Patents

Literature

63 results about "Glycerol dehydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

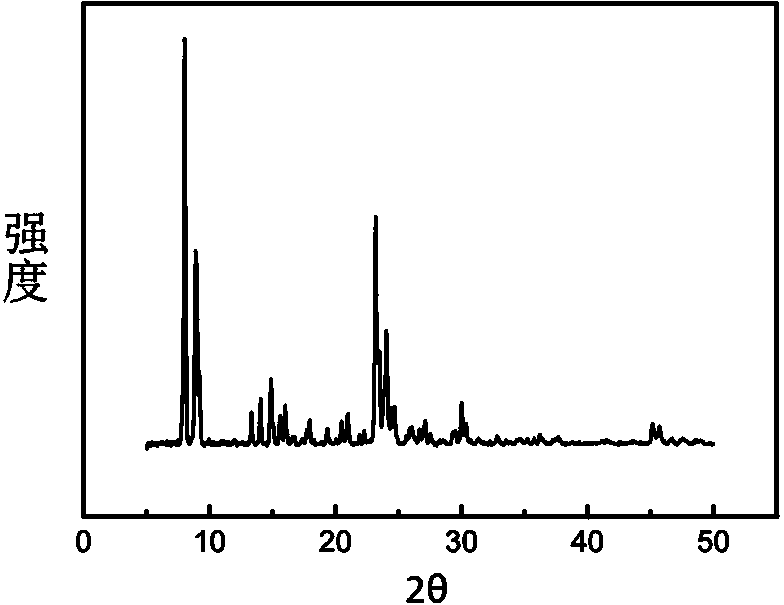

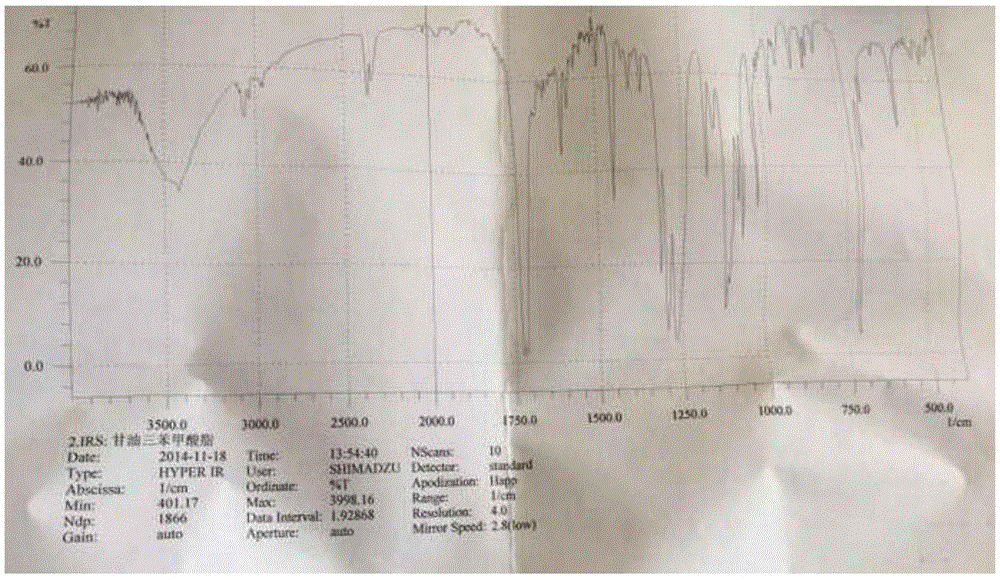

Heteropolyacid-modified Zr-MOF catalyst as well as preparation method and application thereof

InactiveCN104857988ASolution to short lifeHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsThermal stabilityGlycerol dehydration

The invention discloses a heteropolyacid-modified Zr-MOF catalyst which is modified by heteropolyacid through a Zr-MOF carrier. The invention further discloses a preparation method for the catalyst and an application of the catalyst to reaction of preparing acraldehyde by catalyzing glycerol dehydration. Compared with the prior art, the obtained catalyst is long in service life, and the glycerol conversation rate and the acraldehyde selectivity are high; the Zr-MOF carrier is good in thermal stability and chemical stability, and the framework structure is kept stable; theacting force between the heteropolyacid and the Zr-MOF carrier is relatively strong, so that the heteropolyacid-modified Zr-MOF catalyst is not liable to lose.

Owner:YANCHENG INST OF TECH

Process for preparing acrolein by glycerin dewatering

ActiveCN101070276AHigh activityHigh selectivityMolecular sieve catalystsOrganic compound preparationAlcoholGlycerol

This invention relates to acidity zeolite catalyst used for glycerol dehydration to perpare acrolein and the reaction craft. Glycerine directly dehydrate to generate acrolein under the condition of acidity zeolite catalyst, 200 to 500deg temperature, 0.001 to 3.0MPa pressure and 0.1 to 100.0h - 1 liquid airspeed, at the same time produce byproduct pyruvic alcohol. The raw material raw glycerine could be mixed liquor of water solution, alcosol, fatty acid ester solution at any ratio.

