Device and method for separating and extracting active components from plant

A plant active ingredient and plant technology, applied in grain processing, presses, manufacturing tools, etc., can solve the problems of insufficient mixing and pulverization of plants, low concentration of extracts, inconvenient use, etc., and achieve simple structure, strong pulverization effect, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

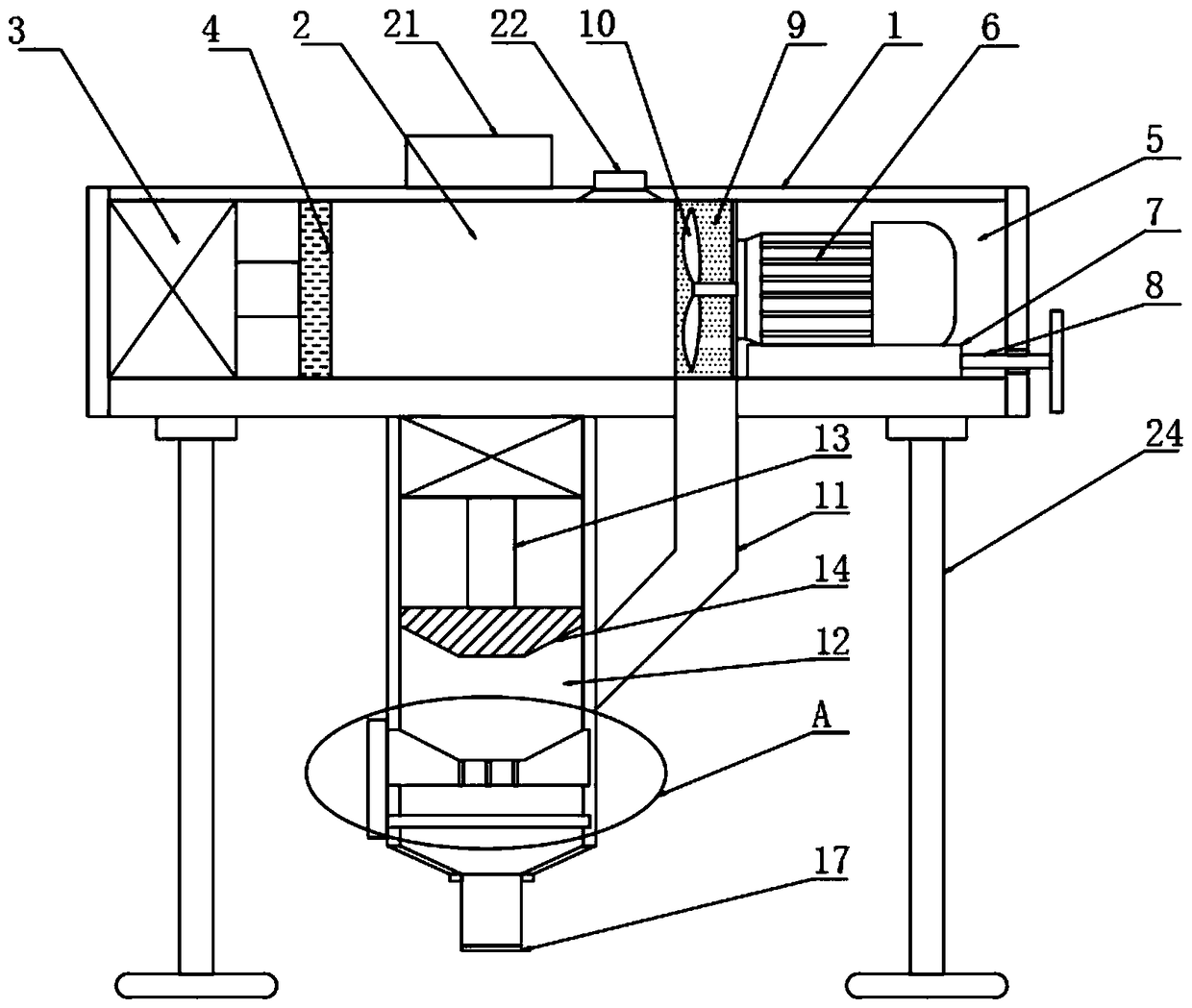

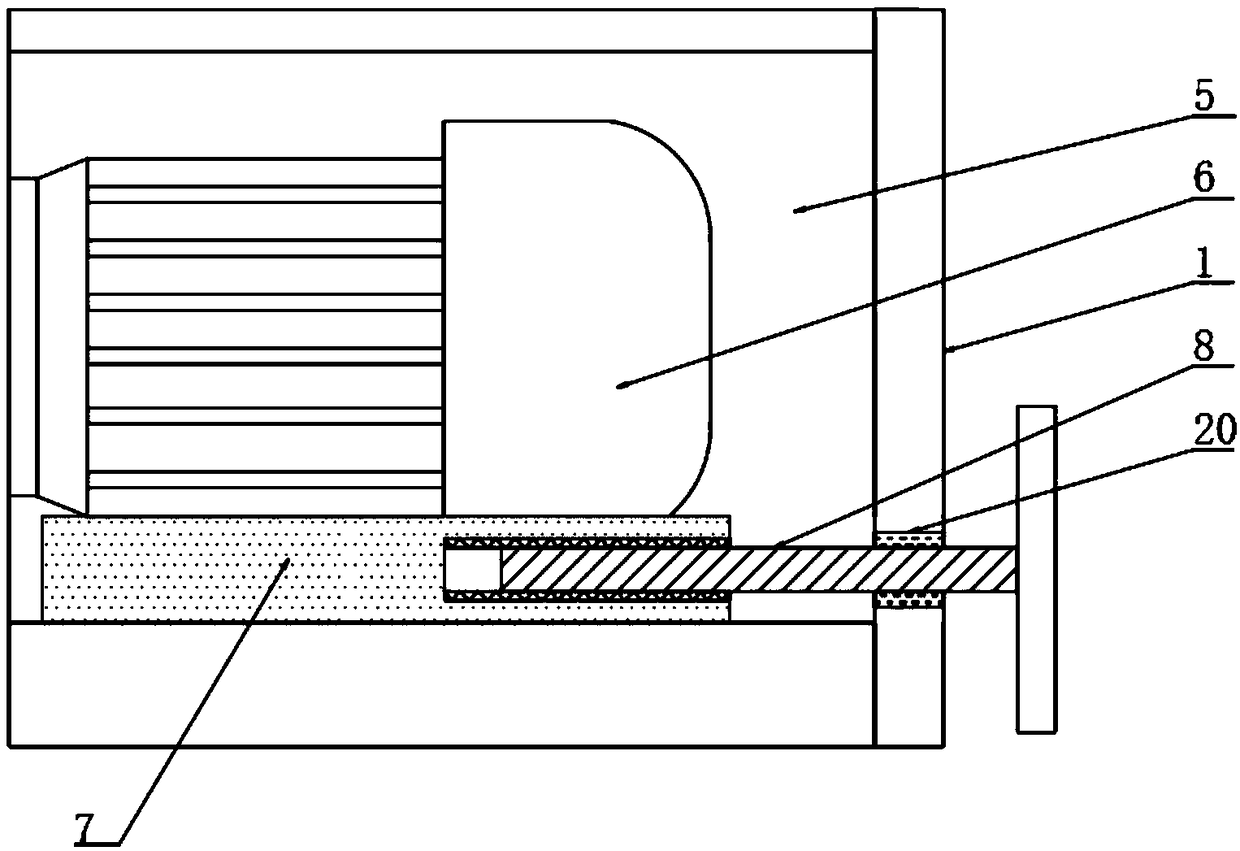

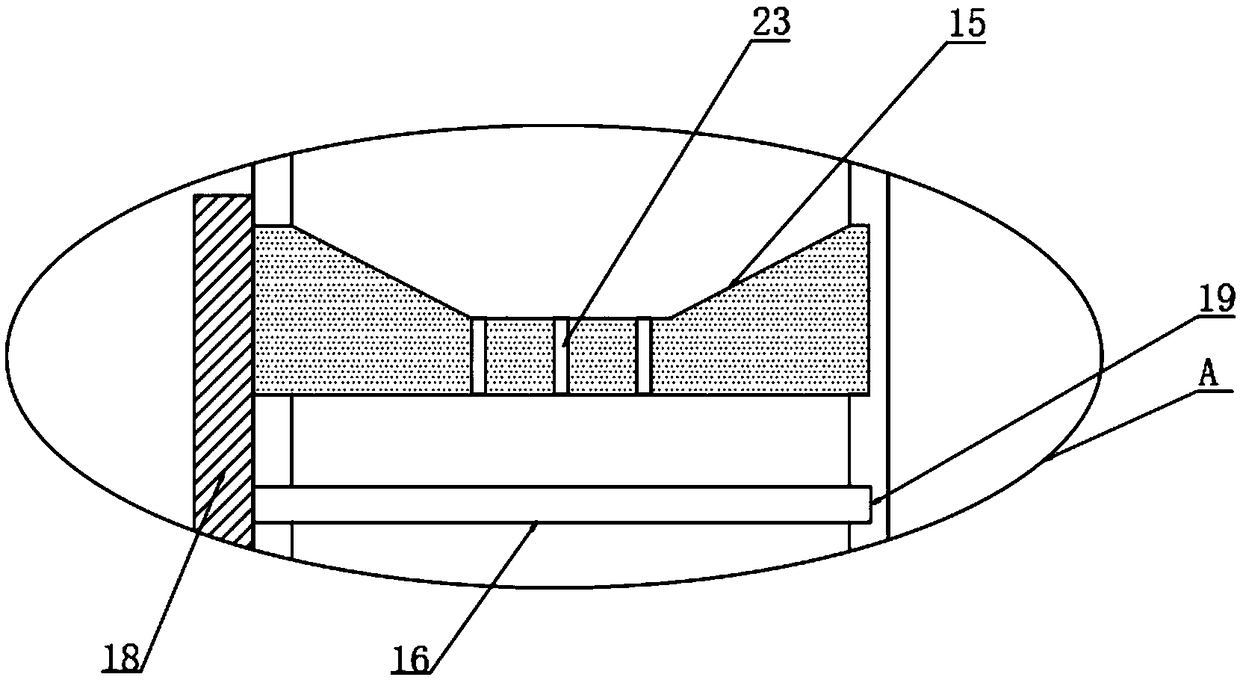

[0025] The present invention provides such as Figure 1-3 The shown device for separating and extracting plant active ingredients includes a box body 1, a feeding chamber 2 is arranged inside the box body 1, a first electric push rod 3 is arranged inside the feeding chamber 2, and a first electric push rod 3 