Device for manufacturing magnetic powder particles

A preparation device and particle technology, which is applied in the field of magnetic powder particle preparation devices, can solve the problems of low crushing efficiency, achieve the effects of improving crushing efficiency, improving uniformity, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

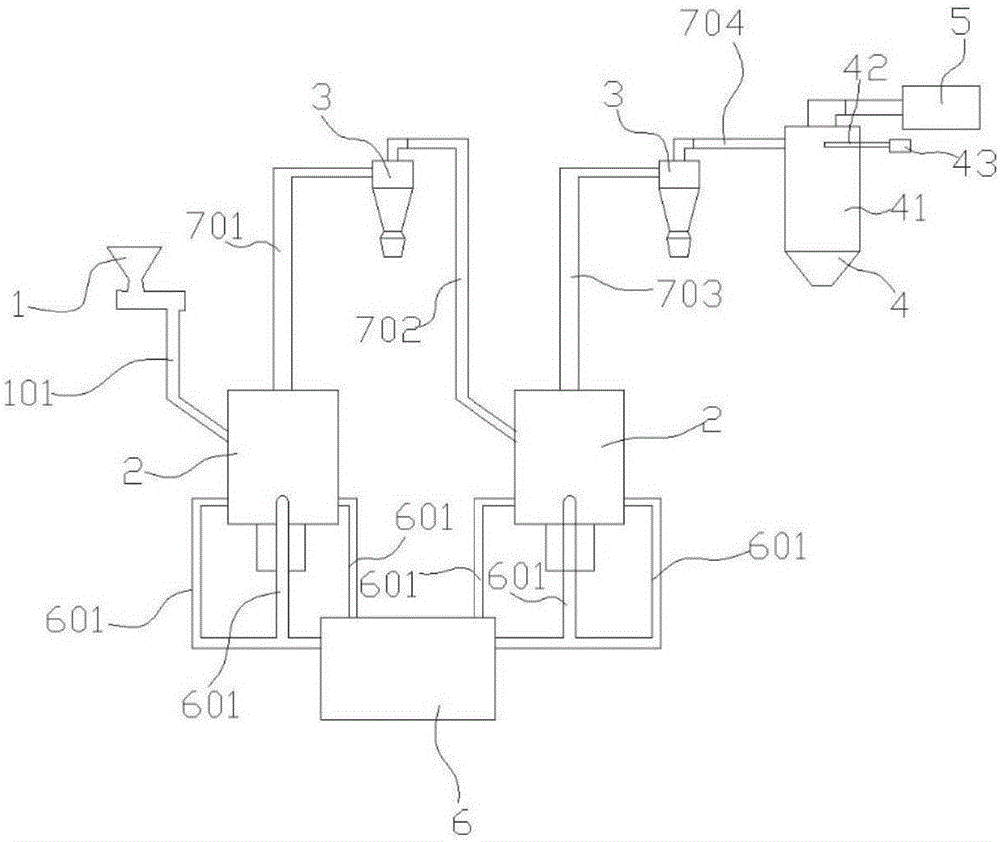

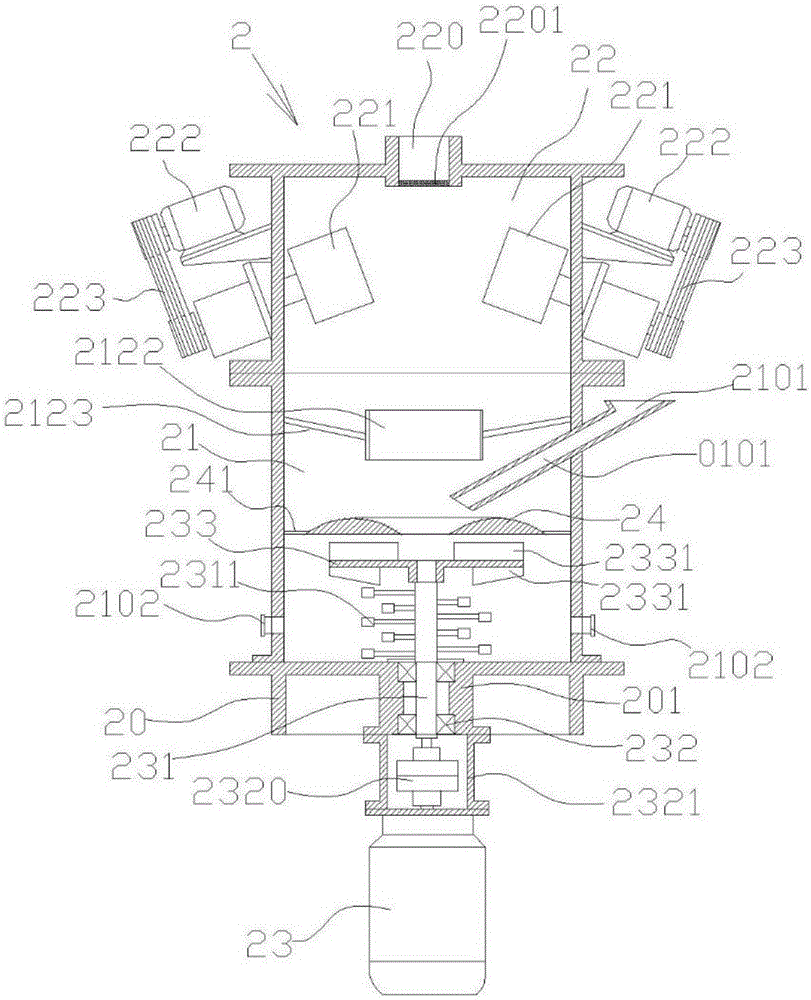

[0031] Such as figure 1 with figure 2 As shown, the preparation device of a kind of magnetic powder particle provided by the present invention comprises automatic feeder 1, multiple groups of pulverizing mechanisms, multiple groups of separating and collecting mechanisms 3 and one group of filtering and collecting mechanisms 4, as preferred, in this aspect of the present invention In the embodiment, include two groups of crushing mechanisms 2 and two groups of separation and collection mechanisms 3, such as figure 1 As shown, the automatic feeder 1 is connected with the first group of crushing mechanism, the first group of crushing mechanism is connected with the first group of separation and collection mechanism 3, the rear of the first group of separation and collection mechanism 3 is connected with the second group of crushing mechanism, and the second group of crushing mechanism The rear of the mechanism is connected with the second group of separation and collection mec...