Owner:SHANGHAI HUAYI NEW MATERIAL

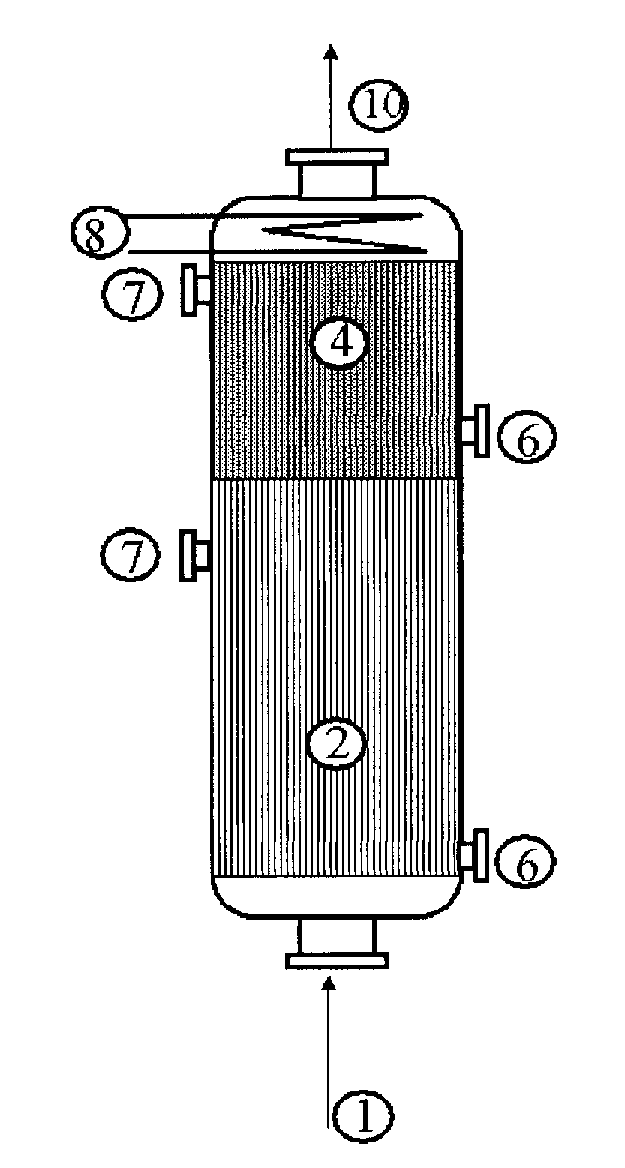

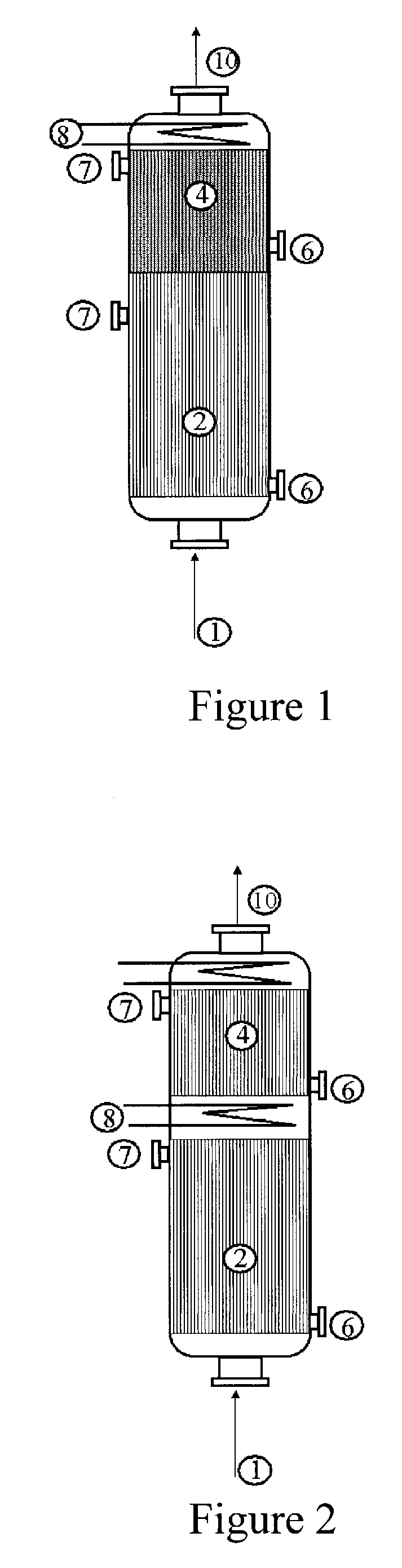

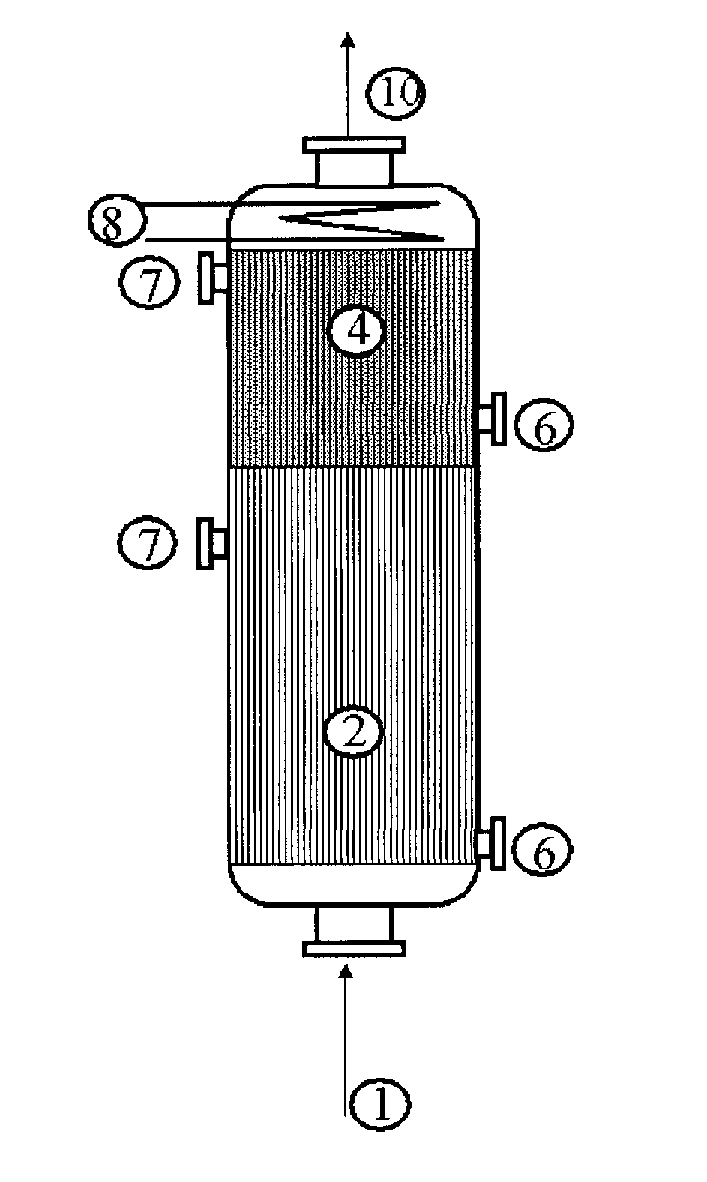

Method for preparing acrylic aldehyde by biological glycerol dehydration

ActiveCN101417928AReduce manufacturing costWide variety of sourcesMolecular sieve catalystsOrganic compound preparationHeteropoly acidGlycerol

The invention discloses a preparation method of acrolein, taking biological glycerol as the raw material and the modified zeolite supported heteropolyacid as catalyst, the method prepares acrolein directly by dehydration reaction. 18 to 30 catalyst are put in the middle section of a normal pressure continuous fixed bed reactor, with the volume space velocity of 1 to 10 h<-1>; under the protection of N2, the catalyst bed raises the temperature to 180 to 540 DEG C, and the biological glycerol solvent which is added with inhibitor is put into the fixed bed reactor from a micro pump; after gasified, the glycerine solution reacts by the catalyst bed. After reaction, the product is absorbed by acetone, then is separated and purified, thus obtaining acetone. The invention adopts the alkali metal, phosphoric oxides, alkali metal compound improved catalyst as carrier to carry heteropoly acid catalyst which is green and environmental catalyst and has the advantages of high activity, regeneration property, no pollution, simple reaction, operation process, low production cost, high mole selectivity of acrolein and high conversion rate of biological glycerol.

