Catalyst for synthesizing cyclohexanediol compounds by catalytic hydrogenation of benzenediol compounds and preparation method for catalyst

A technology for catalytic hydrogenation of cyclohexanediol, applied in the preparation of organic compounds, preparation of hydroxyl compounds, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of long reaction time and consumption of Ni-Al alloy Large, easy to produce alkaline waste liquid and other problems, to achieve the effect of low industrial cost, strong selectivity, and good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

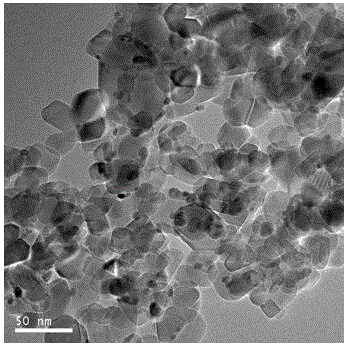

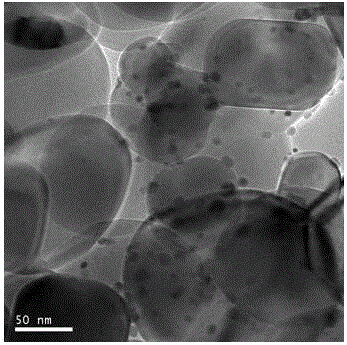

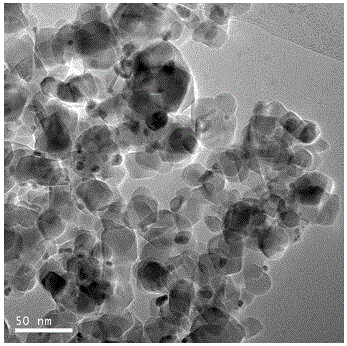

[0033] Preparation of Catalyst A. Weigh 0.5g of titanium dioxide and dissolve it in a 10ml aqueous solution in a round-bottomed flask, keep stirring and keep a constant temperature, set the temperature to 0°C, add 0.054g solid palladium nitrate dihydrate under constant stirring, continue stirring for 12 hours, close Stir, stand still for 12 hours, remove excess aqueous solution by rotary evaporation, dry overnight, calcinate at 400 ° C for 6 hours, and finally reduce at 300 ° C for 6 hours under a hydrogen atmosphere to obtain a titanium dioxide-supported noble metal palladium catalyst A, the loading amount of noble metal palladium is 5 %, that is, the mass ratio of titanium dioxide to precious metal is 100:5.

Embodiment example 2

[0035] Preparation of Catalyst B. Weigh 0.5g of titanium dioxide and dissolve it in a 10ml aqueous solution in a round-bottomed flask, keep stirring continuously and keep a constant temperature, the temperature is set to 20 ° C, add 0.0416g palladium chloride solid under constant stirring, continue stirring for 12 hours, close the stirring , stand still for 12 hours, remove excess aqueous solution by rotary evaporation, dry overnight, calcinate at 300 ° C for 8 hours, and finally reduce at 200 ° C for 8 hours under a hydrogen atmosphere to obtain a titanium dioxide-supported precious metal palladium catalyst B, the loading of precious metal palladium is 5%

Embodiment example 3

[0037] Preparation of Catalyst C. Weigh 0.5g of titanium dioxide and dissolve it in a 10ml aqueous solution in a round-bottomed flask, stir continuously and keep a constant temperature, the temperature is set to 40 ° C, add 0.0583g of palladium chloride solid under constant stirring, continue stirring for 6 hours, close the stirring , stand still for 12 hours, remove excess aqueous solution by rotary evaporation, dry overnight, calcinate at 200 ° C for 8 hours, and finally reduce at 300 ° C under hydrogen atmosphere for 4 hours to obtain a titanium dioxide-supported noble metal palladium catalyst B, the loading of noble metal palladium is 7% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com