Soil strip breaking mechanism of no-tillage planter

A planter and loosening technology, which is applied in the field of agricultural machinery, can solve the problems of poor contact between seeds and soil, easy formation of air cavities, and small width of loosened soil, so as to achieve good performance of sliding and cutting into soil, increase service life, and crush soil The effect of increasing the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings.

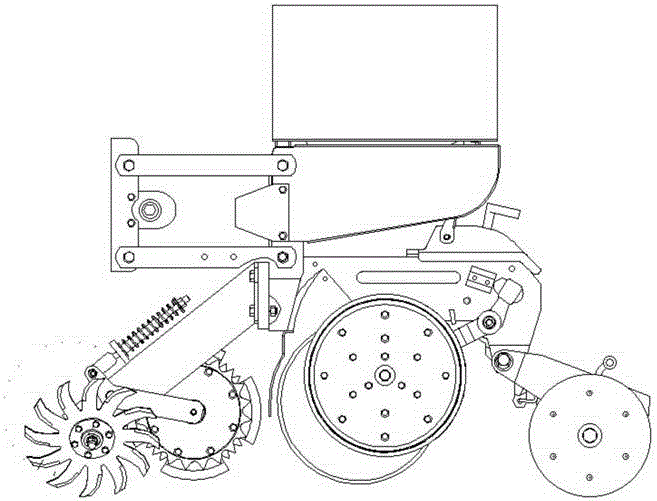

[0049] Such as figure 1 As shown, a no-tillage seeder strip soil loosening mechanism is installed at the front end of the sowing unit, and is used to loosen the soil in the sowing range in advance when the no-tillage seeder advances.

