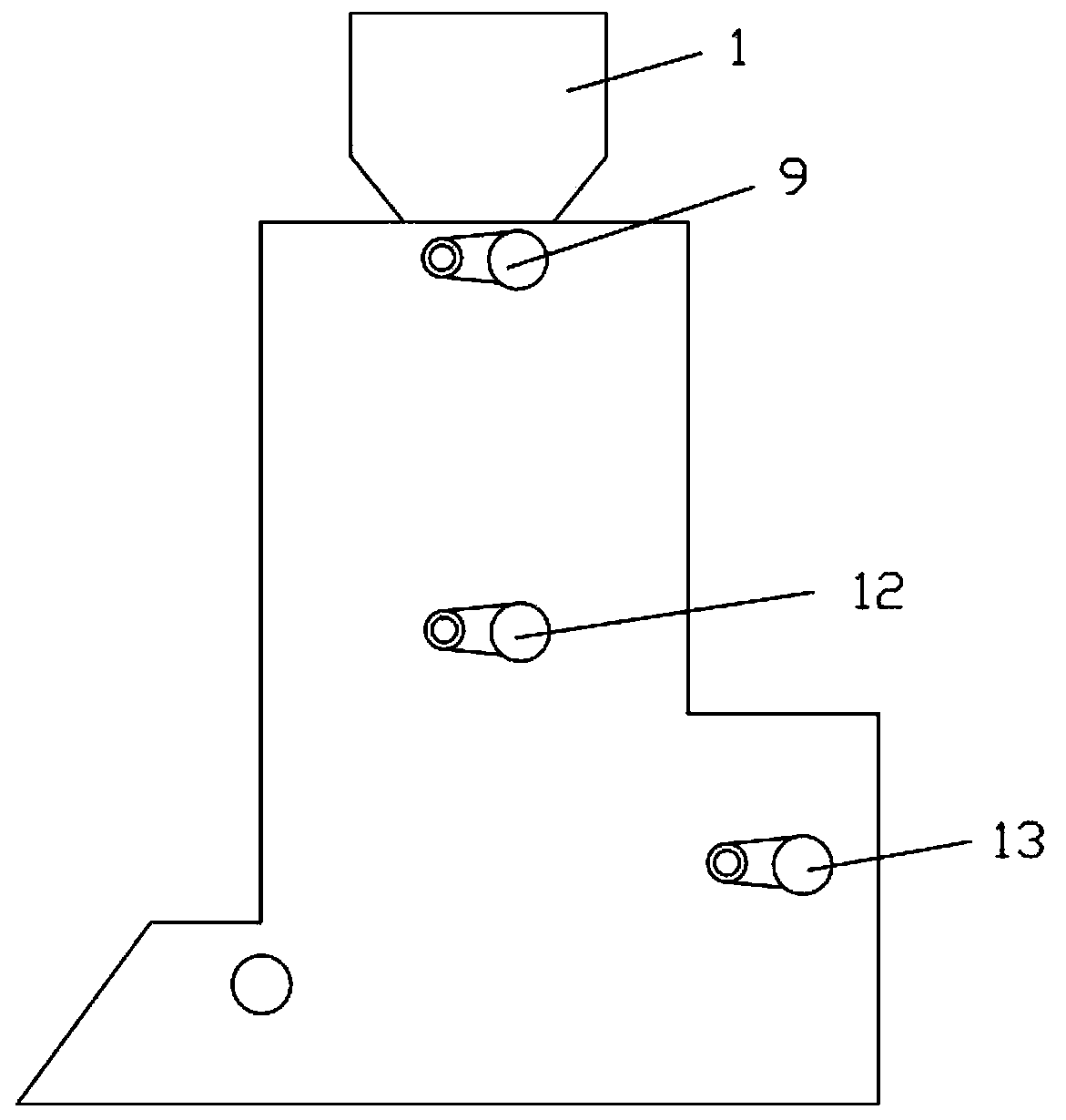

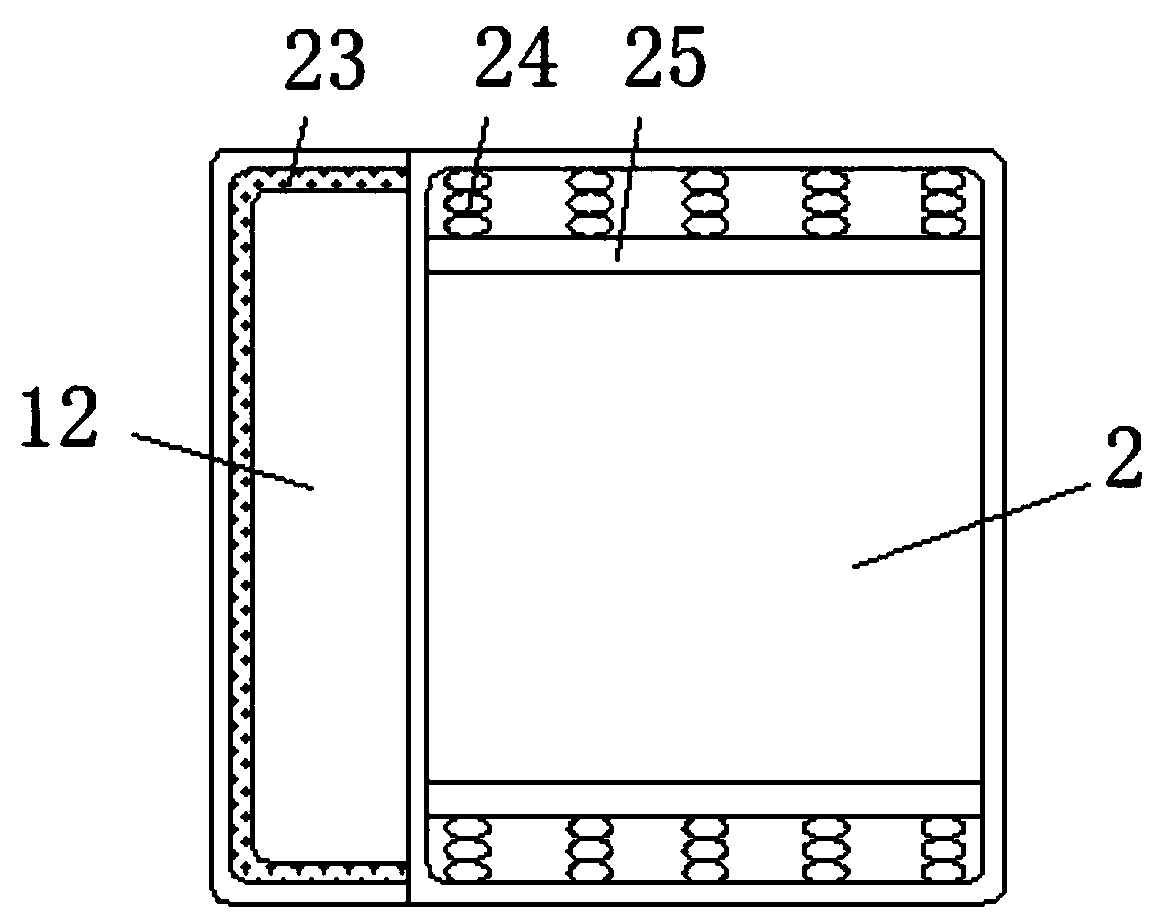

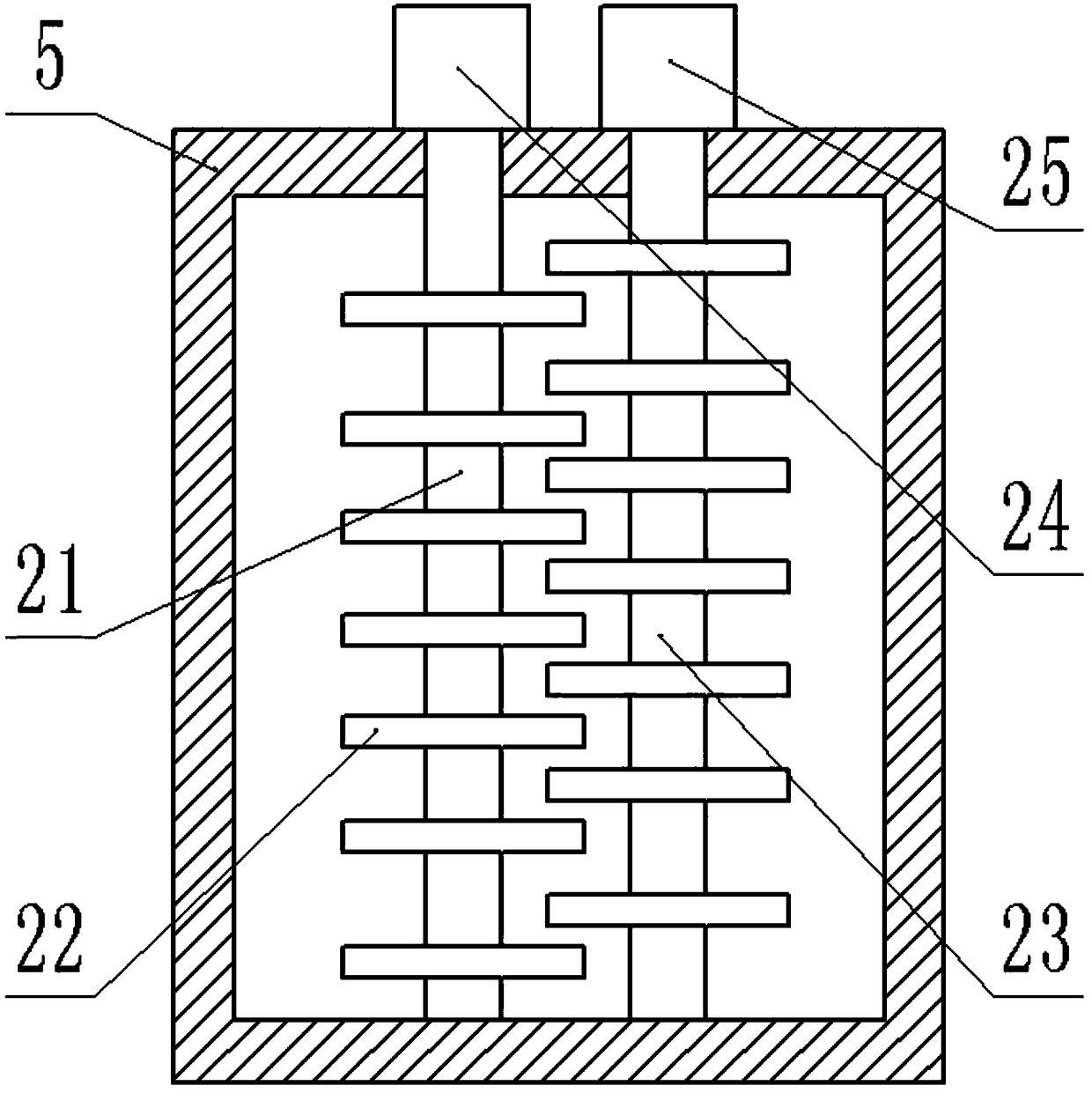

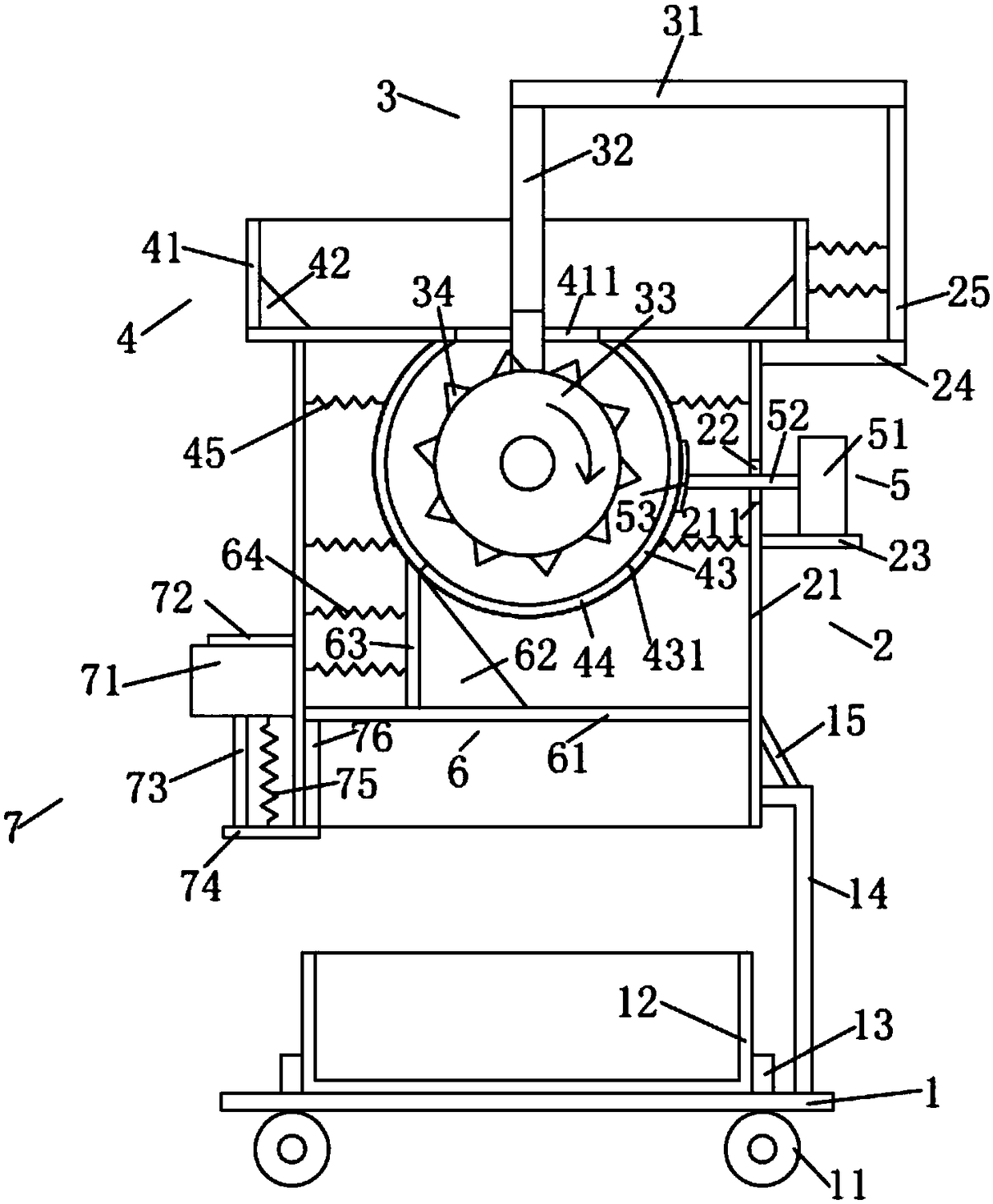

Disassembling and recovering device of electronic technological waste product

ActiveCN106944456ADismantled completelyFully crushedSolid waste disposalGrain treatmentsWaste productLeft wall

The invention relates to a disassembling and recovering device, in particular to a disassembling and recovering device of an electronic technological waste product. The disassembling and recovering device of the electronic technological waste product can effectively disassemble and recover the electronic technological waste product. The disassembling and recovering device of the electronic technological waste product comprises a disassembling box, a driving mechanism, third bearing seats, a third rotary rod, a spiral rod, breaking knives and the like. The driving mechanism is connected to the upper portion of the left side of the disassembling box, a first filter net is connected to the upper portion inside the disassembling box, and the third bearing seats are symmetrically connected to the upper portions of the left wall and the right wall of the disassembling box; and the third bearing seats are connected with the third rotary rod, and the left end of the third rotary rod is connected with the driving mechanism. According to the disassembling and recovering device of the electronic technological waste product, the driving mechanism is firstly arranged for the reason that by controlling work of a motor, the purpose that the electronic technological waste product is completely disassembled by means of the method that the breaking knives are driven by the third rotary rod to continuously make alternating rotation in a clockwise and counter-clockwise while the electronic technological waste product is constantly conveyed through the spiral rod to make side-to-side movement is achieved.

