Cement admixture containing vanadium titano-magnetite tailings and preparation method and application of cement admixture

A technology of vanadium-titanium magnetite and admixtures, which is applied in cement production, etc., which can solve problems such as the preparation method of cement admixtures to be studied, the inability to use cement admixtures, and the lack of pozzolanic activity, etc., to achieve low equipment maintenance costs and reduce processing The effect of less cost and equipment wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing cement mixture from vanadium-titanium magnetite tailings, the sample is from the vanadium-titanium magnetite tailings in Panzhihua, Sichuan, and the vanadium-titanium magnetite tailings include: 1.0-5.5% by mass fraction TiO 2 , 10.0-20.0% CaO, 8.0-20.0% Al 2 o 3 and 40.0-65.0% SiO 2 , the mass fraction of each component of the vanadium-titanium magnetite tailings can be within the above range, the tailings -0.075 microns account for 60%, and the main gangue minerals in the tailings are chlorite, feldspar, pyroxene and other silicon-alumina salt minerals. The method specifically includes the following steps:

[0028](1) Mixing and slaking: the ratio of each component is: vanadium-titanium magnetite tailings account for 92.95%, lime accounts for 5.00%, sodium silicate accounts for 2%, and triethanolamine accounts for 0.05%. The specific steps are as follows: after drying the vanadium-titanium magnetite tailings, weigh 1859g of vanadium-titaniu...

Embodiment 2

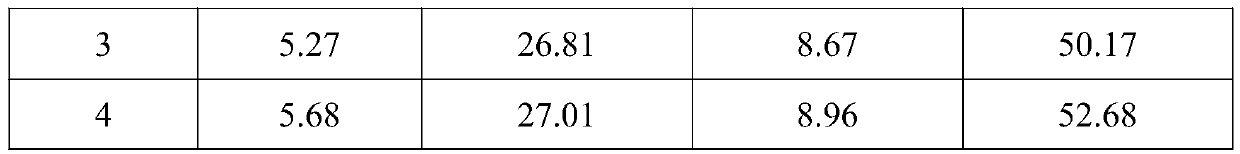

[0038] Sample No. 4 was selected to prepare cement with different dosages, and the specific formula is shown in Table 3.

[0039] Table 3 Cement formulations of different particle size samples

[0040] Tailings-based cement mixture / % Clinker / % plaster / % 0 97 3 5 92 3 10 87 3 15 82 3 20 77 3 30 67 3

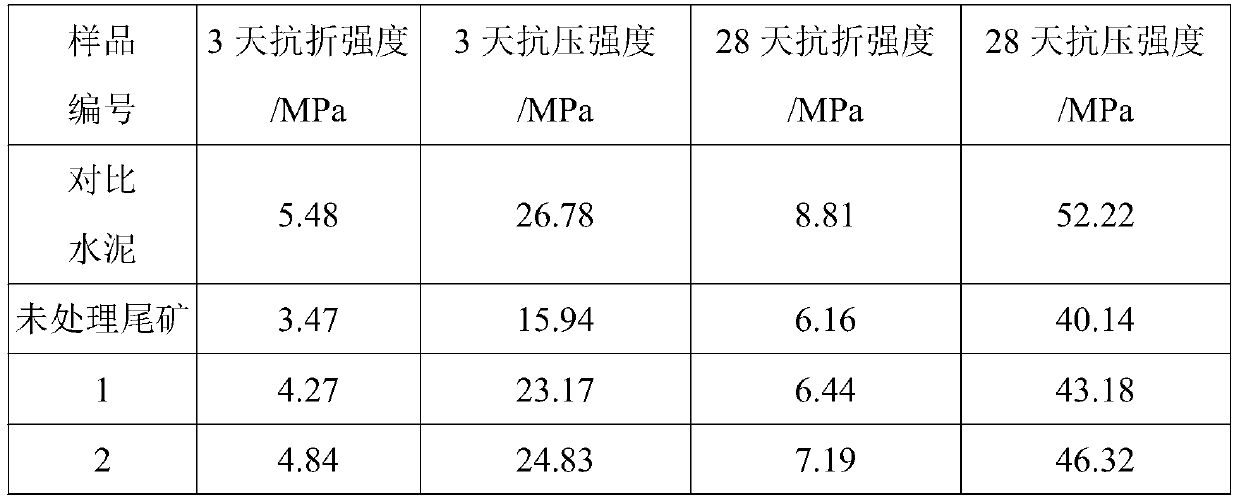

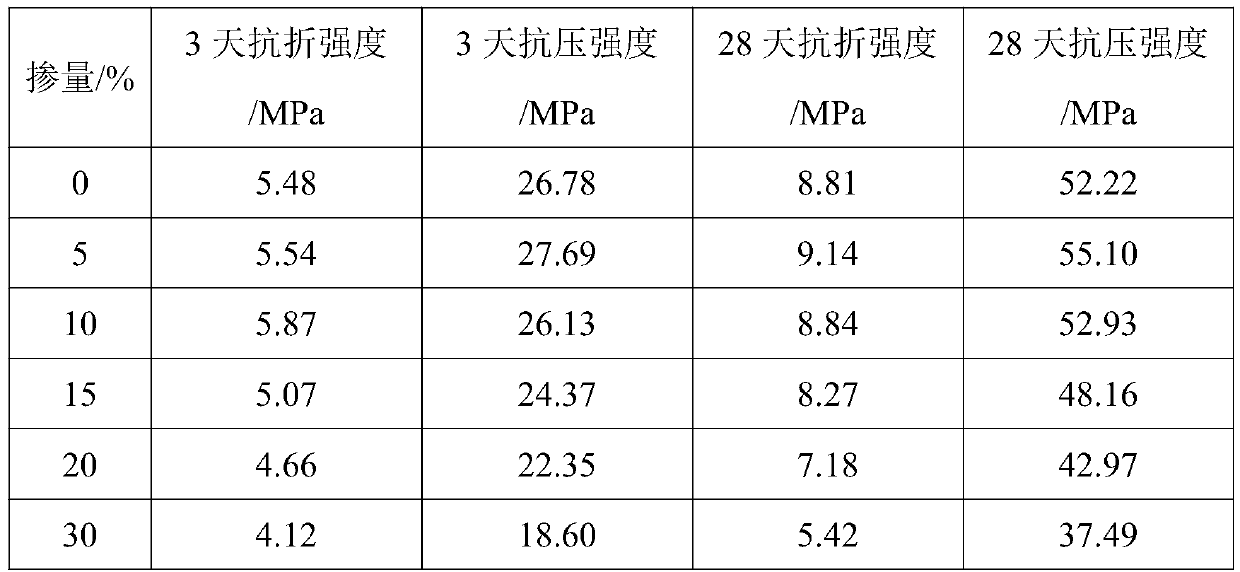

[0041] The strength of cement mortar with different content is shown in Table 4.

[0042] Table 4 Strength of cement mortar with different content of tailings-based cement mixture

[0043]

[0044] As can be seen from Table 4, the vanadium-titanium-magnetite tailings-based cement mixture prepared by the invention can replace part of the cement clinker, and its cement mortar strength still meets the national standard, thereby realizing the vanadium-titanium-magnetite tailings Optimal utilization of mine resources.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com