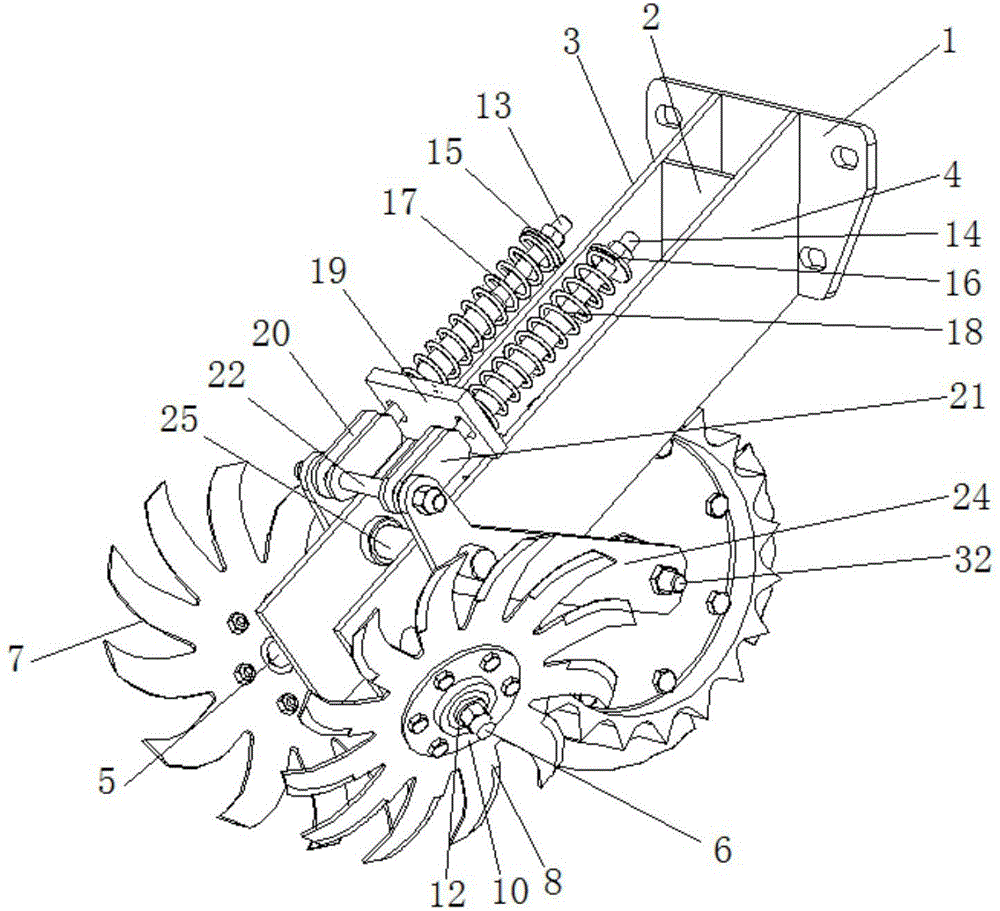

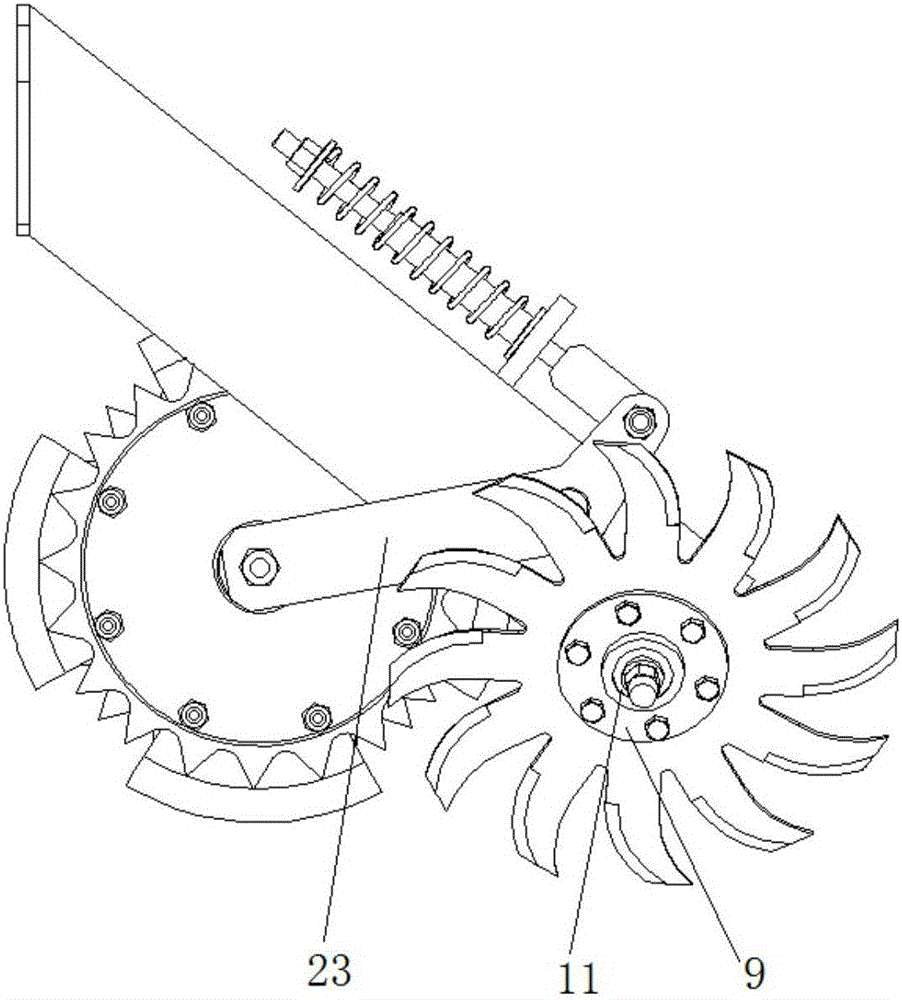

[0050] Such as figure 2 As shown, a no-tillage seeder belt loosening soil mechanism is composed of a connecting frame, a star-shaped cutter head assembly and a soil crushing wheel assembly. The connecting frame includes a fixed plate and two parallel support plates vertically fixed on the front end of the fixed plate. The No. 1 star-shaped cutterhead 7 of the star-shaped cutterhead assembly is arranged on the outside of the No. 1 bracket plate 3 of the connecting frame through the No. 1 star-shaped cutterhead fixed shaft 5, and the No. 2 star-shaped cutterhead 8 of the star-shaped cutterhead assembly The No. 2 star-shaped cutter head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com