Owner:溧阳常大技术转移中心有限公司

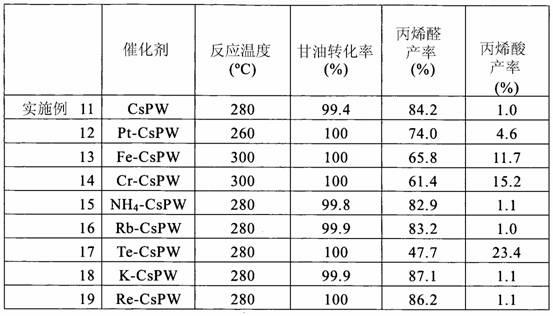

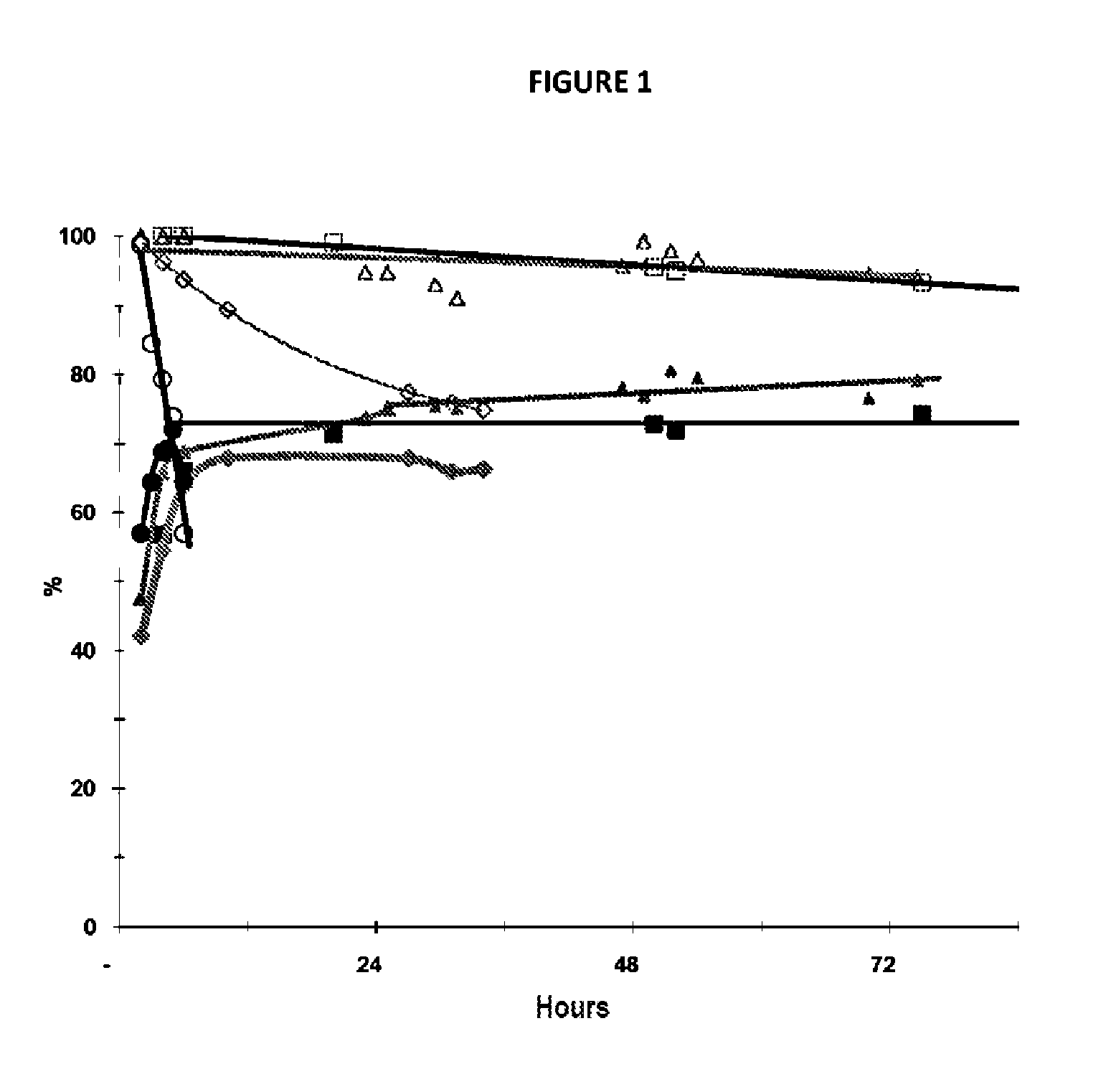

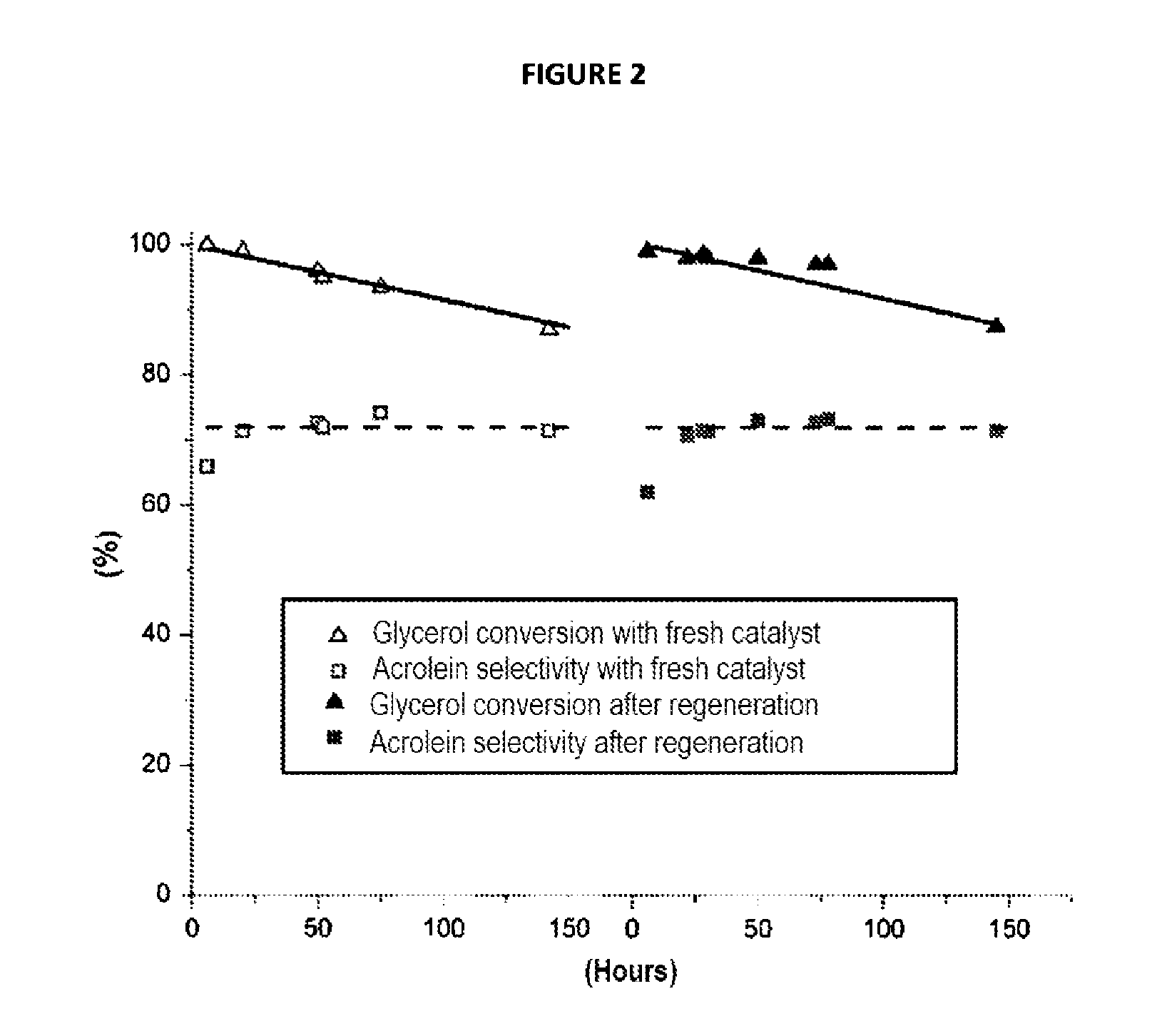

Process for manufacturing acrolein or acrylic acid from glycerin

InactiveCN102066301APhysical/chemical process catalystsOrganic compound preparationPolymer sciencePtru catalyst

The subject of the present invention is a process for preparing acrolein by dehydration of glycerin, characterized in that the dehydration is carried out in the presence of a catalyst comprising mainly a compound in which protons in a heteropolyacid are exchanged at least partially with at least one cation selected from elements belonging to Group 1 to Group 16 of the Periodic Table of Elements. The process according to the invention permits to obtain acrolein at higher yield.

Owner:ARKEMA FRANCE SA

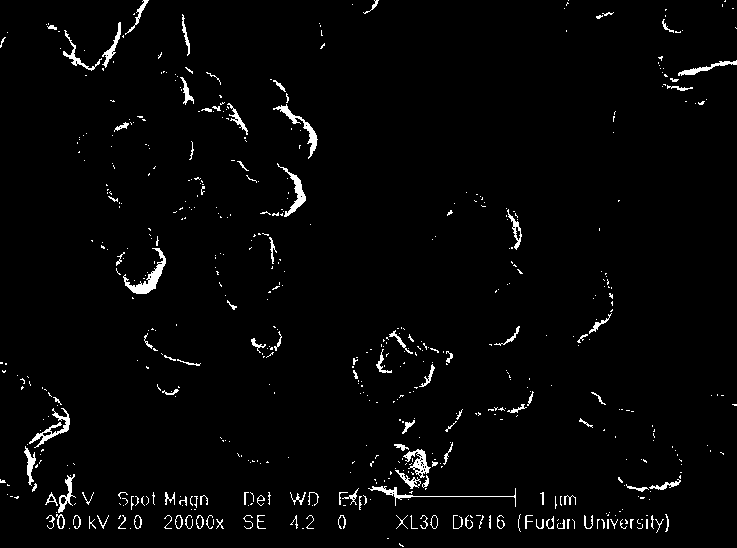

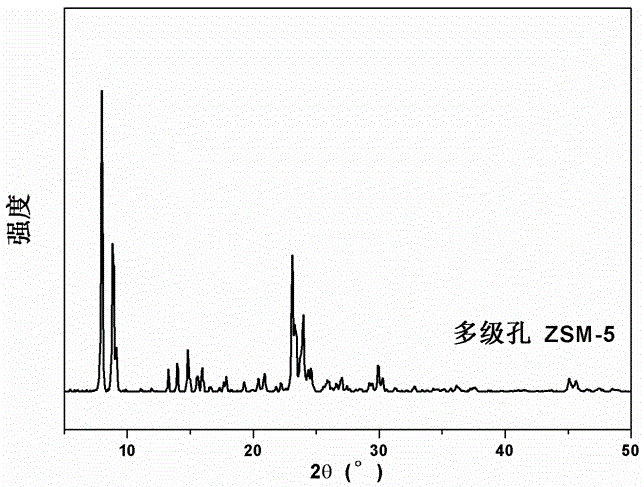

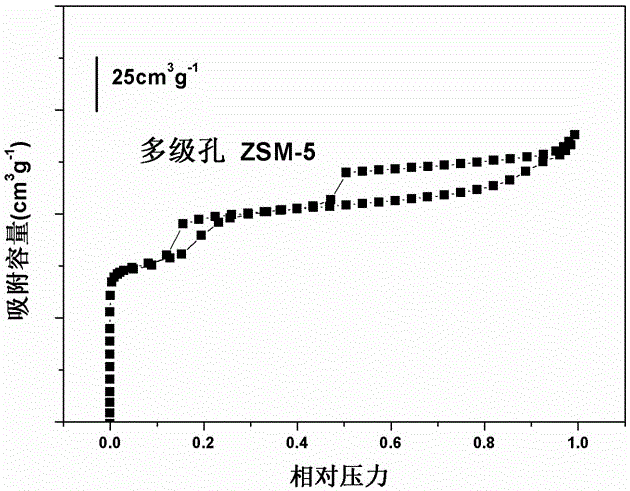

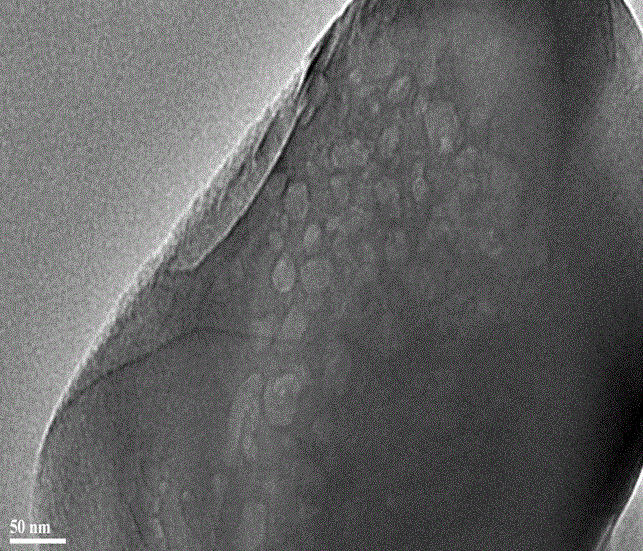

Hierarchical porous ZSM-5 zeolite catalyst for preparing acrolein through glycerin dehydration as well as preparation method and application of hierarchical porous ZSM-5 zeolite catalyst

InactiveCN103638965AHigh activityHigh selectivityMolecular sieve catalystsOrganic compound preparationInorganic saltsPtru catalyst

The invention belongs to the technical field of chemical catalysts, particularly relates to a hierarchical porous ZSM-5 zeolite catalyst for preparing acrolein through glycerin dehydration as well as a preparation method and application of the hierarchical porous ZSM-5 zeolite catalyst and also provides a method for synthesizing hierarchical porous ZSM-5 zeolite with high crystallinity, controllable particle size, controllable Si / Al ratio and controllable appearance at high yield, low time consumption and low (no) template agent dosage, wherein the hierarchical porous ZSM-5 zeolite is synthesized by introducing a small amount of MFI zeolite crystal seeds and parts of inorganic salt additives to a general synthesis system (a silicon source, an aluminum source, an alkaline source and water) and regulating the synthesis ratio and reaction conditions. The prepared catalyst has the characteristics such as controllable quantity of acid sites, large special surface area, short mass transfer path and the like, can be used for the catalytic reaction for preparing acrolein through the glycerin dehydration and has favorable catalytic activity, selectivity and stability.

