Polyester film processing device and method

A processing device and technology of polyester film, applied in grain processing, flat products, household appliances, etc., can solve the problems of inability to roll the film and adjust the width of film forming, and achieve the effect of uniform film composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

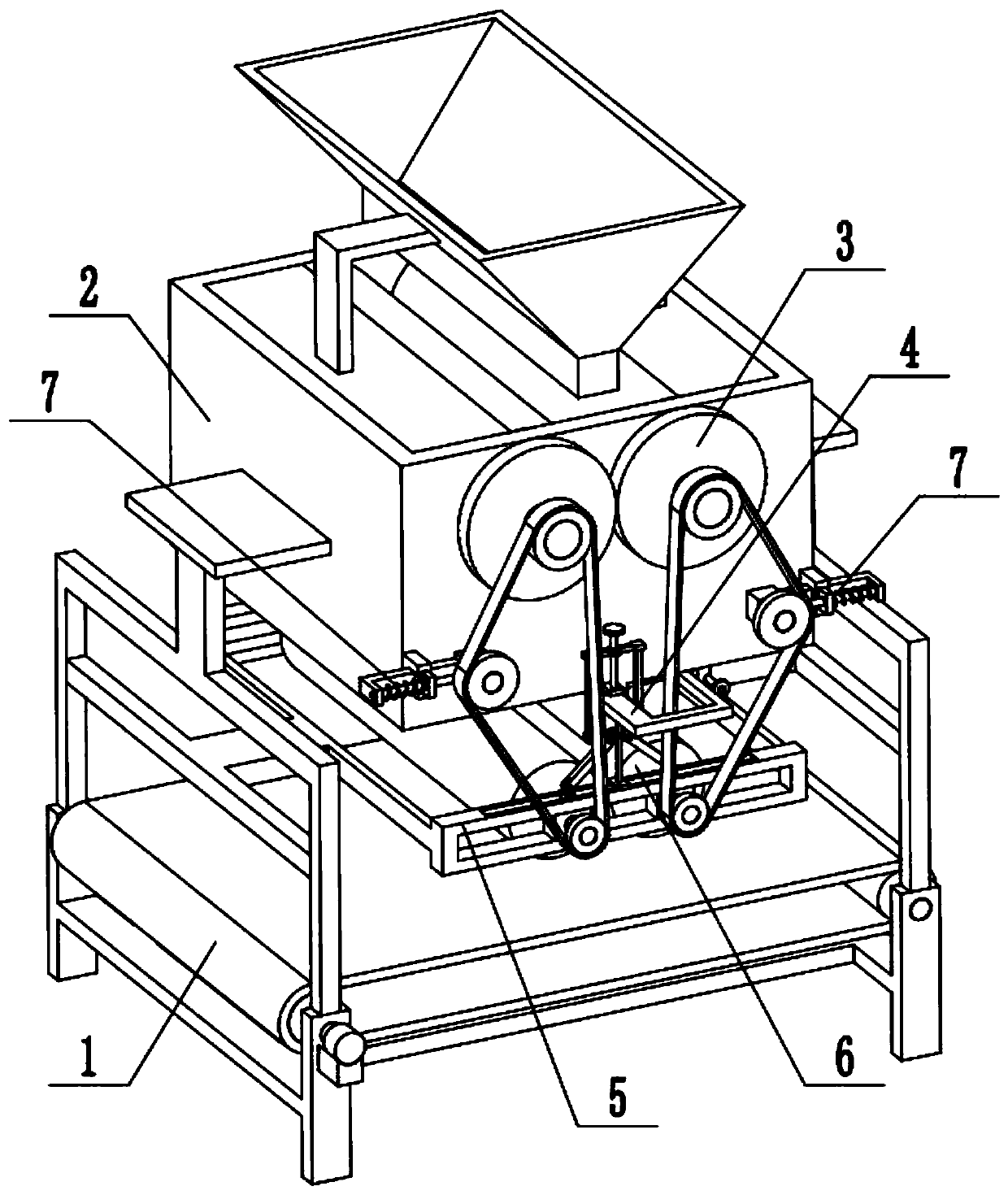

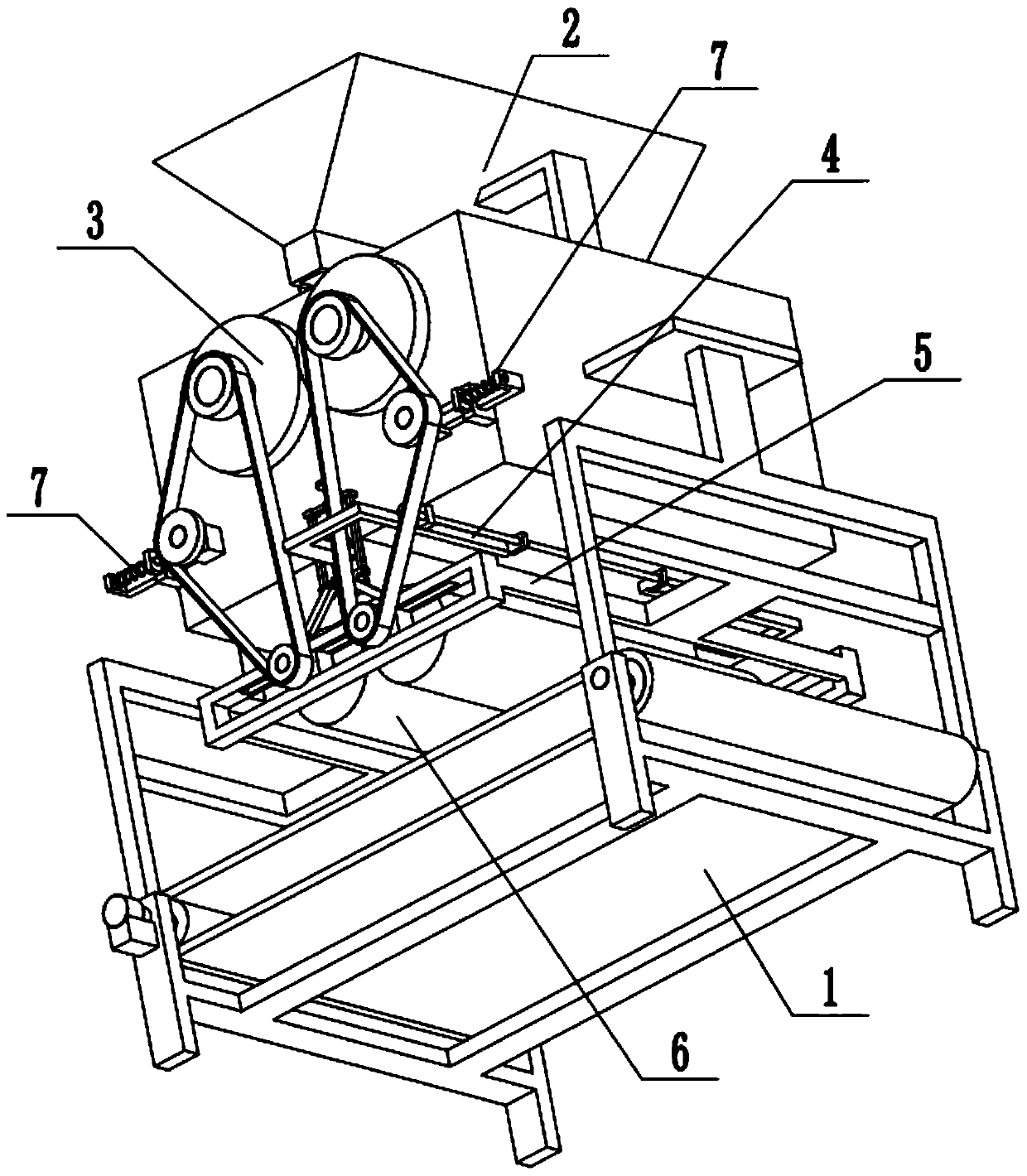

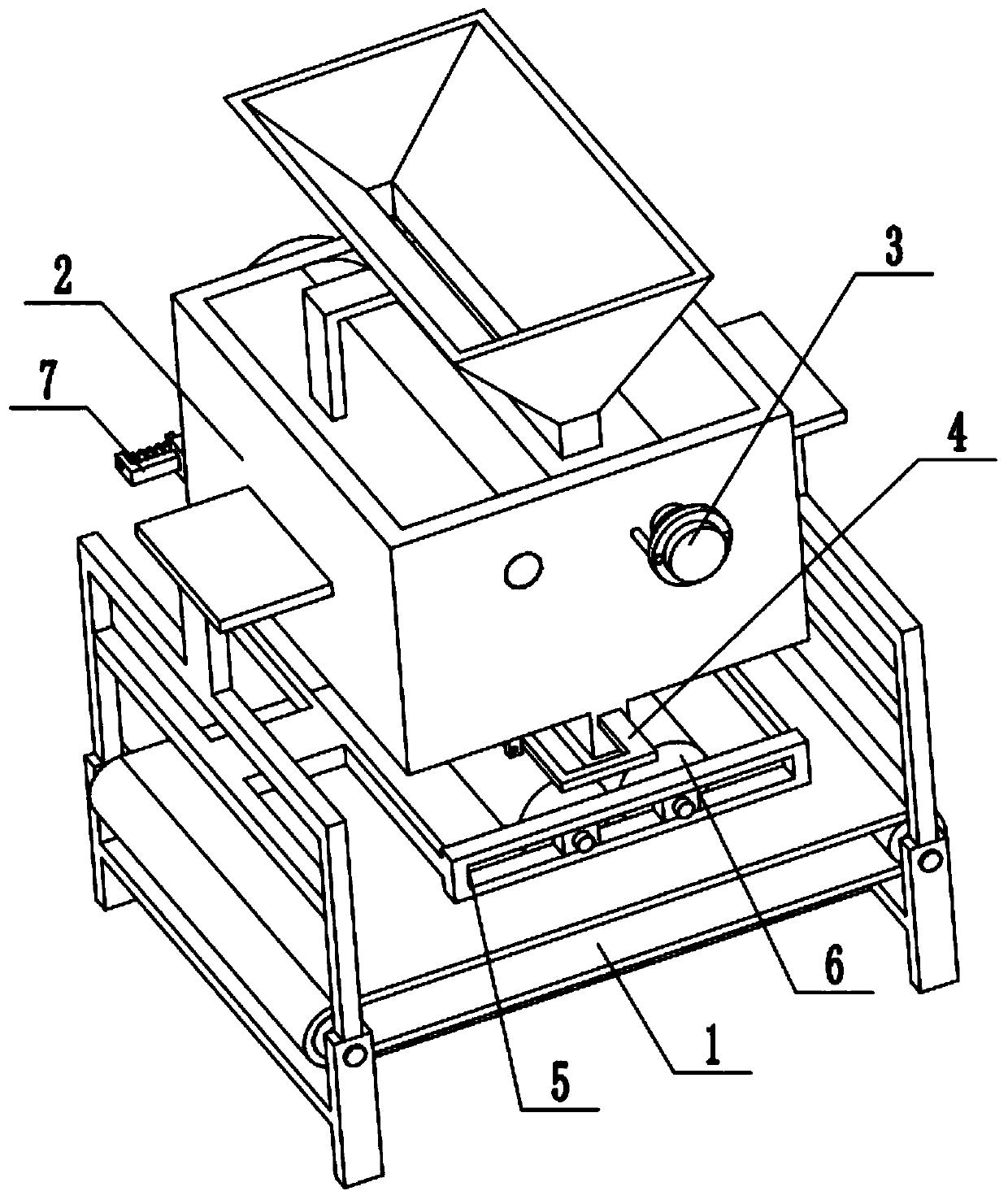

[0040] Combine below Figure 1-15 Description of this embodiment, a polyester film processing device, including a conveyor frame 1, a crushing box assembly 2, a crushing wheel set 3, a width adjustment mechanism 4, a carriage 5, a rolling mechanism 6 and a tensioning mechanism 7, the The crushing box assembly 2 is set on the conveying frame 1, the crushing wheel set 3 is set on the crushing box assembly 2, the width adjustment mechanism 4 is connected with the crushing box assembly 2, the carriage 5 is fixedly connected to the crushing box assembly 2, rolling The mechanism 6 is movably connected to the carriage 5, the width adjustment mechanism 4 is located between the crushing box assembly 2 and