Owner:华新绿源(内蒙古)环保产业发展有限公司

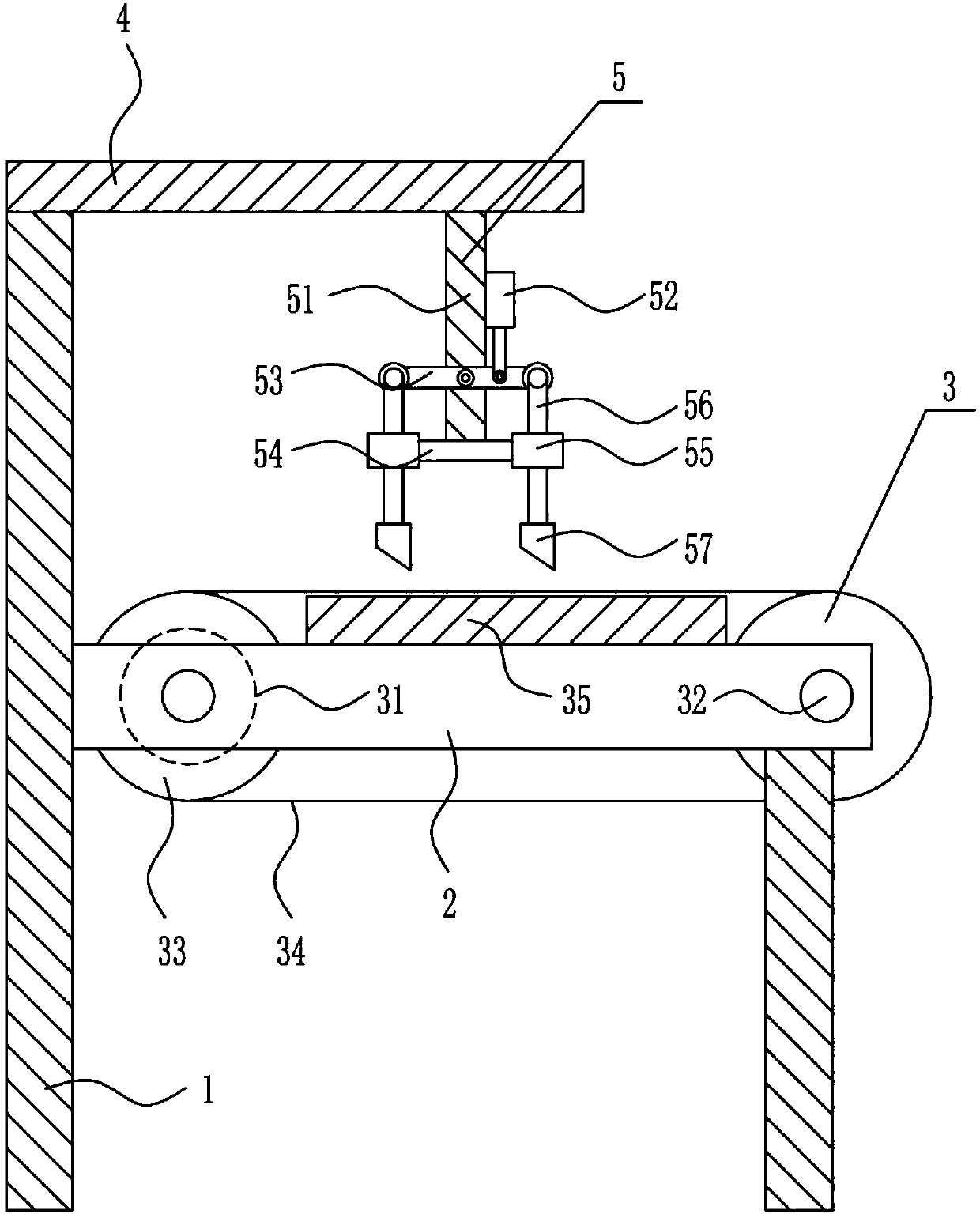

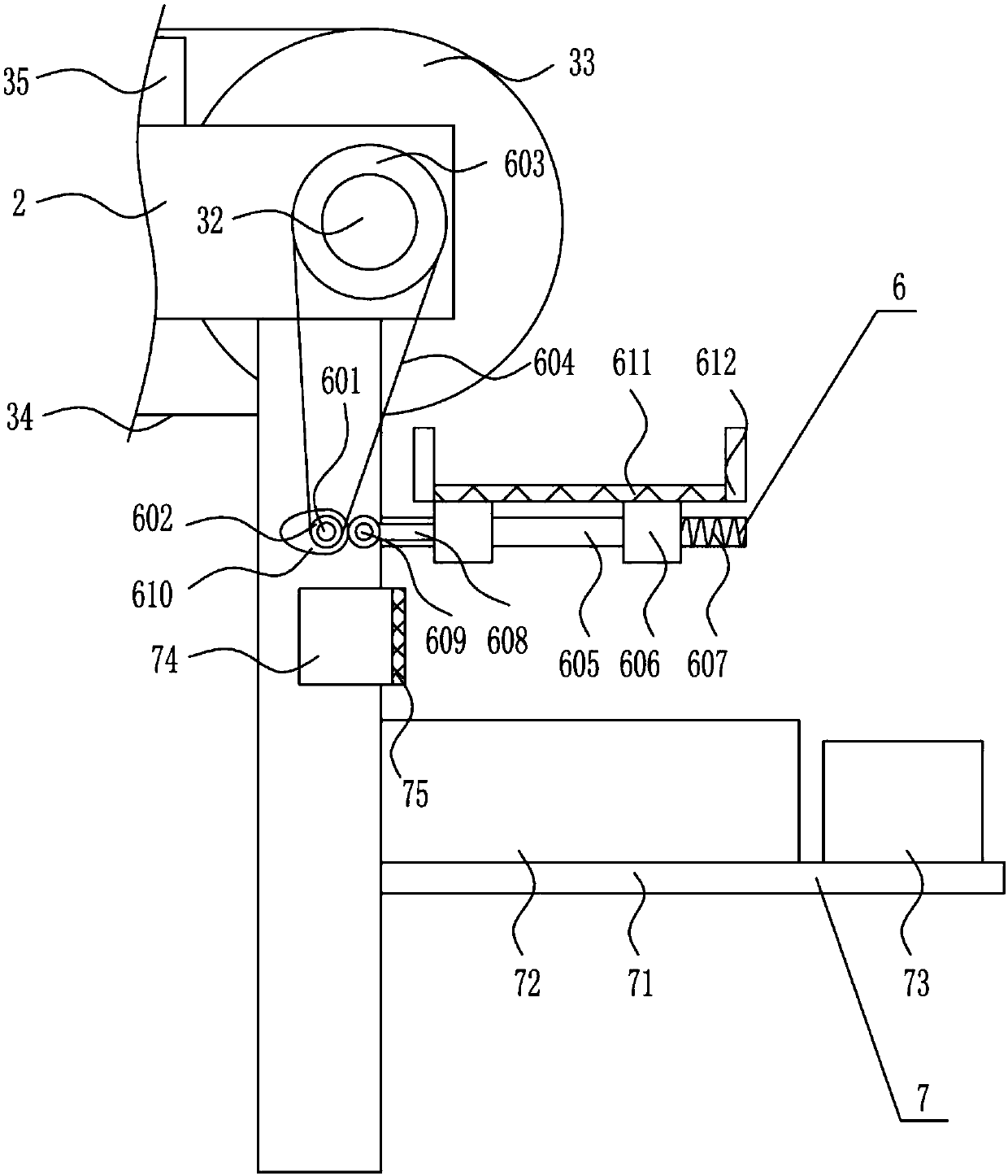

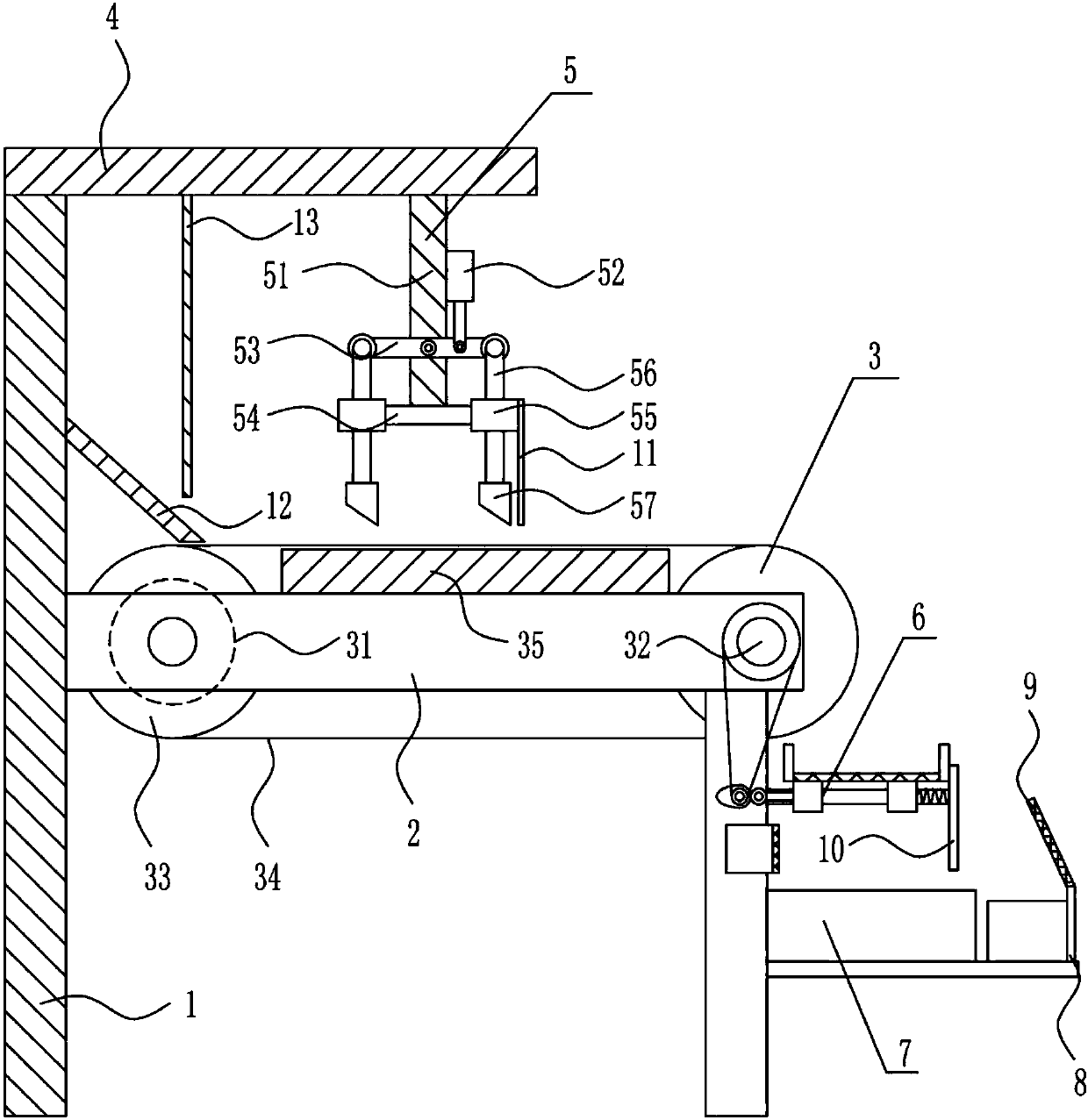

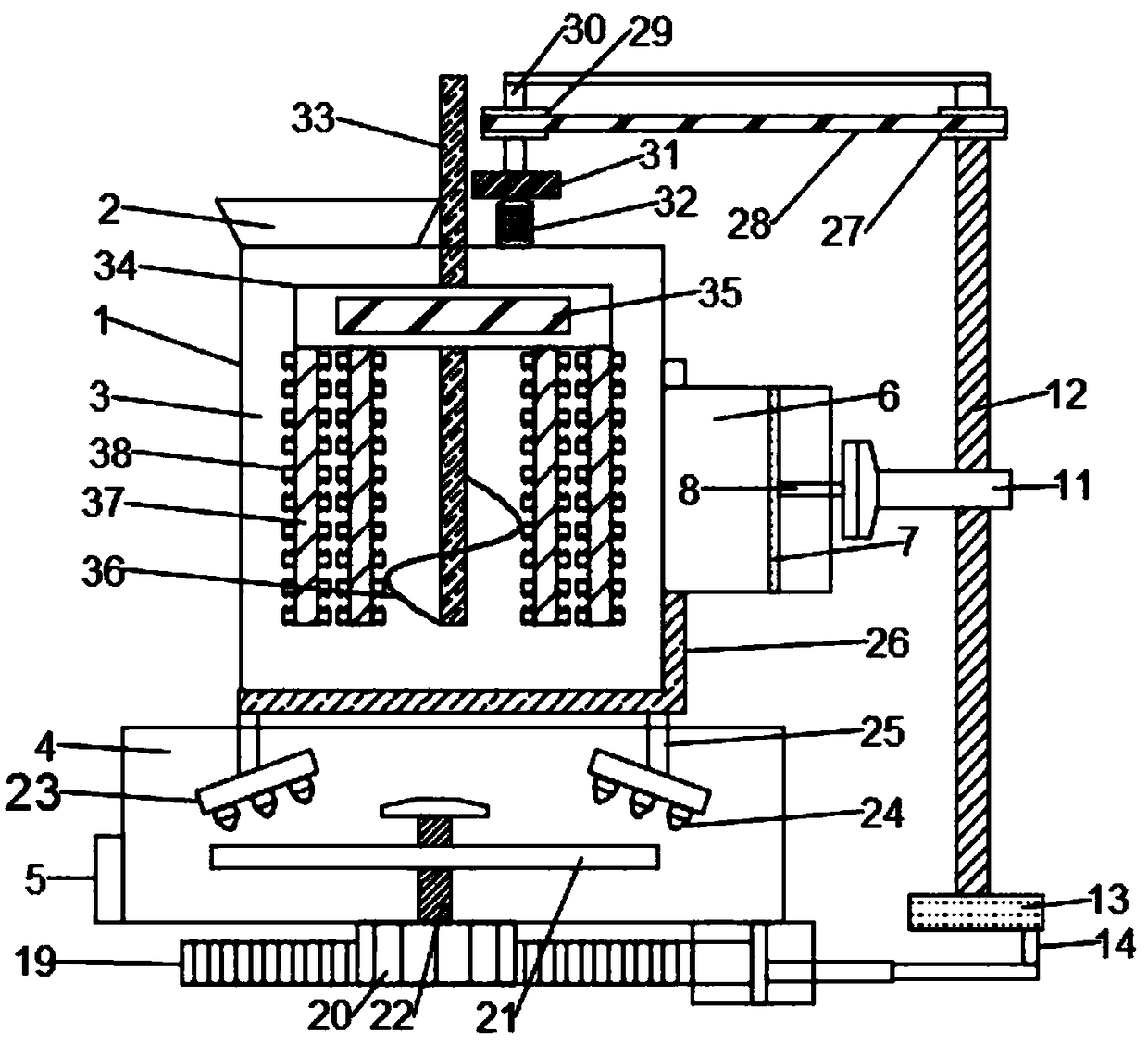

Plastic mold waste recycling device

The invention relates to a recycling device, in particular to a plastic mold waste recycling device. The technical problem to be solved by the invention is to provide a plastic mold waste recycling device with good crushing effect, high recycling rate, simple operation, and reduced labor force. In order to solve the technical problems, the invention provides such a plastic mold waste recycling device, comprising support legs and the like, wherein a first support plate is connected between left and right support legs in the middle, and a delivery mechanism is arranged on the first support plate; the right side of the top of the left support leg is horizontally connected with a second support plate, and a cutting mechanism is arranged at the bottom of the second support plate. Through the mutual cooperation of the delivery mechanism and the cutting mechanism, the plastic waste is completely crushed; meanwhile, the optimization of a screening mechanism and a removal mechanism is utilizedto achieve the effects of good crushing effect, high recycling rate, simple operation, and reduced labor force.

Owner:金吉祥

Polyester film processing device and method

ActiveCN111002520AUniform compositionReduce widthFlat articlesGrain treatmentsPolyesterPolymer science

The invention discloses a polyester film processing device and method. The polyester film processing device comprises a conveying rack, a crushing box assembly, a crushing wheel set, a width adjustingmechanism, a sliding frame, a rolling mechanism and tensioning mechanisms. With the polyester film processing device and method of the invention adopted, a plastic film can be rolled; the formed filmis uniform in component; and the forming width and thickness of the film can be controlled. The method comprises the following steps that: 1, plastic particles for processing a plastic film are putted into a feeding box; 2, the crushing wheel set is started to grind the large plastic particles; 3, the large plastic particles are ground into fine plastic particles, and the fine plastic particles fall into a crushing cylinder, the crushing cylinder heats and melts the fine plastic particles, and liquid plastic flows out of the width adjusting mechanism; 4, the crushing wheel set drives the rolling mechanism to rotate through the two tensioning mechanisms, the rolling mechanism rolls a flowing-out plastic film, and an air blower cools and forms the rolled film; and 5, the formed plastic filmis outputted through the conveying rack.

Owner:GUANGDONG HUIQI NEW MATERIAL CO LTD

Efficient crushing device with double-speed rebound plate

The invention discloses an efficient crushing device with a double-speed rebound plate, and relates to the technical field of solid-waste crushing devices. The crushing device comprises a crushing device housing, a charge hole, a discharge hole, a primary crushing mechanism and a secondary crushing mechanism, wherein a square bounding plate, a square supporting steel plate and a telescopic air cylinder for driving the square supporting steel plate to move back and forth are sequentially connected in the bottom of the crushing device housing from top to bottom; the bottom of the telescopic air cylinder is fixedly arranged in the bottom of the crushing device housing; the lower end of the square bounding plate is equipped with buckles