Owner:FUDAN UNIV

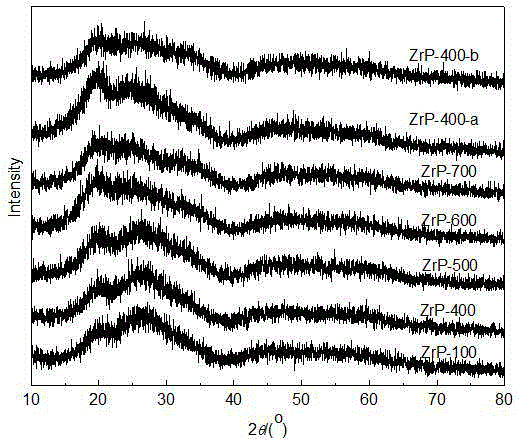

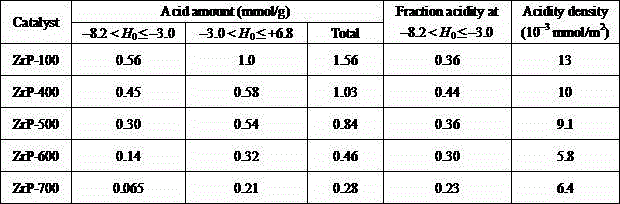

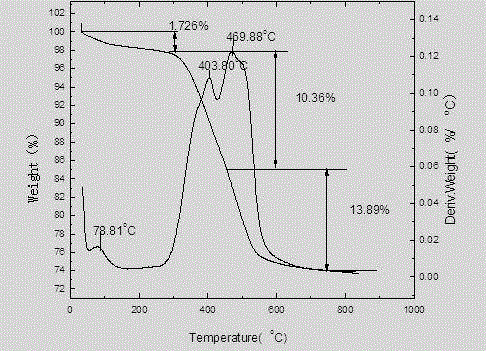

Zirconium phosphate catalyst and its application in preparation of acrolein through glycerin dehydration

InactiveCN104368368AHigh catalytic activityImprove stabilityPhysical/chemical process catalystsOrganic compound preparationPtru catalystPhysical chemistry

The invention relates to a catalyst for preparing acrolein through glycerin dehydration, and a preparation method thereof. The catalyst is prepared through co-precipitating an ammonium biphosphate solution (NH4H2PO4) and a ZrOCl2 solution, the activity of the catalyst is closely related to the acid center on the surface, and the roasting temperature can change the strength and number of the acid center on the surface of the catalyst. The activity of the catalyst increases with the roasting temperature and is maximum when the roasting temperature reaches 400DEG C, and higher roasting temperature causes the decrease of the yield of acrolein on the catalyst. The zirconium phosphate catalyst for the preparation of acrolein through glycerin dehydration has the advantages of high activity and good reaction stability, and is a very promising glycerin dehydration catalyst.

Owner:EAST CHINA UNIV OF SCI & TECH

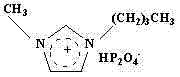

Method for preparing acrolein by catalyzing glycerin dehydration with solid-supported acidic ionic liquid

ActiveCN102267882ALow priceLow costOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystReaction temperature

The invention discloses a preparation method of acrolein, and relates to the field of acrolein preparation by catalyzing dehydration of glycerol. The preparation method is characterized in that: glycerol is used as a raw material, an immobilized ionic liquid is used as a catalyst, and acrolein is prepared by dehydration; the used ionic liquid is acidic ionic liquid [BMIM]BF4 (1-butyl-3-methylimidazolium terafluoroborate) or [BMIM]H2PO4, and the acidic ionic liquid is immobilized by impregnation; the molar selectivity of the acrolein prepared by adding 1-8% of hydroquinone used as a polymerization inhibitor to 10-60% of glycerol aqueous solution used as a reaction solution and reacting under the conditions of atmospheric pressure, reaction temperature of 240-360 DEG C and volume space velocity of 5-15 / h can reach 90.4%; and the conversion rate of glycerol can reach 100%. The preparation method has the advantages that the immobilized acidic ionic liquid has higher selectivity in the dehydration reaction of glycerol, the acrolein yield is higher, the reaction stability is good, and the life of the catalyst is long.

Owner:CHANGZHOU UNIV

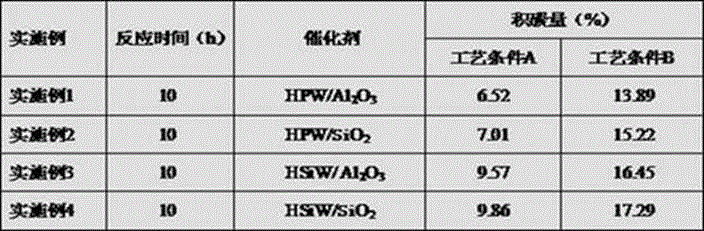

Process for preparing acrylic aldehyde by using selective glycerol dehydration and preparation method of catalyst thereof

InactiveCN101879456AHigh activityIncrease reaction rateOrganic compound preparationCarbonyl compound preparationPhosphomolybdic acidFixed bed

The invention discloses a process for preparing acrylic aldehyde by using selective glycerol dehydration and a preparation method of a catalyst thereof. Heteropolyacid / a carrier is disclosed in the expression of the catalyst, wherein the heteropolyacid is one of silicotungstic acid, phosphotungstic acid and phosphomolybdic acid, and the carrier is one of activated aluminium oxide, kieselguhr, activated carbon, rutile type titanium dioxide and kaoline. The catalyst is prepared by using a constant-pore volume dipping method. When the catalyst is used in a fixed-bed miniature reaction device, the transformation rate of glycerol is 13.5%-80.6%, and the selectivity of the acrylic aldehyde is 49.0%-90.5%. When used for carrying out the process for preparing acrylic aldehyde by using glycerol dehydration, the catalyst has the advantages of high catalyst activity, high reaction speed, high selectivity for the acrylic aldehyde and the like, and the main byproduct is hydroxyl acetone.

Owner:JIANGSU UNIV

Acrylic acid preparation method

InactiveUS20090018362A1Organic compound preparationCarbonyl compound preparationGlycerolGlycerol dehydration

The invention relates to a method for preparing acrylic acid from propylene, comprising the oxidation of propylene to acrolein and a second step comprising the oxidation of acrolein to acrylic acid, including a glycerol dehydration step preformed in the presence of a gas containing propylene and, more specifically, in the presence of the reaction gas originating from the propylene to acrolein oxidation step. The inventive method enables the use, in part, of renewable raw material, while increasing acrylic acid production.

Owner:ARKEMA FRANCE SA

Catalyst used for preparing hydroxy acetone by glycerol dewatering, preparation and application thereof

InactiveCN101698151AHigh activityHigh yieldCarbonyl compound preparation by oxidationMetal/metal-oxides/metal-hydroxide catalystsCopper chromiteGlycerol

The invention relates to a catalyst used for preparing hydroxy acetone by glycerol dewatering, preparation and an application thereof. The main component of the catalyst is copper chromite. A metal auxiliary agent is respectively one of the components of zinc, aluminum, magnesium, zirconium, titanium and the like and is prepared by a dipping method. The auxiliary agent metal is in the catalyst in an oxide form of the auxiliary agent metal. The catalyst is suitable for preparing the hydroxy acetone by crude glycerine dewatering. The catalyst has simple preparation process, and the introduction of the metal auxiliary agent can enhance the activity of the catalyst, lower the reaction temperature obviously, enhance the yield of the hydroxy acetone and prolong the service life of the catalyst.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Acrolein Preparation Method

ActiveUS20080319233A1Increase productionEffective recoveryOrganic compound preparationCarbonyl compound preparationGlycerolGlycerol dehydration

The invention relates to a method for preparing acrolein from propylene, consisting of a first glycerol dehydration step preformed in the presence of a gas containing propylene and, more specifically, in the presence of the reaction gas originating from the propylene to acrolein oxidation step. The inventive method enables the use, in part, of renewable raw material, while increasing acrolein production.

Owner:ARKEMA FRANCE SA

Process for production of acrolein from glycerol

ActiveUS20100168472A1Organic compound preparationCarbonyl compound preparation by oxidationPolyolefinPolybutylene

The present invention relates to a process for producing acrolein by liquid phase dehydration of glycerol by preparing a mixture of a catalyst suspended in an organic solvent comprising one or more vinyl polymers and glycerol; and then mixing and heating the mixture to between 150° C. and 350° C. to dehydrate the glycerol and form acrolein. The vinyl polymers are selected from the group consisting of polyolefins, polystyrene, and mixtures thereof. The polyolefins may be polyethylene, polypropylene, polybutylene, polyisobutylene, polyisoprene, polypentene, or mixtures thereof. The acrolein may be subjected to vapor phase oxidation in the presence of a catalyst, such as a mixed metal oxide, to produce acrylic acid.

Owner:ROHM & HAAS CO

Acrolein Preparation Method

ActiveUS7531699B2Increase productionEffective recoveryOrganic compound preparationCarbonyl compound preparationGlycerolGlycerol dehydration

The invention relates to a method for preparing acrolein from propylene, consisting of a first glycerol dehydration step preformed in the presence of a gas containing propylene and, more specifically, in the presence of the reaction gas originating from the propylene to acrolein oxidation step. The inventive method enables the use, in part, of renewable raw material, while increasing acrolein production.

