Machining equipment applied to biological straw fertilizers

A technology for biological straw and processing equipment, applied in the field of straw processing, can solve the problems of poor pulverization effect and inability to pulverize straw, and achieve the effects of reducing shaking, reducing noise and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

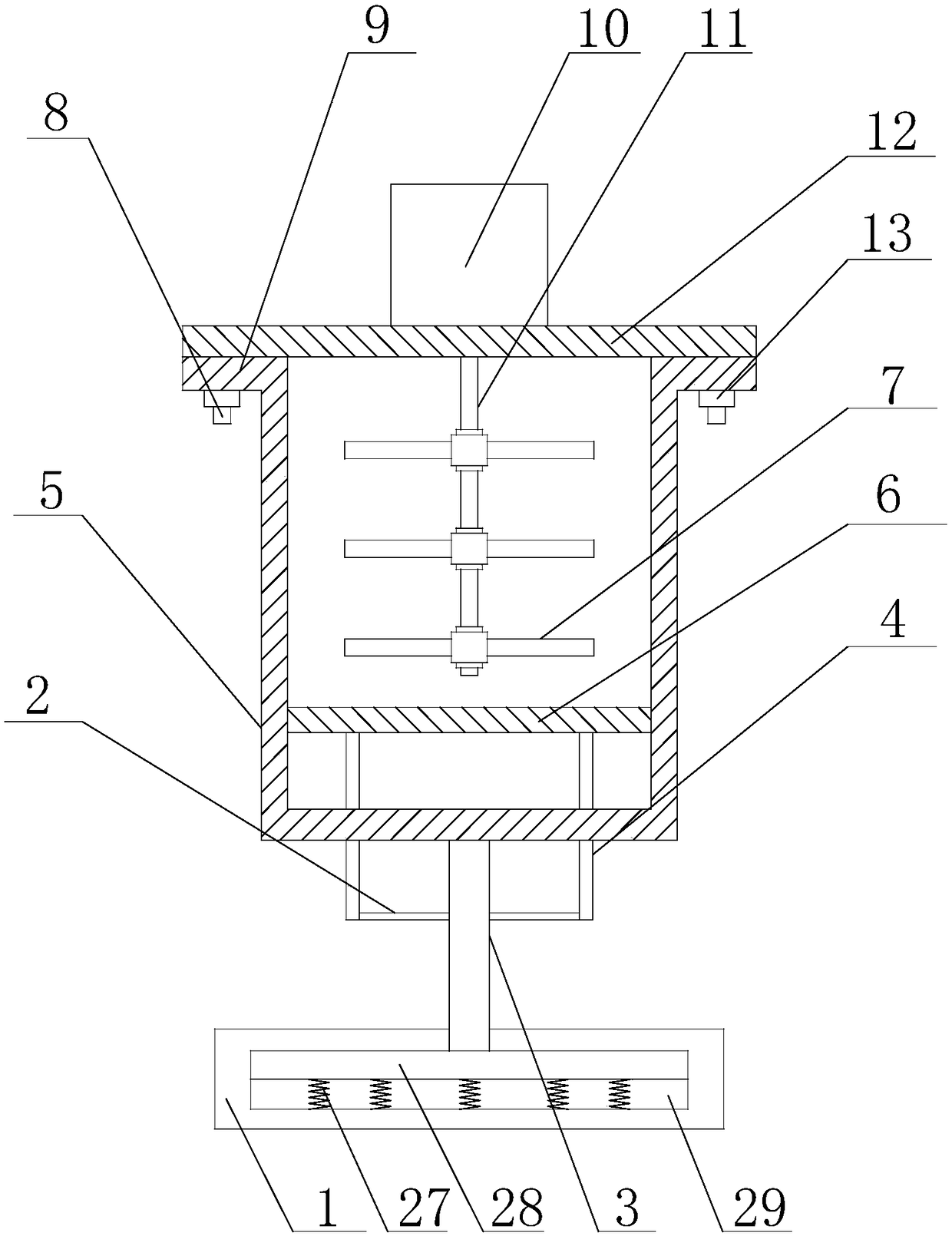

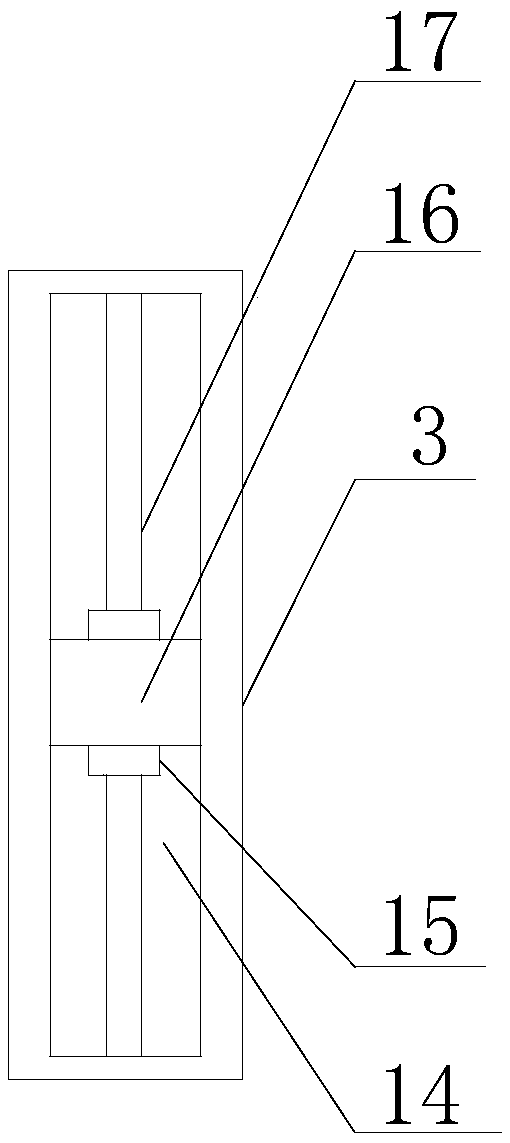

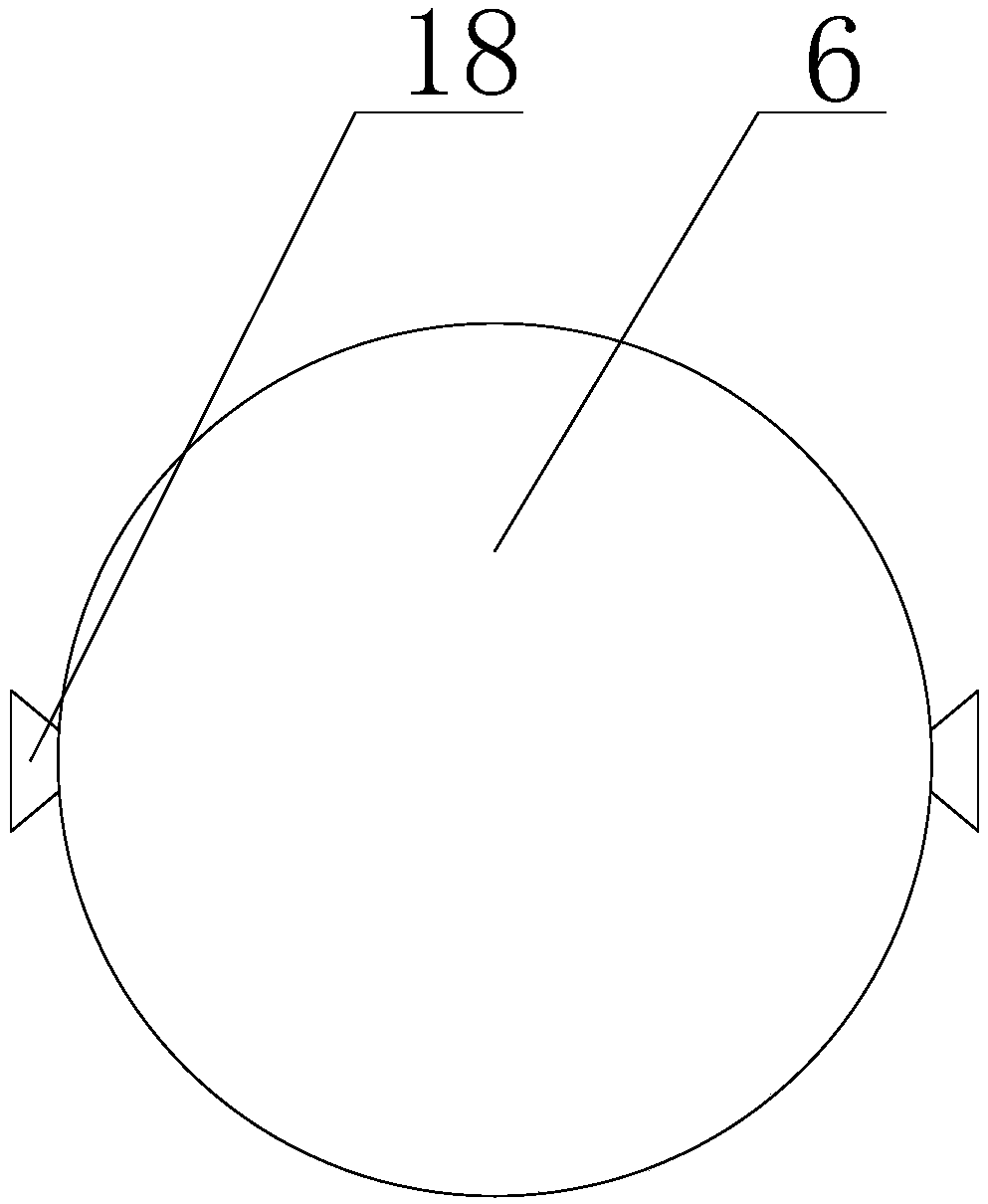

[0028] like Figure 1 to Figure 6As shown, the processing equipment for biological straw fertilizer application of the present invention includes a base 1, and the inside of the base 1 is provided with a placement cavity 29, and a shock absorbing element is arranged in the placement cavity 29, and the shock absorbing element includes a shock absorbing plate 28 and Some shock absorbers 27, shock absorbers 27 are springs, have certain shock absorbing function, described shock absorbers 27 are all positioned at the bottom of shock absorber 28, and the top of base 1 is provided with support plate 3, and support plate 3 is positioned at base 1, and the support plate 3 is inserted vertically in the placement cavity 29 and connected with the shock absorber 28. When the support plate 3 is vibrated in the vertical direction, the support plate 3 will act on the shock absorber 3 force, the shock absorber 27 will reduce the vibration of the shock absorbing plate 3, thereby reducing the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com