Resin composition for insulation film, and insulation film and circuit board containing same

A resin composition and composition technology, applied in the direction of printed circuit components, etc., can solve problems such as inability to meet advanced applications, and achieve the effects of good dielectric properties and fast cross-linking reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

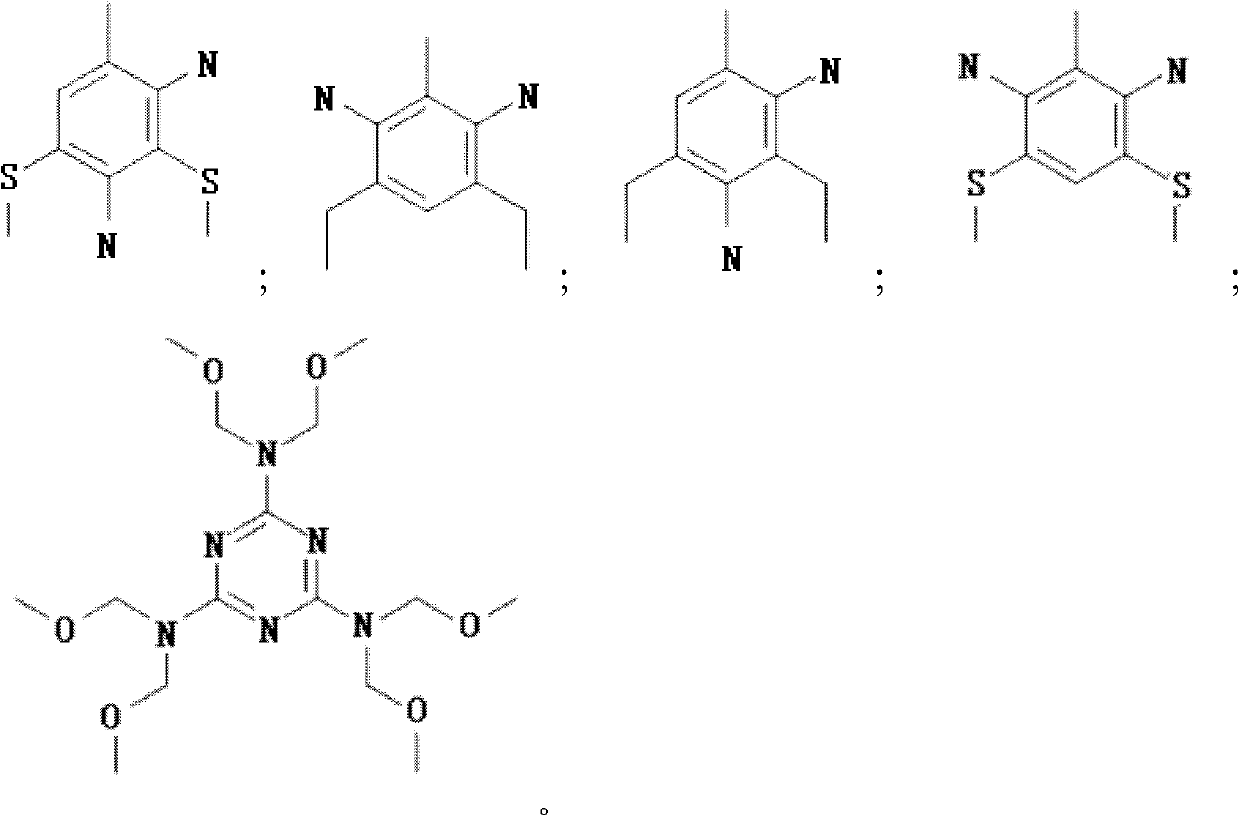

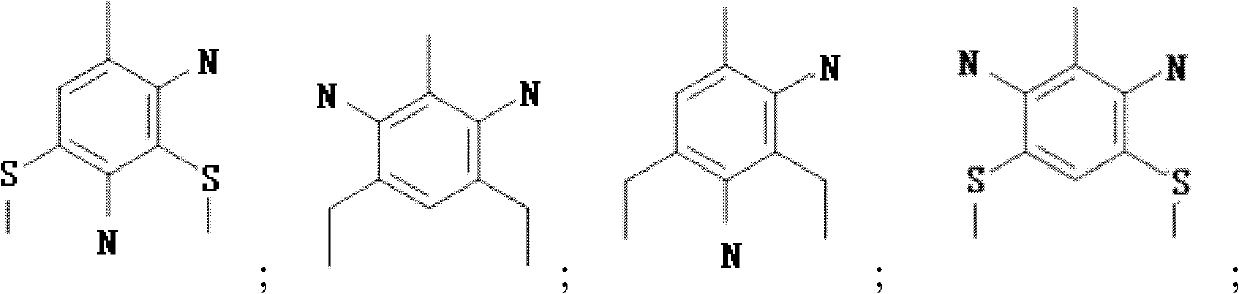

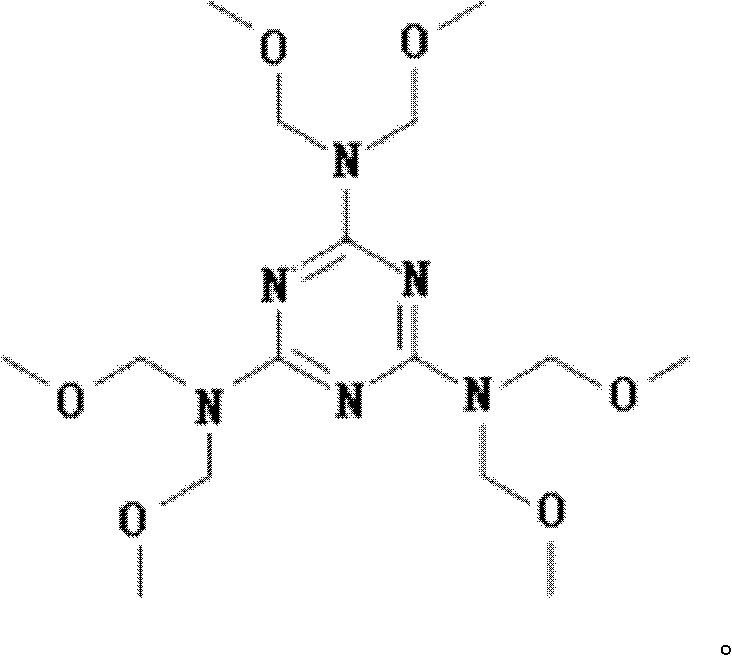

Method used

Image

Examples

Embodiment 1

[0034] 20 g of polybutadiene-styrene-divinylbenzene terpolymer resin (Ricon 257) was dissolved in 180 g of toluene to prepare a 10% toluene solution. Add 100g epoxy resin (HP-6000), 6g di-tert-butylhydroquinone (DTBHQ), 15g polyphenylene ether modified cyanate ester resin (BTP- 6020S), 50g of spherical silica (Suzuki Grease B-6C) as an inorganic filler, 10g of hydrotalcite (inorganic filler), 4g of elongation adhesive (ethacure 100), 0.5g of tetraphenylboron tetrabenzene Base phosphine (catalyst) and 0.008g cobalt naphthoate (catalyst), 2g dicumyl peroxide (DCP) and 3g di-tert-butyl peroxide (perbutyl D). Then, 200 g of 10 wt% Ricon 257-containing toluene solution was added to the aforementioned reaction flask to prepare a dispersed resin composition.

Embodiment 2