the rolling mechanism 6, two tensioning mechanisms 7 are provided, and the two tensioning mechanisms 7 are symmetrically arranged on the crushing box assembly 2 , the two ends of the crushing wheel set 3 are connected to the two ends of the rolling mechanism 6 through a tension mechan...

specific Embodiment approach 2

[0042] Combine below Figure 1-15 To illustrate this embodiment, the conveyor frame 1 includes a conveyor belt frame 1-1, a first motor 1-2, a first rotating shaft 1-3, a second rotating shaft 1-4, a conveyor belt roller 1-5 and a conveyor belt 1-6; the first motor 1-2 is fixedly connected to one side of the conveyor belt frame 1-1 through the motor frame, the output shaft of the first motor 1-2 is connected to the first rotating shaft 1-3 through a coupling, and the first rotating shaft 1 -3 and the second rotating shaft 1-4 are respectively rotated and connected to the two ends of the conveyor belt frame 1-1, and a conveyor belt roller 1-5 is fixedly connected to the first rotating shaft 1-3 and the second rotating shaft 1-4 respectively, two The conveyor belt rollers 1-5 are connected through the transmission of the conveyor belt 1-6; the crushing box assembly 2 is arranged on the conveyor belt frame 1-1. Connect the first motor 1-2 to the power supply and the control swit...

specific Embodiment approach 3

[0044] Combine below Figure 1-15 To illustrate this embodiment, the crushing box assembly 2 includes a crushing cylinder 2-1, a fixed frame 2-2, a baffle plate 2-3, a feed box 2-4, an L-shaped frame 2-5 and a rectangular channel 2- 6. The two ends of the crushing tube 2-1 are respectively fixedly connected to a fixed frame 2-2, and the two fixed frames 2-2 are respectively fixedly connected to the two ends of the conveyor frame 1-1, and the upper end of the crushing tube 2-1 is fixedly connected symmetrically Two baffles 2-3, the feed box 2-4 are fixedly connected to the two baffles 2-3 through two L-shaped frames 2-5, and the lower end of the crushing cylinder 2-1 is provided with a rectangular slot 2-6 The width adjustment mechanism 4 is located at the lower end of the crushing tube 2-1, and the crushing wheel set 3 is located on the crushing tube 2-1; the inner wall of the crushing tube 2-1 is provided with an electric heating wire. The plastic granules are put into the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com