High-efficient crushing device for raw materials of thermal insulation bricks

A high-efficiency pulverization and insulation brick technology, applied in the direction of grain processing, etc., can solve the problems of small contact area between pulverizing balls and insulation brick raw materials, poor pulverization effect, etc., and achieve the effect of improving pulverization efficiency, sufficient pulverization treatment, and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

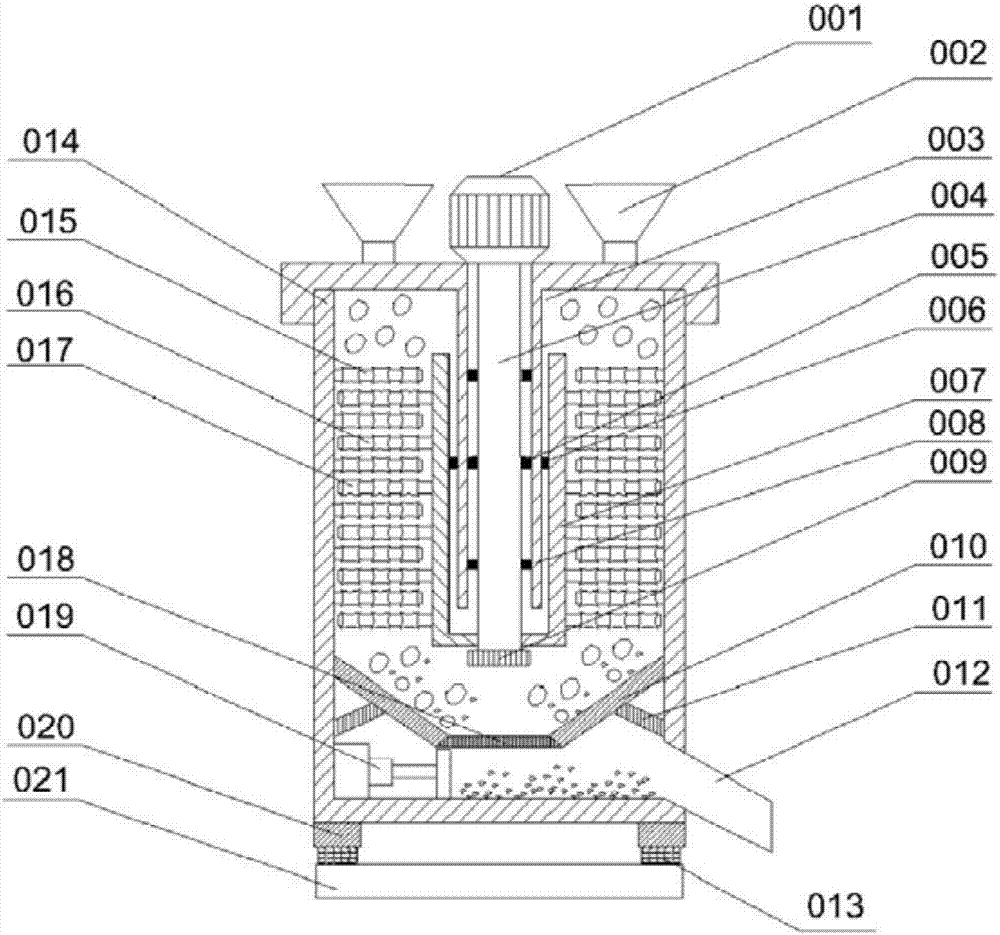

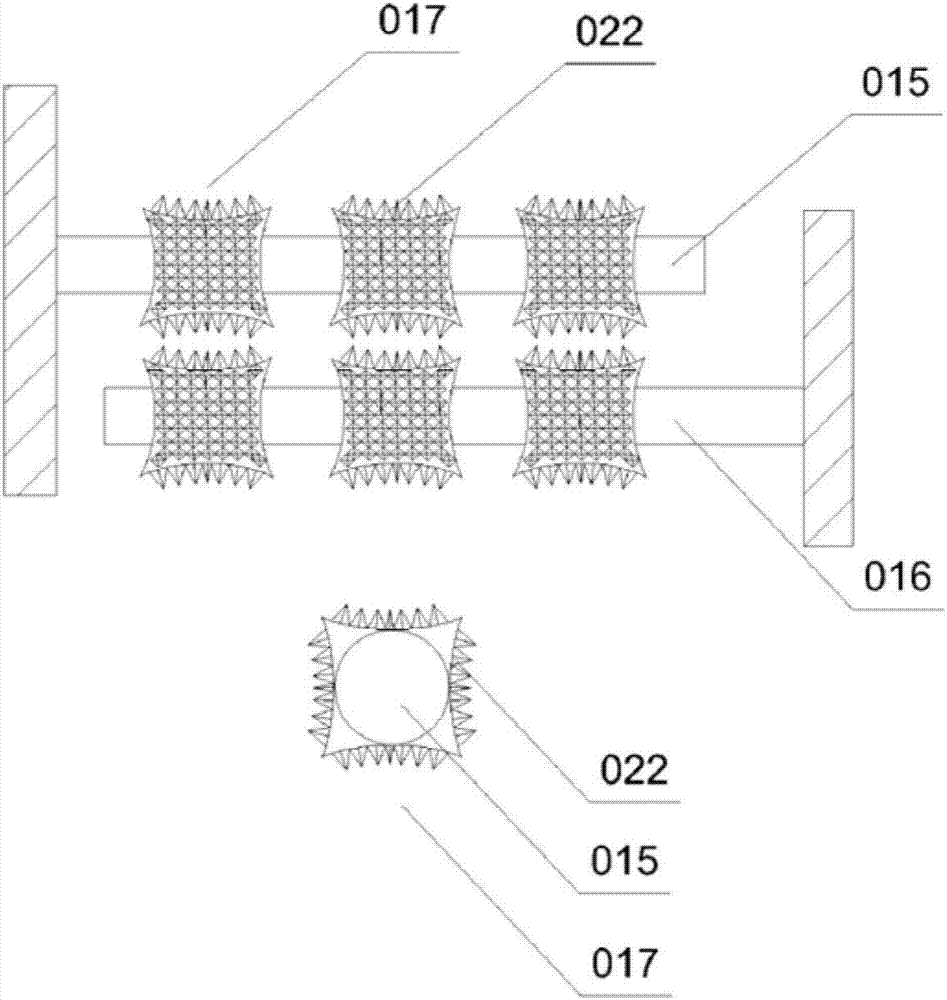

[0028] like Figure 1-2As shown, this embodiment provides a high-efficiency crushing device for thermal insulation brick raw materials, including a crushing shell 014, the upper and lower ends of the crushing shell 014 are respectively provided with a feed port 002 and a discharge port 012, and the crushing shell 014 is provided with a rotating mechanism 003, the crushing housing 014 is provided with a motor 001 that provides power for the rotating mechanism 003, the rotating mechanism 003 is provided with a number of first crushing rods 016, and the inner wall of the crushing housing 014 is provided with a number of first crushing rods. The crushing rods 016 are arranged alternately with the second crushing rods 015. The first crushing rods 016 and the second crushing rods 015 are equipped with a plurality of crushing assemblies 017. The crushing assemblies 017 are arranged in a square block structure. The four faces of the structure are all sunken inwards, and a plurality of...

Embodiment 2

[0031] like figure 1 As shown, the present embodiment is further optimized on the basis of embodiment 1, and the specific implementation scheme is as follows:

[0032] The rotating mechanism 003 includes a rotating shaft 004, a hollow protective cylinder 008 connected to the upper cover of the crushing shell 014, and a hollow support cylinder 007. A bearing 005 is arranged between the rotating shaft 004 and the hollow protective cylinder 008. The hollow protective cylinder The outside of 008 and the inside of the hollow support tube 007 are provided with a mounting bearing 2006, and the lower end of the rotating shaft 004 is fixedly connected with the hollow support tube 007 outside the hollow protective tube 008 by locking bolts 009.

[0033] In this embodiment, by installing the installation bearing between the rotating shaft and the hollow protective cylinder, and installing the second bearing on the outside of the hollow protective cylinder and the inside of the hollow sup...

Embodiment 3

[0035] like figure 1 As shown, the present embodiment is further optimized on the basis of embodiment 1, and the specific implementation scheme is as follows:

[0036] Two elastic plates 010 are arranged symmetrically at the bottom of the crushing shell 014 , and a screen 018 is arranged between the two elastic plates 010 .

[0037] In this embodiment, two spring boards are arranged symmetrically at the bottom of the crushing shell, so that the raw materials of the insulation bricks will fall after passing through the crushing force of the crushing components on the first crushing rod and the second crushing rod, and rebound after colliding with the spring boards. After the raw material rebounds, it is again crushed by the crushing force of the prismatic crushing blade on the crushing assembly, and the raw material is further finely crushed, further improving the crushing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com