Pulverizer structure with secondary pulverizing function and pulverizer

A technology of secondary pulverization and pulverizer, which is applied in the fields of feed, grain processing, food science, etc., to achieve the effect of improving stability, improving uniformity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

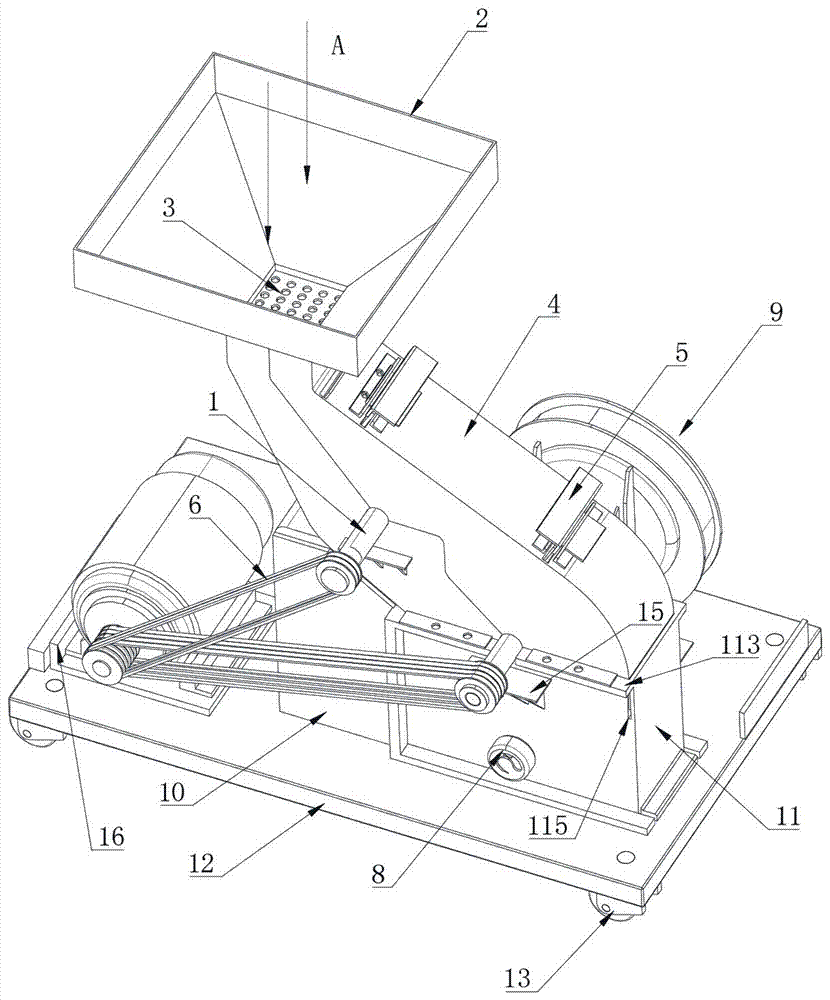

[0038] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

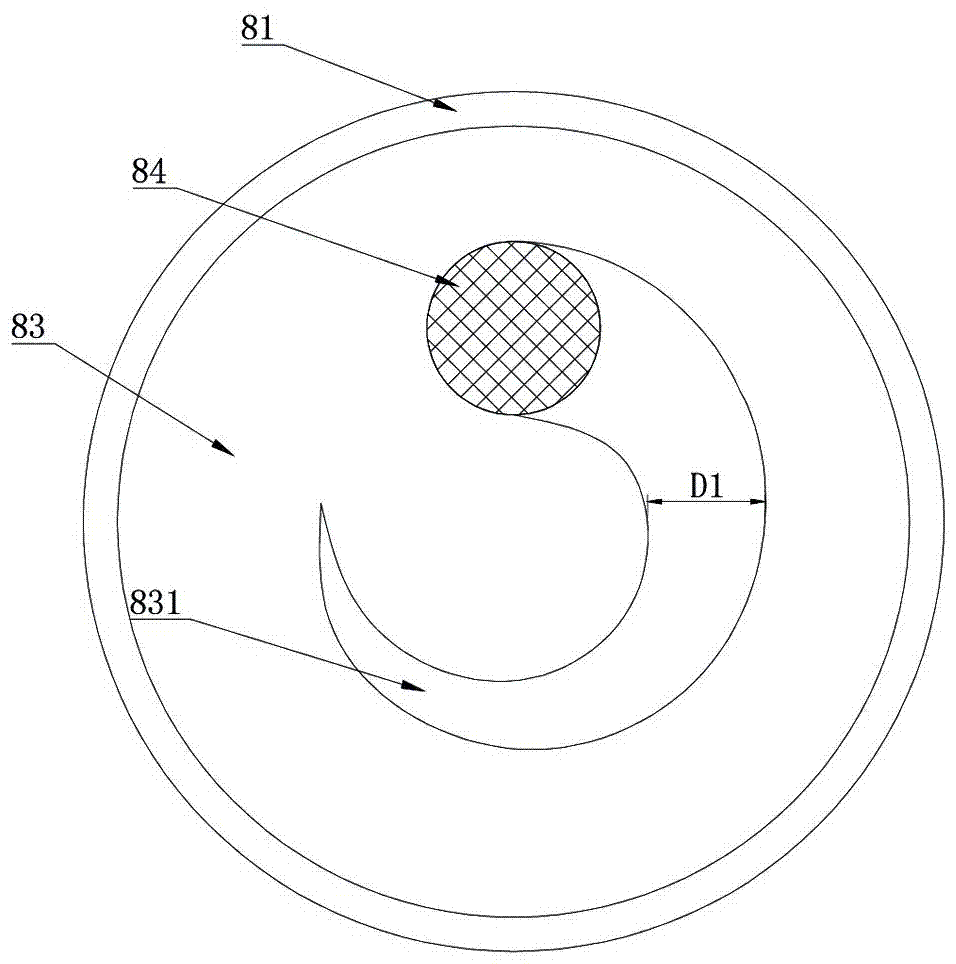

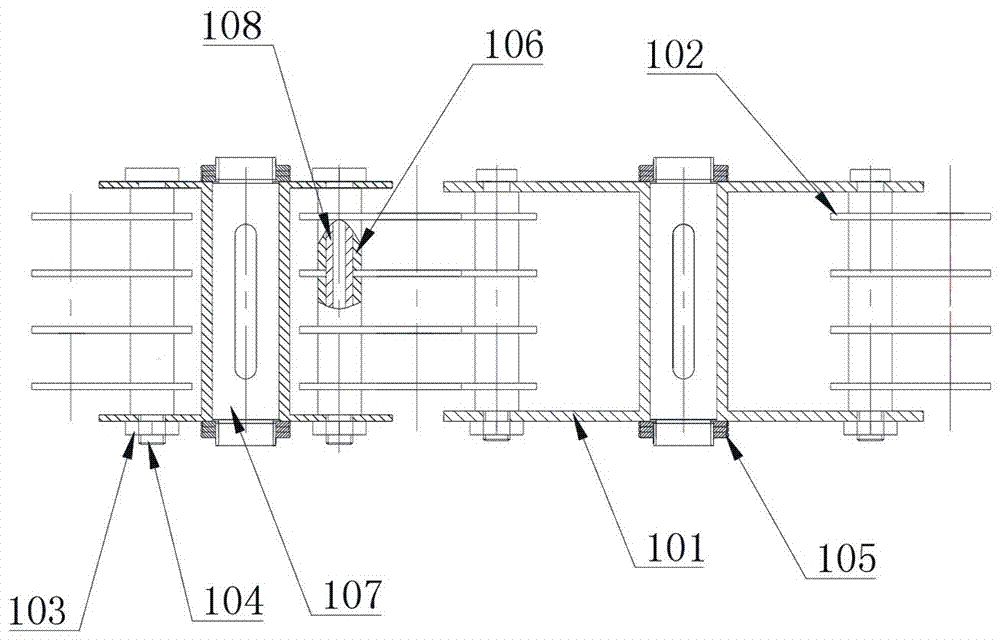

[0039] Such as Figures 1 to 2 As shown, the pulverizer structure with secondary pulverization function of the present invention includes more than two rotors 1, and the rotor 1 includes a main shaft 107 and more than two hammer frames 101, and the main shafts 107 of adjacent rotors 1 are arranged in parallel; the hammer frames 101 are vertical Fixedly installed on the main shaft 107, hammer 102 is installed on the circumference of the hammer frame 101, the angle between the line between the centerlines of the main shaft 107 of two adjacent rotors 1 and the projection point on the plane perpendicular to the main shaft 107 and the horizontal line for α , and 35°≤ α ≤45° (in this embodiment, α is 40°). More than two rotors 1 destroy the formation of air circulation, reduce the difficulty of primary crushing, and are beneficial to the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com