Method for preparing acrolein by catalyzing glycerin dehydration with solid-supported acidic ionic liquid

A technology of acidic ionic liquid and catalyzed glycerin, which is applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of organic compounds, etc., can solve the problems of harsh reaction conditions, high cost, and no one has tried it, and achieve low raw material cost, The effect of fast speed and low raw material price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

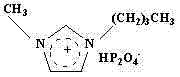

Image

Examples

Embodiment 1

[0026] Take 16.41g of 1-methylimidazole in a four-necked flask, then add toluene, add 32.88g of bromo-n-butane in a constant pressure dropping funnel, then heat to 80°C and react for 12 hours to obtain a pale yellow liquid and Colorless liquid, a light yellow liquid was separated, washed with ethyl acetate, and dried in a vacuum drying oven for 8 hours to obtain a light yellow liquid [BMIM]Br. Take 28.55g [BMIM]Br in a four-necked flask and add HBF dropwise 4 , Heated in a water bath to 65°C, reacted for 6 hours to obtain a viscous liquid, washed 3 times with ether, and dried in vacuum to obtain an ionic liquid [BMIM]BF 4 .

[0027] The activated carbon (AC) is crushed to 18-30 mesh, the catalyst is prepared by the impregnation method, and the amount of acidic ionic liquid [BMIM] BF4 used is calculated according to the loading amount of 10% (based on the weight of the carrier as 10g), and anhydrous Ethanol is used as a solvent, the acidic ionic liquid is weighed to prepare a solu...

Embodiment 2

[0030] Ionic liquid [BMIM]BF 4 The synthesis is as in Example 1. The activated carbon (AC) is crushed to 18-30 mesh, the catalyst is prepared by the impregnation method, and the acidic ionic liquid [BMIM]BF is calculated according to the load of 15%. 4 Use absolute ethanol as the solvent, weigh the acidic ionic liquid to prepare a solution, then pour the broken carrier into the prepared acidic ionic liquid solution, and immerse it for 24 hours. After drying and calcining, the catalyst is obtained.

[0031] Put 5ml 18~30 mesh with 15% [BMIM]BF 4 The / AC catalyst is charged into the middle section of a fixed-bed reactor with continuous flow at normal pressure, and the upper and lower sections are filled with 10ml quartz sand. After the system is checked and sealed, slowly increase the temperature of the catalyst bed to 260°C, and then drive a 15% aqueous bioglycerin solution containing 3% polymerization inhibitor hydroquinone into the fixed bed reactor through a micro pump. The li...

Embodiment 3

[0033] Ionic liquid [BMIM]BF 4 The synthesis is as in Example 1, the SiO 2 Crush to 18-30 mesh, prepare the catalyst by impregnation method, calculate the acidic ionic liquid [BMIM]BF according to the load of 20% 4 Use absolute ethanol as the solvent, weigh the acidic ionic liquid to prepare a solution, then pour the broken carrier into the prepared acidic ionic liquid solution, and immerse it for 24 hours. After drying and calcining, the catalyst is obtained.

[0034] Load 5ml 18~30 mesh with 20% [BMIM]BF 4 / SiO 2 The catalyst is charged into the middle section of a fixed-bed reactor with continuous flow at normal pressure, and the upper and lower sections are filled with 10 ml of quartz sand. After the system is checked and sealed, slowly increase the temperature of the catalyst bed to 280°C, and then drive a 25% aqueous bioglycerin solution with 4% polymerization inhibitor hydroquinone added into the fixed bed reactor through a micro pump. The liquid hourly space velocity is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com