Hydraulic array for roller mills

A grinding machine and grinding technology, applied in the field of hydraulic system devices, can solve problems such as pressure rise, high pipeline costs, and hysteresis, and achieve the effect of reducing damage and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

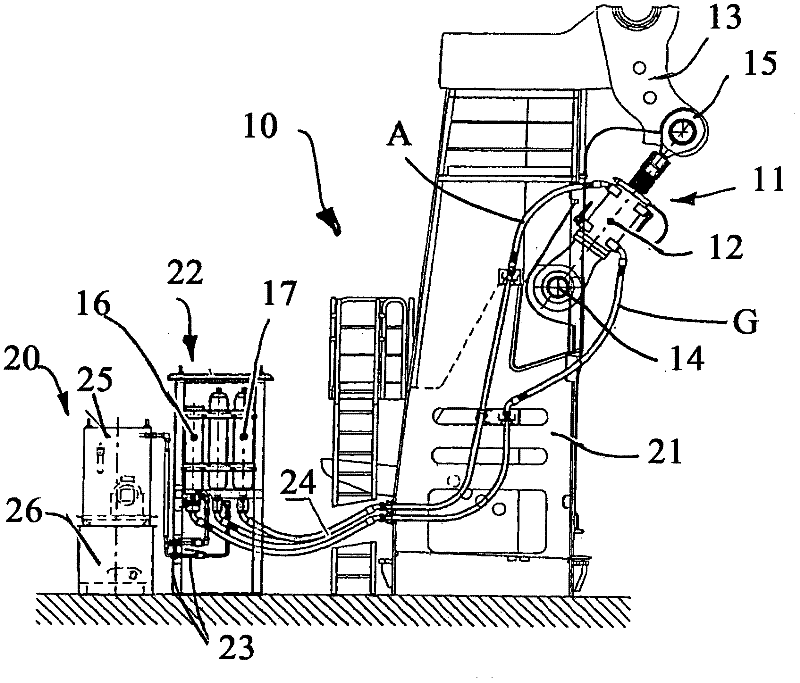

[0030] figure 1 Shown is a hydropneumatic spring system 10 for a LOESCHE type air roller mill of modular design. According to the invention, a spring unit 11 is assigned to each grinding roller (not shown).

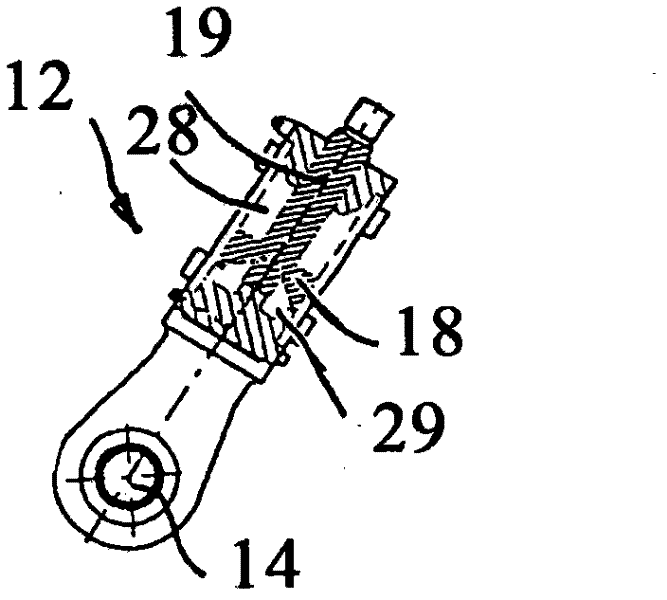

[0031] The spring unit 11 of each grinding roller has one or two hydraulic cylinders 12 depending on the size of the roller module (and thus especially the size of the grinding roller), which are connected to the grinding roller via a swing rod 13 Rollers (not shown) are attached. The hydraulic cylinder 12 is fastened to the frame 21 or to the mill floor via the pivot hole 14 and to the pivot lever 13 via the connecting rod head 15 .

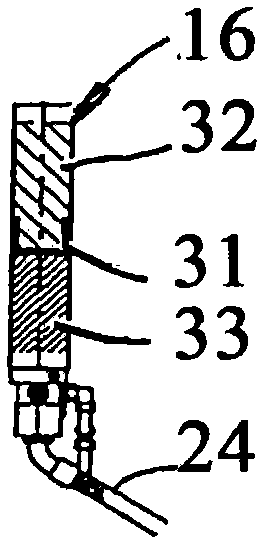

[0032] Each spring unit 11 of the grinding roll is assigned its own hydraulic supply unit 20 . The hydraulic supply unit 20 includes a motor-driven pump, valves and shut-off devices, a grinding pressure regulation system or electric control and operating elements for switching the different operating states of the roller springs.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com