Patents

Literature

304 results about "Hydroquinol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface Deposition of Small Molecules to Increase Water Purification Membrane Fouling Resistance

InactiveUS20120111791A1Efficient use ofEasy to retouchMembranesSemi-permeable membranesCoated membraneHydroquinone Compound

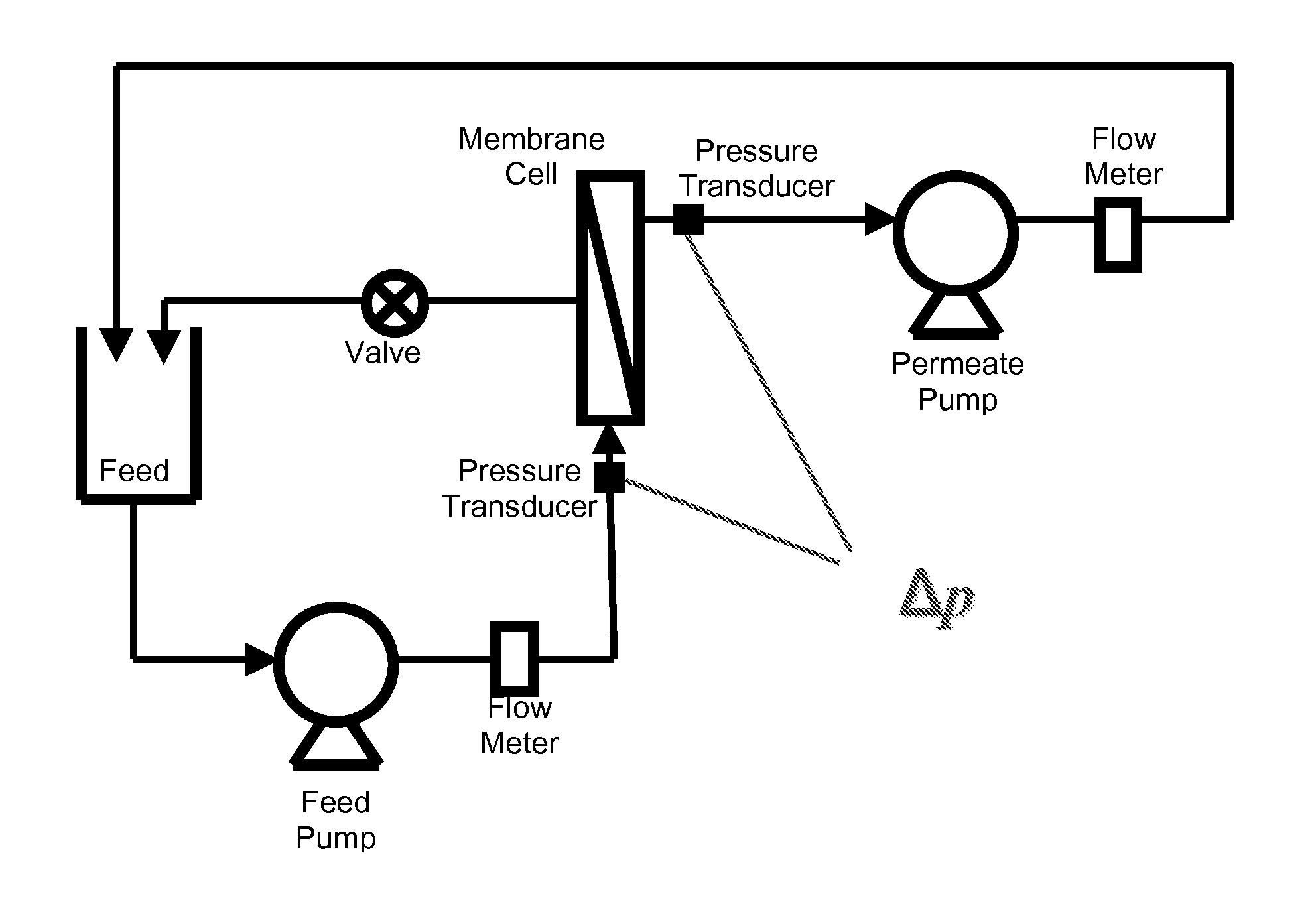

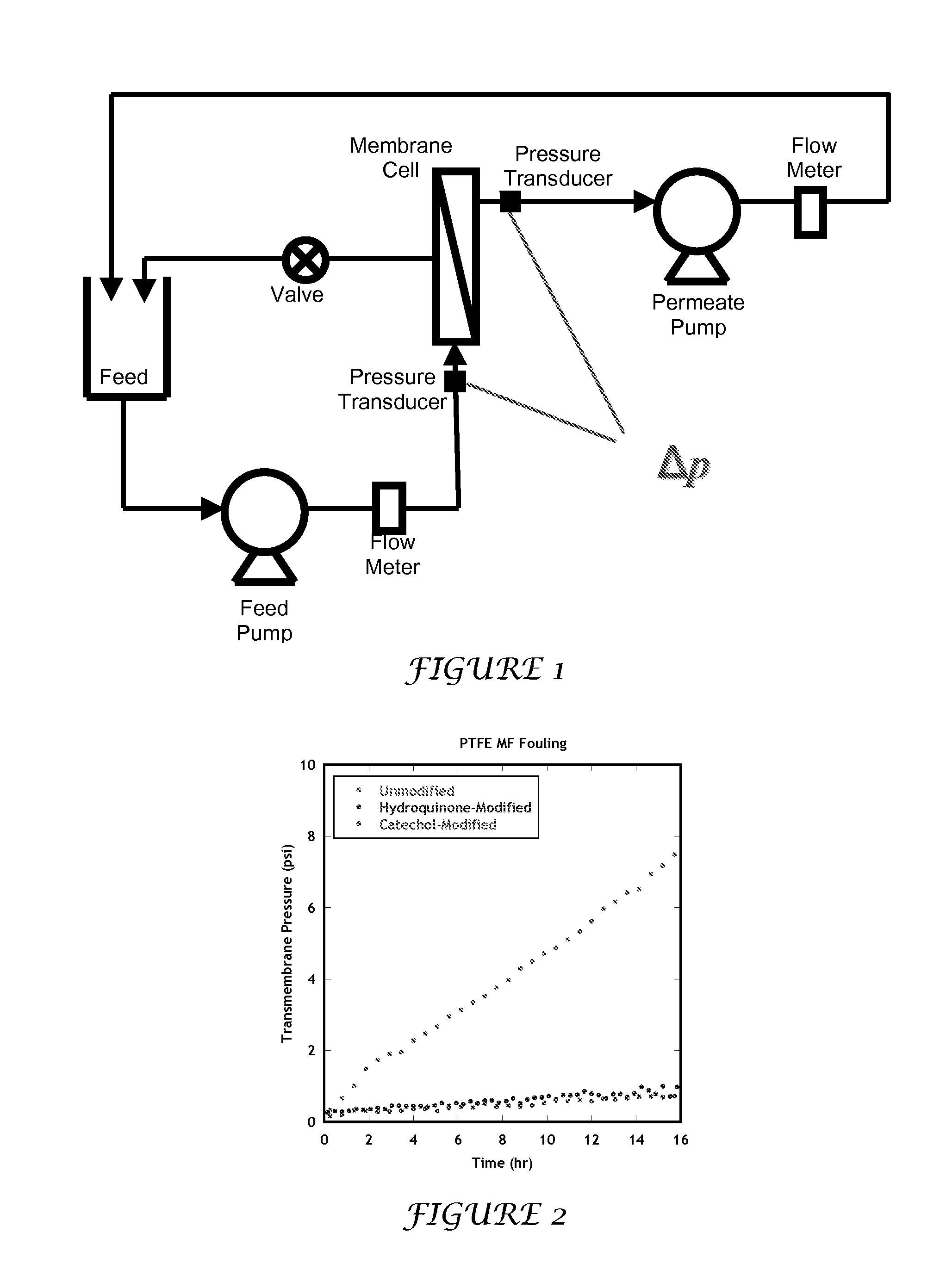

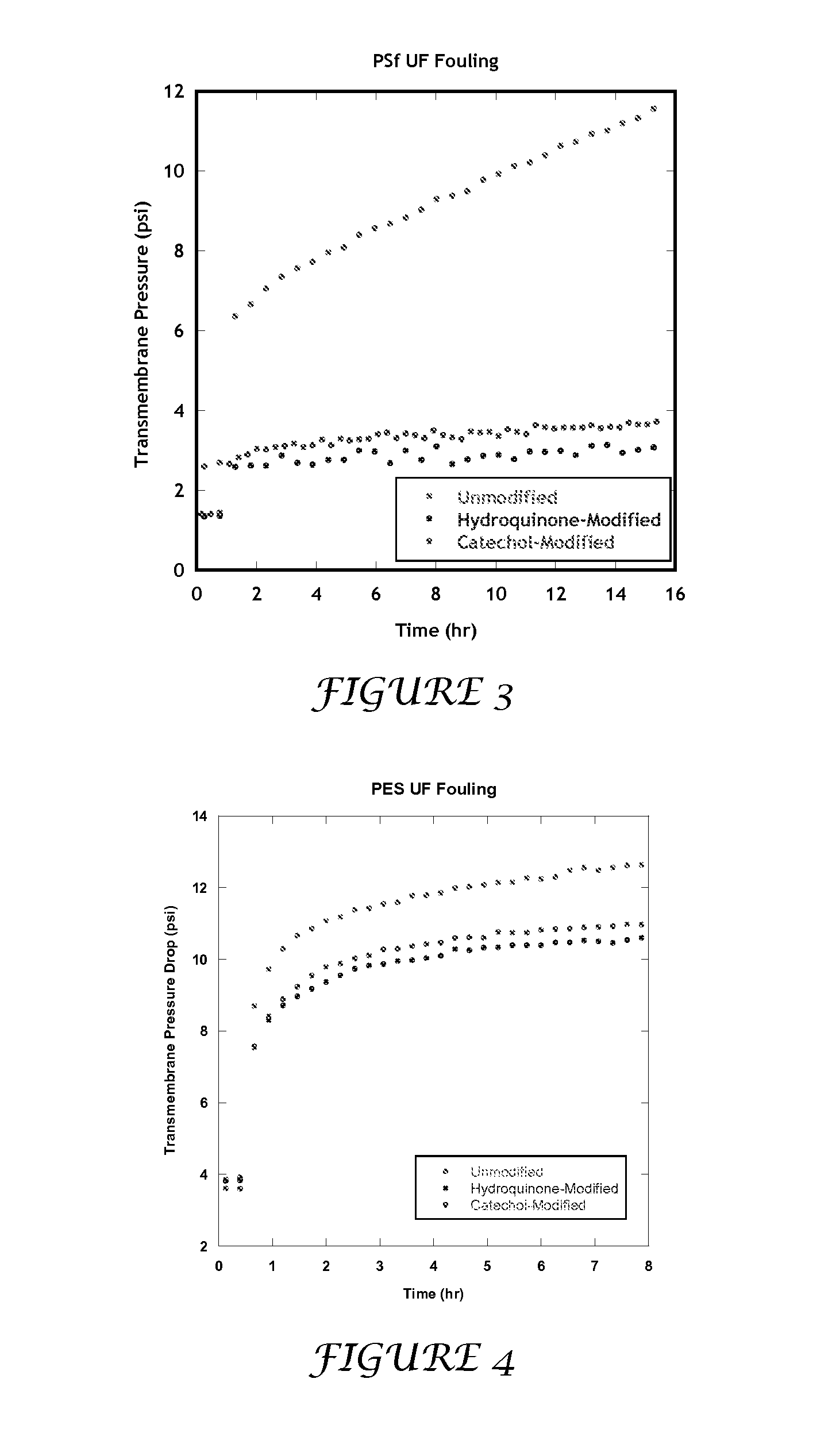

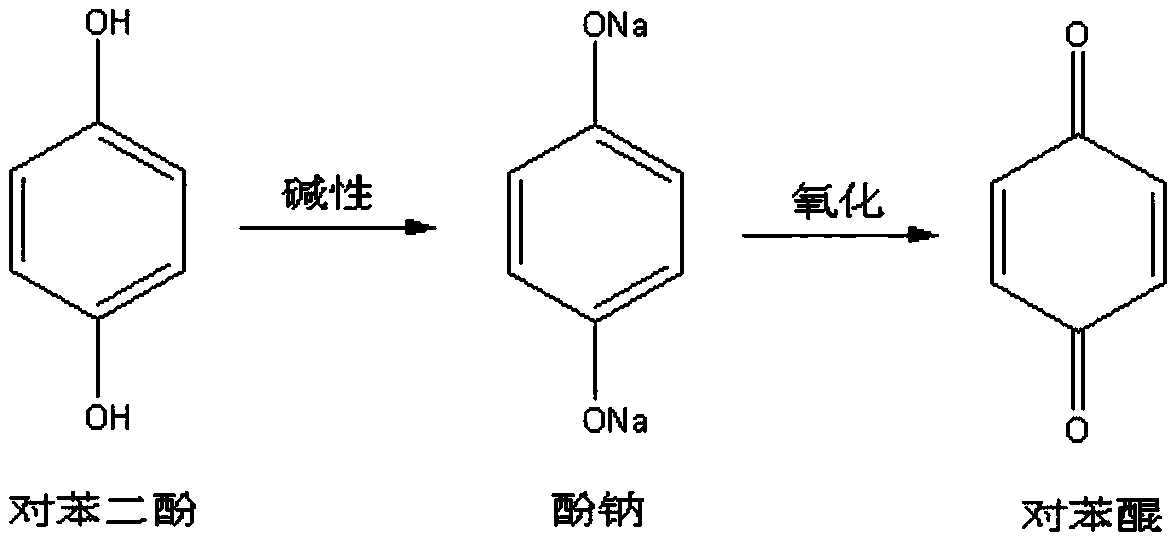

The present invention includes methods and compositions for liquid separation and water purification. The present invention includes a purification membrane having a polymer matrix purification membrane that has been treated with hydroquinone, catechol, and / or dopamine coated membrane with a high water flux.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Resin composition for insulation film

ActiveUS20130245161A1Low dielectric constantLow DfDomestic articlesThin material handlingPolymer sciencePtru catalyst

A resin composition includes (A) 100 parts by weight of epoxy resin; (B) 20 to 100 parts by weight of polybutadiene styrene divinylbenzene graft terpolymer resin; (C) 2 to 20 parts by weight of di-tert-butylhydroquinone (DTBHQ); (D) 5 to 50 parts by weight of polyphenyl ether modified cyanate ester resin; and at least one of (E) inorganic filler, (F) chain extending sealing agent, and (G) catalyst. The resin composition is characterized by specific ingredients and proportions thereof to attain high heat resistance, low dielectric constant Dk, and low dielectric dissipation factor Df, and being halogen-free, and therefore is applicable to protective film of printed circuit boards, insulating protective film of electronic components, and resin insulation film of leadframes.

