Environmental-friendly crushing and dedusting device for concrete wastes

A technology of concrete waste and dust removal device, which is applied in the direction of dust removal, grain treatment, and separation of dispersed particles, which can solve the problems of poor crushing ability of concrete waste and achieve the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

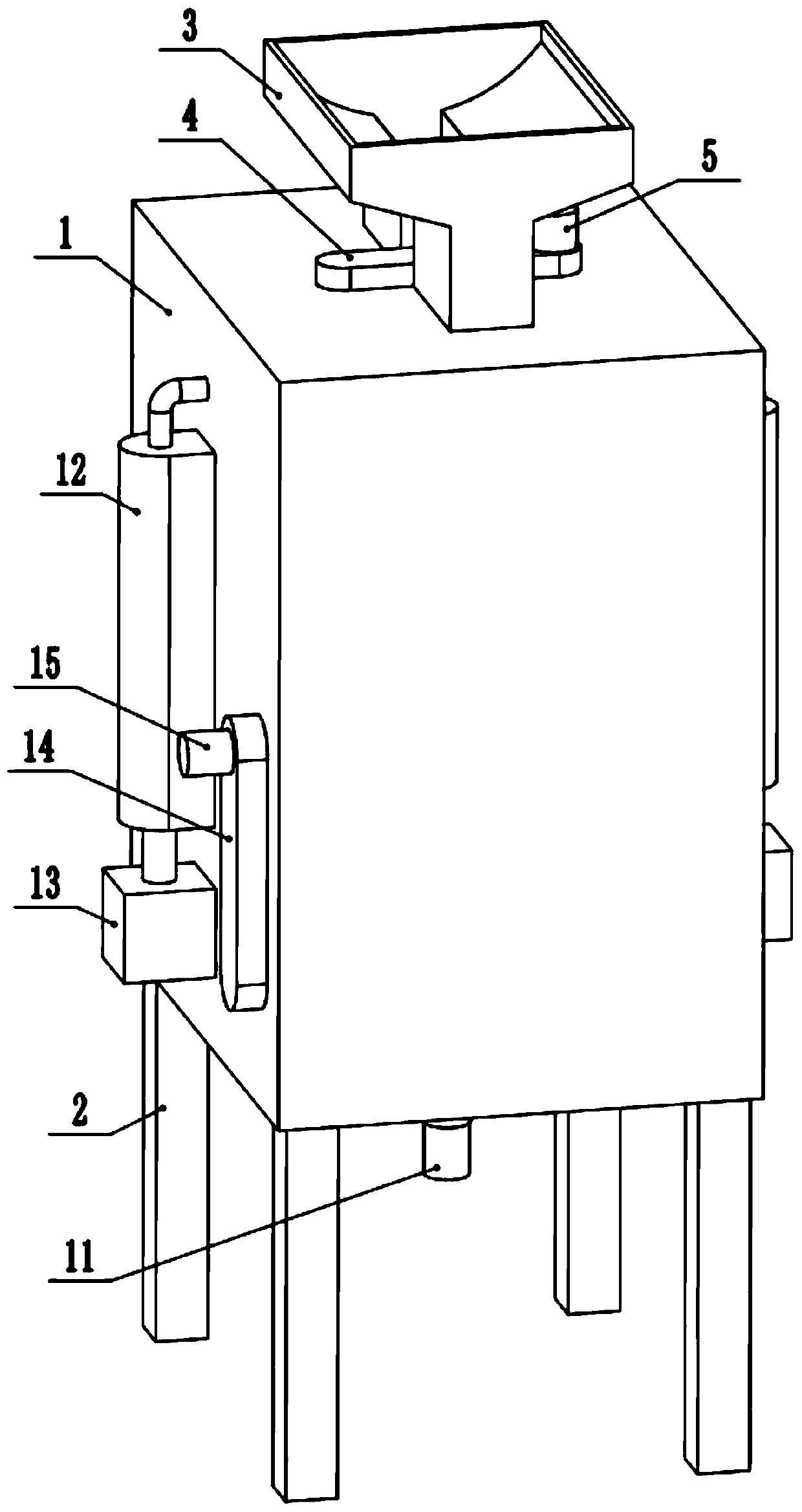

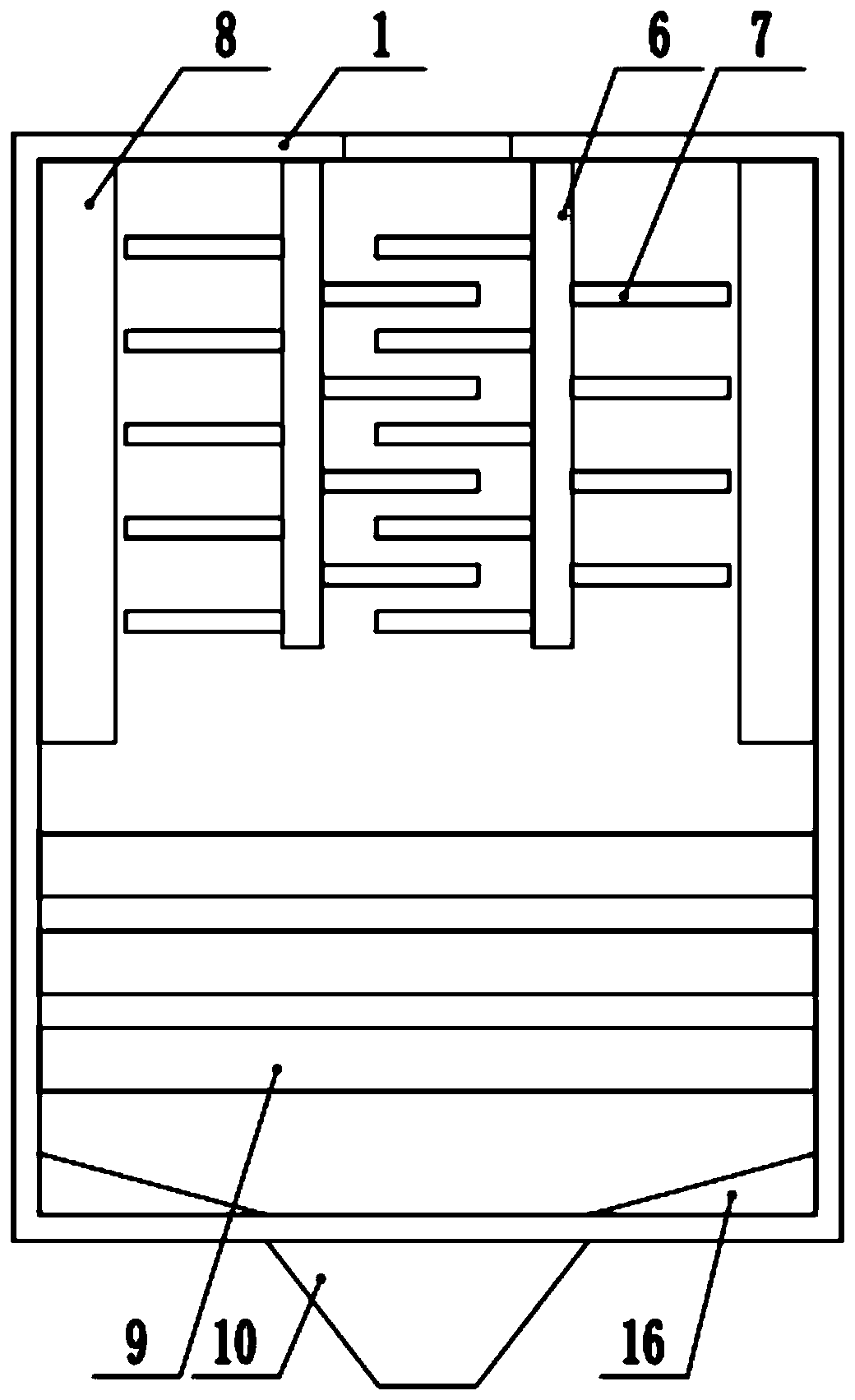

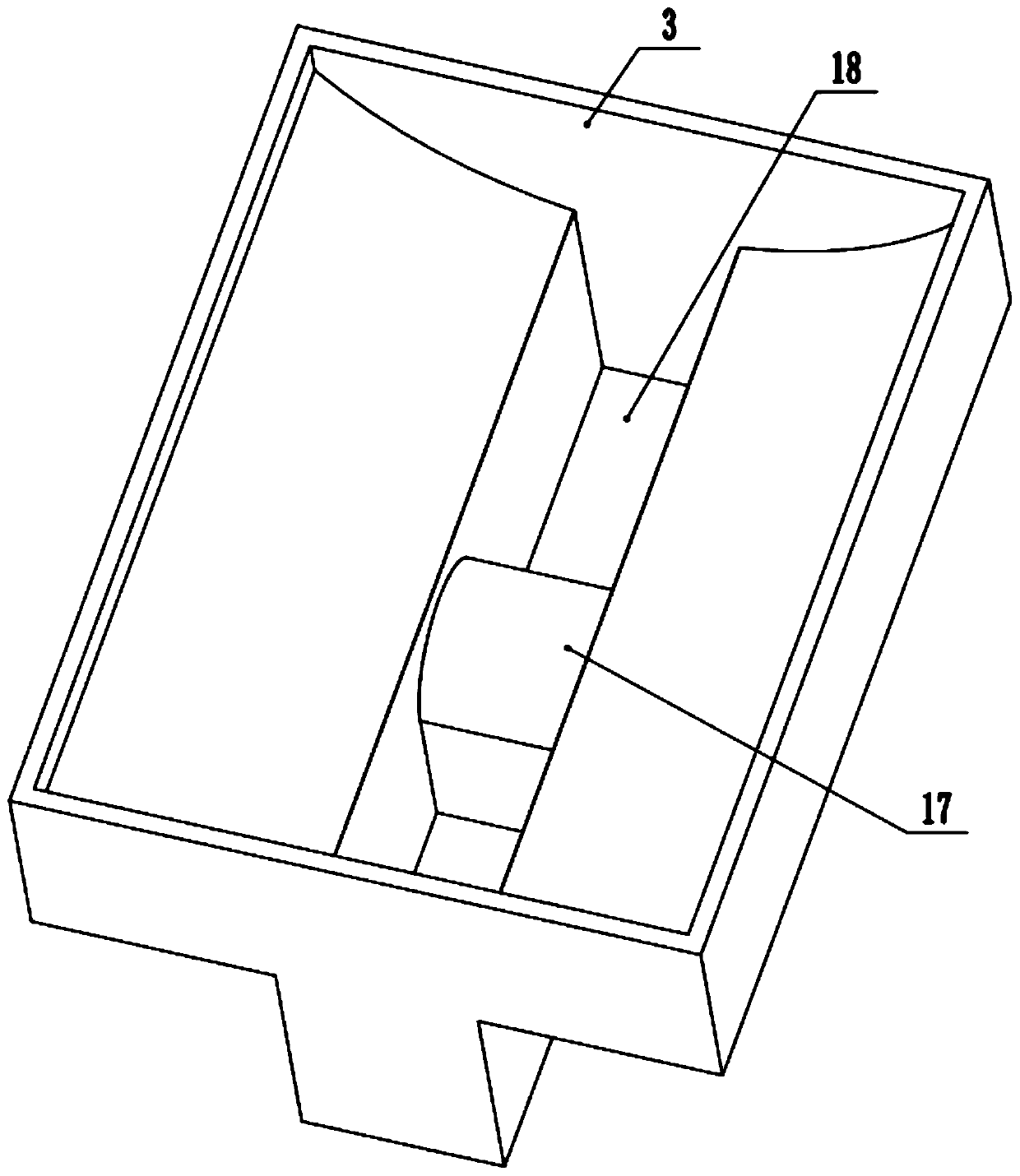

[0024] see Figure 1-3 , an environment-friendly crushing and dedusting device for concrete waste, comprising a treatment box 1, the four corners of the bottom of the treatment box 1 are fixedly connected to the support legs 2, the top of the treatment box 1 is fixedly connected to the feed hopper 3, and the top of the treatment box 1 is equipped with a primary crushing device, the bottom of the primary crushing device is provided with a secondary crushing device, both sides in the processing box 1 are fixedly connected to the negative pressure cover 8, and the outside of the processing box 1 is fixedly connected to the negative pressure blower 13, and the input end of the negative pressure blower 13 is connected to the An air cleaning device 12 is connected between the negative pressure covers 8 , the center of the bottom end of the processing box 1 is fixedly connected with a discharge cover 10 , and the bottom end of the discharge cover 10 is fixedly connected with a dischar...

Embodiment 2

[0032] see Figure 1-3 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that both ends of the bottom of the processing box 1 are fixedly connected to the material guide base 16, and the top of the material guide base 16 is inclined.

[0033] The present invention can fully crush the concrete waste by setting the primary crushing device and the secondary crushing device, and can absorb and purify the dust generated by crushing by setting the negative pressure cover 8 and the air purification device 12, so as to effectively protect the environment Protect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com