I; buckles II which correspond to the buckles I are arranged on the square supporting steel plate; a spring pulling hook is connected between the buckles I and the corresponding buckles II; the primary crushing mechanism comprises a rotary shaft I, as well as spiral crushing tools, cylindrical-tooth tools and a motor I which are alternatively and uniformly distributed on the rotary shaft I according to the periphery; and the secondary crushing mechanism comprises a rotary shaft II as well as crushing tools and a motor II which are uniformly distributed on the rotary shaft II according to the periphery. By combining a rebound device, crushing efficiency is improved.

Owner:弘毅天承知识产权股份有限公司

Construction waste crushing device

InactiveCN110893363AFully crushedMeet processing needsGrain treatmentsArchitectural engineeringStructural engineering

The invention discloses a construction waste crushing device. The crushing device comprises a feeding box, a first crushing box, a second crushing box and a third crushing box which are arranged in sequence. The feeding box is vertically arranged at a top of the first crushing box and is connected with a feeding port in the top of the first crushing box through a first crushing shaft. A bottom ofthe first crushing box is connected with the feeding port of the second crushing box through a second crushing shaft. A screening device is arranged in the second crushing box. A tail end of the screening device is connected with the third crushing box through a third crushing shaft. Through treatment of the crushing shafts in the crushing boxes for three times, construction wastes can be fully crushed, a treatment requirement of the construction wastes is satisfied, an operator can conveniently carry out recycling, and the construction wastes which are not crushed can be placed in a crusher again to be crushed.

Owner:徐州山美环保科技发展有限公司

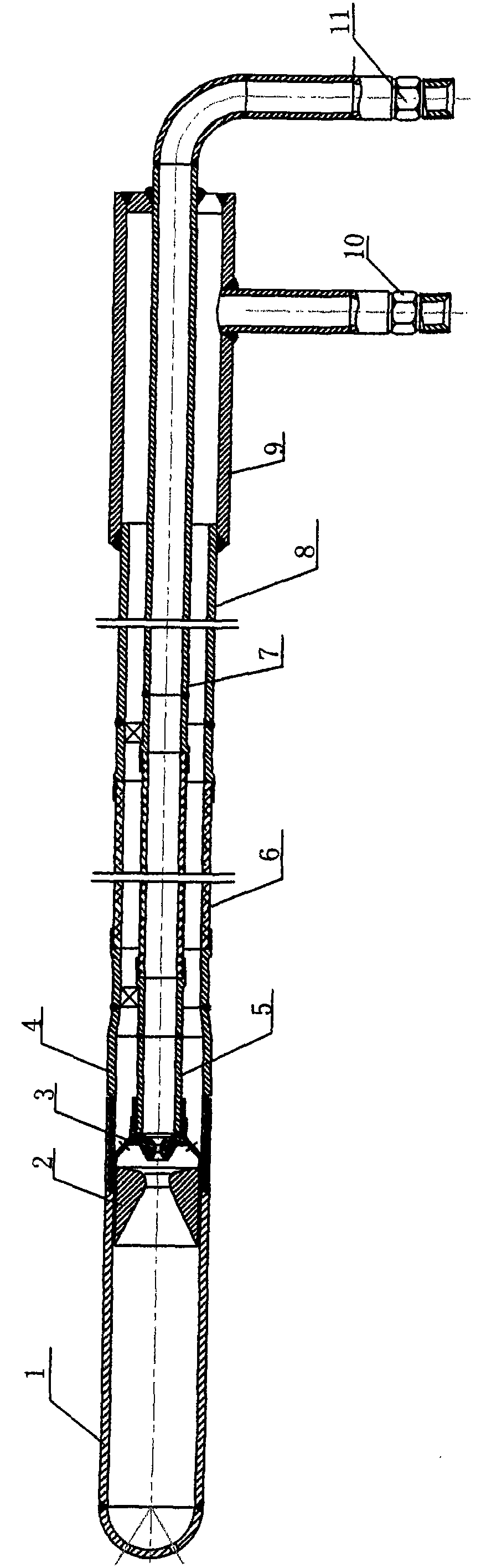

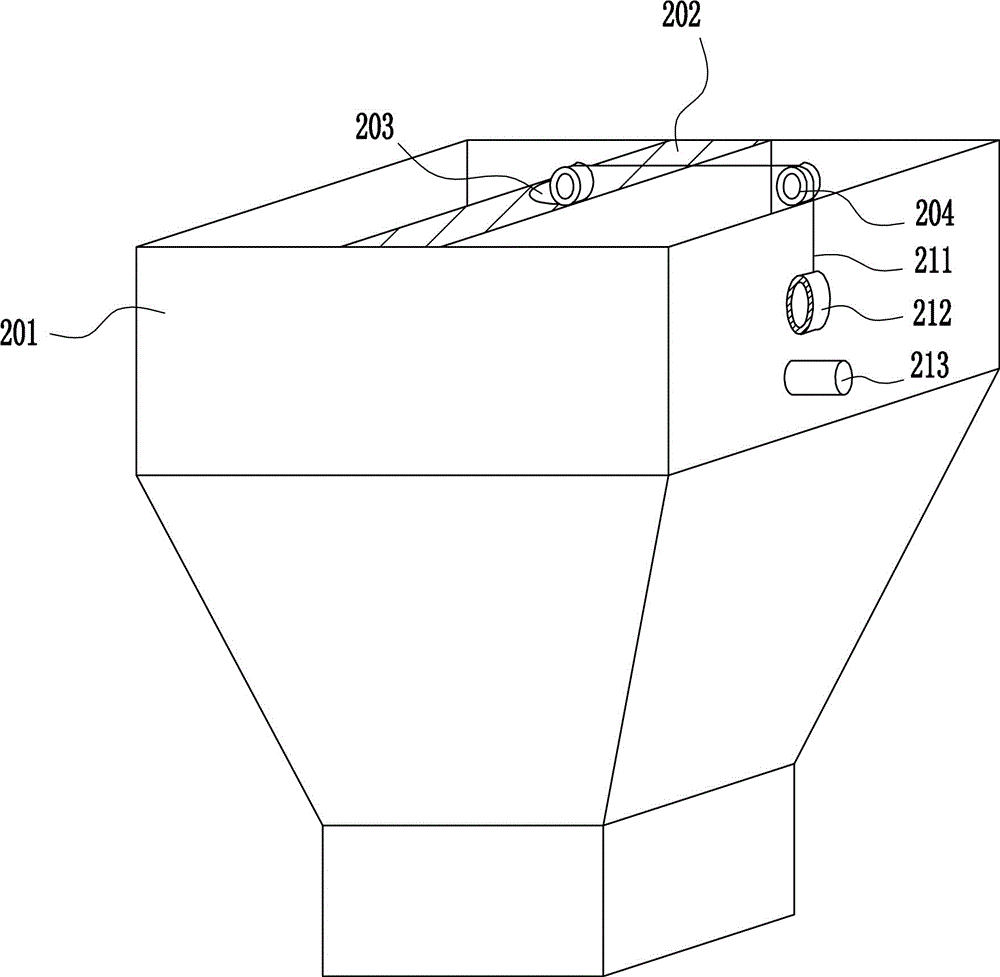

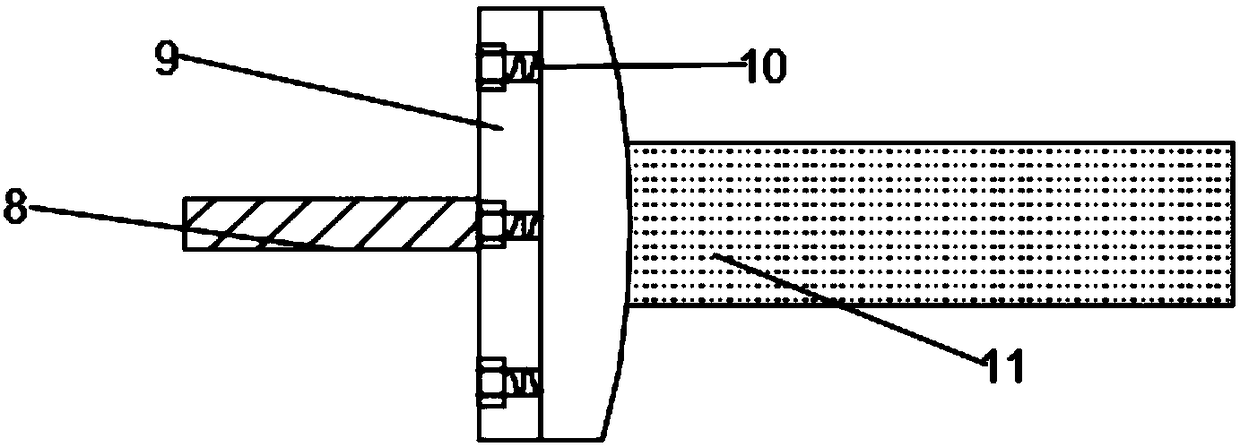

Injection-type high atomized oil gun

The invention discloses an injection-type high atomized oil gun and relates to the technical field of an apparatus. A key technology of 'providing a mixing cavity and a scale body' is adopted; an oil interface is fixed together with the rear end of an oil gun inner pipe; the oil gun inner pipe is fixed together with a hole on a rear-end end cap of an oil gun fixing pot head; the front end of the oil gun inner pipe is fixed together with the rear end of an inner short circuit through an inner metal hose; the front end of the inner short circuit is fixed together with a jet nozzle; a taper wall of the jet nozzle is fixed together with a rear end section of a mixing cavity; the rear end section of the mixing cavity at the front end of the jet nozzle is fixed together with the scale body; the rear end of the mixing cavity is fixed together with the front end of the outer short circuit; the rear end of the outer short circuit is connected with the front end of the metal hose; the rear end of the metal hose is fixed together with the front end of an oil gun outer pipe; the rear end of the oil gun outer pipe is fixed together with the front end of the oil gun fixing pot head; the oil gun fixing pot head is also fixed together with a gas interface through a pipeline. The injection-type high atomized oil gun is an oil gun of burning diesel oil to start a coal-fired thermal power plant boiler and stably burn at low load, is simple and delicate in structure, stable and reliable in effect, easy to manufacture and low in cost.

