Zirconium phosphate catalyst and its application in preparation of acrolein through glycerin dehydration

A catalyst, acrolein technology, applied in the preparation of phosphorus compounds, carbon-based compounds, preparation of organic compounds, etc., can solve the problems of low value of crude glycerin, affecting the industrial economy of biodiesel, etc., and achieve good catalytic stability and activity. and highly selective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

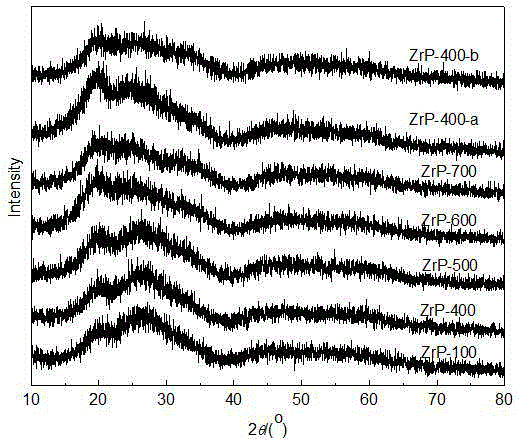

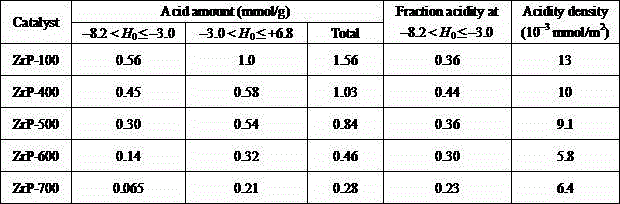

[0016] Ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) aqueous solution (1.0mol / L, 64ml) was added dropwise to zirconium oxychloride (ZrOCl 2 ·8H 2 O) in an aqueous solution (1.0 mol / L, 32 ml), the resulting mixture was stirred overnight at room temperature, then suction filtered, washed with water until the pH of the filtrate reached 6, and tested for the absence of Cl with silver nitrate solution. – until, then dry the white precipitate at 100°C for 12 h, and dry the obtained powder at 200 o C was calcined for 4 hours to obtain the catalyst. The catalyst was pressed into 20-40 meshes for activity testing. The elemental analysis results showed that the molar ratio of phosphorus to zirconium in the material was 1.54.

[0017] Take the above 0.5g catalyst (20-40 mesh) and put it in the middle of the reactor, and fix the two ends of the bed with quartz wool and quartz sand, and play the role of preheating and vaporizing the raw materials. Before the reaction, the catalyst...

Embodiment 2

[0019] Ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) aqueous solution (1.0mol / L, 64ml) was added dropwise to zirconium oxychloride (ZrOCl 2 ·8H 2 O) in an aqueous solution (1.0 mol / L, 32 ml), the resulting mixture was stirred overnight at room temperature, then suction filtered, washed with water until the pH of the filtrate reached 6, and tested for the absence of Cl with silver nitrate solution. – Then, the white precipitate was dried at 100°C for 12 h, and the dried powder was dried at 400 o C was calcined for 4 hours to obtain the catalyst, and the elemental analysis results showed that the molar ratio of phosphorus to zirconium in the material was 1.54. The catalyst was pelletized into 20-40 mesh for activity testing.

[0020] Take the above 0.5g catalyst (20-40 mesh) and put it in the middle of the reactor, and fix the two ends of the bed with quartz wool and quartz sand, and play the role of preheating and vaporizing the raw materials. Before the reaction, the ca...

Embodiment 3

[0022] Ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) aqueous solution (1.0mol / L, 64ml) was added dropwise to zirconium oxychloride (ZrOCl 2 ·8H 2 O) in an aqueous solution (1.0 mol / L, 32 ml), the resulting mixture was stirred overnight at room temperature, then suction filtered, washed with water until the pH of the filtrate reached 6, and tested for the absence of Cl with silver nitrate solution. – until, then dry the white precipitate at 100°C for 12 h, and dry the obtained powder at 500 o C was calcined for 4 hours to obtain the catalyst, and the elemental analysis results showed that the molar ratio of phosphorus to zirconium in the material was 1.54. The catalyst was pelletized into 20-40 mesh for activity testing.

[0023] Take the above 0.5g catalyst (20-40 mesh) and put it in the middle of the reactor, and fix the two ends of the bed with quartz wool and quartz sand, and play the role of preheating and vaporizing the raw materials. Before the reaction, the catal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com