Owner:ELITE MATERIAL

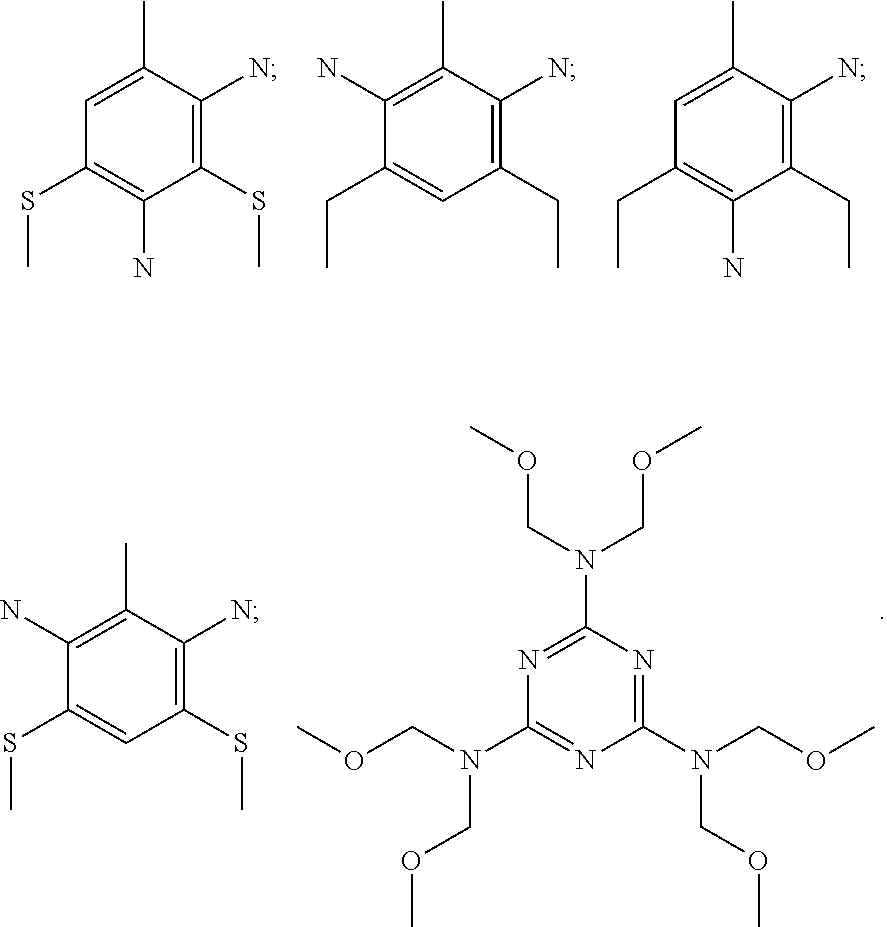

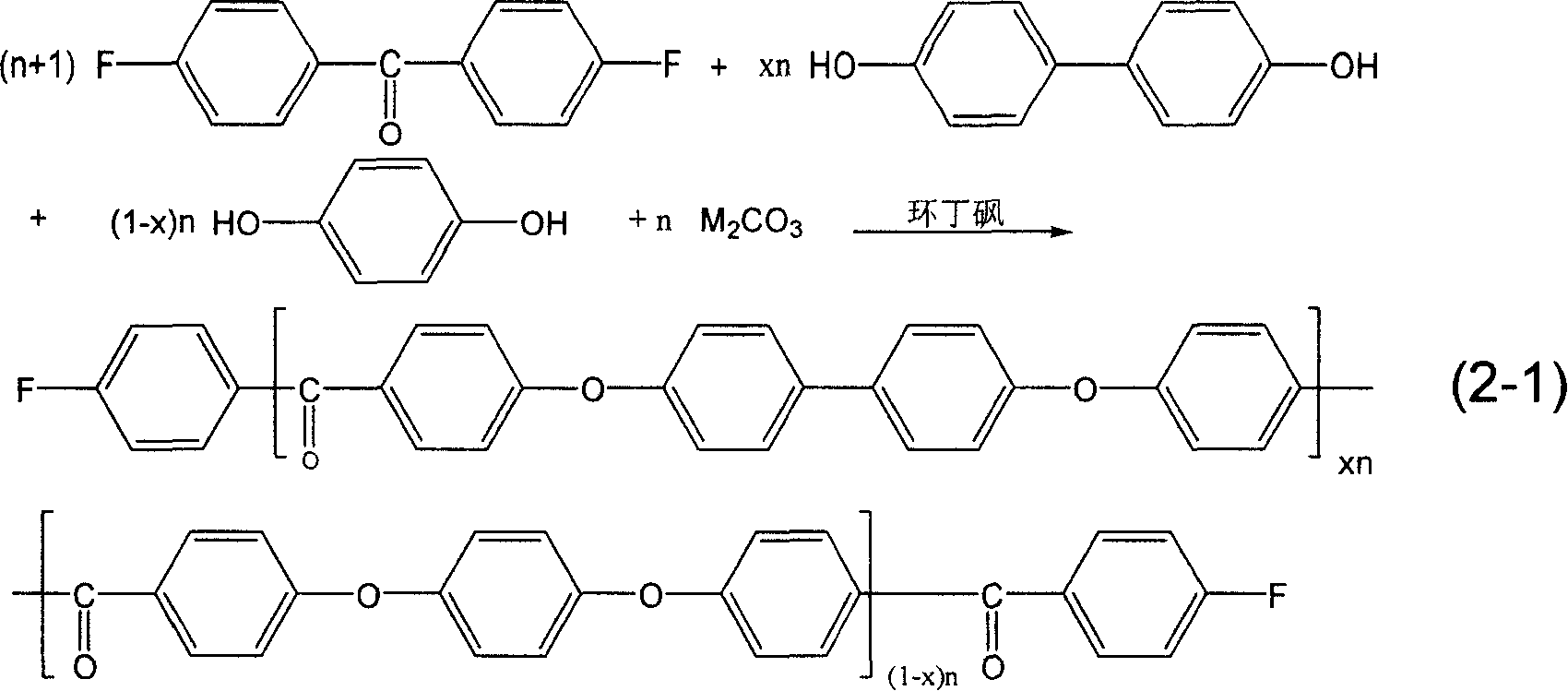

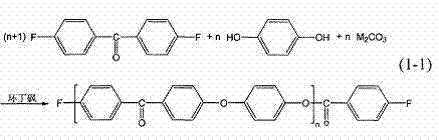

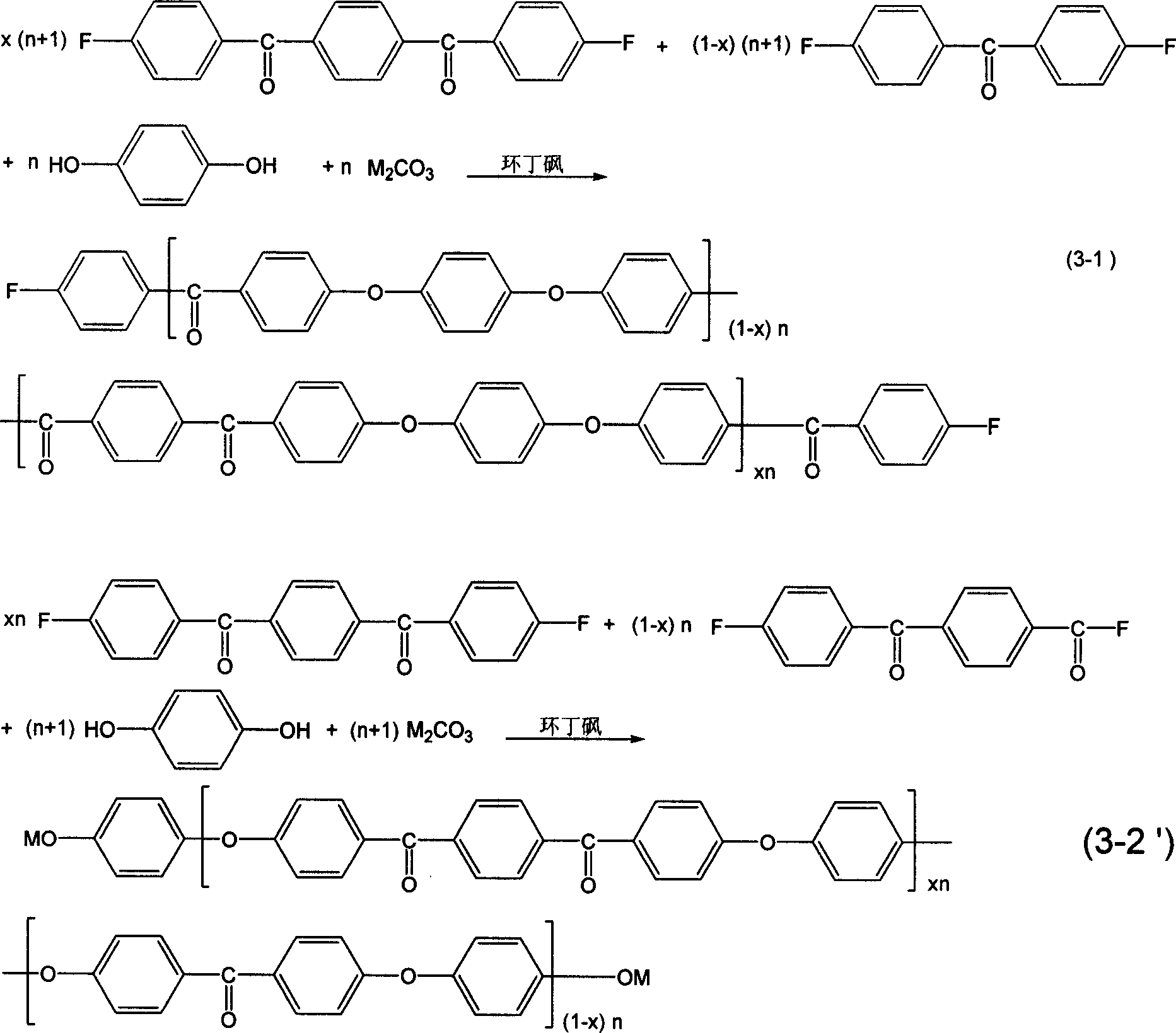

Synthesis method of ternary copolymer containing PEDEK and PEEK using sulfolane as solvent

The invention relates to a method for preparing polyetheretherketone and polyetheretherketone terpolymer by using sulfolane. It comprises following steps: the mole number of 4, 4'- difluoro diphenyl ketone is more than that of eldopaque and diphenol by 0.1-1%, the solid content in reaction system is 15-30%; filling dimethylbenzene with its mass being 10-20% of that of organic solvent, stirring, heating, adding mixed salt of alkali metal carbonate when monomer is totally dissolved and the temperature is between 75 to 85 Deg. C, reacting at constant temperature 230-260 Deg. C for 1-3 hours, stopping reaction, pouring product into cold water, cooling and disintegrating and filtering, boiling solid product with deionized water for several times, drying refined powder material in baking box, and getting said final product.

Owner:长春吉大特塑工程研究有限公司

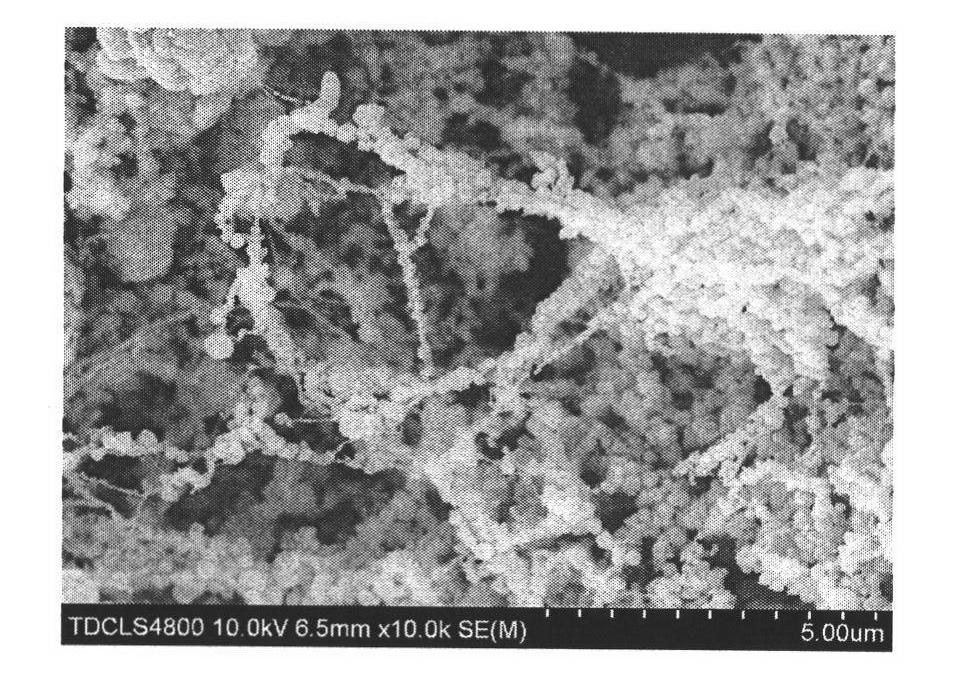

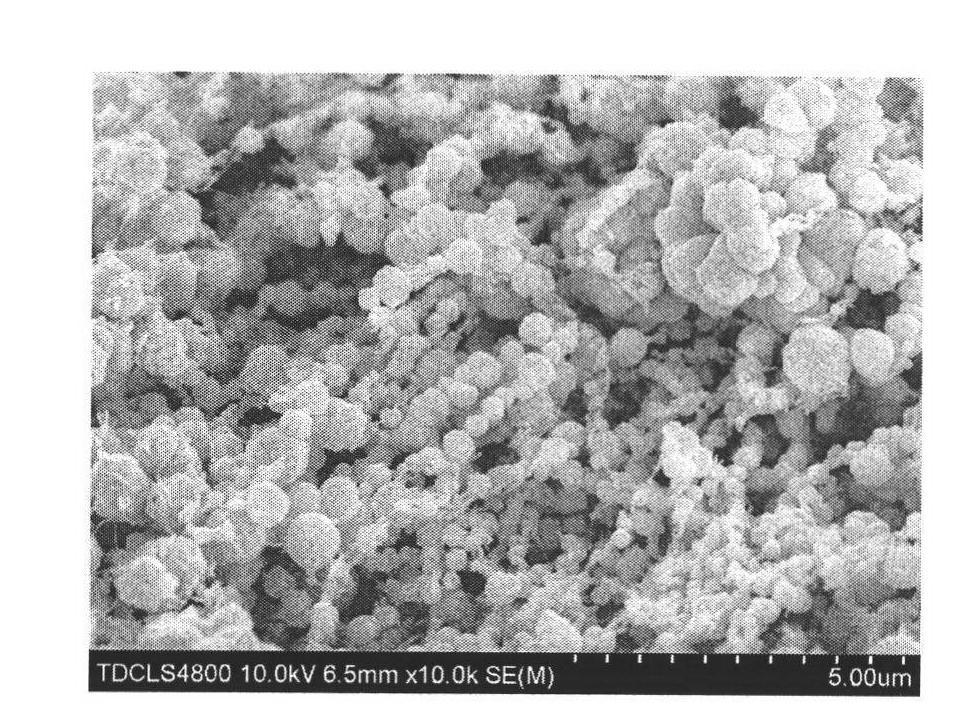

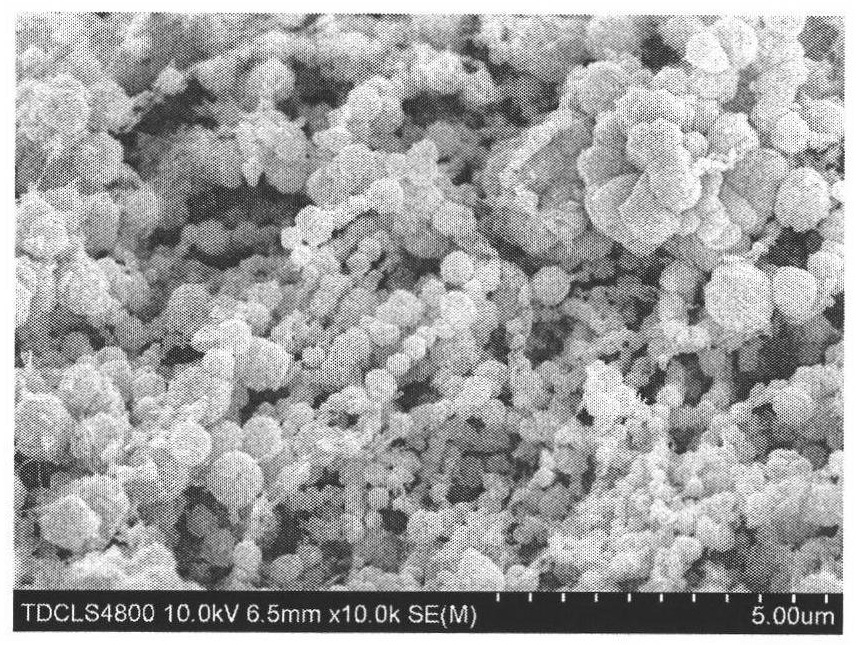

Method for preparing cuprous oxide/ bacterial cellulose nano composite material

InactiveCN102121038AMaintain nanostructureOvercoming the disadvantages of difficult recyclingMaterial nanotechnologyCopper oxides/halidesGas detectorHydroquinone Compound

The invention relates to a method for preparing a cuprous oxide / bacterial cellulose nano composite material. The preparing method comprises the following steps of: obliquely inoculating acetobacter xylinum strains into culture solution, and culturing the strains to obtain a bacterial cellulose gel film; performing surface activation treatment on the bacterial cellulose gel film in sulfuric acid solution and sodium hypochlorite solution respectively; and sequentially soaking the surface activated bacterial cellulose gel film into Cu(NO3)2 solution and hydroquinone solution to perform reduction reaction to obtain the cuprous oxide / bacterial cellulose nano composite material. The method has the advantages that: the preparation process is simple; and the prepared composite material keeps the nano structure of cuprous oxide particles, simultaneously has good strength performance, and has wide application prospect on the aspects of electrode devices, catalysts, gas sensitive sensors and the like.