Owner:HUNAN DATANG ENERGY SAVING SCI & TECH CO LTD

Device capable of effectively carrying out solid-liquid separation on kitchen garbage

The invention discloses a device capable of effectively carrying out solid-liquid separation on kitchen garbage. The device comprises a body, a rolling separation cavity, a sewage collection cavity, asmashing cavity, a sewage inlet, a garbage outlet and a motor, wherein the left side of the body is provided with the rolling separation cavity, the sewage inlet is formed in the upper portion of therolling separation cavity, the sewage collection cavity is formed in the lower portion of the rolling separation cavity, the smashing cavity is arranged on the right side of the sewage collection cavity, and the garbage outlet is formed in the lower portion of the right side of the smashing cavity; and the motor is installed at the bottom of the body, and the output end of the motor is fixedly connected with a first rotary shaft. The device is reasonable in design, various procedures can be completed just through one working motor, the purposes of energy saving and environment friendliness are achieved, sufficient solid-liquid separation and crushing can be carried out on garbage, and finally the garbage can be recycled and reused.

Owner:赵广海

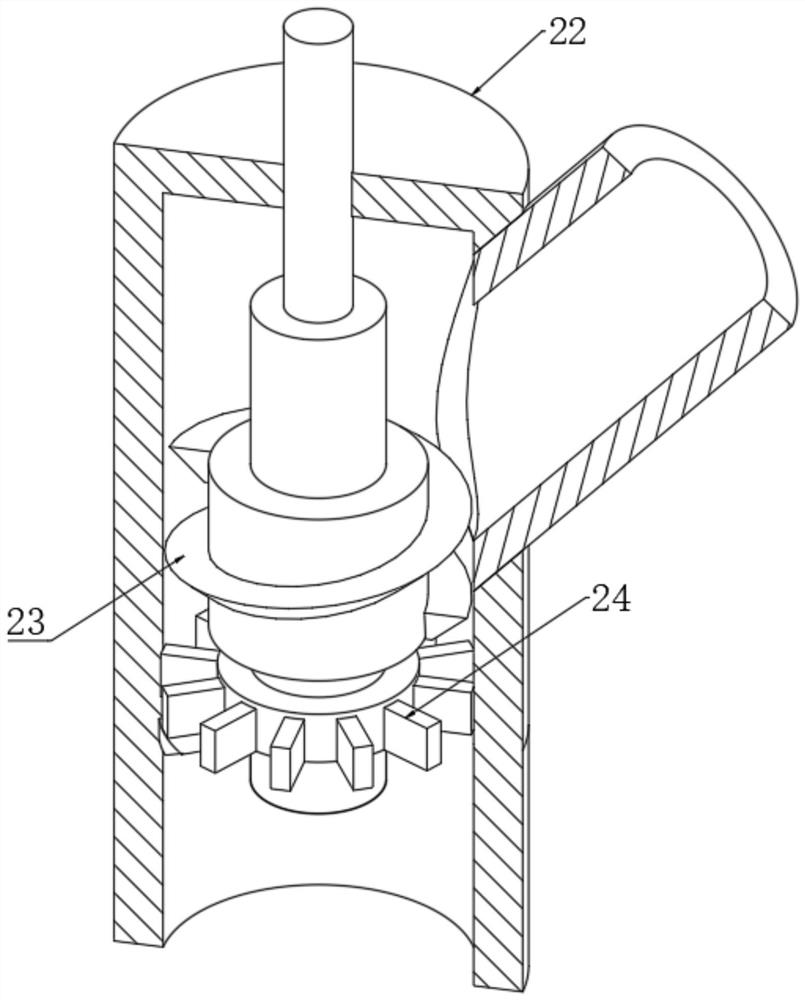

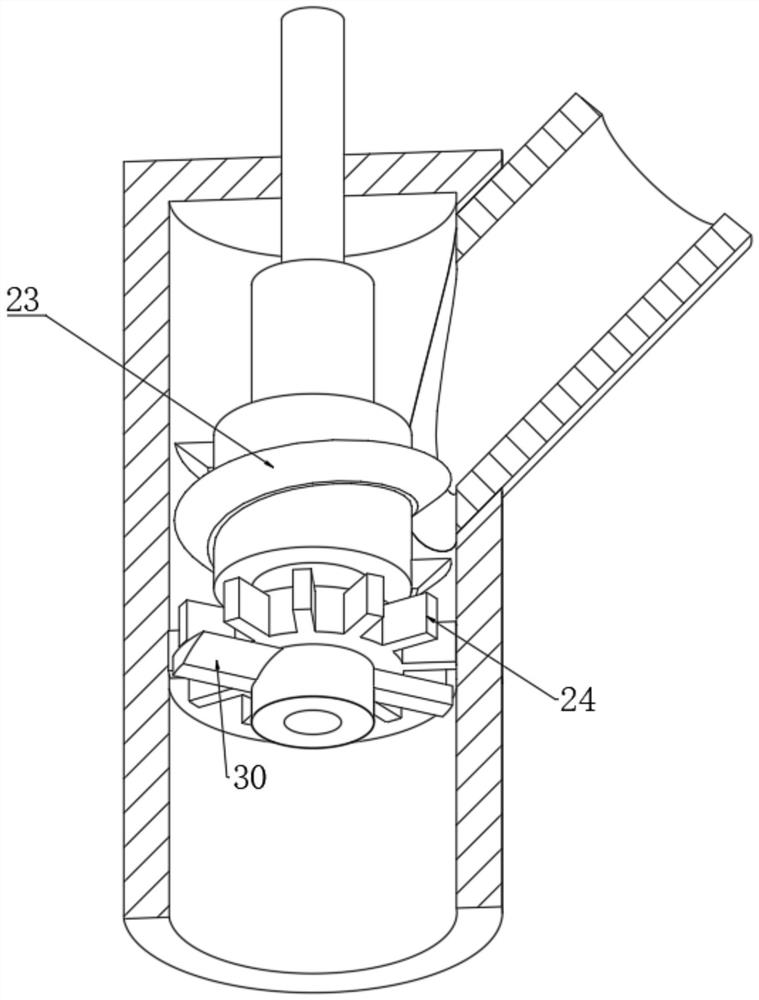

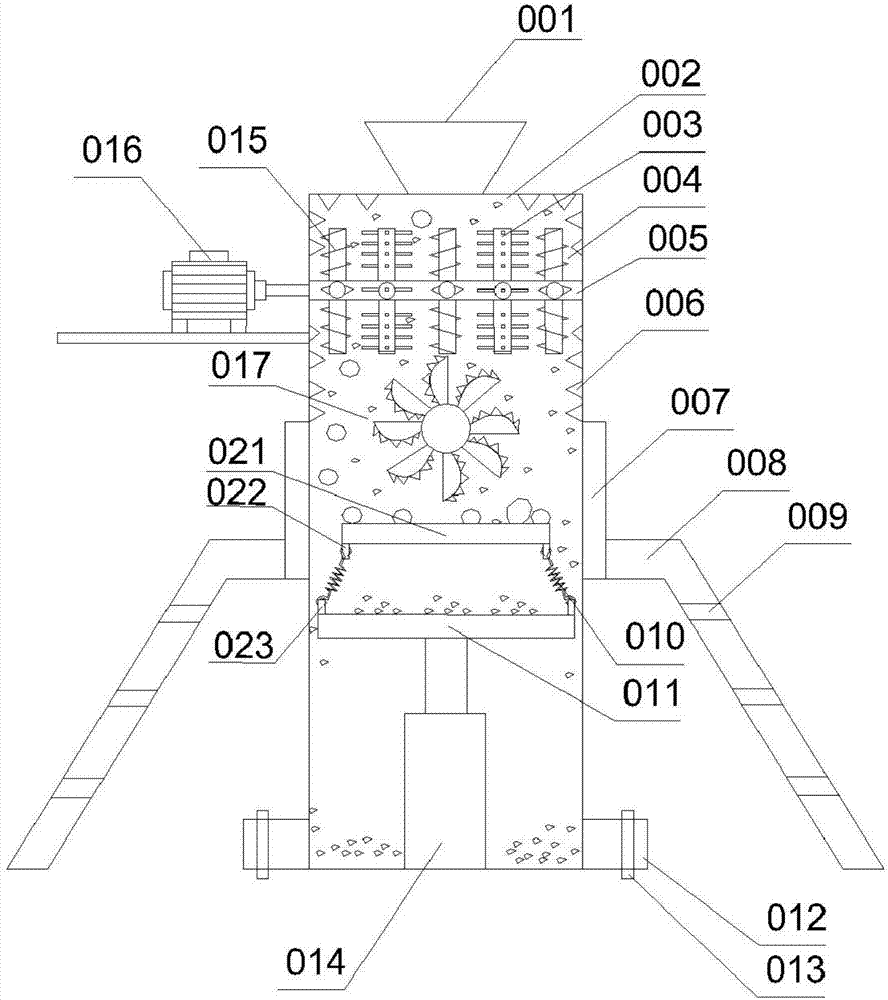

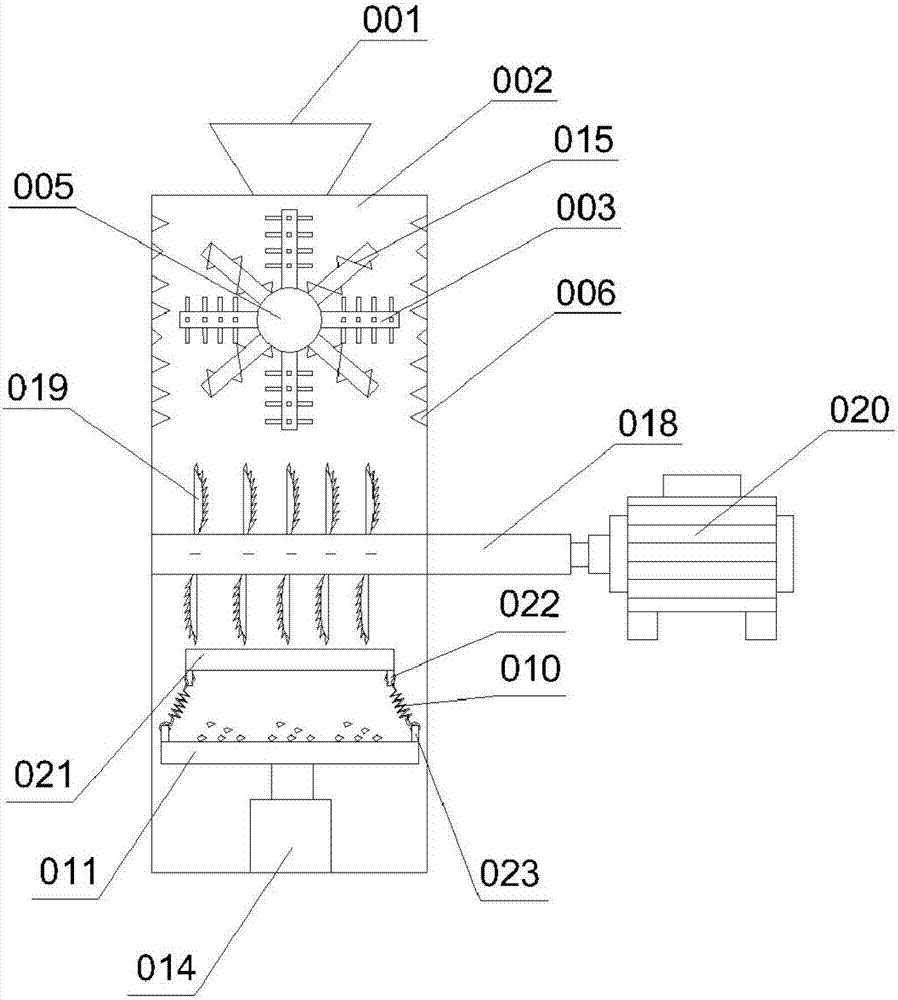

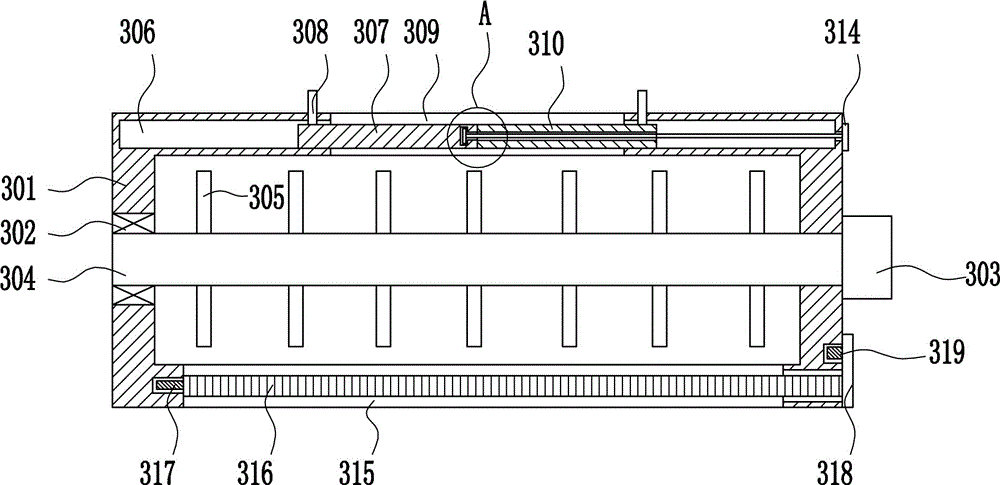

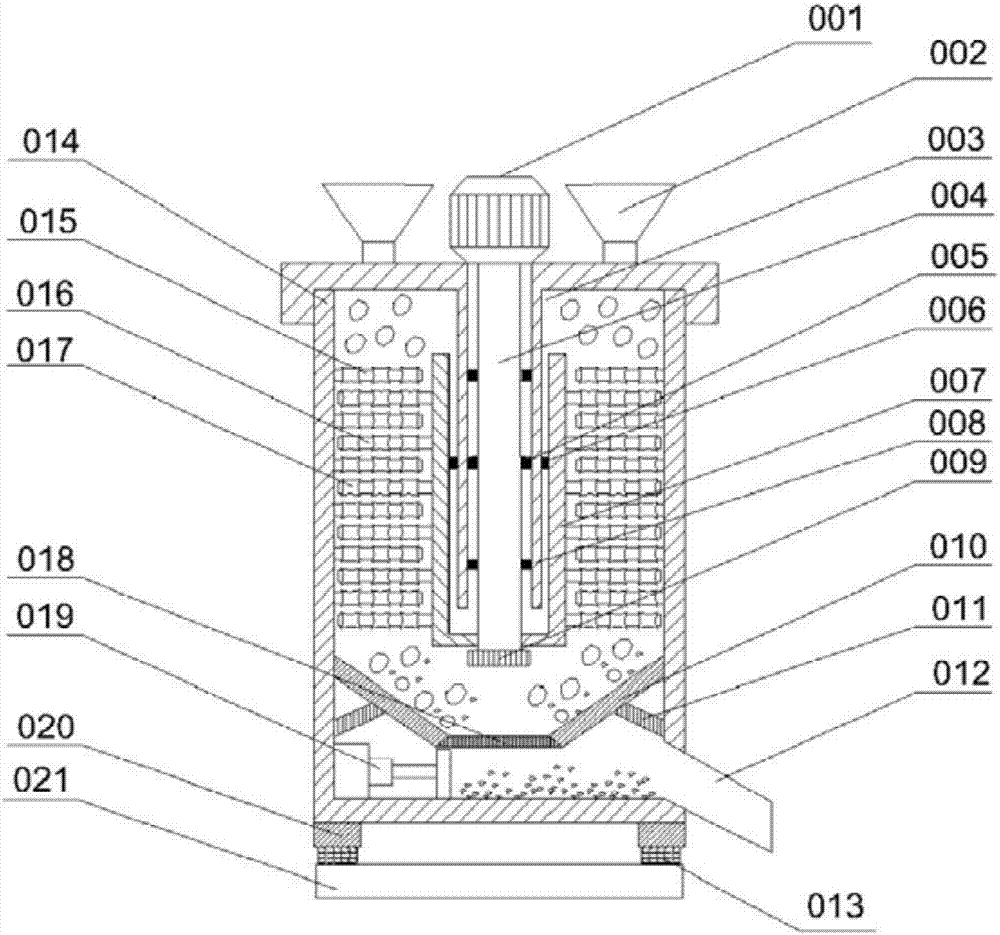

Novel waste accumulator fully crushing equipment

ActiveCN106733033ATo achieve the purpose of stopping feedingEasy to dredgeGrain treatmentsWaste management