Embodiment 2

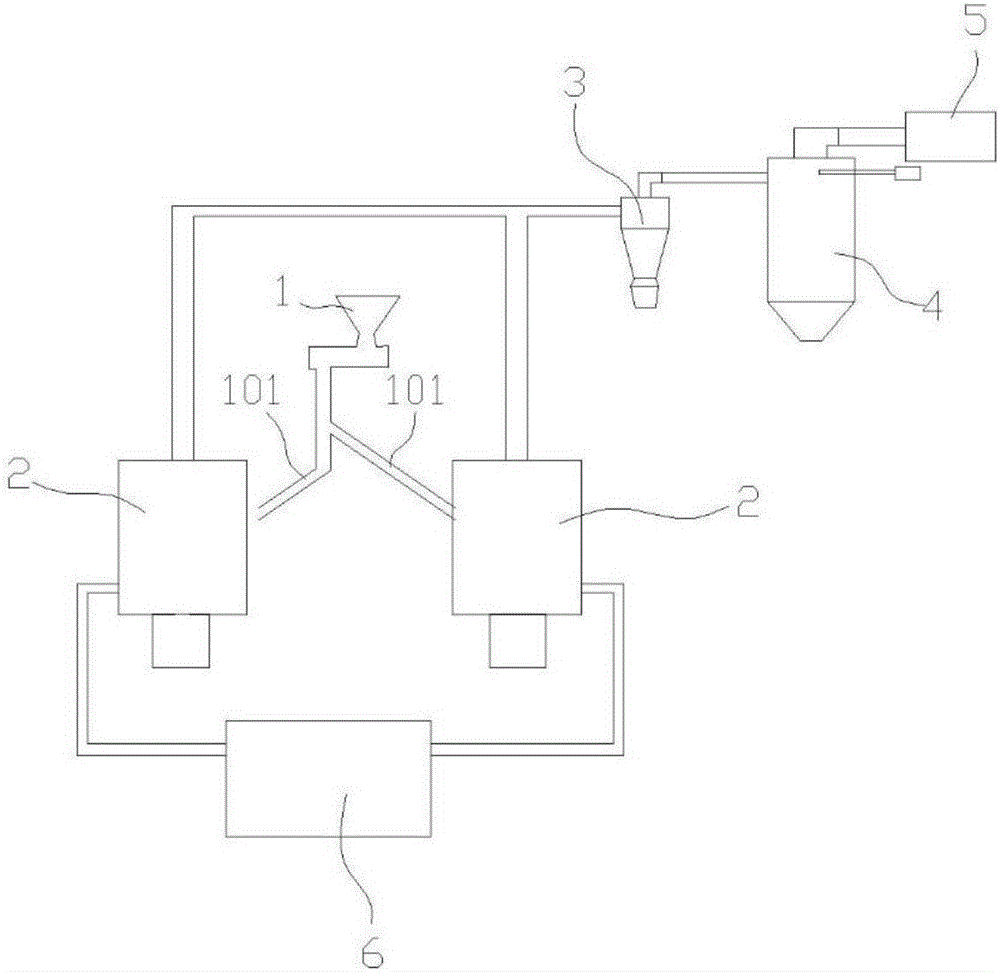

[0044] Such as image 3 As shown, the preparation device for magnetic powder particles provided by the second embodiment of the present invention is basically the same as that in Example 1, except that it includes two groups of crushing mechanisms and one group of separation and collection mechanisms 3, such as image 3 As shown, the automatic feeder 1 passes through two feed pipes 101 into two groups of crushing mechanisms respectively, and the two groups of crushing mechanisms are all connected to the separation and collection mechanism 3, that is, the two groups of crushing mechanisms and the separation and collection mechanism 3 are connected in parallel, and the separation and collection mechanism 3 is connected with filter collection mechanism 4. In addition, in this embodiment of the present invention, the pore size of the filter screen 2201 covered by the discharge port 220 of the crushing mechanism 2 is 7 μm, and in this embodiment of the present invention, the centra...

Embodiment 3

[0046] Such as Figure 4 , a preparation device for magnetic powder particles provided by the third embodiment of the present invention is basically the same as that in Example 1, the difference lies in the structure of the crushing mechanism 2 .

[0047] Such as Figure 4 As shown, the crushing chamber 21 of the crushing mechanism 2 is a hollow cylinder, and an air inlet 2102 is provided at the bottom of its peripheral surface. A feeding port 2101 is opened on the upper end peripheral surface of the crushing chamber 21, such as Figure 4 As shown, there is a feed channel 0101 leading from the air inlet 2101 to the center of the crushing chamber 21 .

[0048] Such as Figure 4 As shown, crushing hammers 2311 are distributed on the peripheral surface of the main shaft 231, and the lengths of the crushing hammers 2311 are not equal, and the crushing hammers 2311 of different lengths are arranged at intervals. The end of the main shaft 232 is connected with a crushing disc 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com