Owner:ARKEMA FRANCE SA

Method for preparing acrolein from glycerol or glycerine

InactiveUS20110288323A1Easy to adjustAvoid reactionCarboxylic acid nitrile preparationOrganic compound preparationIridiumNiobium

The invention relates to a method for preparing acrolein from glycerol or glycerine, comprising dehydrating glycerol or glycerine in the presence of a catalyst consisting of at least a) a mixed oxide of zirconium and at least one metal, said metal being selected from niobium, tantalum and vanadium, b) a zirconium oxide and at least one metal oxide, the metal being selected from niobium, tantalum and vanadium, c) a silicon oxide and a mixed oxide of zirconium and at least one metal, the metal being selected from tungsten, cerium, manganese, niobium, tantalum, titanium, vanadium and silicon, d) a silicon oxide and a mixed oxide of zirconium and at least one metal, the metal being selected from tungsten, cerium, manganese, niobium, tantalum, vanadium and titanium, e) a titanium oxide and a mixed oxide of zirconium and at least one metal, said metal being selected from tungsten, cerium, manganese, niobium, tantalum, titanium, vanadium and silicon, f) a titanium oxide and a mixed oxide or zirconium and at least one metal, said metal being selected from tungsten, cerium, manganese, niobium, tantalum, titanium, vanadium and silicon. The method can be used for producing -3-(methylthio)propionic (MMP) aldehyde, 2-hydroxy-4-methylthiobutyronitrile (HMTBN), methionine and analogues thereof from acrolein.

Owner:AVEATIS ANIMAL NUTRITION SA +1

Method for preparing acraldehyde catalyst by glycerol dehydration

InactiveCN107115877AThe reaction process is simpleHigh activityOrganic compound preparationCatalyst activation/preparationFixed bedGlycerol

The invention discloses a method for preparing an acraldehyde catalyst by glycerol dehydration. The method comprises the following steps: firstly, adopting zirconium phosphate as a carrier, selecting one or more of Cu(NO3)2, Fe(NO3)3, Co(NO3)2, (NH4)2Mo2O7, Ce(NO)3 and Ni(NO3)2 as active ingredients, and obtaining an MOx / ZrP catalyst by using an impregnation method; secondly, controlling the reaction temperature at 200 to 400DEG C under the condition of a fixed bed, selecting the MOx / ZrP as the catalyst and 10 to 100 percent of glycerine aqueous solution as a raw material and nitrogen as carrier gas and then carrying out a reaction of preparing acraldehyde by the glycerol dehydration. According to the method disclosed by the invention, the catalyst can be prepared simply and conveniently; better activity still can be maintained after being used for several times; meanwhile, the conversion rate of glycerol is between 80 percent to 100 percent and the selectivity of the acraldehyde is between 50 percent to 100 percent.

Owner:YANGZHOU UNIV

Method of prolonging service life of catalyst in dehydration of glycerol for production of acrolein

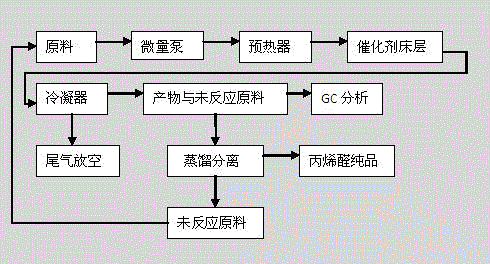

InactiveCN102718637ALow priceNo pollution in the processOrganic compound preparationCarbonyl compound separation/purificationPtru catalystFixed bed

The invention discloses a method for prolonging the service life of catalyst in dehydration of glycerol for production of acrolein. Reaction conditions in a fixed-bed reactor are changed for reaction of aqueous solution of glycerol of certain concentration at the low temperature of 240 DEG C and high space velocity of 15h-1, the product acrolein and unreacted glycerol are separated, and thus carbon deposition of the catalyst can be well inhibited and unreacted raw materials can be recycled. By adopting the process, the carbon deposition of the catalyst can be greatly inhibited, so that the catalyst can maintain high activity in a long time. Meanwhile, the problem of low conversion rate of raw materials under the conditions can be solved due to separation of the product, and the process is efficient and environmentally friendly.

Owner:CHANGSHU RES INSTITUE OF NANJING UNIV OF SCI & TECH

Acrylic acid based on renewable raw materials, water-absorbing polymer structures, and method for the production thereof by means of dehydration

InactiveCN101153003ALiquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationGas phaseAcrolein

The invention relates to a method comprising at least the following steps: a) glycerin is dehydrated so as to obtain a dehydrated product containing acrolein; b) the dehydrated product is subjected to gas phase oxidation so as to obtain a monomer gas containing acrylic acid; c) the monomer gas is contacted with a quenching agent so as to obtain a quench phase containing acrylic acid; d) the quench phase is reprocessed so as to obtain a monomer phase containing acrylic acid. A liquid phase (a1) and a gas phase (a2) are provided during the dehydration process, a plurality of gas bubbles being produced in the liquid phase (a1). The invention further relates to a method for producing polymers by polymerizing acrylic acid, preferably for producing water-absorbing polymers, the water-absorbing polymers obtained by means of said method, a compound, a method for producing a compound, the compound obtained by means of said method, and other chemical products.

Owner:EVONIK DEGUSSA GMBH

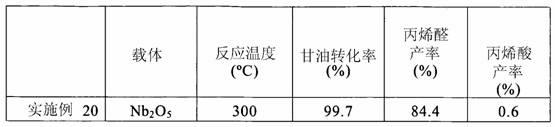

Novel glycerol dehydration catalyst and production method therefor

InactiveCN103201031AHigh yieldIncrease productivityOxygen-containing compound preparationOrganic compound preparationGlycerolHydrothermal synthesis

Provided is a novel catalyst that can produce acrolein and acrylic acid in high yields using glycerol as starting material. The disclosed glycerol dehydration catalyst has niobic oxide synthesized by hydrothermal synthesis as the main component.