Owner:烟台金潮宇科蓄电池有限公司

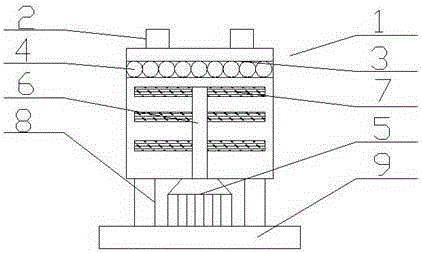

Chinese herbal medicine smashing device

The invention discloses a Chinese herbal medicine smashing device which comprises a body. The body comprises feeding openings, a smashing layer, a variable-frequency motor and stirring shafts. Multiple feeding openings are formed above the body. The smashing layer is arranged at the top end in the body. A base is arranged below the body. The variable-frequency motor is arranged between the base and the body. The output part of the variable-frequency motor is connected with the stirring shafts. The surface of the stirring shaft is provided with multiple transverse stirring shafts. Multiple supporting frames are arranged between the body and the base. The Chinese herbal medicine smashing device has the beneficial effects of being reasonable in structural design, good in smashing effect, convenient to use and the like.

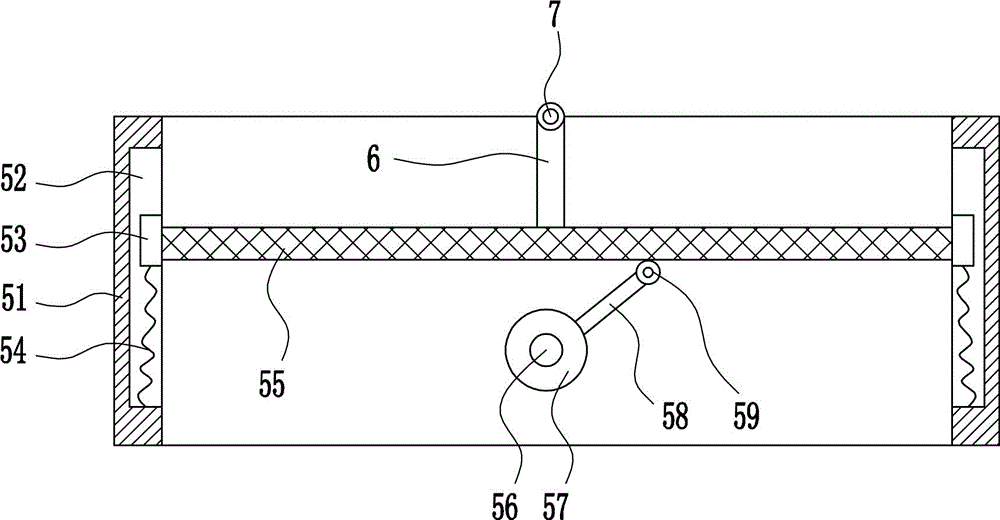

Food and drug drying device

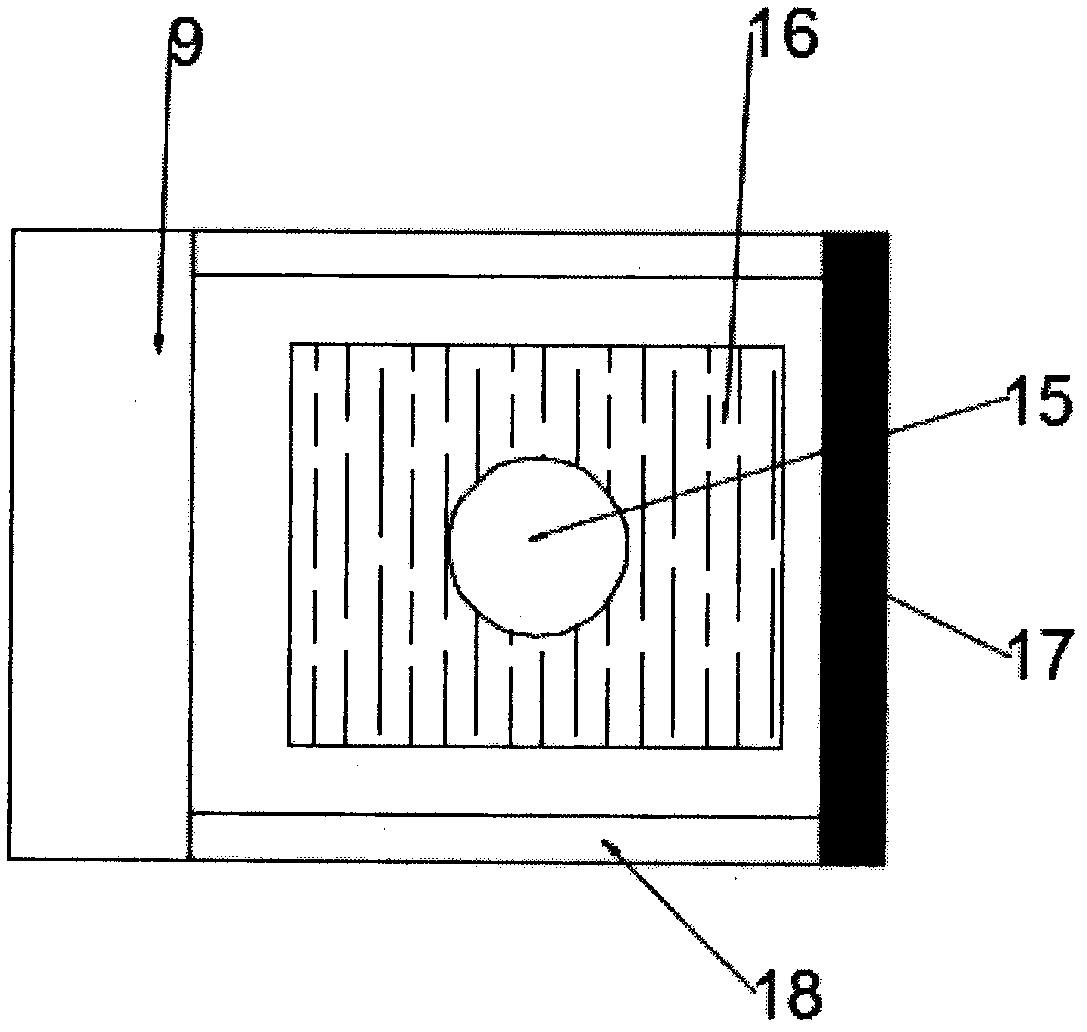

ActiveCN110186258AImprove practicalityAvoid dryingDrying gas arrangementsDrying solid materialsEngineeringCam

The invention discloses a food and medicine drying device, and relates to the technical field of foods and medicines. The drying device comprises a drying box, wherein a mesh plate is arranged in thedrying box; the lower surface of the mesh plate is overlapped with top ends of four cams; and the four cams are respectively clamped outside two rotating shafts. According to the drying device, through mutual cooperation of a first switch, a second motor, a half gear, a toothed plate, a sliding block, a pulley, a hot air fan, a second spring, a second switch, a first motor, the rotating shafts, the cams and the mesh plate, the defect that the hot air fan can only dry the surface of the food or the medicines, so that the underneath stacked foods and medicines are completely dried under the vertical movement of the mesh plate; and moreover, the wet or large size foods and medicines can be crushed through the horizontal movement of the pulley, so that the large size foods or medicines are completely dried as well, and the practicability of the device is improved.