Owner:TIANJIN UNIV

New green synthesizing process for ketocoumaran compound

The invention discloses a new green synthesizing process for a ketocoumaran compound. The synthesizing process comprises the following steps: in the absence of a solvent, performing condensation reaction of a mandelic acid compound and hydroquinol under the action of a little amount of acid catalyst to obtain a full condensed intermediate, wherein the acid catalyst is selected from one of 10 to 37 percent concentrated hydrochloric acid, 60 to 98 percent concentrated sulfuric acid, fuming sulfuric acid, 80 to 98 percent phosphoric acid, polyphosphoric acid, p-toluenesulfonic acid, trifloromethanesulfonic acid, benzoic acid, ammonium acetate, ammonium chloride, KF, TiC14, NiCl2, CuSO4, Cu(OAc)2, ZnCl2, AlCl3, Fe(NO3)3, FeCl3 and SnCl2; and performing oxidation reaction of full condensed intermediate under the action of an oxidant to obtain a final product ketocoumaran compound. The synthesizing process of the invention is simple, and has low energy consumption and little environmental pollution.

Owner:ZHEJIANG UNIV OF TECH

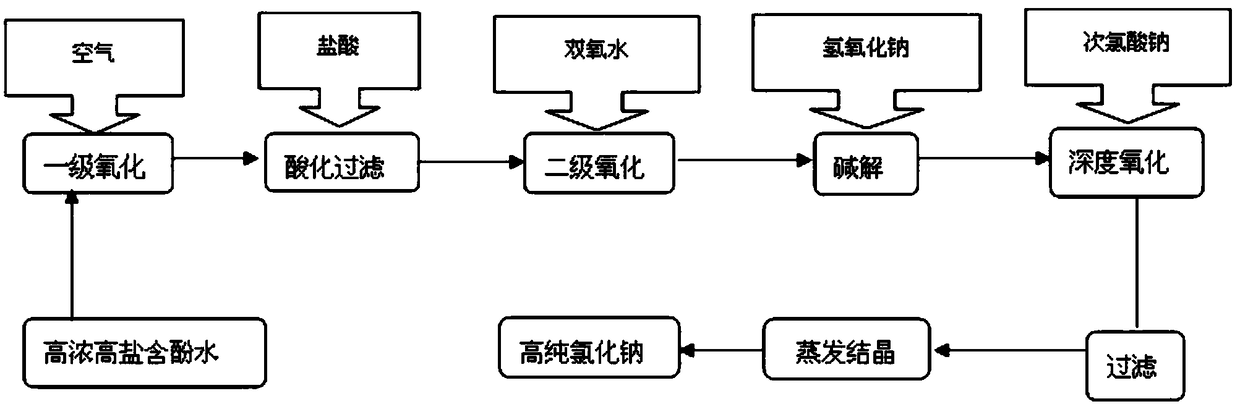

Process for harmless disposal of high-concentration high-salt phenol-containing wastewater and recovery of high-purity sodium chloride

InactiveCN109020032ALow costNo secondary pollutionWater contaminantsMultistage water/sewage treatmentChemical treatmentChemical industry

The invention especially relates to a process for harmless disposal of high-concentration high-salt phenol-containing wastewater and recovery of high-purity sodium chloride, belonging to the field oftreatment of high-concentration high-salt wastewater in the pesticide and chemical industry. According to the invention, a combination of physical treatment and chemical treatment is adopted; a treatment idea taking a hydroquinone oxidation intermediate as an oxidation target is employed; a multi-stage step-by-step composite oxidation manner is utilized; air oxidation is implemented at the first stage to precipitate insoluble precipitates; by means of filtration, the CODs of wastewater can be reduced by about 40%; hydrogen dioxide oxidation is conducted at the second stage, and reaction conditions are controlled to remove small-molecular organic matters in the wastewater; a strong oxidant is employed in the third-stage oxidation for deep oxidation; and high-purity sodium chloride in the wastewater having undergone multi-stage oxidation treatment is recovered by using an MVR evaporation process, and the recovered sodium chloride meets the internal quality standard of enterprises, and has a content of 95% or more. With the process of the invention, the recycling of the by-product sodium chloride can be realized while the treatment cost of the phenol-containing wastewater is reduced,so the purpose of resourceful disposal is achieved.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