Owner:NIPPON KAYAKU CO LTD +1

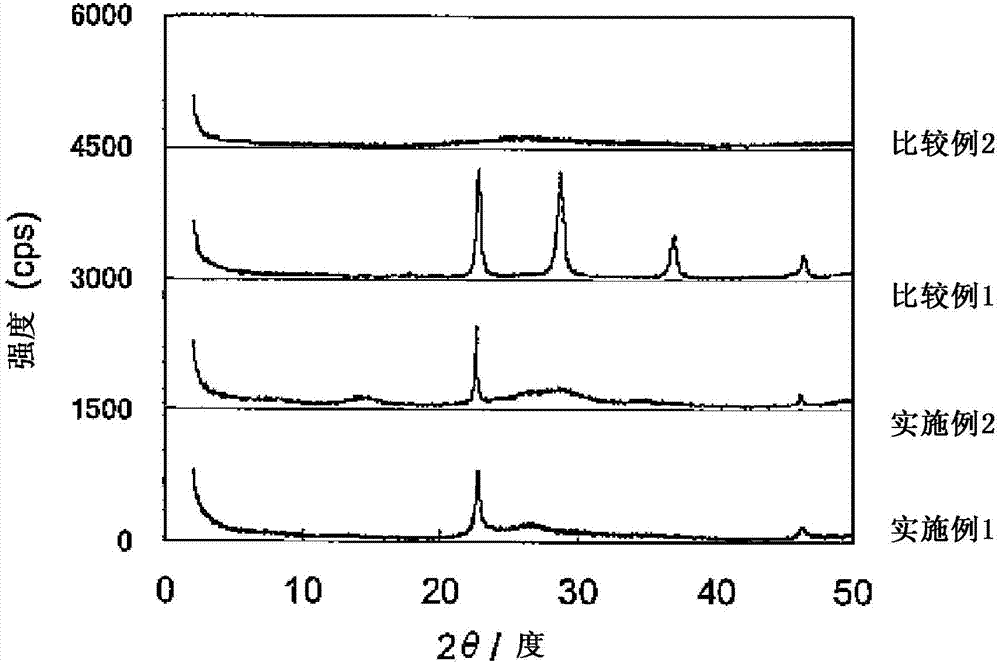

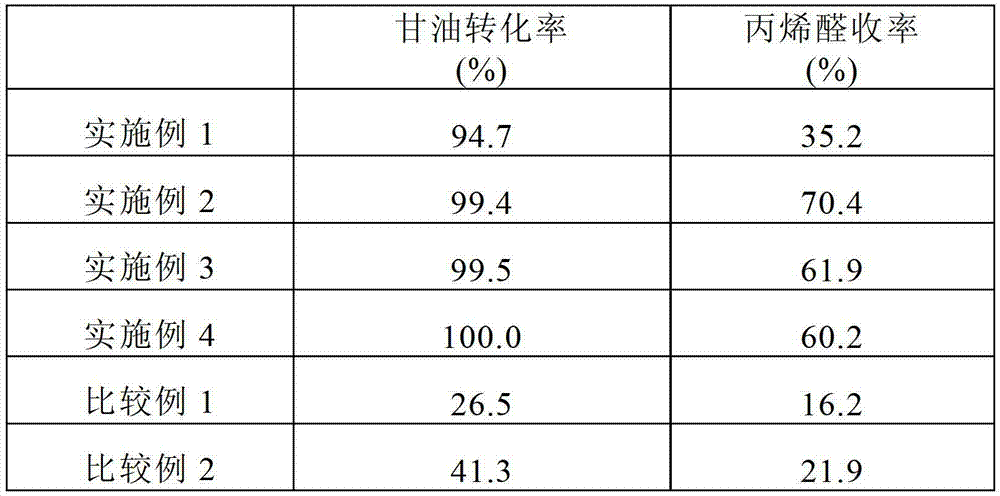

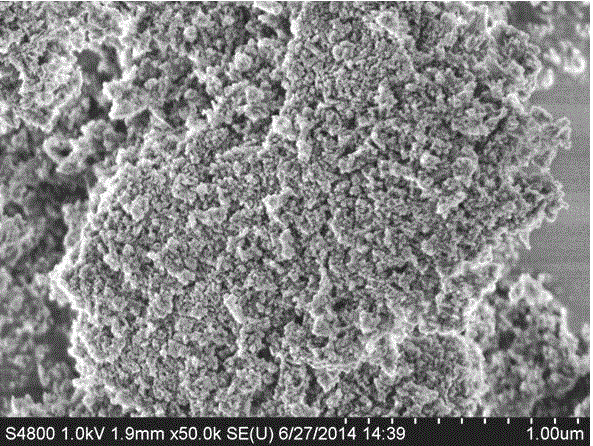

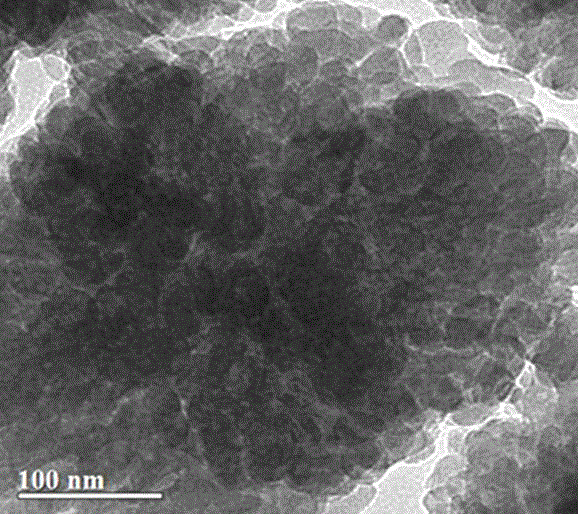

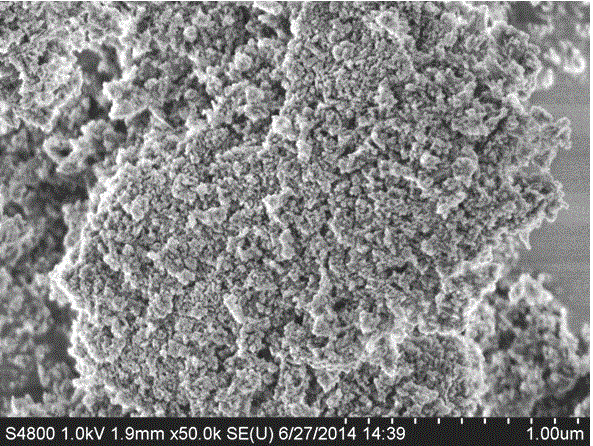

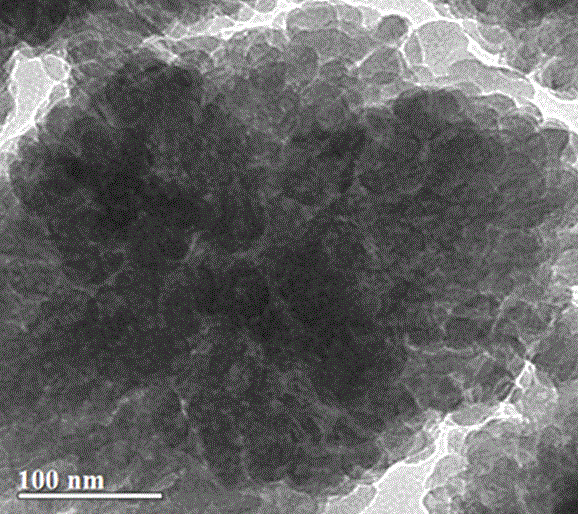

Nano ZSM-5/gamma-Al2O3 composite catalyst for preparing acraldehyde by glycerol dehydration, and preparation method and application thereof

InactiveCN104475147AGood carbon capacityHigh activityMolecular sieve catalystsOrganic compound preparationChemical industryPtru catalyst

The invention belongs to the technical field of chemical industry catalysts, and particularly relates to a nano ZSM-5 / gamma-Al2O3 composite catalyst for preparing acraldehyde by glycerol dehydration, and a preparation method and application thereof. In the presence of nano ZSM-5, nano gamma-Al2O3 is prepared by a precipitation process, and the nano ZSM-5 and nano gamma-Al2O3 are uniformly mixed to obtain the composite catalyst with strong interaction. The nano ZSM-5 / gamma-Al2O3 composite catalyst solves the problems of poor ZSM-5 stability and low gamma-Al2O3 selectivity in the acraldehyde catalytic reaction by glycerol dehydration. The prepared catalyst has excellent catalytic activity, selectivity and stability in the glycerol dehydration reaction.

Owner:FUDAN UNIV

Process for preparing catalyst used in production of unsaturated aldehyde and/or unsaturated carboxylic acid by dehydration reaction of glycerin, and catalyst obtained

InactiveUS20130066100A1High yieldHigh productivityMolecular sieve catalystsOrganic compound preparationAldehydeGlycerol

A process for preparing a catalyst used in a production of acrolein and acrylic acid by dehydration reaction of glycerin, characterized by the steps of mixing a solution of heteropolyacid or constituents of heteropolyacid, a solution of at least one metal selected from elements belonging to Group 1 to Group 16 of the Periodic Table of Elements or its onium and a carrier to obtain a solid substance, and then of effecting at least one time of calcination before said solid substance is used in the dehydration reaction of glycerin.A catalyst obtained by the process for use in a production of acrolein and acrylic acid by dehydration reaction of glycerin.A process for preparing acrolein by catalytic dehydration of glycerin carried out in the presence of the catalyst and under a pressurized condition.A process for preparing acrylic acid obtained by oxydation of acrolein obtained.A process for preparing acrylonitrile obtained by ammoxidation of acrolein obtained.

Owner:NIPPON KAYAKU CO LTD

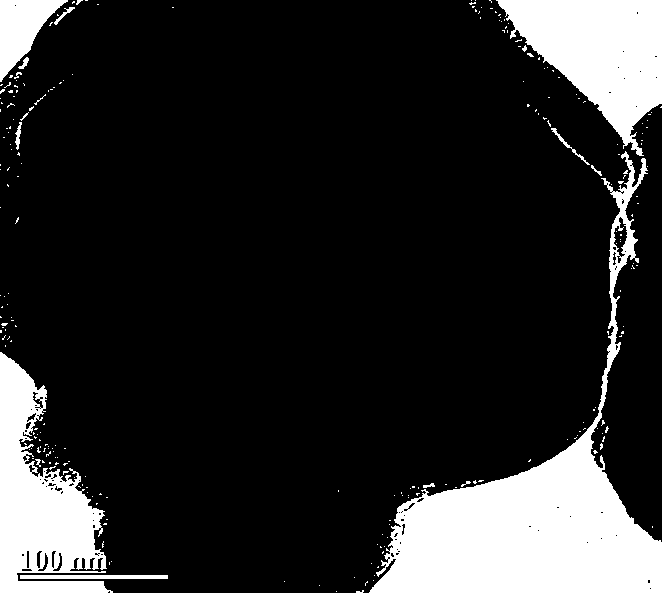

Multistage pore ZSM-5 catalyst for preparing acrolein by glycerol dehydration and preparation method of catalyst

InactiveCN105621452AEasy to synthesizeDefects that inhibit the growth processMolecular sieve catalystsOrganic compound preparationMolecular sieveAlcohol

The invention belongs to the technical field of chemical catalysts and particularly relates to a multistage pore ZSM-5 catalyst for preparing acrolein by glycerol dehydration and a preparation method of the catalyst. The catalyst comprises a multistage pore ZSM-5 molecular sieve which comprises rich transgranular mesopores; the preparation method comprises the steps that cheap silicon source, aluminium source and organic template reagent are dissolved in water, cavatition of ultrasonic wave and fierce mechanical agitation are used, few small molecular alcohol is added as a cosolvent, and a multistage pore ZSM-5 molecular sieve with MFI structure property is synthesized with a hydrothermal method. The multistage pore ZSM-5 molecular sieve which comprises rich transgranular mesopores is obtained through the cheap preparation technology, the crystal grain is large, the hydrothermal stability is good, and high selectivity and high stability are shown in the acrolein preparation process by glycerol dehydration.

Owner:FUDAN UNIV

Acrylic acid preparation method

InactiveUS7880034B2Increase productionEfficient heatingOrganic compound preparationCarbonyl compound preparationGlycerolGlycerol dehydration

The invention relates to a method for preparing acrylic acid from propylene, comprising the oxidation of propylene to acrolein and a second step comprising the oxidation of acrolein to acrylic acid, including a glycerol dehydration step preformed in the presence of a gas containing propylene and, more specifically, in the presence of the reaction gas originating from the propylene to acrolein oxidation step. The inventive method enables the use, in part, of renewable raw material, while increasing acrylic acid production.

