Material pulverizer with dust removal function

A pulverizer and pulverizer motor technology, which is applied in the field of material pulverizers and dust-removable material pulverizers, can solve the problems of pulverizers without dust removal, poor ventilation, and production difficulties, so as to improve production efficiency and product quality. Easy to adjust and maintain, easy to carry and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

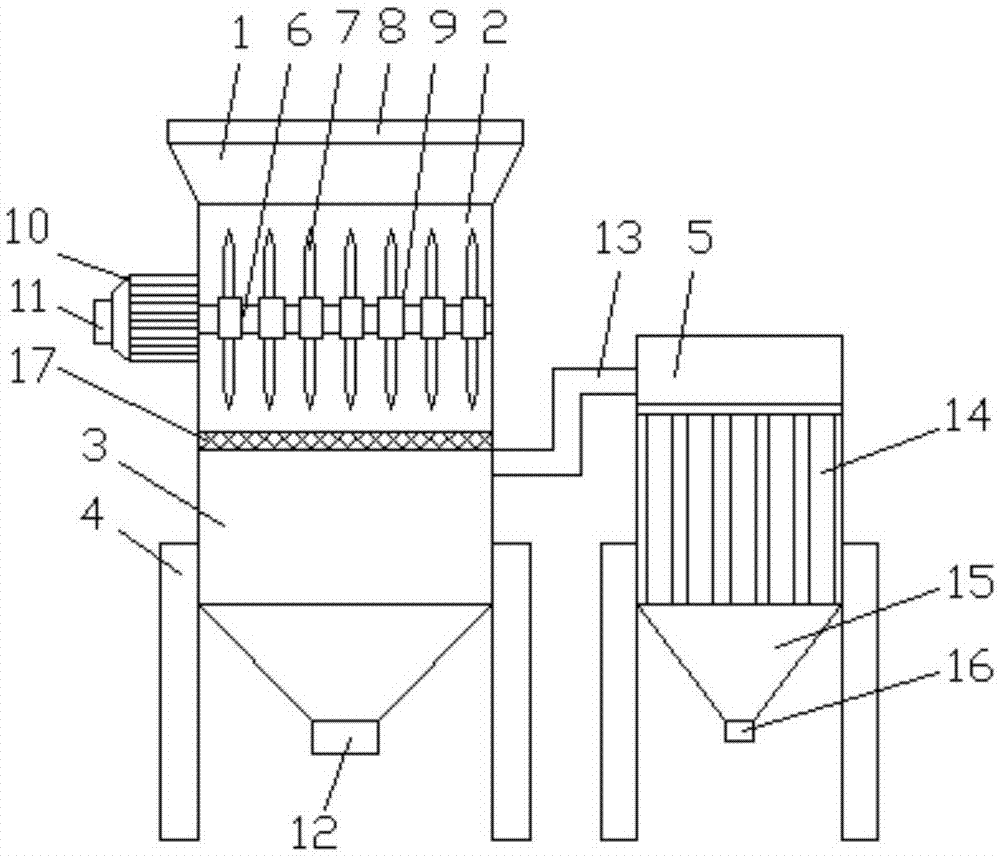

[0017] Example: see figure 1 , a kind of dedusting material pulverizer of the present invention comprises pulverization chamber 2, separation chamber 3, dedusting chamber 5, pulverization rotating shaft 6, feeding cover 8, pulverization motor 10, dust removal bag 14 and vibrating screen 17, and described pulverization chamber 2 A feed hopper 1 is arranged on the upper side, and a crushing shaft 6 is arranged inside the crushing chamber 2, and the crushing shaft 6 axially penetrates the crushing chamber 2, and a crushing motor 10 is fixedly installed at one end of the crushing shaft 6, and the crushing motor 10 10 is arranged on the outer wall of the crushing chamber 2, the lower side of the crushing chamber 2 is provided with a separation chamber 3, the lower side of the separation chamber 3 is provided with a separation outlet 12, and the upper side of the separation chamber 3 is provided with a dust discharge pipe 13, so The other end of the dust discharge pipe 13 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com