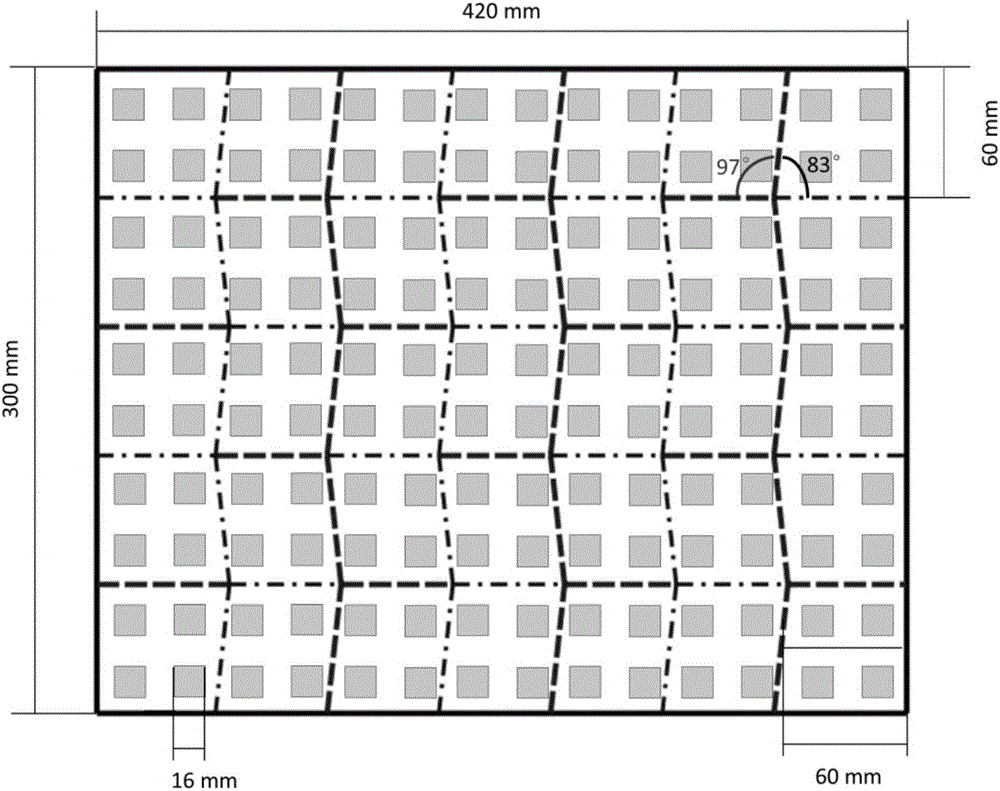

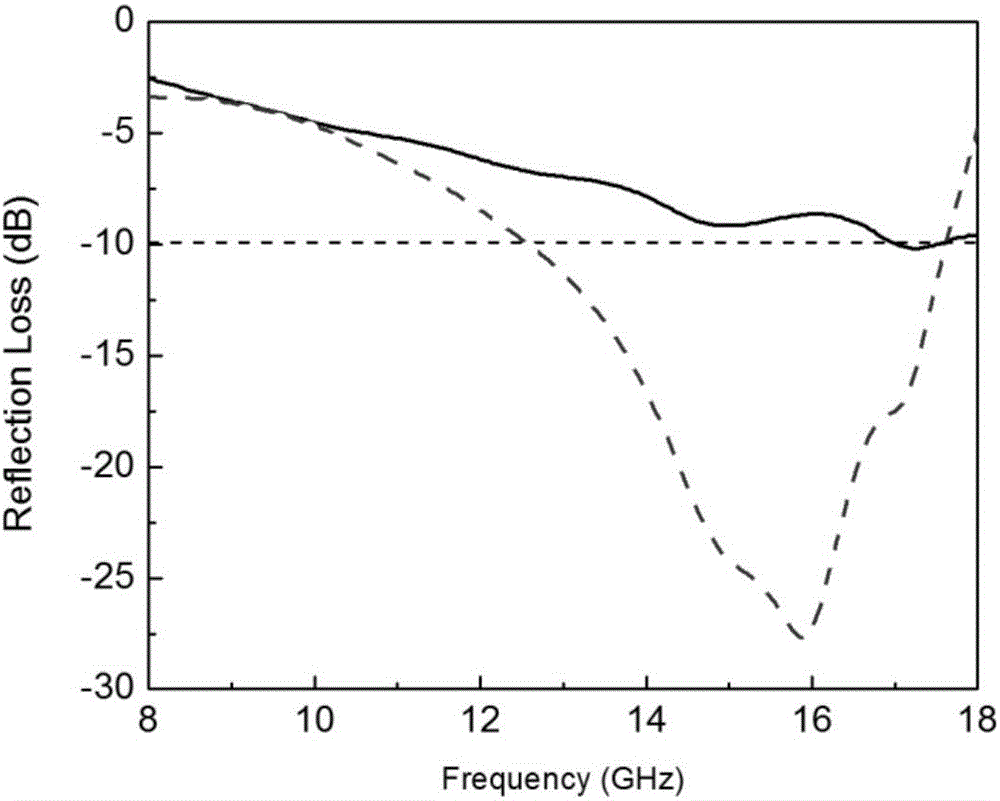

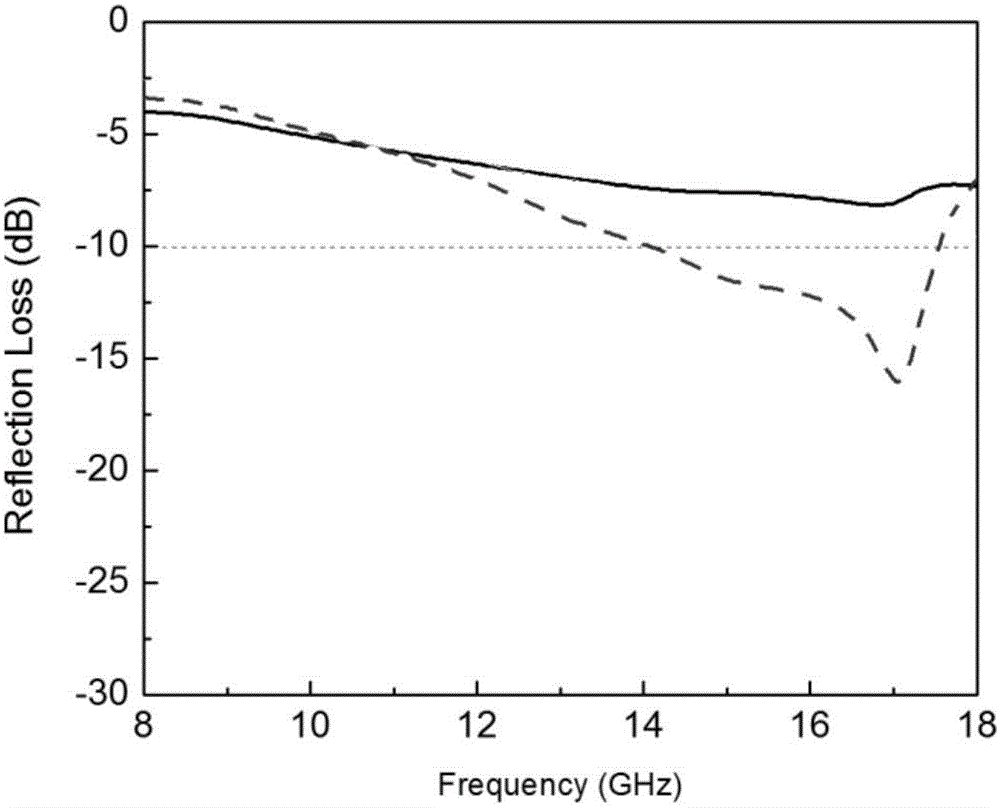

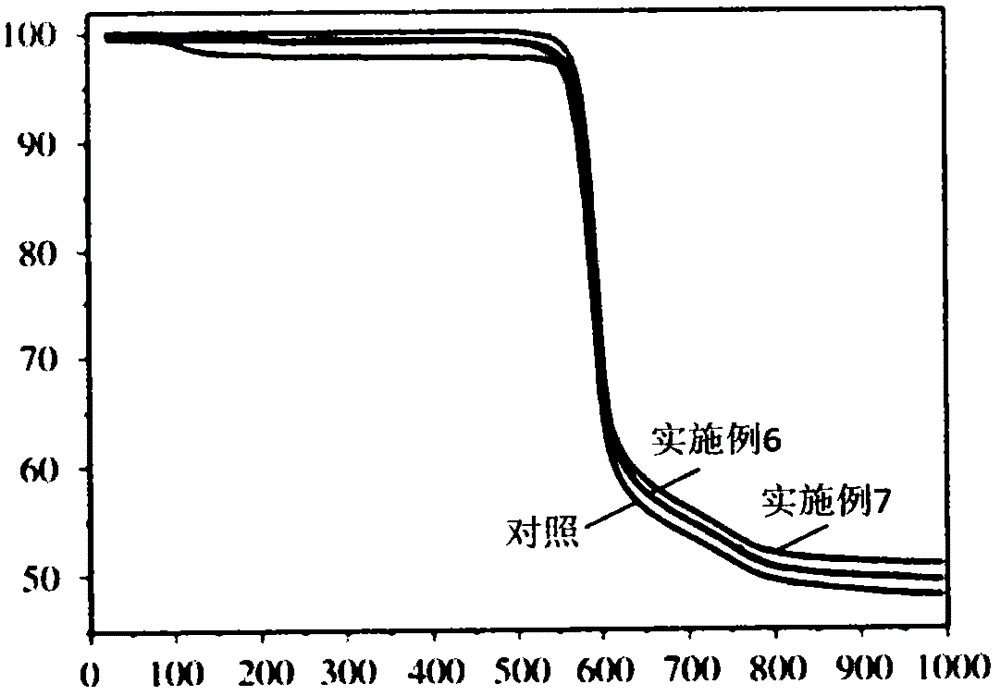

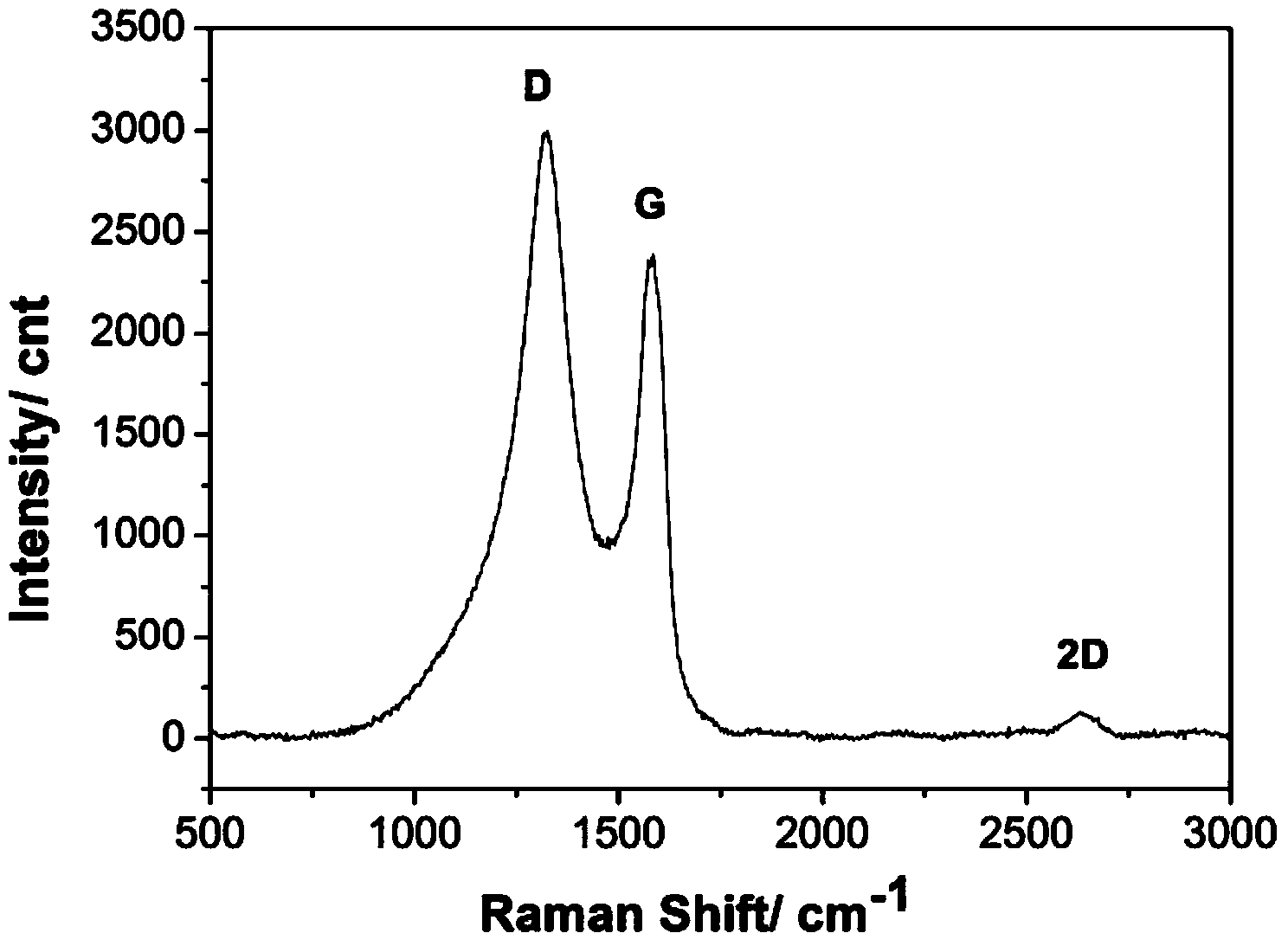

Miura - Ori origami structure electromagnetic stealthl plate of loaded graphene metamaterial unit

The invention is a miura - Ori origami structure electromagnetic stealth plate of loaded graphene metamaterial unit. An electromagnetic stealth plate of the invention is prepared by immersing a substrate in a mixture of hydroquinone and graphene oxide and sealing a heat treatment so as to attach absorbing medium to the substrate; after removing and cleaning, drying by freeze treatment to obtain graphene Weaving; graphene woven cloth is immersed in an epoxy resin precursor solution, paved, heated, and cured, to get an electromagnetic stealth plate; the electromagnetic stealth plate in accordance with Miura - Ori origami method of processing creases, so that the electromagnetic stealth plate along the crease Deformation; and in the electromagnetic stealth plate on the plate surface of the super-material unit.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

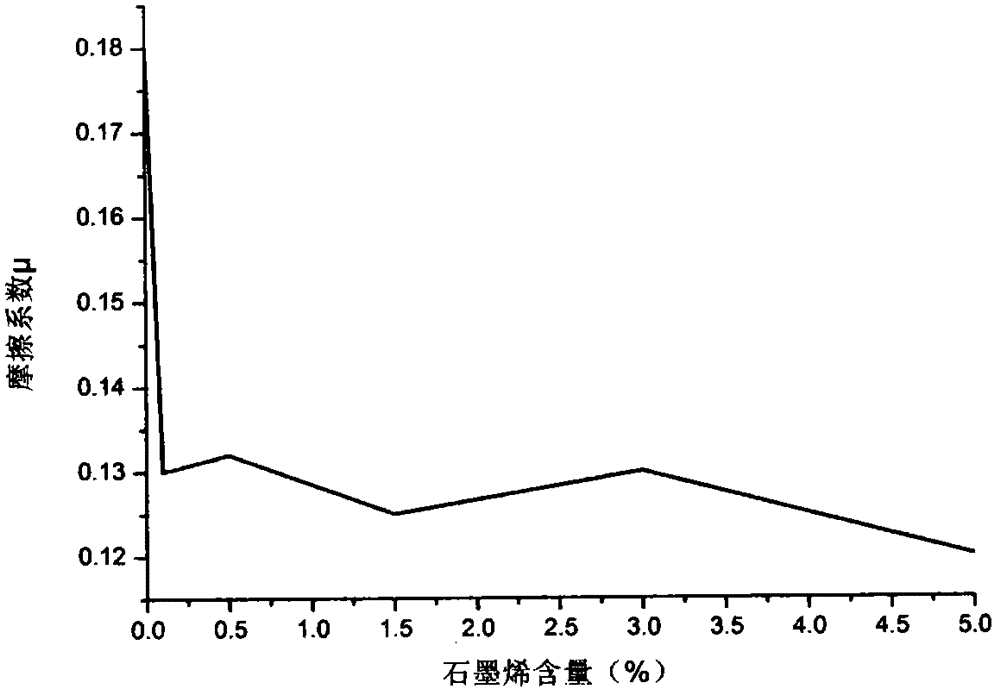

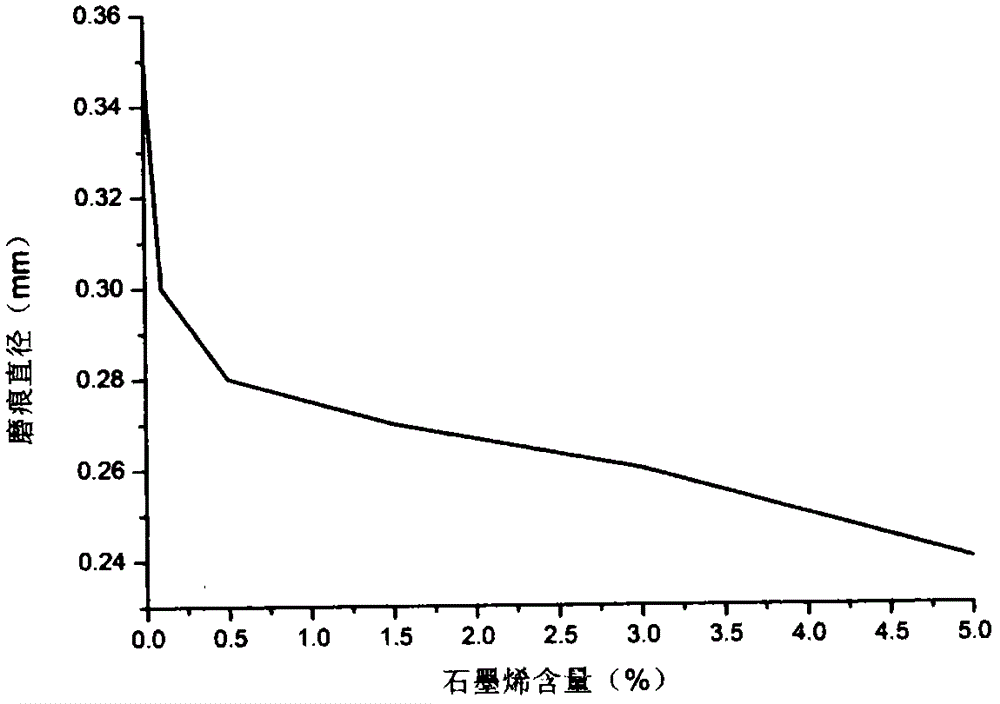

Graphene polyether-ether-ketone composite coating and preparation method thereof

InactiveCN105086740AImprove thermal conductivityImprove toughnessCoatingsMechanical propertyCompatibilization

The invention provides a graphene polyether-ether-ketone composite coating and a preparation method thereof. The coating is prepared from the following raw materials: 4,4'-difluorobenzophenone, hydroquinone, a condensing agent, a surfactant, graphene and octaphenyl-POSS. According to the invention, graphene is directly added during the preparation process of the composite coating, so thermal conductivity of the composite coating is improved; meanwhile, the graphene itself has a good mechanical property and a good structural reinforcing property, so toughness of the composite coating is improved. The added octaphenyl-POSS in the invention is used as a nanometer functional material, has good compatibility with the polyether-ether-ketone body and the graphene, and is easy to be dissolved in an organic solvent; only a small amount of the octaphenyl-POSS is needed to be added and can facilitate dispersion of a graphene filler; meanwhile, the octaphenyl-POSS can be used as a nanometer spherical lubrication-assisting agent to improve the wear resistance and lubricating property of the coating. Moreover, compared with the prior art, the production process of the graphene polyether-ether-ketone composite coating in the invention is simple and good in operability.

Owner:NINGBO GRAMMY KITCHENWARE

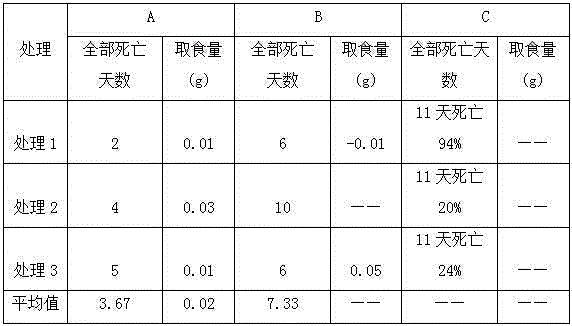

Termite pheromone attractant and termite trap-killing agent using termite pheromone attractant

ActiveCN104522082AFix for keeping lures shortImprove booby effectBiocidePest attractantsDismutaseActive enzyme

The invention relates to a termite pheromone attractant and a termite trap-killing agent using the attractant, and belongs to the technical field of termite trap-killing agents. The termite pheromone attractant comprises the following components: hydroquinone, arbutin, oleic acid, glucose, cyclohexanhexol, mannose, 2,6-di-tert-butyl paracresol, amino acid, a biological active enzyme, salt, codlemone, gloeophyllum trabeum, ethanol, 2-phenoxyethanol, n-hexane, dismutase, poria cocos, coriolus versicolor, tall gastrodia tuber, edible fungus, lucid ganoderma, bee honey, maltose, fermented sugarcane powder, fermented straws and acetone. The termite pheromone attractant disclosed by the invention synchronously has the functions of a termite phagostimulating pheromone and a termite trace pheromone by adding a chemical pheromone into a termite trap-killing agent, and can be used for significantly increasing the eating amount of termites on the trap-killing agent and improving the trap-killing effects of the termite trap-killing agent; and meanwhile, the termite pheromone attractant has extreme sensitivity and high specificity.

Owner:贺彬

High-fire resistance modified polyethylene tube material

The invention discloses a high-fire resistance modified polyethylene tube material. The high-fire resistance modified polyethylene tube material comprises high density polyethylene, silicone resin, polypropylene, an ethylene-propylene-diene monomer, maleic anhydride-grafted polyphenyl ether, tert-butyl hydroperoxide, ferriferrous oxide, barium sulfate, nanometer calcium carbonate, calcium silicate whisker, polyacrylonitrile fibers, an antistatic agent, a lubricant, an anti-oxidant and a fire retardant. The fire retardant is prepared by adding polyethylene, silicone rubber, maleic anhydride and benzoyl peroxide into a mixture, carrying out mixing to obtain a uniform mixture, adding the mixture into an extruder, carrying out primary granulation to obtain a modifier, adding aluminum hydroxide nanometer fibers, carbon nanotubes, zinc borate, magnesium hydroxide, powdered steatile and the modifier into the extruder, carrying out secondary granulation and mixing the granules, triphenyl phosphate, hydroquinol bis(diphenylphosphate) and polysulfonyldiphenylene phenyl phosphonate to obtain a uniform mixture. The high-fire resistance modified polyethylene tube material has the advantages of high strength, good pressure resistance, heat resistance, flame resistance and long service life.