is arranged inside the first feeding chamber. The output end of an electric push rod 3 is provided with a push block 4, a cavity 5 is provided on one side of the feeding chamber 2, a motor 6 is provided inside the cavity 5, and a slider 7 is provided at the bottom of the motor 6, so One side of the slider 7 is provided with a rotating shaft 8, and a crushing chamber 9 is provided between the cavity 5 and the feeding chamber 2, so as to crush the plants evenly, and a blade 10 is arranged inside the crushing chamber 9, and the crushing chamber 9 is provided with a blade 10. The bottom of the cavity 9 is provided with a feed pipe 11, the other side of the feed pipe 11 is prov...

Embodiment 2

[0034] A method for separating and extracting active ingredients of plants, including the device for separating and extracting active ingredients of plants, further comprising the following steps:

[0035] S1: put the plant into the feeding cavity 2 through the feeding port 21;

[0036] S2: the first electric push rod 3 pushes the plant to slide through the push block 4, and the nozzle 22 sprays the solution on the plant surface;

[0037] S3: Rotate the rotating shaft 8, so that the rotating shaft 8 drives the slider 7 to slide back and forth, and the slider 7 drives the motor 6 on the top to slide back and forth, and the output shaft of the motor 6 drives the blade 10 to rotate, crushing the plants entering the crushing chamber 9, stirring The crushed plants enter the extrusion chamber 12 through the feeding pipe 11;

[0038] S4: the second electric push rod 13 stretches downward, so that the extrusion head 14 fixed at the output end of the second electric push rod 13 squeez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com