Biotechnological material ultrafine-crushing device

An ultra-fine pulverization, high-tech technology, applied in the field of biotechnology, can solve the problems of poor pulverization effect, large particles, unable to meet the actual needs of use, etc., and achieve the effect of strong pulverization effect and small particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

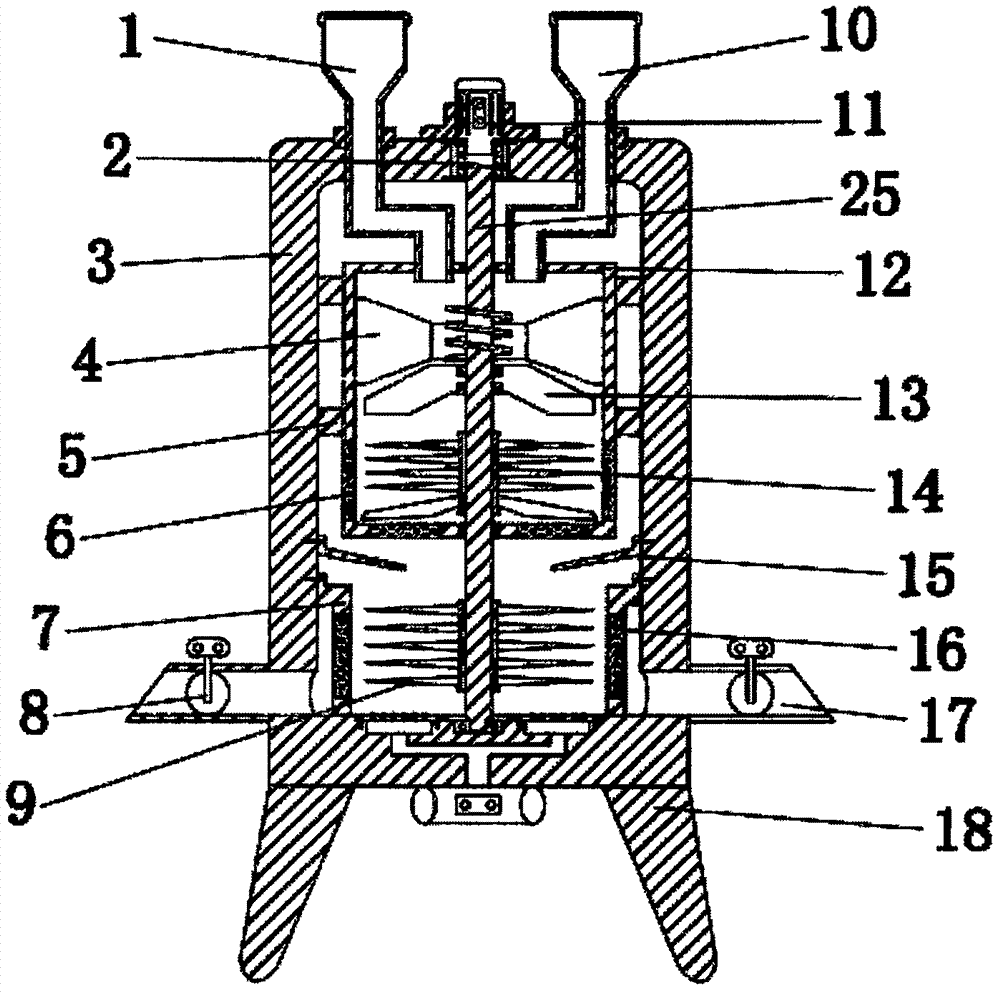

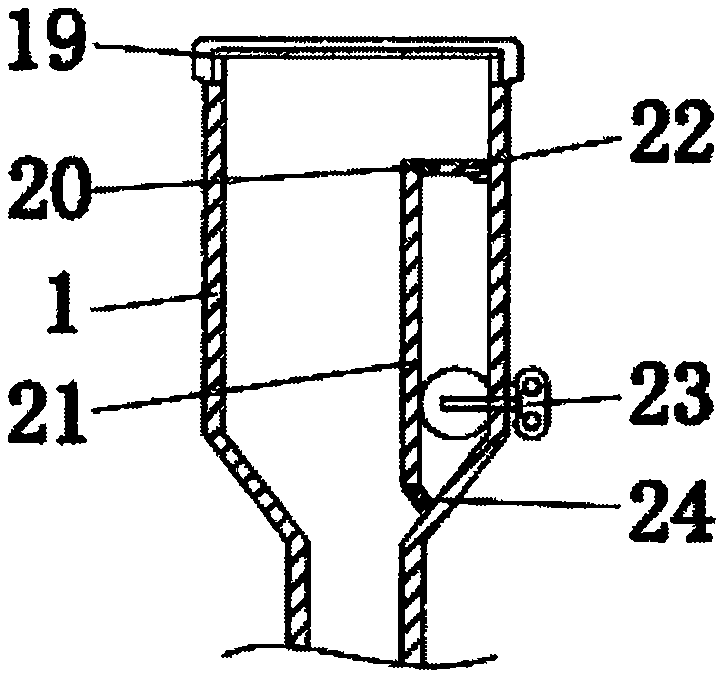

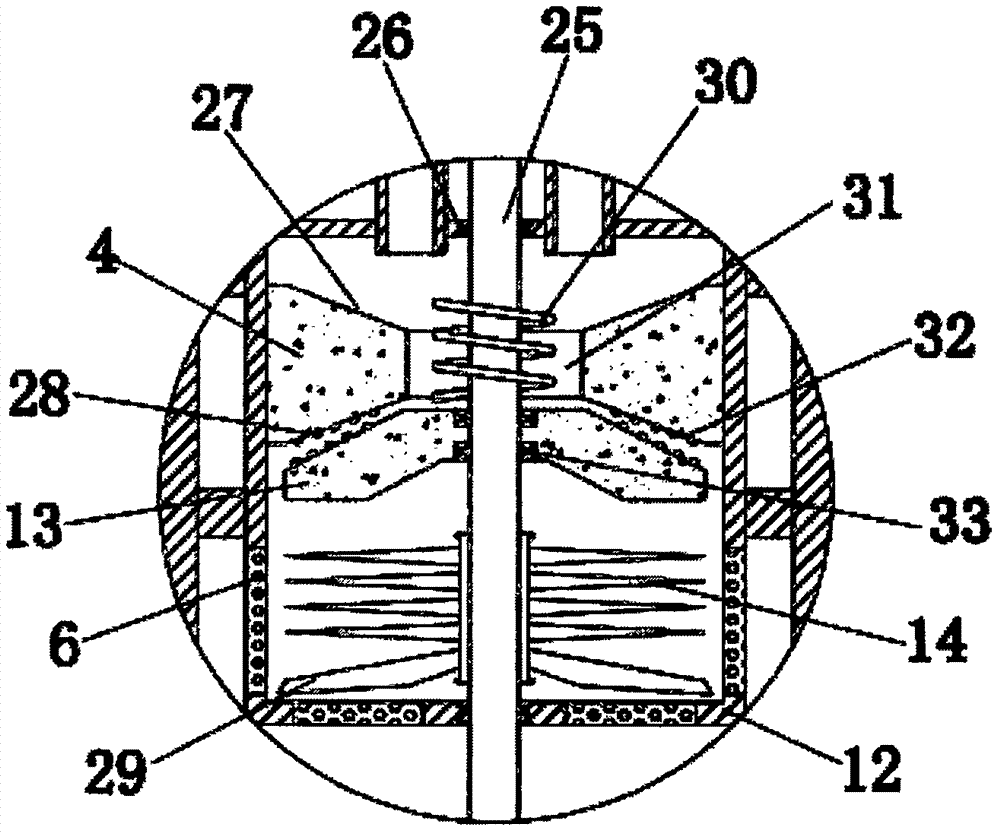

[0019] Example 1: Please refer to Figure 1-4 , the present invention provides a technical solution: a biotechnology material ultrafine pulverization device, including a housing 3, the bottom of the housing 3 is equipped with a leg 18, and the left and right sides of the top of the housing 3 are connected with first Enter the hopper 1 and the second hopper 10, the top of the first hopper 1 and the second hopper 10 are equipped with a sealing cover 19, when the material is pulverized, pour it into the first hopper 1 and the second hopper 10, the first The inner right side of the feeding hopper 1 and the second feeding hopper 10 is equipped with an auxiliary material cylinder 21, the top of the auxiliary material cylinder 21 is provided with an end cap 22, and the end cap 22 is connected with the auxiliary material cylinder 21 through the movable part 20, and the inner bottom of the auxiliary material cylinder 21 A material control valve 23 is installed at the end, and the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com