Owner:安徽宁国市高新管业有限公司

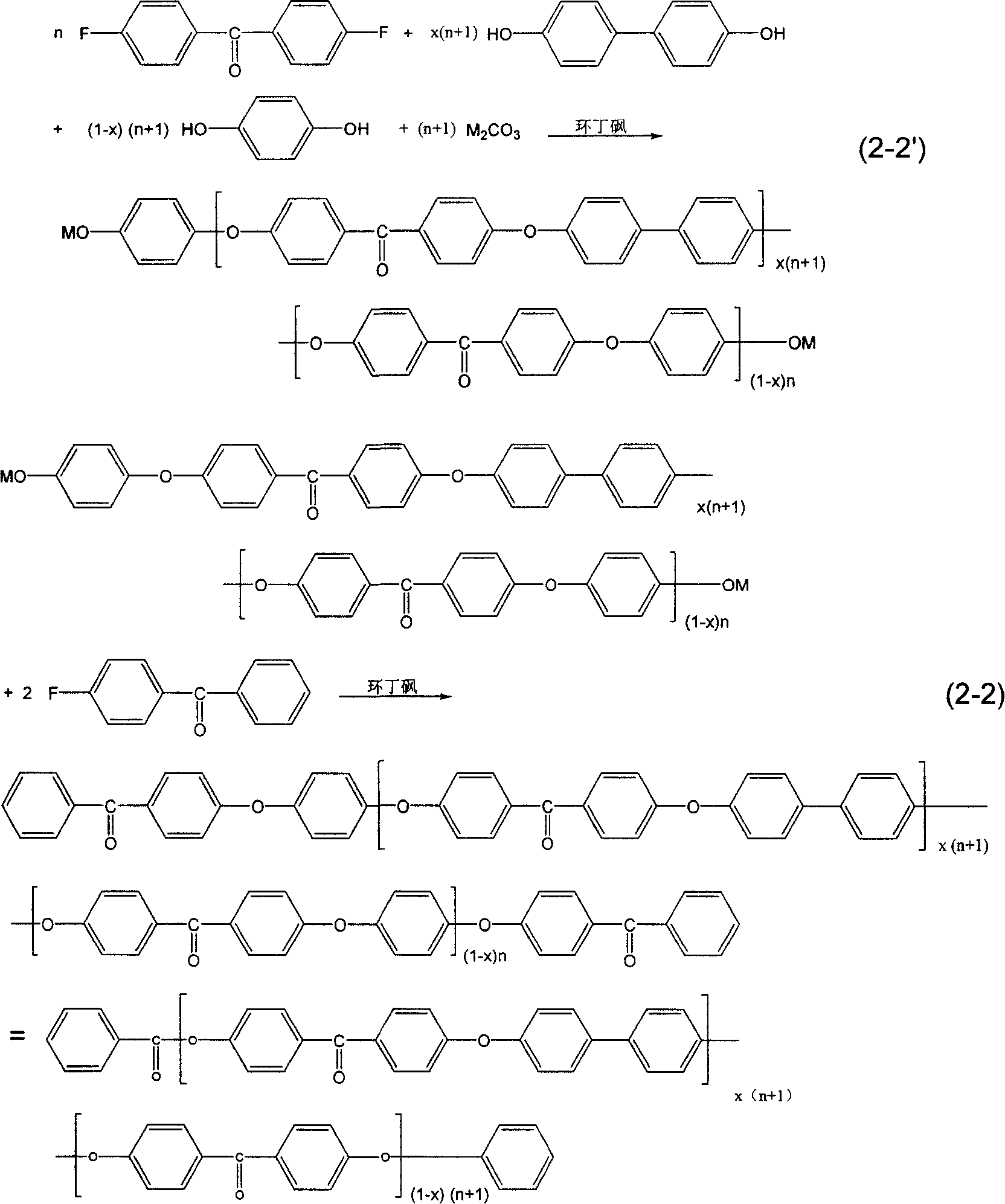

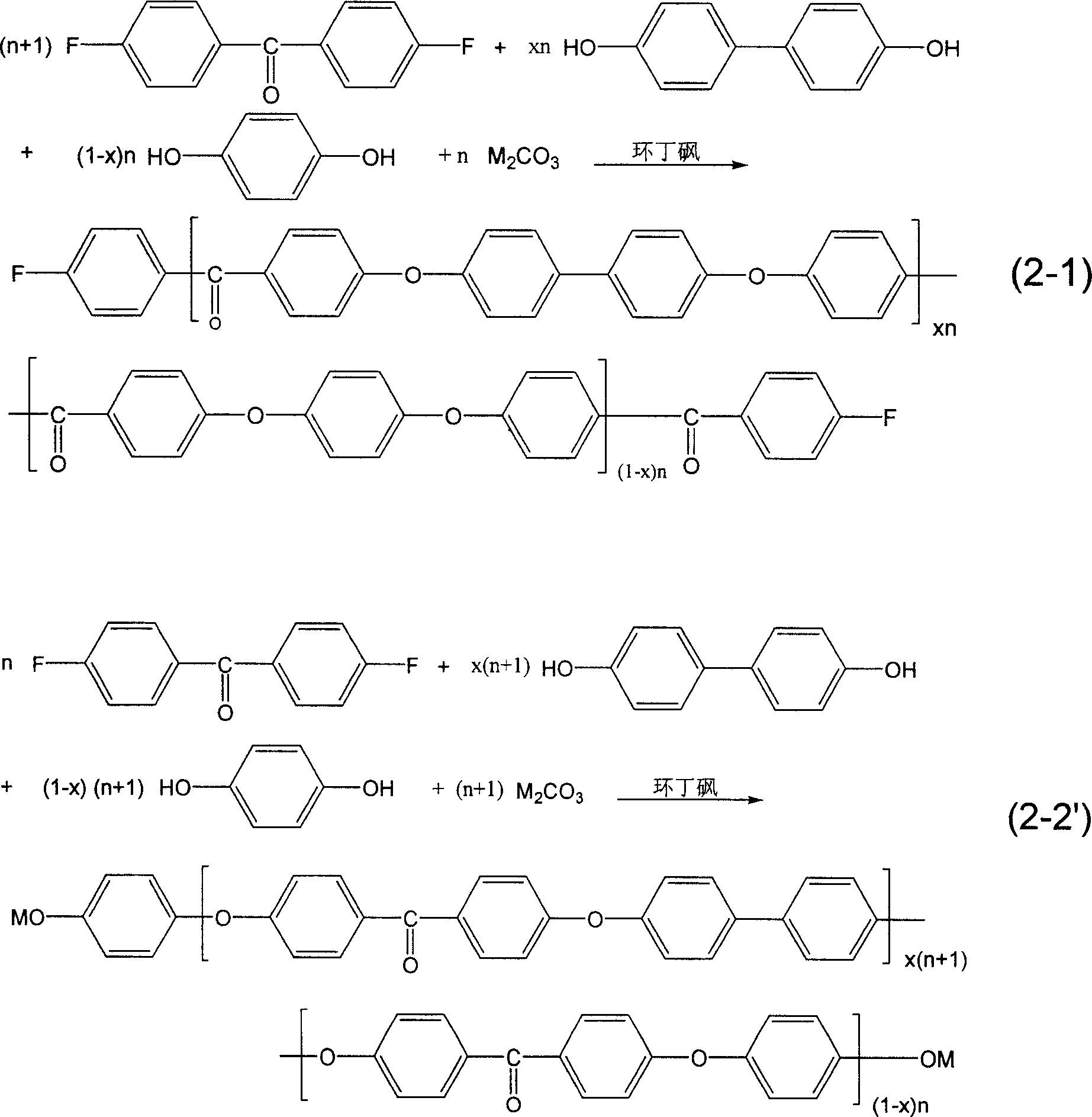

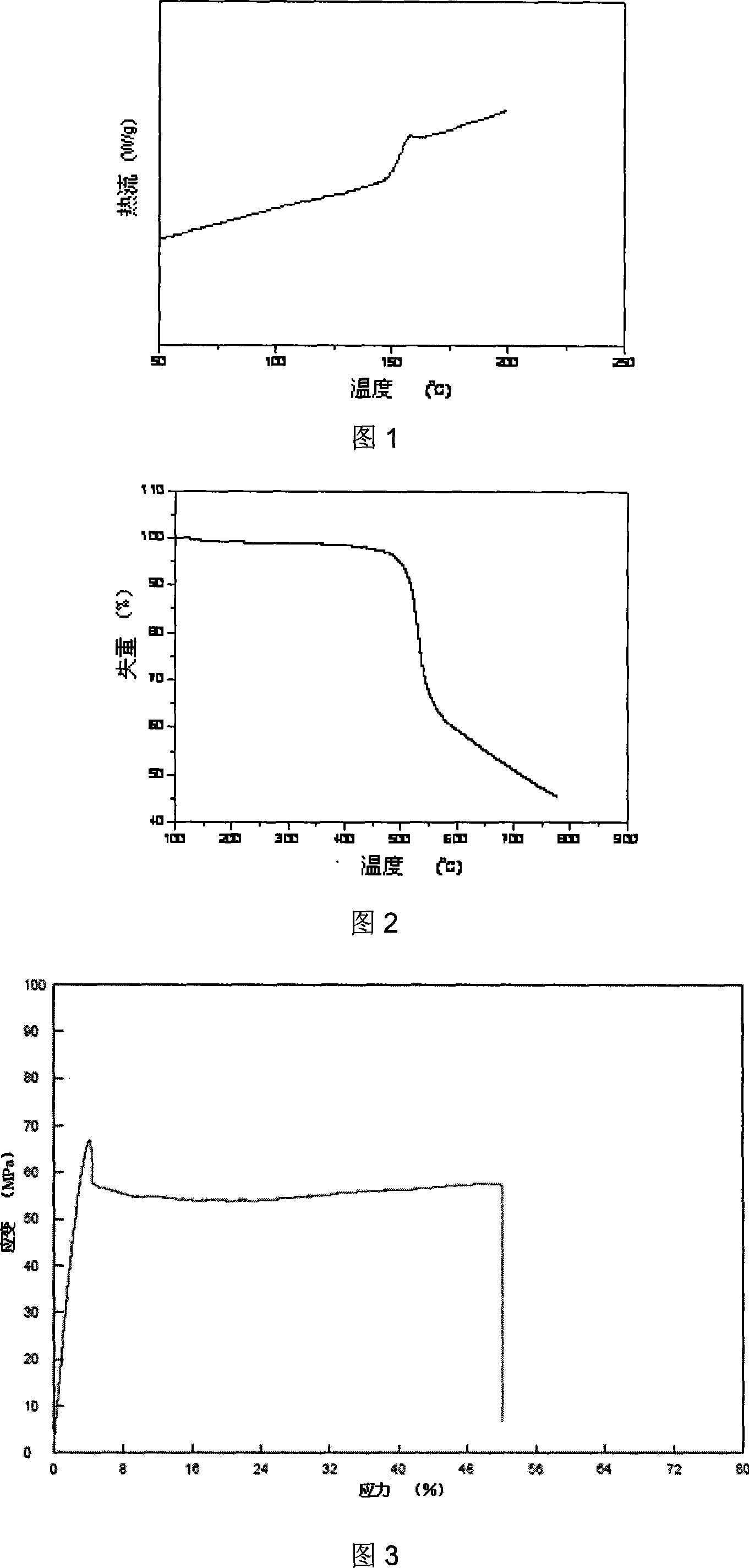

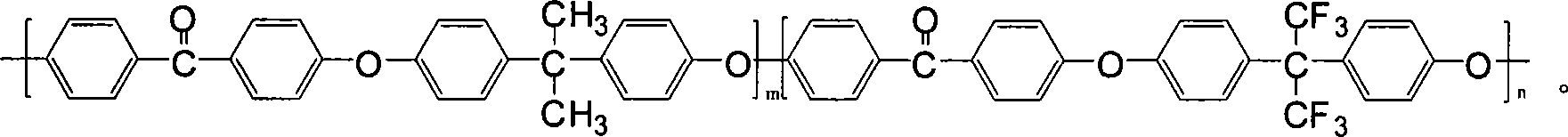

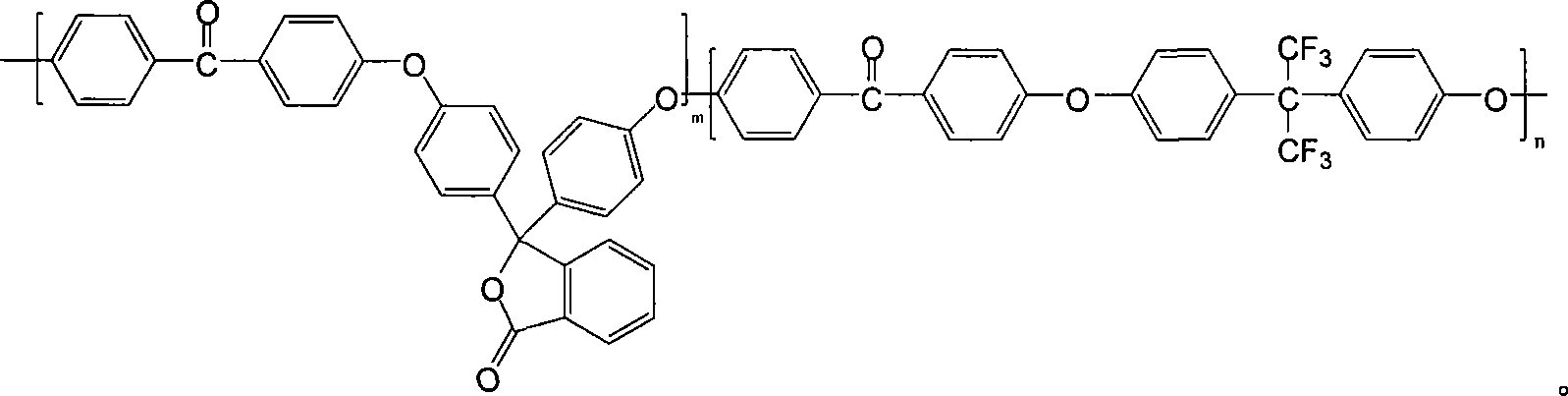

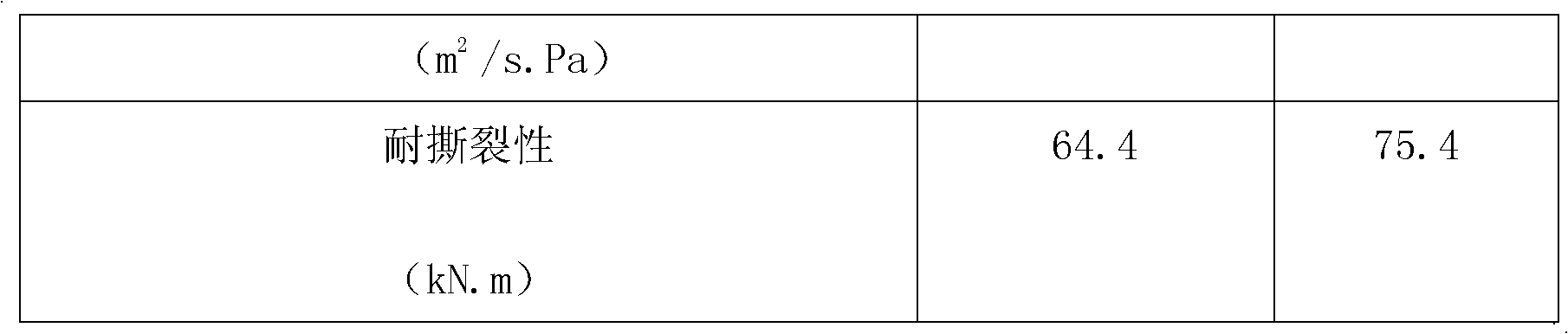

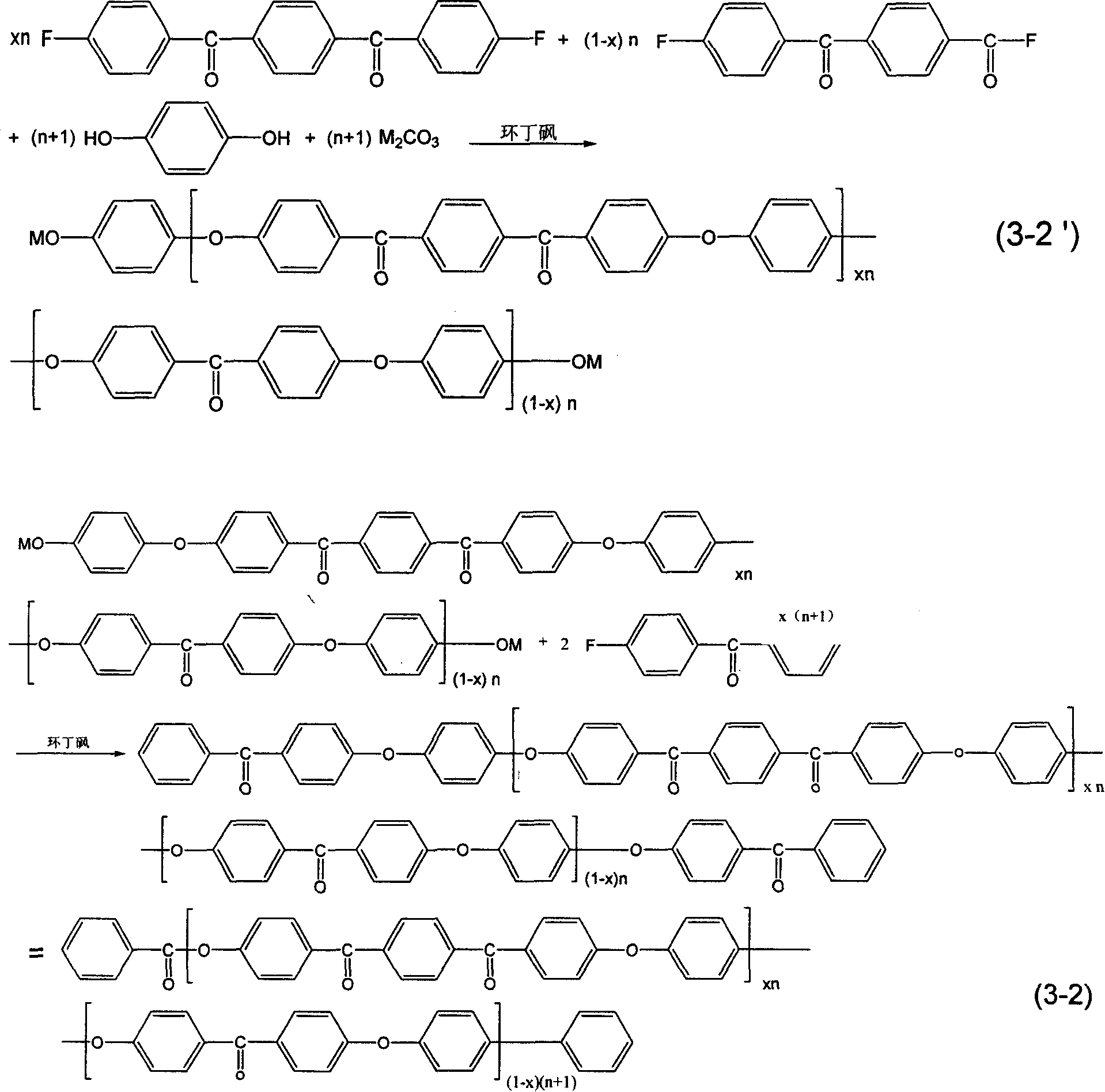

Soluble fluorine-containing polyaryl ether ketone high-performance material, preparation method thereof and mixed film of the same and epoxy resin

The invention relates to a new fluorine polyaryletheretherketone soluble high-performance material, process for preparation and the blend film material formed by the epoxide resin. The process for preparation comprises the following procedures: regarding 4,4'- difluorobenzophenone or 4,4'-difluorotribenzodiketone and mixing bisphenol monomer as the material; controlling the proportion of bisphenol hexaflurate A ( or trifluoromethyl phenyl eldopaque) and bisphenol A ( or fenolftaleina) in the segment of polymer via the way of nucleophilic substitution reaction; getting the new fluorine polyaryletheretherketone soluble high-performance material; furthermore, selecting the immobilized liquid epoxide resin and the functional polymer blend film prepared by the new fluorine polyaryletheretherketone soluble high-performance material in order to achieve the functionalization of polyaryletheretherketone material for meeting the aim of the different applying range and extending the processing window. The blend film material is suitable for high-performance composite material resin base field, microelectronic insulating material field, optical waveguide device field and air permoselective membrane field and the like.