Owner:ARKEMA FRANCE SA

Method for preparing acrolein by glycerol dehydration

ActiveCN108947786AHigh catalytic activityImprove conversion rateMolecular sieve catalystsOrganic compound preparationMolecular sieveChemical reaction

The invention discloses a method for preparing acrolein by glycerol dehydration catalyzed by a ZSM-5 nanometer molecular sieve with a hollow structure. The method includes the following steps: first preparing a ZSM-molecular sieve, then uniformly mixing and stirring the prepared ZSM-5 molecular sieve with an alkaline substance aqueous solution, performing alkali treatment under stirring at 40-80 DEG C, and preparing the ZSM-5 nanometer molecular sieve with the hollow structure by centrifugal washing, drying, and roasting after the treatment is performed; and finally, preparing the acrolein bythe glycerol dehydration under catalysis of the ZSM-5 nanometer molecular sieve with the hollow structure. In chemical reactions, the prepared ZSM-5 nanometer molecular sieve is beneficial to diffusion of mass transfer of reaction molecules, thereby effectively improving the conversion rate of glycerol and the yield of the acrolein, and the anti-deactivation performance of a catalyst can be effectively improved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Preparation method of recombinant organism 3-hydracrylic acid

The invention relates to a preparation method of 3-hydracrylic acid, which can be explained by the production of 3-hydracrylic acid (3-HP) from glycerol in a bacterial host. 3-HP is a useful raw material for production of a polymeric material. A genetic engineering bacteria host of two enzymes is enough to produce 3-HP. One enzyme is glycerol dehydratase and the other enzyme is acetaldehyde dehydrogenase. The recombinant microorganism host, which is allowed to be established, can synthesize 3-HP from glycerol or glucose used as a starting material. Glycerol or glucose is converted and then transformed into 3-HP.

