Vibrating subsoiler

A subsoiling shovel and vibrating technology, which is applied in the field of subsoiling operation parts, can solve the problems of small subsoiling operation range, poor subsoiling soil fineness, and low soil fineness, so as to achieve simple and convenient adjustment and trouble-free operation Less, the effect of improving the ability of crushing soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

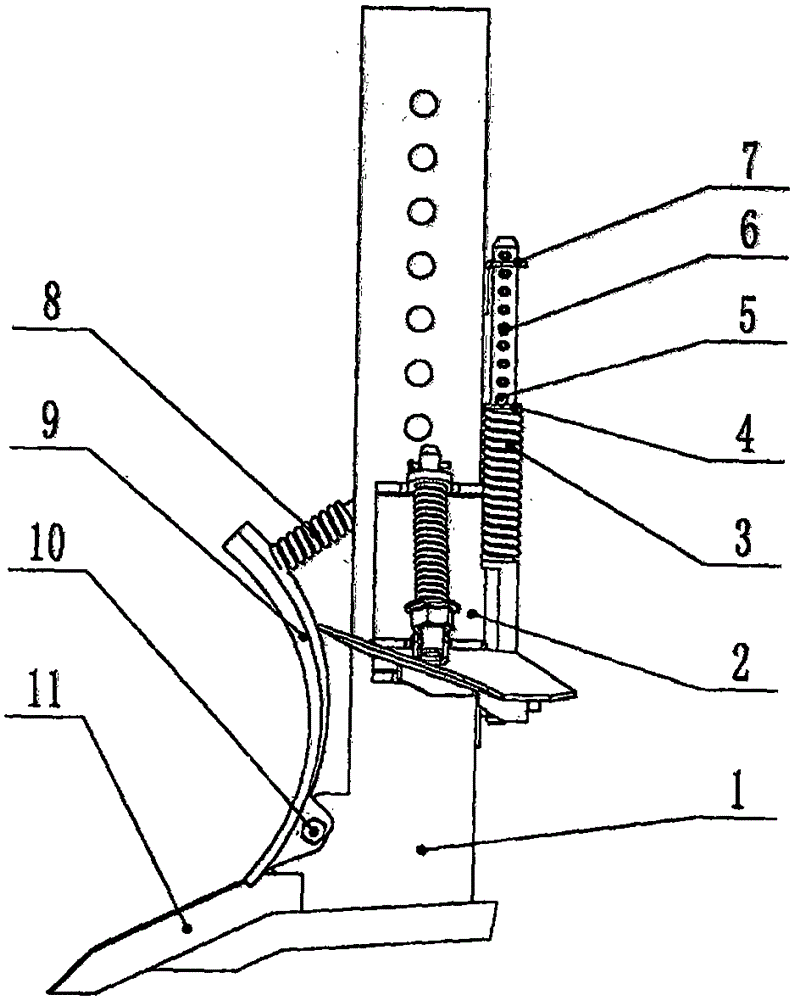

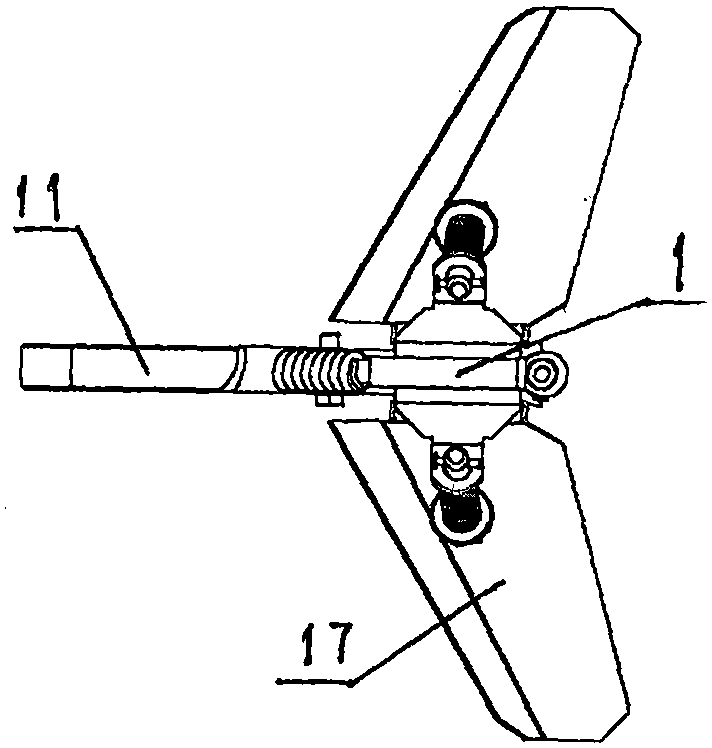

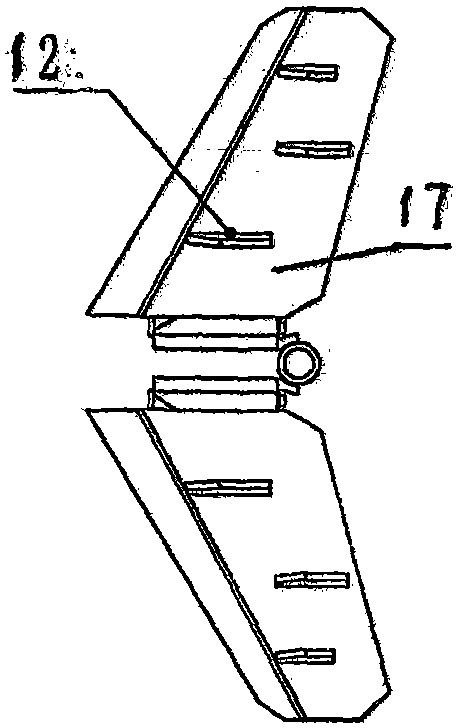

[0012] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A vibratory subsoiling shovel includes a subsoiling shovel main body 1 and a shovel head 11 fixedly mounted on the bottom of the front side of the subsoiling shovel main body 1. Even install the curved surface share body 9, connect and install the share body pressure spring 8 between the upper side of the curved surface share body 9 and the front side of the subsoiling shovel main body 1; The hanging lug 7 is fixed, the vertical shaft 6 with the spring pressure adjustment hole is plugged and fixed on the hanging lug 7, and the washer 4 and the main pressure spring 3 are mounted on the matching shaft sleeve 13 that can move up and down axially on the vertical shaft 6 Set on the vertical shaft 6, the upper end surface of the main pressure spring 3 is in contact with the washer 4, and the upper end surface of the main pressure spring 3 is axially positioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com