[0036] 30 g of polybutadiene-styrene-divinylbenzene terpolymer resin (Ricon 257) was dissolved in 170 g of toluene to prepare a 15% toluene solution. Add 100g epoxy resin (PB-3600), 2g di-tert-butyl hydroquinone (DTBHQ), 30g polyphenylene ether modified cyanate ester resin (BTP-6020S), and 100g as inorganic in a 1000ml reaction flask. Filled spherical silica (Suzuki Grease B-6C), 10g hydrotalcite powder (inorganic filler), 4g refining extension adhesive (ethacure 100), 0.5g tetraphenyl boron tetraphenyl phosphine (catalyst) and 0.008g cobalt naphthoate (catalyst), 2g dicumyl peroxide (DCP) and 3g di-tert-butyl peroxide (perbutyl D). Then, 200 g of 15 wt% Ricon 257-containing toluene solution was added to the aforementioned reaction flask to prepare a dispersed resin composition.

Embodiment 3

[0038] 40 g of polybutadiene-styrene-divinylbenzene terpolymer resin (Ricon 257) was dissolved in 160 g of toluene to prepare a 20% toluene solution. Add 100g epoxy resin (NC-3000), 6g di-tert-butyl hydroquinone (DTBHQ), 45g polyphenylene ether modified cyanate ester resin (BTP-6020S), 120g as inorganic Filled spherical silica (Suzuki Grease B-6C), 10g hydrotalcite powder (inorganic filler), 4g refining extension adhesive (ethacure 100), 0.5g tetraphenyl boron tetraphenyl phosphine (catalyst) and 0.008g cobalt naphthoate (catalyst), 2g dicumyl peroxide (DCP) and 3g di-tert-butyl peroxide (perbutyl D). Then, 200 g of 20 wt% Ricon 257-containing toluene solution was added to the aforementioned reaction flask to prepare a dispersed resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com