Hierarchical porous ZSM-5 zeolite catalyst for preparing acrolein through glycerin dehydration as well as preparation method and application of hierarchical porous ZSM-5 zeolite catalyst

A ZSM-5 and zeolite catalyst technology, which is applied in the direction of molecular sieve catalysts, carbon-based compound preparation, chemical instruments and methods, etc., can solve the problems of fast deactivation and achieve low cost, simple synthesis, and high selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

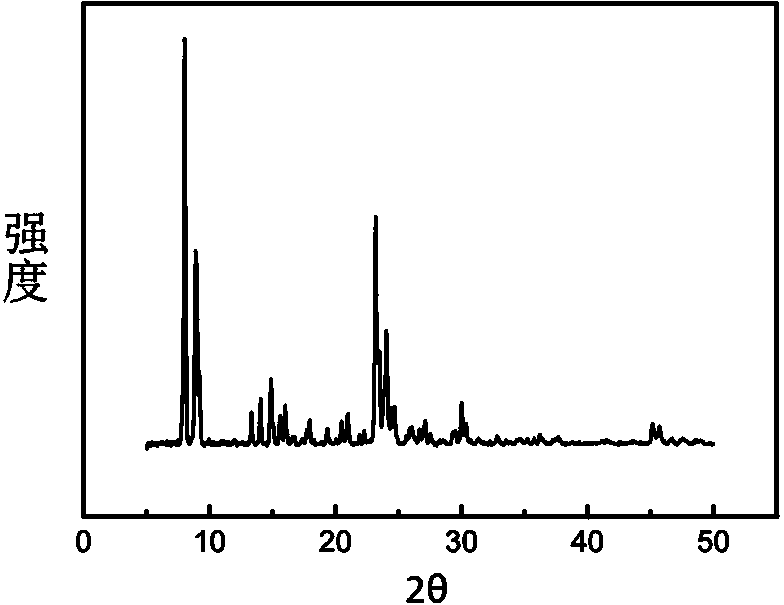

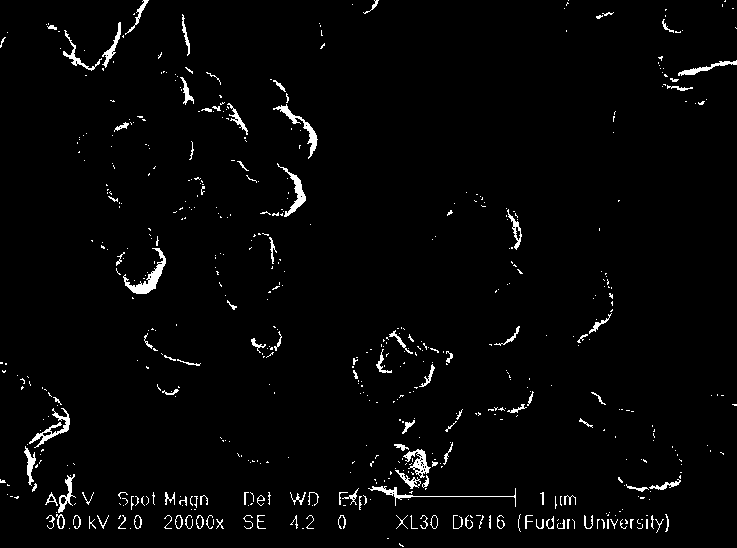

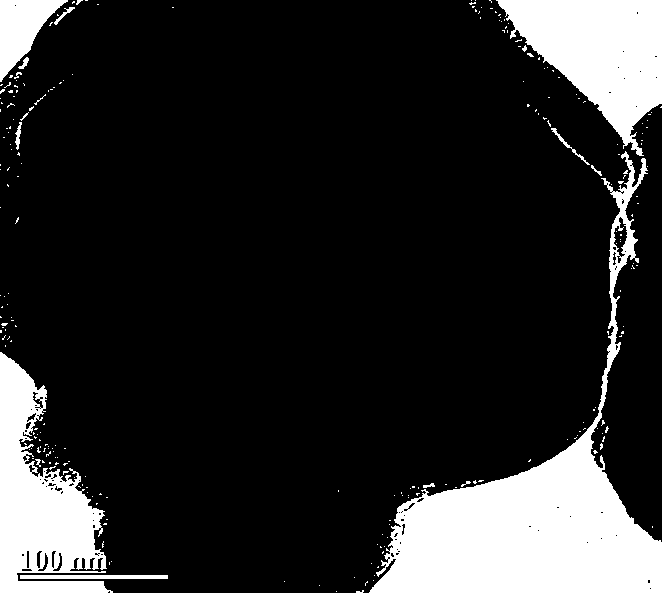

[0030] Prepare the initial gel in the following molar ratios: 1SiO 2 : 0.004Al 2 o 3 : 0.14Na 2 O : 0.3KCl : 0.1TPABr : 30H 2 O, silica sol, aluminum sulfate, and sodium hydroxide were dissolved in deionized water respectively, and potassium chloride, tetrapropylammonium bromide, and 5wt% 200nm-sized MFI seed crystals were added under constant stirring. The above mixture was stirred and aged at room temperature for 2 hours, then put into a stainless steel static crystallization kettle with a polytetrafluoroethylene liner, and reacted at 140° C. for 12 hours.

[0031] After crystallization, cool, filter and wash with deionized water for 3-4 times, and then dry the obtained sample at 80-120°C. The product is calcined in a muffle furnace or a tube furnace to remove the template agent, generally in an air atmosphere at 550 ° C for 4 to 6 hours. Then use ammonium nitrate solution with a concentration of 5wt% at 80°C for three consecutive ion exchanges (solution volume / produc...

Embodiment 2

[0033] Prepare the initial gel in the following molar ratios: 1SiO 2 : 0.004Al 2 o 3 : 0.15Na 2 O : 0.3KCl : 0.1TPABr : 60H 2 O, silica sol, aluminum sulfate, and sodium hydroxide were dissolved in deionized water respectively, and potassium chloride, tetrapropylammonium bromide, and 5 wt % MFI seed crystals of 200 nm in size were added under constant stirring. The above mixture was stirred and aged at room temperature for 2 hours, then put into a stainless steel static crystallization kettle with a polytetrafluoroethylene liner, and reacted at 120° C. for 12 hours.

[0034] After crystallization, cool, filter and wash with deionized water for 3-4 times, and then dry the obtained sample at 80-120°C. The product is calcined in a muffle furnace or a tube furnace to remove the template agent, generally in an air atmosphere at 550 ° C for 4 to 6 hours. Then use ammonium nitrate solution with a concentration of 5wt% at 80°C for three consecutive ion exchanges (solution volum...

Embodiment 3-6

[0036] The steps in this embodiment are exactly the same as those in Embodiment 1 above. The difference is that during the preparation of the reaction mixture, the Na used 2 O / Si 2 O changed from 0.14 to 0.10, 0.12, 0.16, 0.18.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com