Single cylinder column sand maker

A technology of sand making machine and cylinder, which is applied in the direction of grain processing, etc., and can solve the problem that the side wall of the main shaft is prone to damage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

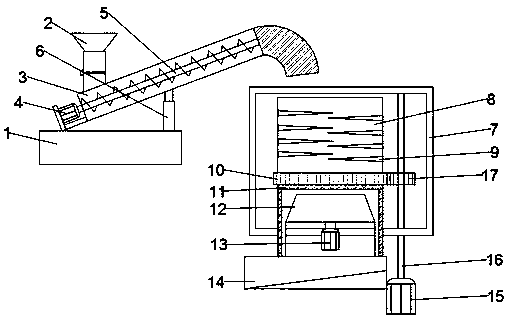

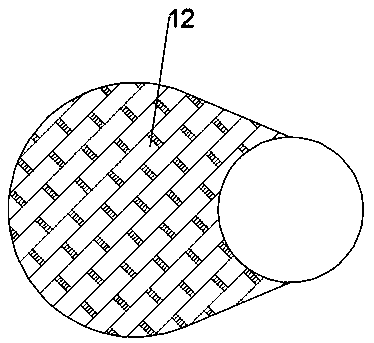

[0017] see Figure 1-2 , in the embodiment of the present invention, a single-cylinder cylindrical sand making machine includes a conveying pipeline 3, a conveying auger 5, an outer shell 7 and a crushing box 8, and the conveying pipeline 3 is used to convey sand and gravel into the crushing box 8 , and the transmission pipeline 3 is arranged obliquely, the lower end of the transmission pipeline 3 is hinged to the upper surface of the support table 1, the transmission pipeline 3 communicates with the crushing box 8, and an outer casing 7 is arranged outside the crushing box 8, and the outer casing 7 and the The crushing box 8 is rotationally connected, and the outer wall of the outer shell 7 is fixedly welded with the outer ring gear 10, and the right side of the outer ring gear 10 is provided with a first gear 17, the first gear 17 is arranged in the outer shell 7, and the second A gear 17 is fixedly welded to the rotating shaft 16, and the lower end of the rotating shaft 16 ...

Embodiment 2

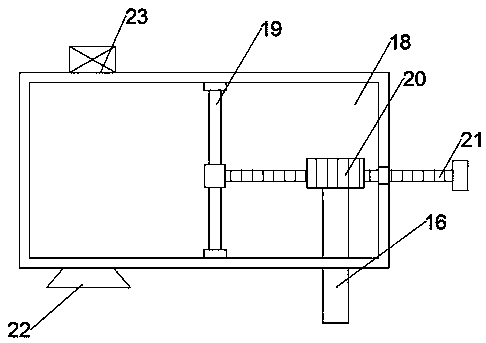

[0024] see Figure 3-4 , in an embodiment of the present invention, a dust collection assembly, a dust collection assembly 18 is arranged above the outer casing 7, the outer casing 7 is fixedly connected to the dust collection assembly 18, and a piston plate 19 is movably installed inside the dust collection assembly 18 The upper and lower ends of the piston plate 19 are slidingly connected to the inner wall of the dust collection assembly 18, the middle position of the right side wall of the piston plate 19 is welded with a rack 21, and the right end of the rack 21 runs through the right side wall of the dust collection assembly 18 , and the rack 21 is slidingly connected to the right side wall of the dust suction assembly 18, and the right half of the cavity of the dust suction assembly 18 is provided with a second gear 20, and the second gear 20 meshes with the rack 21 The upper end of the rotating shaft 16 runs through the lower wall of the dust suction assembly 18, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com