Owner:SHANDONG CENT FOR DISEASE CONTROL & PREVENTION

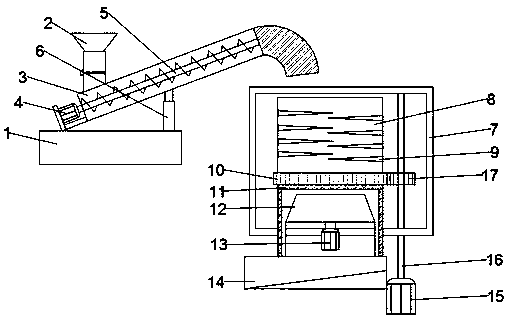

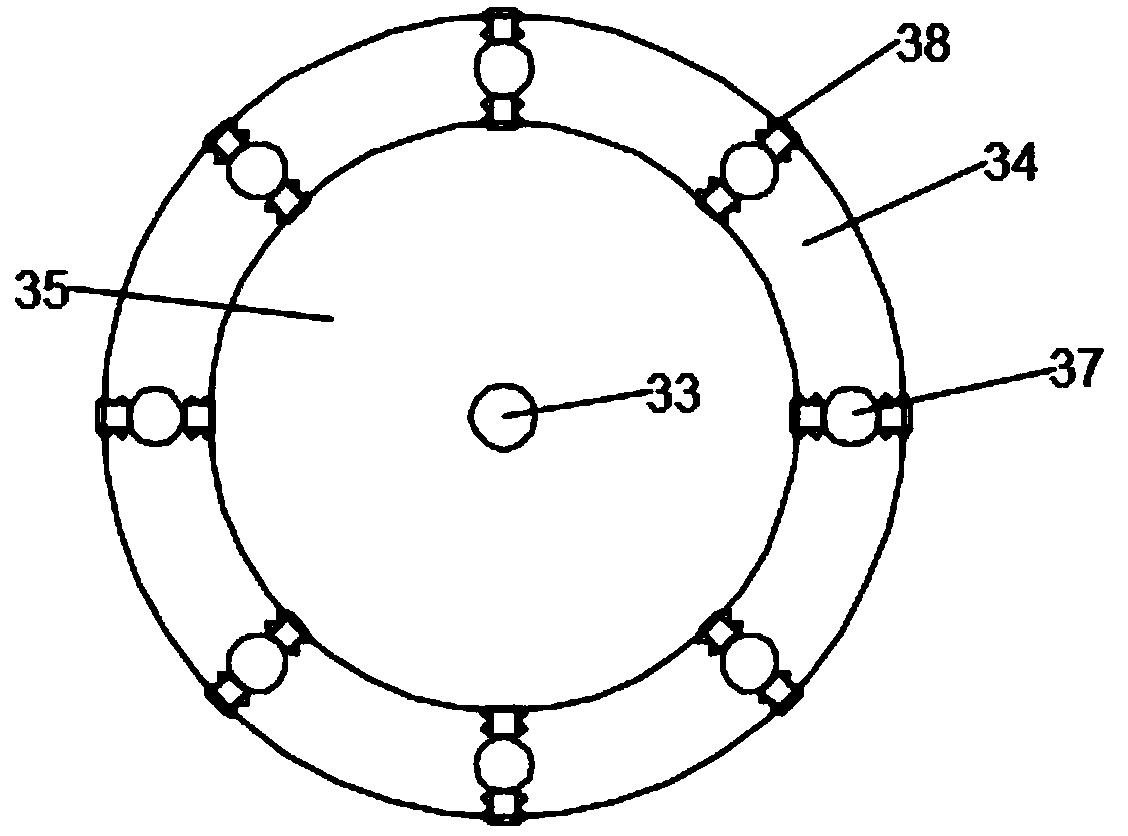

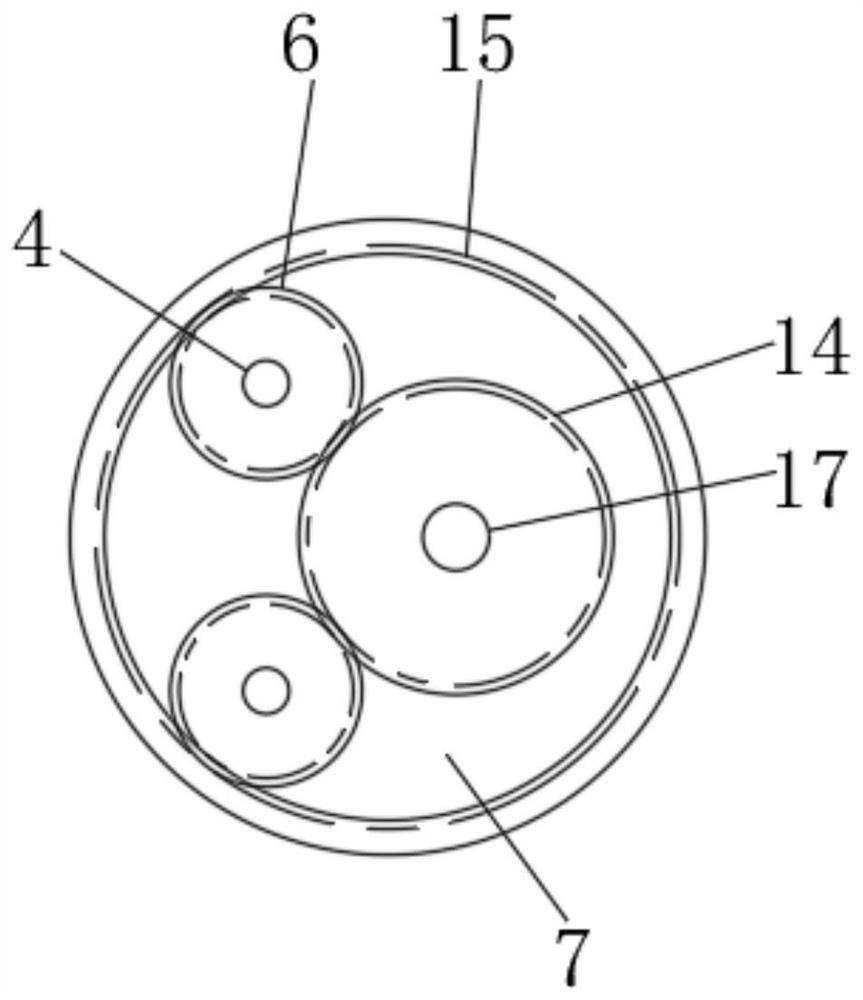

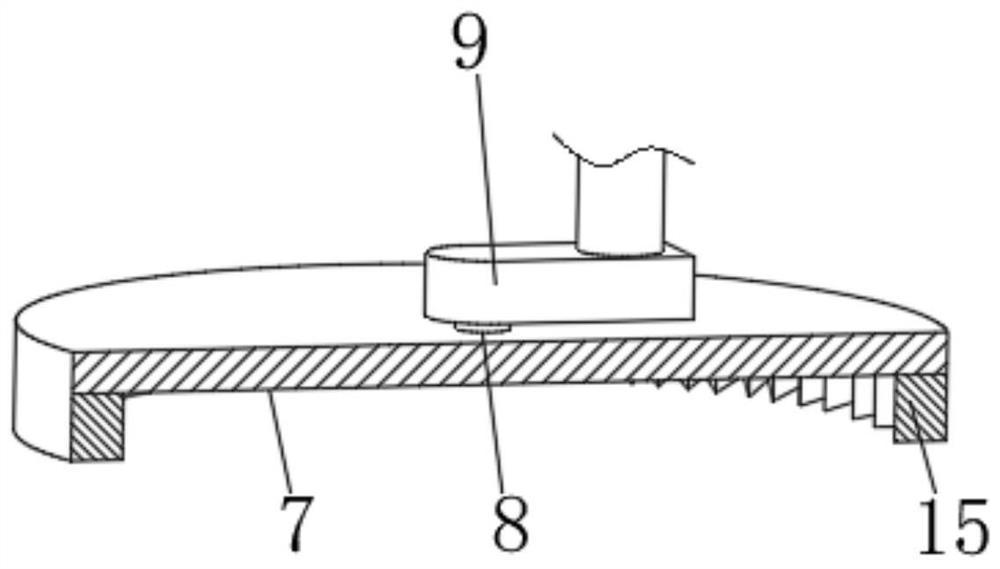

Single cylinder column sand maker

The invention discloses a single cylinder column sand maker, belongs to the technical field of sand making equipment and aims to solve the problem that a main shaft side wall is easily broken when being hit by gravel as a main shaft is placed inside a sand making cylinder when a conventional sand maker is used. The single cylinder column sand maker is technically characterized by comprising a conveying pipeline, a conveying packing auger, a shell and a crushing tank, wherein the conveying pipeline is used for conveying gravel into the crushing tank; the conveying pipeline is arranged in an inclined manner; the lower end of the conveying pipeline is hinged with the upper surface of a support platform; the conveying pipeline is communicated with the crushing tank; the shell is arranged outside the crushing tank; an outer tooth ring is fixedly welded with the outer wall of the shell; a first gear is arranged on the right side of the outer tooth ring. By adopting the single cylinder columnsand maker, automatic feeding can be achieved, the working intensity of operators can be alleviated, meanwhile, the gravel can be sufficiently crushed at multiple stages, and dust made in the gravelcrushing process can be prevented from being discharged, so that external environments and life security of operators can be protected, and the sand maker is applicable to popularization.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

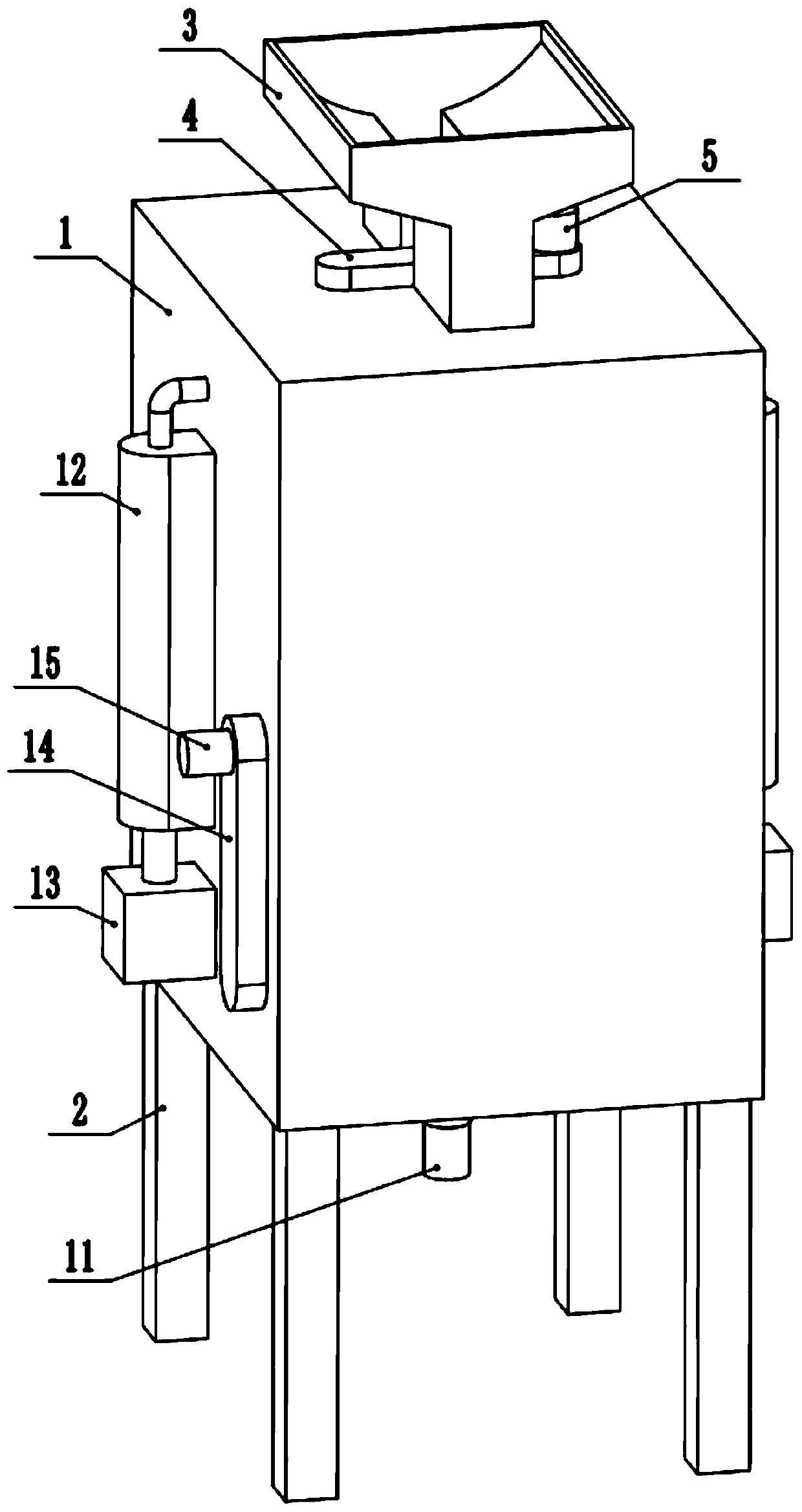

Screw conveyor discharge hole dry sludge crushing mechanism

InactiveCN108686811AEasy to transportFully processedCleaning using liquidsGrain treatmentsSludgePulp and paper industry

The invention discloses a screw conveyor discharge hole dry sludge crushing mechanism, and relates to the technical field of sludge treatment equipment. The screw conveyor discharge hole dry sludge crushing mechanism comprises a screw conveyor, wherein a feeding hole is formed in the top of the screw conveyor; a discharge hole is formed in the bottom of the screw conveyor, and a crushing treatmentbox is fixedly connected to one end of the discharge hole; a water inlet pipe is arranged above the crushing treatment box, a spray head is arranged below the water inlet pipe, and the spray head penetrates through the top of the crushing treatment box; and baffles are rotatably connected to both side walls of an inner cavity of the crushing treatment box. According to the screw conveyor discharge hole dry sludge crushing mechanism, through the arrangement of a brush, the water inlet pipe and the spray head, the surface of a roller and the inner cavity of the crushing treatment box can be cleaned conveniently, and the crushing treatment can be carried out conveniently; through the connection of the screw conveyor and the crushing treatment box, the work efficiency of workers is improved;and through the arrangement of a stirring rod and a stirring motor, sludge can be further stirred and crushed after roller processed, and the sludge is treated more adequately.

Owner:浙江奥力环保设备有限公司

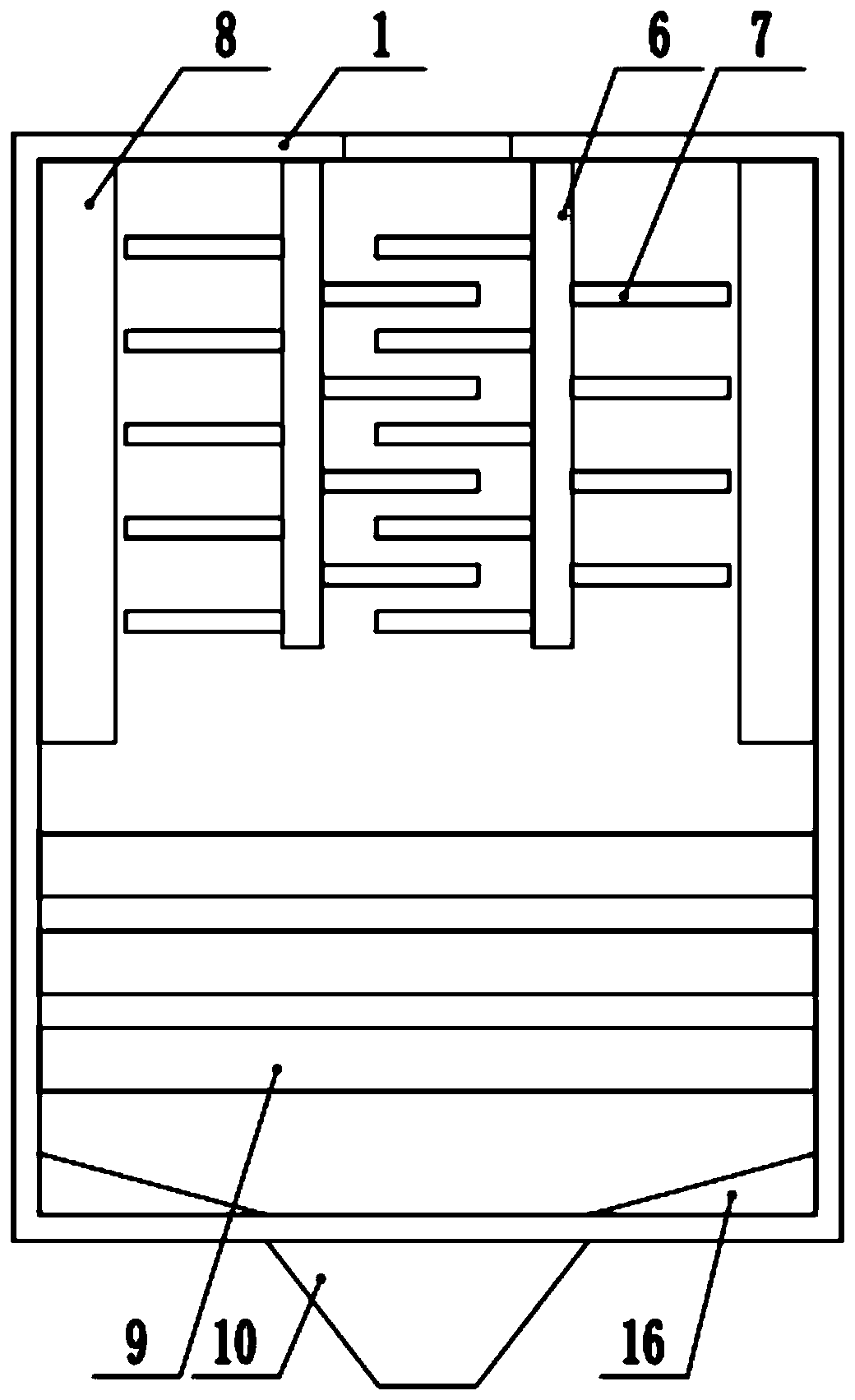

Plastic crushing machine capable of discharging impurities

InactiveCN108704735AEvenly brokenFully crushedNon-rotating vibration suppressionGrain treatmentsCrusherImpurity

The invention relates to a plastic crushing machine capable of discharging impurities. The crushing machine comprises a supporting frame and a sound insulation cotton; a crushing box is fixed to the upper end of the supporting frame, a second feeding opening is formed in the right side of the upper end of the crushing box, a control box is arranged on the left side of the crushing box, a hydraulicpump is arranged on the upper end inside the control box, six crushing knives are arranged in the crushing box, plastic crushing treatment is more sufficient, directions of knife edges between everytwo adjacent crushing knives are different, during rotation, the plastic stirring directions are different, the plastic not achieving the crushing effect flows up and down in the crushing box in a reciprocated manner, the plastic can make repeated contact with the breaking knives to be crushed, the plastic can be subject to repeated crushing treatment, the plastic crushing is more uniform, the time needed by crushing is reduced, the crushing efficiency of the crushing machine is improved, the six crushing knives are connected with the same first motor through a belt, and the manufacturing costof the crushing machine is reduced.

Owner:WUHU LINGMENG E COMMERCE CO LTD

Closed environment-friendly type soil remediation equipment

ActiveCN108480374AWell mixedFully crushedContaminated soil reclamationGrain treatmentsSoil remediationAgricultural engineering

The invention discloses closed environment-friendly type soil remediation equipment. The closed environment-friendly type soil remediation equipment comprises an equipment body, a feeding port, a drugliquid mixing cavity and a mounting seat, the upper part of the left side of the equipment body is provided with the feeding port, the lower part of the feeding port is connected with a smashing cavity, a drug liquid spraying cavity is formed in the lower part of the smashing cavity, a worm located on the right side of the feeding port is fixedly mounted in the middle of the upper surface of thesmashing cavity, a worm gear is arranged on the right side of the worm, and the mounting seat is arranged in the smashing cavity; the right side of the smashing cavity is provided with the drug liquidmixing cavity, the left side of the drug liquid mixing cavity is welded to the middle of the right side wall of the smashing cavity, and the drug liquid spraying cavity is symmetrically and obliquelyprovided with the drug liquid temporary storage cavities; and a second rotary shaft is arranged in each drug liquid spraying cavity. The closed environment-friendly type soil remediation equipment can achieve repeated smashing and crushing treatment on the soil, the phenomenon that the soil cannot sufficiently absorb the drug liquid because the soil is agglomerated is avoided, and remediation ofsoil is effectively achieved.

