Powder depolymerization beater

A technology of dispersing machine and depolymerization, applied in the field of dispersing machine, can solve the problems of unadjustable vortex airflow in the dispersing cavity and grading cavity, limitation of crushed materials, etc., to achieve the best crushing effect, energy saving and versatility strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

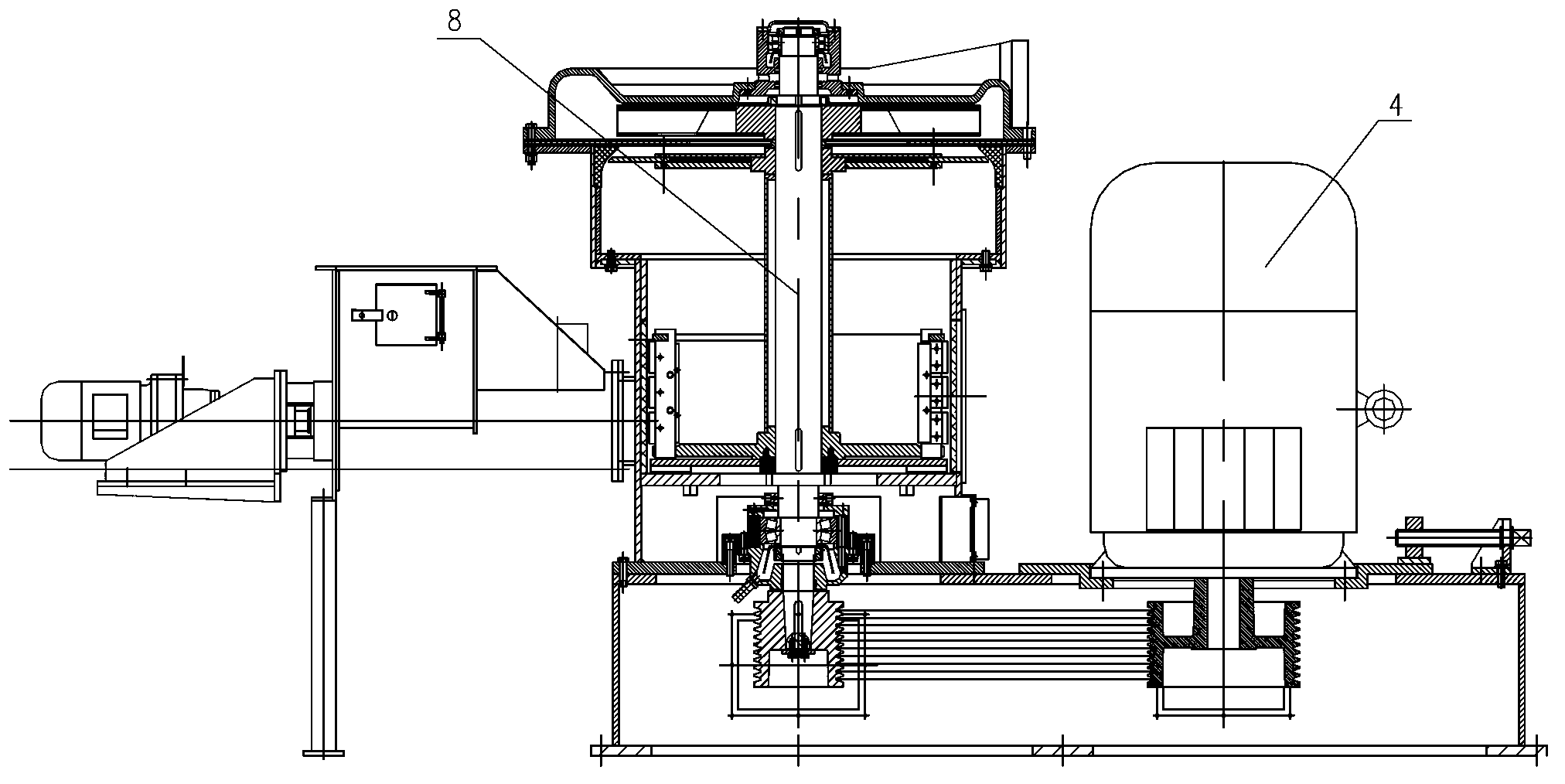

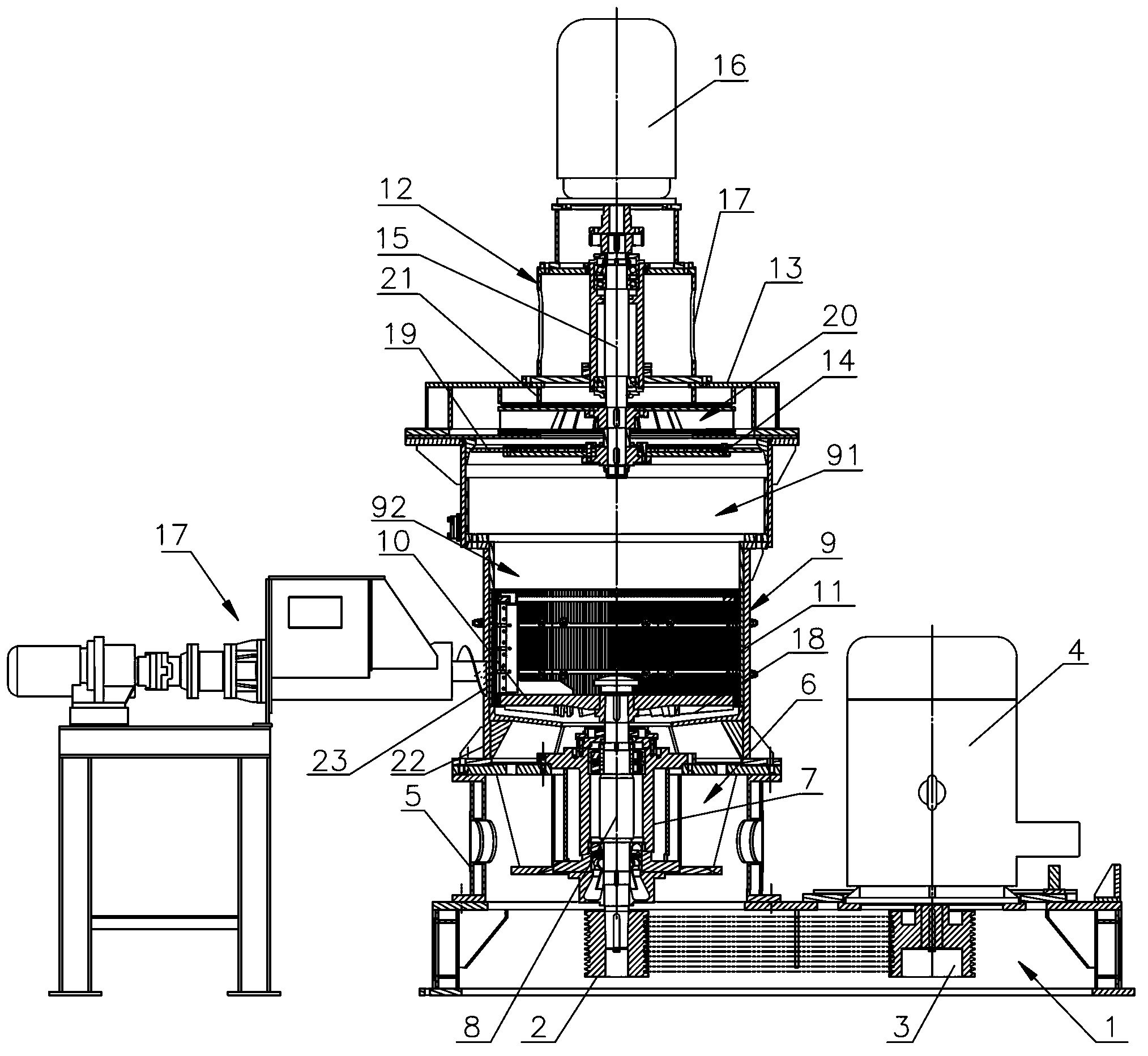

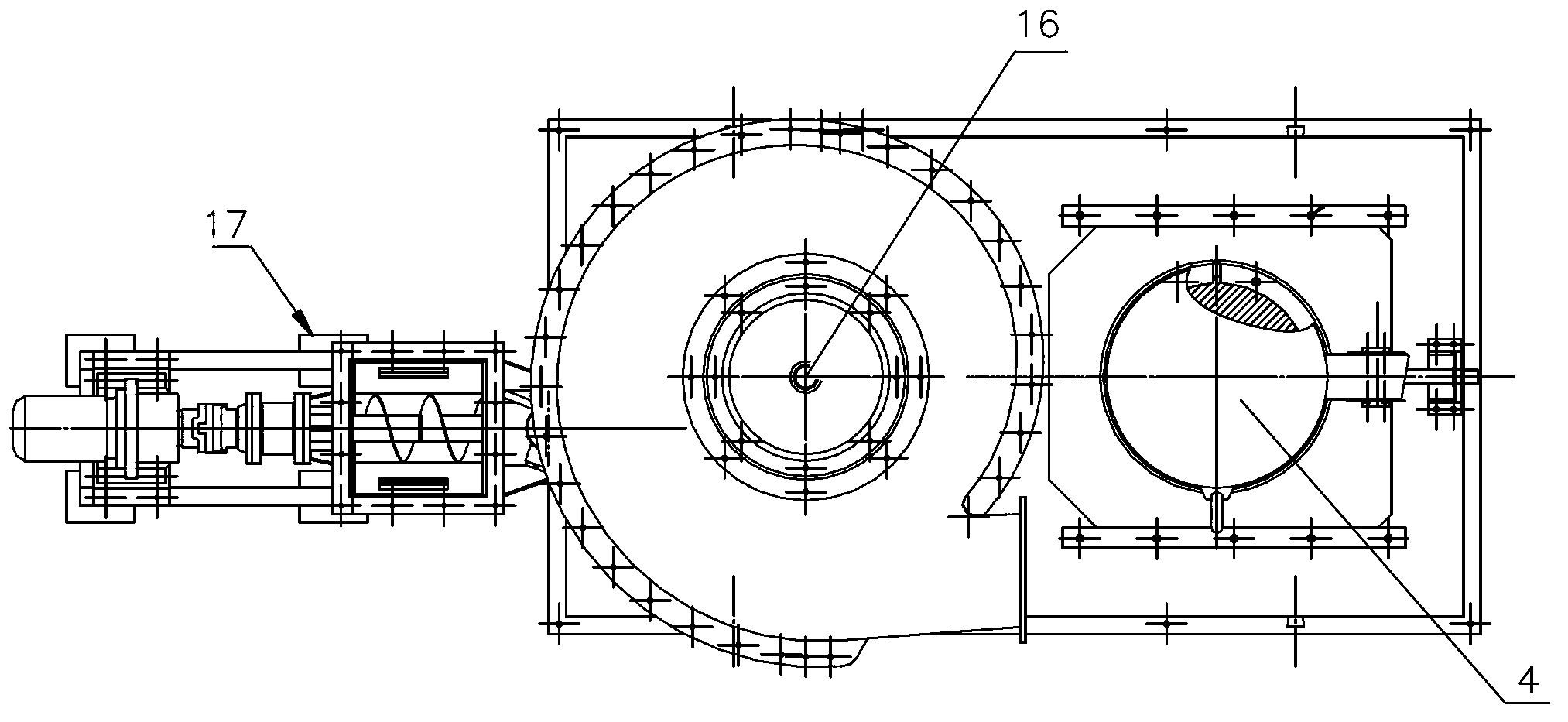

[0024] Such as figure 2 , 3 , 4, the present invention includes a casing 9, and the casing 9 includes a grading chamber 91 and a dispersing chamber 92 distributed from top to bottom, and the dispersing chamber 92 has a pulverizing machine with the crushing main shaft 8 as the center of rotation for crushing the material. Mechanism, the classification chamber 91 has the classification mechanism that discharges the crushed material with the classification spindle 15 as the center of rotation. The crushing mechanism is driven by the crushing motor 4, and the classification mechanism is driven by the classification motor 16. coincide.

[0025] The grading mechanism includes a grading housing 13 and a grading wheel 14 located in the grading chamber 91. The grading housing 13 is fixedly connected to the top of the casing 9. The grading main shaft 15 is supported in the grading housing 13 through a bearing seat. The grading wheel 14 is installed on the The bottom end of the main s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com