Owner:XINCHANG GUANYANG TECH DEV

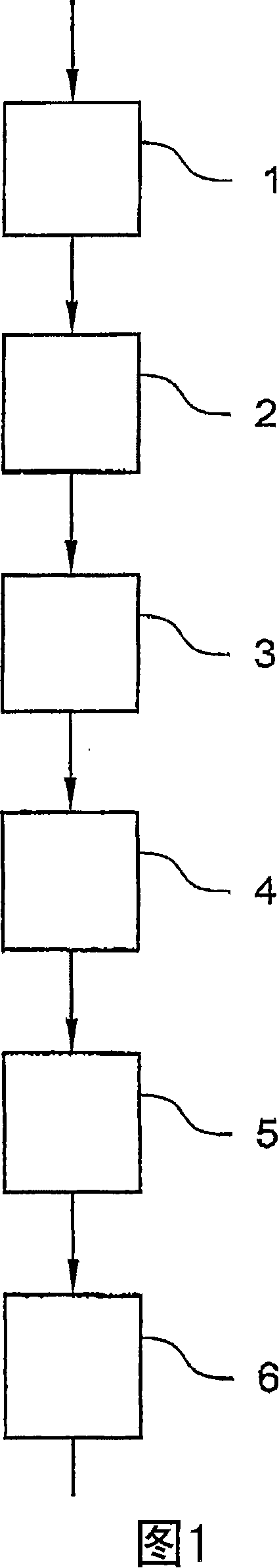

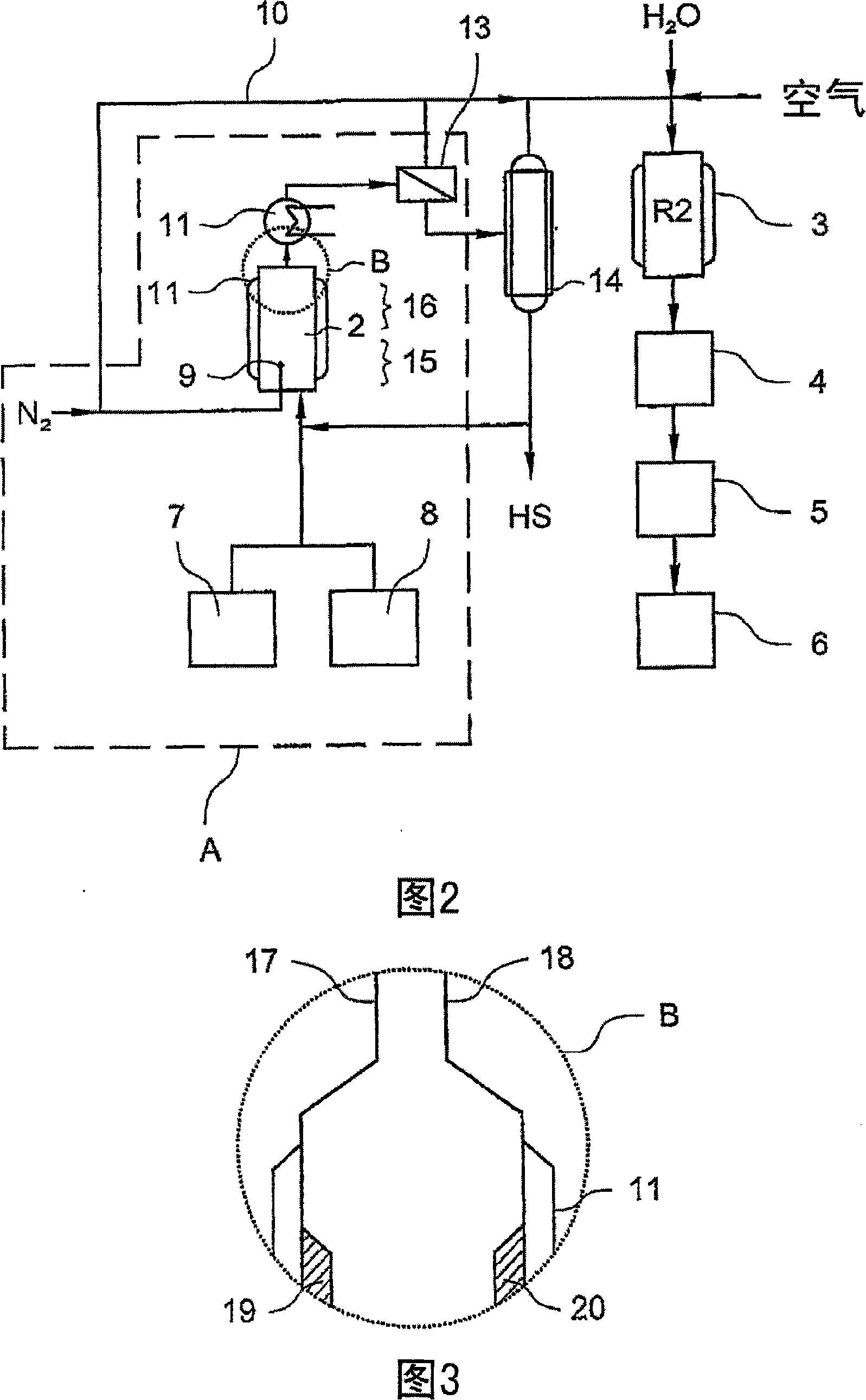

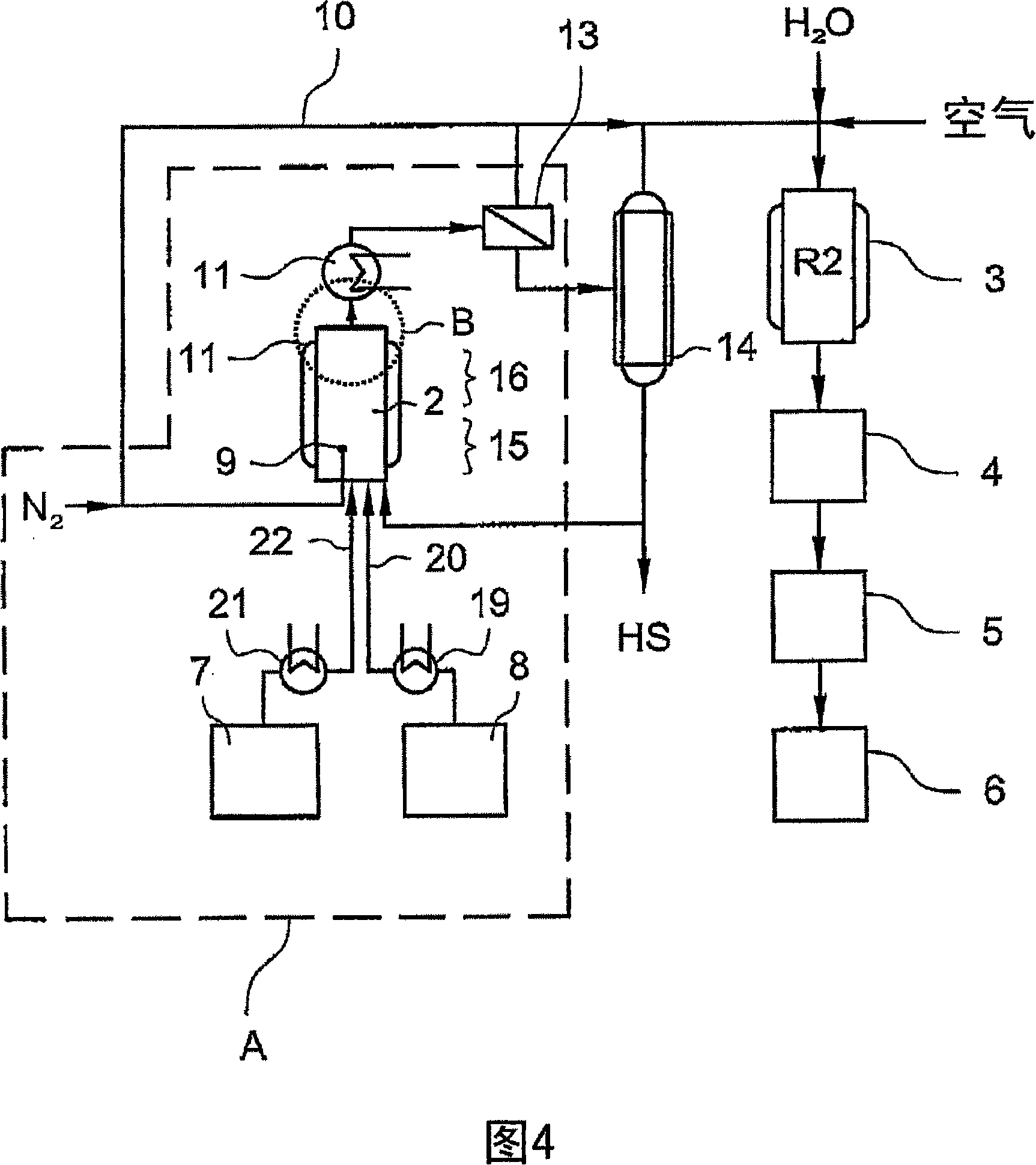

Process for manufacturing acrolein and/or acrylic acid from glycerol

The present invention relates to the manufacture of bioresourced acrolein and bioresourced acrylic acid from glycerol as starting material and more particularly comes within the scope of a process for the manufacture of acrolein and acrylic acid according to which the reaction for the dehydration of glycerol to give acrolein is carried out and a stage of oxidizing a water-rich phase separated from the reaction mixture coming from this dehydration reaction is carried out, before it is recycled to the glycerol dehydration stage. This oxidation treatment prevents organic impurities from accumulating during the process, while minimizing the consumption of water and the discharge of polluted aqueous streams.

Owner:ARKEMA FRANCE SA

Production method of glycerin tribenzoate

InactiveCN105348104AReduce generationReduce the impactOrganic compound preparationCarboxylic acid esters preparationBenzoic acidAlkaline earth metal

Owner:浙江合糖科技有限公司

Production technology of 1,3-propylene glycol by using glycerol fermentation method

InactiveCN103146766AImprove conversion rateShorten fermentation timeBacteriaMicroorganism based processesBiotechnologyHeterologous

The invention discloses a production technology of 1,3-propylene glycol (PDO) by using a biological fermentation method, belonging to the technical field of biochemical engineering. The production technology comprises the following steps of: preparing 2'-dehydroxylase gene (sisII) from 3',4'-double dehydroxylase gene of sisI in micromonospora inyoensis through genetic recombination, DNA (deoxyribonucleic acid) rearrangement and the like; cloning to obtain sisII; constructing the sisII to a pET30a expression vector, and performing heterologous expression in E.coli BL21 to construct engineering bacteria BL21-sis for synthesizing 1,3-propylene glycol through glycerol dehydration; performing immobilization by a supramolecular self-assembly template method; fermenting to synthesize 1,3-propylene glycol in a glycerol-containing culture medium; and obtaining the product 1,3-propylene glycol through fermentation liquid filtration, organic solvent extraction and the like. The method for preparing 1,3-propylene glycol has the advantages of short production period, simple equipment, environmental friendliness, easiness in operation and control, cheap raw materials and the like, facilitates industrial production and has great practical value.

Owner:XUZHOU KAIMIKE NEW MATERIALS

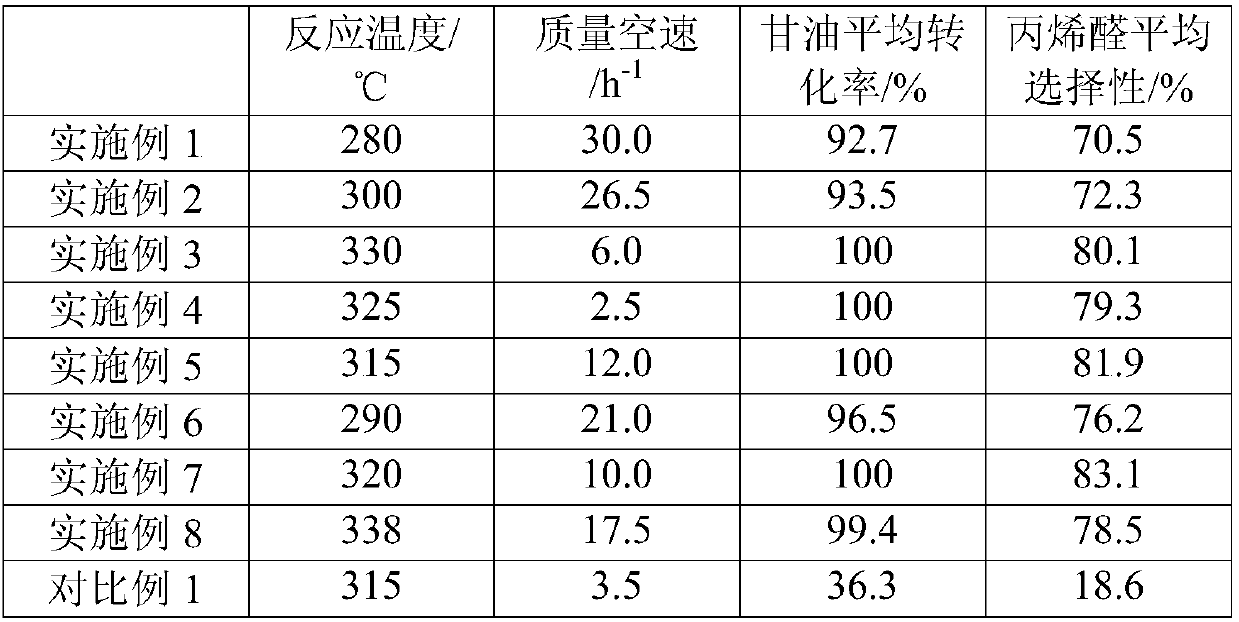

Method for preparing acrolein by dehydrating glycerin

ActiveCN109836320AHigh activityIncrease acidityMolecular sieve catalystsOrganic compound preparationIon exchangeGlycerol

The invention discloses a method for preparing an acrolein catalyst by dehydrating glycerin. The method comprises the following steps: carrying out acid treatment on a molecular sieve, carrying out alkali treatment, filtering and washing the treated molecular sieve to neutrality, drying the molecular sieve, and carrying out ion exchange and calcining to convert the molecular sieve into a hydrogentype hierarchical porous molecular sieve; and dehydrating glycerin in a fixed bed reaction at a reaction temperature of 280-340 DEG C with the prepared hierarchical porous molecular sieve as the catalyst, a 10-50 wt% aqueous glycerin solution as a raw material and nitrogen as a carrier gas to produce the acrolein. The method has the advantages of simplicity in catalyst preparation and operation,low cost, and the obtained modified molecular sieve material has a high activity, and allows the glycerin conversion rate to be 90-100% and the acrolein selectivity to be 70-85% when applied to the dehydration of glycerin to produce acrolein.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

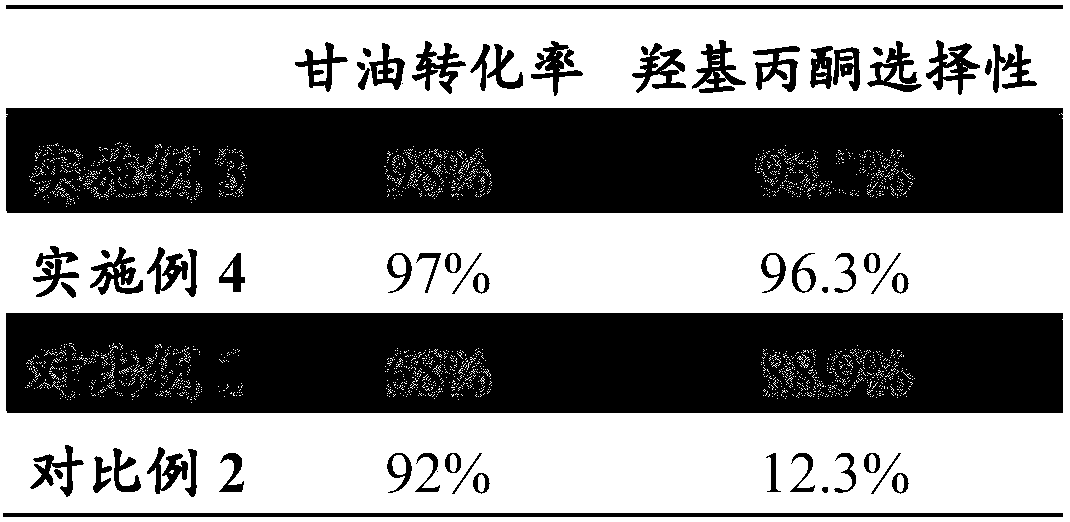

Method for preparing hydroxyacetone by glycerol dehydration

InactiveCN109665952AHigh activityImprove stabilityMolecular sieve catalystsOrganic compound preparationGlycerolNano copper

The invention discloses a method for preparing hydroxyacetone by glycerol dehydration. A supported Cr2Cu2O5 / SAPO-11 catalyst is used, SAPO-11 is fully used as a carrier, the prepared supported nano copper chromite catalyst is high in activity and good in stability, a pure glycerol feed can be used for replacing glycerol solution feed, the conversion rate of glycerol is 97% or above, and the selectivity of the hydroxyacetone is 95% or above.

Owner:浙江昊唐商业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com