Owner:JIANGSU FENGYE TECH ENVIRONMENTAL PROTECTION GRP CO LTD

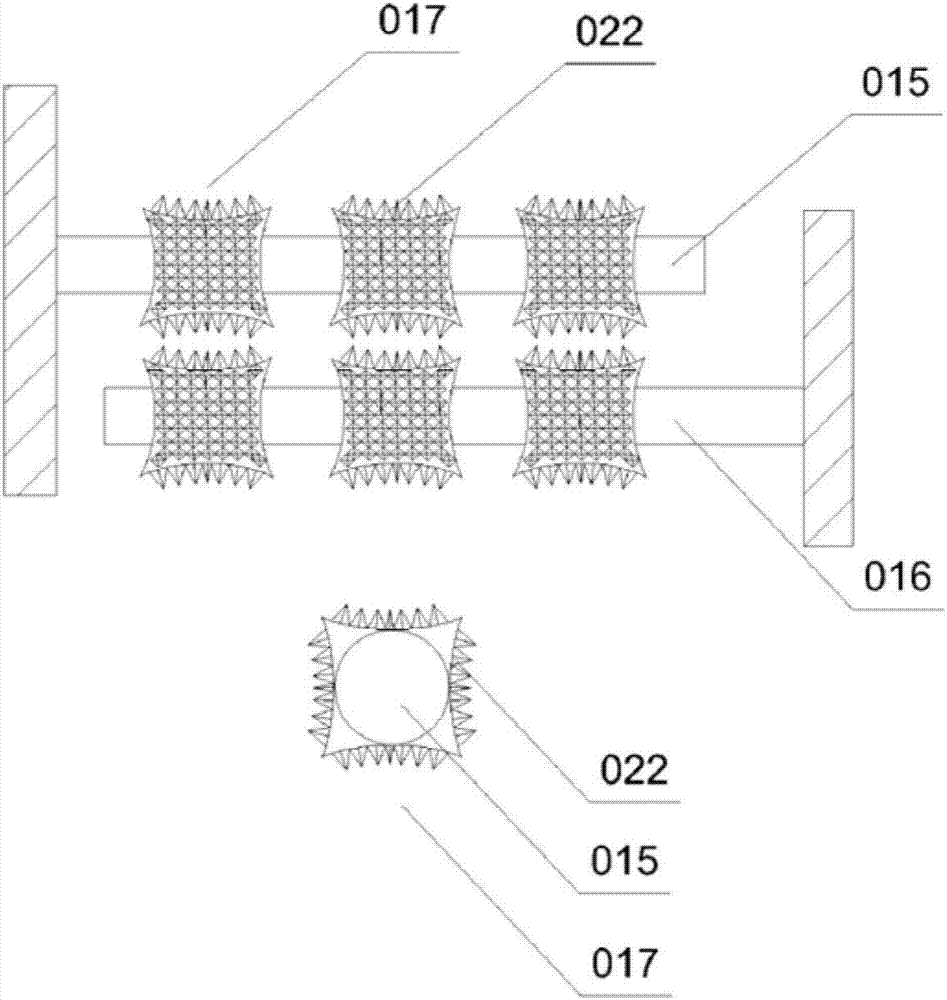

High-efficient crushing device for raw materials of thermal insulation bricks

The invention discloses a high-efficient crushing device for raw materials of thermal insulation bricks, and relates to the technical field of thermal insulation brick production. The device comprises a crushing shell; a feeding port is formed in the upper end of the crushing shell and a discharging port is formed in the lower end of the crushing shell; a rotating mechanism is arranged in the crushing shell; a motor for providing power for the rotating mechanism is arranged outside the crushing shell; a plurality of first crushing rods are arranged on the exterior of the rotating mechanism; a plurality of second crushing rods which are arranged in a staggered mode with the first crushing rods are arranged on the inner wall of the crushing shell; a plurality of crushing assemblies are arranged on the first crushing rods and the second crushing rods in a sleeved mode; the crushing assemblies are arranged as a square block structure; four faces of the square block structure are recessed inwards; and the four surfaces are provided with a plurality of prismatic crushing cutters. According to the device, the structure is simple; the multiple crushing assemblies are arranged on the crushing rods, so that the contact area between the raw materials and the crushing cutters is increased, and thus the crushing efficiency is improved; raw material collection is sufficient; and the damage degree of the whole device is reduced.

Owner:弘毅天承知识产权股份有限公司

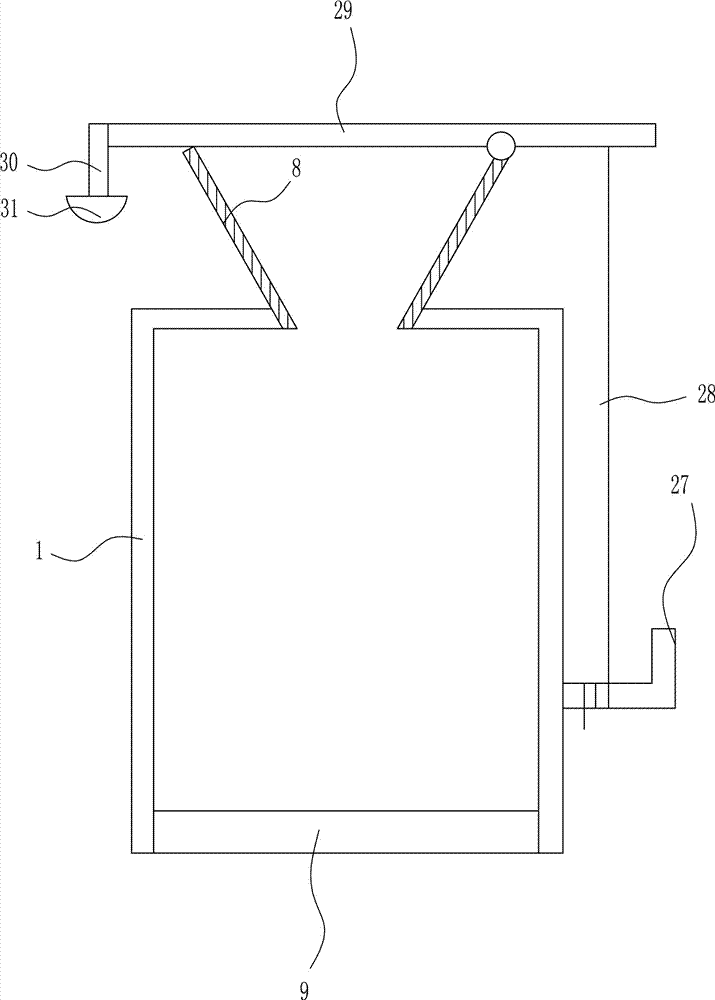

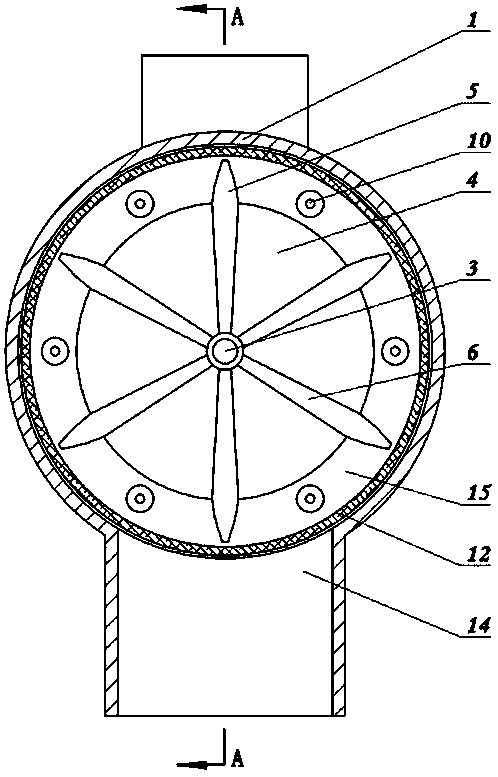

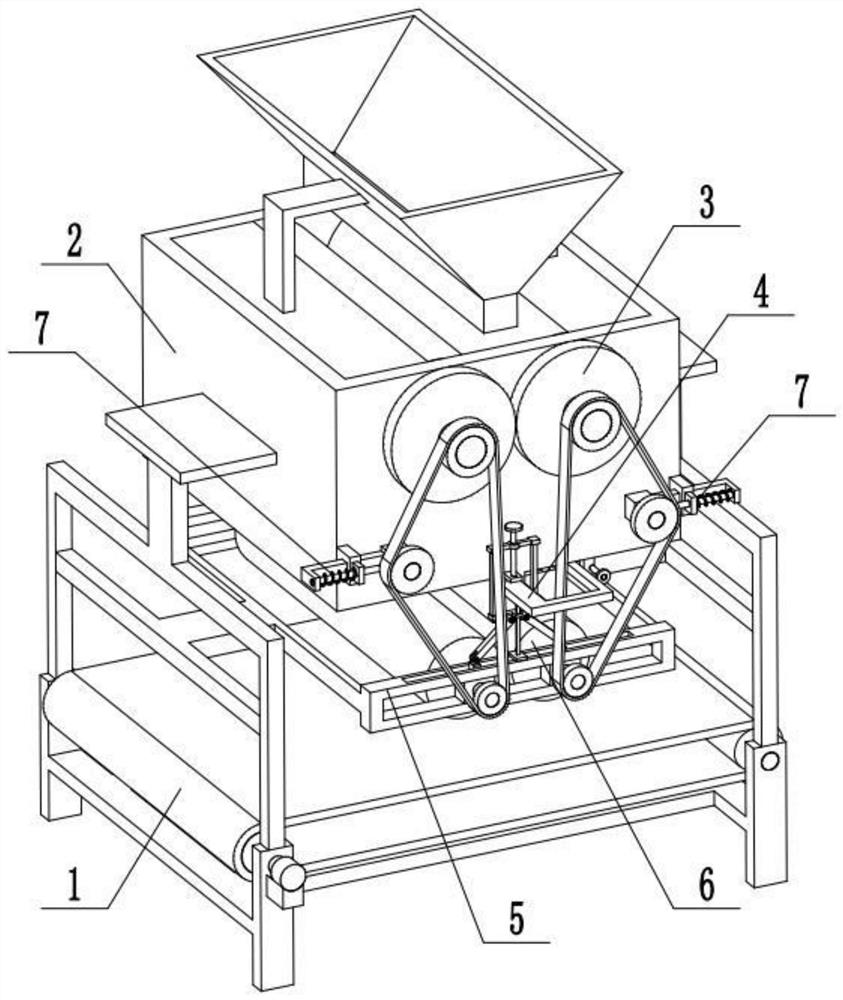

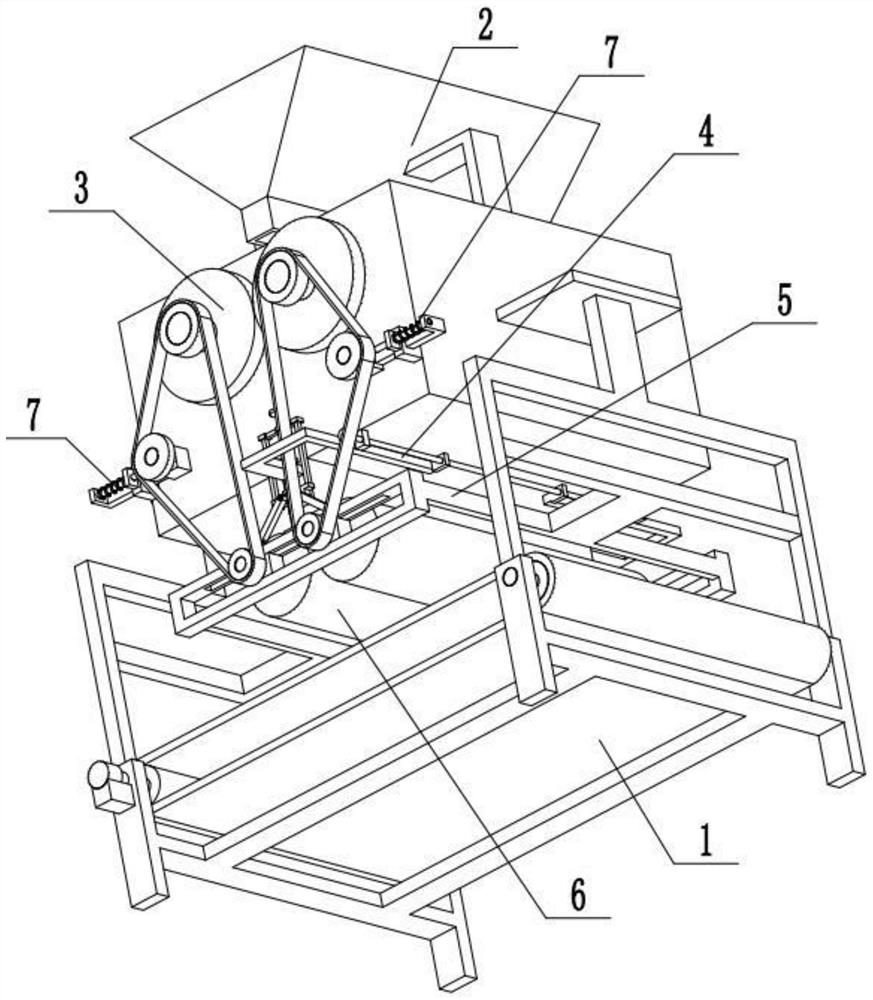

Portable straw smashing and drying device

InactiveCN108174706AExtended stayReduce laborDispersed particle separationDrying gas arrangementsEngineeringMechanical engineering

The invention provides a portable straw smashing and drying device and belongs to the field of smashing and drying devices. The device includes a shell body, an oblique baffle, a smashing device and afiltering device; the shell body is cubic and is vertically placed, and a smashing cavity is formed in the shell body; the left end of the smashing cavity is provided with a connection port connectedto the shell body; a material conveying device is arranged at the left end of the connection port; the material conveying device includes a rotating motor, a material conveying shell, material conveying vanes, a feeding port and a rotating main shaft; the rotating motor is arranged at the upper end and fixedly connected to the upper surface of the material conveying shell, and the connected rotating main shaft is arranged at the lower end of the rotating motor; the lower end of the rotating main shaft is connected to the inner surface of the material conveying shell, and the fixedly connectedmaterial conveying vanes are arranged on the rotating main shaft; the material conveying shell is spiral; a connected exhaust pipe is arranged at the upper end of the smashing cavity; the smashing device connected to the shell body is arranged at the lower end of a filtering net. The device is simple in structural design, convenient to use, high in smashing and drying efficiency, low in price andconvenient to popularize.