Owner:JILIN UNIV

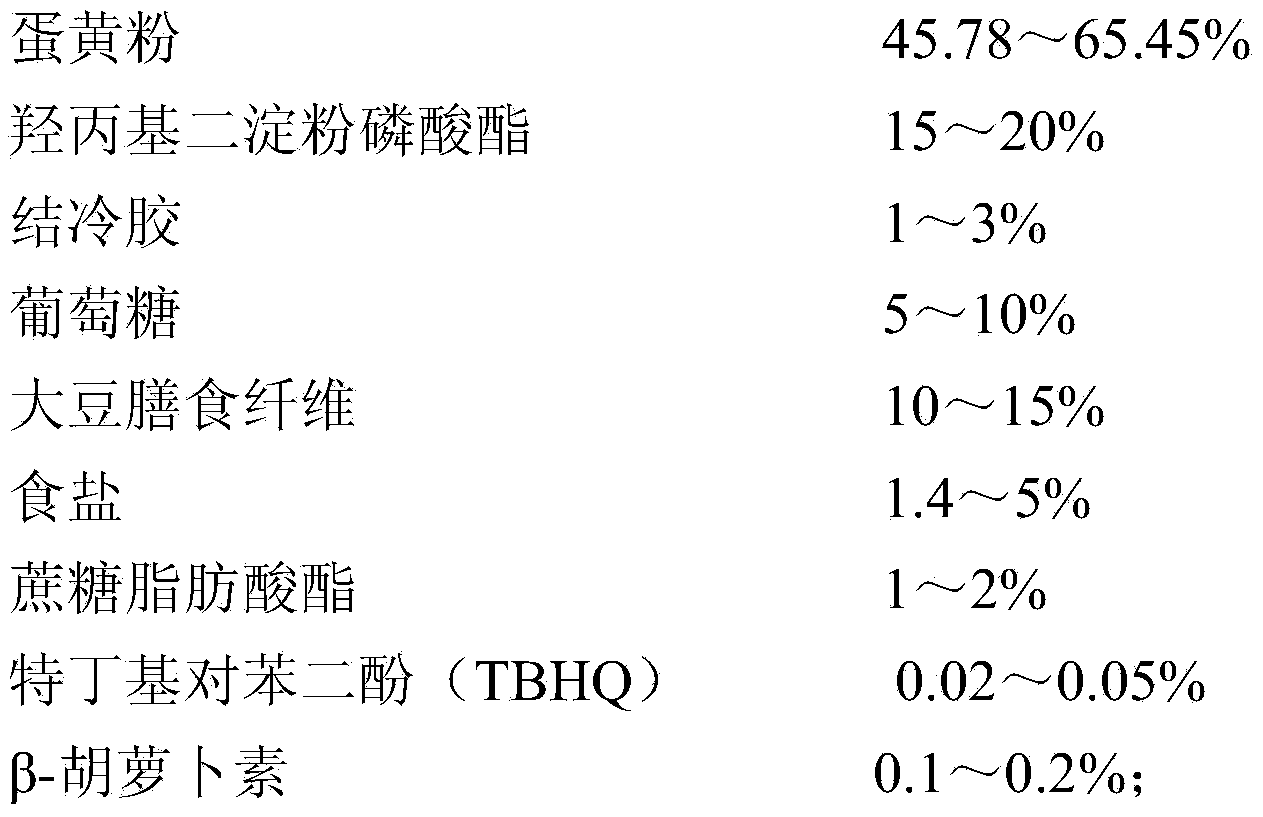

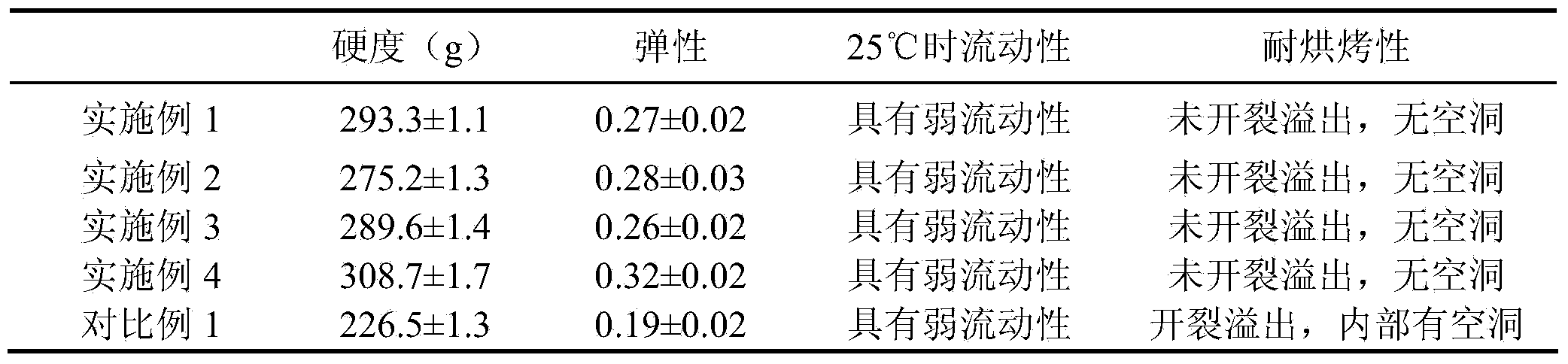

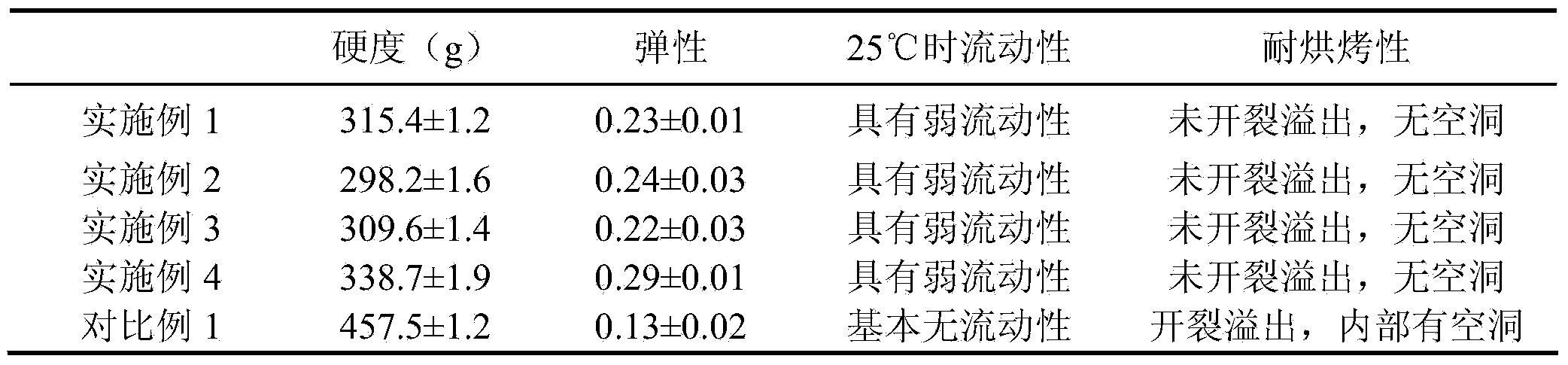

Quicksand-type stuffing with long shelf life and resistant to bake and premixed flour and manufacturing method thereof

The invention provides quicksand-type stuffing with a long shelf life and resistant to bake and premixed flour and a manufacturing method thereof. The premixed flour of the quicksand-type stuffing comprises, by mass percent, 45.78-65.45% of egg yolk powder, 15-20% of hydroxy propyl distarch phosphate, 1-3% of gellan gum, 5-10% of glucose, 10-15% of soybean dietary fibers, 1.4-5% of salt, 1-2% of sucrose fatty acid ester, 0.02-0.05% of tertiary butylhydroquinone and 0.1-0.2% of beta-carotene. The ingredients are mixed to obtain the premixed flour of the quicksand-type stuffing. The premixed flour is combined with malt syrup, anhydrous ghee, edible glycerol and citric acid so that the quicksand-type stuffing can be manufactured. The quicksand-type stuffing has taste and egg yolk flavor approximate to traditional golden quicksand-type stuffing, and is resistant to bake and long in shelf life.

Owner:广州合诚实业有限公司

Resin composition for insulation film, and insulation film and circuit board containing same

ActiveCN103319853AImprove heat resistanceLow dielectric constantPrinted circuit detailsPolymer sciencePtru catalyst

The invention provides a resin composition for an insulation film, and the insulation film and a circuit board containing the same. The resin composition comprises: (A) 100 parts by weight of epoxy resins; (B) 20 to 100 parts by weight of a polybutadiene styrene divinylbenzene graft terpolymer resin; (C) 2 to 20 parts by weight of di-tert-butylhydroquinone; (D) 5 to 50 parts by weight of a polyphenylene ether modified cyanate ester resin; and optionally containing at least one of the following components: (E) an inorganic filler, (F) a refined extending sealing agent and (G) a catalyst. By containing the specific components and proportions, the resin composition can achieve high heat resistance, low dielectric constant and low dissipation factor, and is halogen-free, and thus the resin composition can be applied in a protection film of a printed circuit board, an insulating protection film of an electronic building brick or a resin insulation film of a lead frame.

Owner:ELITE MATERIAL

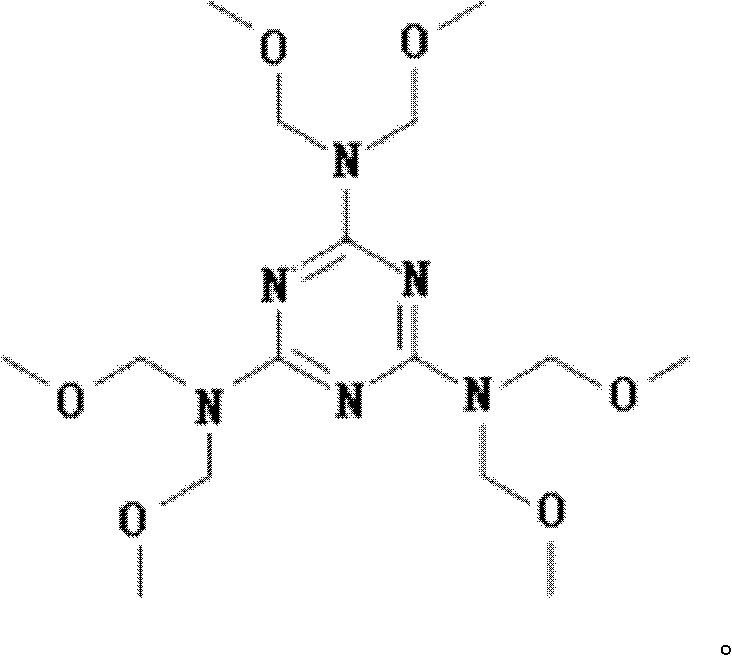

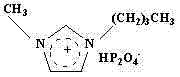

Method for preparing acrolein by catalyzing glycerin dehydration with solid-supported acidic ionic liquid

ActiveCN102267882ALow priceLow costOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystReaction temperature

The invention discloses a preparation method of acrolein, and relates to the field of acrolein preparation by catalyzing dehydration of glycerol. The preparation method is characterized in that: glycerol is used as a raw material, an immobilized ionic liquid is used as a catalyst, and acrolein is prepared by dehydration; the used ionic liquid is acidic ionic liquid [BMIM]BF4 (1-butyl-3-methylimidazolium terafluoroborate) or [BMIM]H2PO4, and the acidic ionic liquid is immobilized by impregnation; the molar selectivity of the acrolein prepared by adding 1-8% of hydroquinone used as a polymerization inhibitor to 10-60% of glycerol aqueous solution used as a reaction solution and reacting under the conditions of atmospheric pressure, reaction temperature of 240-360 DEG C and volume space velocity of 5-15 / h can reach 90.4%; and the conversion rate of glycerol can reach 100%. The preparation method has the advantages that the immobilized acidic ionic liquid has higher selectivity in the dehydration reaction of glycerol, the acrolein yield is higher, the reaction stability is good, and the life of the catalyst is long.

Owner:CHANGZHOU UNIV

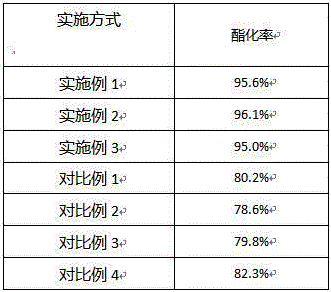

Preparation technology of tert-butyl acrylate

InactiveCN104987288AHigh yieldIncrease profitOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePtru catalyst

The invention discloses a preparation technology of tert-butyl acrylate. Acrylic acid, isobutene, an acidic catalyst and a polymerization inhibitor undergo an esterification reaction at 40-120DEG C under 1.0-5.0MPa under an isobutene volume space velocity of 0.5-5.0 / h according to a molar ratio of acrylic acid to isobutene of 1.0:1.0-5.0:1.0, the polymerization inhibitor comprises tert-butylcatechol, p-hydroxyanisole, 2,5-di-tert-butylhydroquinone and diphenylamine according to a weight ratio of 1:3:2:7, and the acidic catalyst is strong-acid cation exchange resin. The method can substantially improve the yield of tert-butyl acrylate.

