Environment-friendly breaker

A crusher, environmental protection technology, applied in grain processing, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of crushers not meeting environmental protection requirements, suffering from lung and respiratory diseases, and extremely serious air pollution, etc. Achieve better and better dust removal effect, improve market competitiveness, and ingenious overall structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

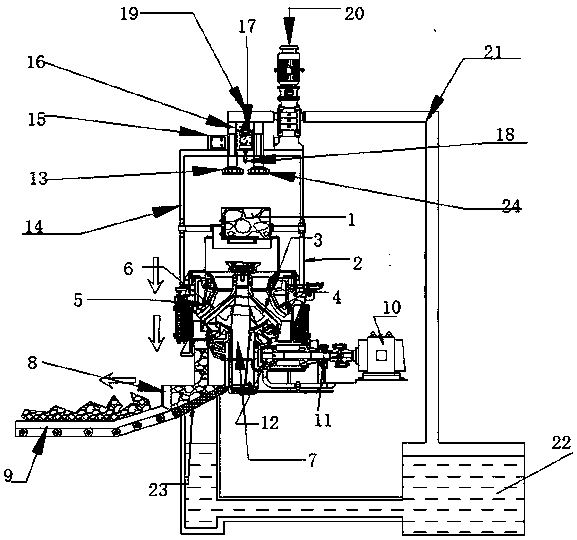

[0016] Embodiment 1: see figure 1 , an environmentally friendly crusher, the environmentally friendly crusher includes a crushing assembly, a power assembly, a dust removal assembly and a filter assembly; the dust removal assembly is partially located at the top of the crushing assembly; the filter assembly is located at the lower end and the right side of the crushing assembly; The assembly is located on the right side of the crushing assembly, and is connected with the crushing assembly through a transmission shaft and a bevel gear. The design structure is simple and clear, and the components are closely connected without interfering with each other, which is easy to maintain in the future. Sleeve 4, fixed cone 5, fixed cone bushing 6, eccentric sleeve 7, discharge port 8 and conveyor belt 9; the movable cone bushing is installed on the surface of the movable cone; the fixed cone bushing is installed on the surface of the fixed cone; the The fixed cone and the movable cone ...

Embodiment 2

[0017] Example 2: see figure 1 , as an improvement of the present invention, the power assembly includes a motor 10, a transmission shaft 11 and a bevel gear 12; the motor is connected to the bevel gear through a transmission shaft; the bevel gear is partially connected to the moving cone. The power transmission mode of bevel gear and transmission shaft can transmit the power generated by the motor to the moving cone to the maximum extent, so as to maximize the crushing power of the moving cone. It not only helps to improve the crushing rate of large ore, but also reduces the energy loss of kinetic energy in the transmission process, and improves the working efficiency of the whole machine.

Embodiment 3

[0018] Embodiment 3: see figure 1, as an improvement of the present invention, the dust removal assembly includes a high-pressure nozzle 13, a nozzle bracket 14, a PLC 15, a multi-stage hydraulic rod 16, a hydraulic rod lifter 17 and a laser range finder 18; the high-pressure nozzle is installed on The lower end of the multi-segment hydraulic rod; the PLC is installed on the spray head bracket, close to the multi-segment hydraulic rod; the hydraulic rod lifter is fixed on the spray head bracket, and is located between two multi-segment hydraulic rods; the The shower head bracket is fixed on the support rod; the laser range finder is arranged at the lower end of the shower head bracket, opposite to the center of the feed inlet. The laser rangefinder is responsible for measuring the vertical distance between the high-pressure nozzle and the raw material in the feed port, so as to determine the most optimal water jet height. If there are too many raw materials at the feeding por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com