Straw recovery device for green agricultural development

A recycling device, agricultural technology, applied in the direction of agriculture, agricultural machinery and implements, applications, etc., to achieve the effect of improving the degree of fineness and preventing jumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

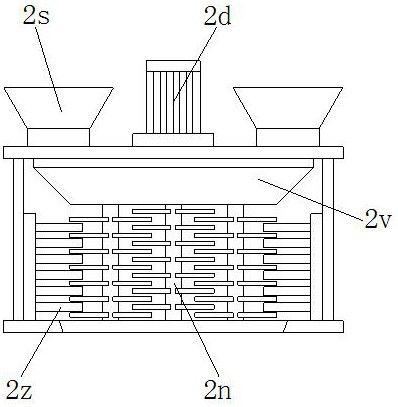

[0022] Wherein, the choke box 2z includes a crushing box z5, a baffle z2, and a torsion shaft z8. The material guide groove v5 is fixedly installed on the upper end of the crushing box z5, and the inner wall of the crushing box z5 is connected to the torsion shaft z8. The outer ends of the baffle z2 are hinged, and the baffle z2 is located at the outer end of the crushing tool 2n. The baffle z2 and the torsion axis z8 are each provided with 14 or 18 pieces, and there are 6 vertically distributed as a group. They are distributed in the inner side of the crushing box z5 in a ring shape, so as to form a blocking space with the crushing cutter 2n rotating outside, so as to prevent the straw from shifting to the outside and making it difficult to contact the crushing cutter 2n for crushing.

[0023] The specific usage and function of this embodiment:

[0024] Example 2:

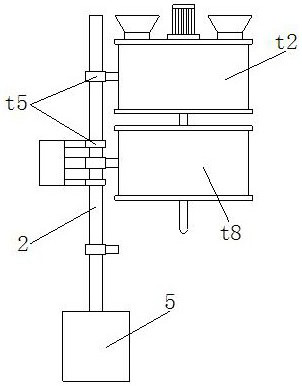

[0025] Wherein, the sieve box 8w includes a sieve box w4, a slide rail w9, a slide block w5, a scraper w8, a s...

Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com