Owner:QILU UNIV OF TECH

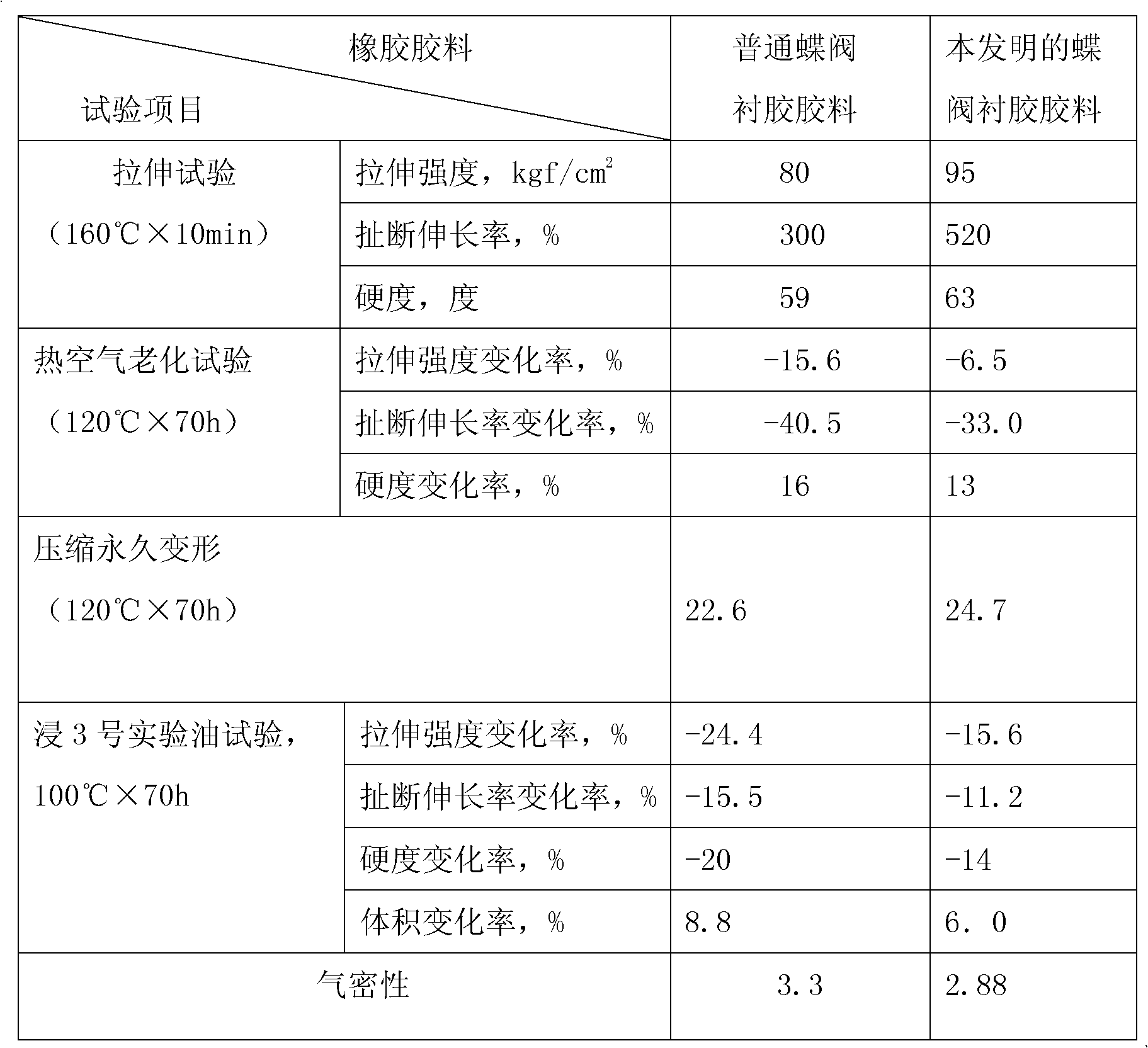

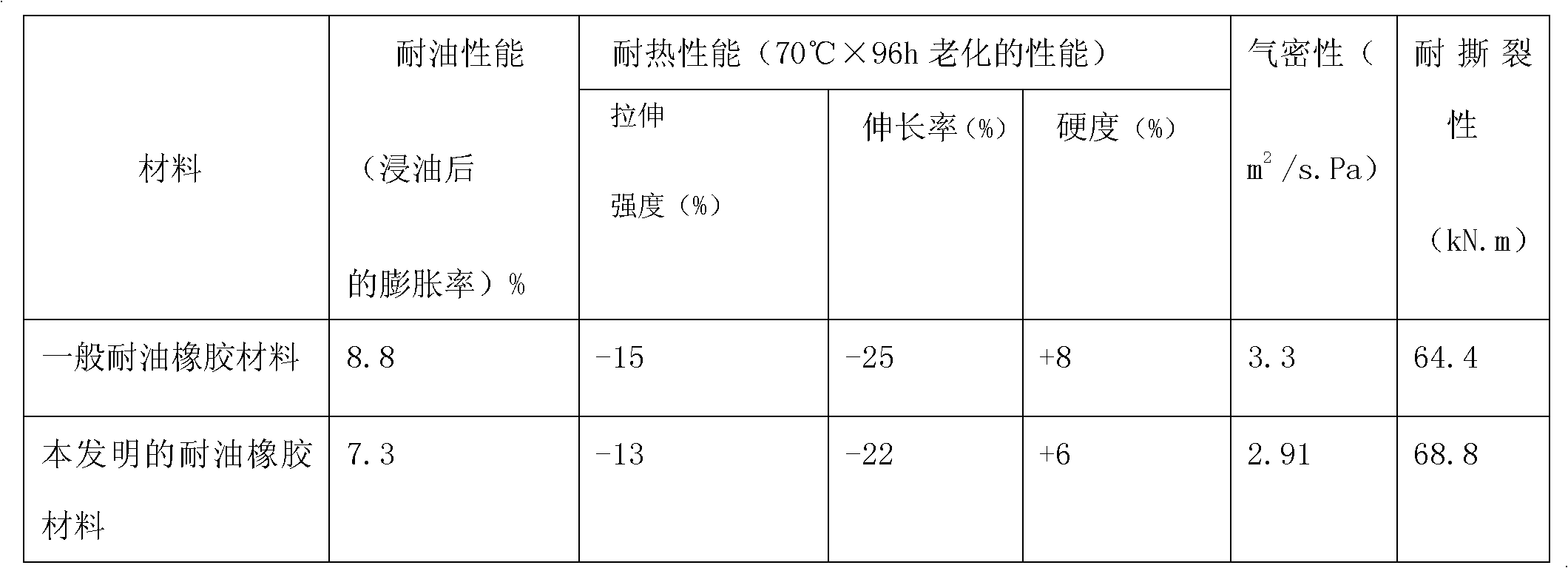

Liner rubber material of liner rubber butterfly valve and preparation method thereof

The present invention discloses a linear rubber material of a linear rubber butterfly, which is obtained through compounding rubber mass A and rubber mass B. The rubber mass A and rubber mass B are respectively composed of the following components in weight percentage: the rubber mass A is composed of: 85-95 part of nitrile butadine rubber, 0.3-0.5 part of sulphur, 4-6 parts of zinc oxide, 3-4 parts of eleaostearic acid, 2 parts of antioxidant, 1-2 parts of 5-di-tert-butylhydroquinone DTBHQ, 1-2 parts of antioxidant RD, 1-2 parts of antioxidant OD, 3-4 parts of paraffin, 22-25 parts of fast extruding furnace black N660, 62-65 parts of high-wearing-resistance furnace carbon N330, 18-22 parts of dioctyl, 25-35 parts of attapulgite, 3-4 parts of promoter M, 1-2 parts of promoter DM, and 1-2 parts of promoter PZ; and the rubber mass B is composed of: 85-95 parts of fluorubber 246, 1-2 parts of zinc stearate, 1-3 parts of antioxidant RD, 0.4-0.6 part of furnace black dispersing agent T-78,1-2 parts of antilux, 45-55 parts of fast extruding furnace black, 10-14 parts of pottery clay, 5-8 parts of dioctyl, 4-6 parts of lead tetraoxide, 0.8 part of vulcanizing agent DTDM, and 1-2 parts of promoter CZ. The linear rubber material of the invention has excellent comprehensive performance. The vulcanized liner rubber butterfly valve has the following characteristics: good air-tightness, high weather resistance, high low-temperature resistance, high oil resistance, low material cost, etc.

Owner:安徽金源流体控制技术有限公司

Method for catalytic synthesis of alpha-arbutin by using lipase

InactiveCN102517362AMild reaction conditionsThe process steps are simpleMicroorganism based processesFermentationALPHA-ARBUTINHydroquinone Compound

The invention relates to a method for catalytic synthesis of alpha-arbutin by using dissociative or immobilized candida lipase. The method comprises the process steps of selection of a reaction system, preparation of immobilized lipase, optimization of reaction conditions, extraction of a product, etc. According to the invention, hydroquinone and sugar mixed according to a mol ratio of 1: 1 to 1: 5 are added into a reaction medium, and lipase is used as a catalyst for a reaction; the reaction lasts for 10 to 120 h at a temperature of 20 to 60 DEG C, and a conversion rate of alpha-arbutin is as high as more than 95%; and the usage amount of lipase is 0.01 to 5 times of the weight of sugar. Alpha-arbutin is synthesized under the catalysis of dissociative or immobilized lipase in the method for the first time, and the method has the advantages of mild reaction conditions, repeated usability of lipase, a short production period, a simple extraction process for the product, etc., thereby enabling production cost to be substantially reduced.

Owner:BEIJING UNIV OF CHEM TECH

Polyether-ether-ketone resin as well as preparation method and application thereof

The invention discloses a preparation method of polyether-ether-ketone resin, and the method comprises the following steps of: adding solvent sulfolane, 4, 4'-DFBP and carbonate / bicarbonate into a reaction container under the condition that protective gas is introduced, heating the reaction container in case of stirring, and discharging moisture and air in a system; after the moisture in the system is completely evaporated, adding hydroquinone and a water-carrying agent in the process of continuously heating, wherein the temperature of the system is 100-200 DEG C; continuously heating, starting water-carrying reaction on the hydroquinone and the carbonate / the bicarbonate to generate the moisture, and continuously taking out the generated moisture by the water-carrying agent, distilling the water-carrying agent after the water carrying is completely carried out, starting polymerization reaction when the temperature reaches 245-265 DEG C, and stopping reaction after 1-5 hours. The invention further discloses polyether-ether-ketone prepared by the method, and an application of the prepared polyether-ether-ketone in a composite material.

Owner:KINGFA SCI & TECH CO LTD +1

Method for synthesizing alpha-arbutin by enzymic method through catalysis

InactiveCN102978265AImprove conversion rateIncrease productivityMicroorganism based processesFermentationBiotechnologyXanthomonas campestris

The invention discloses a method for synthesizing alpha-arbutin by an enzymic method through catalysis. The method comprises the following steps of: 1, culturing a slant seed: taking a xanthomonas campestris CGMCC (China General Microbiological Culture Collection Center) NO.1243 strain, and inoculating the xanthomonas campestris CGMCC NO.1243 strain in a slant culture medium for culturing; 2, culturing a liquid strain: selecting a ring strain, inoculating the ring strain in a basic fermentation culture medium, and placing on a table concentrator for oscillating and culturing to obtain a seed culture solution; 3, adding the seed culture solution in the basic fermentation culture medium, oscillating and culturing for 24-48h, freezing, centrifugally collecting thalli, washing the thalli with a PBS (Phosphate Buffer Solution) for 2-3 times, ultrasonically crushing at a low temperature, centrifuging, and taking supernate, namely intracellular crude enzyme; and 4, adding cane sugar and hydroquinone in the intracellular crude enzyme for reacting, and separating and purifying a reaction product to obtain the alpha-arbutin. The method disclosed by the invention has the advantages of high production efficiency, high transformation rate of the hydroquinone, low cost, short process flow and the like.

Owner:韦慧芳 +1

Preparation method of esterified material by utilizing polymerized rosin and methacrylic acid oxhydryl ester

InactiveCN102660193AImprove the ability of deep processingImprove oxidation resistanceNatural resin chemical modificationPtru catalystWarm water

The invention discloses a preparation method of esterified material by utilizing polymerized rosin and methacrylic acid hydroxyl ester. The method comprises the following steps of: fusing 10 parts by weight of polymerized rosin in a heating way, adding 0.1-2 parts by weight of catalyst and 0.5-2.5 parts by weight of polymerization inhibitor, dropwise adding 10-50 parts by weight of methacrylic acid hydroxyl ester, controlling the system temperature at 200-210 DEG C in the process of dropwise adding, and heating to 220-230 DEG C after dropwise adding so as to react for 3-8 hours; and cooling to 80 DEG C, adding 50-100 ml of gasoline so as to dissolve an esterified material, filtering, distilling under reduced pressure, washing with warm water, and drying under vacuum, so as to obtain the wine red and transparent esterified material, wherein the catalyst is zinc oxide, and the polymerization inhibitor is hydroquinone. The preparation method has the advantages that the raw materials are low in price and easy to obtain, the synthetic process is simple, the preparation method is environmentally-friendly and non-toxic, the prepared esterified material is good in oxidation resistance and thermal stability, and the like, thereby being widely applicable to the fields of coating materials, adhesives, ink, and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Preparation and application of isobutylcyanoacrylate medical adhesive

The present invention provides a medical adhesive which has the advantages of short adhesion time, good flexibility of adhesive layer, sufficient hemostasis, high adhesion strength and short break-off time. The invention is characterized in that the medical adhesive is manufactured by the following inventive formula and technique, wherein the inventive formula is as follows: 30-75 parts of alpha-isobutyl cyanoacetate by weight, 3.5-23.5 parts of formaldehyde by weight, 0.15-1.55 parts of polymerization inhibitor by weight, 0.1-15.5 parts of pH adjusting agent by weight, and 0.5-19.3 parts of stabilizing agent. The inventive technique comprises the following steps: executing polycondensation reaction with alpha-isobutyl cyanoacetate, formaldehyde and hexa-hydrogen pyridine as pH adjusting agent, executing suction-filtering to the product after water cleaning, and vacuum drying; adding the material which is executed with vacuum drying in a fractionating flask, then adding phosphoric acid as pH adjusting agent, tricresyl phosphate as stabilizing agent and hydrochinone as polymerization inhibitor, mixing to uniform, installing a capillary tube of SO2 protective gas, starting depolymerization, distilling, collecting the component with constant boiling point, and packaging or pouring-in. The medical adhesive can be applied to the aspects of medicine, health-care, beauty treatment, daily life, etc.

Owner:孙丽华

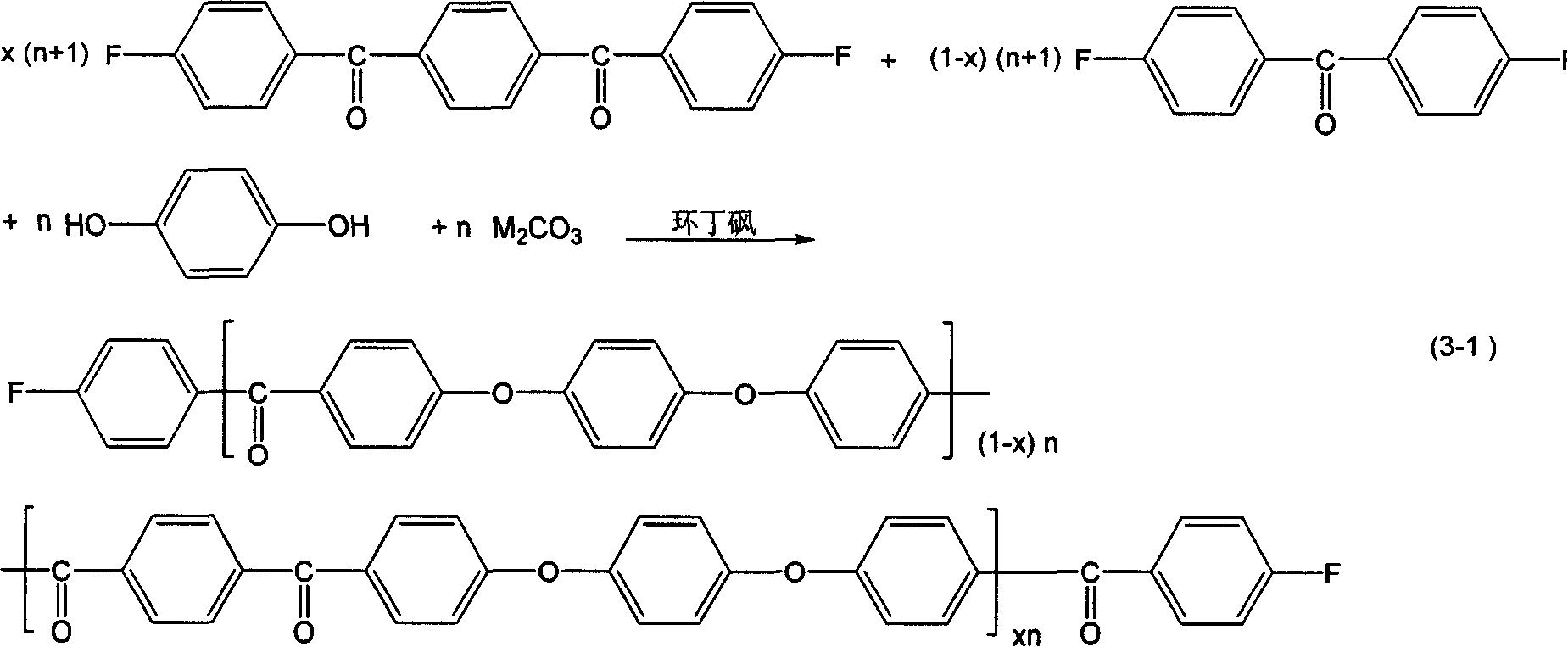

Synthesis method of ternary copolymer containing PEEK and poly(ether ether ketone ketone)s using sulfolane as solvent

The invention relates to a method for preparing polyetheretherketone and polyetheretherketone terpolymer by using sulfolane. It comprises following steps: the mole number of 4, 4'- difluoro diphenyl ketone and 4, 4'- difluoro triphen dione is more than that of eldopaque by 0.1-1%, the mle number of 4, 4'- difluoro triphen dione is 1-4% of that of total fluorin and acetone, the solid content in reaction system is 15-30%; filling dimethylbenzene with its mass being 10-20% of that of organic solvent, stirring, heating, adding mixed salt of alkali metal carbonate when monomer is totally dissolved and the temperature is between 75 to 85 Deg. C, reacting at constant temperature 230-260 Deg. C for 1-3 hours, stopping reaction, pouring product into cold water, cooling and disintegrating and filtering, boiling solid product with deionized water for several times, drying refined powder material in baking box, and getting said final product.