Owner:ZHENGZHOU HAOEN ELECTRONICS INFORMATION TECH CO LTD

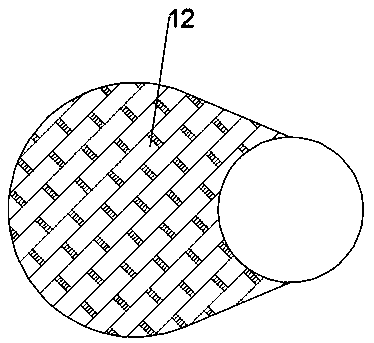

Traditional Chinese medicine crusher having auxiliary grinding function

The invention discloses a traditional Chinese medicine crusher having an auxiliary grinding function. A rotary disc is fixed to a rotating shaft of the crusher; radial protruding ribs are uniformly distributed on the rotary disc and crushing teeth are arranged on the rotary disc; the periphery of the rotary disc is provided with an annular inner layer filter screen; meanwhile, L-shaped auxiliary teeth extend outwards from the outer side of the rotary disc; movable grinding teeth are distributed at the inner sides of axial rods of the auxiliary teeth; periphery supporting rods are fixedly arranged inside a housing; the outer side of each periphery supporting rod is provided with stationary grinding teeth; and the stationary grinding teeth and the movable grinding teeth are embedded into each other in a concave-convex manner. The traditional Chinese medicine crusher disclosed by the invention can be used for fully crushing medicinal materials by utilizing the crushing teeth in a centralregion of the rotary disc, can also be used for separating thick materials into a grinding region by utilizing the inner layer filter screen, and can perform crushing machining again on the thick materials by mutual friction and collision of the movable grinding teeth and the stationary grinding teeth.

Owner:郑州海擎电子技术有限公司

Environment-friendly electronic product plastic shell waste recycling device

InactiveCN108556209AFully crushedImprove crushing efficiencyPlastic recyclingMechanical material recoveryWaste recyclingScrap

The invention discloses an environment-friendly electronic product plastic shell waste recycling device which comprises a bottom plate, a frame device, a crushing device, a filtering device, a first electric cylinder device, a grinding device and a second electric cylinder device, wherein the frame device is arranged on the bottom plate, the crushing device and the filtering device are arranged onthe frame device, the first electric cylinder device is arranged on the right side of the crushing device, the grinding device is arranged on the lower portion of the filtering device, and the secondelectric cylinder device is arranged on the left side of the grinding device. According to the device, plastic shell waste can be sufficiently crushed, the crushed waste is recycled, crushing efficiency is high, crushed plastic particles can be screened, so that the plastic particles meeting needed sizes of particle diameters are conveniently screened out, and post processing is facilitated.

Owner:广州市鹭江远科技有限公司

Environmental-friendly crushing and dedusting device for concrete wastes

InactiveCN111468269AFully crushedEffective protectionDispersed particle filtrationDirt cleaningArchitectural engineeringDust control

The invention discloses an environmental-friendly crushing and dedusting device for concrete wastes, and relates to the technical field of concrete processing. The environmental-friendly crushing anddedusting device for the concrete wastes comprises a treatment box, wherein support legs are fixedly connected to four corners of the bottom part of the treatment box; a feed hopper is fixedly connected to the top end of the treatment box; a primary crushing device is arranged on the top part in the treatment box; a secondary crushing device is arranged under the primary crushing device; negativepressure covers are fixedly connected to two sides in the treatment box; a negative pressure fan is fixedly connected to the outer part of the treatment box; an air purification device is connected between the input end of the negative pressure fan and each negative pressure fan; a material discharge cover is fixedly connected to the center of the bottom end of the treatment box; and a material discharge pipe is fixedly connected to the bottom end of the material discharge cover. According to the environmental-friendly crushing and dedusting device for the concrete wastes provided by the invention, through arranging the primary crushing device and the secondary crushing device for sufficiently crushing the concrete wastes, and through arranging the negative pressure covers and the air purification devices for absorbing and purifying dust produced by smashing, the environment is effectively protected.

Owner:新沂新硕混凝土有限公司

Textile dye preparation system and method

ActiveCN113333131AGuarantee processing qualityQuality improvementRotary stirring mixersGrain treatmentsManufacturing engineeringMechanical engineering

The invention relates to the technical field of kitchen dye preparation, in particular to a textile dye preparation system and method. The dye preparation method of the textile dye preparation system comprises the following steps that 1, raw materials are poured into a processing box, a rolling plate rotates, and a plurality of cutting knives move towards the outer side to cut off the raw materials; 2, a main shaft moves downwards to drive a bearing frame and the rolling plate to move downwards to smash the raw materials, the main shaft rotates to drive the bearing frame and the rolling plate to rotate to grind the raw materials, and in the process, a rotating ring rotates to drive rotating blades to move and rotate at the same time; 3, a scraper rotates to drive the scraper to rotate, and the scraper rotates to push out the raw materials in the processing box; and 4, the raw materials flow into a mixing barrel, a stirring rod rotates to uniformly stir the raw materials and water in the mixing barrel, and the device can turn over the crushed raw materials, scatter the raw materials which are rolled and adhered together, and enable small raw materials buried in powder to leak out and to be continuously crushed.

Owner:宿迁虹光化学工业有限公司

Disposable medical plastic waste treatment device

ActiveCN112355024BRealize sieving processFully crushedTransportation and packagingSolid waste disposalThermodynamicsMedical equipment

The invention discloses a disposable medical plastic waste treatment device, which belongs to the technical field of medical equipment and solves the problem that the storage box of the existing device cannot separate the waste from solid and liquid, resulting in cross-contamination of the waste, and increases the follow-up It is difficult to deal with the problem; its technical features are: including a processing box, a separation chamber and a liquid storage chamber are arranged in the processing box, the separation chamber is arranged above the liquid storage chamber, and a solid-liquid storage chamber is provided between the separation chamber and the liquid storage chamber. The separated screening assembly is equipped with an extruding assembly in the separation chamber; the embodiment of the present invention is provided with a crushing assembly, and the setting of the crushing assembly realizes sufficient crushing of the waste in the crushing chamber, and at the same time, the rotation of the strengthening assembly can further strengthen the At the same time, the setting of the sieving component realizes the sieving treatment of medical waste and reduces the cost of medical waste treatment.

Owner:SUZHOU CHAOSHUOFAN PLASTIC PROD CO LTD

Medicine uniform mixing device for animal husbandry and veterinary medicine

InactiveCN113274933AEasy to stir and mixStir to mix fully and evenlyRotary stirring mixersTransportation and packagingAnimal scienceMedicine

The invention discloses a medicine uniform mixing device for animal husbandry and veterinary medicine. The device comprises a processing box body, a heater, a base, a first motor and a second motor, wherein the right upper end of the processing box body communicates with a water inlet pipe, stirring blades are rotationally connected in the processing box body through a rotating shaft, and a worm wheel is fixedly connected to the outer surface of the upper end of the rotating shaft. And the front end of the worm is fixedly connected with a belt, the crushing roller is rotationally connected to the interior of the upper end of the processing box body, and a middle shaft at the rear end of the crushing roller is fixedly connected with the output end of a second motor through a bolt. According to the medicine uniform mixing device for animal husbandry and veterinary medicine, the medicine can be fully and uniformly stirred and mixed conveniently, the caking phenomenon and the influence on feeding are avoided, the inner wall of the medicine box can be fully cleaned conveniently, the medicine adhesion phenomenon on the inner wall of the medicine box is avoided, and the later use is influenced; meanwhile, the medicine in the medicine box can be conveniently and uniformly put, and the phenomenon that feeding is affected due to accumulation is avoided.

Owner:ZHENGZHOU VOCATIONAL UNIV OF INFORMATION & TECH

Slurry stirring device capable of removing wound textile

PendingCN113399069APlay a role of support and protectionFully crushedCleaning using toolsGrain treatmentsFiberWire rod

The invention discloses a slurry stirring device capable of removing wound textile. The slurry stirring device comprises a processing shell, wherein the lower surface of the processing shell is fixedly connected with a limiting seat, the lower surface, close to the edge, of the processing shell is provided with a discharging hole, the upper surface of the limiting seat is rotationally connected with a cylinder in a limiting mode, a through hole allowing the machining shell to rotate in a limited mode is formed in the lower surface of the machining shell, a motor is fixedly connected to the lower surface of the limiting seat, and a first shaft is fixedly connected to the top of an output shaft on the motor. Through cooperative use of the structures, the problems that in the actual use process, due to the fact that in traditional stirring equipment, the crushing and grinding efficiency of raw materials is not high enough, the raw materials are difficult to supplement in time, meanwhile, the blades used for cutting are also prone to winding textile wires and adhering crushed wire fibers, the follow-up cutting quality of the blade is not enough, so that the quality is difficult to guarantee, and inconvenience is brought to use.

Owner:吴飞

Equipment capable of separating waste liquor generated in industrial production

InactiveCN108379910AEfficient separationImprove crushing efficiencyGrain treatmentsStationary filtering element filtersLiquid wasteEnergy conservation

The invention discloses equipment capable of separating waste liquor generated in industrial production. The equipment comprise a feed opening, a first separation chamber, a first filter screen, a second separation chamber, a second filter screen and a waste liquor collecting chamber, wherein the feed opening is formed in the upper part of the first separation chamber; a feeding mechanism is arranged inside the first separation chamber; the first filter screen is arranged at the bottom of the first separation chamber; the second separation chamber is arranged at the lower part of the first filter screen; the second filter screen is arranged at the lower part of the second separation chamber; the lower part of the second filter screen is connected with the waste liquor collecting chamber; arolling chamber is arranged on the right side of the first separation chamber; a crushing chamber is arranged on the right side of the rolling chamber. The equipment disclosed by the invention has the advantages of energy conservation, environmental protection and reasonable structure; the equipment can sufficiently separate the waste liquor and sufficiently crush residues in the waste liquor andis suitable for popularization.

Owner:赵广海

Ecological restoration device for electroplating waste land contaminated soil

InactiveCN111229801AFully crushedPromote repairTransportation and packagingMixersSoil remediationEnvironmental engineering

The invention discloses an ecological remediation device for electroplating waste land contaminated soil, belongs to the technical field of soil remediation, and solves the problems that an existing device cannot crush blocky soil so that the treatment efficiency is reduced. The device is technically characterized in that the device comprises a base, a repairing box mounting base and a repairing box, the repairing box mounting base is arranged on the upper portion of the base, the repairing box is fixedly mounted on the repairing box mounting base, a mixing cavity is formed in the repairing box, a pretreatment cavity is formed in the upper portion of the repairing box, a pretreatment mechanism is arranged in a pretreatment cavity, the pretreatment cavity communicates with the mixing cavity, and a stirring mechanism is arranged in the mixing cavity. The device is easy to operate, the mixing assembly is arranged, caked soil can be fully smashed, accordingly, the contact area of the soiland a remediation liquid is increased, soil remediation is facilitated, the height of the remediation box mounting base is flexible and adjustable, and the soil conveying burden is relieved.

Owner:JILIN JIANZHU UNIVERSITY

Municipal garbage treatment device

The invention discloses a municipal garbage treatment device, and relates to the field of municipal engineering. The municipal garbage treatment device comprises a box body, wherein a feeding port isformed in a side end of the box body, a motor is arranged at the upper end of the box body, an output shaft of the motor is connected with an eccentric rod, the other end of the eccentric rod is rotationally connected with a transmission shaft, the transmission shaft is rotationally connected with a support, the lower end of the support is fixedly connected with a gear ring, the gear ring is in meshed transmission with a rotating gear, the lower end of the rotating gear is fixedly connected with a rotating shaft, crushing blades are uniformly distributed on the rotating shaft, the rotating gear is in meshed transmission with a fixed gear, and the lower end of the fixed gear is fixedly connected with a stand column. According to the municipal garbage treatment device, under the transmissionof the eccentric rod, the transmission shaft, the support, the gear ring, the fixed gear and the rotating gear, the crushing blades can revolve and rotate to crush garbage, and the linkage type transmission mode is adopted, so that synchronous treatment of crushed compression is realized, and the device is simple to operate; and moreover, the combined type movement track of the rotating shaft isutilized, so that the garbage is fully crushed, and the defect that garbage cannot be crushed thoroughly by a garbage crushing device is overcome.

Owner:郭进

A kind of polyester film processing device and method

ActiveCN111002520BUniform compositionReduce widthFlat articlesGrain treatmentsPolyesterPolymer science

A kind of polyester film processing device and method of the present invention comprise conveying frame, crushing box assembly, crushing wheel group, width adjustment mechanism, carriage, rolling mechanism and tensioning mechanism; Beneficial effect is that the present invention can carry out plastic film Roll pressing, the composition of the formed film is uniform, and the width and thickness of the film forming can be controlled. The process is as follows: 1. Put the plastic particles used for processing plastic film into the feed box; 2. Start the crushing wheel group to grind the large plastic particles; 3. The large plastic particles are ground into fine pieces and fall into the into the crushing cylinder, the crushing cylinder heats and melts the finely divided plastics, and the liquid plastics flow out from the width adjustment mechanism; 4. The crushing wheel set drives the rolling mechanism to rotate through two tensioning mechanisms, and the rolling mechanism controls the outflowing plastic film. Rolling, the blower cools and forms the rolled film; 5. The formed plastic film is output through the conveyor frame.

Owner:GUANGDONG HUIQI NEW MATERIAL CO LTD

Device for extracting active ingredients in burdock

PendingCN114225471ARealize shreddingFully cleanedGas solvent extractionSolid solvent extractionDistillationProcess engineering

The invention discloses a device for extracting active ingredients in burdock. The device comprises a cleaning barrel internally provided with a material placing rack, a crushing rod is arranged in the crushing chamber; a feeding hole formed in the distillation chamber is hermetically communicated with a discharging hole formed in the bottom of the crushing chamber through a feeding pipeline; the condensation assembly comprises a condenser communicated with the distillation chamber through a breather pipe, a receiving bottle communicated with the breather pipe is arranged below the condenser, and the filter plate is located below the feed port and the breather pipe; the negative pressure pump is hermetically communicated with the distillation chamber through a gas delivery pipe; the steam generator is hermetically communicated with the distillation chamber through a steam conveying pipeline I; and the drying box is in sealed communication with the receiving bottle through a liquid conveying pipe, one end of the liquid conveying pipe extends into the drying box, and an atomizing nozzle is fixedly arranged at the end. According to the burdock cleaning device, damage-free cleaning of burdock for active ingredient extraction is achieved, full extraction of all active ingredients in the burdock is achieved, and the requirement for processing and utilizing all the active ingredients in the burdock is met.

Owner:XUZHOU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com