Owner:长春吉大特塑工程研究有限公司

Rice fertilizer synergist

The rice fertilizer synergist for each tone of fertilizer consists of RE 0.5-4.0 kg, borax 0.5-5.0 kg, hydroquinol 0.5-3.5 ke, cyanoguanidine 0.5-2.5 kg and silicon fertilizer 5.0-35.0 kg. It is solid powdered matter, water soluble, smell-less, safe and suitable for various varieties of rice, and has no toxic side effect and environmental pollution. It can raise the fertilizer utilization greatly and rice yield.

Owner:HUNAN AGRICULTURAL UNIV

Chloroprene rubber adhesive agent and preparation method thereof

InactiveCN103045134AWith finishFunctionalAldehyde/ketone condensation polymer adhesivesGraft polymer adhesivesPolymer scienceBenzoyl peroxide

The invention discloses a chloroprene rubber adhesive agent and a preparation method thereof, aiming at solving the problem that the attractive appearance of the shoes is affected because the existing synthetic material always becomes aged and yellow rapidly. The chloroprene rubber adhesive agent provided by the invention comprises chloroprene rubber, a solvent and an additive, wherein the additive consists of the following components based on the weight percentage of the chloroprene rubber: 10-20% of titanium dioxide, 5-10% of light calcium carbonate, 3-6% of zinc oxide, 7-10% of magnesium oxide, 0.15-0.3% of aluminate coupling agent, 20-25% of methyl methacrylate, 0.7-1.0% of benzoyl peroxide, 0.4-0.6% of hydroquinone, 0.4-0.7% of 2,6-di-tert butyl p-cresol and 15-20% of tert butyl phenolic resin; and the weight ratio of the chloroprene rubber to the solvent is 1: (5.2-6.5). The chloroprene rubber adhesive agent disclosed by the invention has double functions of coating and binding, and is resistant to become aged and yellow.

Owner:CHENGDU SHENGERJIA SCI & TECH

High oil-resistant sealing element rubber material and its preparation method

The invention discloses a high oil-resistant sealing element rubber material, which is mixed by A and B rubber compounds in equal proportion. The two rubber compounds have the following material components by weight: A rubber compound: 85-95 of nitrile-butadiene rubber, 0.3-0.5 of sulphur, 4-6 of zinc oxide, 3-4 of eleaostearic acid, 1-2 of an anti-oxidant 2, 5-ditert-butylhydroquinone-DTBHQ, 1-2 of an antiager RD, 1-2 of an antiager 4010NA, 3-4 of paraffin, 22-25 of fast extruded carbon black N660, 62-65 of high abrasion carbon black, 18-22 of dioctyl-phthalate, 25-35 of calcium carbonate, 3-4 of an accelerator DM, 1-2 of an accelerator TMTD, 1-2 of an accelerator TETD; B rubber compound: 82-87 of monohomopolymerized epichlorohydrin rubber, 12-18 of copolymerized epichlorohydrin rubber, 1-2 of zinc stearate, 1-3 of an antiager RD, 0.4-0.6 of Gum easy T-78, 1-2 of rhein wax, 45-55 of fast extruded carbon black, 10-14 of diatomite, 5-8 of dioctyl-phthalate, 4-6 of lead tetraoxide, 0.4-0.6 of sulphur, and 1-2 of an accelerator Na-22. The rubber material can be used to produce oil-resistant sealing elements (oil cylinder sealing gaskets) with the advantages of oil resistance, thermoresistance, air impermeability, flame retardation and tear resistance and low cost.

Owner:芜湖禾田汽车工业有限公司

Method for preparing whitening cosmetic containing dogwood extract

ActiveCN103263363AInhibit biosynthesisInhibitory activityCosmetic preparationsToilet preparationsPhosphoric Acid EstersCornus officinalis fruit extract

The invention discloses a method for preparing a whitening cosmetic containing a dogwood extract, including: a first step of extracting extracts of dogwood, bupleurum and rose by ethanol; a second step of heating C18 alcohol, inositol hexaphosphate, glycerol, and stearic acid for melting, adding tert-Butylhydroquinone for dissolving to get an oil phase; a third step of adding borax, glycerol monostearate and purified water into Chinese herb extracts to get a water phase; and a fourth step of adding the oil phase into the water phase for emulsification, and adding essence to get the cosmetic with the effect of whitening and removing freckles. The cosmetic can improve skin metabolism, promote blood circulation, increase skin nutrition, effectively remove free radicals, eliminate pigmentation, fade skin wrinkles and pigmentation, and make skin to be delicate, smooth, white and flexible.

Owner:GUANGDONG BAWEI BIOLOGICAL TECH CO LTD

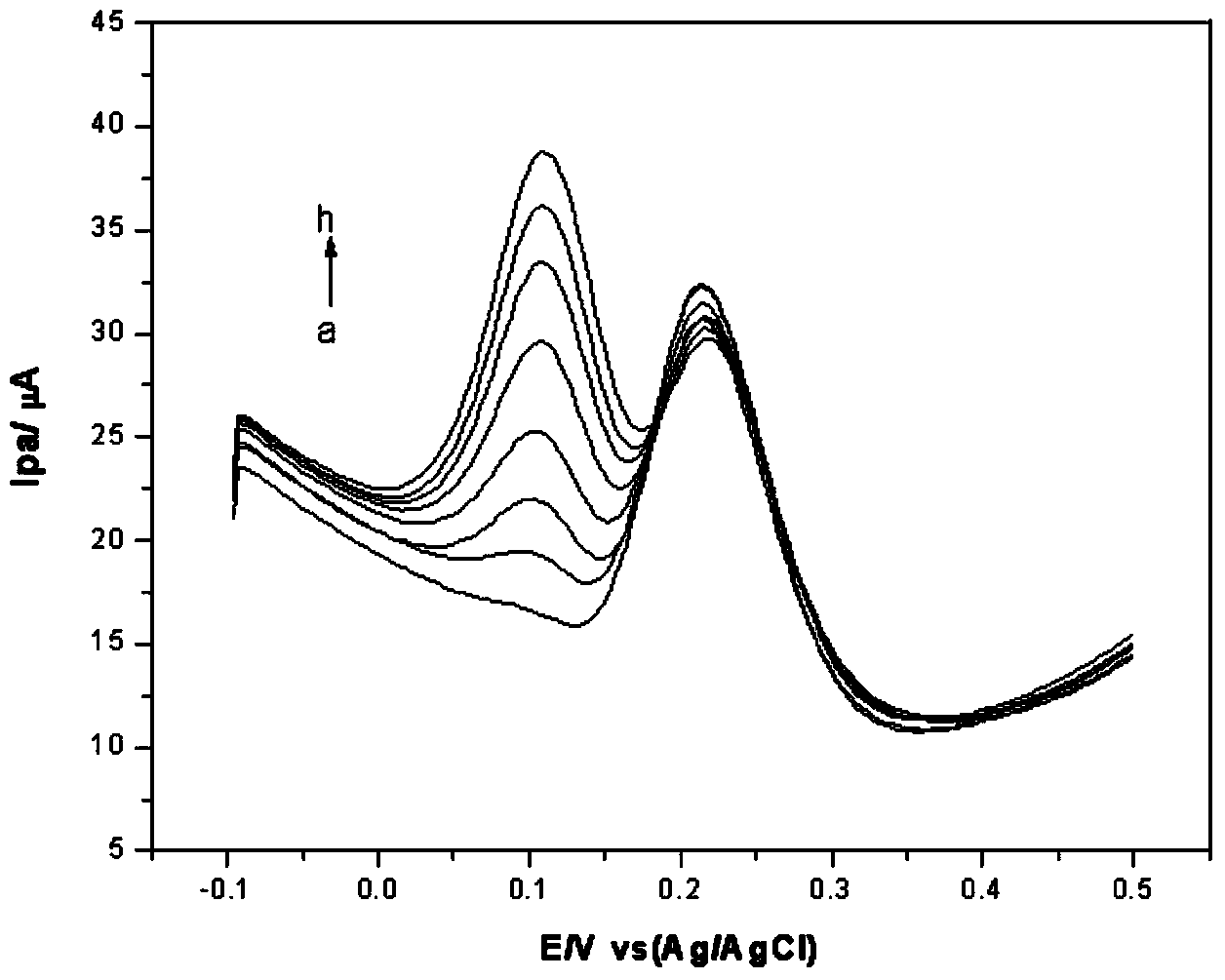

Preparation method of glassy carbon electrode for detecting pyrocatechol and/or paradioxybenzene in water

InactiveCN104280436AHigh sensitivityImprove stabilityMaterial electrochemical variablesNitrogen doped grapheneUltrasonic dispersion

The invention relates to a preparation method of a glassy carbon electrode for detecting pyrocatechol and / or paradioxybenzene in water. The method comprises the following steps: (1) adding deionized water into nitrogen doped graphene oxide until the concentration of the nitrogen doped graphene oxide in the deionized water is 2mg / mL, and carrying out ultrasonic dispersion for 2 hours to obtain dispersion liquid, wherein the nitrogen doped graphene oxide is synthesized from ammonium carbonate and monolayer graphene oxide as a precursor according to a weight ratio of (100 to 1) to (120 to 1) by virtue of a hydrothermal method; (2) polishing a bare glass carbon electrode with an effective diameter being 3mm to form a mirror surface, then sequentially carrying out ultrasonic treatment in absolute ethyl alcohol and deionized water for 5 minutes and drying; and (3) dropwise adding 10 microliter of dispersion liquid prepared by the step (1) on the surface of the bare glass carbon electrode treated by the step (2), and then drying to obtain the glassy carbon electrode. The glassy carbon electrode prepared by the method can be used for detecting pyrocatechol and / or paradioxybenzene in water, and is high in sensitivity, high in stability and high in repeatability.

Owner:GUANGZHOU INGSENS SENSOR TECH

Processed and roasted coffee bean and method for production of processed and roasted coffee bean

The present invention provides refined roasted coffee beans having a Hunter L value of 10 to 30 and a hydroxyhydroquinone content of not higher than 30 mg / kg by contacting an aqueous solvent with raw material roasted coffee beans. The invention also provides a process for producing refined roasted coffee beans, which includes contacting raw material roasted coffee beans having a Hunter L value of 12 to 35, with coffee bean-derived extract-containing water selected from water containing an extract derived from roasted coffee beans having a Hunter L value of 40 or more and water containing an extract derived from raw coffee beans.

Owner:KAO CORP

Novel electronic package composite material and fabrication method thereof

ActiveCN105789145AHigh thermal conductivityImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesPolyvinyl alcoholAluminium alloy

The invention provides a novel electronic package composite material and a fabrication method thereof. The fabrication method comprises the following steps of firstly, mixing silicon carbide, corn starch, maltodextrin powder, carbamide, natural japan tallow, erucyl amide, nanometer silicon dioxide, thermoplastic polyimide, polyvinyl formal, waterborne polyurethane, tertiary butylhydroquinone, calcium carbonate and water, ball-milling the mixture by a ball milling machine, placing the mixture in a baking oven for drying after stirring the mixture by a high-speed agitator, and sieving the mixture to remove blocks and large particles; secondly, placing the obtained product in a die, carrying out compression molding, and placing the product in a muffle furnace for sintering to obtain a pre-fabricated member; and finally, carrying out vacuum press infiltration on the pre-fabricated member, 6061 aluminum alloy and high-purity aluminum to obtain the novel electronic package composite material. The novel electronic package composite material provided by the invention is high in heat conductivity and has high heat dissipation performance, meanwhile, the novel electronic package composite material is relatively low in thermal expansion coefficient and stable in structure and performance.

Owner:JIANGSU TETRA NEW MATERIAL TECH

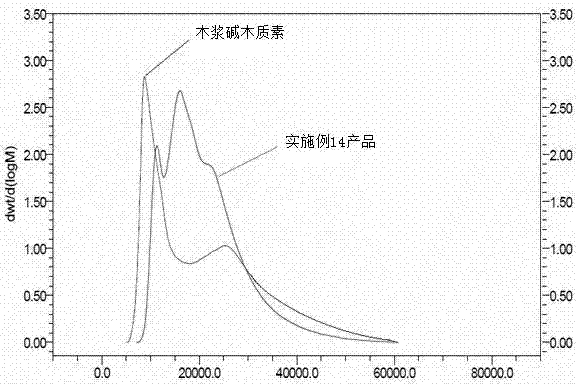

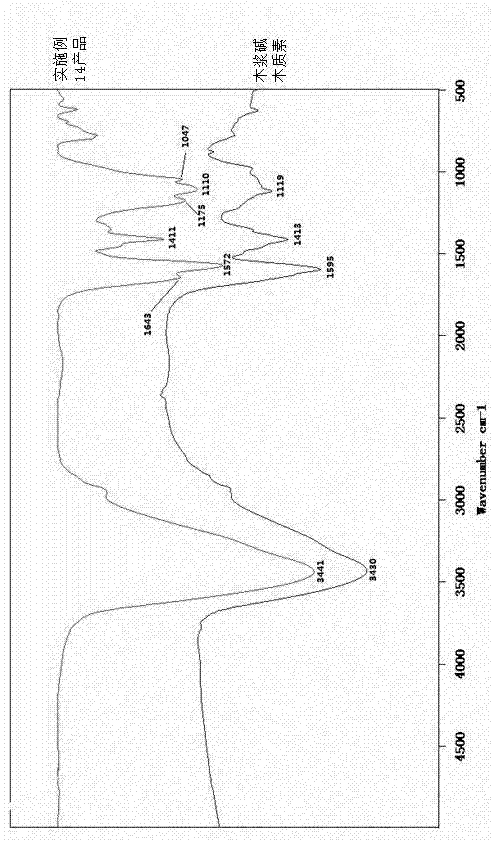

Lignin serial coal water slurry dispersing agent and preparation method thereof

ActiveCN103045317AIncreased average molecular massImprove hydrophilicityLiquid carbonaceous fuelsSulfite saltPolyethylene glycol

The invention relates to lignin serial coal water slurry dispersing agent and a preparation method thereof, and belongs to the technical field of dispersing agent which is prepared by coal water slurry. The dispersing agent comprises the following raw material components in parts by weight: 1,000 parts of alkali lignin, 20 to 50 parts of polyethylene glycol, 2 to 10 parts of carboxylic acid, 1 to 5 parts of concentrated sulfuric acid, 0.1 to 1 part of hydroquinone, 20 to 60 parts of acrylic acid, 60 to 150 parts of vinyl monomer, 200 to 400 parts of sodium sulfite, 300 to 500 parts of acetaldehyde solution, 30 to 50 parts of oxidant and 10 to 20 parts of reducing agent. Compared with the prior art, the lignin serial coal water slurry dispersing agent adopts the alkali lignin as a raw material, so that the cost is reduced, the average molecular mass of the lignin is remarkably improved, the hydrophily is obviously enhanced, and the dispersing effect is prominently improved; and in addition, the dispersing agent has the advantages of low cost, simple preparation technique, more generality of raw materials, wide sources of the raw materials, cheaper price and good modifying effect; and the resource utilization is implemented for wastes, so that the environmental pollution from the wastes is reduced.

Owner:DONGFANG ELECTRIC CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com